Liquid discharge control method of bleaching pulp system

A control method and pulp bleaching technology, applied in the direction of washing/replacing pulp treatment liquid, pulp bleaching, pulp dehydration, etc., can solve problems such as waste of raw materials, pulp quality that cannot meet production needs, instability, etc., to ensure washing and bleaching The quality of pulp operation and the effect of avoiding waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

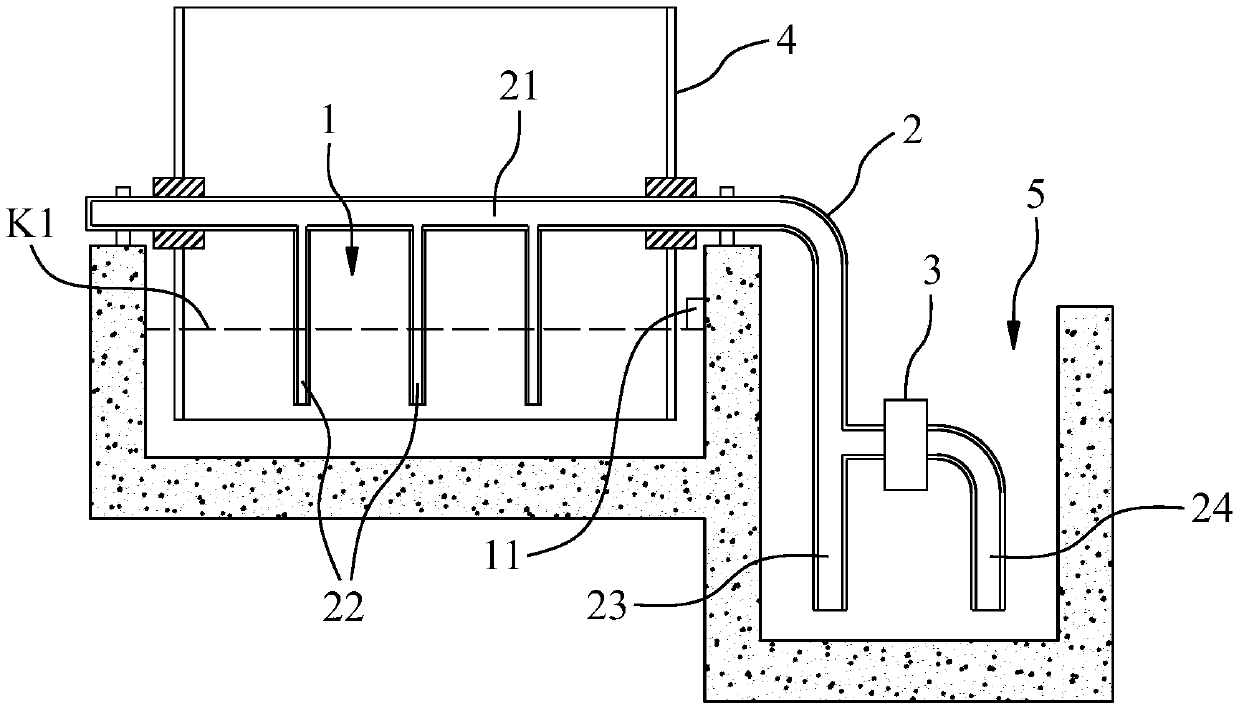

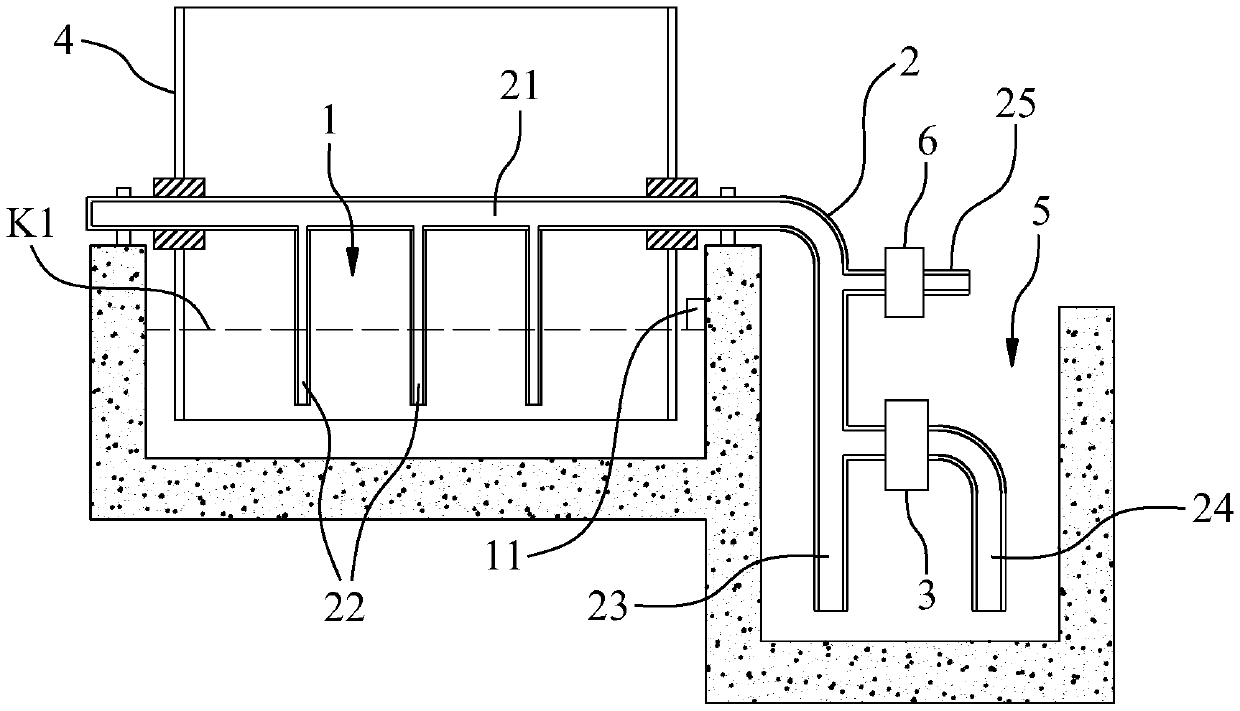

[0011] The specific implementation manner of the present invention will be further described in detail below by describing the embodiments in conjunction with the accompanying drawings.

[0012] A liquid discharge control method for a pulp bleaching system, comprising the following steps:

[0013] A. Set a liquid level sensor 11 on the tank wall of the pulp tank 1 in the pulp bleaching system, and the liquid level sensor 11 is set at the water level height warning value K1, and K1 is close to the notch of the pulp tank 1;

[0014] B. A liquid pumping device 3 is provided on the drain pipe 2 for discharging the filtrate in the slurry tank 1, and the liquid level sensor 11 collects the water level information in the slurry tank 1 to monitor the water level in the slurry tank 1; when the slurry tank When the water level in 1 is greater than K1, the liquid pumping device 3 starts and discharges liquid from the inside of the slurry tank 1, and when the water level in the slurry tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com