Sampling device and method for detecting nitrogen content of molten steel by oxygen, nitrogen and hydrogen analyzer

The technology of an oxygen, nitrogen and hydrogen analyzer and sampling device is applied in the direction of sampling device and test sample preparation, etc., which can solve the problems of detecting nitrogen content and the inability to use spark direct reading detector, etc., and achieves simple operation, reduced smelting time and Cost of production, effect of simple devices and methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

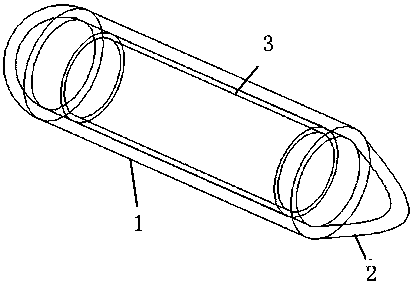

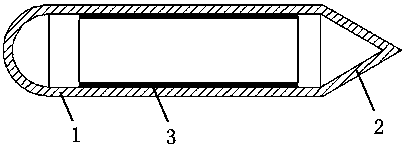

[0032] A heat of 316LN steel was smelted, and the nitrogen content in the design composition was 0.015 (mass percentage). Before smelting, the sampling device is installed on the sampling gun. When the end point of smelting needs component detection, the conical head 2 of the glass container 1 is inserted into the molten steel at a certain safe distance, the high-temperature molten steel melts the conical head 2, and the molten steel is pumped out by using the vacuum inside the glass container 1. Into the glass container 1, the oxygen in the molten steel reacts with the aluminum foil 3, so as to avoid inaccurate detection caused by air bubbles in the sample during the cooling process. The insertion process lasts for about 3 seconds, and after the molten steel fills the glass container 1, it is quickly taken out and water-cooled. After knocking off the glass layer, the sample to be tested can be obtained. There are no air holes on the surface and inside of the sample, and the...

example 2

[0034] A furnace of Cr18Mn18N non-magnetic austenitic stainless steel was smelted, and the design composition nitrogen content was 0.50. Before smelting, install the sampling device on the sampling gun. When the composition is detected at the end of smelting, insert the conical head 2 of the glass container 1 into the molten steel from a certain safe distance. After inserting for 3 seconds, take it out and water-cool it. The test sample can be obtained by knocking the glass layer on the surface and removing the surface layer of the sample by car. There are no pores on the surface and core of the sample, meeting the testing requirements. Sent to testing center for testing. The test result is 0.496, which is close to the design component.

example 3

[0036] A furnace of 317LN steel was smelted, and the nitrogen content in the design composition was 0.10. Install the device on the sampling gun before smelting. When sampling, insert the conical head 2 of the glass container 1 into the molten steel from a certain safe distance. The insertion process lasts for 2 seconds, then take it out and cool it with water. After knocking off the glass layer, the surface layer of the sample is removed by car to obtain the test sample, and the surface and interior of the sample have no pores. Sent to the testing center for testing, the testing result was 0.112, which was close to the design composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com