Rapid efficient iron-removing whitening method for low-grade raw material

A low-grade, high-efficiency technology, used in clay products, other household appliances, household appliances, etc., can solve the problems of high energy consumption in the calcination process, residual in raw materials, strong sulfuric acid corrosion, etc. Low, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

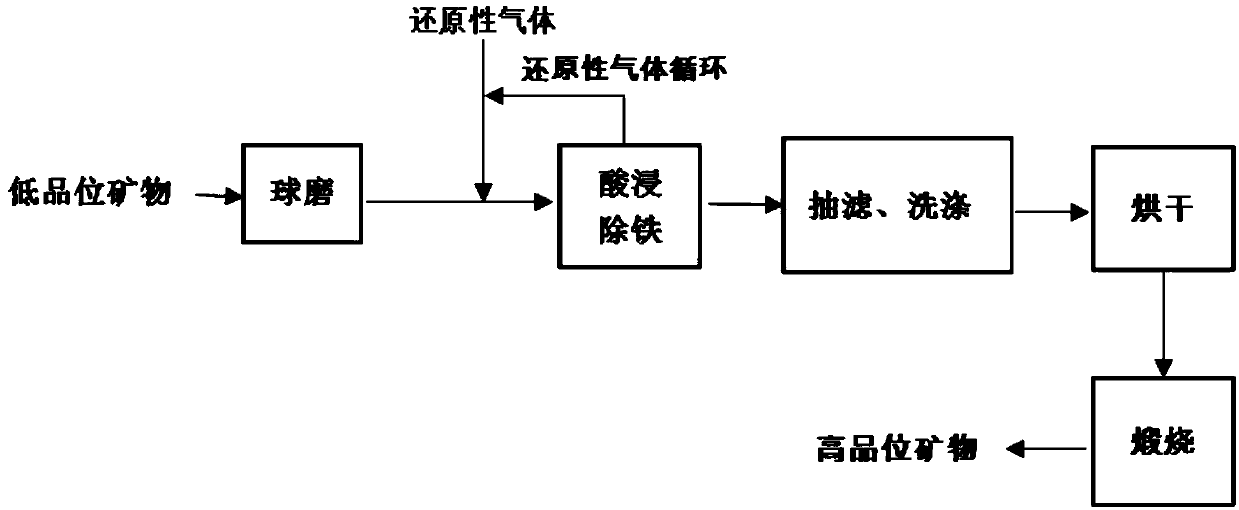

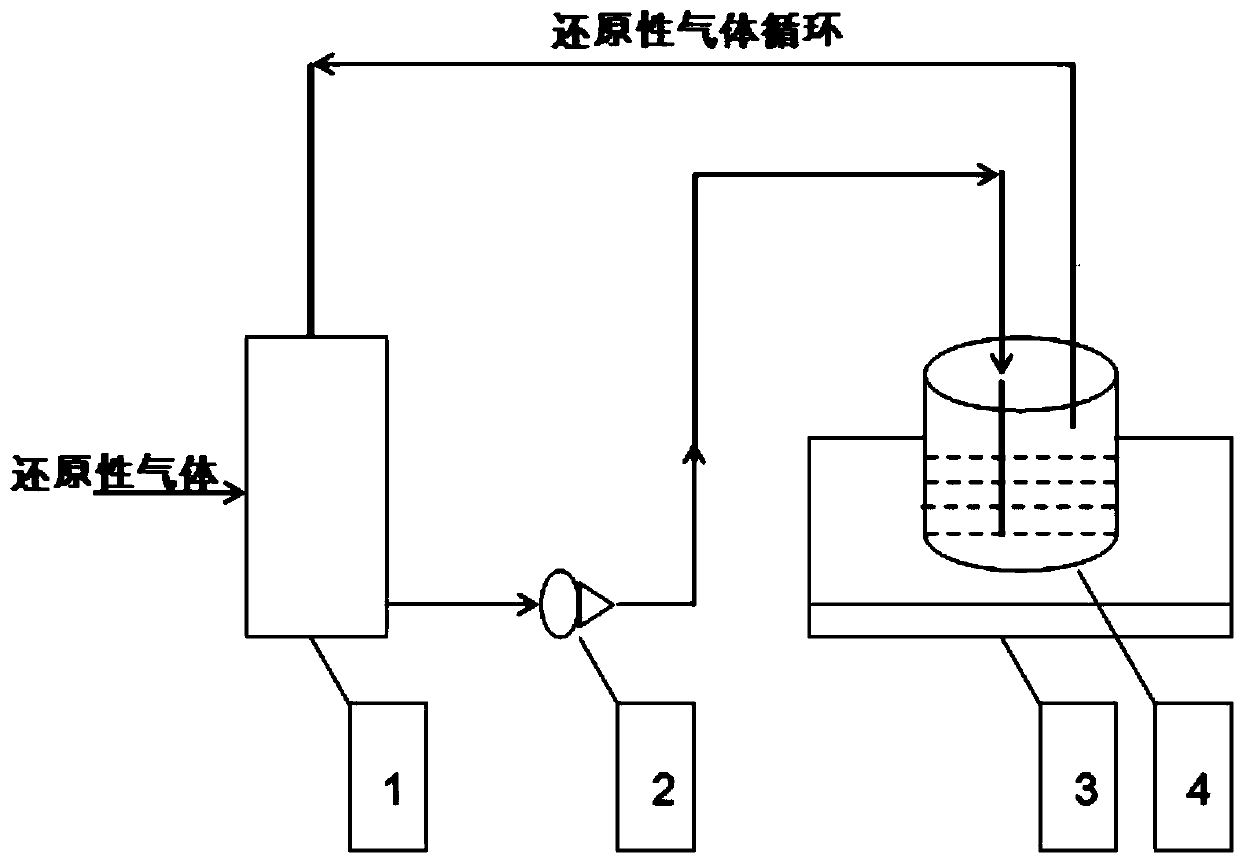

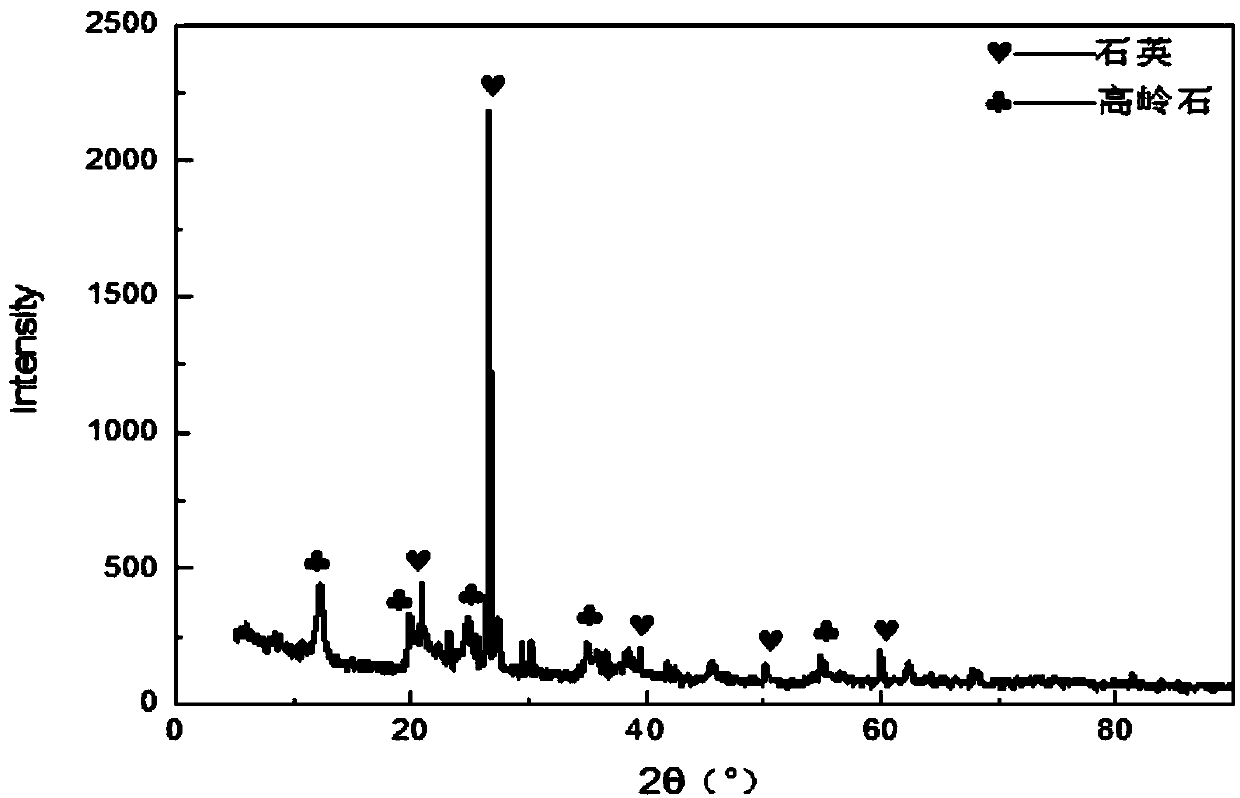

[0031] A method for rapid and high-efficiency iron removal and whitening of low-grade raw materials, the preparation process is as follows figure 1 As shown, the reaction device is as figure 2 As shown, the XRD pattern of low-grade raw materials is as follows image 3 shown, including the following steps:

[0032] (1) Ball mill the low-grade raw material through a 200-mesh sieve, then weigh 5g of the low-grade raw material, add 100ml of water to prepare a slurry;

[0033] (2) Add oxalic acid so that its concentration in the pulp is 0.01mol / L;

