System for performing iron removal on iron-containing solution

A solution and solution supply technology, applied in the chemical and metallurgical fields, to achieve the effect of improving the recovery rate, improving the iron removal efficiency and equipment utilization rate, and solving the problems of land occupation and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

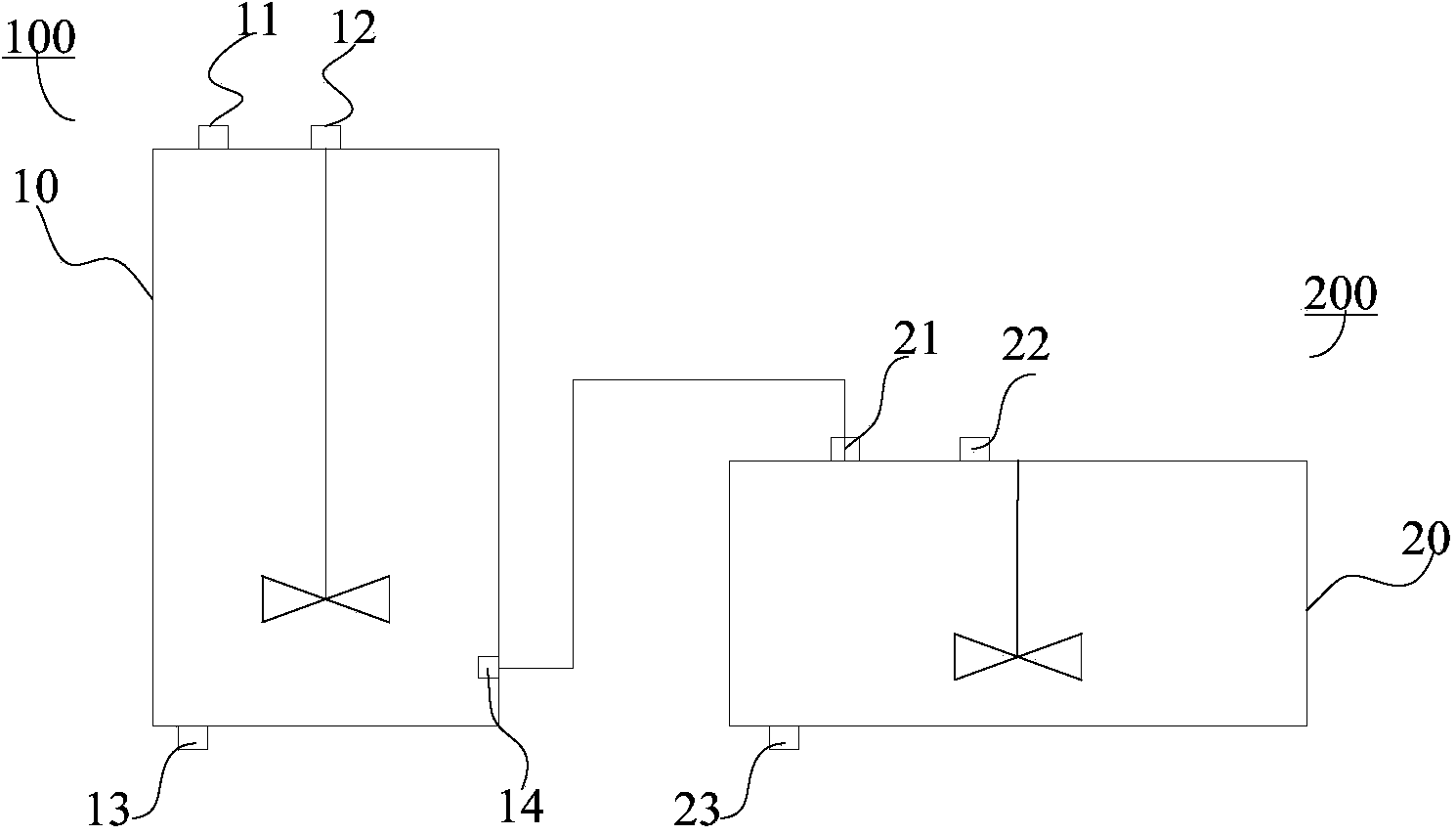

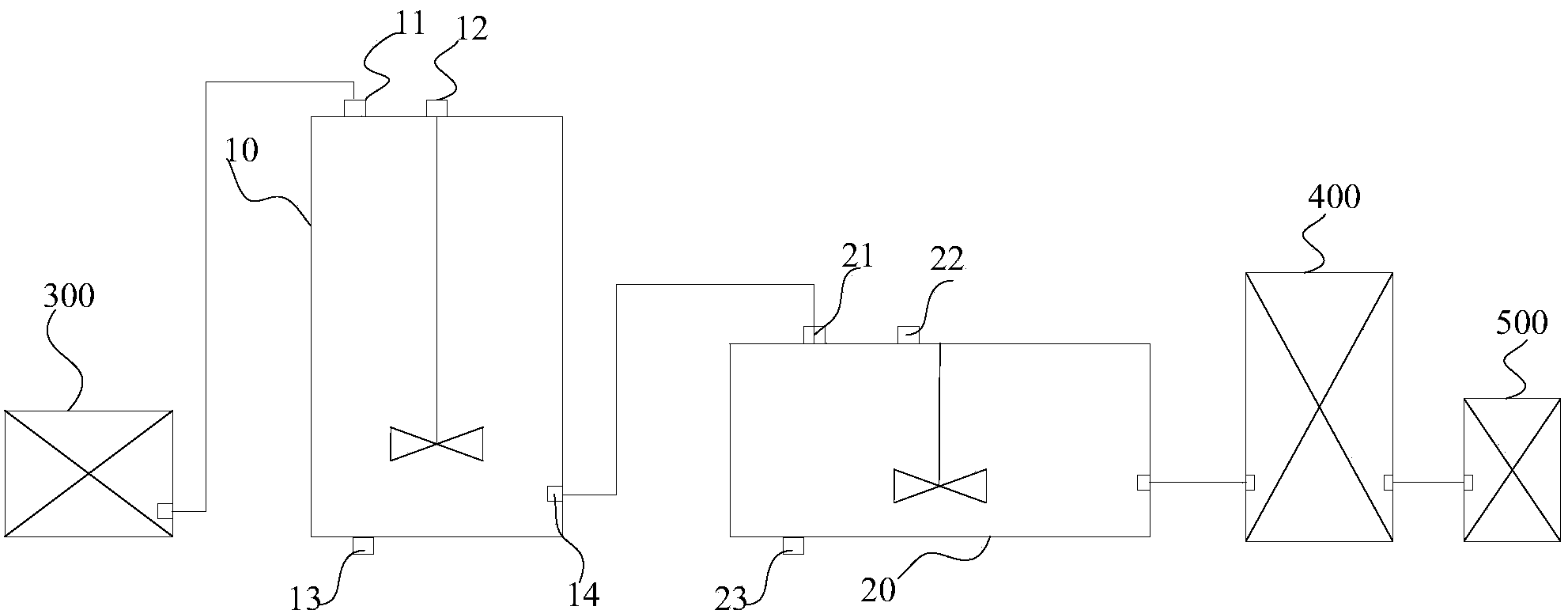

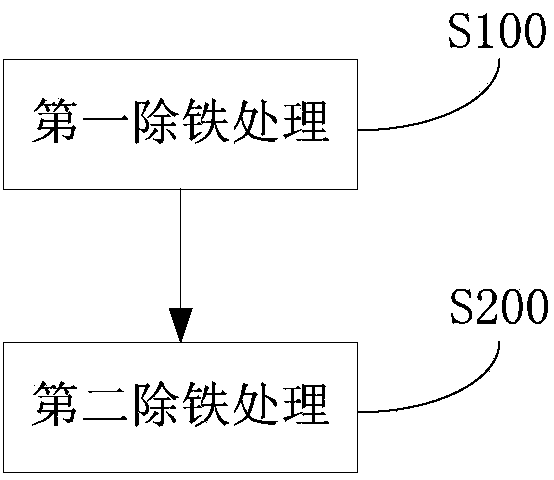

Method used

Image

Examples

Embodiment 1

[0061] According to the method for removing iron from iron-containing solution according to the embodiment of the present invention, iron-containing nickel sulfate solution is processed:

[0062] at 1m 3 vertical reactor and 3m 3 In a horizontal reactor, at 1m 3 The flow rate of / h is added to the iron-containing solution, the solution contains 60g / L of nickel and 25g / L of iron (as Fe 2+ meter), the pH value is 2.5, and the reaction temperature is maintained at 190°C. The iron-precipitated solution is flashed, filtered and washed to obtain iron-containing products (precipitation) and iron-precipitated liquid (filtrate), and the iron-precipitated liquid is returned to the system for circulation use.

[0063] The iron-containing product is determined to contain 60-68% iron, <0.3% nickel and <1% sulfur, which can be sold as cement or iron ore or further produced as iron red products.

Embodiment 2

[0065] According to the method for removing iron from iron-containing solution according to the embodiment of the present invention, iron-containing copper sulfate solution is processed:

