Method for measuring content of oxygen, nitrogen and hydrogen in titanium alloy

A hydrogen content and titanium alloy technology, applied in the direction of measuring devices, test metals, test samples, etc., can solve the problems of low-content gas element sample test influence, cumbersome steps, etc., to eliminate blank interference, simple method, saving Analyze cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with specific examples.

[0019] (1) Take a high-purity electrolytic nickel plate with an oxygen, nitrogen and hydrogen content less than 0.01% for surface grinding and rust removal, cut into strips with a width of about 0.5-2.5mm, and cut into regular lengths with a mass of 1.50±0.10g Square nickel particle flux;

[0020] (2) pickling in 75mL glacial acetic acid + 25mL nitric acid + 2mL hydrochloric acid pickling solution for 40-50s, to remove the trace oxides on the surface of the nickel grains that have not been completely polished or the sand grains embedded in the surface when the grinding wheel is polished, Use an ultrasonic cleaner and acetone organic reagent to quickly clean and decontaminate, and store in a sealed plastic bottle after drying.

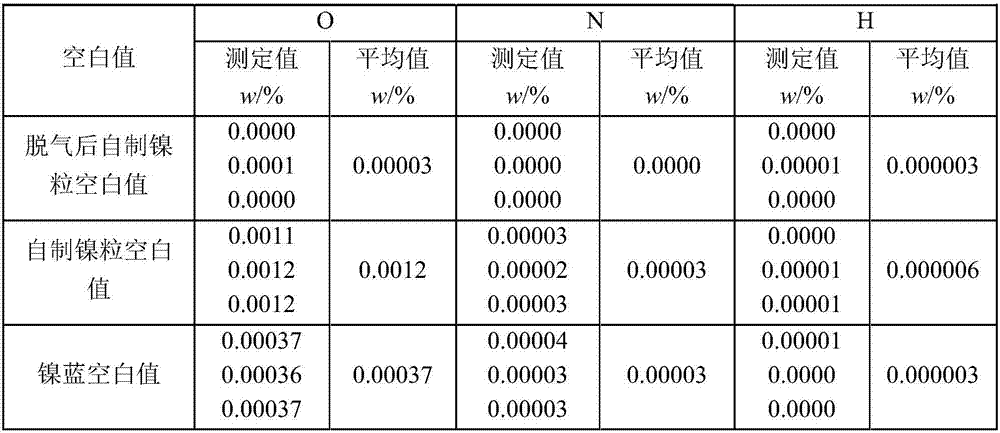

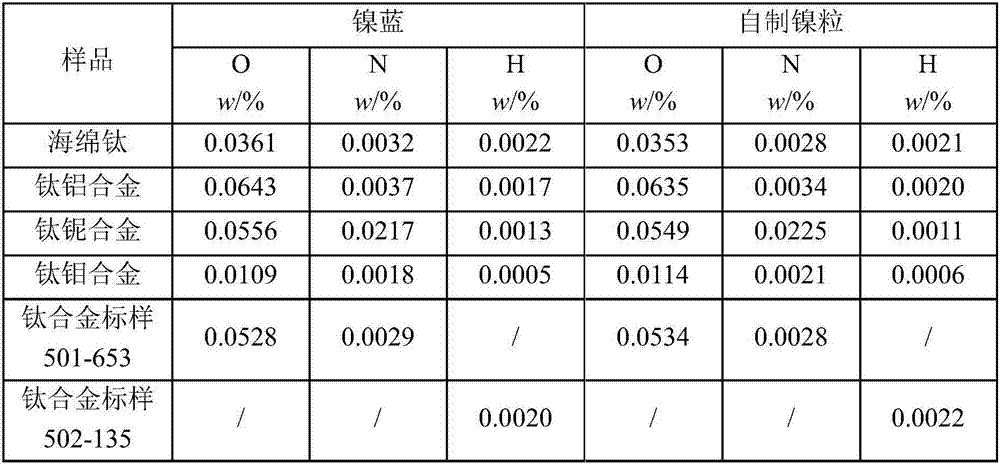

[0021] (3) After the electrode is lowered, manually put the nickel particle flux into the high-purity graphite crucible of the oxygen, nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com