Patents

Literature

40results about How to "Moisture resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

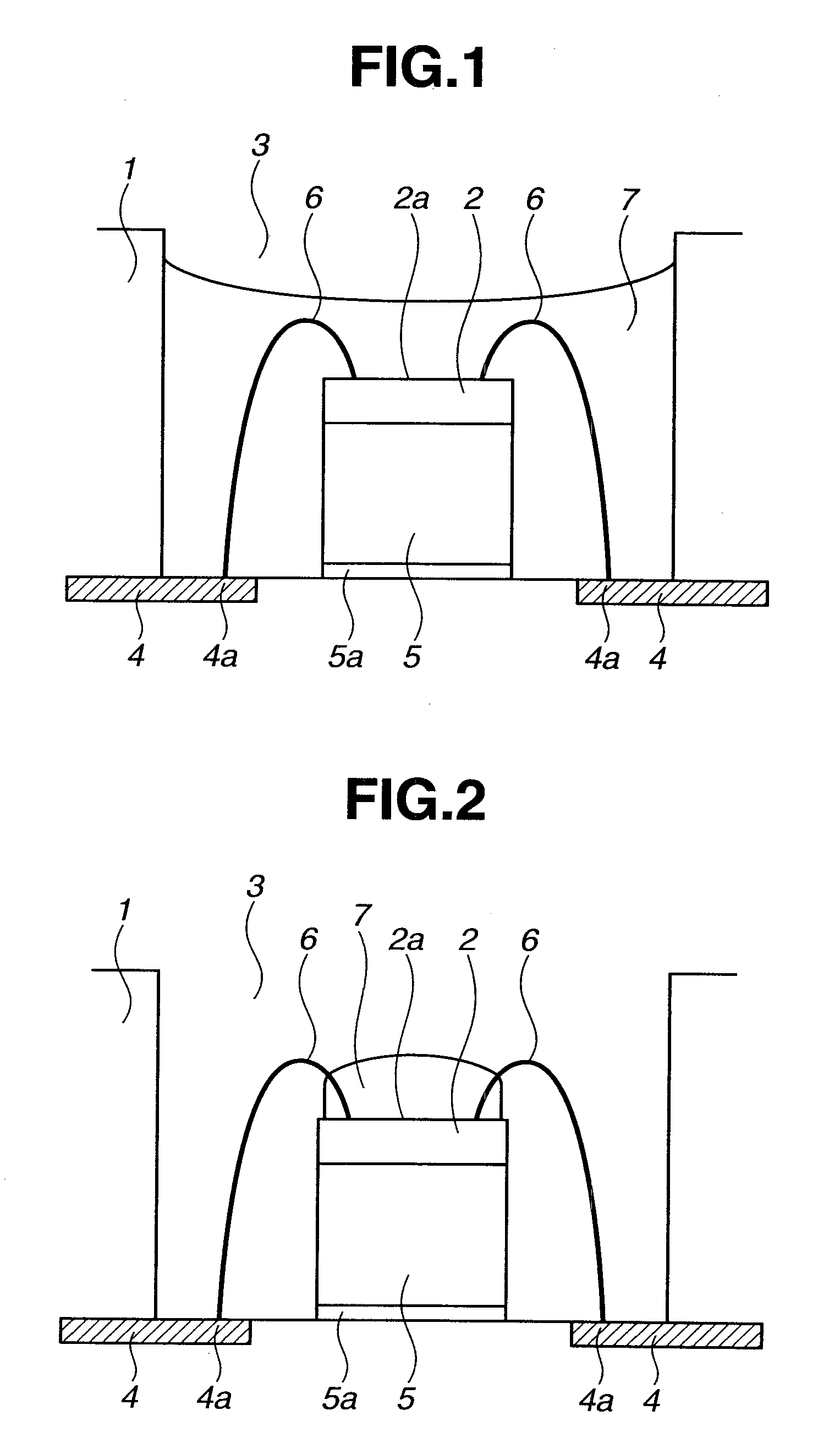

Solar cell module

InactiveUS20050199279A1Easy to solveImprove moisture resistancePV power plantsPhotovoltaic energy generationVitrificationSilver paste

