Fast detection device and method for position of lower step liner of rolling mill

A detection device and a technology for step pads, which are applied in the field of step pads under rolling mills, can solve the problems that the finishing mill does not have the rolling conditions, the production interruption of the rolling line, and the long time, so as to shorten the processing time, improve the operation rate of the rolling mill, and improve the production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

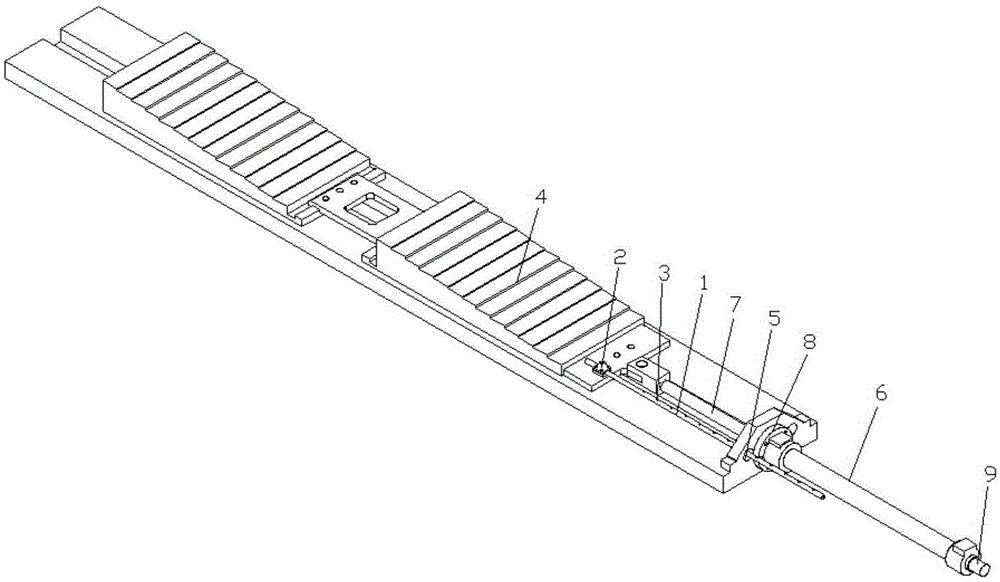

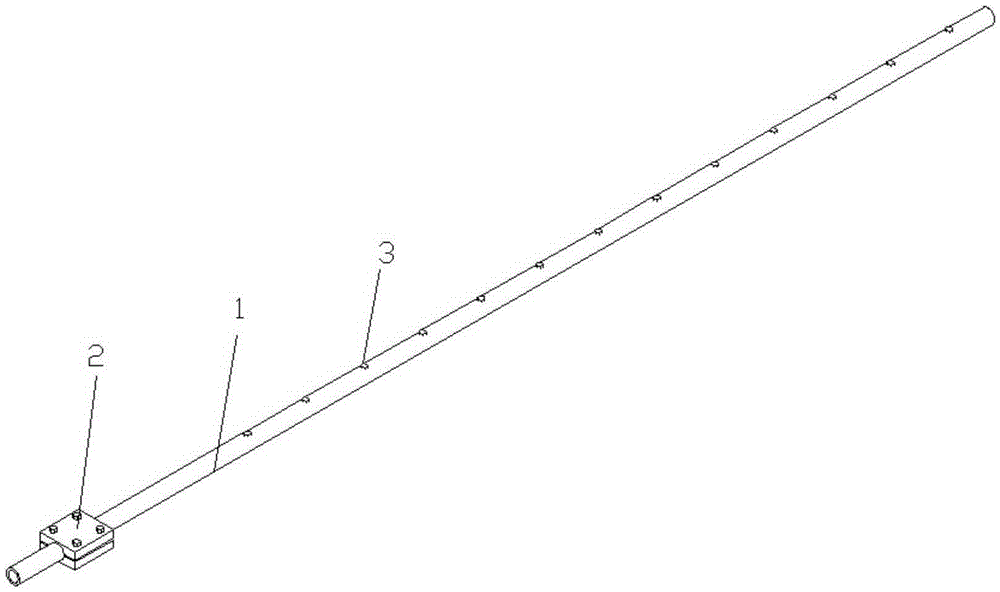

[0017] Such as Figure 1-2 As shown, a rapid detection device for the position of the lower step pad of a rolling mill includes a scale rod 1 and a fixed pipe clamp 2. Same number of stages as lower step pad 4.

[0018] The reading part can be a bump or a groove or a straight line, etc. The number of the reading part is thirteen, which corresponds to the number of steps of the lower step pad, and the distance between two adjacent reading parts is 150mm .

[0019] The scale rod is a cylindrical rod, and the fixed pipe clamp consists of two symmetrically arranged rectangular blocks with semicircular grooves in the center. The two sides of the two rectangular blocks are connected by bolts, and the diameter of the semicircular groove is slightly smaller than the scale. The diameter of the rod.

[0020...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com