Natural ventilation dry-wet combined cooling tower with air precooling and winter freeze preventing functions

An air pre-cooling and natural ventilation technology, applied in the field of cooling towers, can solve the problems of increased back pressure of power plant units, decreased unit economy, and reduced heat exchange temperature difference, saving electric energy, solving water reduction, and enhancing suction. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

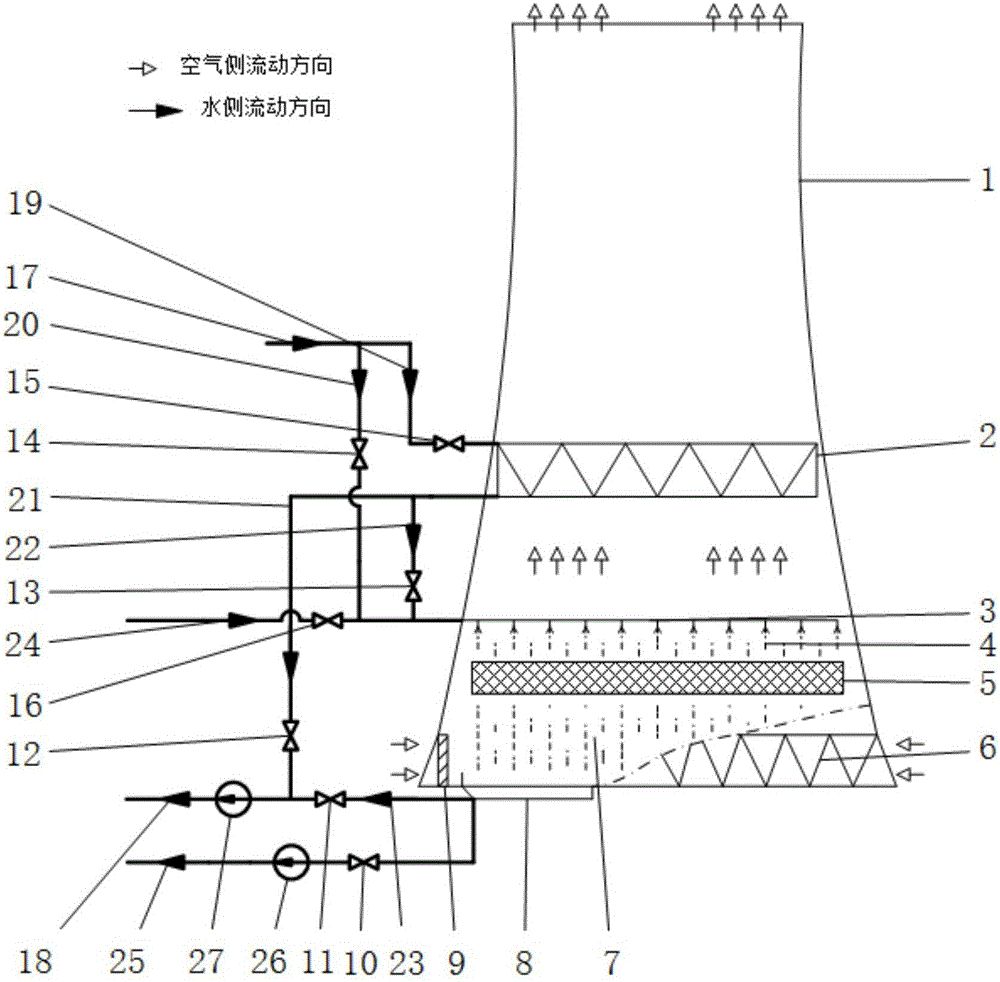

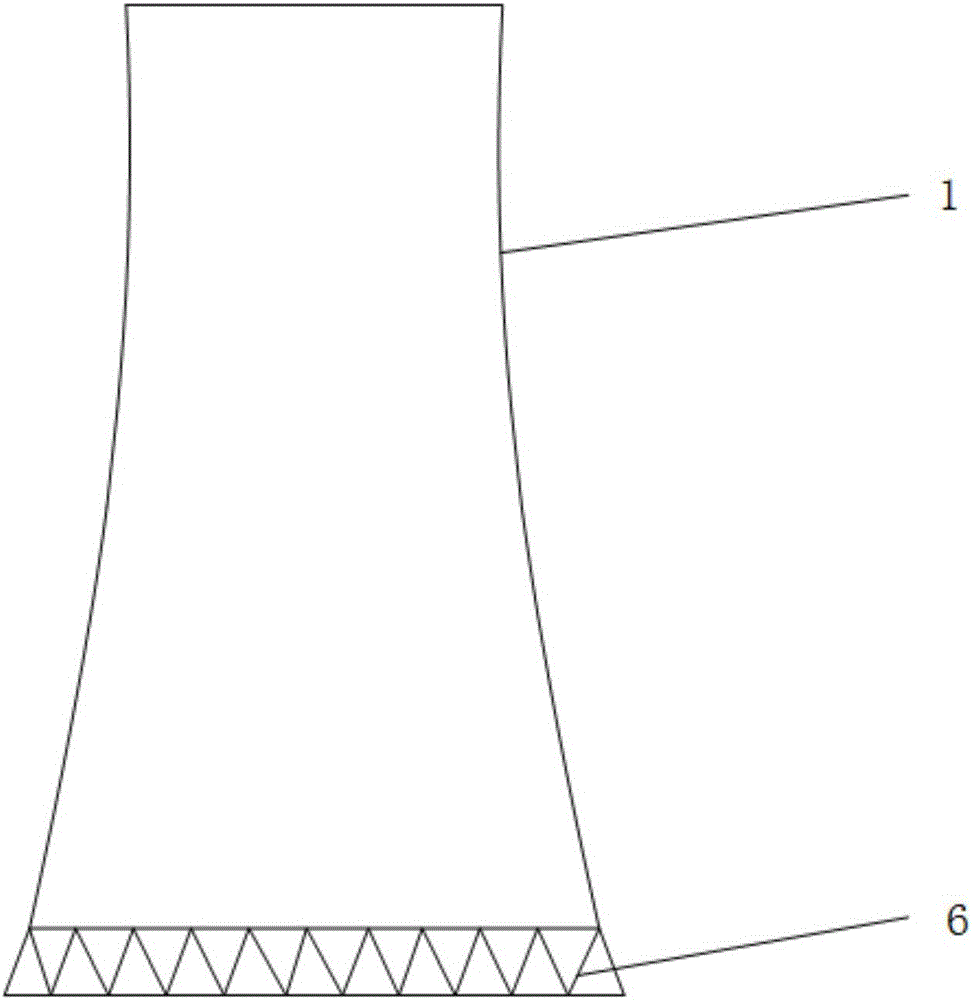

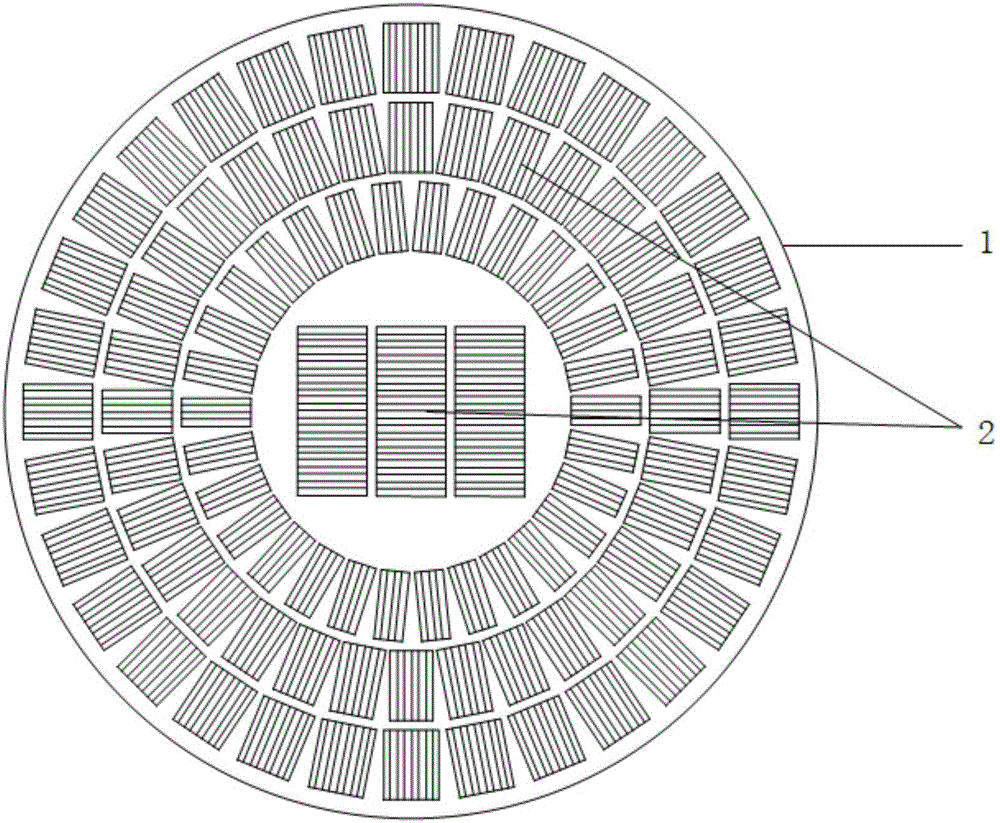

[0044] like Figure 1-Figure 2 Shown is a naturally ventilated dry-wet combined cooling tower with air precooling and winter antifreeze functions. The tower body 1 adopts a hyperbolic structure and is supported on the ground by a support structure 6. The support structure 6 is an "X"-shaped column or a "person" "Shaped column; the dry-cooling section and the wet-cooling section are integrated vertically in the tower body 1, and the dry-cooling section is located above the wet-cooling section, so that the installation height of the dry-cooling section equipment is higher than that of the dry-cooling section equipment in traditional indirect air cooling. The dry cooling section includes a dry cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com