Method for preserving foodstuffs

a food preservation and food technology, applied in the field of stabilizing foods, can solve the problems of flushing out of containers, especially harmful to the stability of foodstuffs, and achieve the effect of improving the economic aspect of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

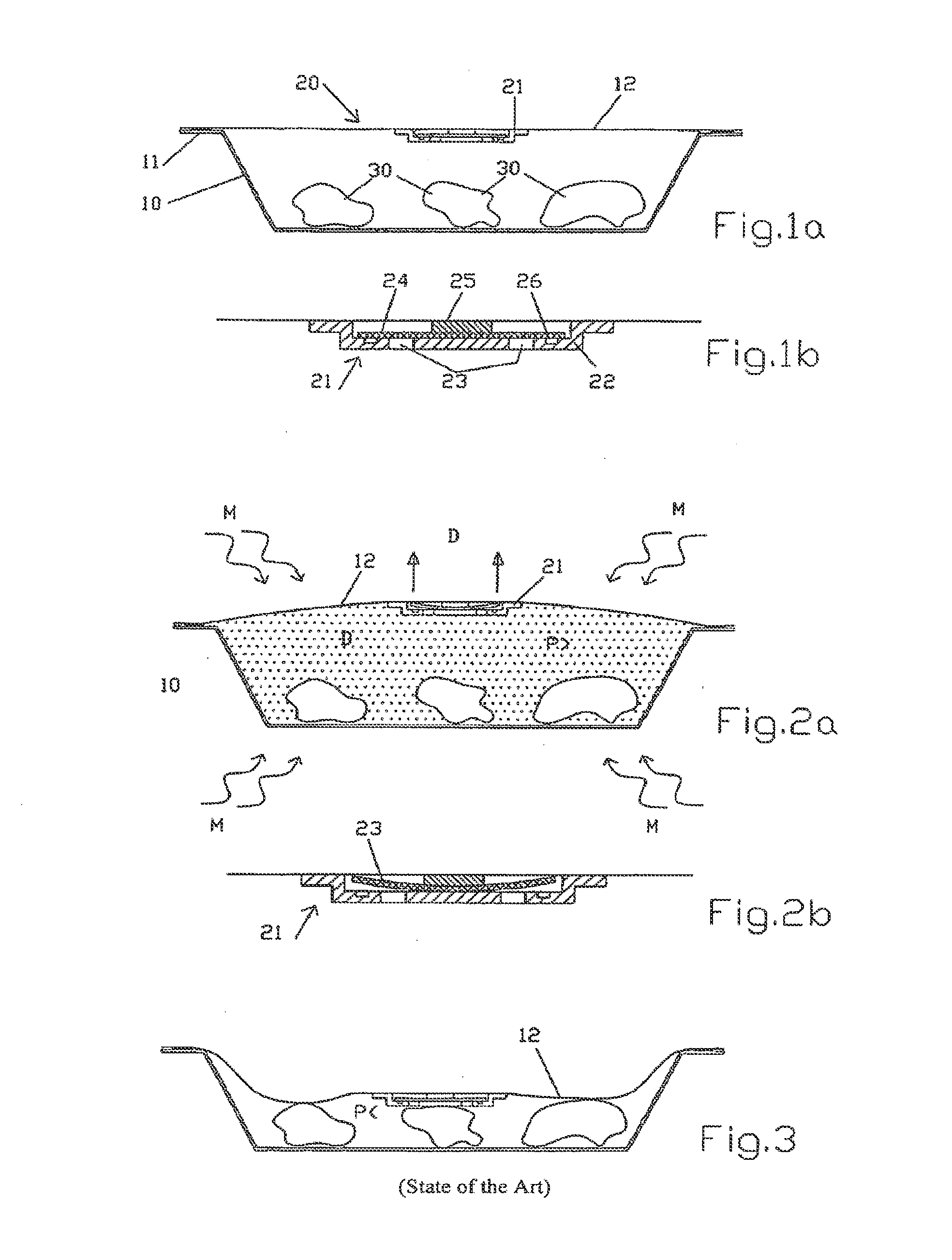

[0037]FIG. 1 shows a shell-shaped container 10 made of plastic with a peripheral edge 11 onto which is welded a cover film 12 also around the edge. The cover film may be a plastic film, optionally in several layers, with a thickness in the range between 40 and 220 μm. A vent opening 20 is provided in the cover film 12 through which a valve 21 that opens automatically under excess pressure and closes again automatically after the pressure has dropped is formed, as is known essentially from EP 1 359 097 A1. Foodstuffs 30, which still have a certain inherent moisture content and are still in a raw fresh state, are contained in the container 10.

[0038]FIG. 1b shows the valve 21 on an enlarged scale. It is made of plastic and has a dimensionally stable valve body 22 in which there are multiple openings 23. The openings 23 are sealed by an elastic membrane 24 which is held in position by a web 25. The sealing effect of the membrane is supported by sealing oil which is present especially in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com