Warning method, warning device and warning system for visual safety stock

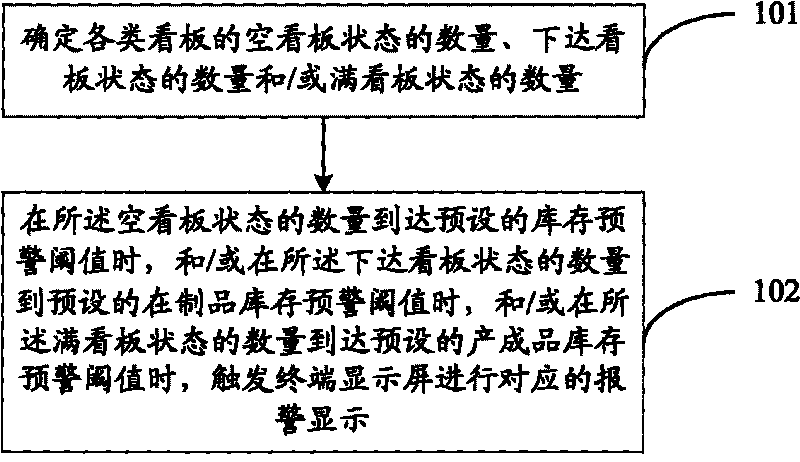

A safety inventory and alarm device technology, applied in the field of information processing, can solve problems such as low capital utilization, manual input errors, and tight capital chains, and achieve the effects of reducing inventory costs, realizing automatic alarms, and avoiding production interruptions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

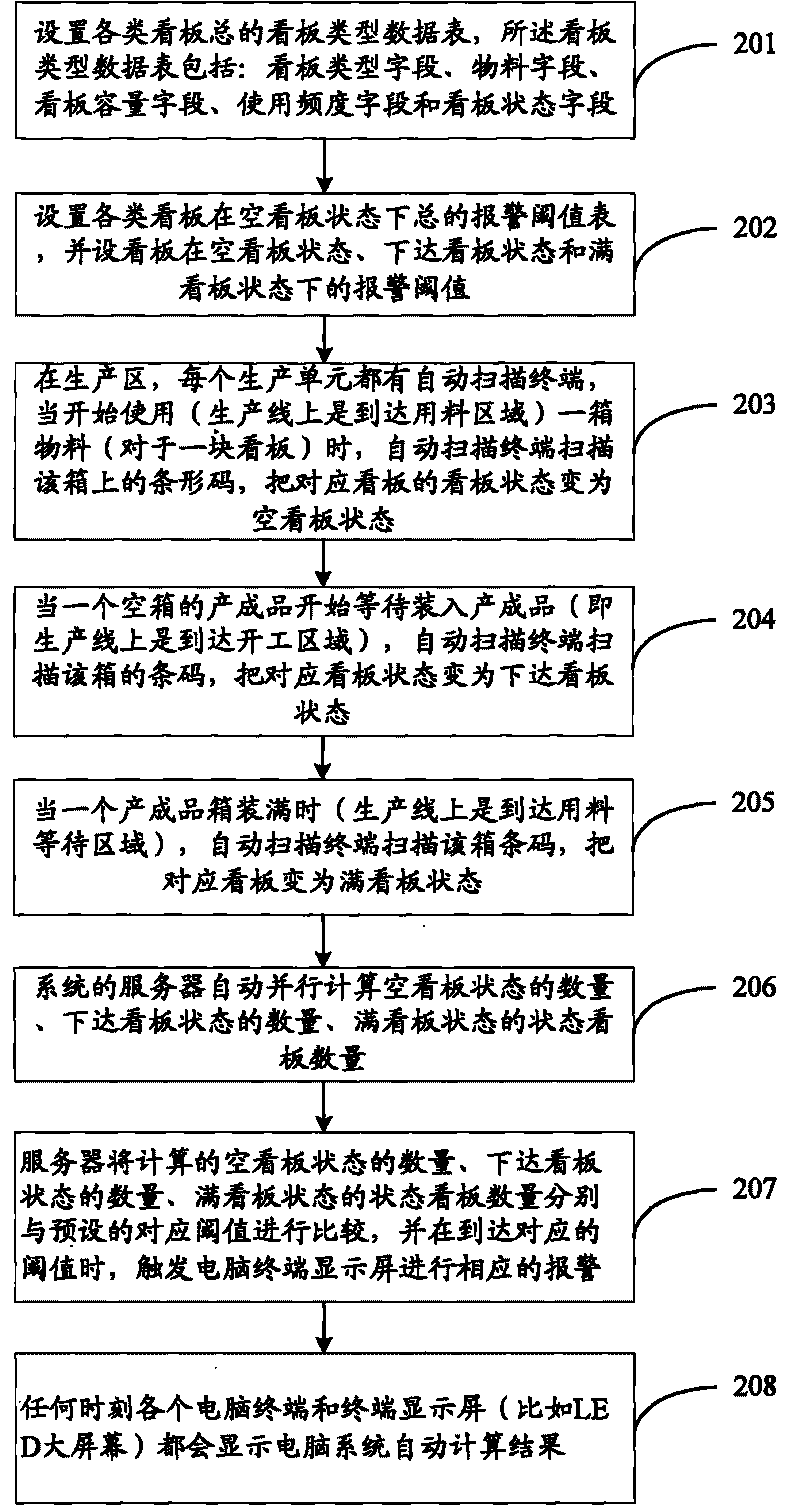

Embodiment Construction

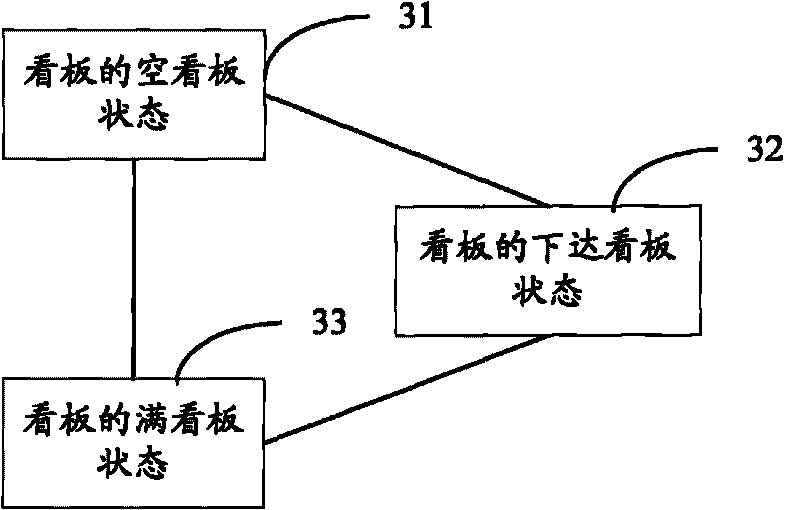

[0063] For ease of understanding, before introducing the present invention, the following terms are explained:

[0064] Kanban: It is a visual pulling system that can easily transmit information when there is a demand for an item. When the continuous flow between the various workstations in the production process cannot be achieved, the kanban and supermarket models are usually used to achieve pull production. Each kanban corresponds to a physical container, and the container capacity of the same type of kanban is standard and fixed.

[0065] Production Kanban: Used to place finished or semi-finished products, there is a standard quantity of containers, and a label with relevant information. In the production process, the cyclic movement of the label from the production unit to the inventory and then to the production unit realizes the production pull.

[0066] Procurement Kanban: A label board with a standard quantity of containers and relevant information used to place raw materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com