Part installation method of part assembly line

A technology of parts installation and installation line, which is applied in the field of parts installation of parts installation line, can solve problems such as unestablished sequence setting methods, and achieve the effect of good work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

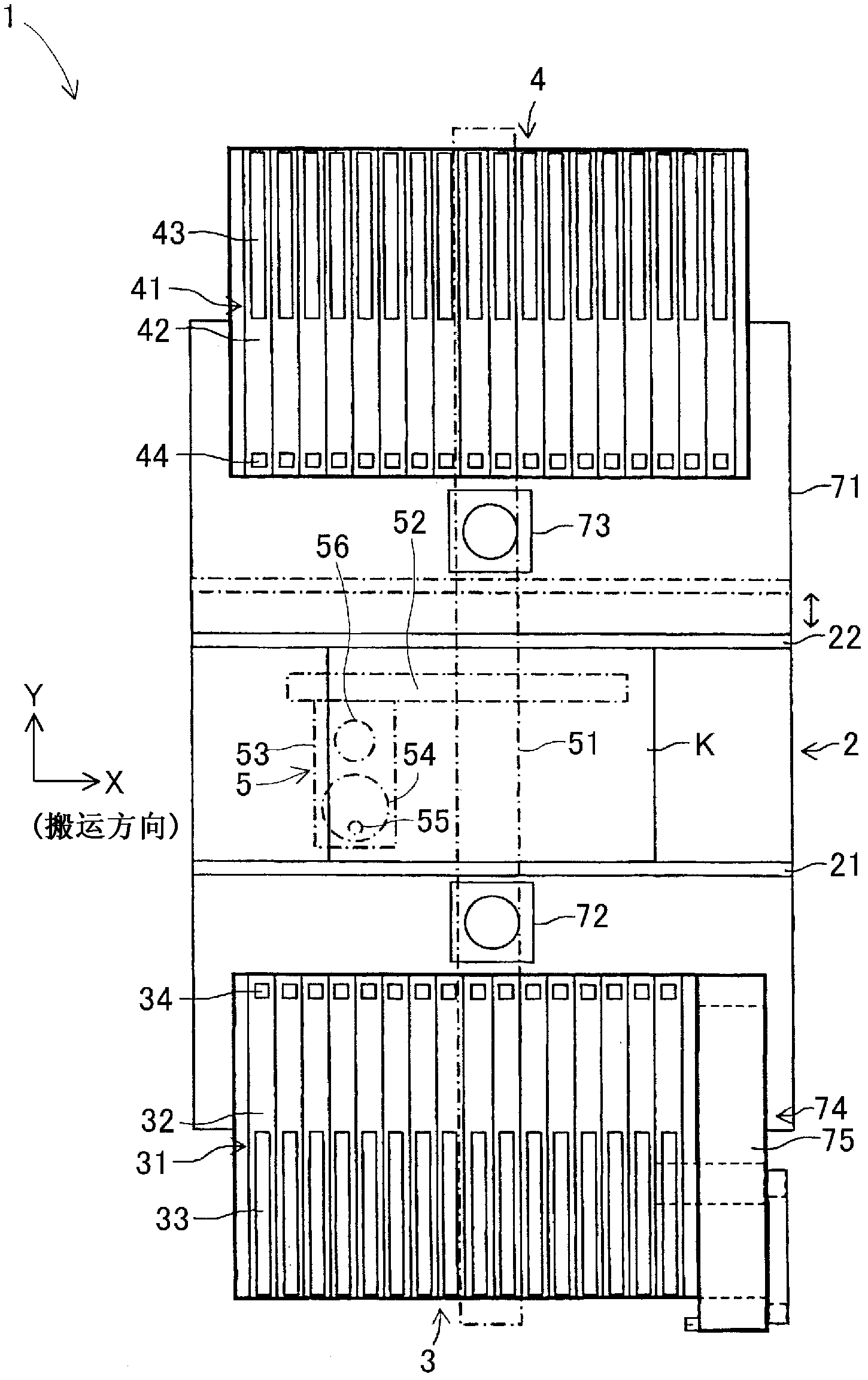

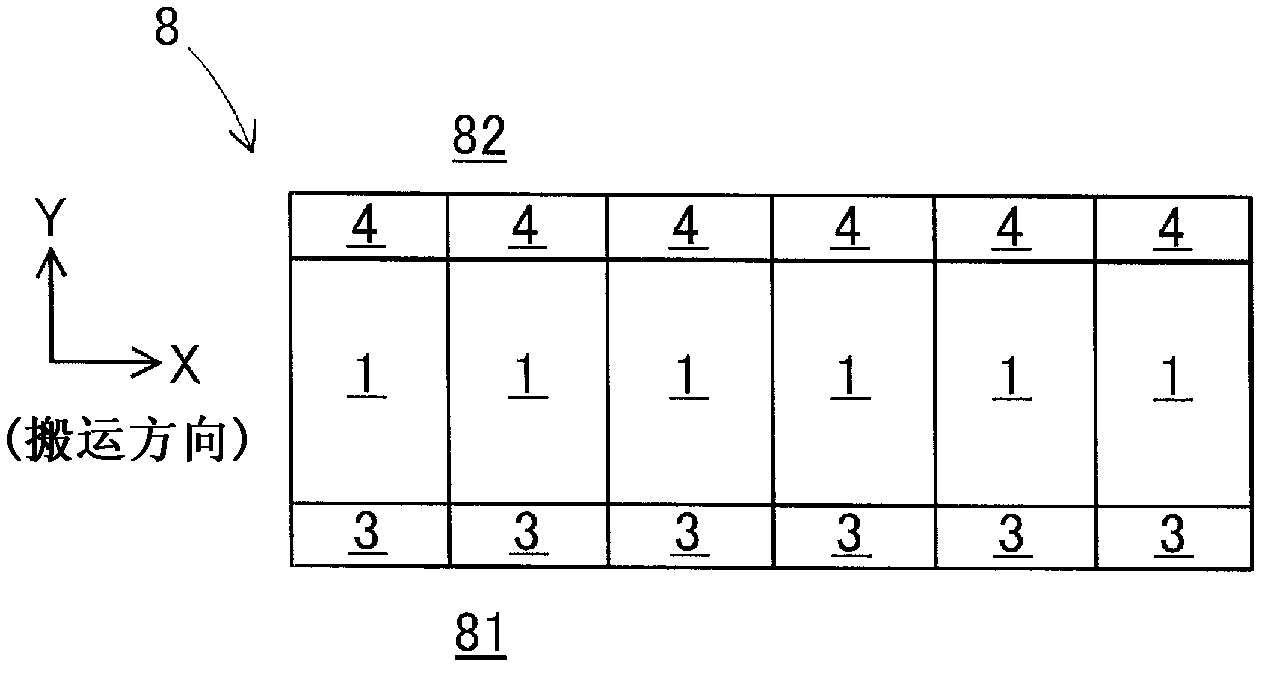

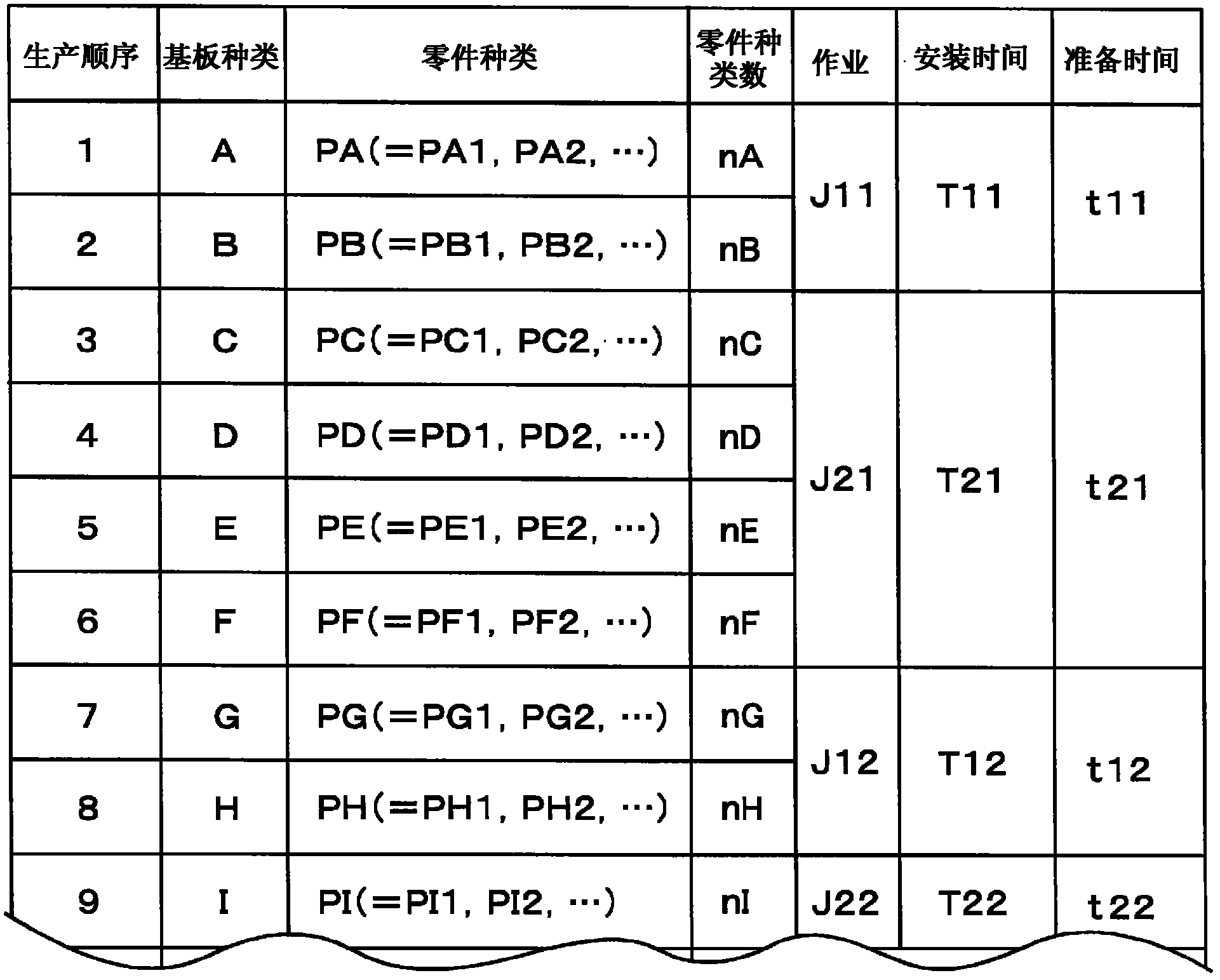

[0041] refer to Figure 1 ~ Figure 4 , the component mounting method of the component mounting line according to the first embodiment of the present invention will be described. First, the configurations of the component mounting machine 1 and the component mounting line 8 will be described. figure 1 It is a plan view showing a schematic structure of the component mounting machine 1 used in the present invention. The component mounting machine 1 is configured by arranging the substrate conveyance device 2 , the first component supply device 3 , the second component supply device 4 , the component transfer device 5 and the like on a base 71 .

[0042] The substrate transfer device 2 is constituted by first and second guide rails 21, 22, a pair of conveyor belts, a clamping device, and the like. The first and second guide rails 21 and 22 extend across the upper center of the base 71 in the conveyance direction (X direction), and are assembled to the base 71 so as to be paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com