Patents

Literature

65results about How to "Eliminate oxygen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

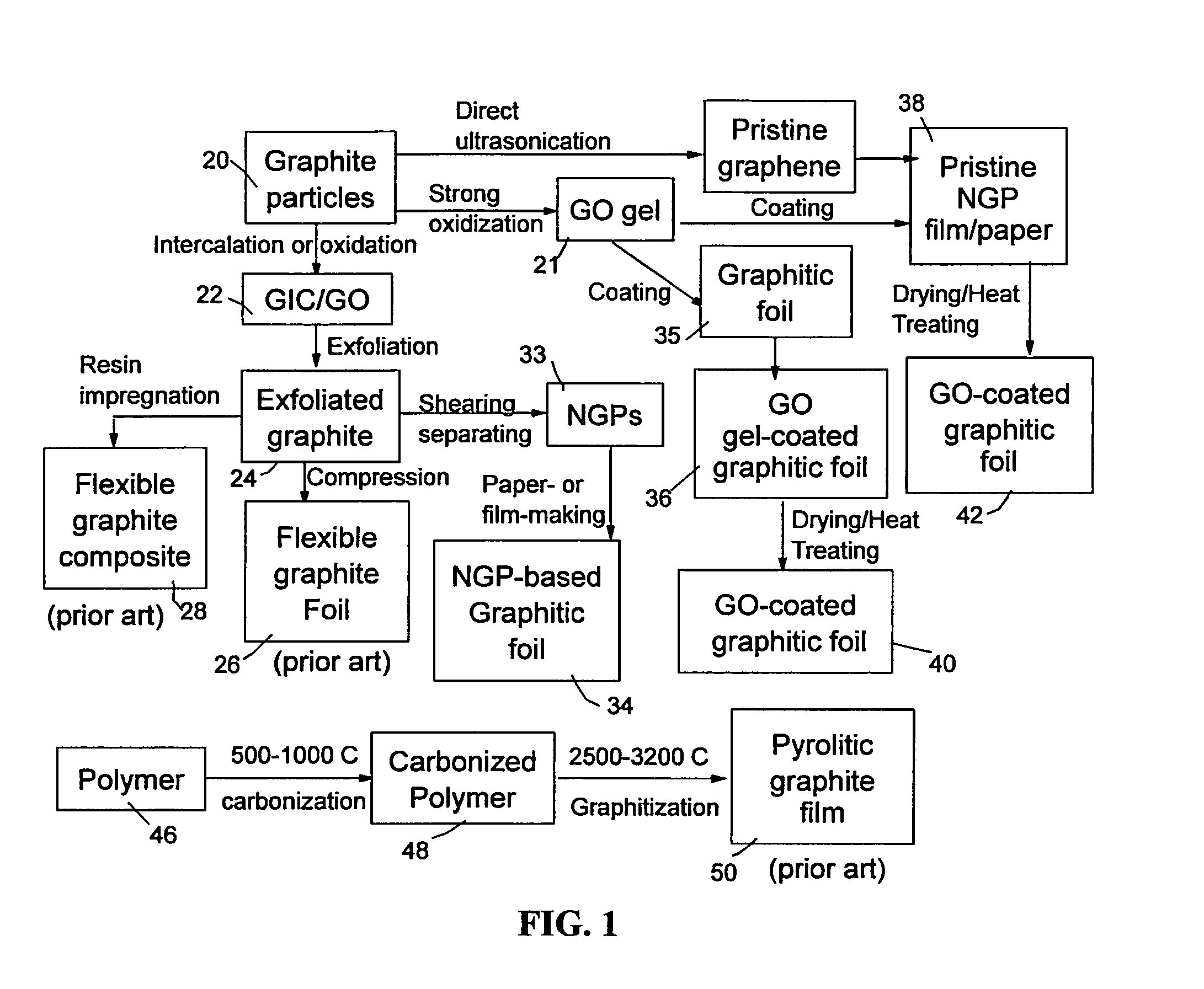

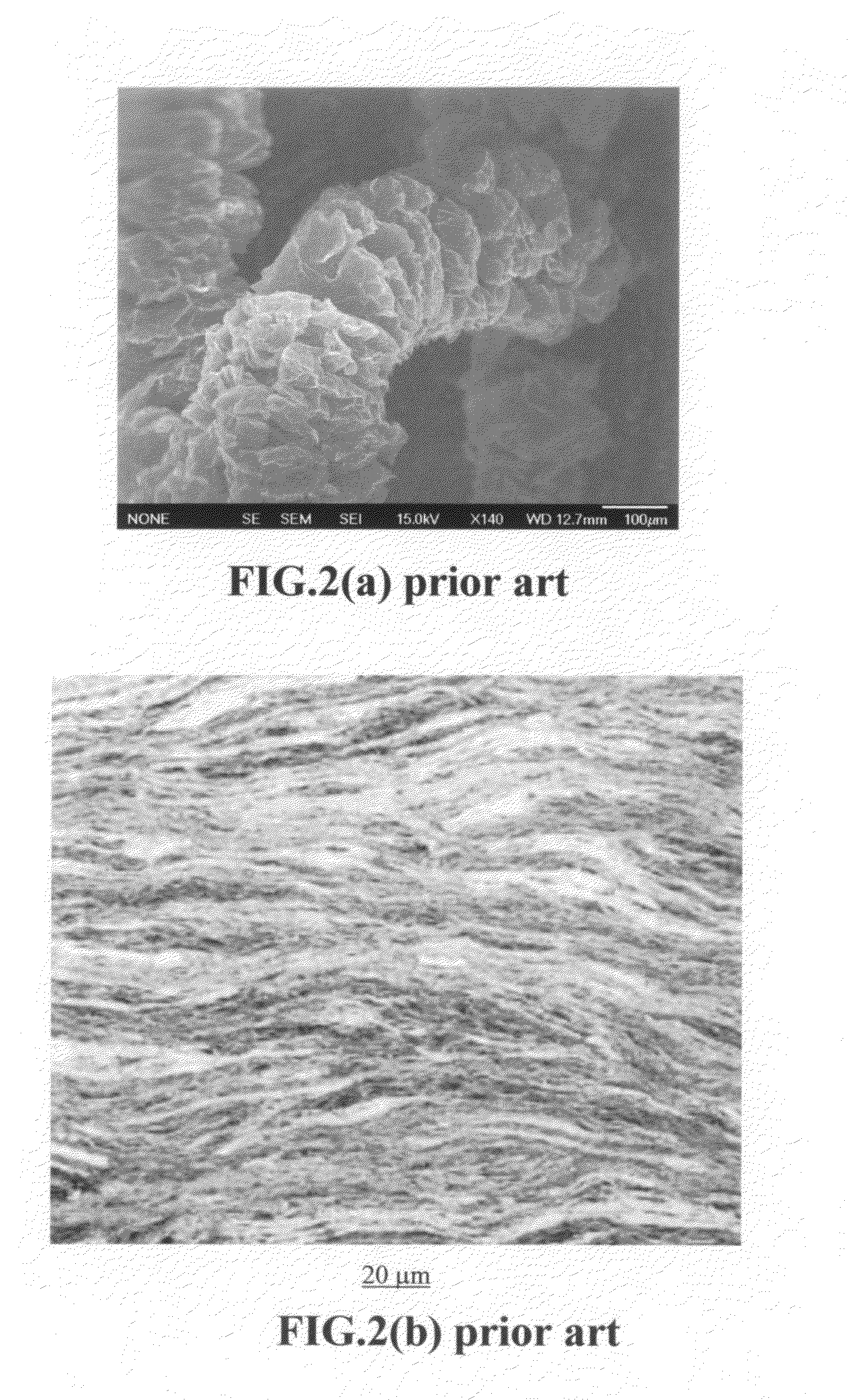

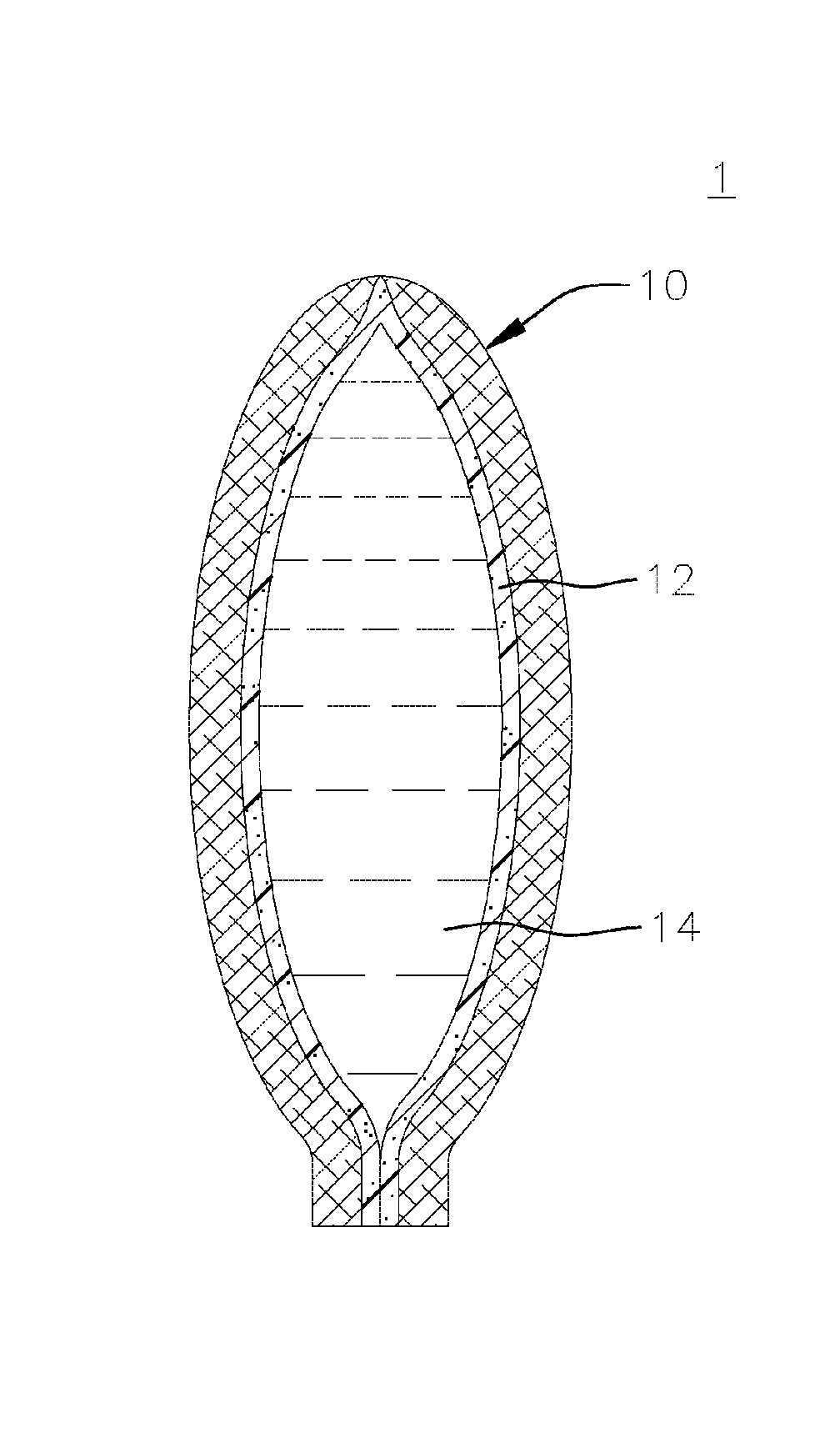

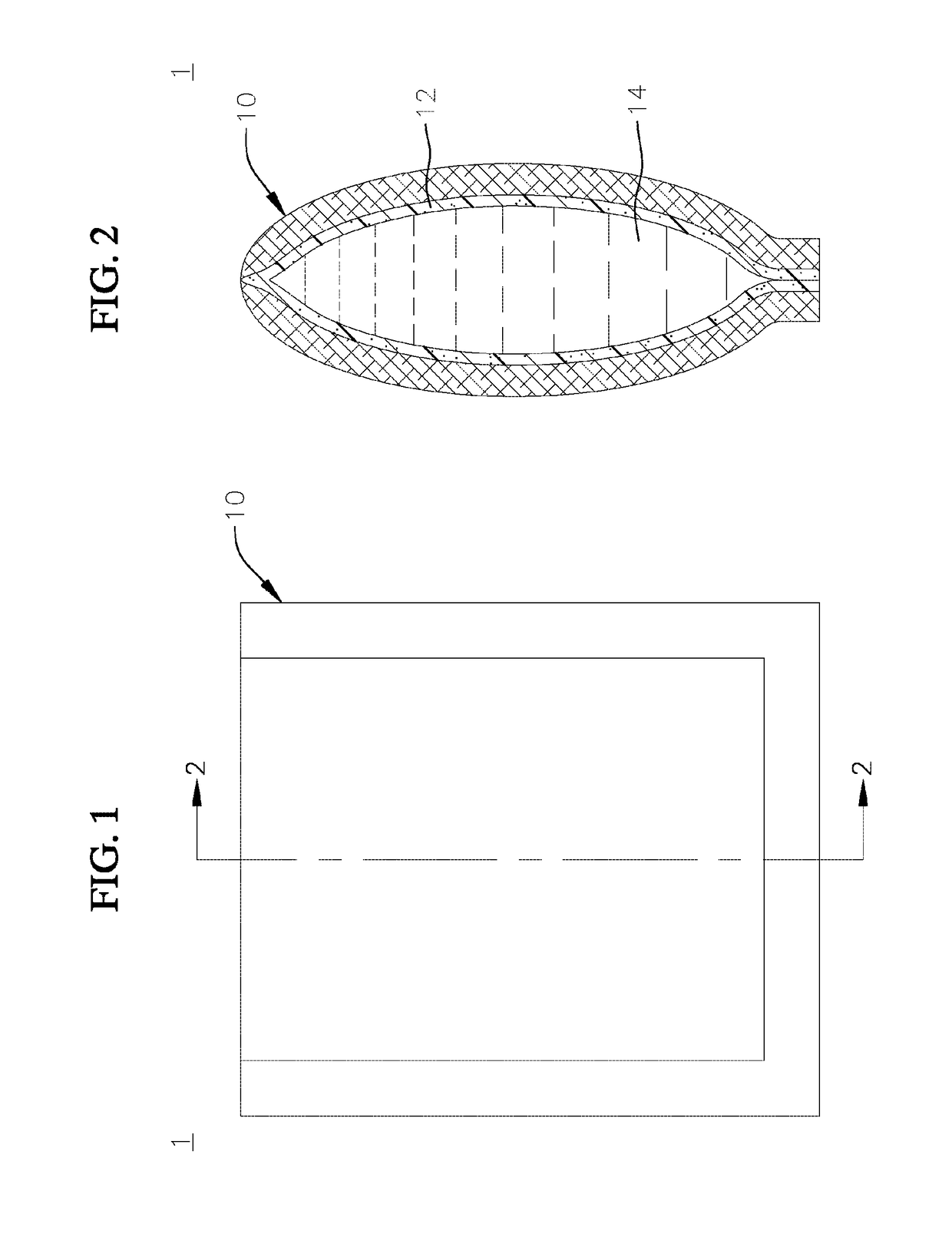

Graphene oxide-coated graphitic foil and processes for producing same

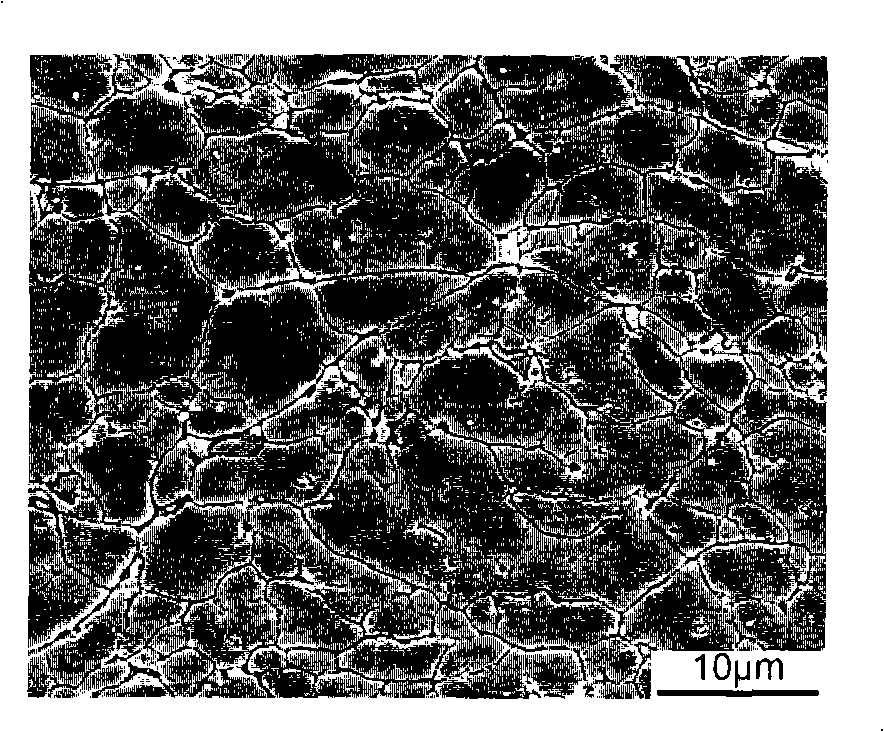

ActiveUS20140127488A1Reduce eliminateImprove surface smoothnessMaterial nanotechnologyGraphiteCarbon compositesFiber