[0034] (3) The above mixture was placed in a reaction device, and hydrogen gas was introduced to carry out iron removal reaction. During the reaction, magnetic stirring was used, the reaction temperature was set at 95° C., and the temperature was kept for 240 minutes;

[0035] (4) After the reaction, use a suction filtration device to separate the solid from the liquid, wash it, and then dry it in an oven at 80°C to obtain a high-gr...

Embodiment 2

[0038] A method for fast and high-efficiency iron removal and whitening of low-grade raw materials, comprising the following steps:

[0039] (1) The low-grade raw material is ball milled through a 200-mesh sieve, then 230g of the low-grade raw material is weighed, and 100ml of water is added to prepare a slurry;

[0040] (2) adding citric acid so that its concentration in the pulp is 3mol / L;

[0041] (3) Put the above mixture in the reaction device, feed in hydrogen to carry out the iron removal reaction, use magnetic stirring during the reaction, set the reaction temperature to 25°C, and keep it warm for 5 minutes;

[0042] (4) After the reaction, the solid-liquid separation is carried out with a suction filtration device, washed, and then put into an oven for drying at 120° C. to obtain high-grade raw materials with low iron content.

[0043] Before iron removal, Fe 2 o 3 The content is 2.98wt%, the natural whiteness is 19.11%, and the calcined whiteness is 20.91%. After...

Embodiment 3

[0045] A method for fast and high-efficiency iron removal and whitening of low-grade raw materials, comprising the following steps:

[0046] (1) Low-grade raw materials are ball-milled through a 200-mesh sieve, then 150g of low-grade raw materials are weighed, and 100ml of water is added to prepare a slurry;

[0047] (2) adding malic acid so that its concentration in the pulp is 1mol / L;

[0048] (3) The above mixture is placed in a reaction device, and carbon monoxide is introduced to carry out iron removal reaction. During the reaction, magnetic stirring is used, the reaction temperature is set to 75° C., and the temperature is kept for 120 minutes;

[0049] (4) After the reaction, use a suction filtration device to separate the solid from the liquid, wash it, and then dry it in an oven at 100°C to obtain a high-grade raw material with low iron content.

[0050] Before iron removal, Fe 2 o 3 The content is 2.98wt%, the natural whiteness is 19.11%, and the calcined whitenes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com