Metallurgical quality modeling method based on factory modeling

A modeling method and factory technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as lack, difficulty in guarantee, poor scalability, etc., to achieve stable and reliable quality, improve configurability, and improve The effect of configurability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

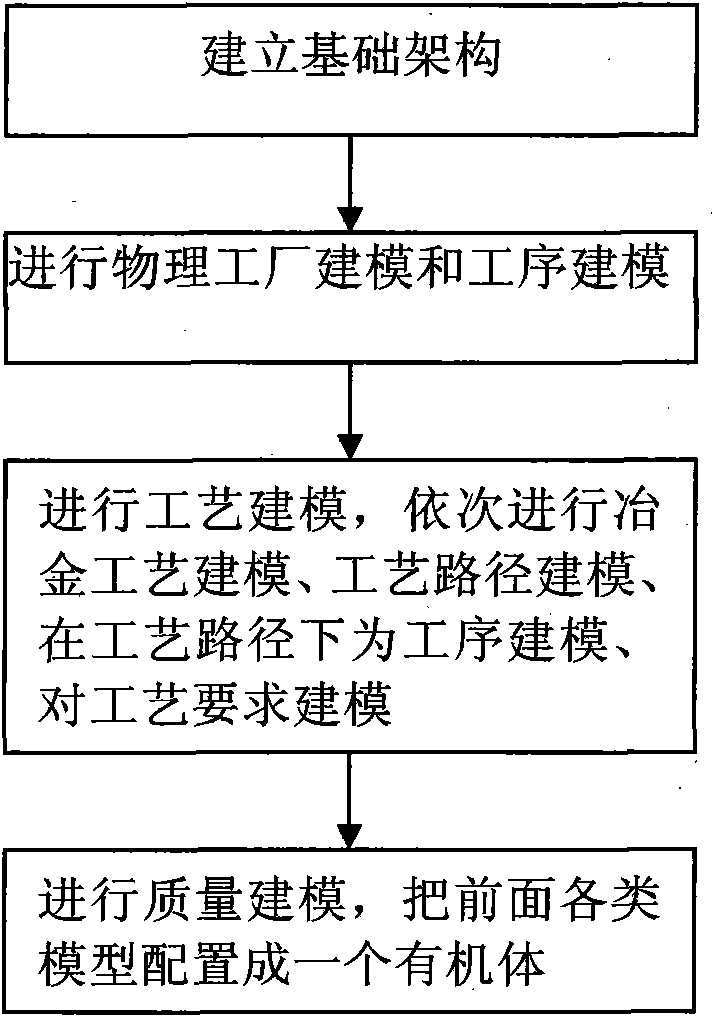

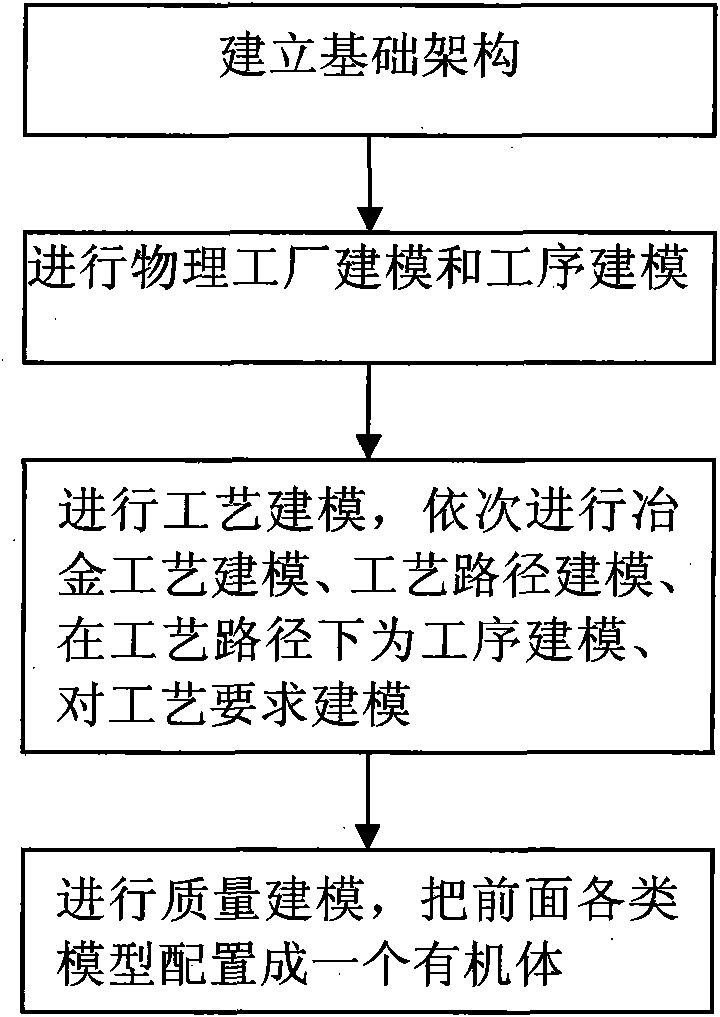

[0018] An embodiment of the metallurgical quality modeling method based on plant modeling of the present invention is as follows figure 1 shown, including the following steps.

[0019] 1. Establish the basic structure, which includes establishing an industry library of sites, regions, work centers, and work units, and forming a set of hierarchical models based on the industry library; creating process entities, product entities, process entities, process path entities, and process requirements entities, and define its properties for each type of entity.

[0020] 2. Carry out physical factory modeling and process modeling, which includes establishing a factory instance starting from the site; establishing a process instance starting from the work center; on the basis of the process entity, configuring attribute values such as process code and process name, so as to instantiate For each metallurgical operation, then associate work centers and process requirements for each m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com