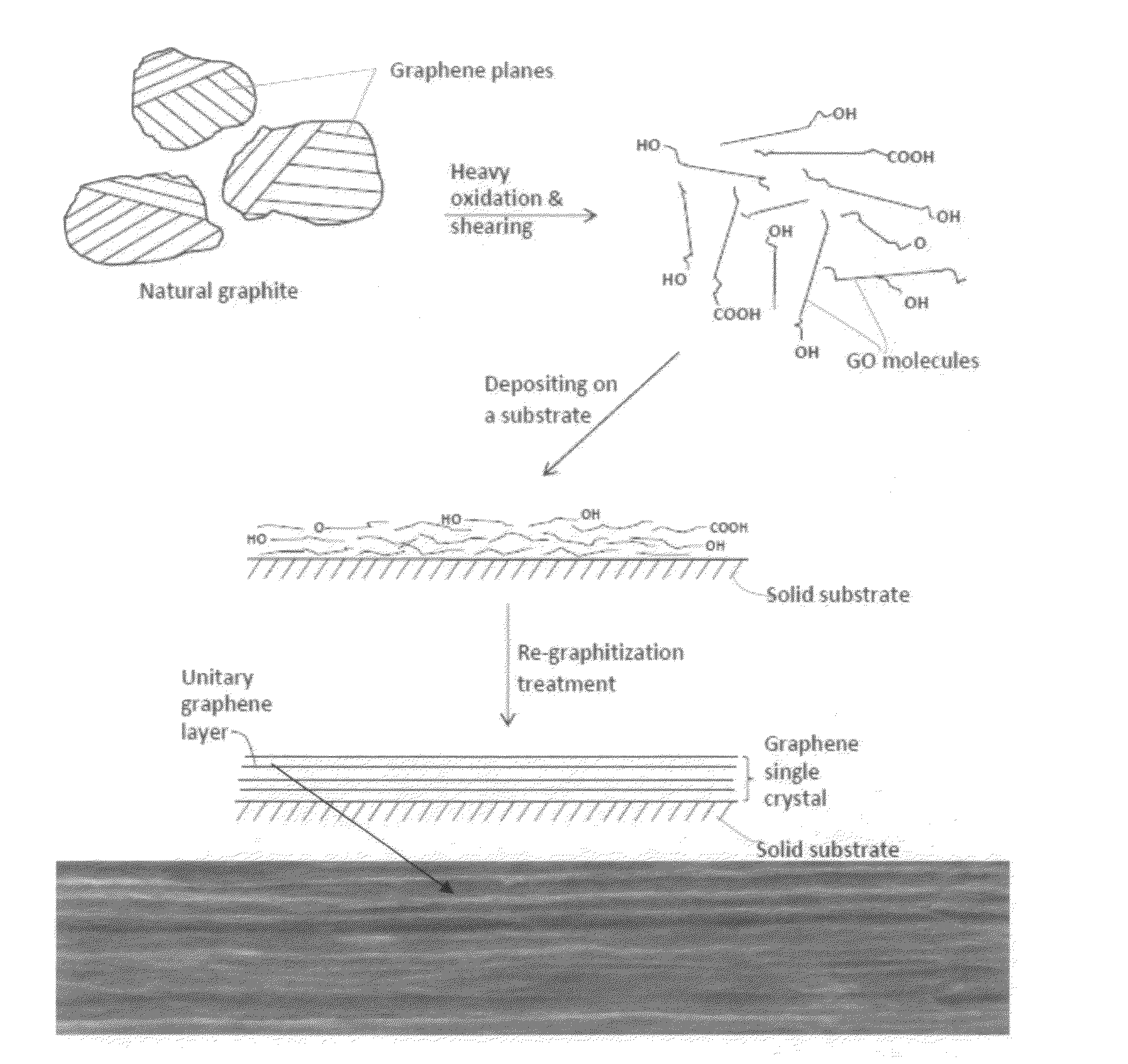

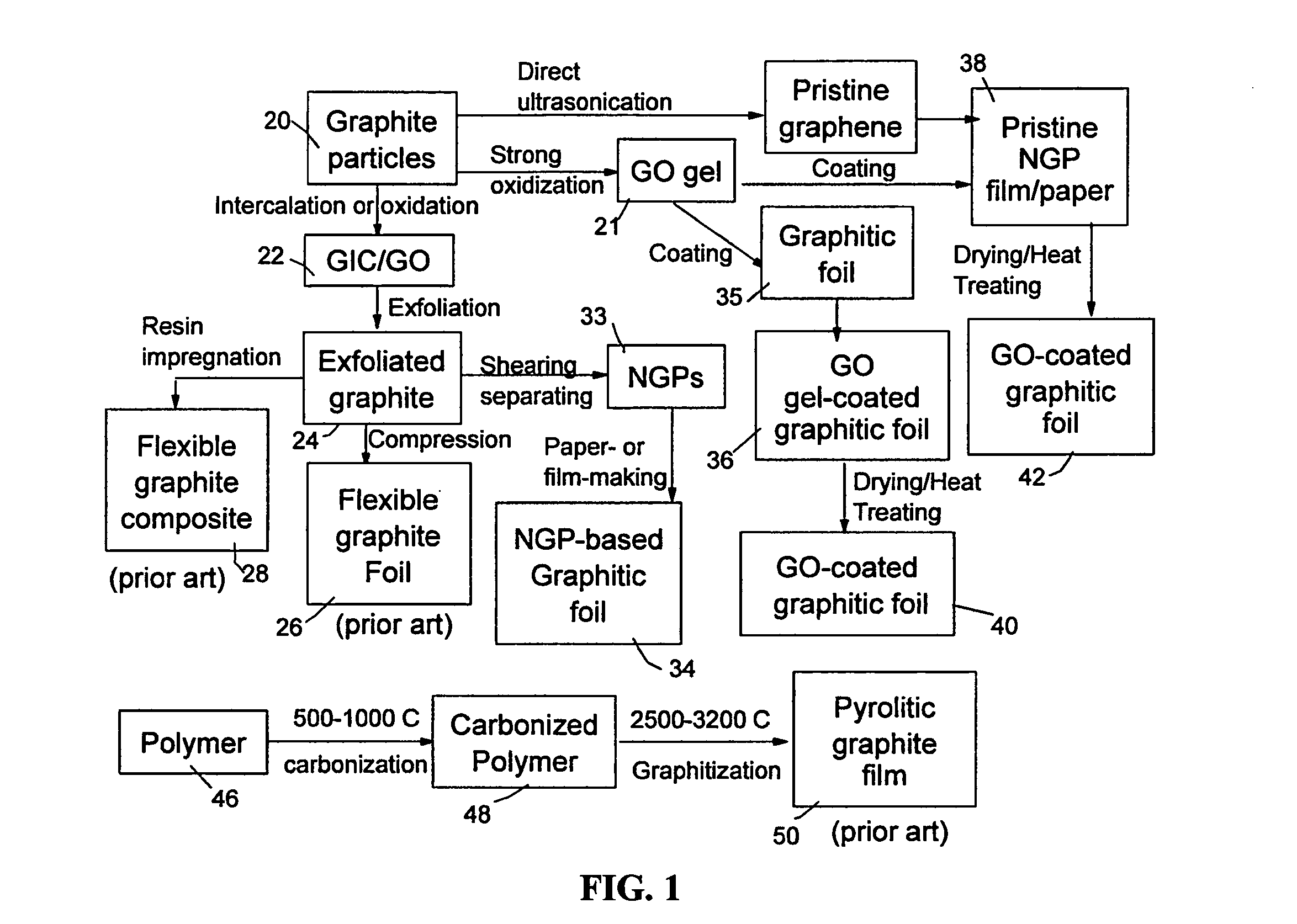

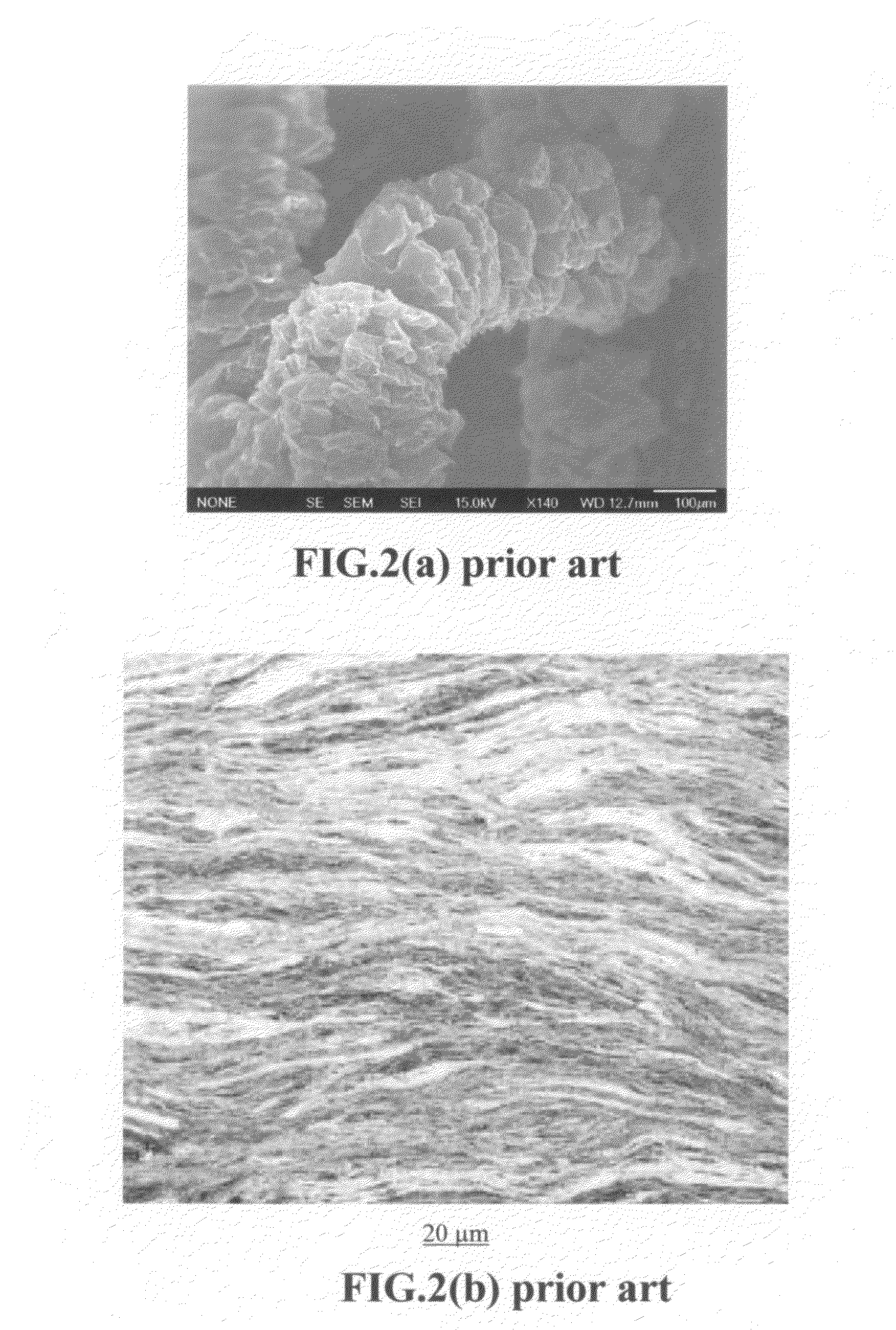

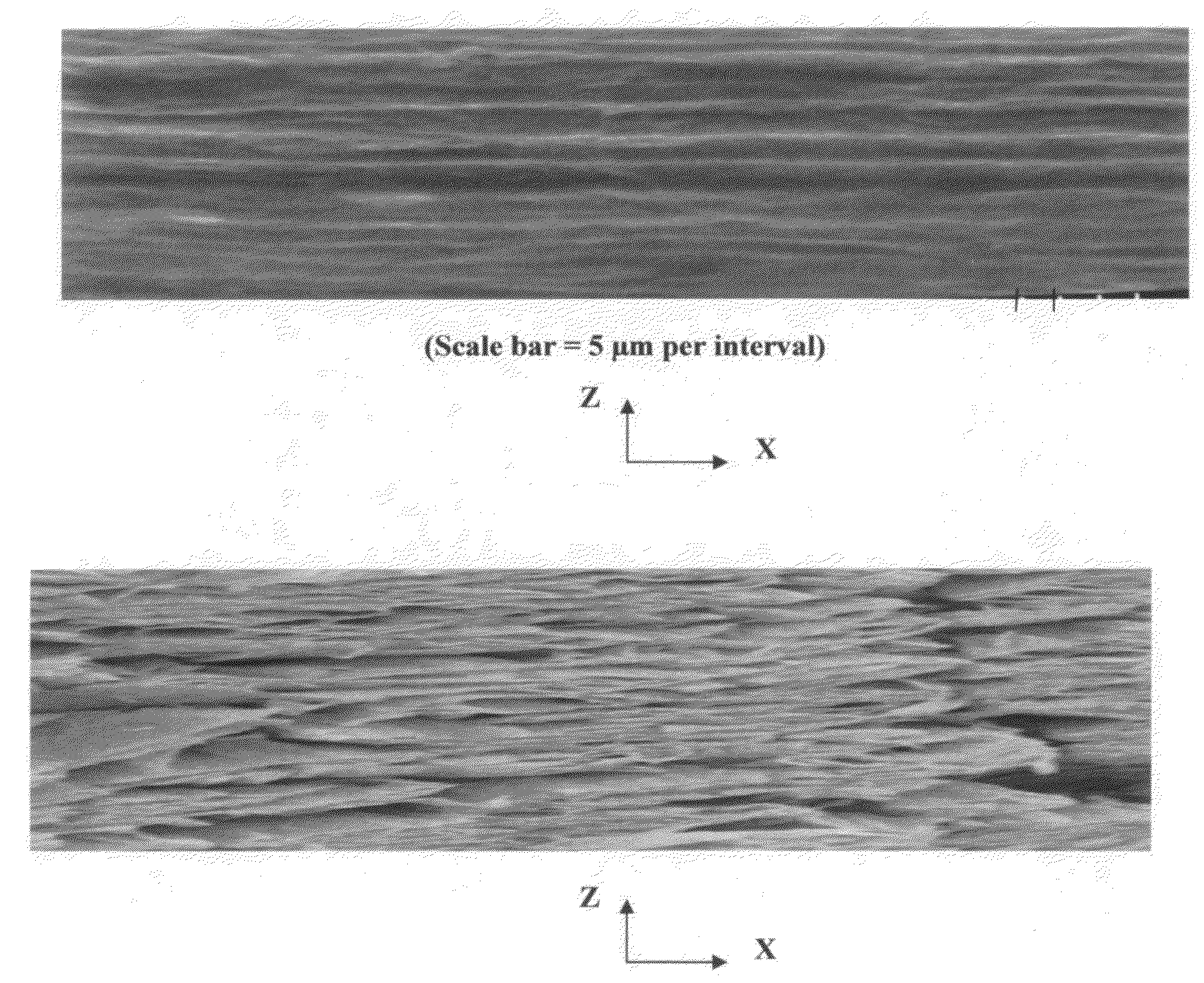

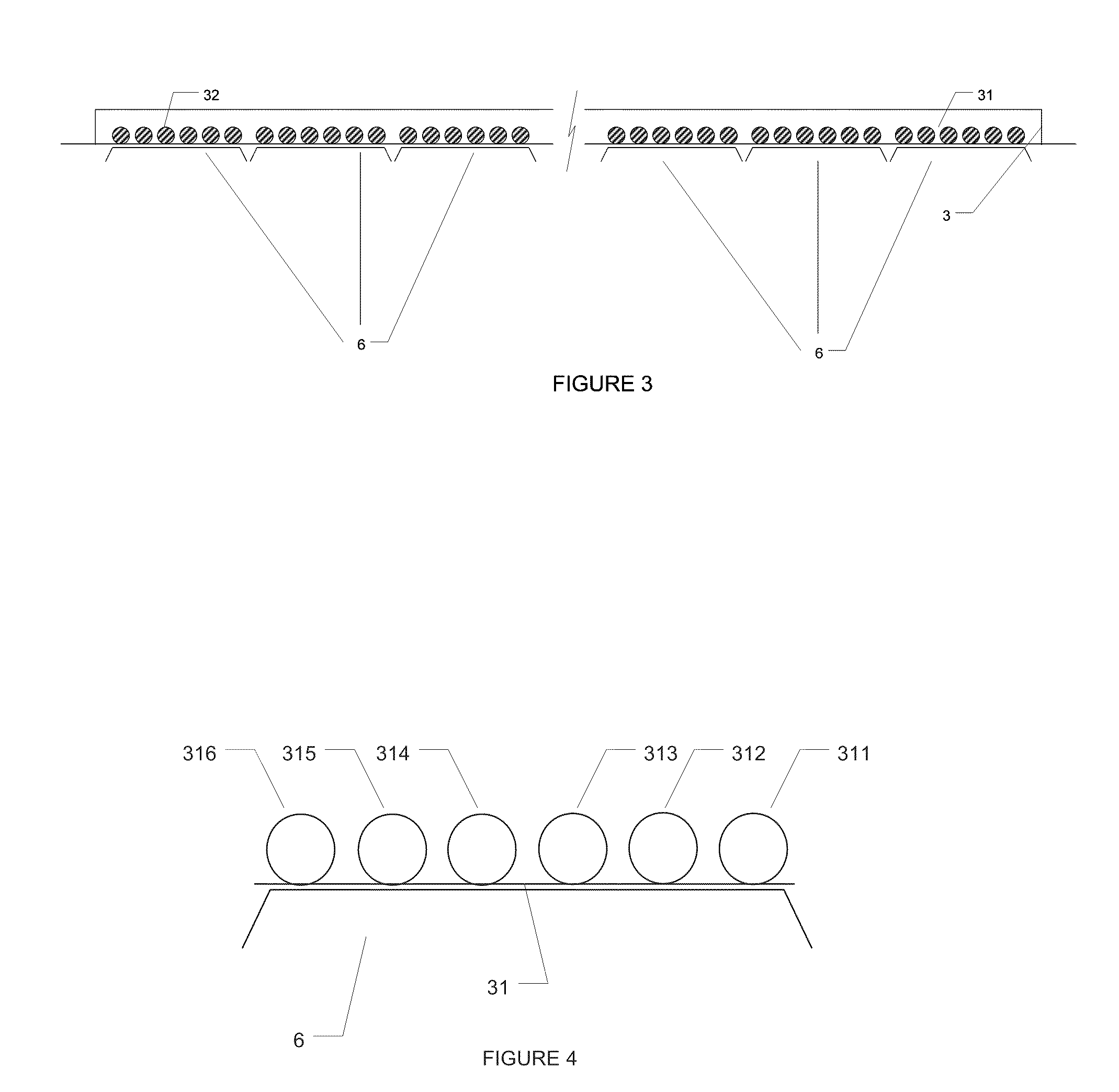

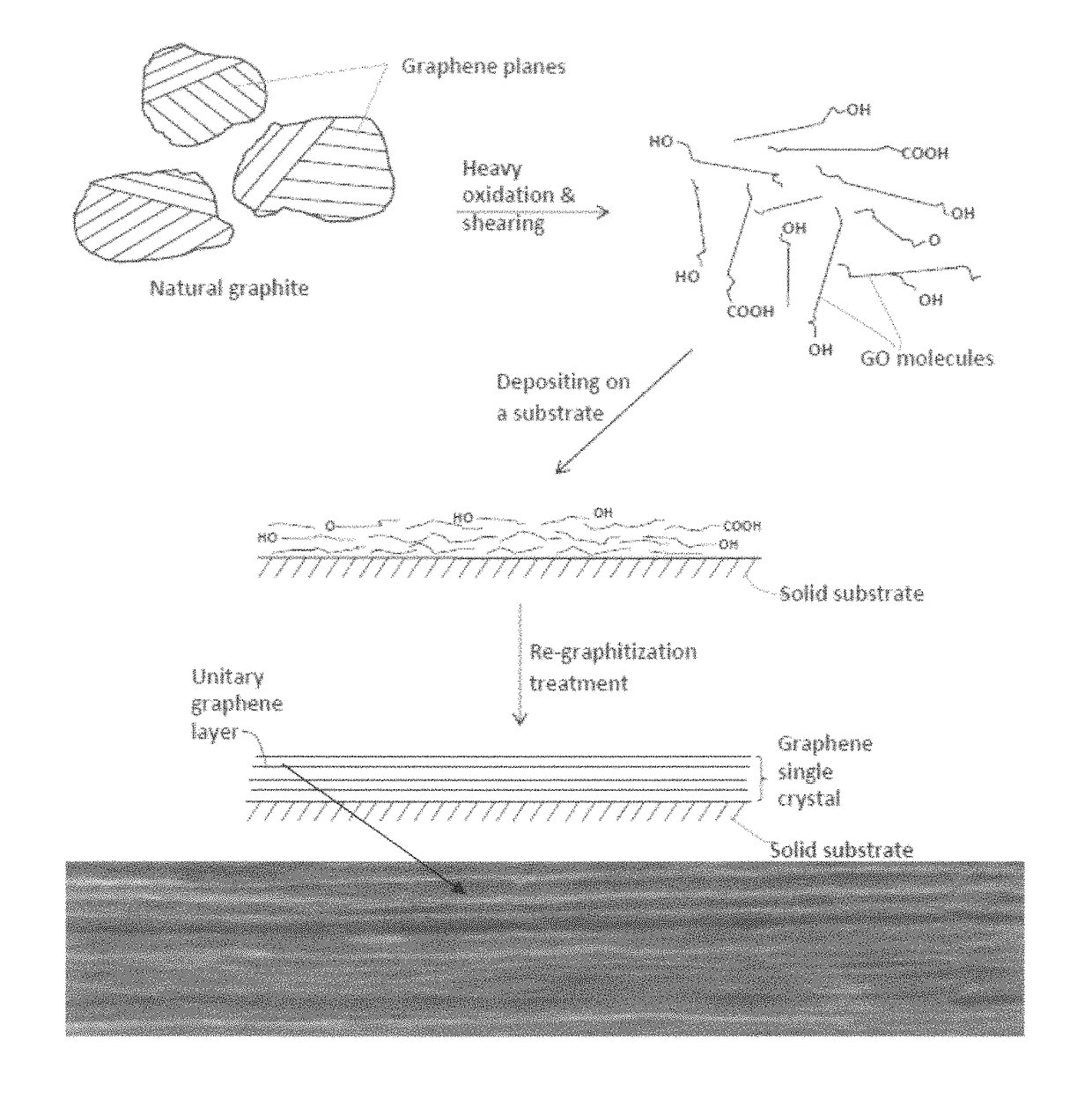

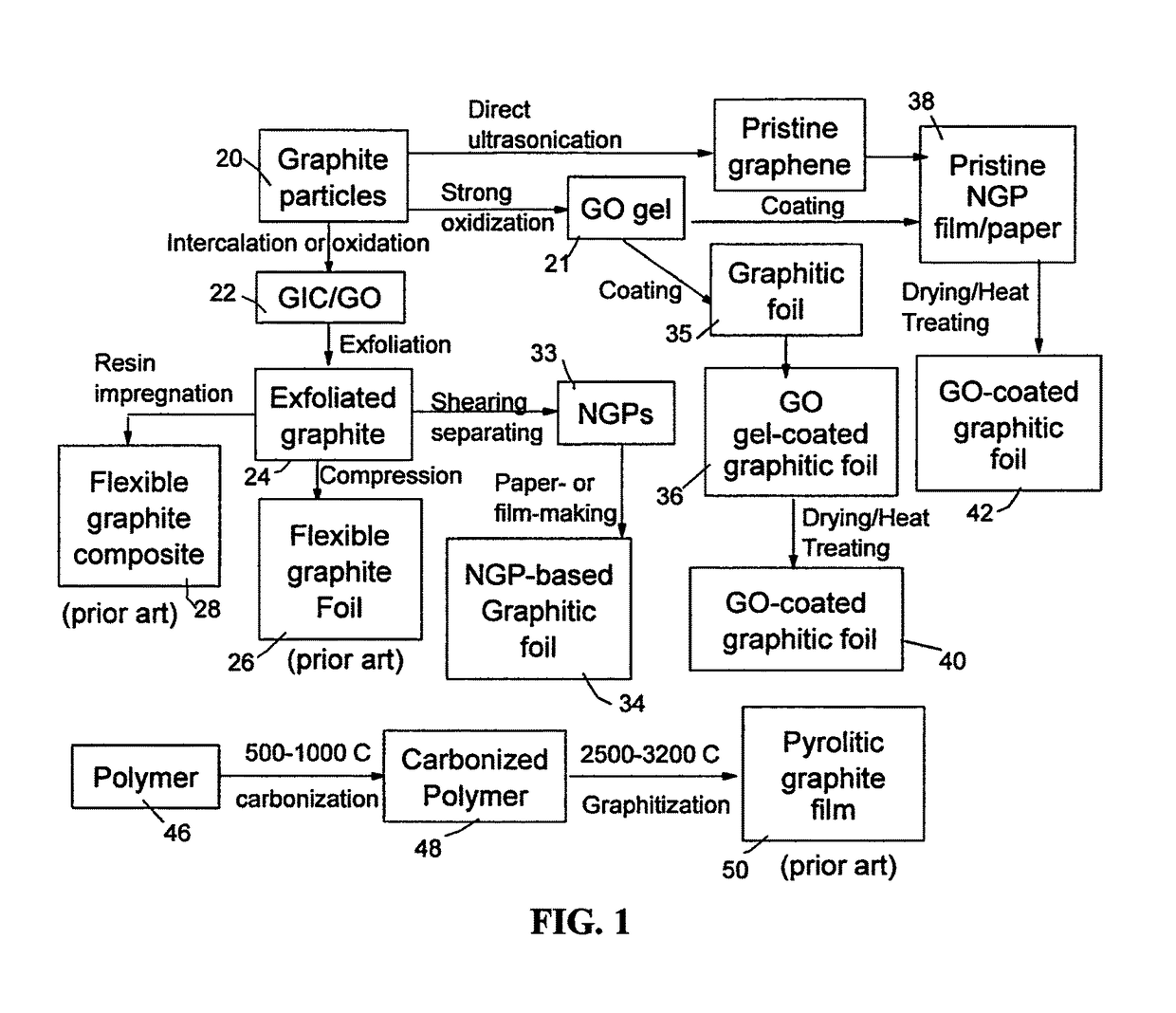

A graphene oxide-coated graphitic foil, composed of a graphitic substrate or core layer having two opposed primary surfaces and at least a graphene oxide coating layer deposited on at least one of the two primary surfaces, wherein the graphitic substrate layer has a thickness preferably from 0.34 nm to 1 mm, and the graphene oxide coating layer has a thickness preferably from 0.5 nm to 1 mm and an oxygen content of 0.01%-40% by weight based on the total graphene oxide weight. The graphitic substrate layer may be preferably selected from flexible graphite foil, graphene film, graphene paper, graphite particle paper, carbon-carbon composite film, carbon nano-fiber paper, or carbon nano-tube paper. This graphene oxide-coated laminate exhibits a combination of exceptional thermal conductivity, electrical conductivity, mechanical strength, surface smoothness, surface hardness, and scratch resistance unmatched by any thin-film material of comparable thickness range.

Owner:GLOBAL GRAPHENE GRP INC

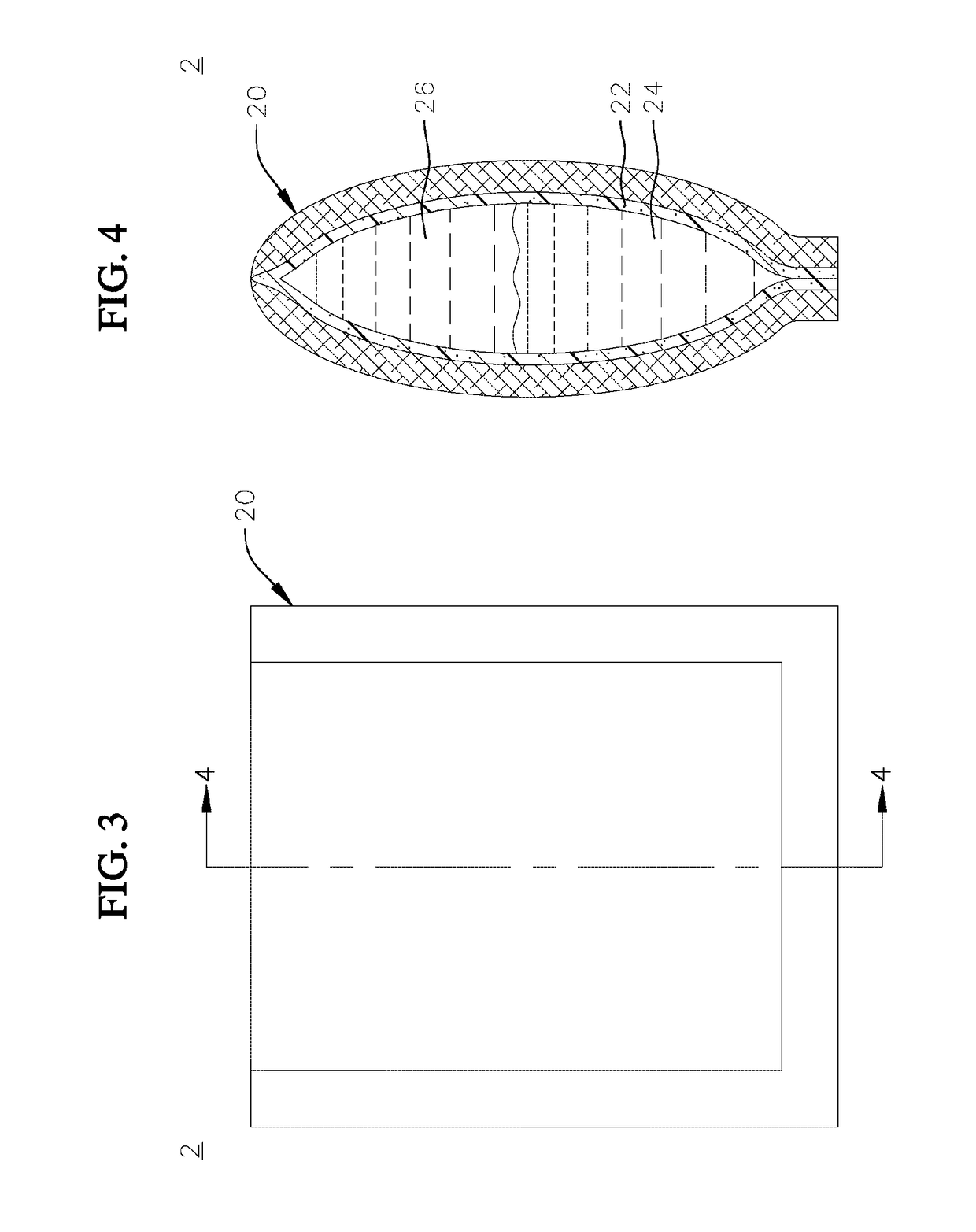

Thermal management system containing a graphene oxide-coated graphitic foil laminate for electronic device application

ActiveUS20140124176A1Improves Structural IntegrityImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesHeat conductingHardness

A heat dissipation system, comprising: (a) an electronic device comprising a heat source, wherein the heat source transmits heat to a second component or an external surface of the device; (b) a heat-conducting layer being positioned such that one of its major surfaces is in operative contact with the heat source such that it is interposed between the heat source and the second component or the external surface. The heat-conducting layer comprises at least one graphene oxide-coated graphitic foil laminate which thermally shields the second component or the external surface from heat generated by the heat source, and wherein the laminate is composed of a graphitic substrate / core layer with at least one primary surface coated with a graphene oxide coating layer. This graphene oxide-coated laminate exhibits a combination of exceptional thermal conductivity, electrical conductivity, mechanical strength, surface hardness, and scratch resistance, making this the most effective heat dissipation system.