[0066] at 1m 3 vertical reactor and 3m 3 In a horizontal reactor, at 1m 3 Add the iron-containing solution at a flow rate of / h, the solution contains 50g / L of copper and 30g / L of iron (as Fe 2+ meter), the pH value is 2.5, and the reaction temperature is maintained at 190°C. The iron-precipitated solution is flashed, filtered and washed to obtain iron-containing products (precipitation) and iron-precipitated liquid (filtrate), and the iron-precipitated liquid is returned to the system for circulation use.

[0067] The iron-containing product is determined to contain 60-68% of iron, <0.2% of copper and <1% of sulfur, which can be sold as cement or iron ore or further produced into iron red products.

Embodiment 3

[0069] According to the method for removing iron from iron-containing solution according to the embodiment of the present invention, iron-containing cobalt sulfate solution is processed:

[0070] at 1m 3 vertical reactor and 3m 3 In a horizontal reactor, at 1m 3 The flow rate of / h is added to the iron-containing solution, the solution contains 30g / L of cobalt and 35g / L of iron (as Fe 2+ meter), the pH value is 2.5, and the reaction temperature is maintained at 190°C. The iron-precipitated solution is flashed, filtered and washed to obtain iron-containing products (precipitation) and iron-precipitated liquid (filtrate), and the iron-precipitated liquid is returned to the system for circulation use.

[0071] It is determined that the iron-containing product contains 60-68% iron, cobalt <0.2%, and sulfur <1%, which can be sold as cement or iron ore or further produced into iron red products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com