Switchable mechanical pump air-exhausting device for vacuum refining of molten steel

A vacuum refining and air extraction device technology, applied to mechanical equipment, pump combinations for elastic fluid rotary piston type/oscillating piston type, pumps, etc., can solve problems such as reduced efficiency, high power consumption, and long pre-pumping time , to achieve the effect of prolonging service life, low energy consumption and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention will be further described.

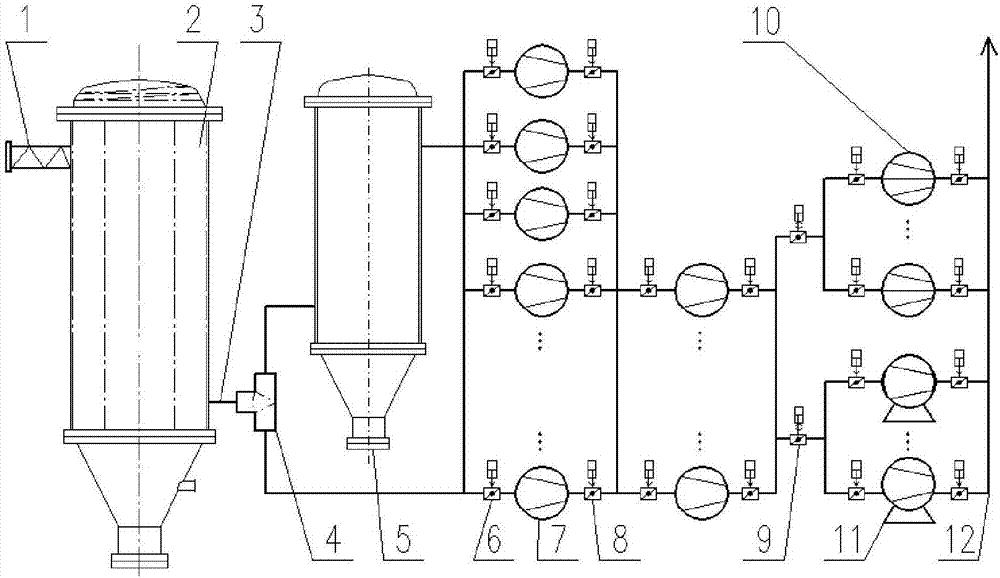

[0019] Such as figure 1 As shown, the device consists of: water-cooled exhaust pipe 1, gas cooler 2, exhaust pipe 3, vacuum quick switching box 4, high-temperature dust filter 5, pump front valve 6, Roots pump unit 7, pump rear valve 8, Switching valve 9, screw pump unit 10, water ring pump unit 11, emptying pipeline 12;

[0020] The pumped pipeline is flanged to the water-cooled pumping pipe 1, the water-cooled pumping pipe 1 is flanged to the gas cooler 2, and the outlet of the gas cooler 2 is connected to the pumping pipe 3; the right side of the pumping pipe 3 is connected to the vacuum quick switching box 4 connection, the vacuum quick switching box 4 can realize the quick switching of on-off in two directions, and one end leads to the high-temperature dust separator 5. The other end is merged with the outlet of the high-temperature dust separator 5 and leads to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com