Owner:GLOBAL GRAPHENE GRP INC

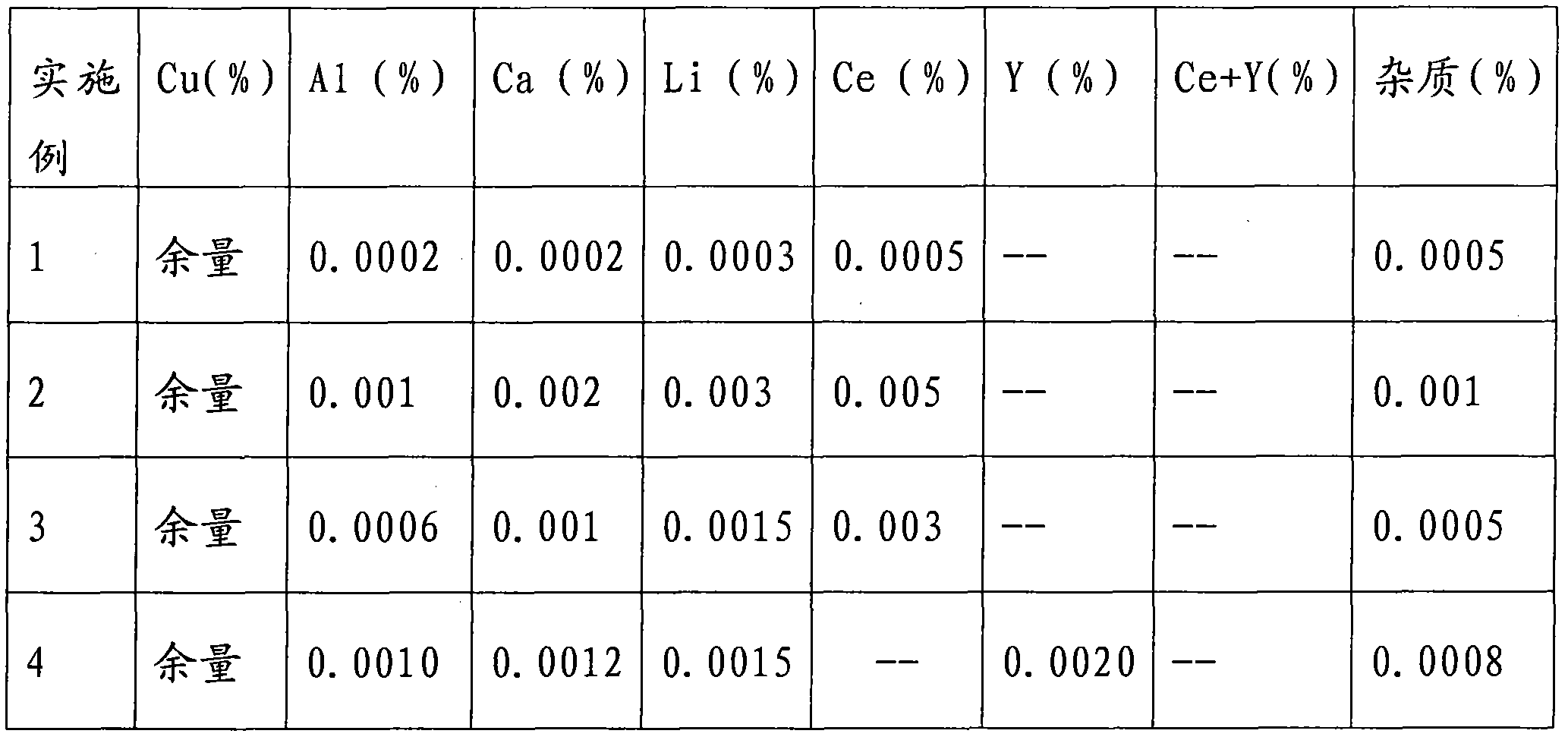

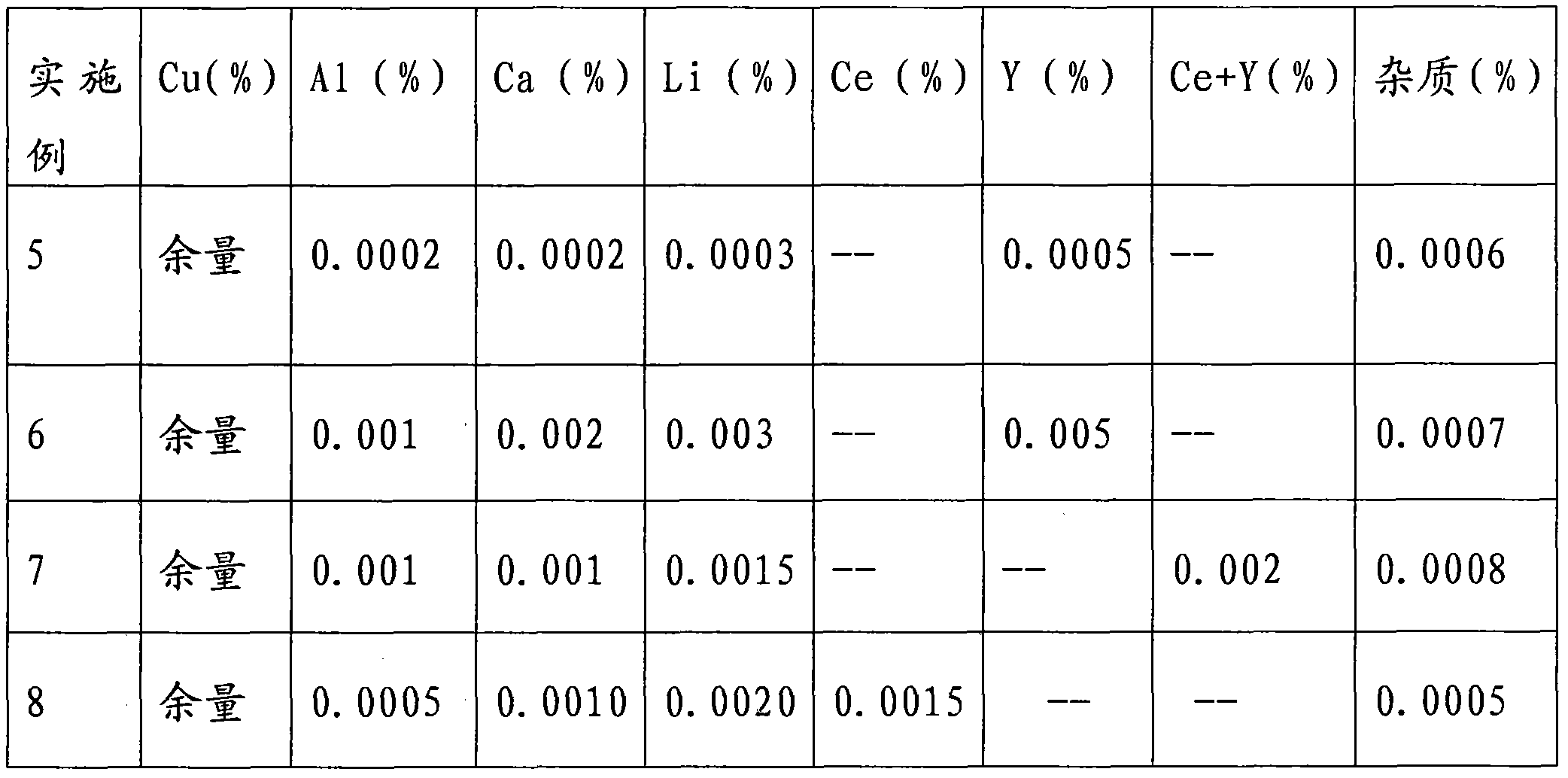

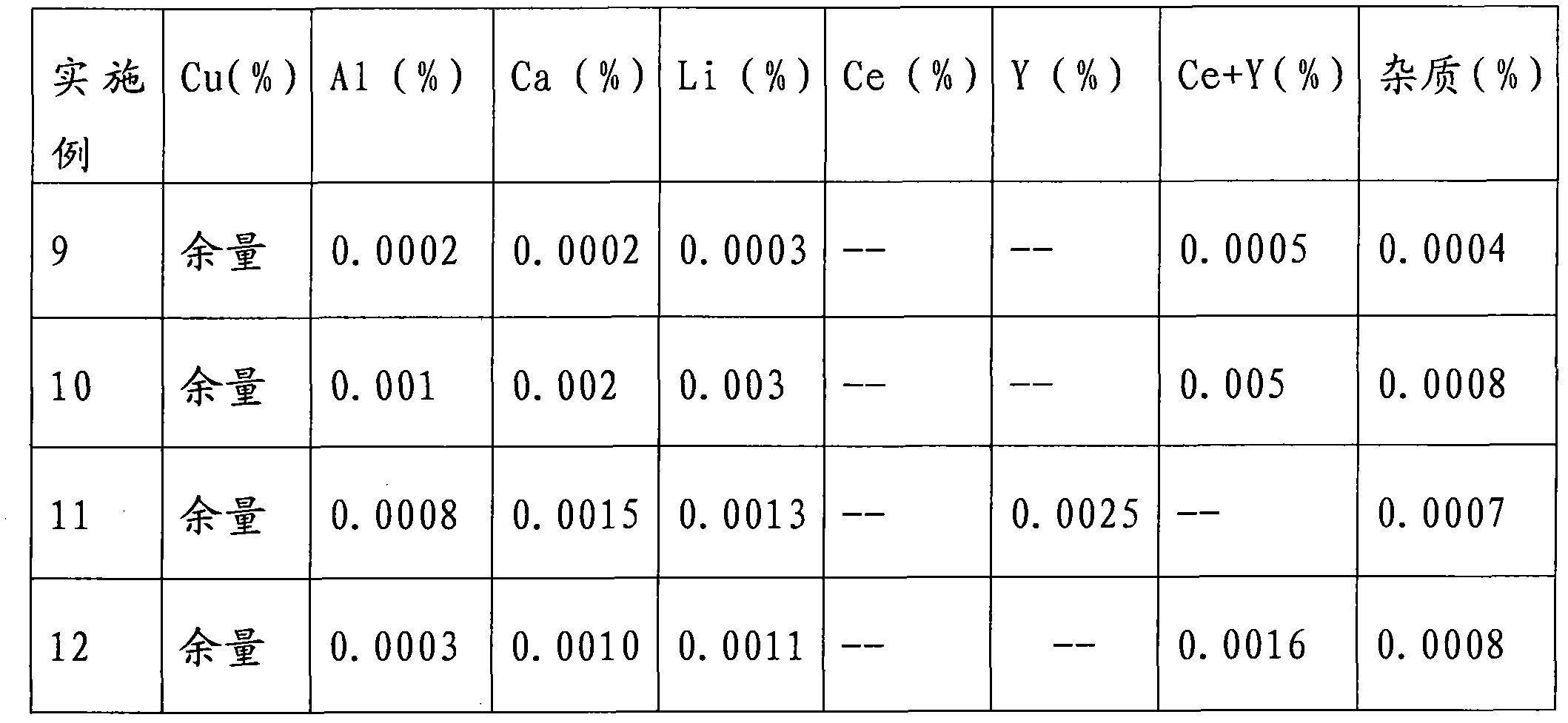

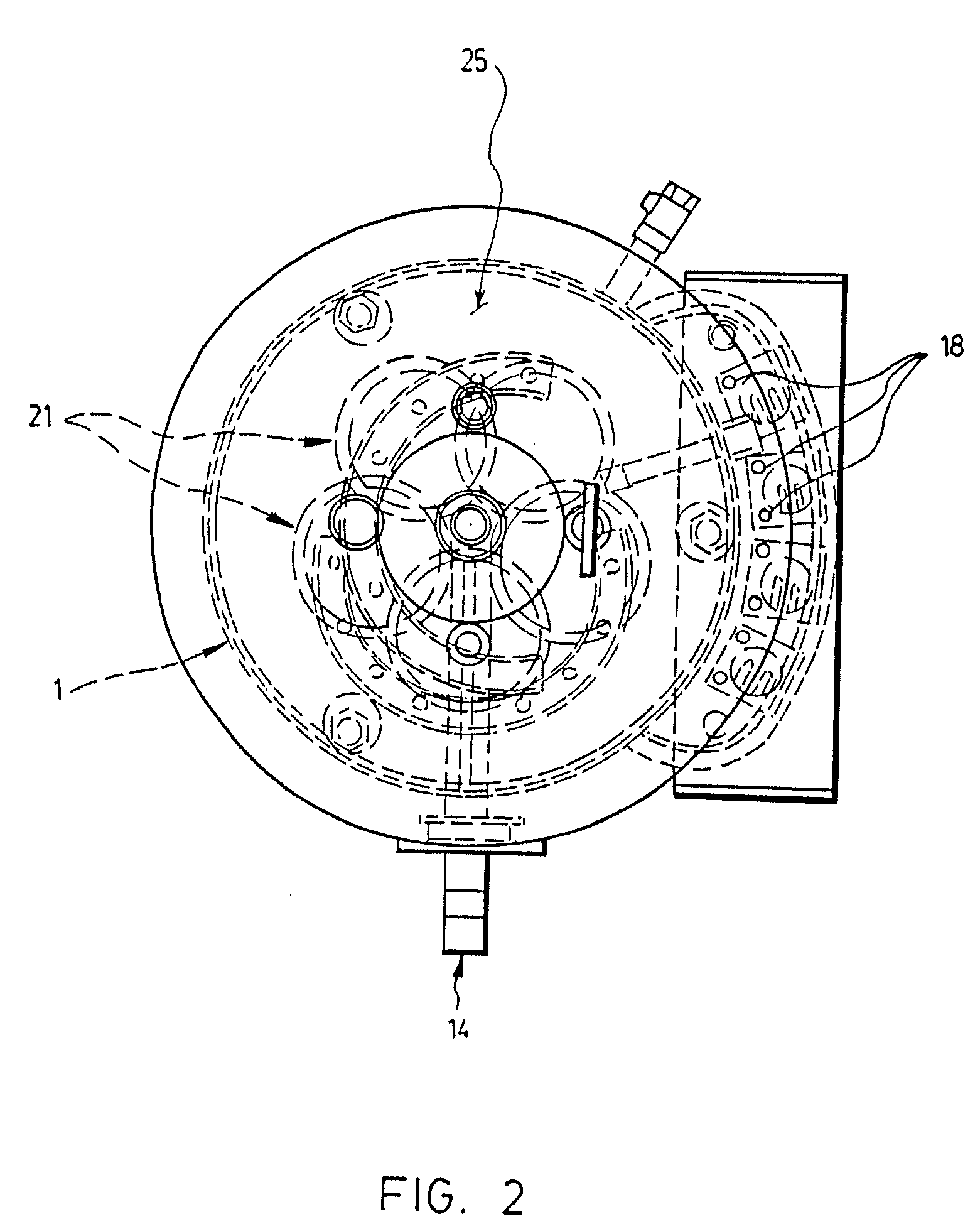

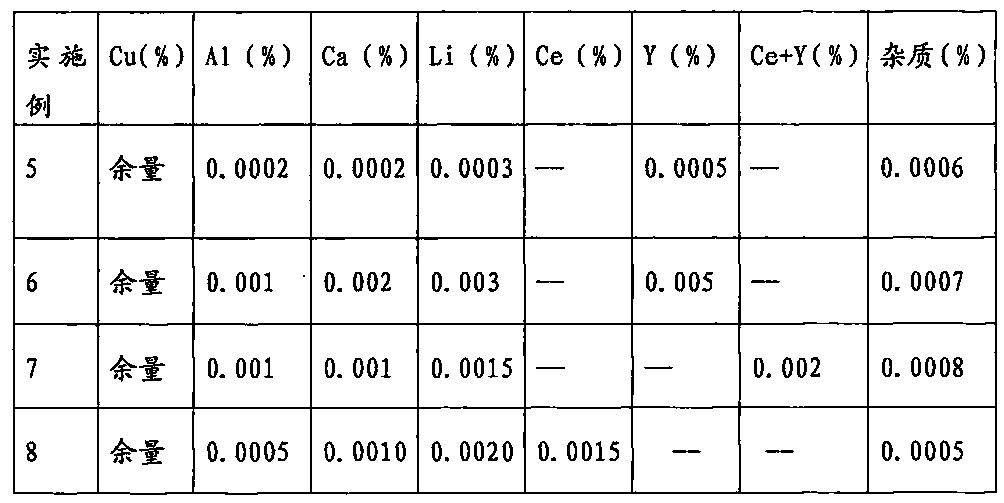

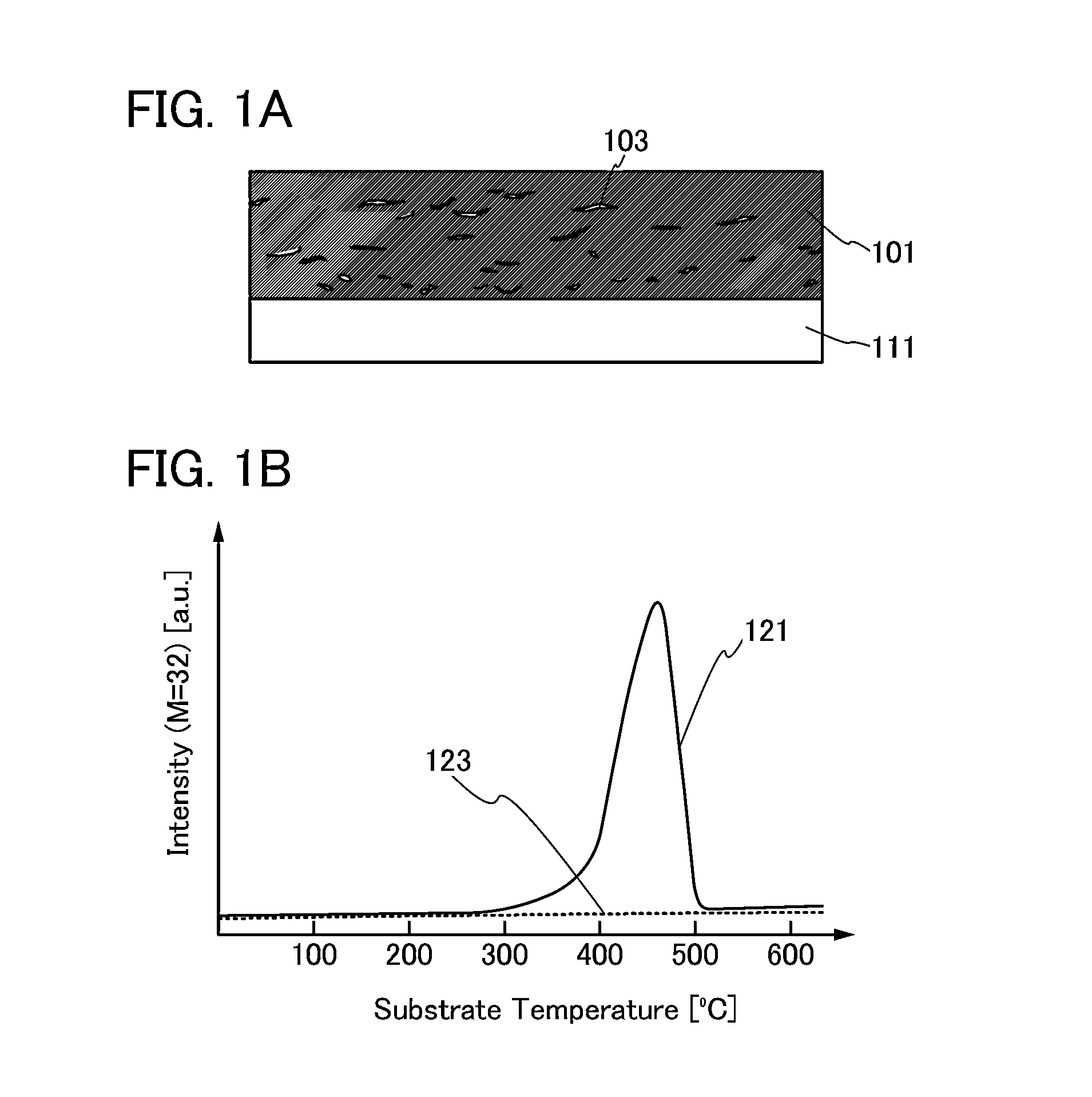

Bonding copper wire and preparation method thereof

InactiveCN101979689AImprove surface oxidation resistanceImprove performanceSingle bars/rods/wires/strips conductorsSolid-state devicesCopper wireCerium

The invention relates to a bonding copper wire and a preparation method thereof. The bonding copper wire comprises the following components in percentage by mass: 0.0003 percent to 0.003 percent of lithium, 0.0002 percent to 0.002 percent of calcium, 0.0002 percent to 0.001 percent of aluminium, 0.0005 percent to 0.005 percent of cerium and / or yttrium, 0.0001 percent to 0.001 percent of other inevitable impurity elements and the balance of copper. The preparation method of the bonding copper wire comprises the following steps of: preparing a middle alloy, preparing an alloy cast ingot, annealing uniformly, heat extrusion, stress relief annealing, drawing, final annealing, winding for multiple coils, packaging, and final protective packaging, wherein in a drawing process, middle stress relief annealing can be performed according to practical needs. The bonding copper wire has better inoxidizability while keeping better conduction and radiation properties; in the preparation process of the bonding copper wire, the uniform annealing is added and the middle stress relief annealing is performed, so that the mechanical property of the prepared bonding copper wire is better.

Owner:蔡元华

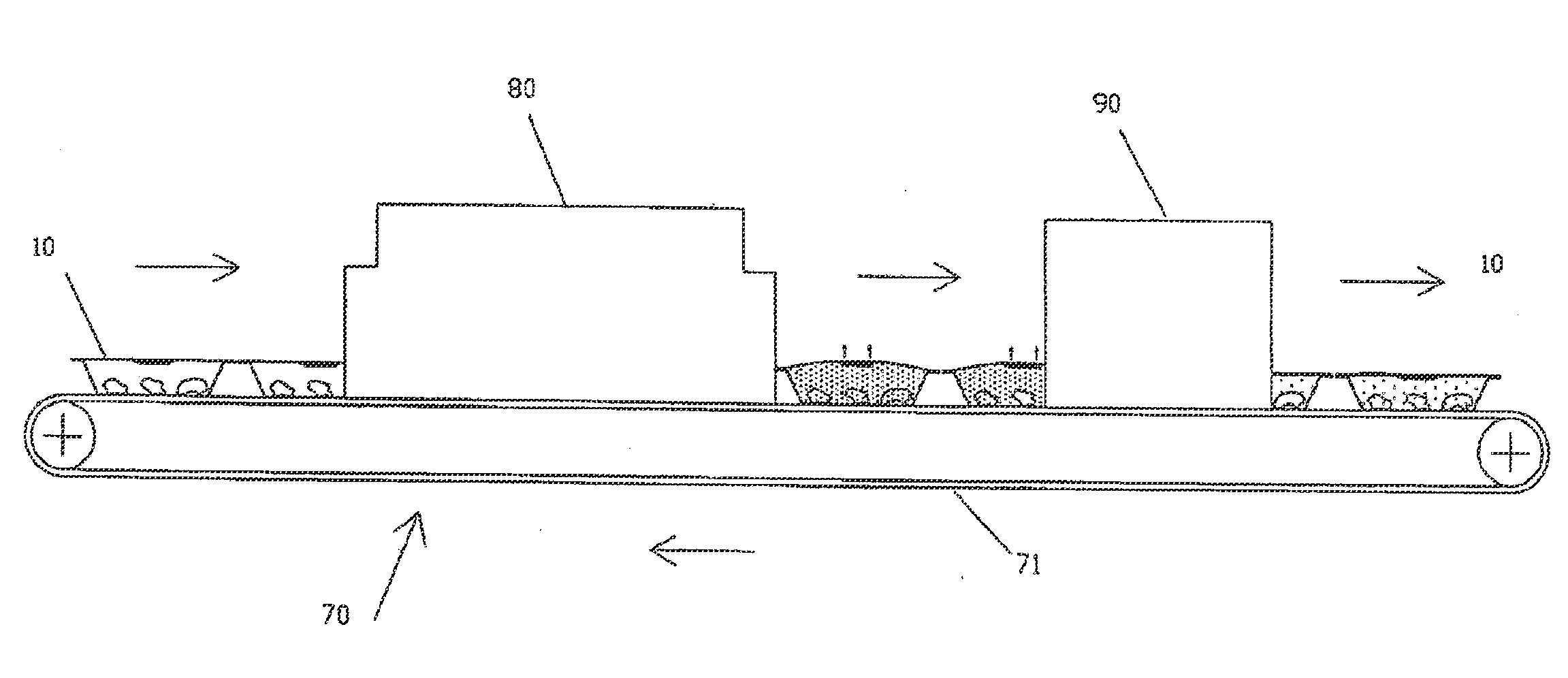

Production of pyrolysis oil

InactiveUS20110213188A1Eliminate needImprove stabilityMolecular sieve catalystsBiofuelsCatalytic pyrolysisReactive gas

Methods for fractional catalytic pyrolysis which allow for conversion of biomass into a slate of desired products without the need for post-pyrolysis separation are described. The methods involve use of a fluid catalytic bed which is maintained at a suitable pyrolysis temperature. Biomass is added to the catalytic bed, preferably while entrained in a non-reactive gas such as nitrogen, causing the biomass to become pyrolyzed and forming the desired products in vapor and gas forms, allowing the desired products to be easily separated.

Owner:VIRGINIA POLYTECHNIC INSTITUTE AND STATE UNIVERSITY

Production technology for continuous casting and rolling of scrap copper

InactiveCN106191462AReduce energy consumptionEliminate oxygenProcess efficiency improvementMetal rolling arrangementsEnvironmental resistanceCerium

The invention belongs to the scrap metal casting technology and relates to production technology for continuous casting and rolling of scrap copper. In order to overcome shortcomings that melted copper generates too many air bubbles, refining purity is not high, too much surface detect during blank casting, radiance and smoothness of the surface of a copper bar are not enough and smelting emissions are not environment friendly during refining, the production technology includes that cerium-rich and yttrium-rich mixed rare earth is adopted to remove oxygen and sulfur from the melted copper, meanwhile, many other impurity elements can also be restored and removed, copper casting organization is obviously improved by adding the rare earth, all performance indexes of the copper bar are improved by the aid of emulsion, hydrochloric acid and an ethanol solution in sequence in order to further improve the radiance and smoothness of the surface of the copper bar, and quality of the copper bar is obviously improved. Through scientific and reasonable technology design, the copper bar good high in purity and good in quality is manufactured, and exhaust gas generated reach international II emission standards though an environment friendly dust removal device.

Owner:JIANGXI ANXUN IND

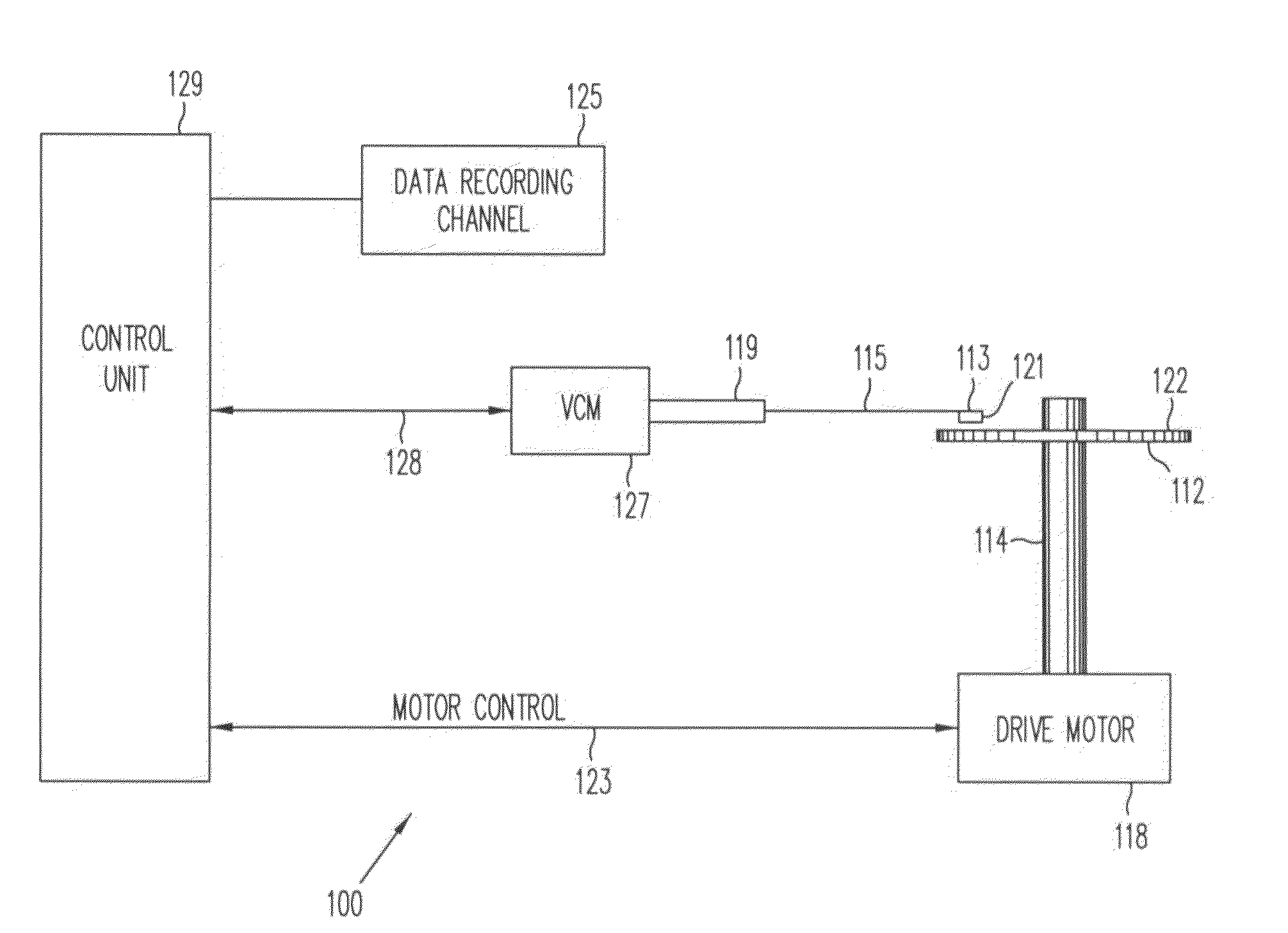

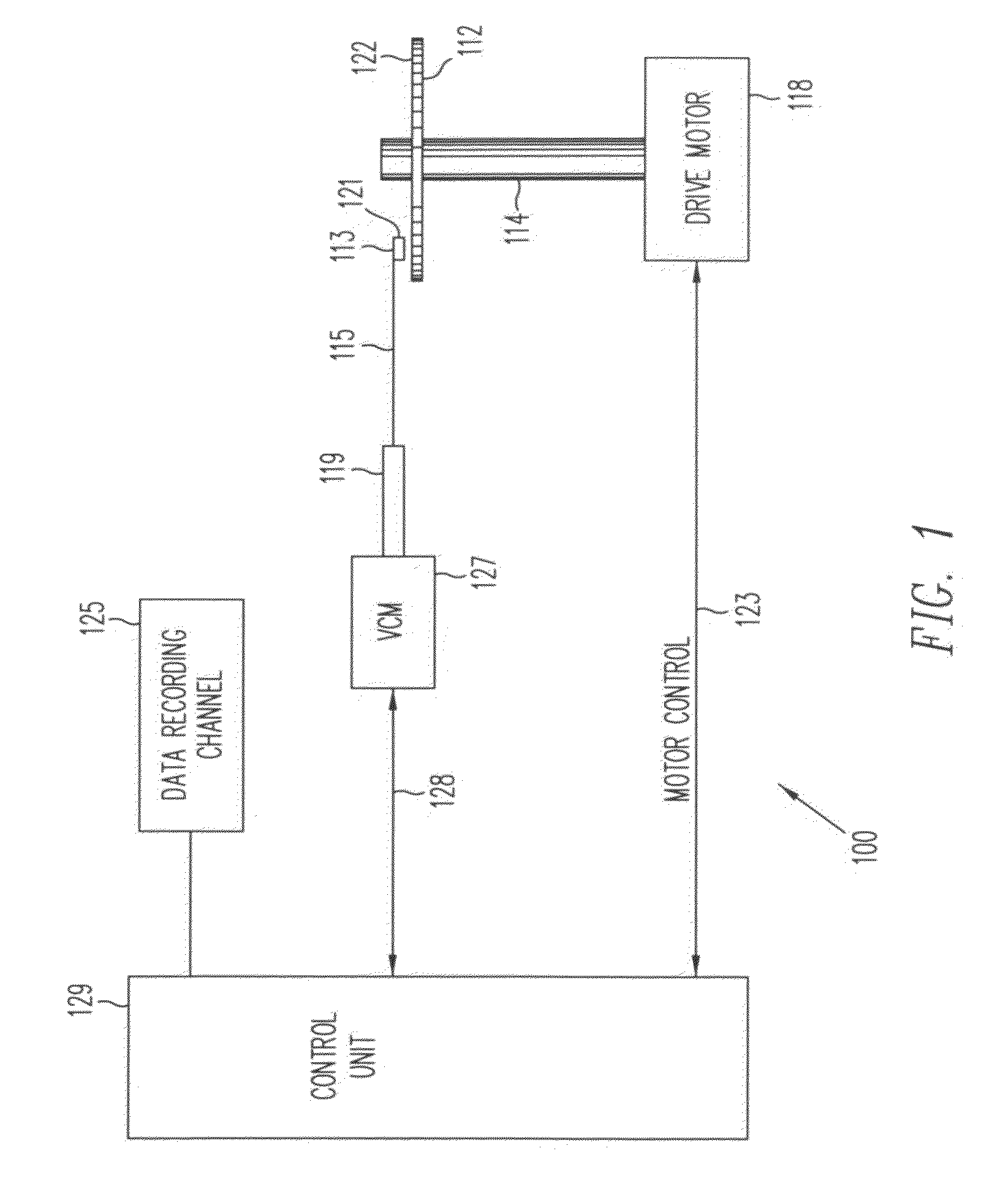

Scheme to protect media and head against corrosion/oxidation in a hard disk drive

InactiveUS20090244769A1Effective oxygen scavengerReduce pressureUndesired vibrations/sounds insulation/absorptionRecord information storageHard disc drivePhysical space

Oxygen scavenger for use in a hard disk drive. The oxygen scavenger removes oxygen from an interior of a hard disk drive to prevent corrosion of corrodible materials in magnetic media or magnetic heads. The oxygen scavenger is incorporated into a film so that it uses a limited physical space within an interior of the hard disk drive. The hard disk drive is either permeable to the outside environment or sealed so that gases from the outside environment are unable to enter the interior of the hard disk drive.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

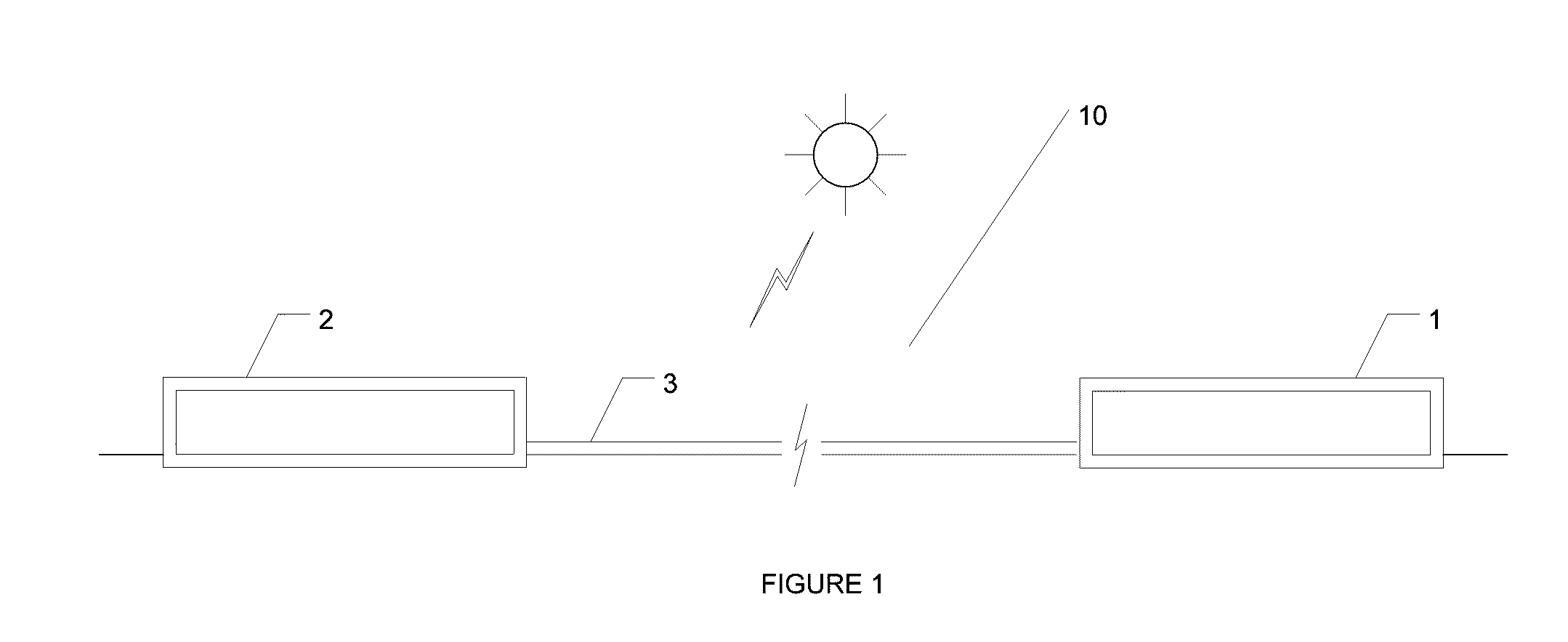

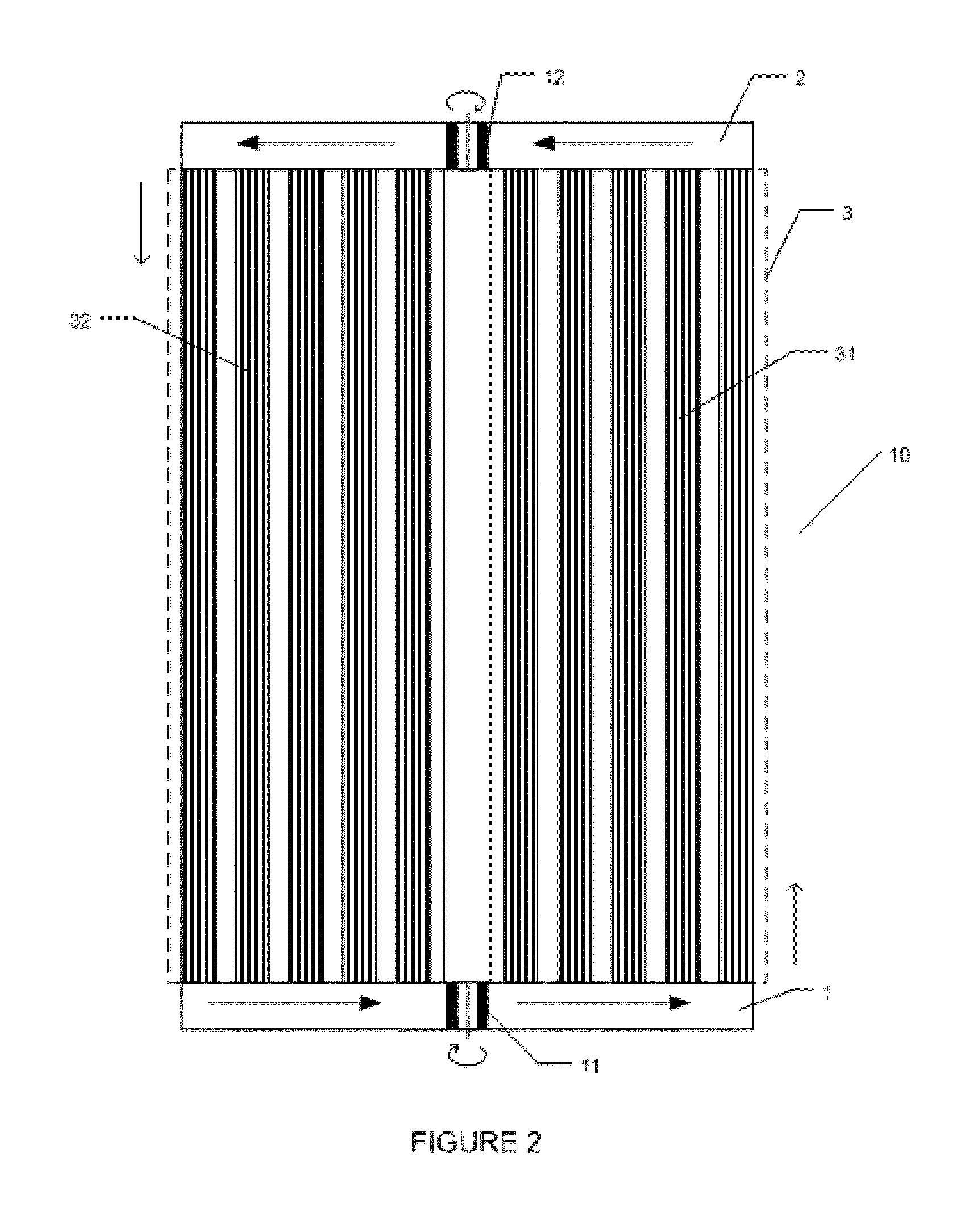

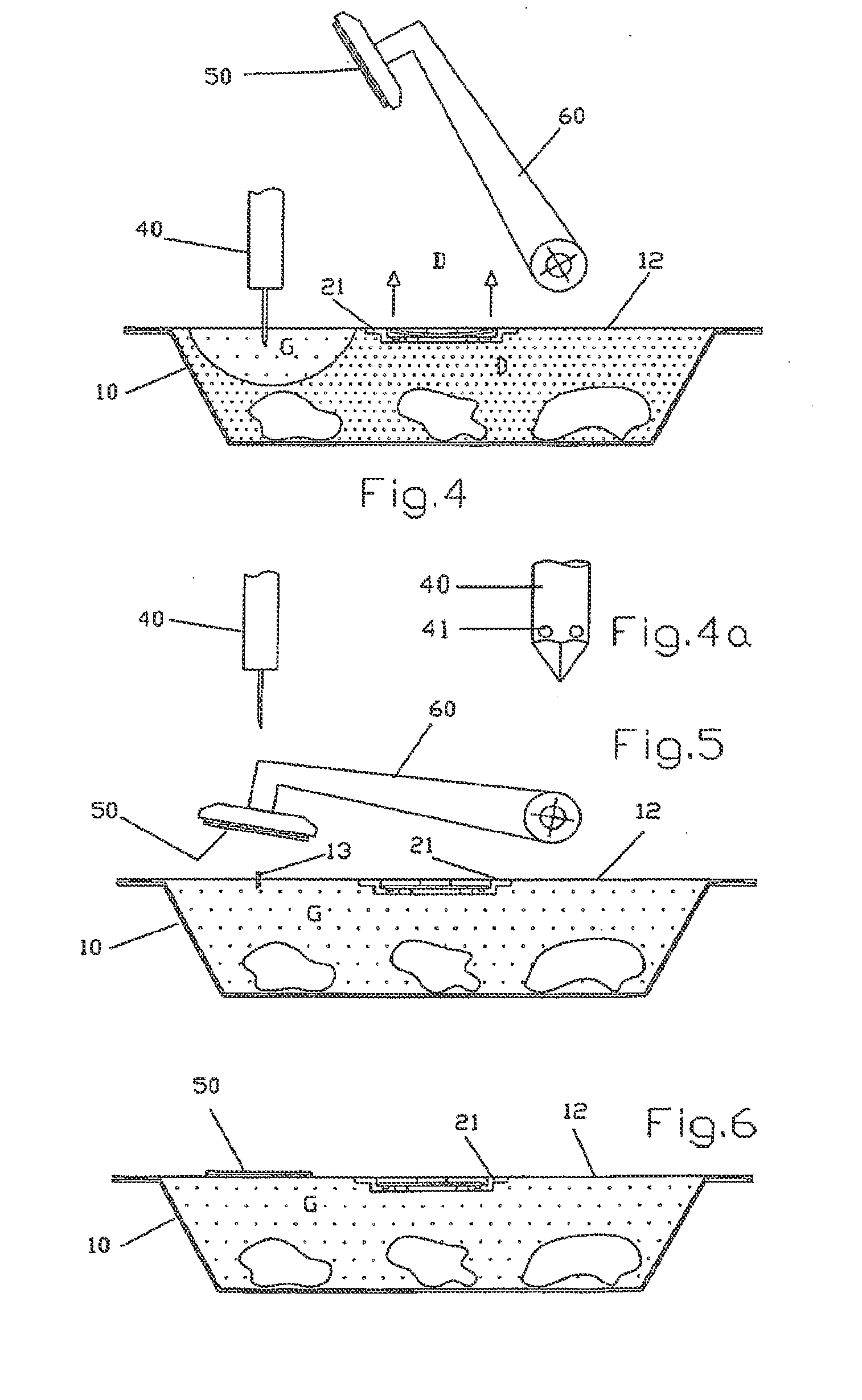

Method and Apparatus for Providing a Photobioreactor

InactiveUS20100178686A1Low costImprove production rateBioreactor/fermenter combinationsBiological substance pretreatmentsHydraulic circuitPhotobioreactor