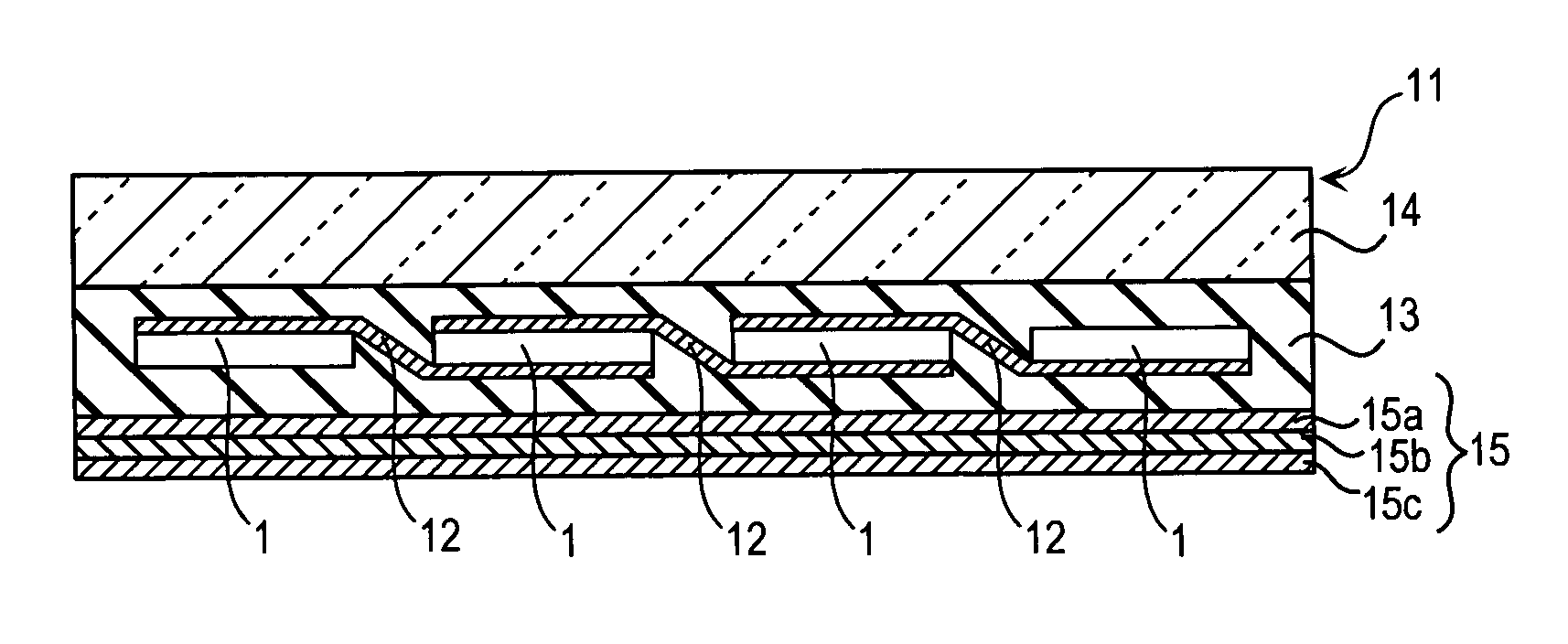

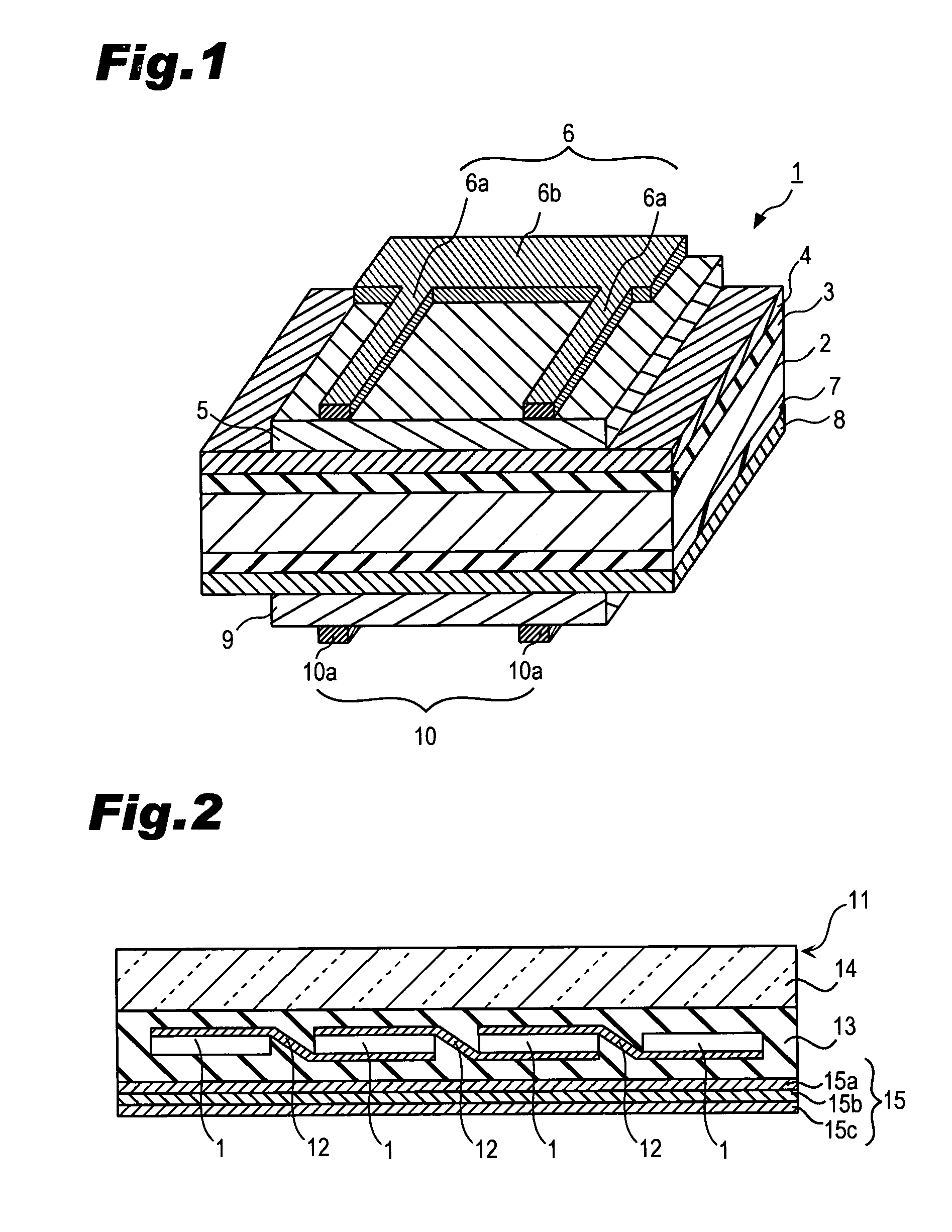

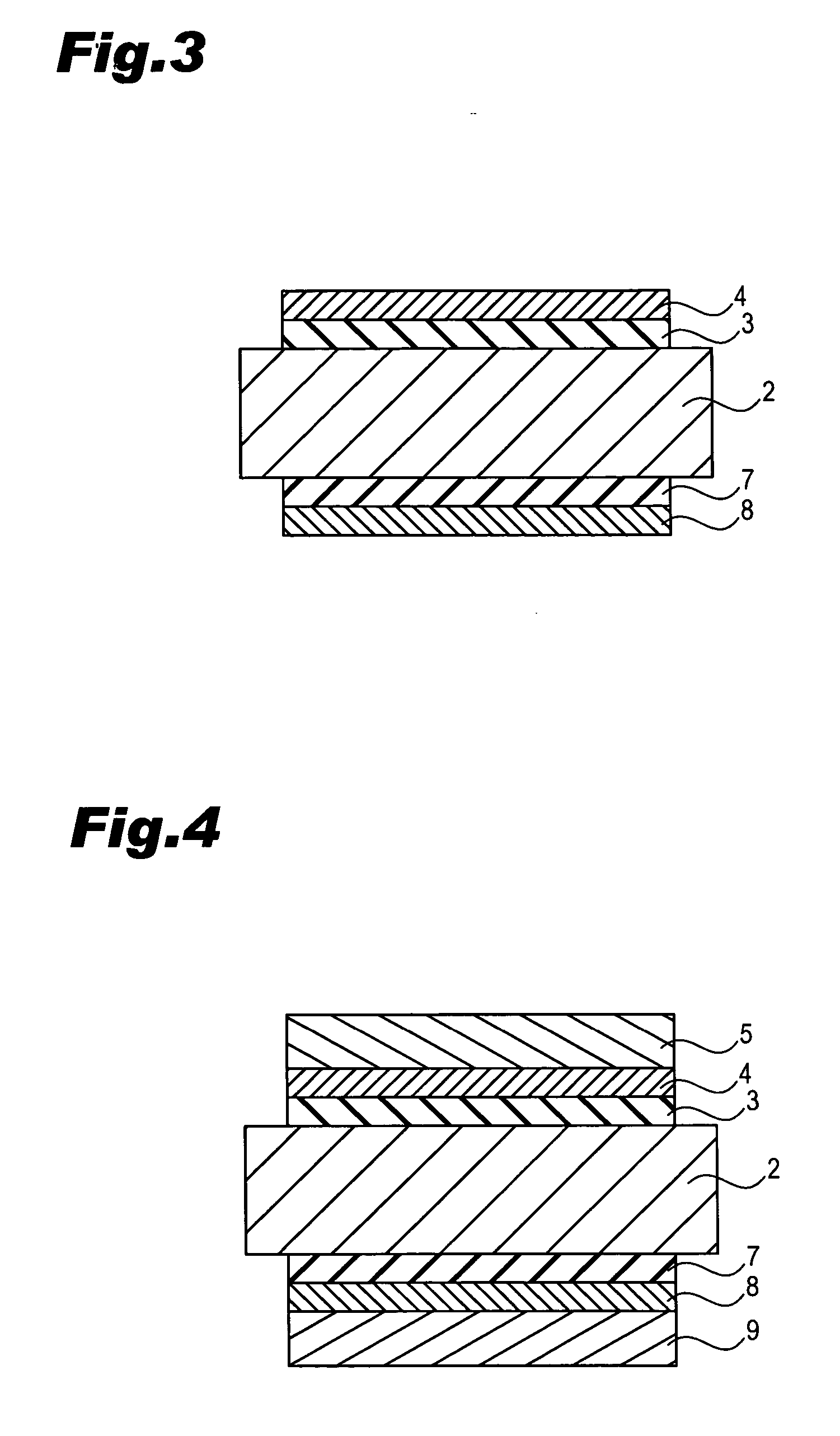

A solar cell module of the present invention was made to improve adhesion between electrodes, which is formed with thermosetting resin containing silver paste, of a solar cell element and connecting tabs coated with lead (Pb) free solder. To achieve this purpose, the solar cell module is comprised of a front surface member, a rear surface protective member, a plurality of solar cell elements provided between the front surface member and the rear surface protective member, and connecting tabs for electrically connecting the solar cell elements to each other through electrodes with the use of lead free solder. The electrodes of the solar cell elements are made of silver paste containing thermosetting resin and silver powder. The thermosetting resin contains epoxy resin at volume ratio of 70% or more having a glass transition rate of 80° C. to 200° C. measured by a TMA method. The connecting tabs coated with lead free solder are soldered to the electrodes.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Curable perfluoropolyether compositions and rubber or gel articles comprising the same

Perfluoropolyether compositions are provided comprising (A) a linear perfluoropolyether compound containing at least two alkenyl groups, having a perfluoropolyether structure comprising recurring units —CaF2aO— in its backbone, and having a Mw of 10,000-100,000; (B) an organosilicon compound containing at least two silicon atom-bonded hydrogen atoms; (C) a reinforcing filler; (D) a hydrosilylation catalyst; and (E) a polyfluoromonoalkenyl compound containing one alkenyl group and having a perfluoropolyether structure in its backbone. The compositions cure into rubber or gel products having improved acid resistance.

