Method for controlling high-speed flying shear

A flying shear control and high-speed technology, which is applied in the direction of tail end control, metal rolling, manufacturing tools, etc., can solve the problems of restricting production line production efficiency and control error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

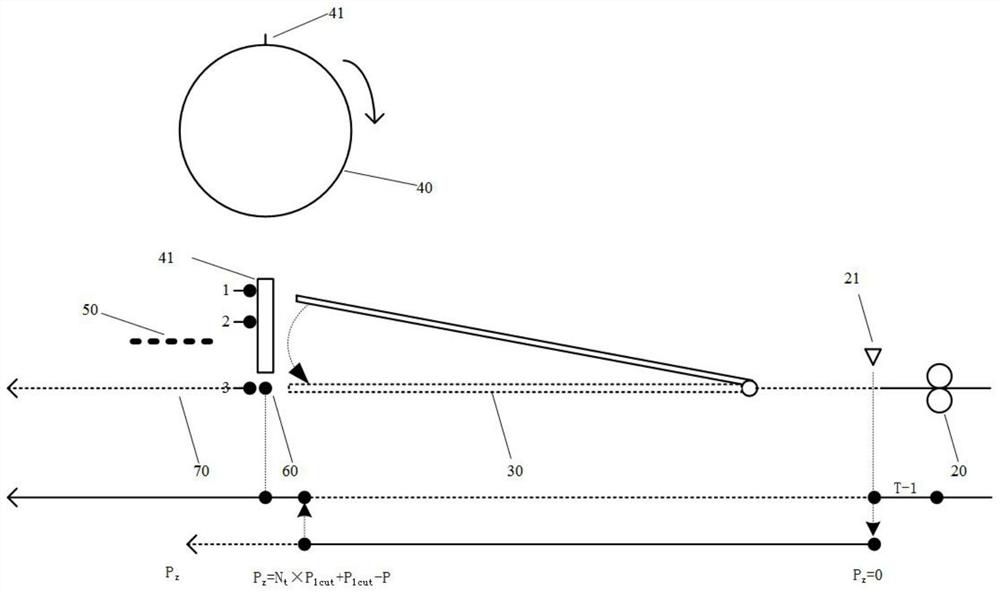

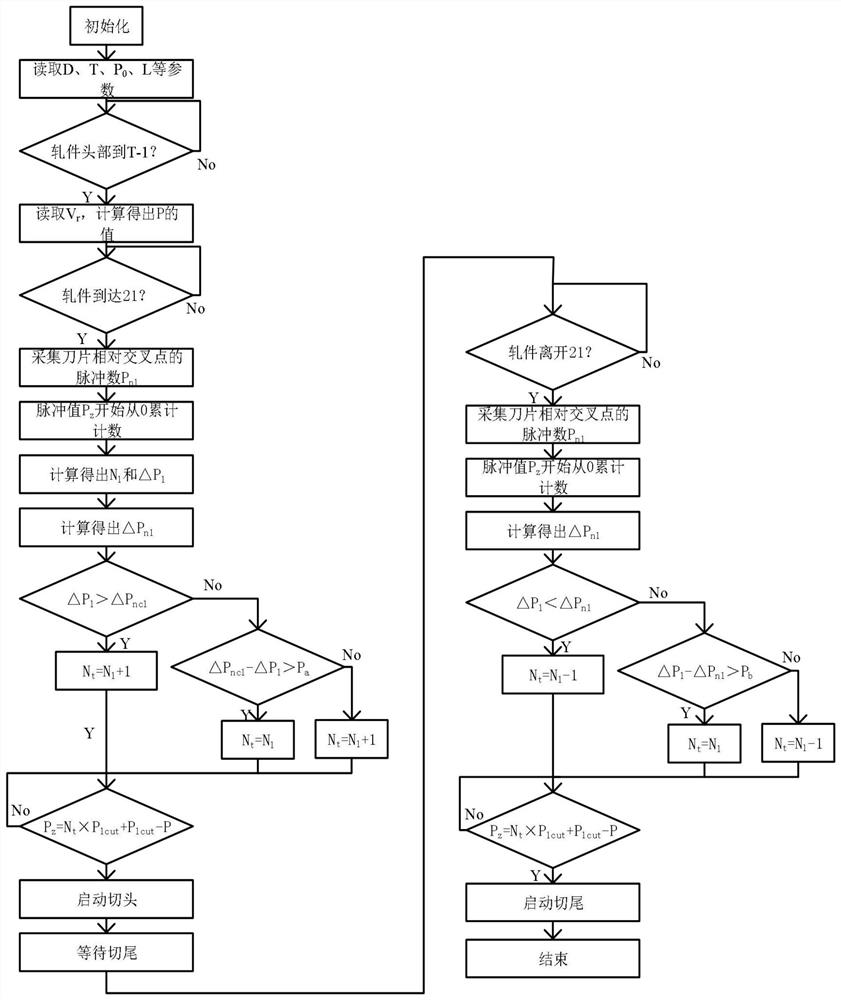

[0041] Such as figure 1 Shown, a kind of high-speed flying shear control method comprises the following steps:

[0042] S1. Use induction devices such as speedometers to detect the speed V of the rolled piece at the sampling stage T-1 r , and according to the velocity V r Calculate the first pulse value P of the forward rotation start of the steel dial 30, the formula is:

[0043] P=T×V r ×P 0 ÷(πD)

[0044] Wherein, T is the time required for the steel puller 30 to move from the broken position 1 to the shear position 2; P 0 is the number of pulses for one revolution of the blade 41; D is the rotation diameter of the blade 41;

[0045] S2. When the rolled piece detection equipment 21 detects the head of the rolled piece, collect the second pulse value P of the blade 41 relative to the intersection point 60 n1, calculate the third pulse value P corresponding to the length between adjacent blades 41 1cut , the formula is:

[0046] P 1cut =(P 0 ×L)÷(πD)

[0047] Wher...

Embodiment 2

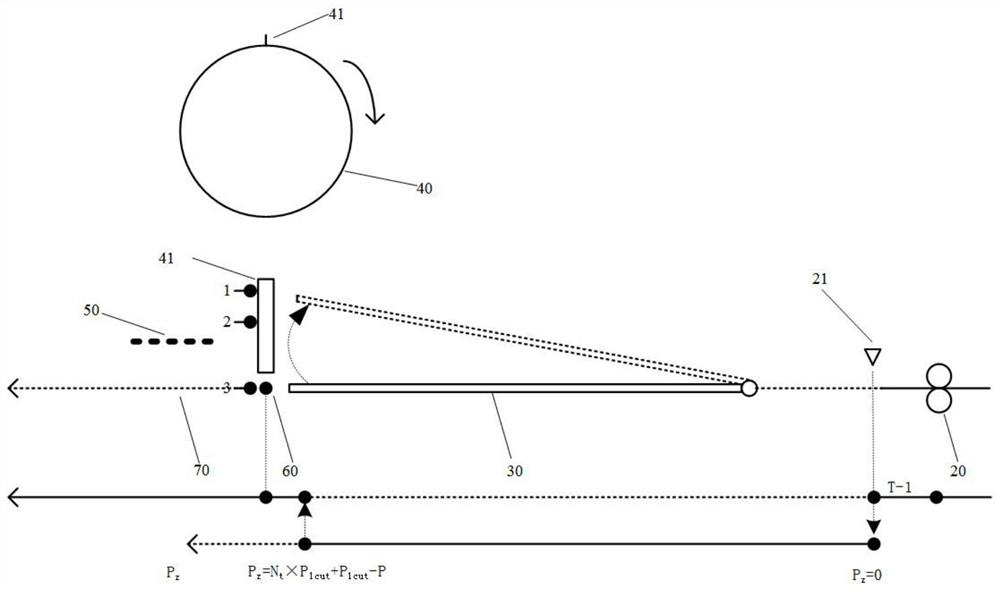

[0059] Such as figure 2 Shown, a kind of high-speed flying shear control method comprises the following steps:

[0060] S1. Use induction devices such as speedometers to detect the speed V of the rolled piece at the sampling stage T-1 r , and according to the velocity V r Calculate the first pulse value P of the reverse start of the steel puller 30, the formula is:

[0061] P=T×V r ×P0÷(πD)

[0062] Wherein, T is the time required for the steel puller 30 to move from the rolling position 3 to the shearing position 2; P 0 is the number of pulses for one revolution of the blade 41; D is the rotation diameter of the blade 41;

[0063] S2. When the rolled piece detection equipment 21 detects the head of the rolled piece, collect the second pulse value P of the blade 41 relative to the intersection point 60 n1 , calculate the third pulse value P corresponding to the length between adjacent blades 41 1cut , the formula is:

[0064] P 1cut =(P 0 ×L)÷(πD)

[0065] Wherein,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com