The present invention provides for a photobioreactor for the cultivation of photosynthetic microorganisms and comprises a hydraulic circuit through which an aqueous solution containing culture of at least one type of photosynthetic organism circulates and gets exposed to a light source. The photobioreactor also comprises a means for feeding carbon dioxide into the system, a means for oxygen degasification, and a means for injecting nutrients into the system. The hydraulic circuit is comprised of two open receiving channels at the same relative elevation, a set of transparent or translucent tubes which connect receiving channels to each other, and at least one fluid moving device to move the fluid from the first to the second receiving channels through the tubes. Each receiving channel also comprises a dam which assists in maintaining two different surface levels of the aqueous solution within the upstream and downstream portions of each receiving channel.

Owner:MARGALEF PERE

Graphene oxide-coated graphitic foil and processes for producing same

ActiveUS9899120B2Reduce eliminateImprove surface smoothnessMaterial nanotechnologyGraphiteFiberCarbon composites

A graphene oxide-coated graphitic foil, composed of a graphitic substrate or core layer having two opposed primary surfaces and at least a graphene oxide coating layer deposited on at least one of the two primary surfaces, wherein the graphitic substrate layer has a thickness preferably from 0.34 nm to 1 mm, and the graphene oxide coating layer has a thickness preferably from 0.5 nm to 1 mm and an oxygen content of 0.01%-40% by weight based on the total graphene oxide weight. The graphitic substrate layer may be preferably selected from flexible graphite foil, graphene film, graphene paper, graphite particle paper, carbon-carbon composite film, carbon nano-fiber paper, or carbon nano-tube paper. This graphene oxide-coated laminate exhibits a combination of exceptional thermal conductivity, electrical conductivity, mechanical strength, surface smoothness, surface hardness, and scratch resistance unmatched by any thin-film material of comparable thickness range.

Owner:GLOBAL GRAPHENE GRP INC

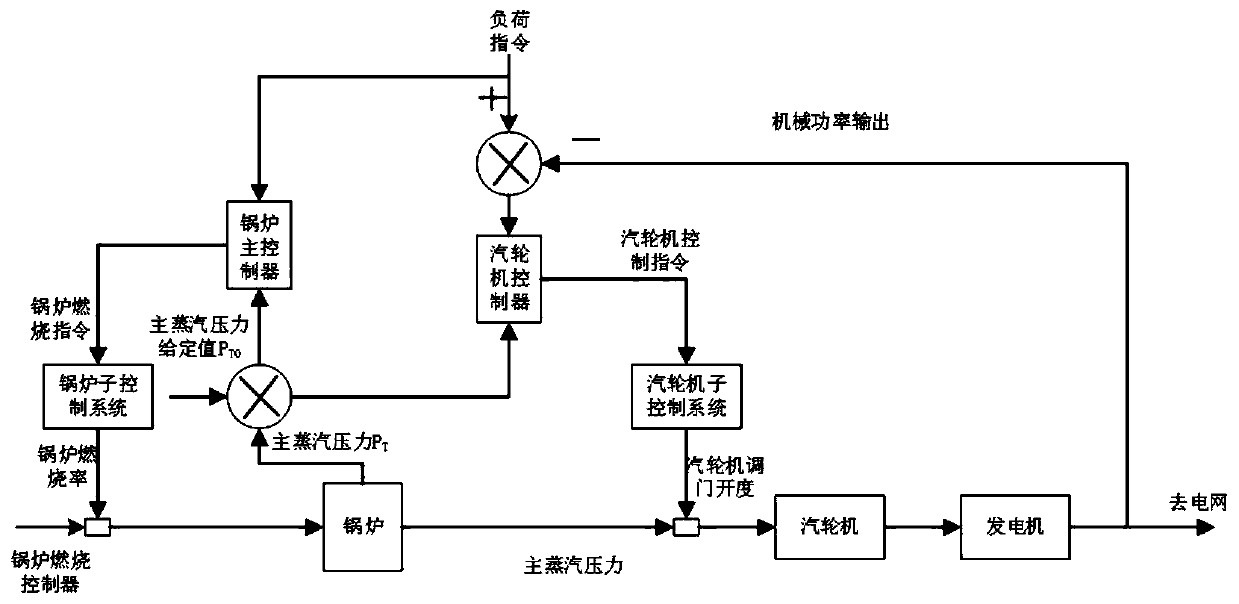

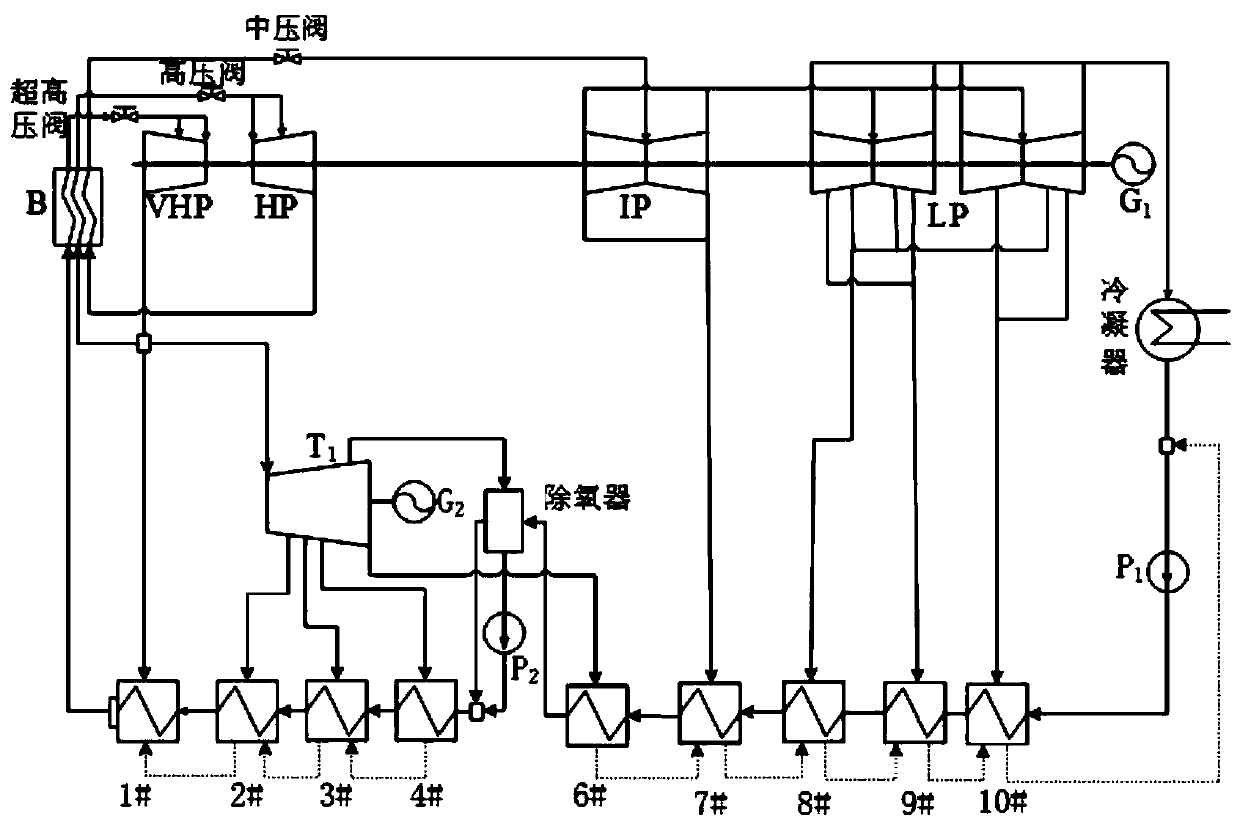

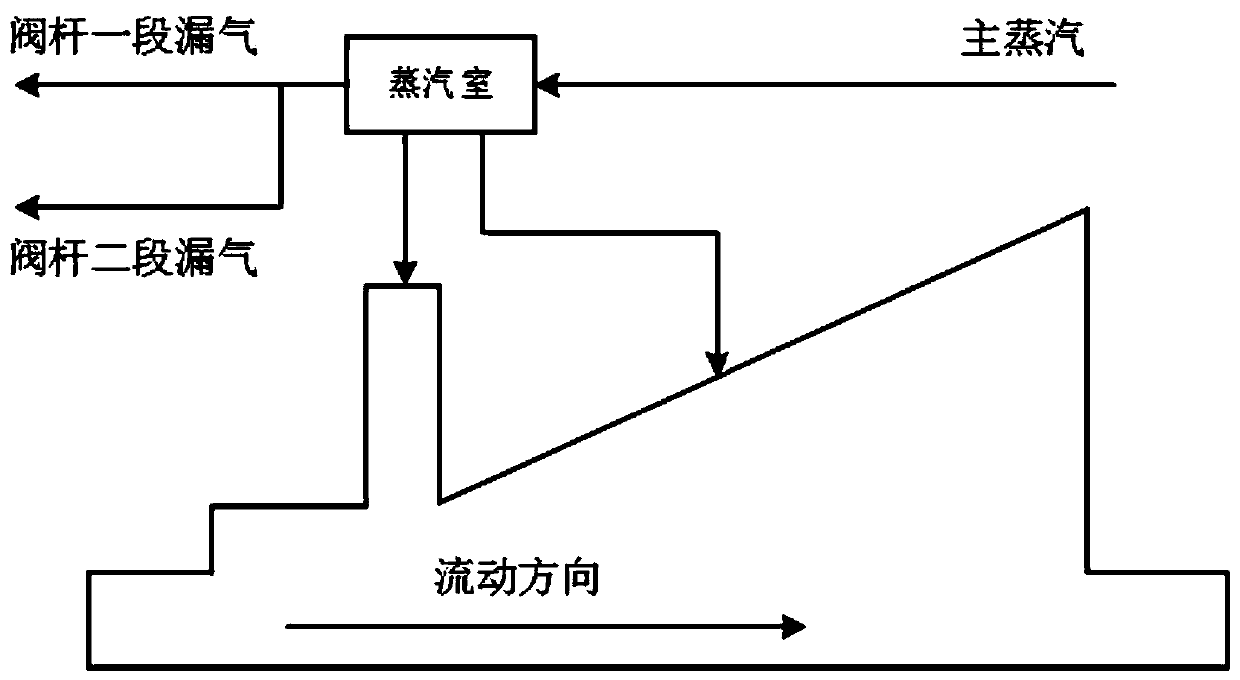

Control system and method for ultra-supercritical secondary reheating unit to participate in power grid primary frequency modulation

PendingCN110792482AAchieve a FMIncrease capacityBoiler controlEngine componentsUltra high pressureControl system

The invention discloses a control system and method for an ultra-supercritical secondary reheating unit to participate in power grid primary frequency modulation. The system comprises an ultrahigh-pressure cylinder regulation valve, a high-pressure cylinder regulation valve, a medium-pressure cylinder regulation valve, a first steam supplementing valve and a second steam supplementing valve; ultrahigh-pressure cylinder regulation valve, the high-pressure cylinder regulation valve and the medium-pressure cylinder regulation valve of a secondary reheating unit can be controlled to simultaneouslyparticipate in power grid primary frequency modulation in a steam supplementing regulation mode. When the practical load of a power grid is higher or lower than a rated load, the frequency of the power grid deflects for 50 HZ; the deflection change of the frequency of the power grid is received by the control system; the opening amplitudes of the ultrahigh-pressure cylinder regulation valve, thehigh-pressure cylinder regulation valve and the medium-pressure cylinder regulation valve are controlled, and the steam inlet flow of each cylinder is changed, so that the mechanical power output of asecondary reheating turbine is changed; and practical power output is matched with the load of the power grid, so that primary frequency modulation of the power grid is realized.

Owner:XI AN JIAOTONG UNIV

Humidity control system

ActiveUS9616382B2Moisture resistanceEliminate oxygenGas treatmentFlexible coversControl systemOxygen

Owner:DESICCARE

Production of pyrolysis oil

Methods for fractional catalytic pyrolysis which allow for conversion of biomass into a slate of desired products without the need for post-pyrolysis separation are described. The methods involve use of a fluid catalytic bed which is maintained at a suitable pyrolysis temperature. Biomass is added to the catalytic bed, preferably while entrained in a non-reactive gas such as nitrogen, causing the biomass to become pyrolyzed and forming the desired products in vapor and gas forms, allowing the desired products to be easily separated.