Owner:SHIN ETSU CHEM IND CO LTD

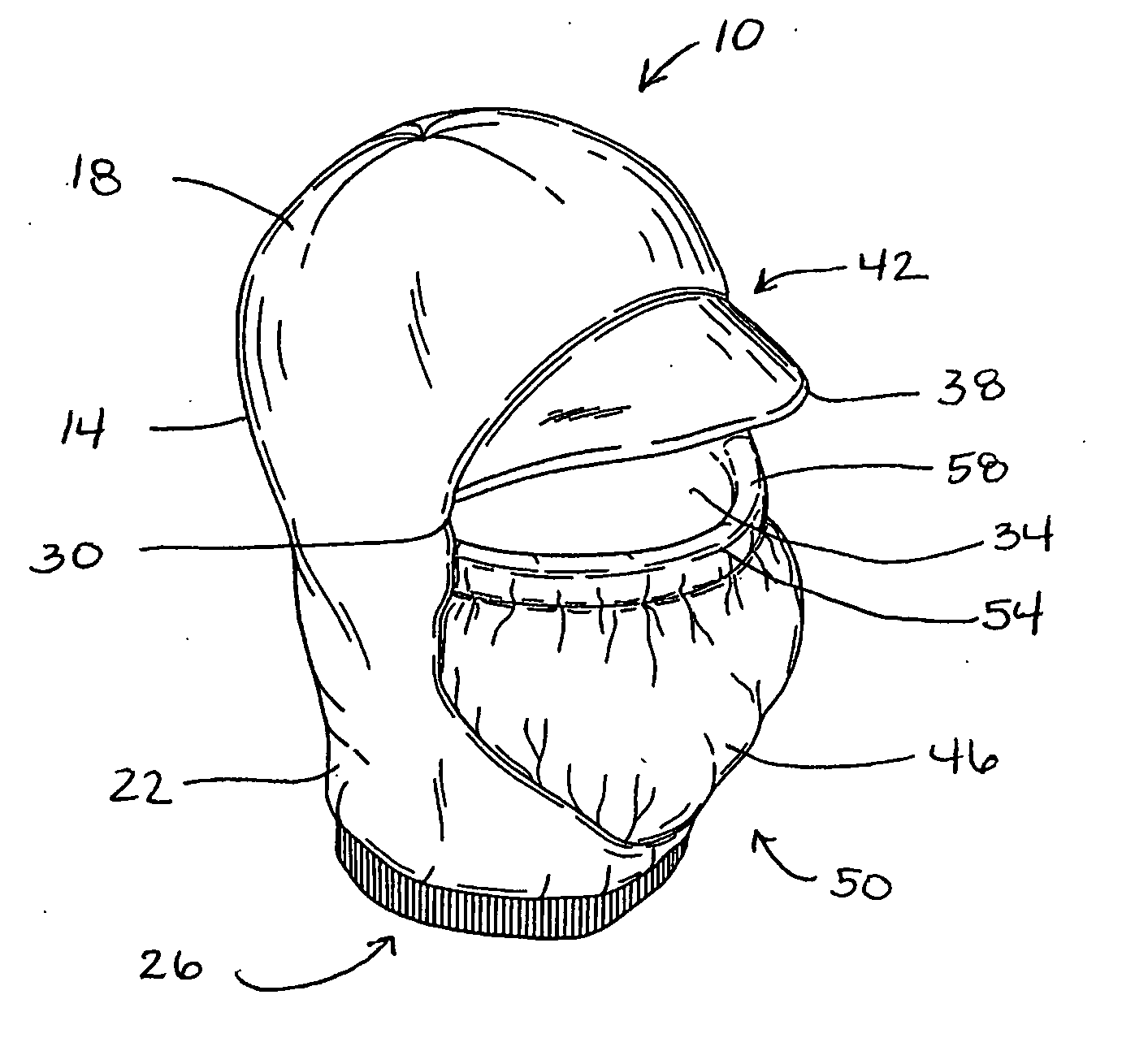

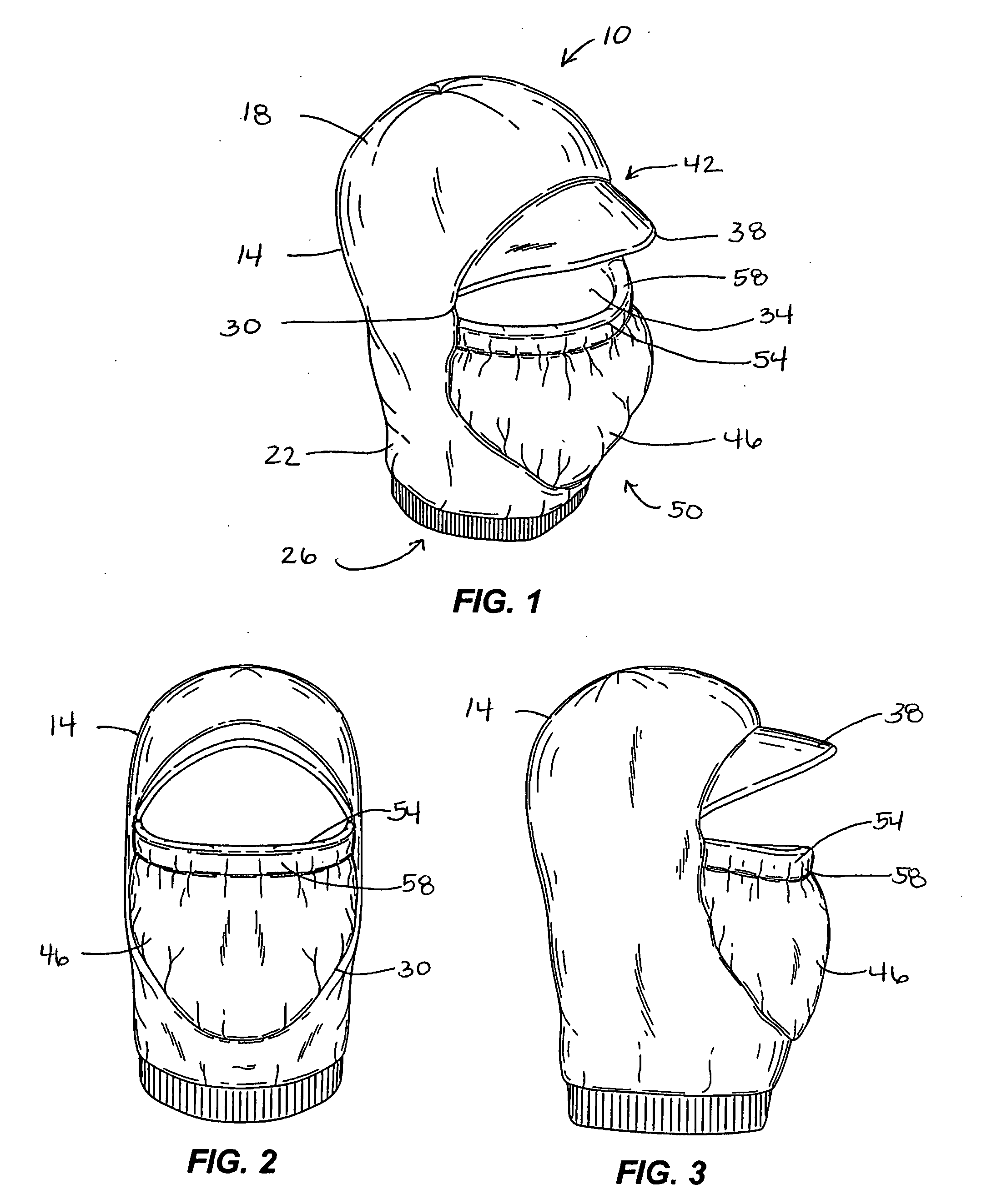

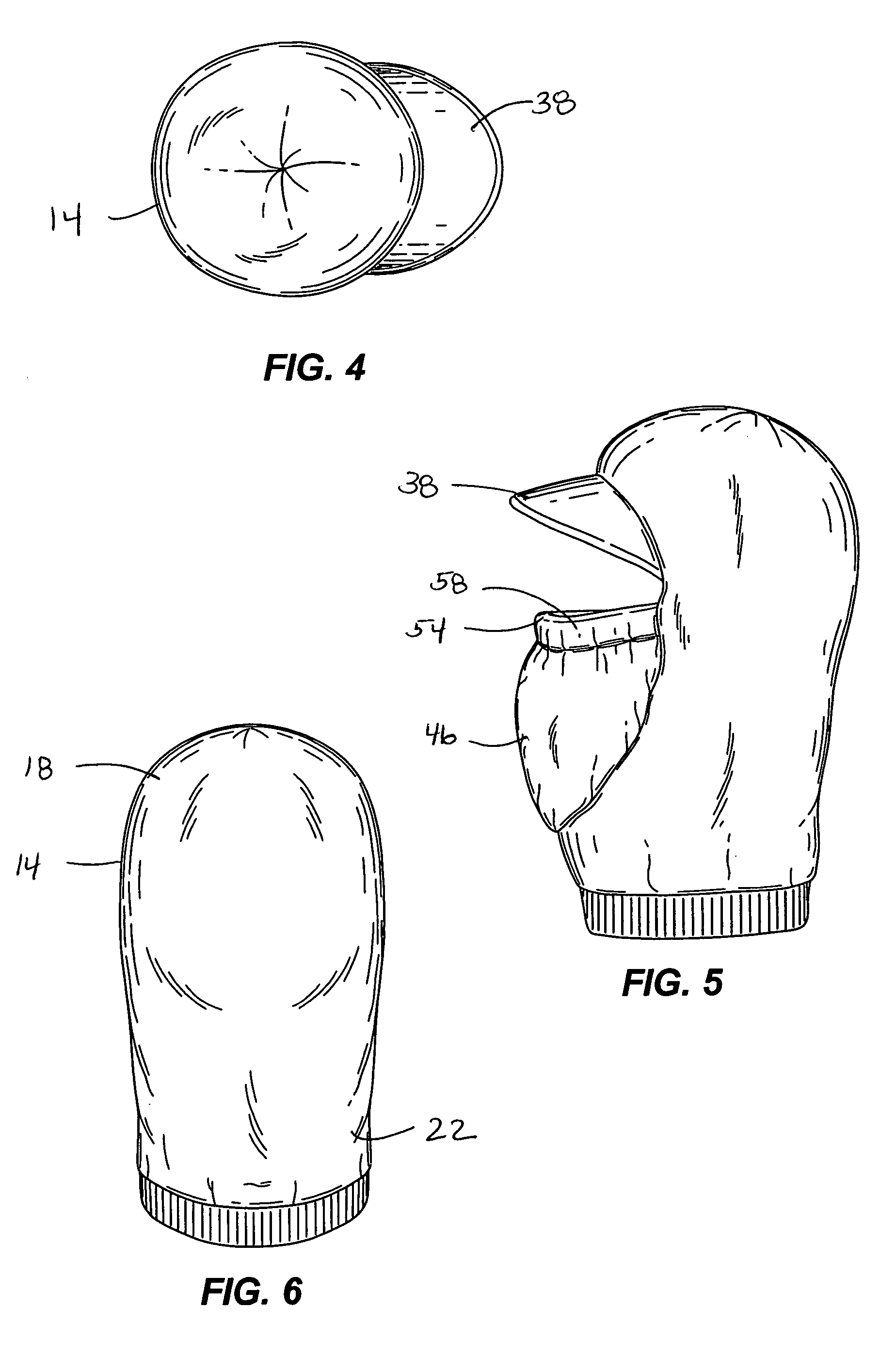

Cold weather garment

A garment to provide protection and shading from the sun or other bright objects and protection from rain, snow, and other precipitation. The garment includes a shell and an opening generally defined by a periphery. The garment includes a flexible member that extends forwardly of the garment and is secured to an upper portion of the periphery. The garment also includes a mask having a flexible membrane that protects the face of the user.

