Steel slag real-time circular iron removal and grinding method

A technology for circulating iron and steel slag powder, applied in chemical instruments and methods, transportation and packaging, solid waste removal, etc., can solve problems such as poor grindability, blockage of equipment and pipelines, and large power of steam milling, and achieve improvement Fragility or wearability, reduction of energy consumption and mechanical loss, and the effect of reducing system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

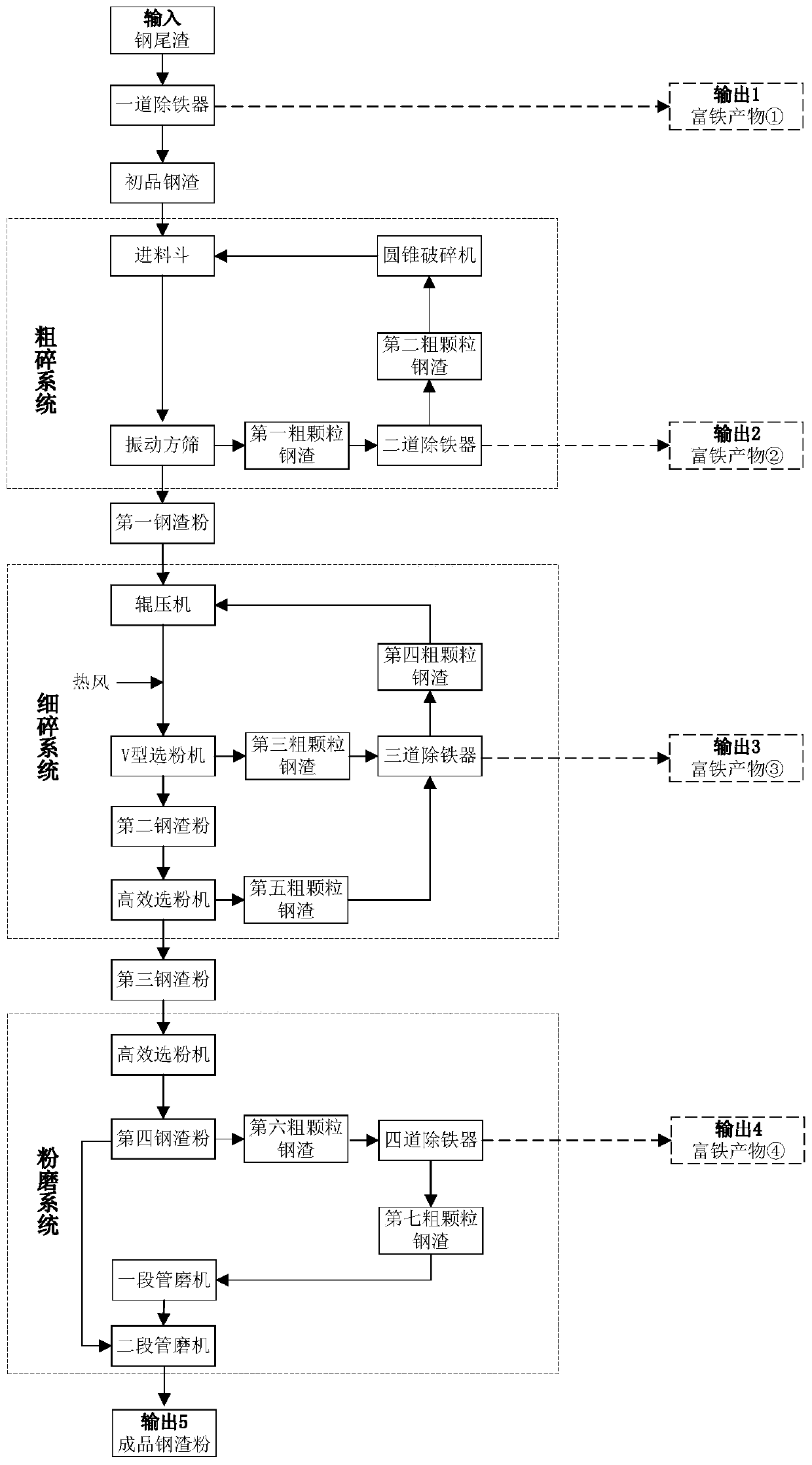

[0030] A method for real-time circulating iron removal and grinding of steel slag, comprising the following steps:

[0031] (1) Feeding and iron removal: After the steel tailing slag particles with a maximum particle size of about 100mm are transported to the raw material warehouse by the unloading truck, they are sent to the receiving bin by the loader, and a suspension broadband iron remover is used on the conveyor belt to carry out a process. Removal of iron, after removal of large metallic iron (iron-rich product ①), the primary product of steel slag is obtained;

[0032] (2) Coarse crushing and iron removal: Use a vibrating screen to screen the steel slag primary product described in step (1), and screen out the first steel slag powder with a particle size of 0-18mm and the first coarse steel slag powder with a particle size ≥ 18mm. Granular steel slag, so that the screened first steel slag powder enters the subsequent fine crushing system; the second coarse steel slag is...

Embodiment 2

[0037] A method for real-time circulating iron removal and grinding of steel slag, comprising the following steps:

[0038] (1) Feeding and iron removal: After the steel tailing slag particles with a maximum particle size of about 100mm are transported to the raw material warehouse by the unloading truck, they are sent to the receiving bin by the loader, and a suspension broadband iron remover is used on the conveyor belt to carry out a process. Removal of iron, after removal of large metallic iron (iron-rich product ①), the primary product of steel slag is obtained;

[0039] (2) Coarse crushing and iron removal: use a vibrating screen to screen the primary steel slag product described in step (1), and screen out the first steel slag powder with a particle size of 0-20mm and the first coarse steel slag powder with a particle size ≥ 20mm. Granular steel slag, so that the screened first steel slag powder enters the subsequent fine crushing system; the second coarse steel slag is...

Embodiment 3

[0044] A method for real-time circulating iron removal and grinding of steel slag, comprising the following steps:

[0045] (1) Feeding and iron removal: After the steel tailing slag particles with a maximum particle size of about 100mm are transported to the raw material warehouse by the unloading truck, they are sent to the receiving bin by the loader, and a suspension broadband iron remover is used on the conveyor belt to carry out a process. Removal of iron, after removal of large metallic iron (iron-rich product ①), the primary product of steel slag is obtained;

[0046] (2) Coarse crushing and iron removal: use a vibrating screen to screen the primary steel slag product described in step (1), and screen out the first steel slag powder with a particle size of 0-20mm and the first coarse steel slag powder with a particle size ≥ 20mm. Granular steel slag, so that the screened first steel slag powder enters the subsequent fine crushing system; the second coarse steel slag is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com