Owner:VIRGINIA POLYTECHNIC INSTITUTE AND STATE UNIVERSITY

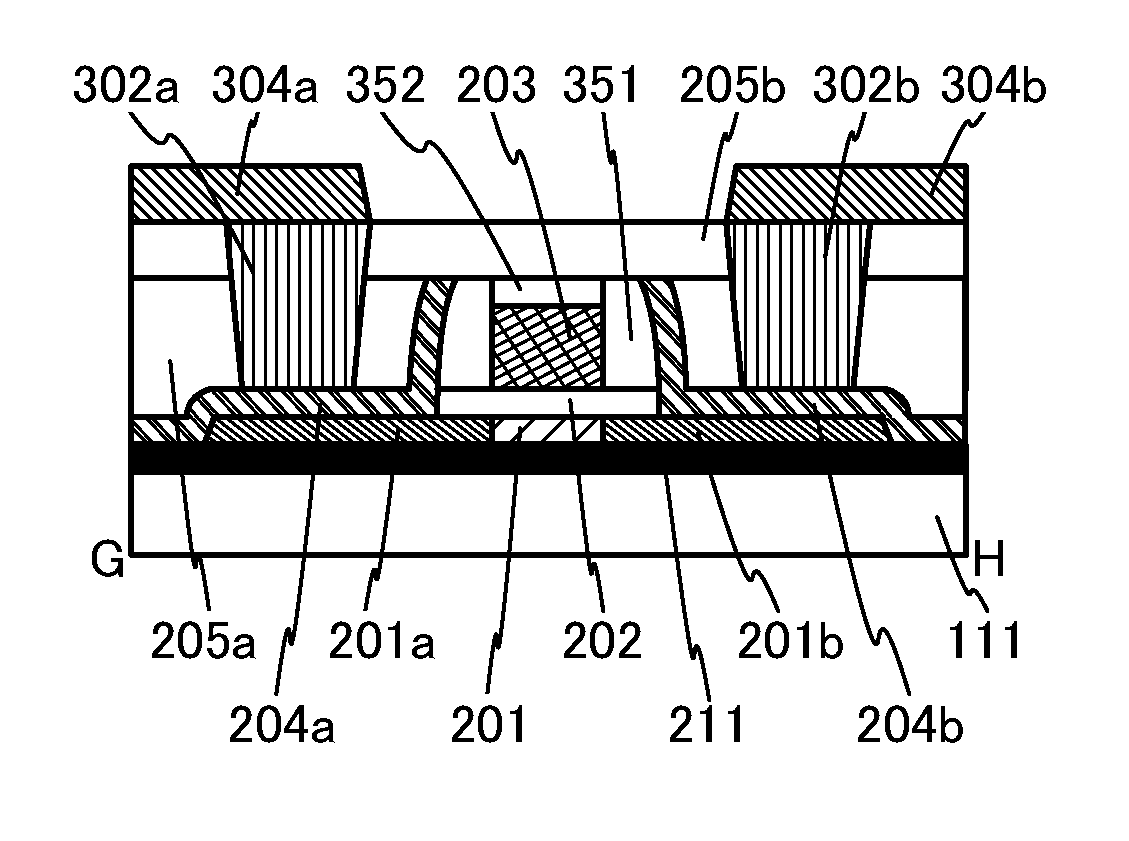

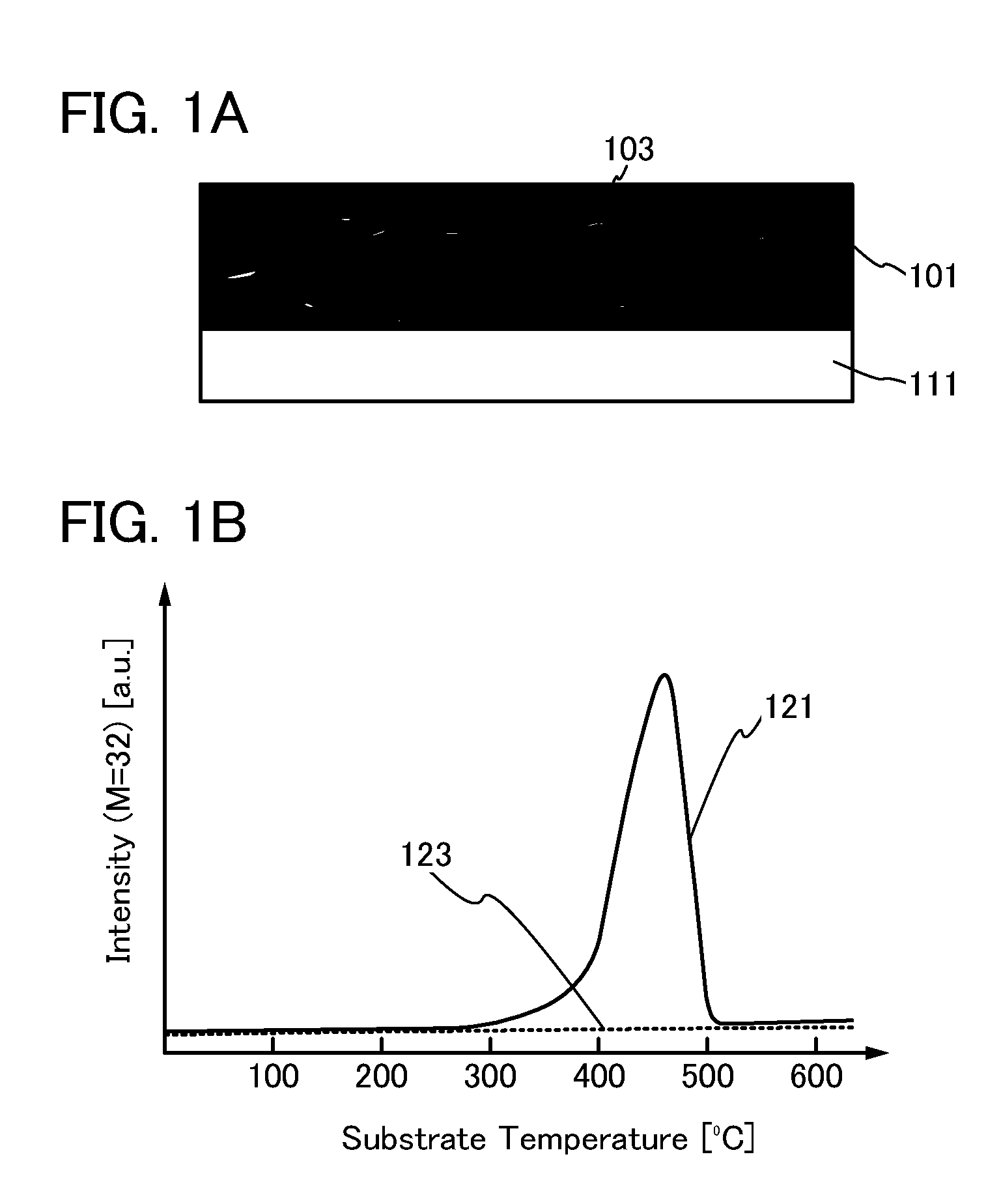

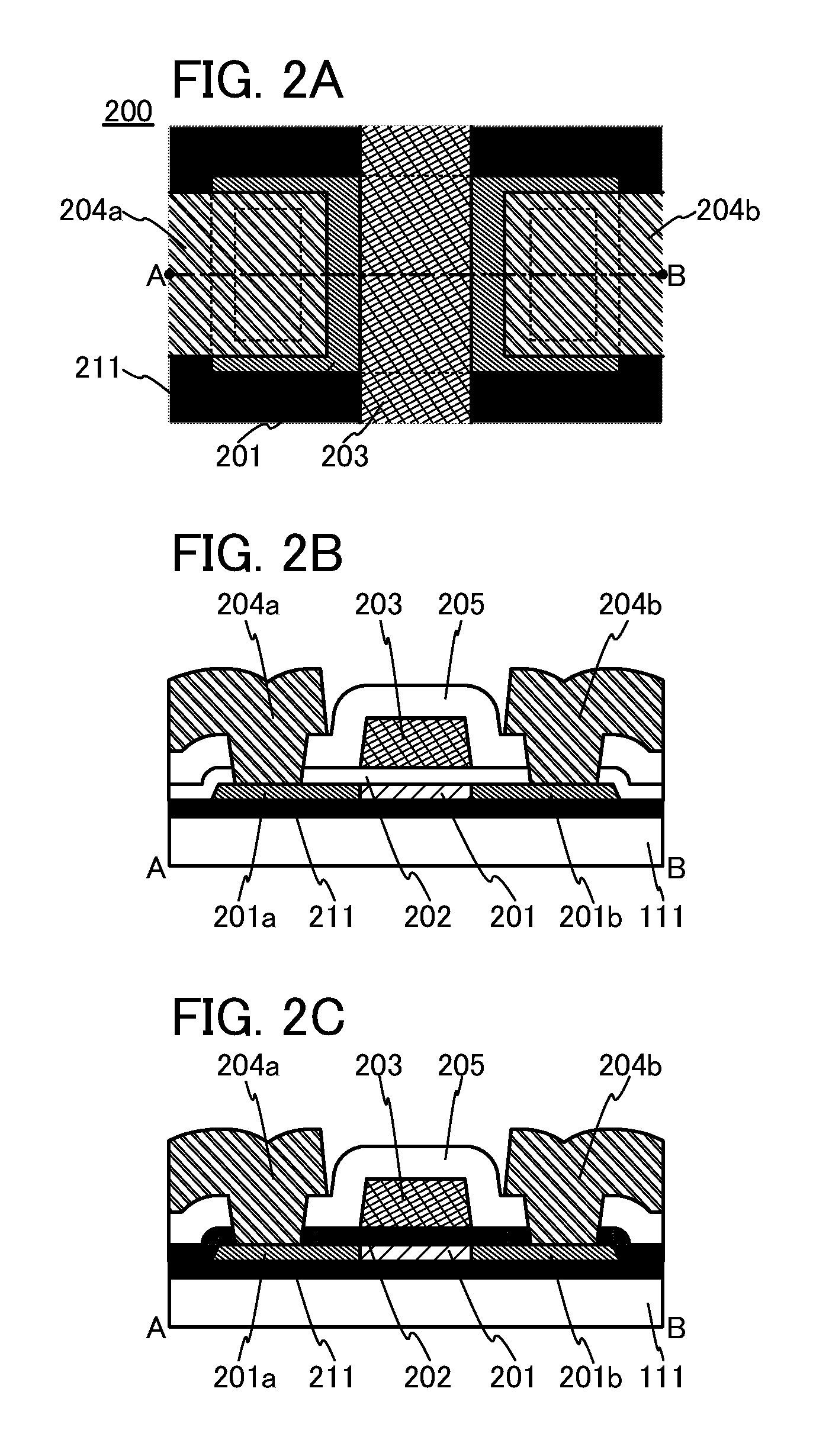

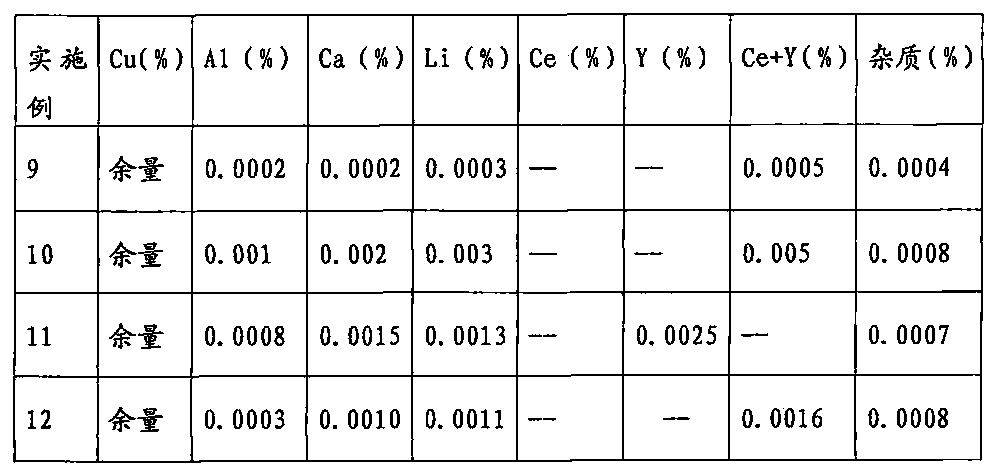

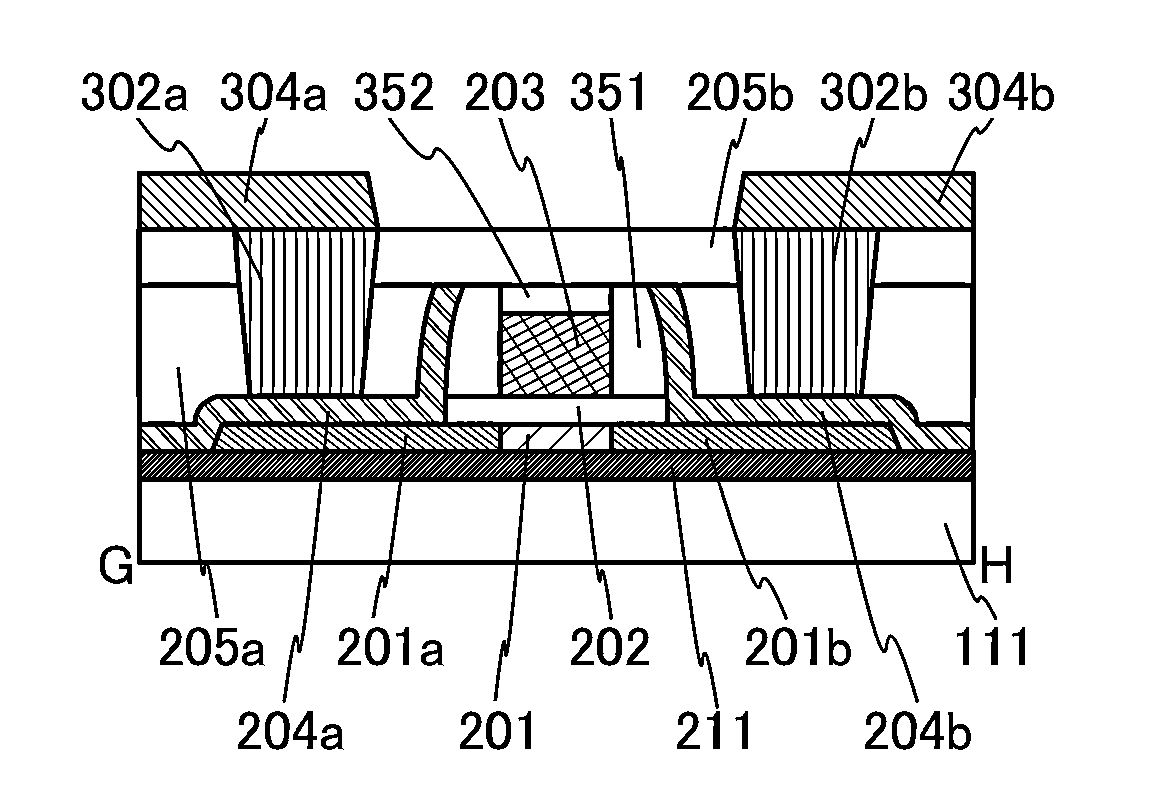

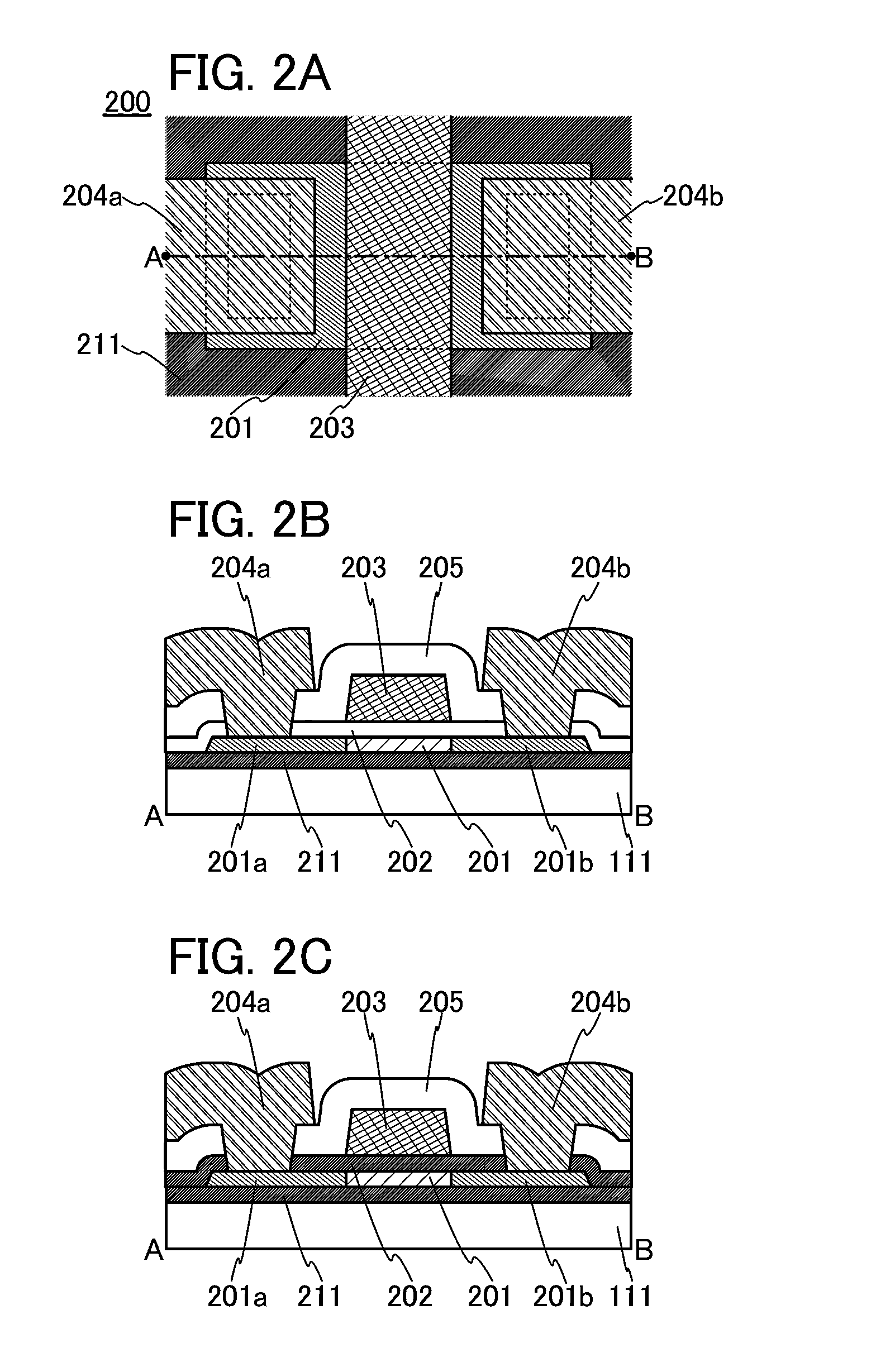

Insulating film, formation method thereof, semiconductor device, and manufacturing method thereof

InactiveUS20130126861A1Adversely affects electrical characteristics of the transistorEliminate oxygenTransistorLayered productsDevice materialSilicon oxide

An amorphous region with low density is formed in an oxide insulating film containing zirconium. The amount of oxygen released from such an oxide insulating film containing zirconium by heating is large and a temperature at which oxygen is released is higher in the oxide insulating film than in a conventional oxide film (e.g., a silicon oxide film). When the insulating film is formed using a sputtering target containing zirconium in an oxygen atmosphere, the temperature of a surface on which the insulating film is formed may be controlled to be lower than a temperature at which a film to be formed starts to crystallize.

Owner:SEMICON ENERGY LAB CO LTD

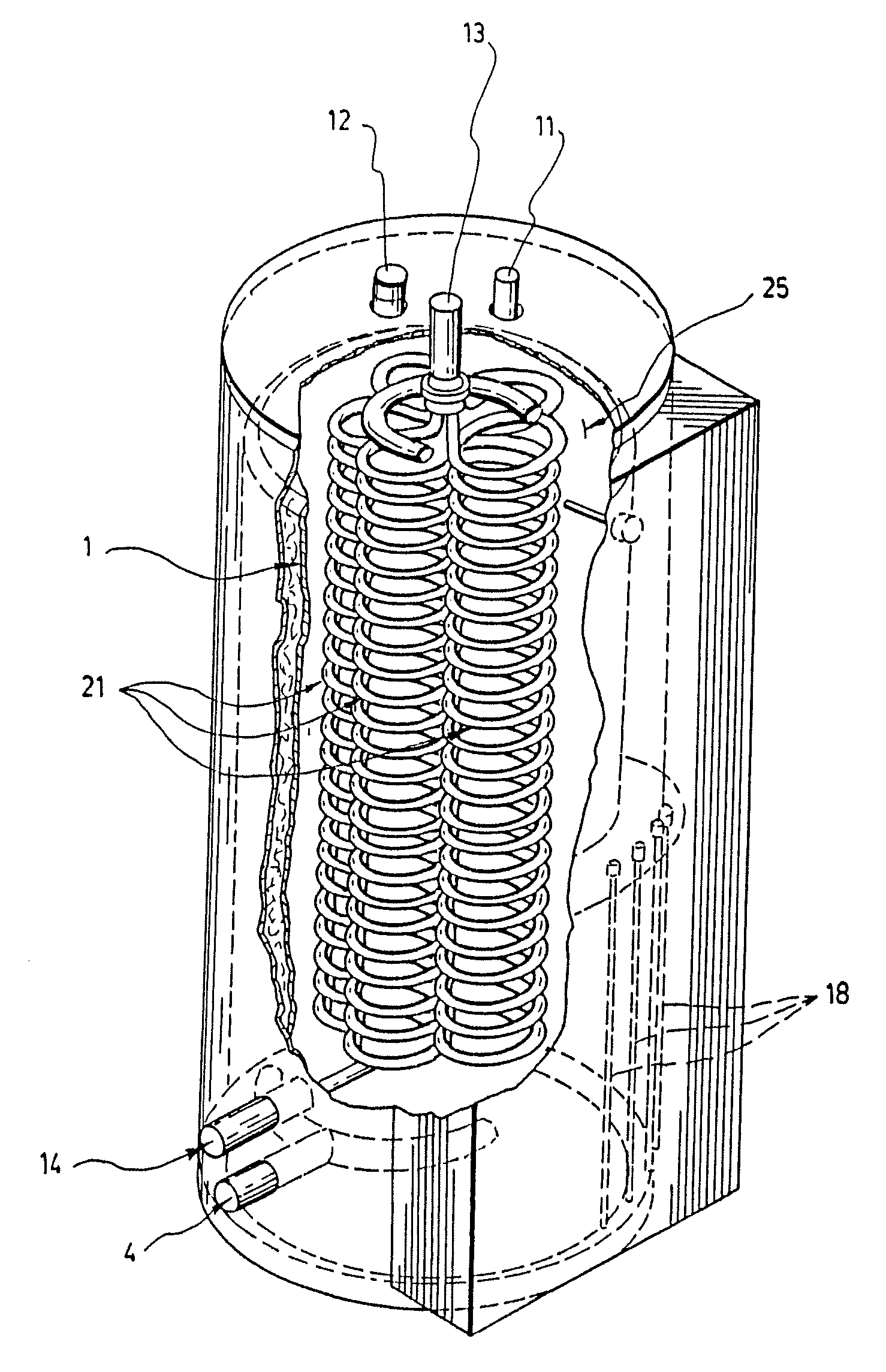

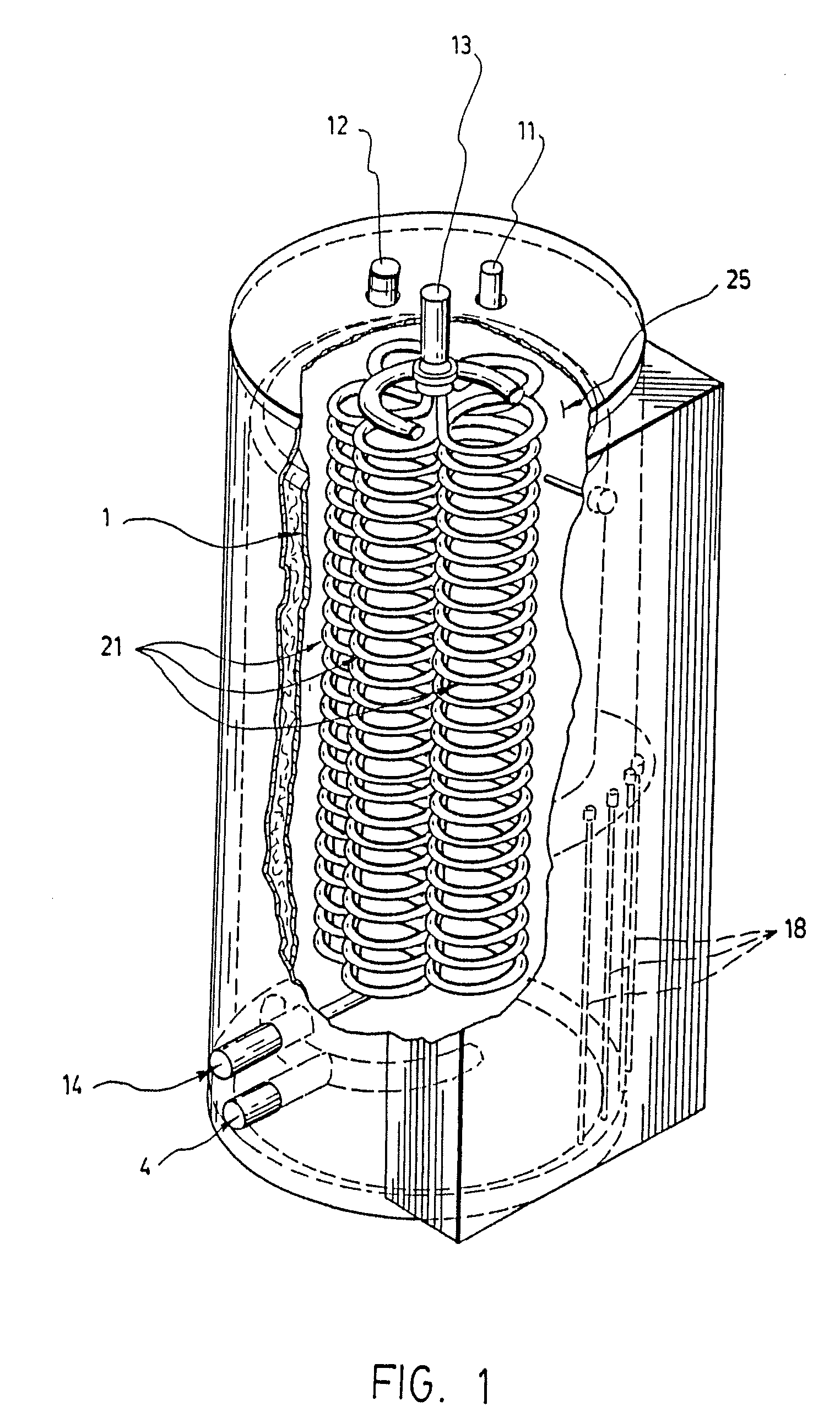

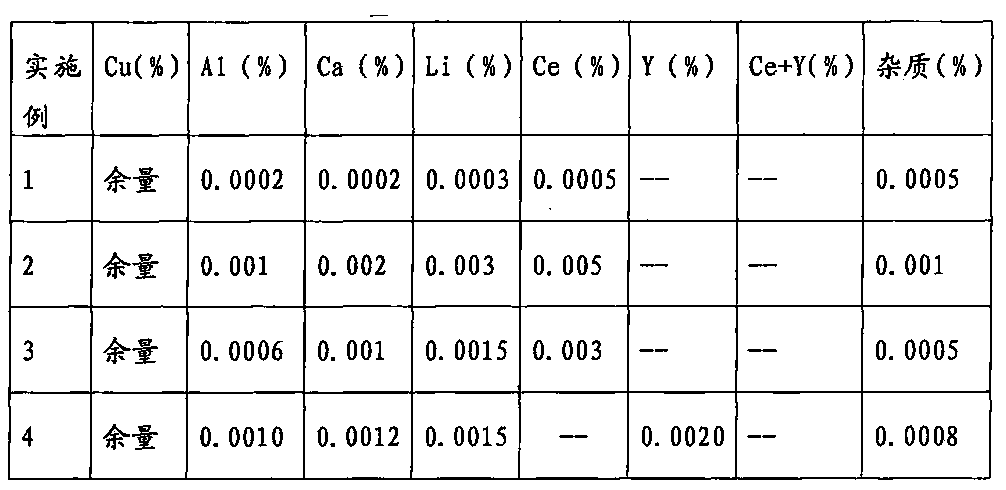

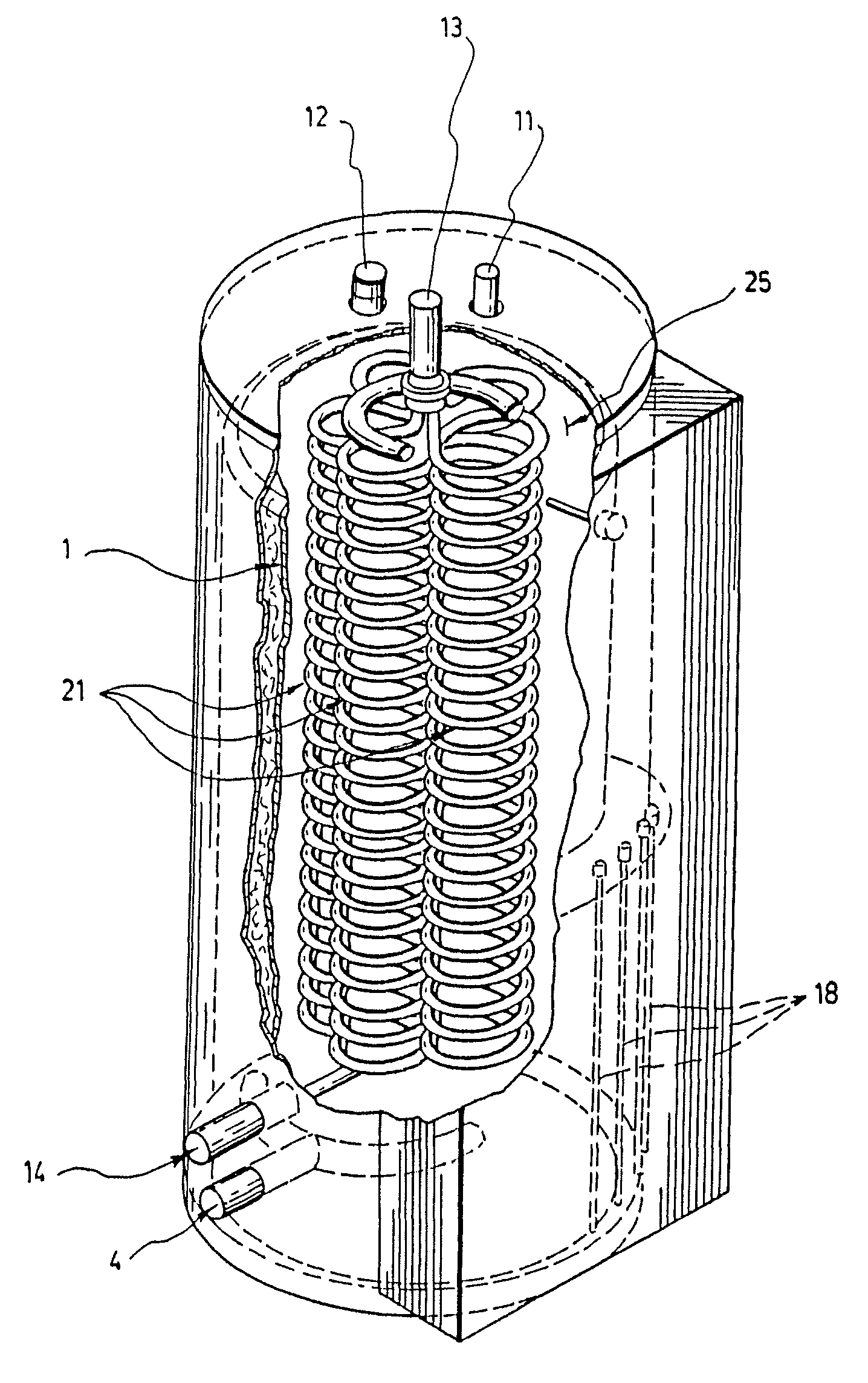

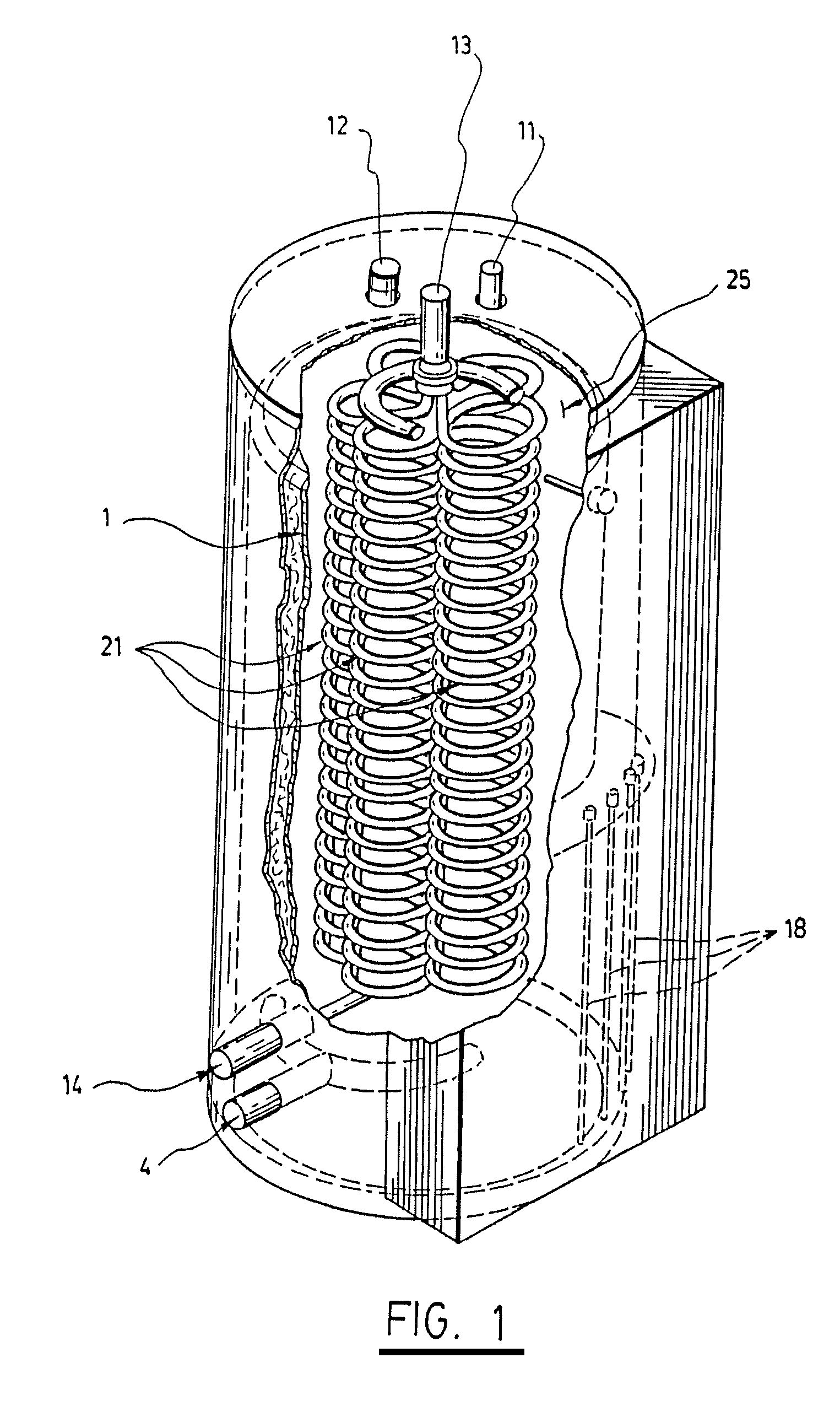

Boiler with an Adjacent Chamber and an Heliciodal Heat Exchanger

ActiveUS20080191046A1Eliminate oxygenLong life-timeInternal combustion piston enginesBoiler water tubesEngineeringDirect communication

Disclosed is a boiler for providing hot water to a heating system of a building and for simultaneously producing hot domestic water. This boiler comprises a heating tank provided with a water inlet and a water outlet through which water for use in the heating system circulates and an adjacent chamber annexed to the heating tank. This adjacent chamber is in direct communication with the heating tank and containing means for heating the water. The boiler also comprises a heat exchanger provided with a water inlet and a water outlet through which circulates the domestic water. This heat exchanger is made of a plurality of tubular coils of helicoidal shape that are located within the heating tank in order to allow heat transfer between the hot water within the heating tank and the domestic water that circulates within the tubular coils.

Owner:GESTION M J P A

Copper bonding wire and preparation method thereof

The invention relates to a copper bonding wire and a preparation method thereof. The copper bonding wire comprises, by mass, 0.0003-0.003% of lithium, 0.0002-0.002% of calcium, 0.0002-0.001% of aluminum, 0.0005-0.005% of cerium or yttrium, 0.0001-0.001% of other inevitable impurity elements and the balance copper. The preparation method of the copper bonding wire comprises the steps of manufacturing of intermediate alloy, manufacturing of alloy ingots, homogenizing annealing, hot extrusion, stress relief annealing, drawing, final annealing, multiple winding subpackaging and final protective packaging, and intermediate stress relief annealing can further be conducted in the drawing process according to the actual demands. The copper bonding wire has better oxidation resistance while maintaining the good conducting and radiating properties, and the prepared copper bonding wire is better in mechanical performance due to the facts that homogenizing annealing is additionally conducted and the intermediate stress relief annealing technique can be conducted according to demands in the preparation process of the copper bonding wire.

Owner:上海铭沣科技股份有限公司

Insulating film, formation method thereof, semiconductor device, and manufacturing method thereof

InactiveUS8969130B2Adversely affects electrical characteristics of the transistorEliminate oxygenTransistorLayered productsPower semiconductor deviceSilicon oxide

An amorphous region with low density is formed in an oxide insulating film containing zirconium. The amount of oxygen released from such an oxide insulating film containing zirconium by heating is large and a temperature at which oxygen is released is higher in the oxide insulating film than in a conventional oxide film (e.g., a silicon oxide film). When the insulating film is formed using a sputtering target containing zirconium in an oxygen atmosphere, the temperature of a surface on which the insulating film is formed may be controlled to be lower than a temperature at which a film to be formed starts to crystallize.

Owner:SEMICON ENERGY LAB CO LTD

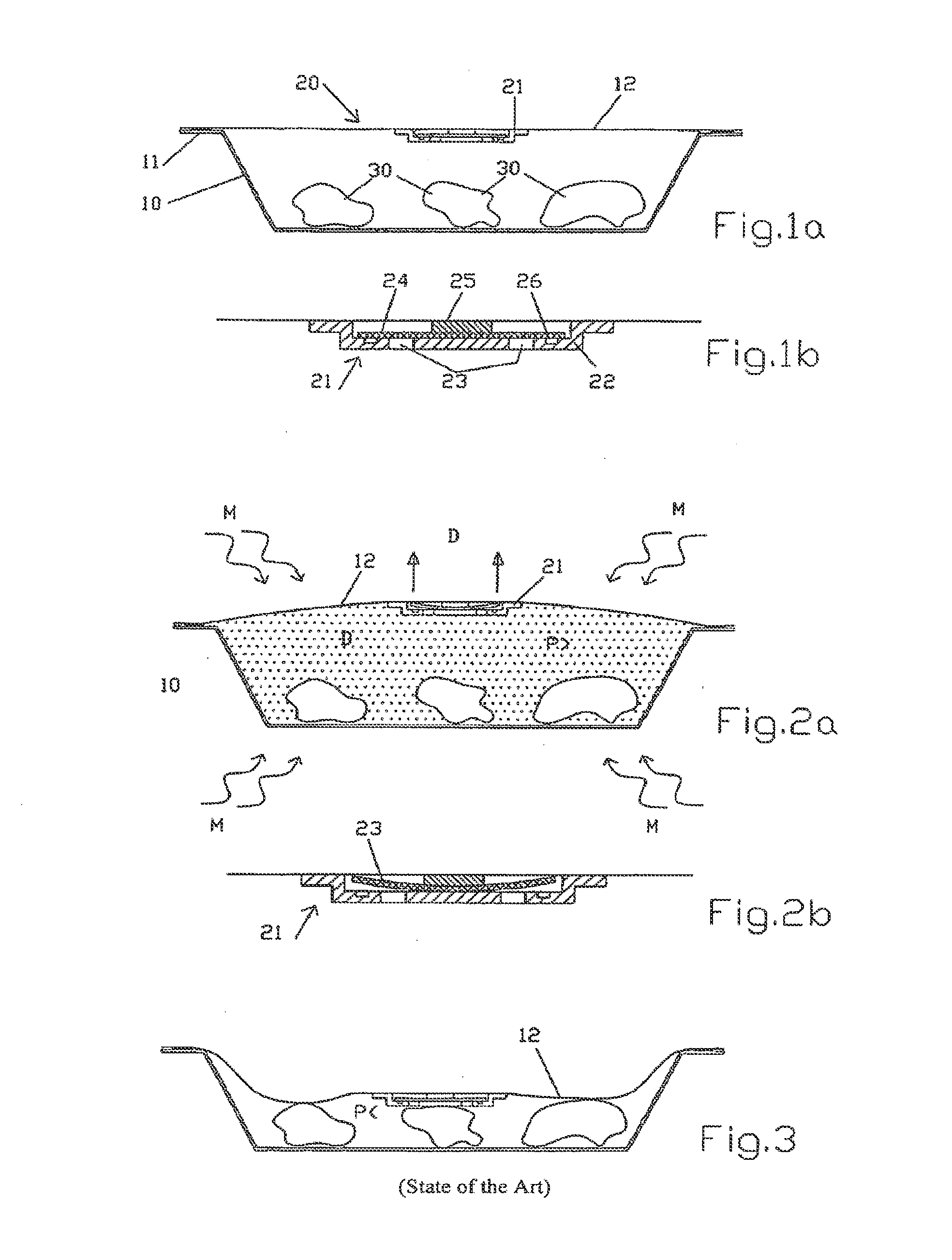

Method for preserving foodstuffs

InactiveUS20140298752A1Performed rapidly and easilyEliminate oxygenVenting meansPackage sterilisationMicrowaveEngineering

A method for preserving foodstuffs, in which the foodstuffs are heated in the moist state in a container suitable for transport and storage with ventilation openings. The foodstuffs are heated for a defined period by a microwave, for at least such a time as hot steam forms in the container and exits through the ventilation openings. Gas is injected into the container after the heating process for at least partial compensation of the pressure drop in the container.

Owner:CONAGRA FOODS RDM INC

Boiler with an adjacent chamber and an helicoidal heat exchanger

ActiveUS8376243B2Eliminate oxygenFacilitate heat exchangeAir-treating devicesInternal combustion piston enginesEngineeringDirect communication

Disclosed is a boiler for providing hot water to a heating system of a building and for simultaneously producing hot domestic water. This boiler comprises a heating tank provided with a water inlet and a water outlet through which water for use in the heating system circulates and an adjacent chamber annexed to the heating tank. This adjacent chamber is in direct communication with the heating tank and containing means for heating the water. The boiler also comprises a heat exchanger provided with a water inlet and a water outlet through which circulates the domestic water. This heat exchanger is made of a plurality of tubular coils of helicoidal shape that are located within the heating tank in order to allow heat transfer between the hot water within the heating tank and the domestic water that circulates within the tubular coils.