Owner:RELIABLE KNITTING WORKS

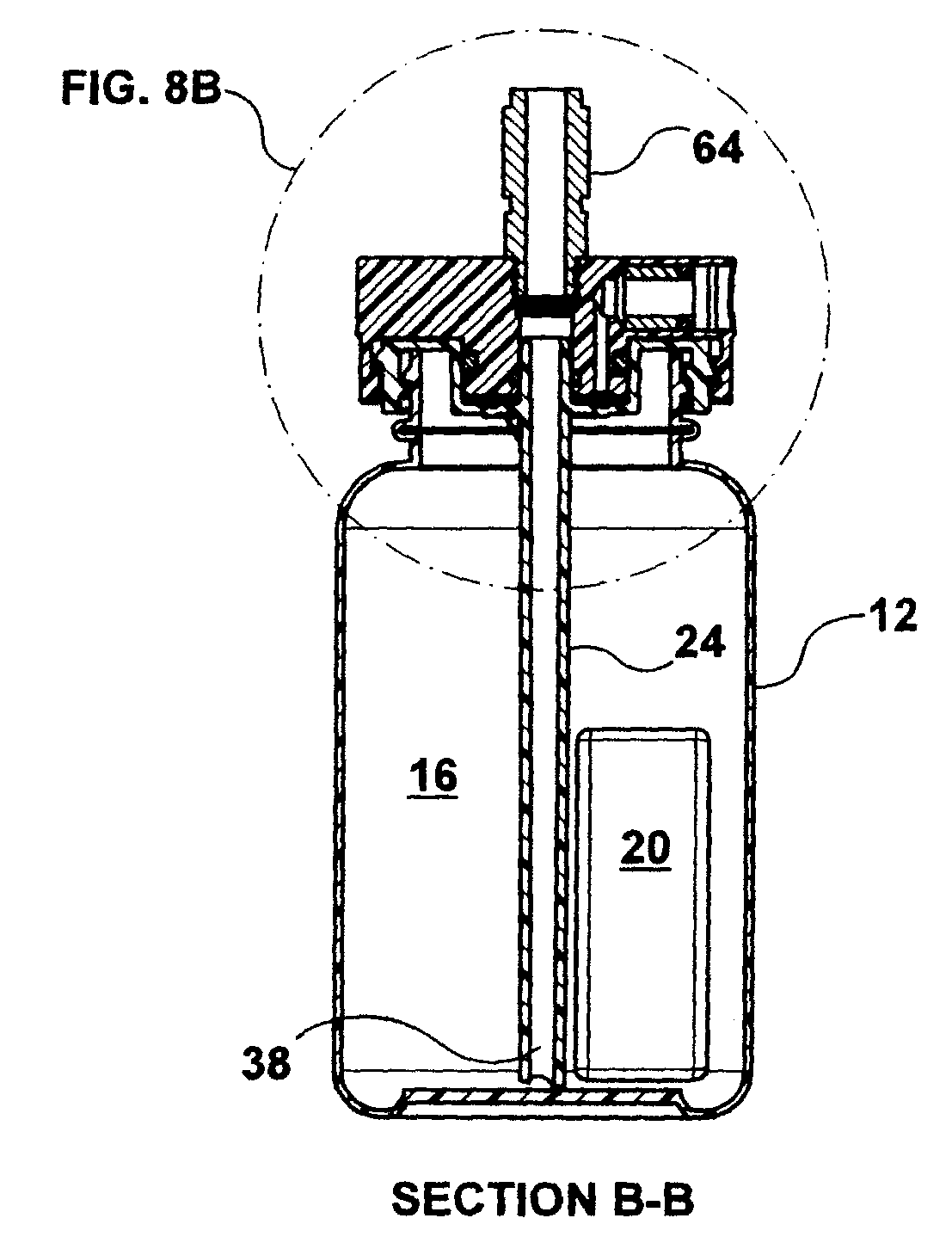

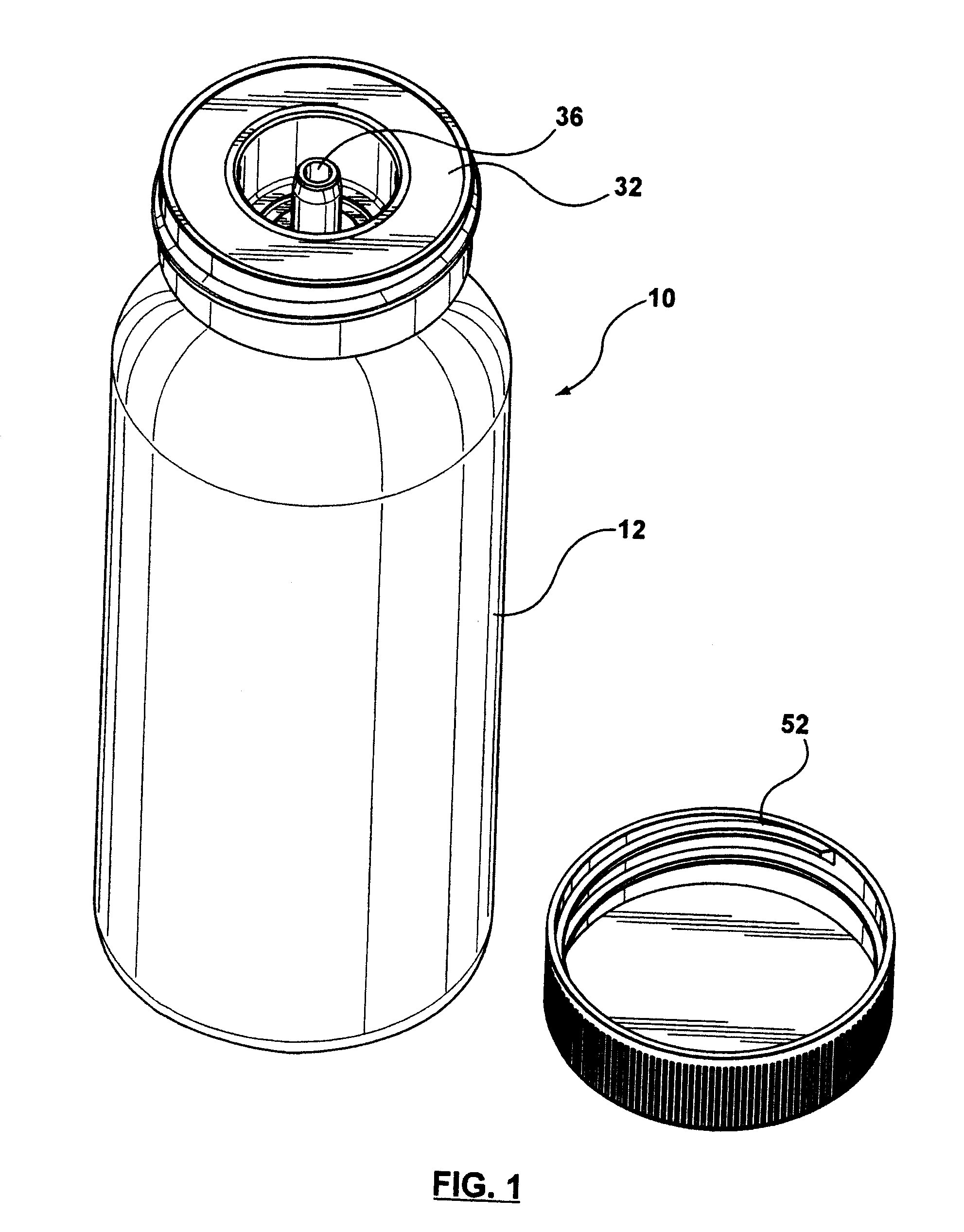

Air conditioning lubricant delivery vessel, method and system

InactiveUS20120272667A1Limited amount of moistureMoisture resistanceClosuresLiquid flow controllersDesiccantProcess engineering

A vessel for use in an air conditioner recharging system contains a desiccant that may limit moisture in a hygroscopic fluid, such as liquid lubricant and / or dye. The vessel may thus limits the amount of moisture introduced as a result of replacing or injecting lubricant. The vessel may contain an amount of pure lubricant for the air-conditioning system, or a lubricant and fluorescent dye to aid in detecting leaks.

