Machine of the tobacco-processing industry

A processing industry and machine technology, applied in the field of machinery in the tobacco processing industry, can solve problems such as undesired multiple shutdowns, achieve the effect of reducing problems and shutdowns, and improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

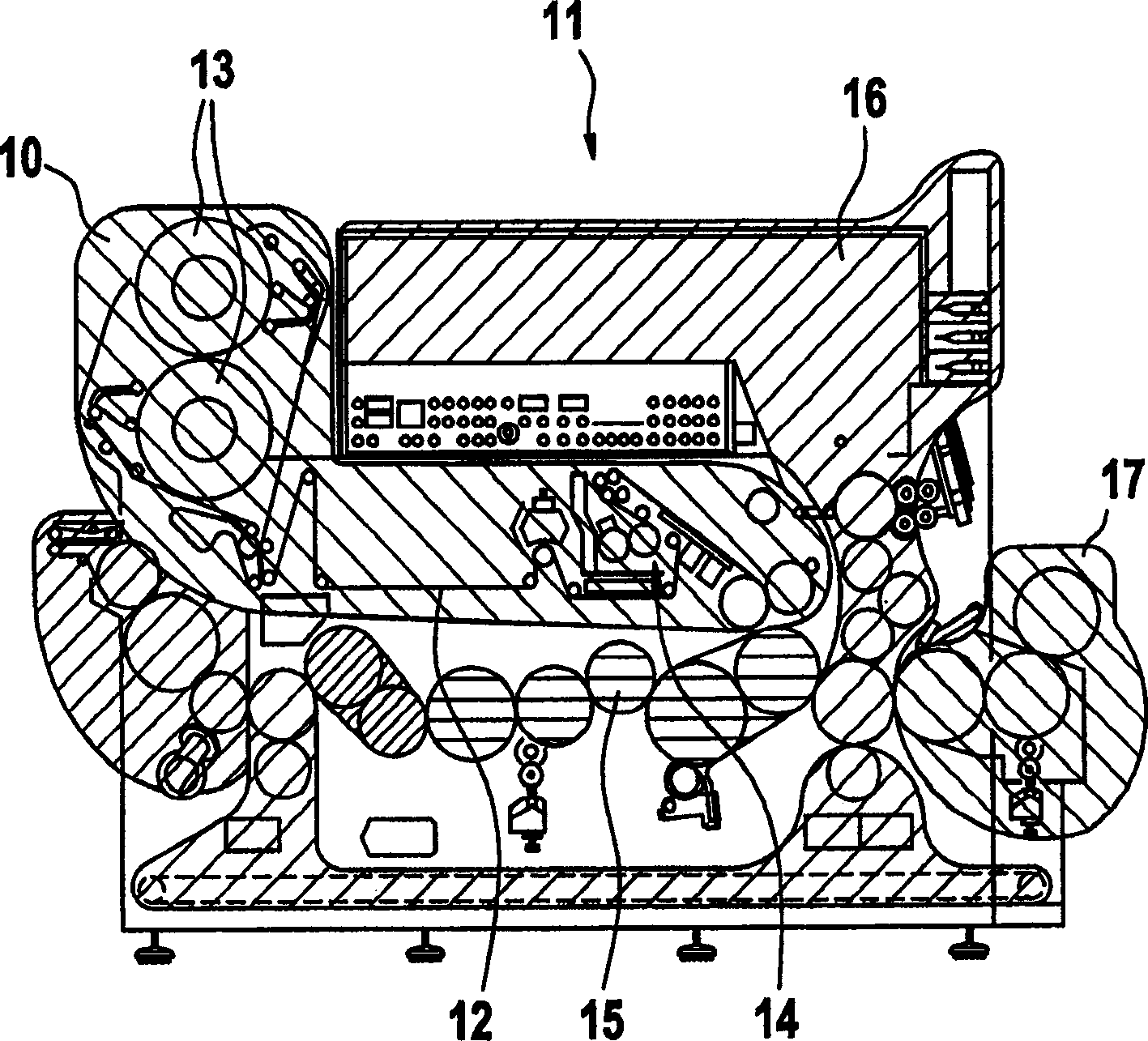

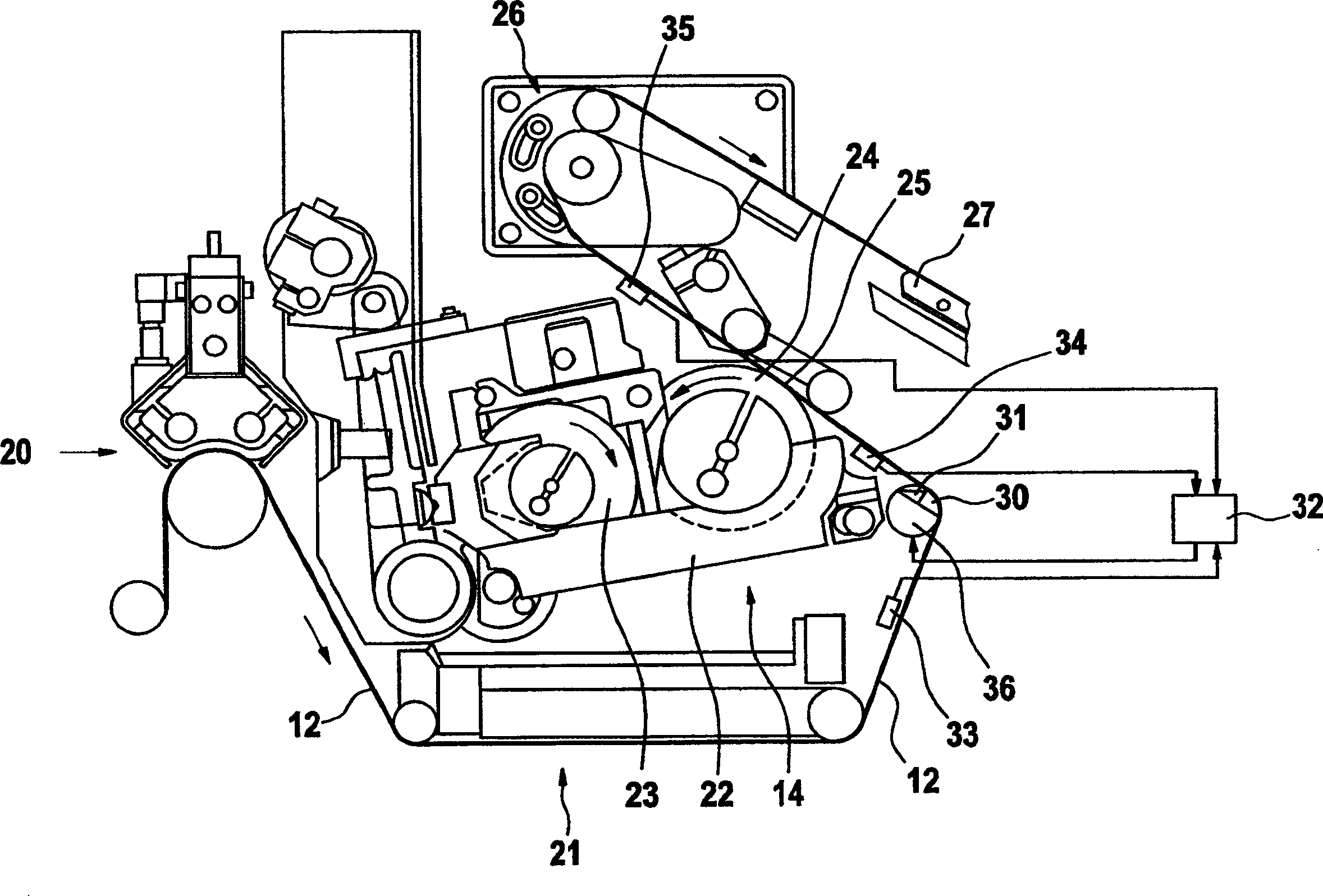

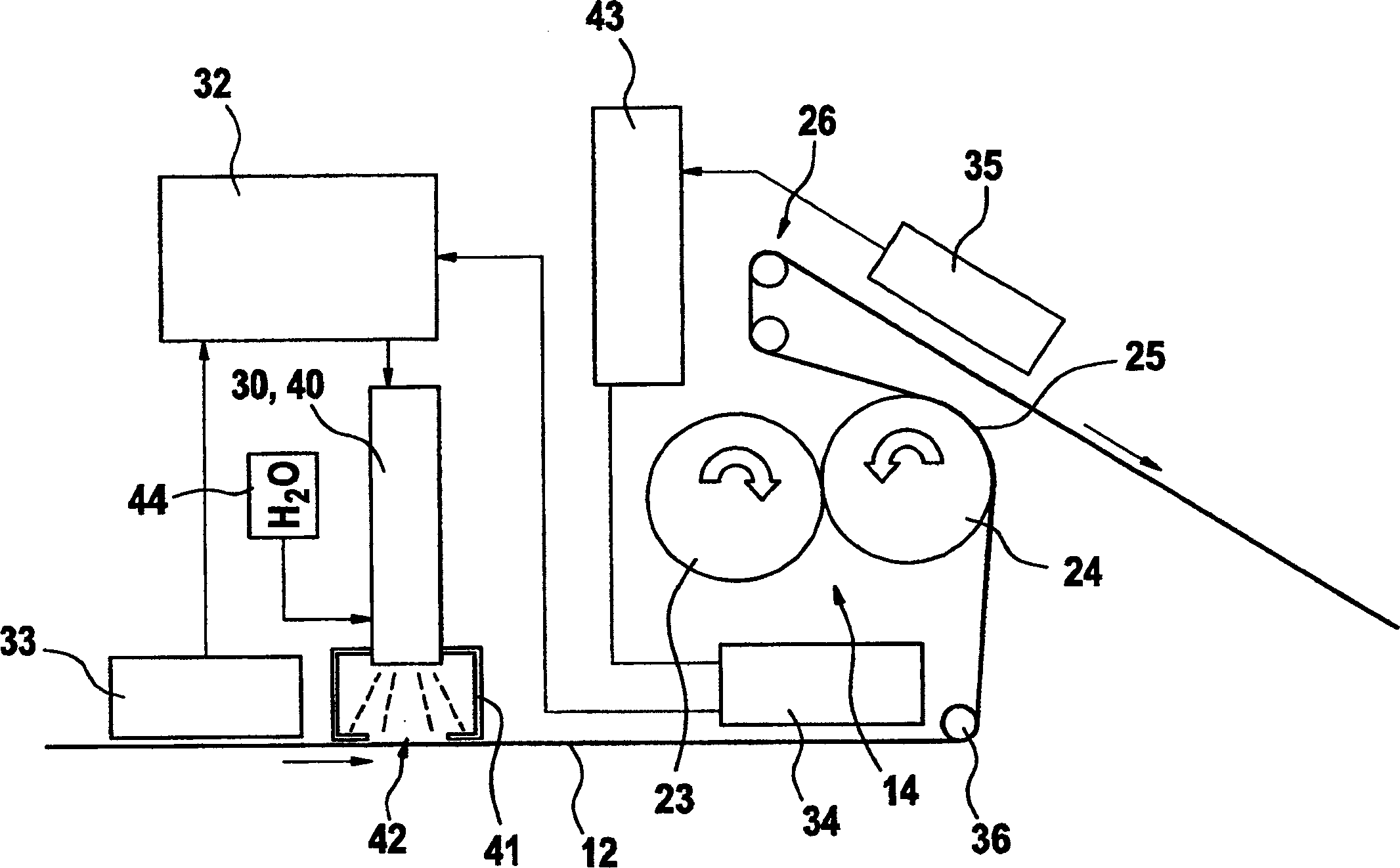

[0017] Figures 1 to 3 It relates to an application in a filter tip attaching machine of a cigarette production machine.

[0018] The movement of the overlay paper 12 can be seen in the overlay paper transfer unit 10 , starting from the reel 13 . After gluing with the gluing unit 14 , the covering paper 12 is conveyed to a cigarette manufacturing unit 15 . There, the glued cover paper 12 is wound around the filters and the tobacco rods which are conveyed by a filter transfer unit 16 and the tobacco rods which are conveyed by a tobacco rod transfer unit 17 and which are bonded to each other to form a filter cigarette.

[0019] The cover paper is moved past the tension roller 20 and the cover edge adjustment device 21 to compensate for axial fluctuations in the movement of the cover paper 12 to the gluing unit 14 . Overlay paper is transported in the figure 2 as indicated by the arrow. The gluing unit 14 includes a gluing tank 22, a gluing roller 23 and a transfer roller 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com