Owner:GESTION M J P A

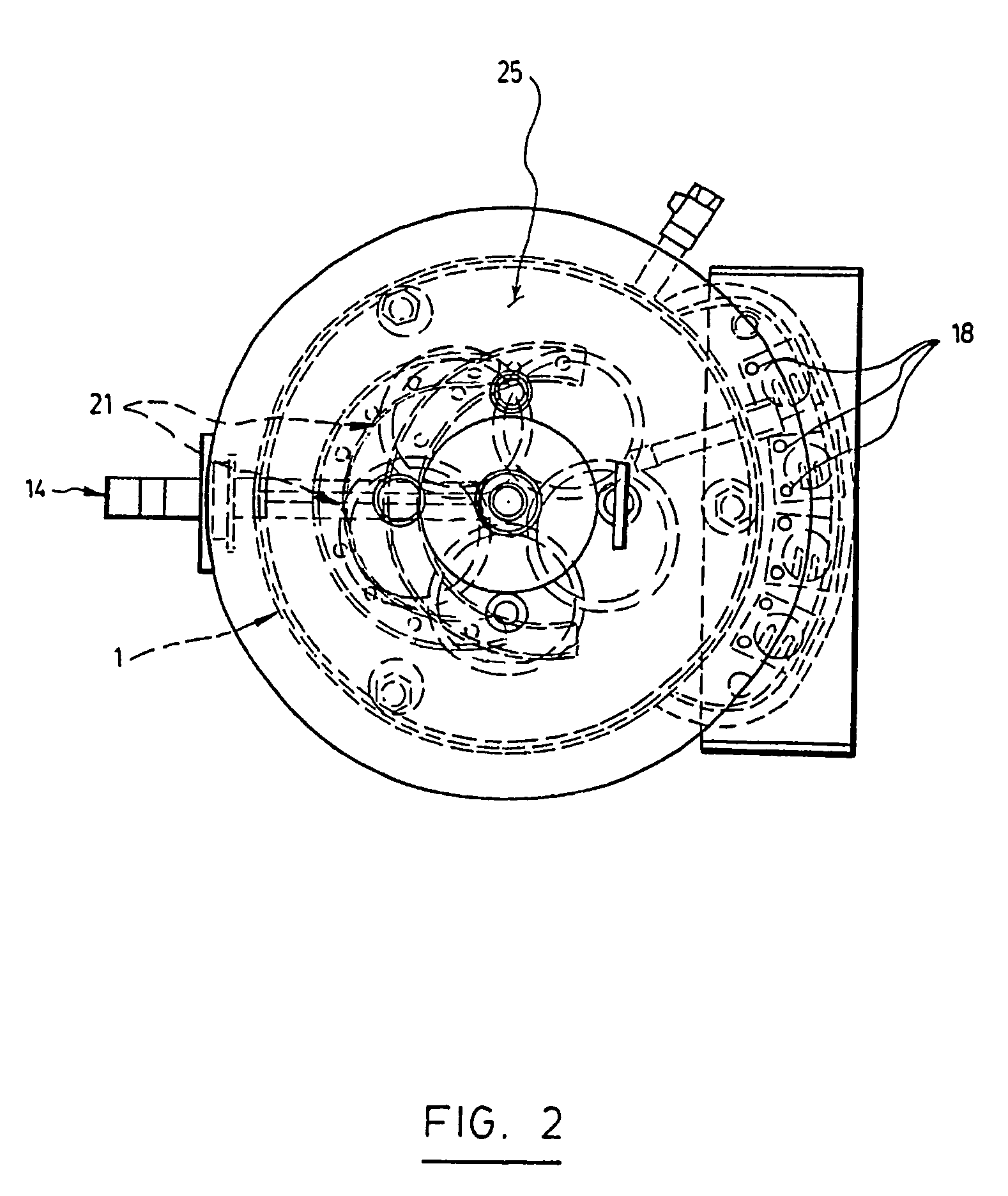

Reduced metal particle high speed micro-forging forming process

The invention relates to a reduced metal particle high speed micro-forging forming process. The process comprises the following steps: a) preparing spherical metal particles through an atomization method, and carrying out the micro-oxidation treatment on the particles; b) reducing the metal particles in a high temperature high pressure reducing cavity so as to make the metal particles obtain high activity fresh surfaces, filling up the high pressure reducing cavity with a gas mixture of inert gas and hydrogen, setting the proportion of the hydrogen to between 1 and 6 percent, and setting the temperature of the metal particles inside the reducing cavity at 0.5Tm to 0.8Tm and the pressure at 20 to 40atm; and c) carrying out the high speed micro-forging forming of the metal particles on a die when the metal particles are accelerated by an accelerator, and obtaining a die surface-shaped material. The body material obtained through the high speed micro-forging forming of the fresh reduced metal particles with a high speed, a high temperature and high surface activity has a metallurgical integrated structure. The process is suitable for the preparation of metal materials with various complex shapes.

Owner:BAOSHAN IRON & STEEL CO LTD

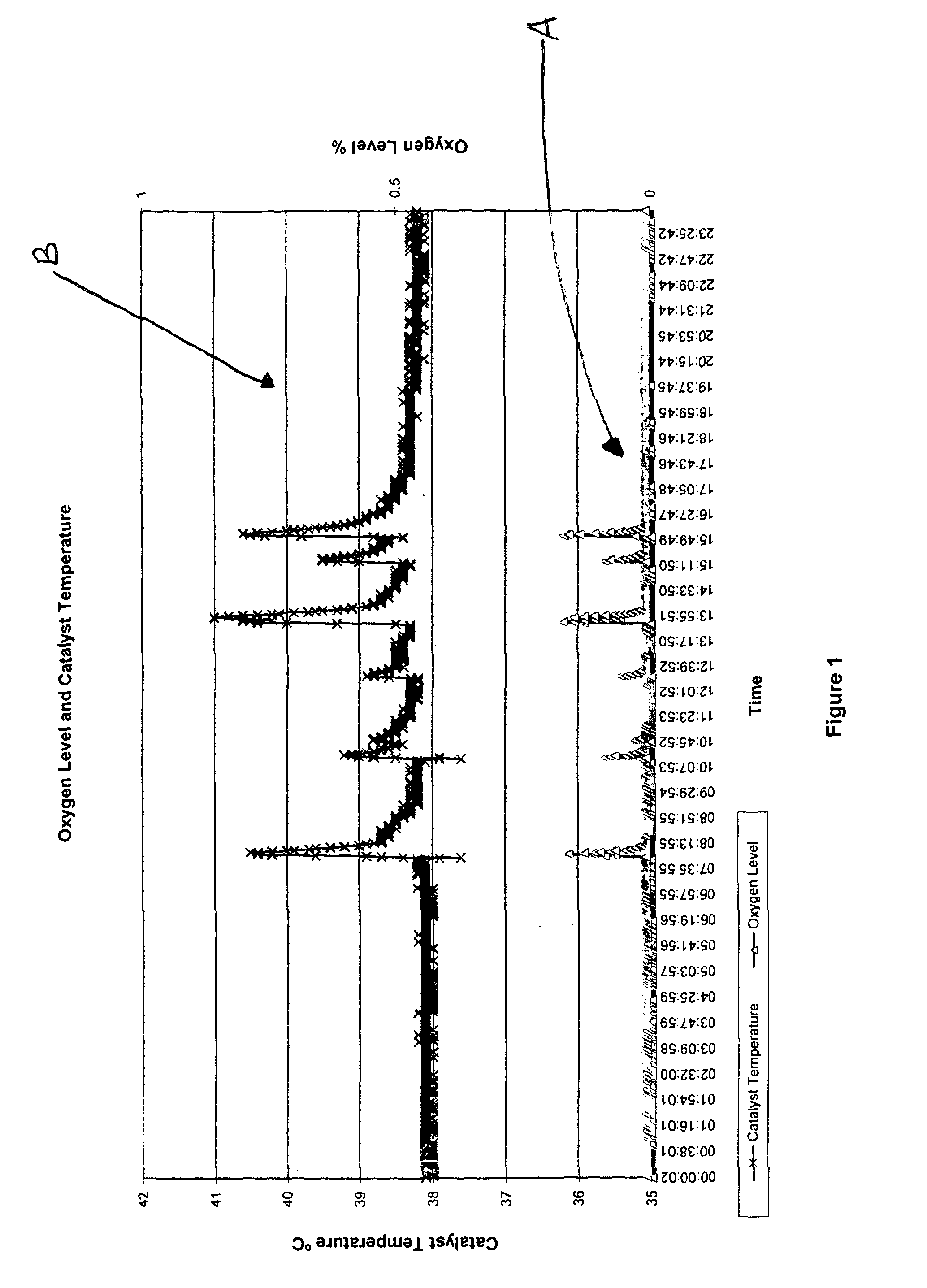

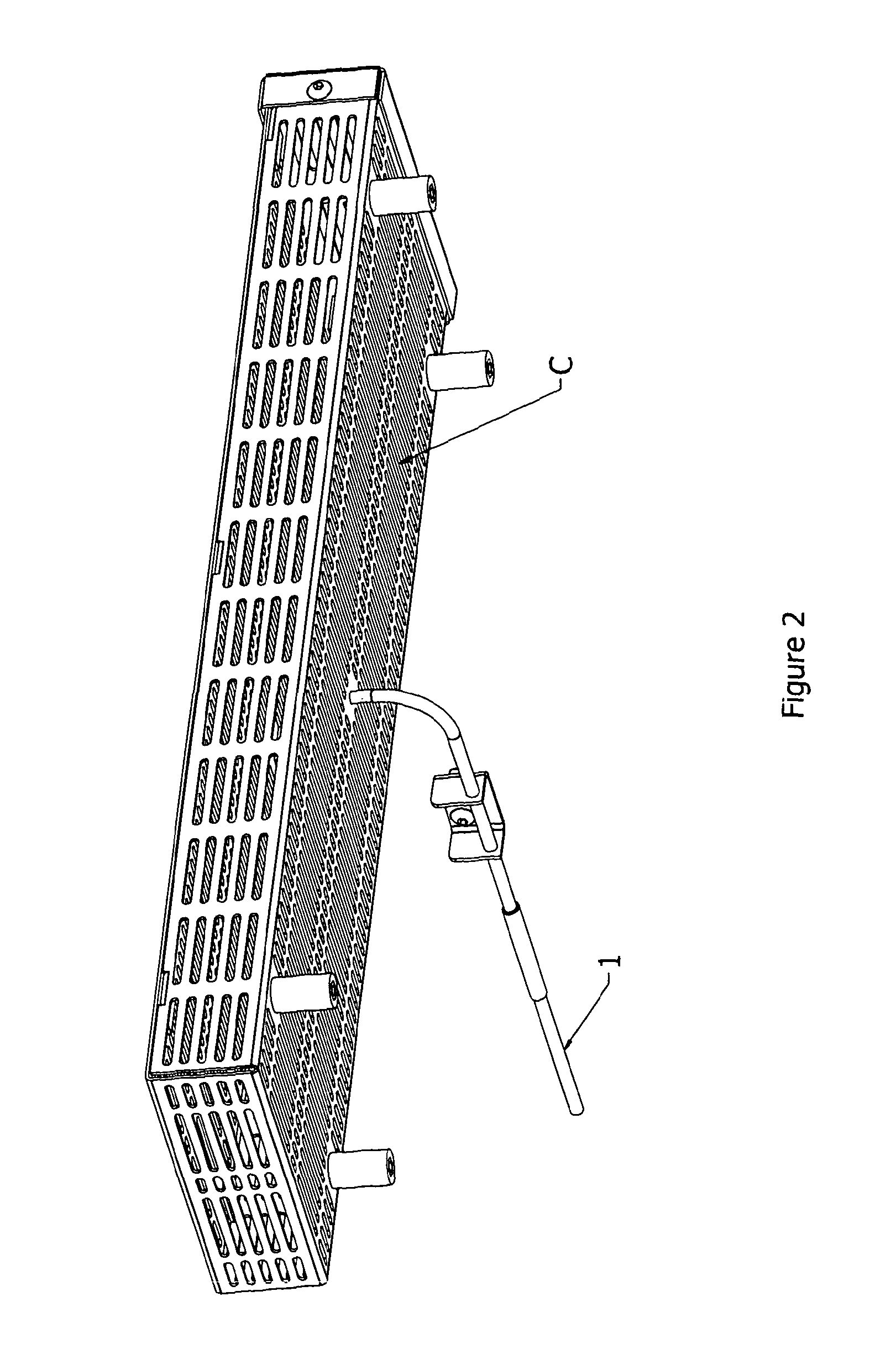

System and method for monitoring the atmosphere of an anaerobic workstation

ActiveUS20130059390A1Improve efficacySolve the lack of activityChemical analysis using catalysisMaterial heat developmentPhysical chemistryOxygen

Aspects of the invention relates to a system and method for determining the efficacy of the catalyst comprising means to detect any temperature change in the catalyst when oxygen is present in the anaerobic workstation and determine the efficacy of the catalyst in accordance with the temperature change. A detectable rise in the temperature of the catalyst is indicative of a catalytic reaction to remove oxygen from the anaerobic work station. Thus, the system determines the catalyst is an active catalyst if the temperature of the catalyst rises when oxygen is present in the anaerobic workstation. The system determines the catalyst is an inactive catalyst if the temperature of the catalyst does not rise when oxygen is present in the anaerobic workstation. Further aspect of the invention relate to a system and method for determining the atmosphere of an anaerobic workstation in accordance with the efficacy of the catalyst of the anaerobic workstation.

Owner:DON WHITLEY SCI

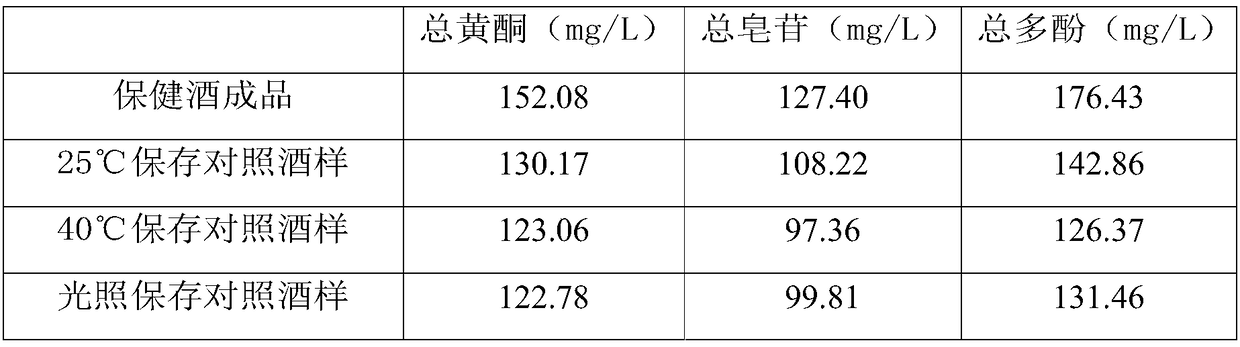

Healthcare wine and method for promoting stability of component and color of healthcare wine

InactiveCN109182013AImprove stabilityEliminate oxygenAlcoholic beverage preparationVitamin CProduct gas

The invention relates to a healthcare wine and a method for promoting stability of component and color of the healthcare wine and belongs to the technical field of the healthcare wine. The method forpromoting stability of component and color of the healthcare wine comprises the following steps: adding vitamin C into wine, stirring and dissolving, thereby acquiring a uniform wine; introducing inert gas or carbon dioxide gas into the uniform wine and removing oxygen in the uniform wine; sealing. According to the method for promoting stability of component and color of the healthcare wine provided by the invention, oxygen in the wine can be removed under the condition that no impurity is introduced, suspended solid or sediment generated from the reaction between oxygen and components in thewine can be avoided during storage and the stability of component and color of the wine is promoted. The invention also relates to the healthcare wine prepared according to the method for promoting stability of component and color of the healthcare wine.

Owner:劲牌持正堂药业有限公司

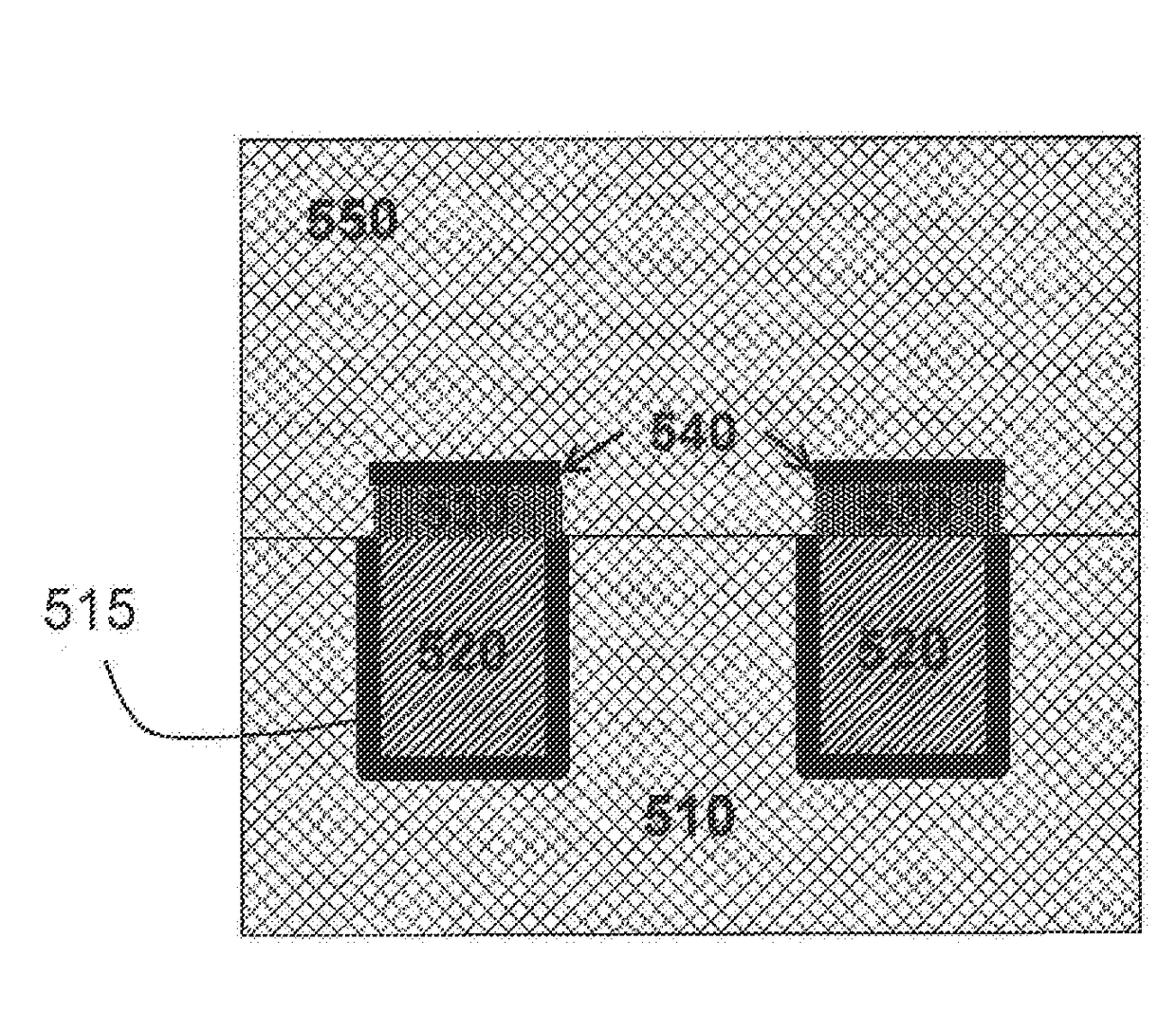

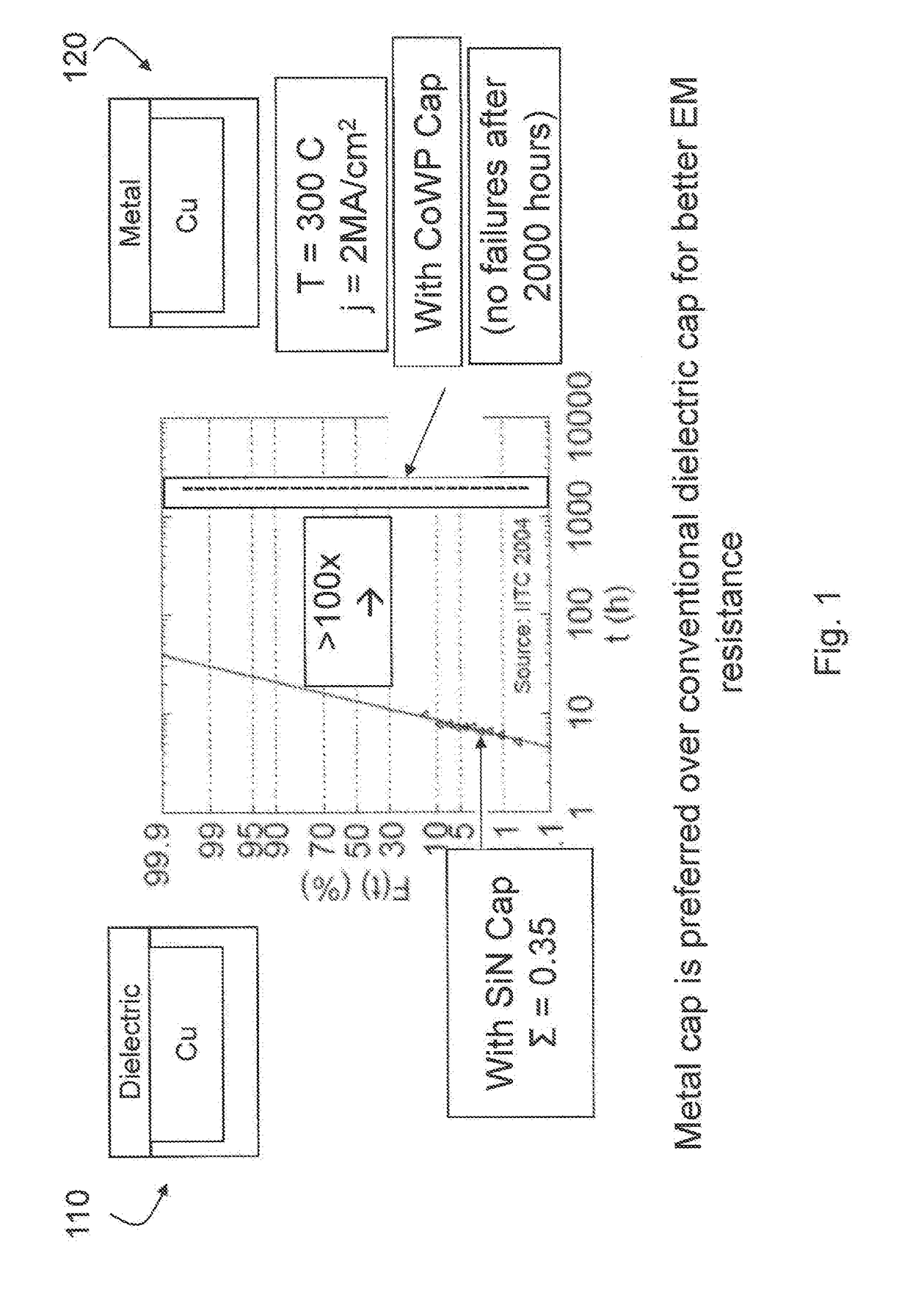

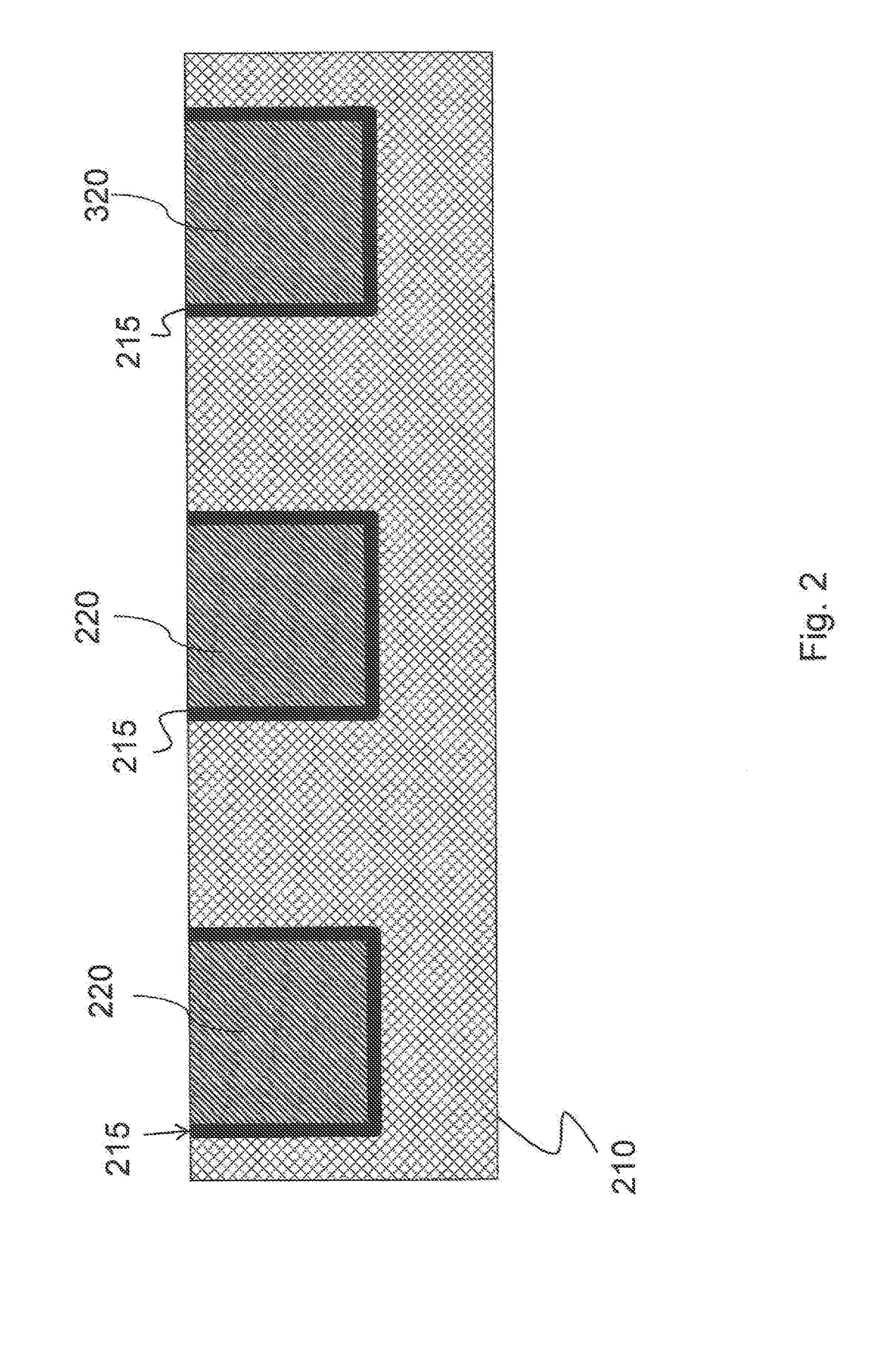

Structure and process for metal cap integration

InactiveUS20170301620A1Eliminate oxygenSemiconductor/solid-state device detailsSolid-state devicesElectroless platingOxygen scavenger

The disclosure relates to semiconductor interconnect structure having enhanced electromigration (EM) reliability in which an oxygen scavenger layer deposited (directly or indirectly) over a surface of conductive material. In one embodiment, the disclosure relates to semiconductor structure having a substrate having a cavity formed therein; a barrier material lining a portion of the cavity; a conductive material formed over the barrier material, the conductive material defining an interconnect layer; a metal cap formed over at least a portion of the conductive material; an oxygen scavenger layer formed over the metal cap layer, the oxygen scavenger layer comprising one or more of Al, TiAl or Al alloys, Mg, TiMg, Mg alloys, and deposited over the metal cap layer using one or more of a Chemical Vapor Deposition (CVD), Atomic Layer Deposition (ALD), Electroless Plating Deposition (ELD) electrodeless deposition techniques; wherein the oxygen scavenger layer removes oxygen from the interface between the conductive material surface and the metal cap layer.

Owner:IBM CORP

Environment-friendly water-permeable concrete and preparation method thereof

The invention discloses environment-friendly water permeable concrete. The concrete is characterized by comprising the following raw materials in parts by weight: 30-40 parts of cement, 3-6 parts of modified nano silicon powder, 1-2 parts of ammonium glycyrrhizinate, 1-2 parts of ethylenediamine tetraacetic acid ferric ammonium salt, 50-60 parts of coarse aggregate, 15-25 parts of vesuvianite, 10-20 parts of rectorite, 10-20 parts of nano zinc oxide coated reinforcing fibers and 20-30 parts of water. The invention also discloses a preparation method of the environment-friendly water-permeableconcrete. The environment-friendly water-permeable concrete disclosed by the invention has the advantages of good water permeability and fatigue resistance, high compressive strength, good freeze-thawresistance, wear resistance, and safety and environmental protection in use.