Owner:CPS PROD CANADA

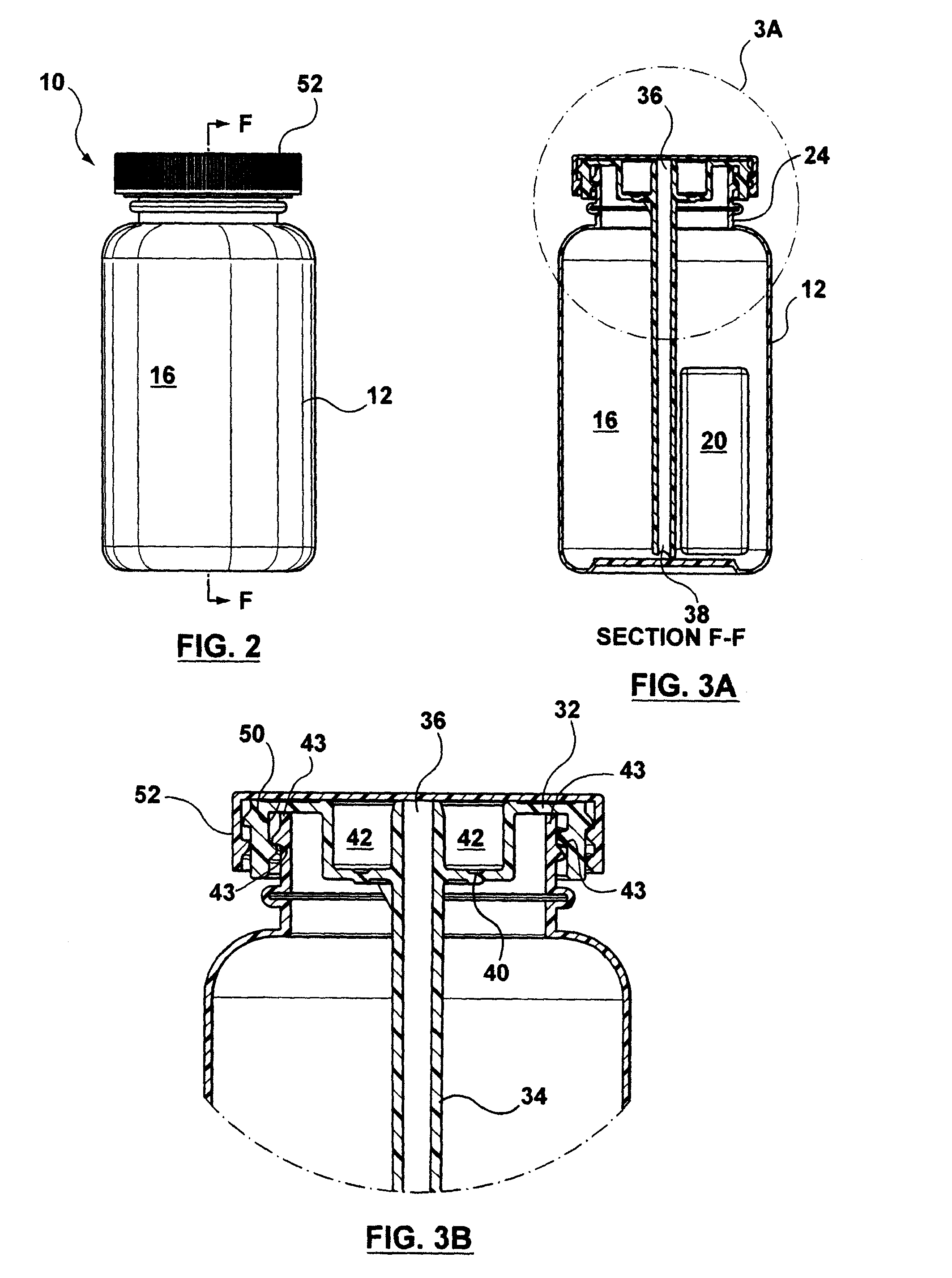

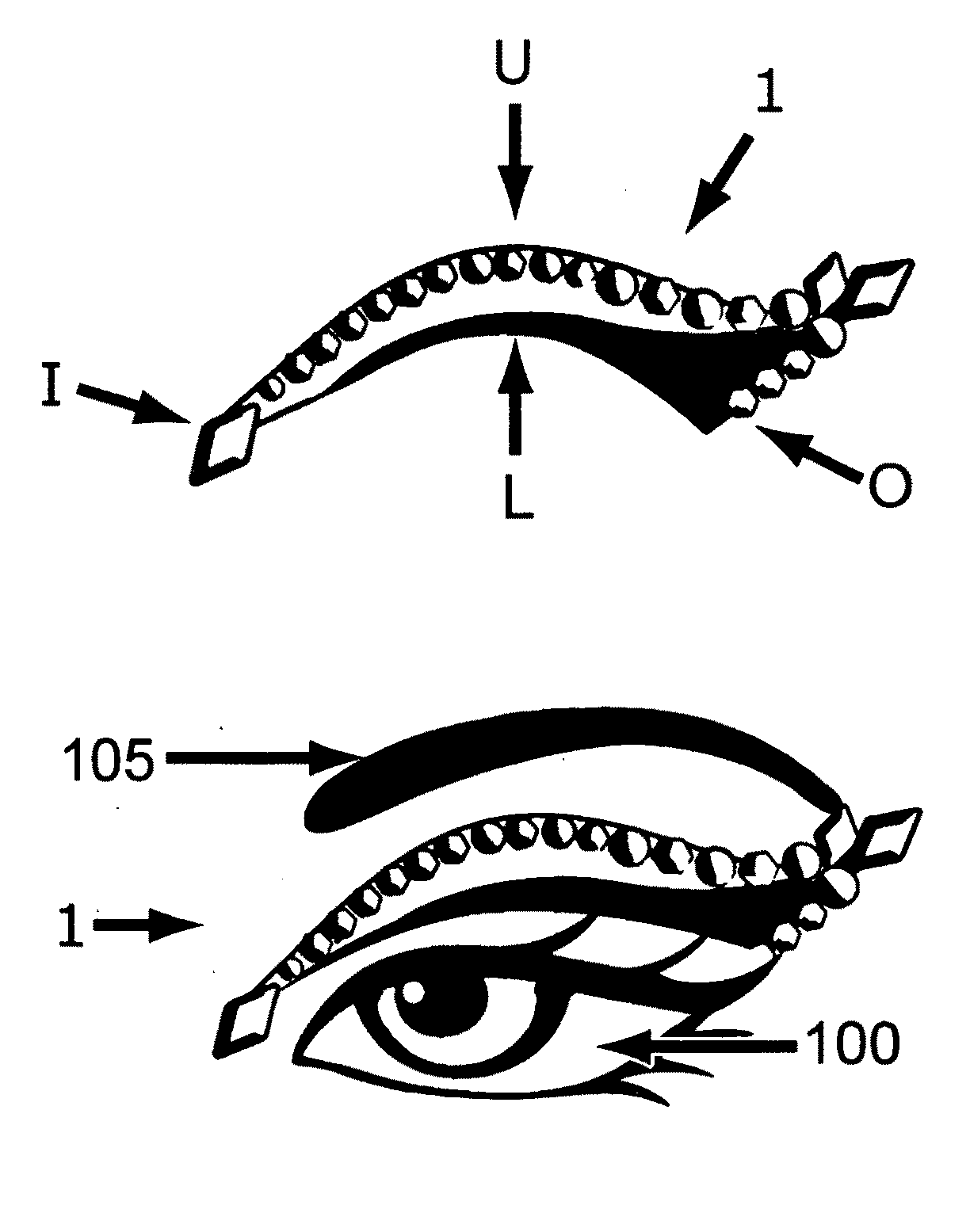

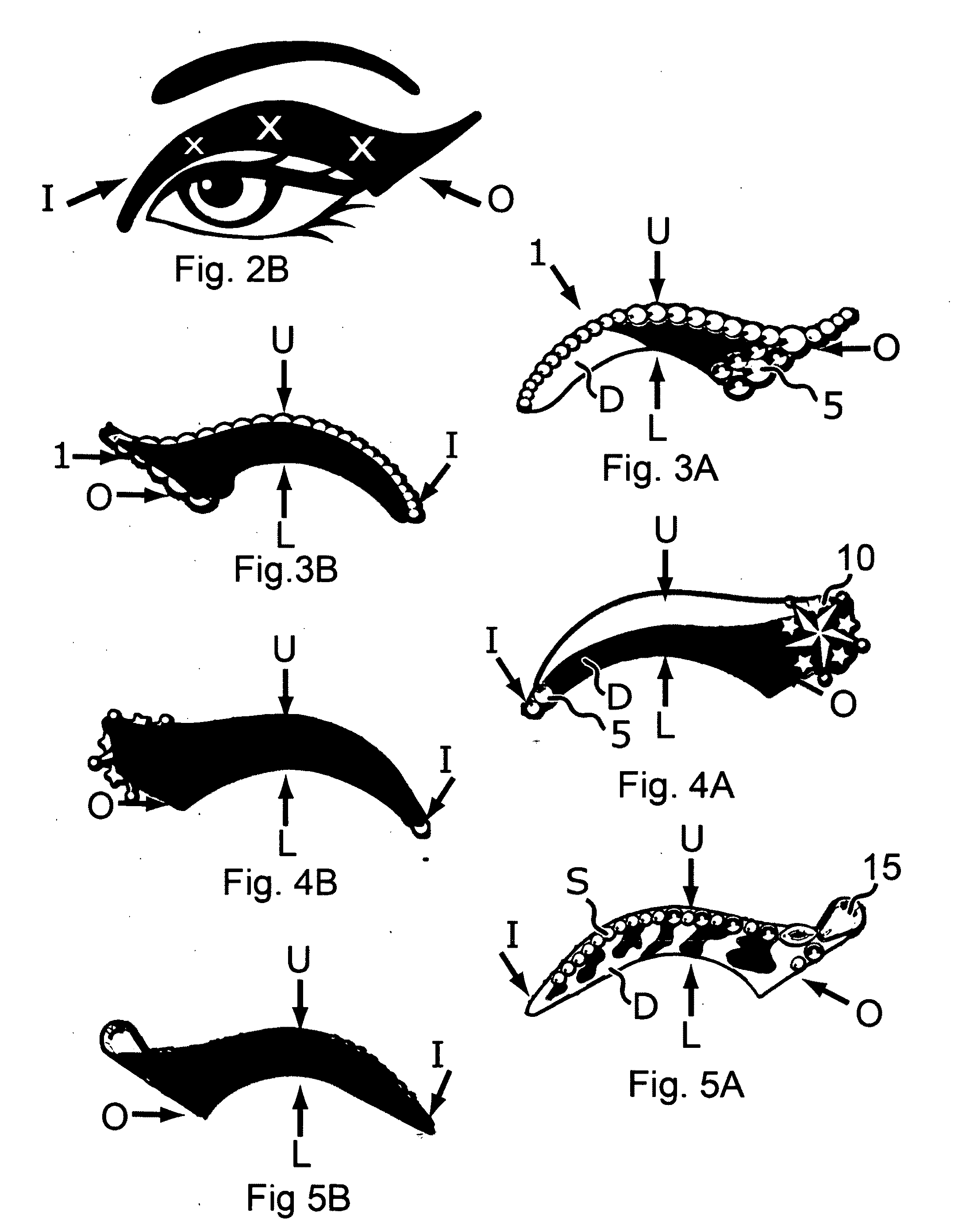

Decorative eyelid covering and process

InactiveUS20100242539A1Moisture resistantSuitable for useLamination ancillary operationsLaminationEyelidEngineering

A flexible eyelid cover includes an adhesive having a decorative design arranged opposite an inner surface of the flexible eyelid cover. The cover is formed from wig adhesive and adheres to an upper eyelid of a wearer. An upper edge of the cover is convex in shape. A lower edge of the cover includes a first curved surface and a second curved surface. The second curved surface is concave in shape and arranged on a region of the upper eyelid distal from the nose. Various designs and ornaments may be adhered to outer surface of the cover.