Owner:威海冠宏商品混凝土有限公司

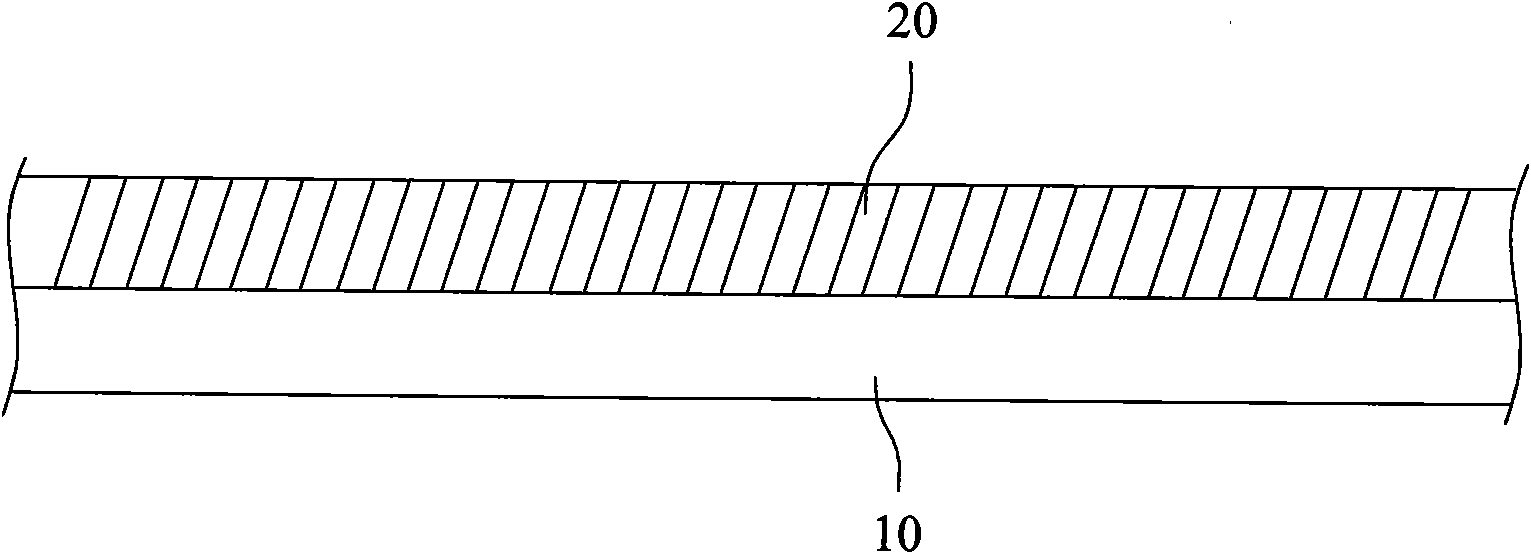

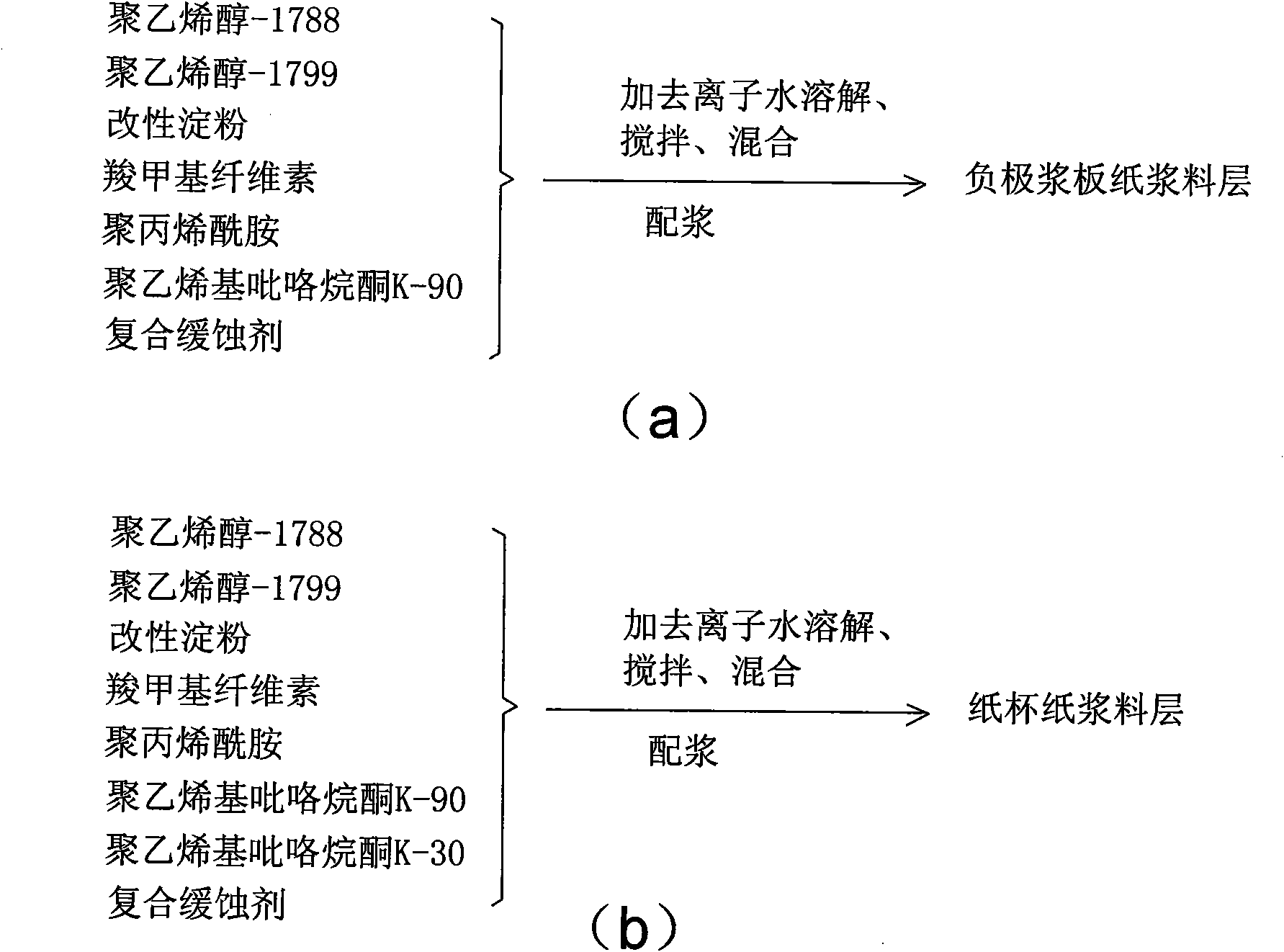

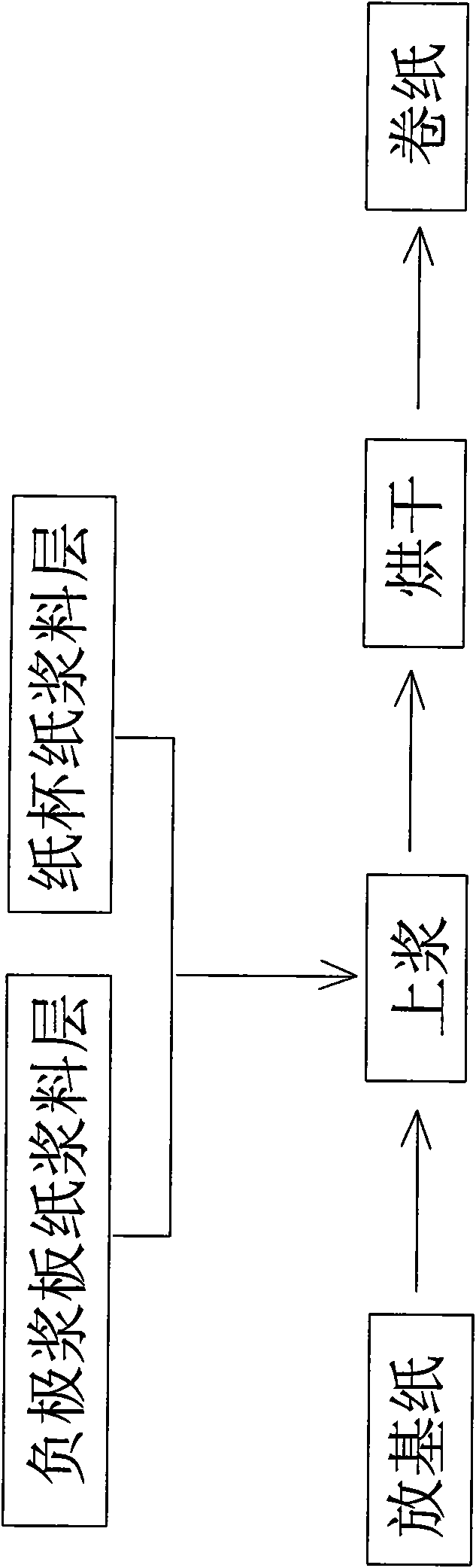

Coated paper for stacked battery and preparation method thereof

InactiveCN101671975AClose contactReduce storage timePaper coatingPaper/cardboardPolyvinyl alcoholManganese

The invention provides coated paper for a stacked battery and a preparation method thereof, wherein, the coated paper comprises base paper and a coating layer coated at the front of the base paper, i.e. single-side coating; and the coating layer is composed of modified starch, polyacrylamide, polyvinyl alcohol, a composite corrosion inhibitor, polyvinyl pyrrolidone and the like. The coated paper for the stacked battery is composed of negative pulp board paper and cup paper (i.e. carbon-clad paper), wherein, the negative pulp board paper has good liquid keeping performance and high isolation performance; and the cup paper has large liquid absorption amount and fast liquid absorption speed, thus meeting the electrical property requirement of high open circuit voltage and low short-circuit current for the stacked zinc-manganese dry cell. The coated paper can meet the industrial production requirement of the stacked battery.

Owner:GUANGDONG ZHAOQING MINGZHU PAPER

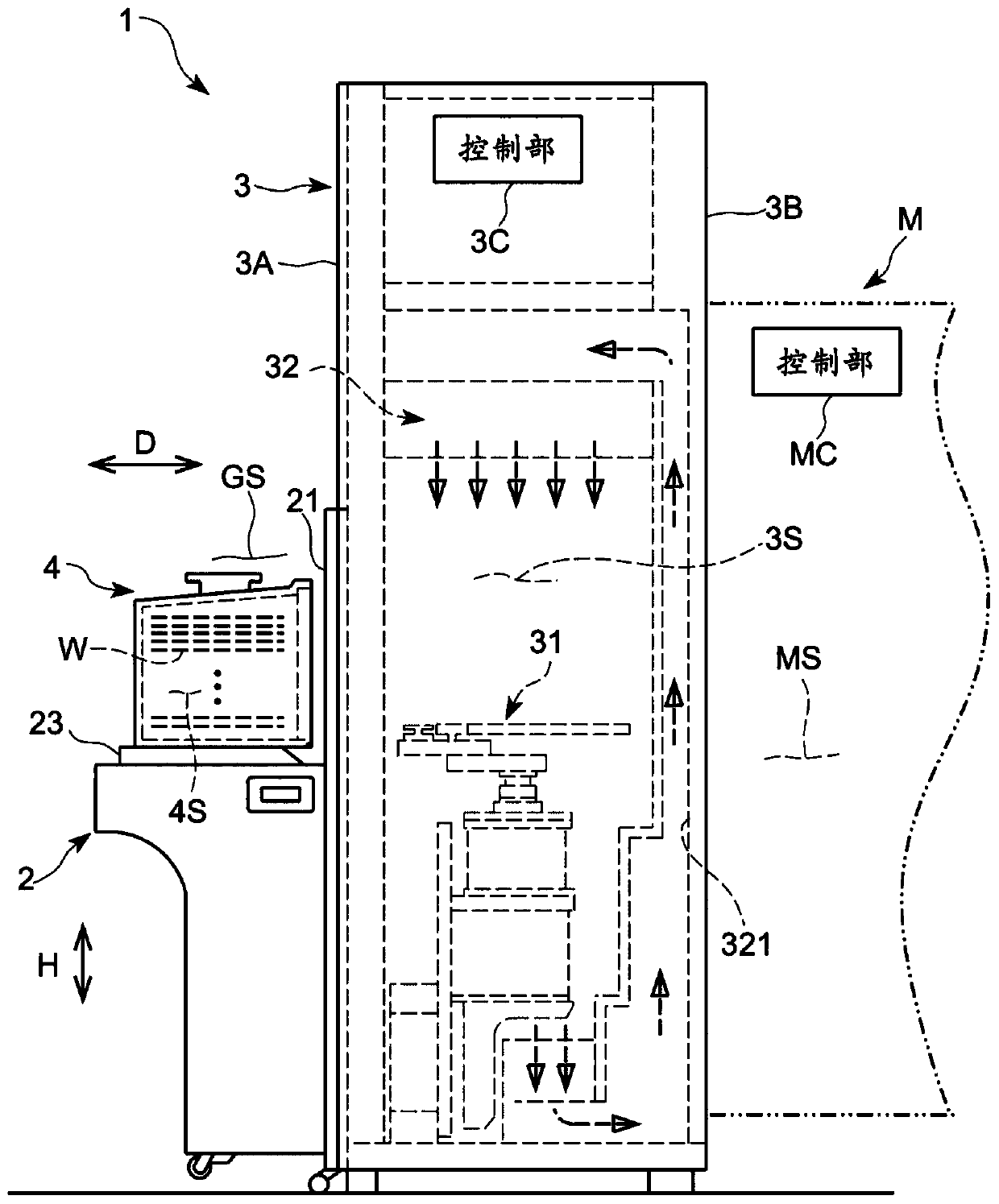

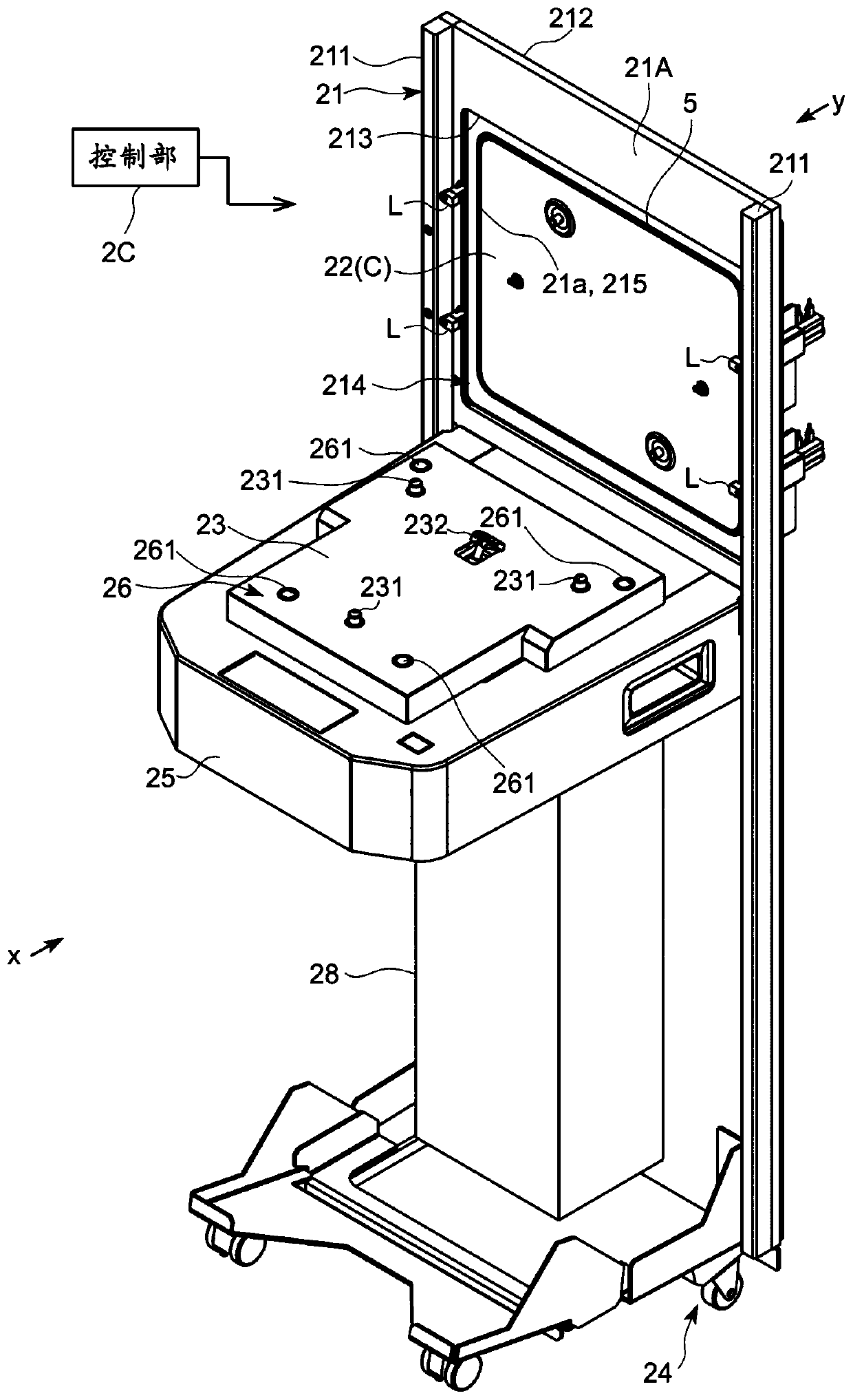

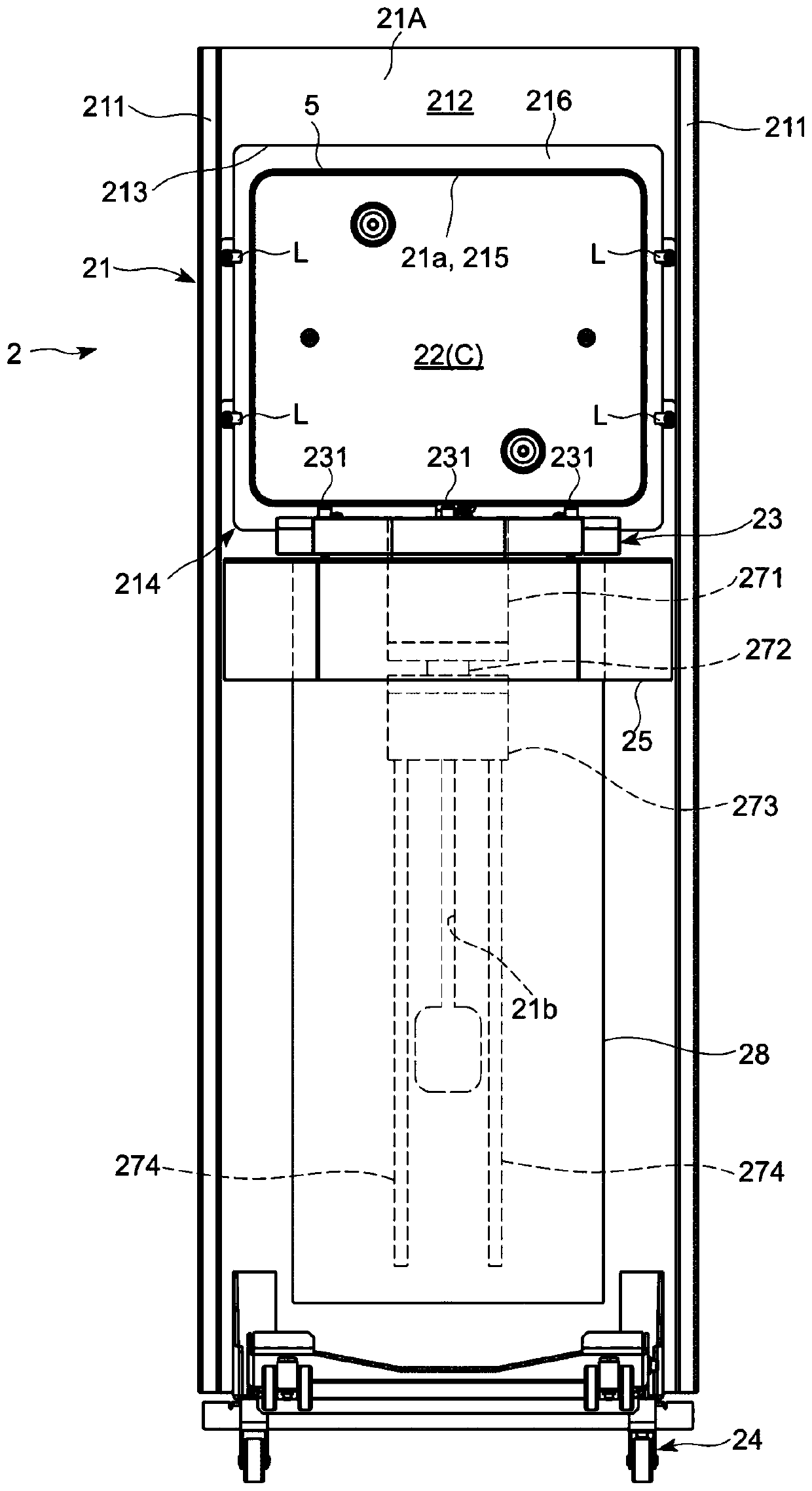

Loading port and efem

PendingCN110349893APrevent or suppress particlesGuaranteed cleanlinessSemiconductor/solid-state device manufacturingConveyor partsPositive pressureEngineering

The invention provides a loading port and an EFEM, which can shorten the time required by the door cleaning process and prevent the undesired gas causing the performance change of the object to be conveyed, namely the wafer, from flowing into the conveying chamber. the first sealing part (5) is arranged between the FOUP4 and the base (21) at a preset position in front of the base (21) in a sealingmode, and the second sealing part (6) is arranged between the loading port door (22) and the base (21) in a closed state of closing the opening part (21a) in a sealing mode. In a door cleaning process in which a gap between a container door and a loading port door (22) and a sealed space (DS) partitioned by a first sealing part (5) and a second sealing part (6) are replaced with gas, a preferentially open part (X) of the first sealing part (5) is preferentially open than the second sealing part (6) by keeping the sealed space (DS) at a positive pressure. At least the gas in the enclosed space(DS) can be discharged through the open part.

Owner:SHINKO ELECTRIC CO LTD

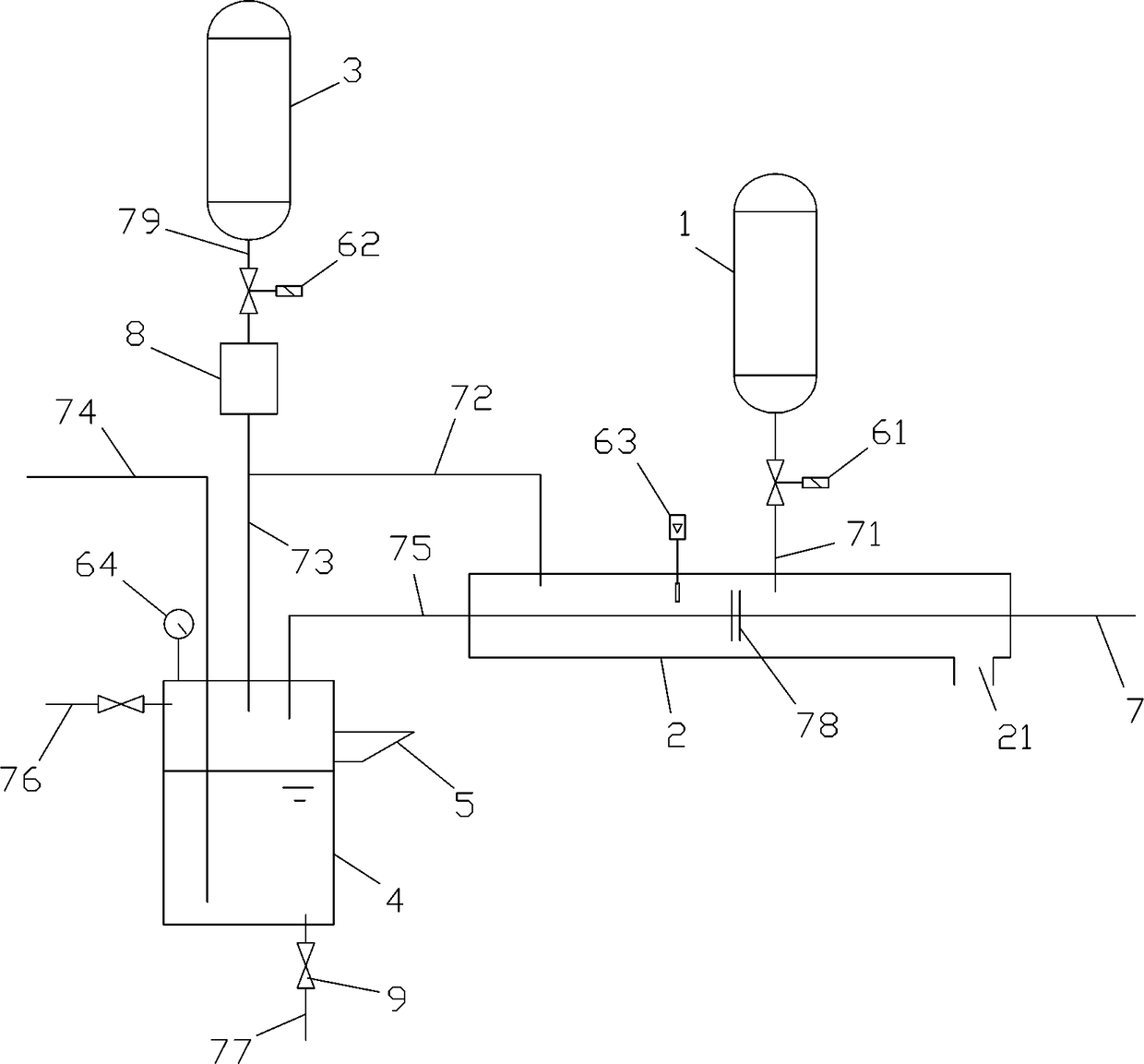

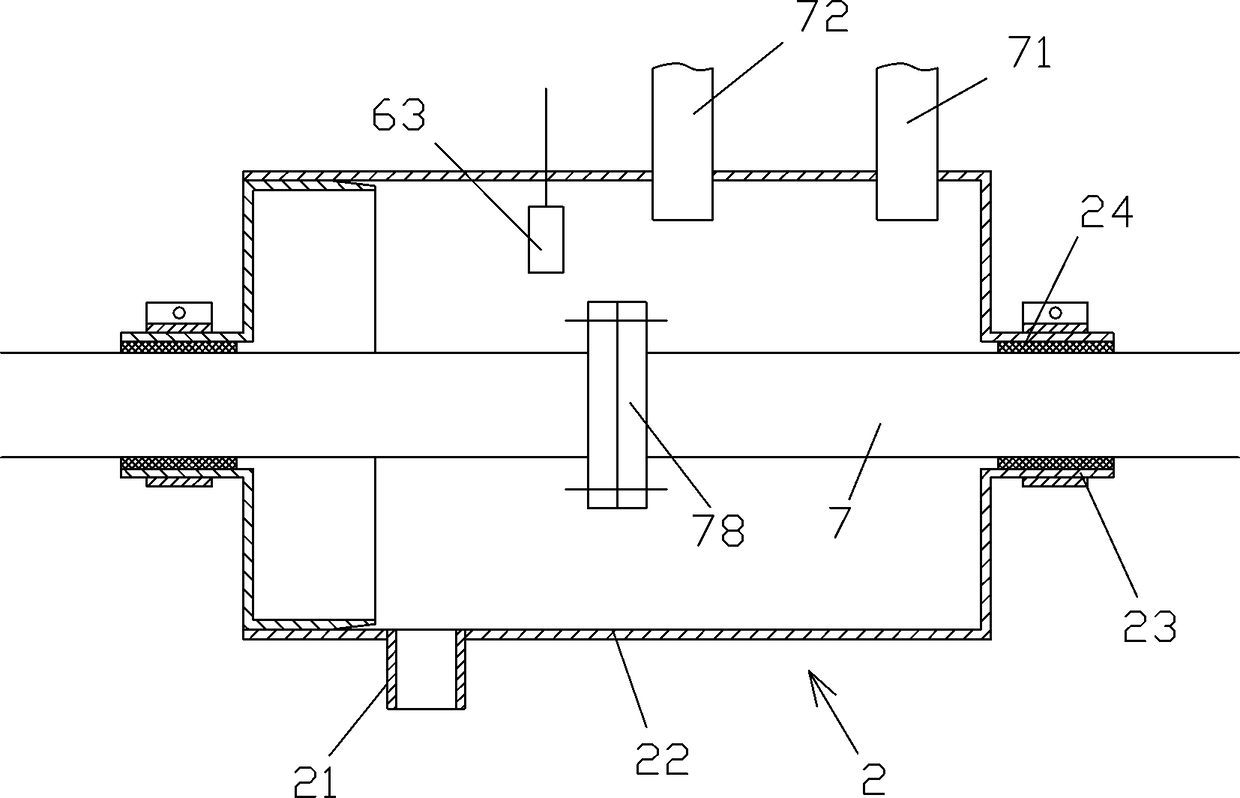

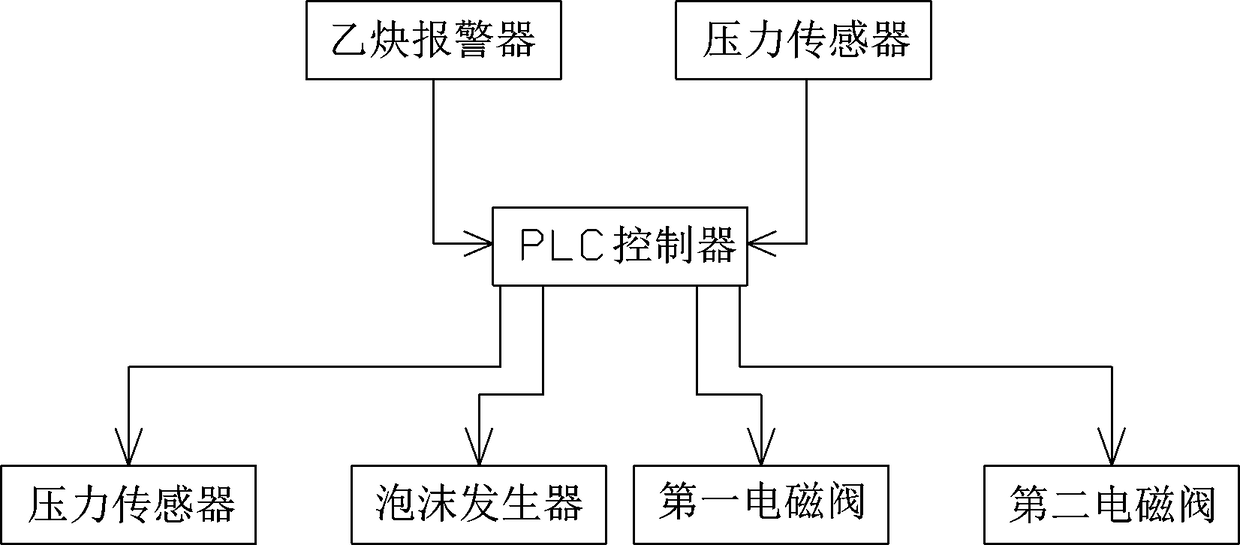

Explosion-proof flame-retardant device for acetylene conveying pipeline

InactiveCN109488883AAvoid ignitionEliminate oxygenPipeline systemsCarbon dioxide cylinderLine tubing

The invention discloses an explosion-proof flame-retardant device for an acetylene conveying pipeline. The device comprises a carbon dioxide cylinder, a shell body and a PLC, wherein the carbon dioxide cylinder communicates with the shell body through a gas inlet pipe, a first electromagnetic valve is installed on the gas inlet pipe, an acetylene alarm is arranged in the shell body, the acetylenealarm is used for transmitting monitored signals to the PLC, the PLC controls the first electromagnetic valve, the shell body is arranged outside a flange in the acetylene conveying pipeline in a sleeve mode, and the lower end of the shell body communicates with an exhaust pipe. According to the device, acetylene leaked from the flange of the pipeline can be effectively prevented from being ignited, and flames in the pipeline can be prevented from spreading to an acetylene generator and a calcium carbide pulverizer.

Owner:宜昌市得心实用气体有限公司

Catalytic cracking process of a lipid-containing feedstock

InactiveUS20120151831A1Increase probabilityReduce carbon footprintCatalytic crackingLiquid carbonaceous fuelsHydrocarbonChemistry

A process for catalytic cracking of a lipid-containing feedstock is provided. The lipid-containing feedstock contains lipids derived from microalgae and a hydrocarbon feedstock. The lipid-containing feedstock is contacted with at least one cracking catalyst at a temperature of at least 450° C., to obtain a product stream; and separating at least one hydrocarbon fraction from the product stream.

Owner:SHELL OIL CO

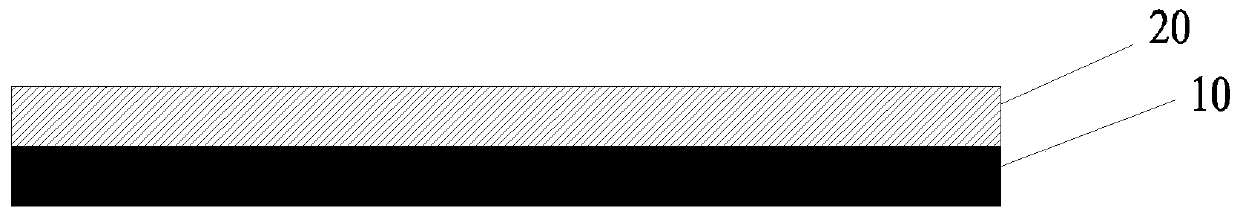

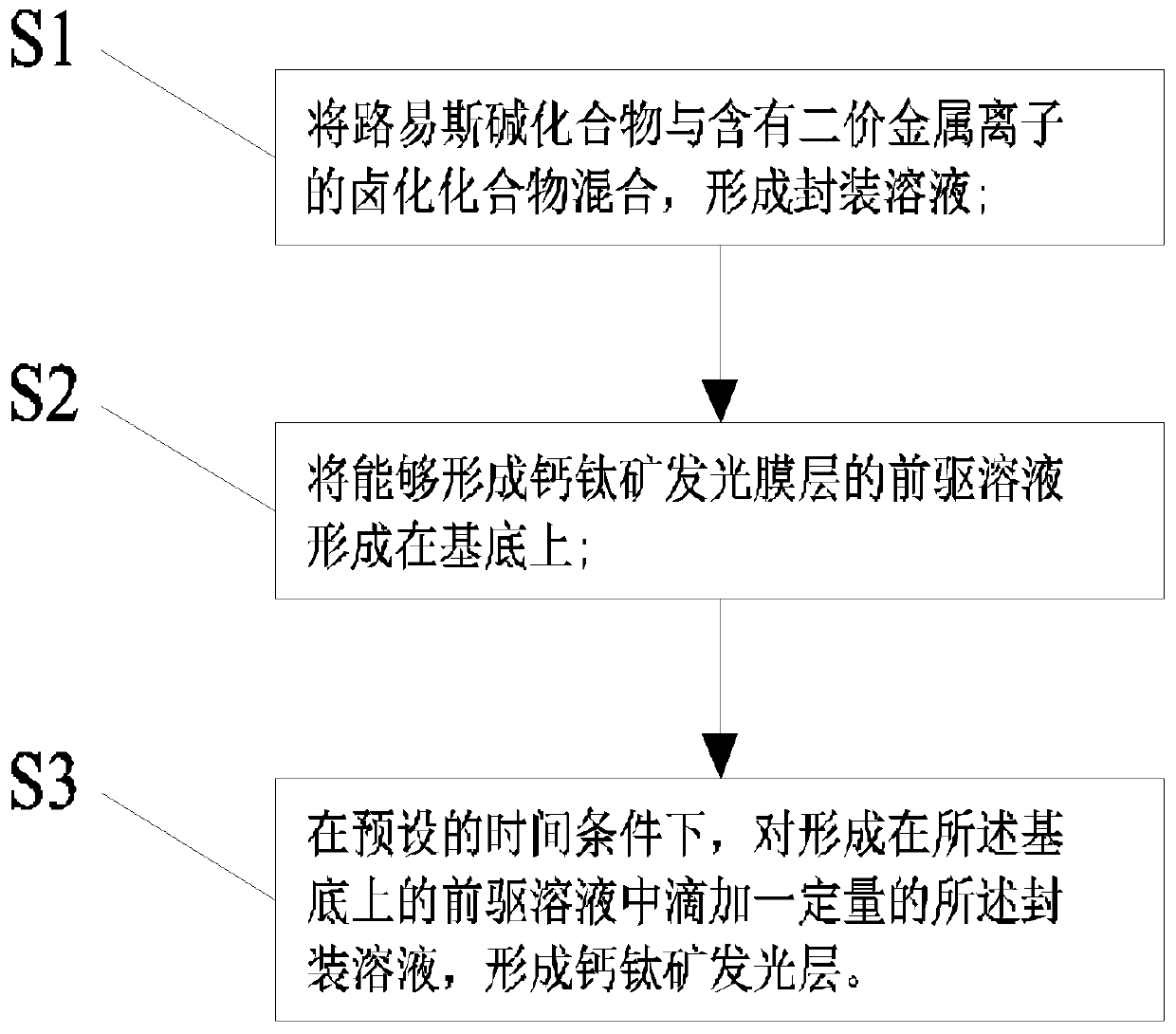

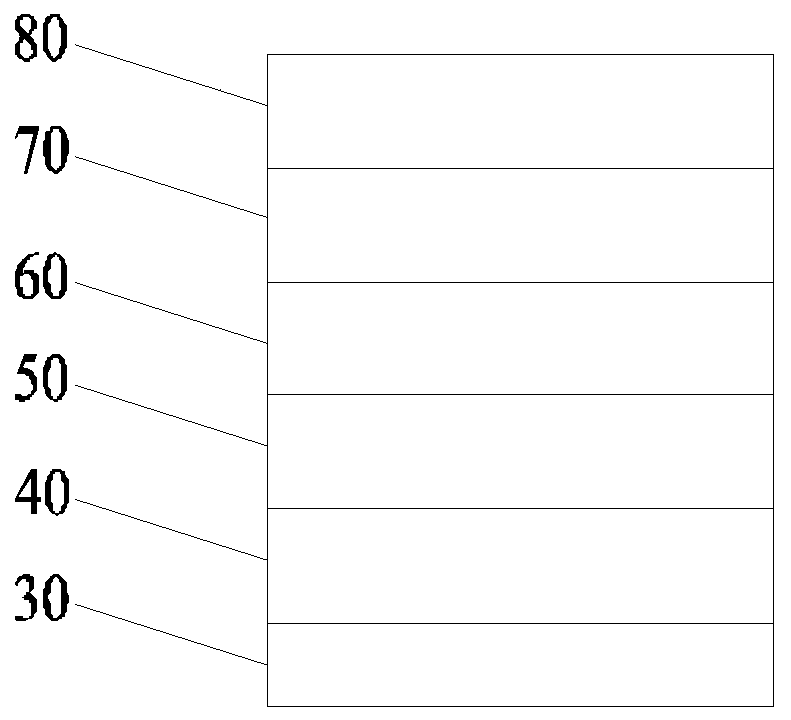

Perovskite light-emitting layer and manfuacturing method thereof, light-emitting device and display device

PendingCN111048676AEliminate oxygenImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite (structure)Display device

The invention provides a perovskite light-emitting layer and a manufacturing method thereof, a light-emitting device and a display device. The perovskite light-emitting layer comprises a perovskite light-emitting film layer and a packaging film layer wrapping the perovskite light-emitting film layer, the packaging film layer comprises a compound A, a general formula of the compound A is X<2+>SO3<2->R, the X<2+> is a divalent metal ion, and the R is a benzene ring structure containing a hydroxyl functional group. Sability of the light-emitting layer is improved, and a service life of the deviceis prolonged.

Owner:BOE TECH GRP CO LTD +1

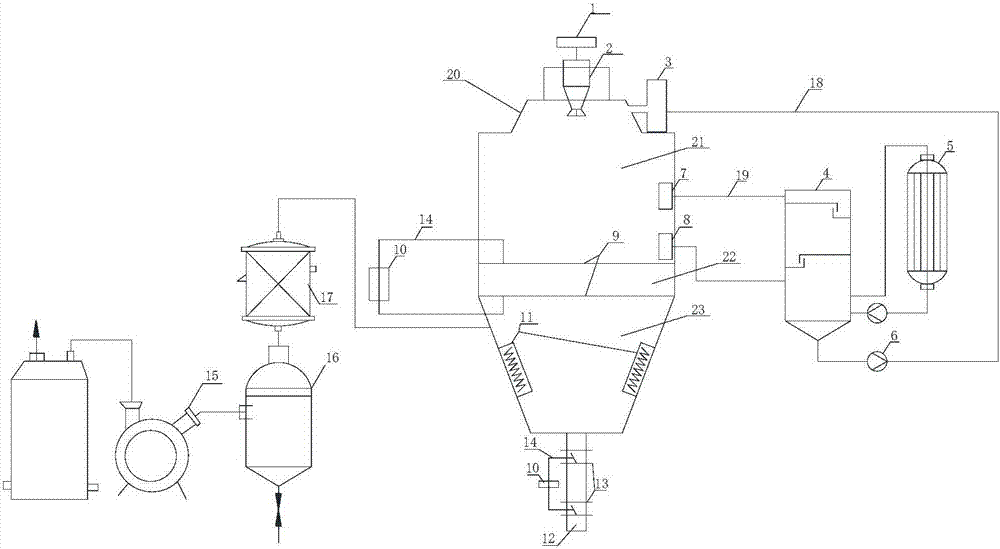

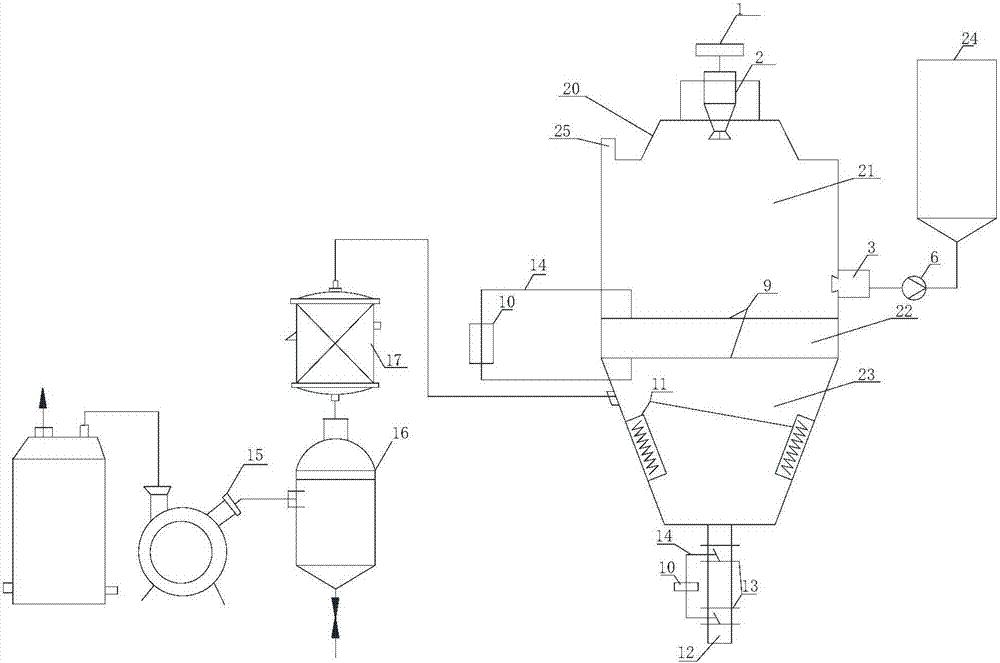

A spray freeze sublimation dryer

ActiveCN105664513BGuaranteed thermal sensitivityKeep aliveSublimationEvaporation by sprayingSolubilityFreeze-drying

The invention provides a spray freezing sublimation drying machine and belongs to the technical field of drying equipment for food, medicine, biological products and the like. The spray freezing sublimation drying machine is applicable to drying liquid materials and specifically comprises a drying tower for spray freezing sublimation, a feeding device is arranged on the upper portion of the drying tower, a spray device is connected to the bottom of the feeding device, two layers of grid type partition plates are arranged in the middle of the drying tower to divide the drying tower into three independent sealed spaces comprising a spray freezing bin, a buffer bin and a vacuum drying bin. The bottom of the drying tower is provided with a discharge outlet. The centrifugal spray freezing bin is connected with a liquid inert heat transfer medium injector, the wall of the spray freezing bin is provided with a gas inert heat transfer medium outlet, the vacuum drying bin is connected with a vacuum pumping device, and the side wall of the vacuum drying bin is provided with a heating device. The spray freezing sublimation drying machine is simple in structure, capable of continuously carrying out spray freezing sublimation drying operation, high in drying efficiency, good in solubility, particularly applicable to spray drying of various heat sensitive liquid materials and good in market prospect.

Owner:ANHUI AGRICULTURAL UNIVERSITY

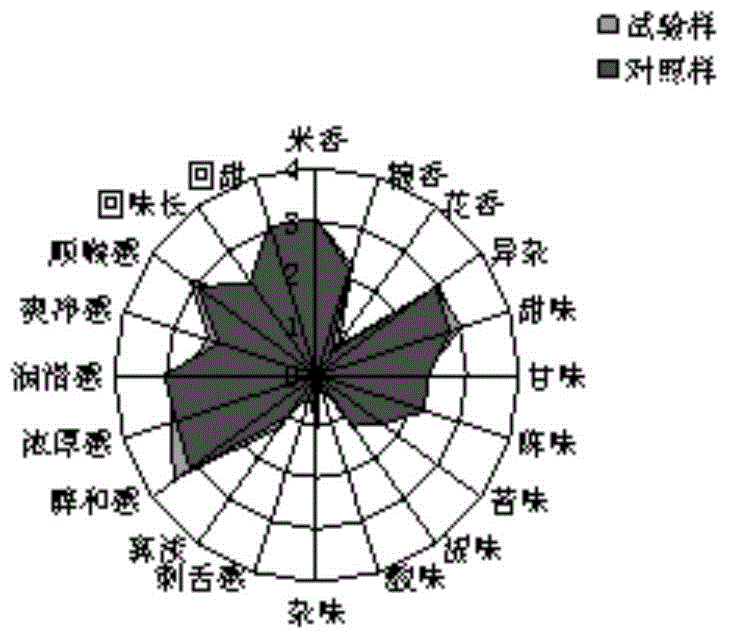

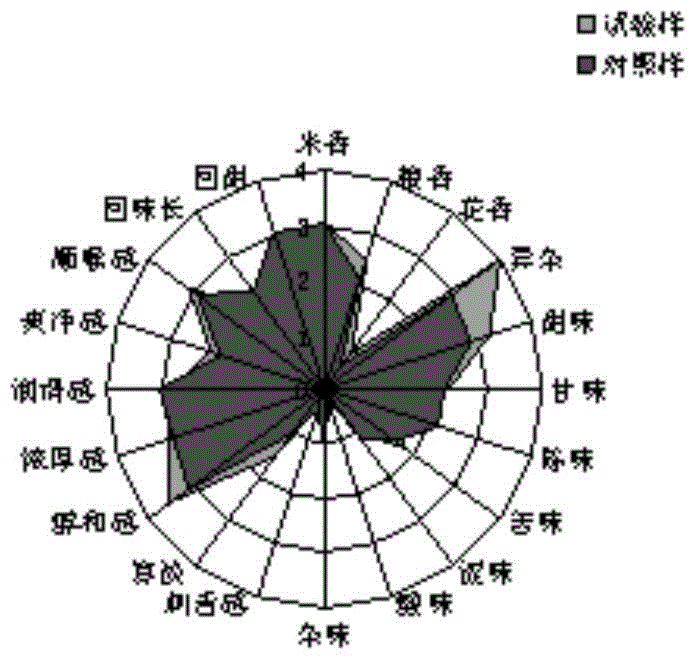

Process and equipment for producing base liquor of white spirits by liquid-state fermentation of raw material

ActiveCN104388248AShorten the growth and reproduction timePrevent subsidenceMicroorganism based processesAlcoholic beverage preparationCooling coilEnzyme

The invention belongs to the technical field of white spirits brewing and discloses a process and equipment for producing base liquor of white spirits by liquid-state fermentation of raw material. The process comprises the following steps: activating saccharomyces cerevisiae through spread cultivation; adding the activated saccharomyces cerevisiae, rice milk and saccharifying enzyme into a fermenting tank together, wherein stirring and introduction of CO2 from the bottom of the fermenting tank are carried out at the same time during the addition process so that materials are mixed uniformly; by the end of the addition of the materials, further introducing CO2 for 5-15min; sealing the tank and fermenting for 4-6 days; after fermenting for 30-36h, introducing CO2 again from the bottom of the fermenting tank and stirring sedimentary rice milk by a mechanical stirring blade at a speed of 16-60r / min at the same time, wherein mash is obtained by the end of fermentation; and distilling the mash to obtain the base liquor. The equipment provided by the invention comprises a tank body and a stirrer, wherein a cooling coil pipe is arranged in the tank body, circular pipe ventilating equipment is arranged at the center of the bottom of the tank body, and a flow guide cylinder is arranged above the circular pipe ventilating equipment. The liquor yield and taste of liquor can be improved by the process and the equipment disclosed by the invention.

Owner:广东省九江酒厂有限公司

Method of Preparing a Liquid, Containing Proteins for Subsequent Separation, by Using One or More Protein-Complexing Agents

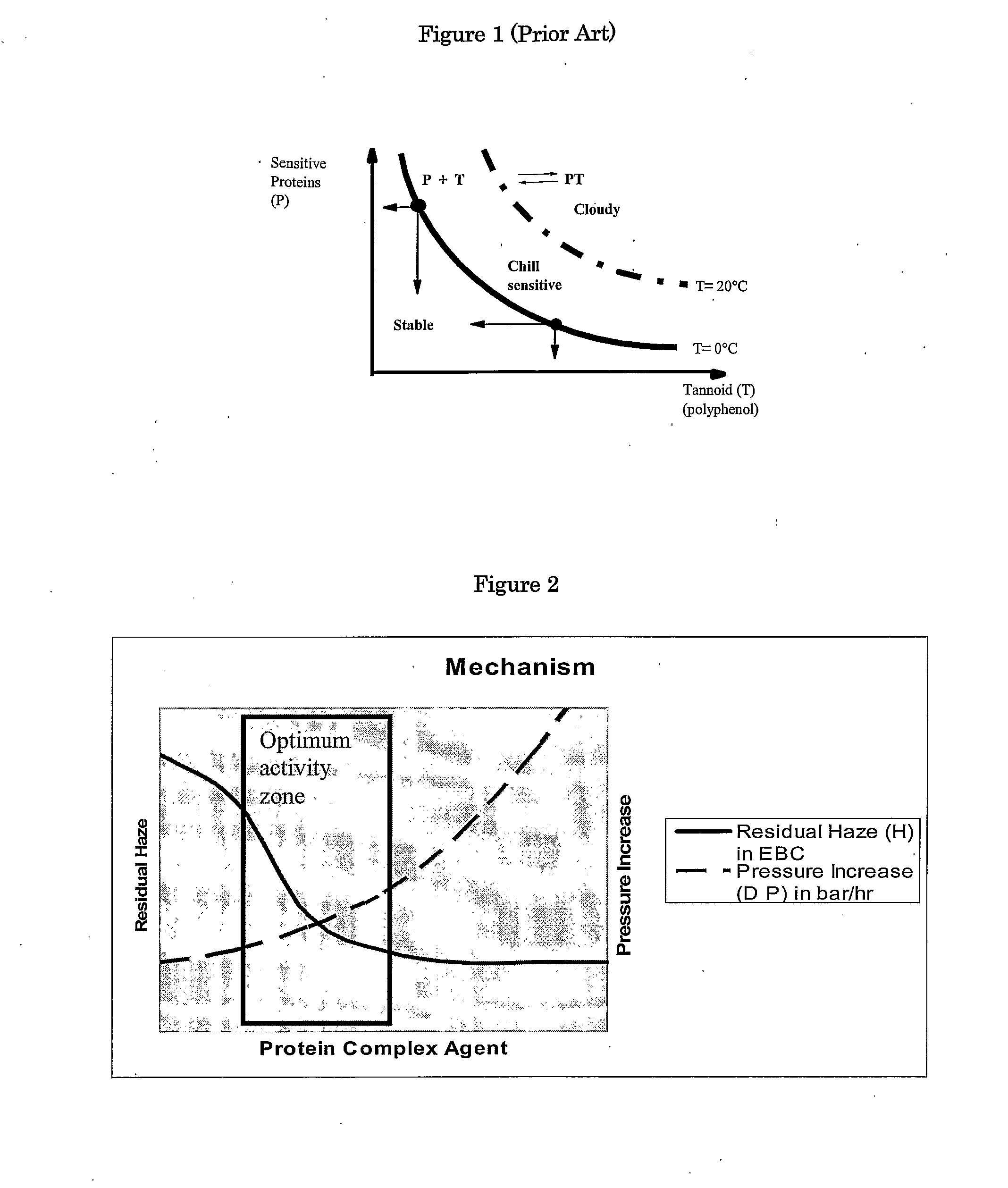

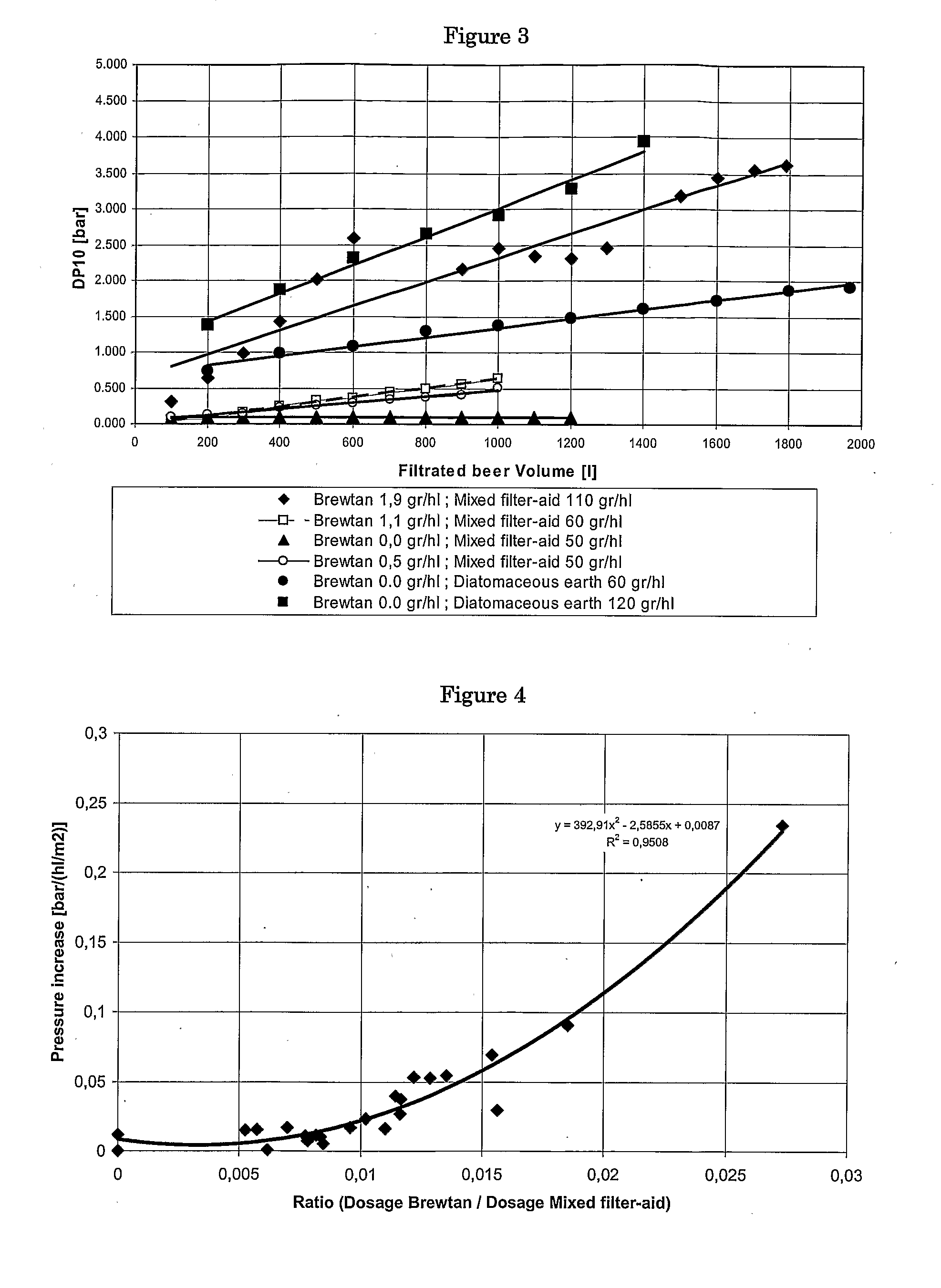

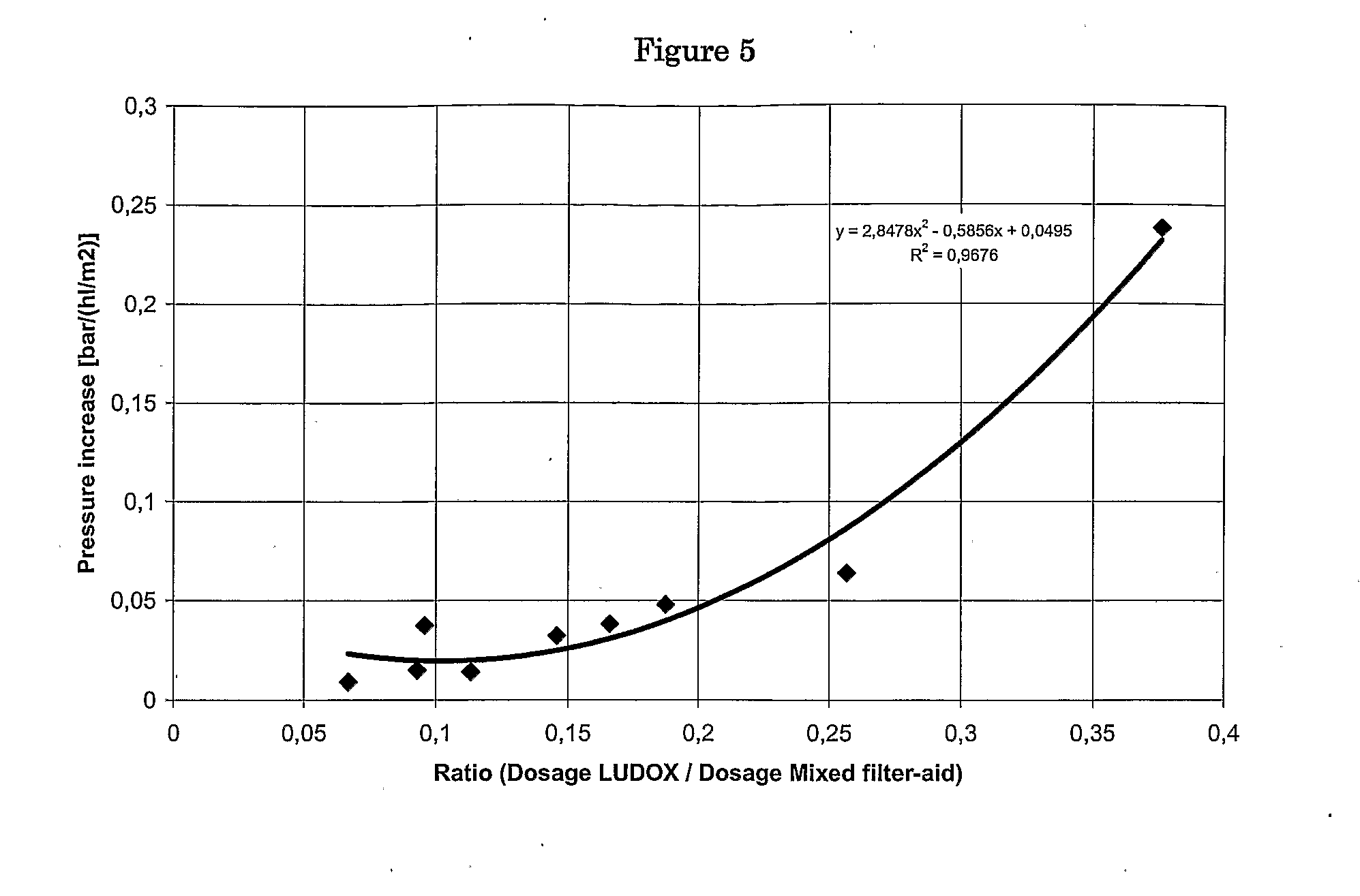

InactiveUS20080275223A1Positive impact on colloidal stabilityEliminate oxygenWine preparationPeptide preparation methodsFiltrationAmount of substance

The invention relates to a method of preparing a liquid, which contains proteins (esp. haze sensitive proteins), for subsequent separation of at least haze-forming material, when predetermined filter aids are used. The method comprises the addition of protein-complexing agent to the liquid, which agent is capable of forming a complex with at least some sensitive proteins of the liquid, to result in a limitation of the residual haze of the liquid, obtained after the separation (e.g. filtration), step.

Owner:ANHEUSER BUSCH INBEV SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com