Owner:MAXEY SHANNON

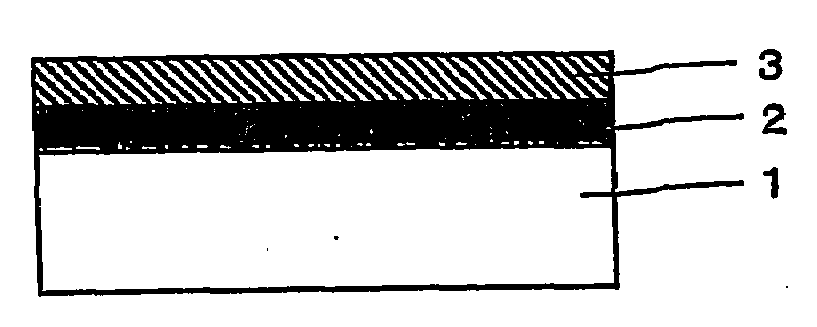

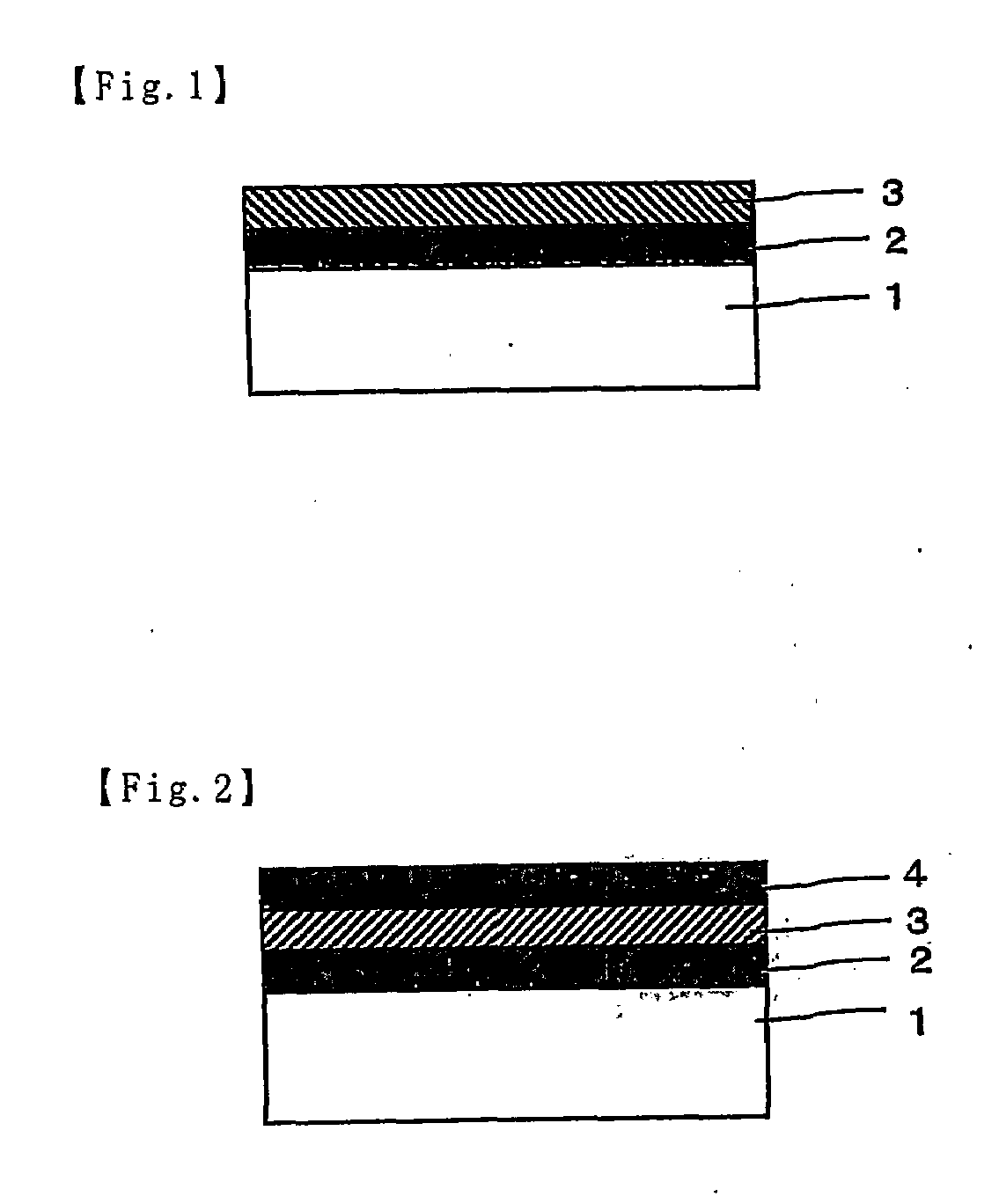

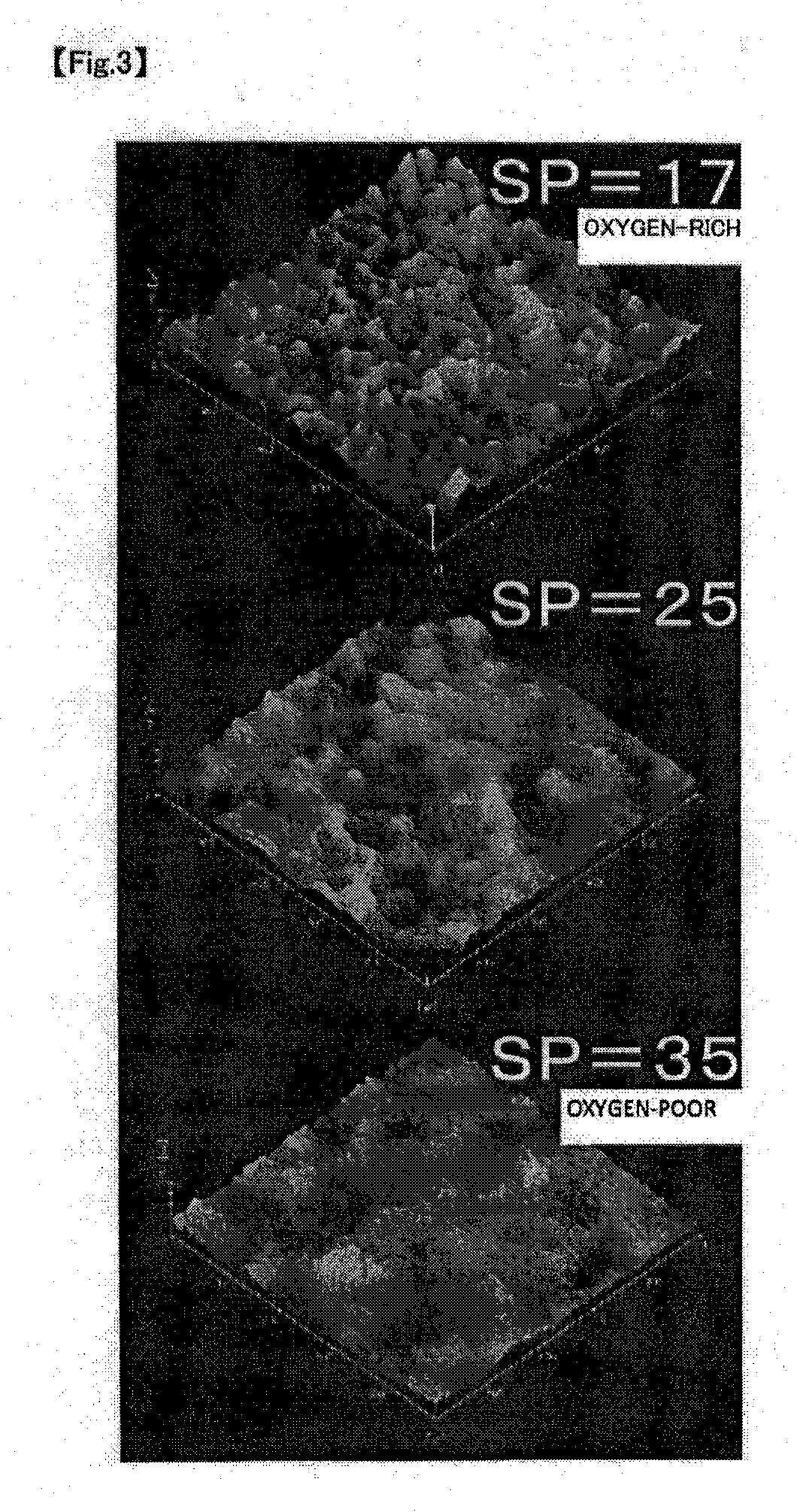

Transparent conductive film and method for production thereof

InactiveUS20090286071A1High crystallinityEasy to controlConductive layers on insulating-supportsSolid-state devicesTransmittanceTransparent conducting film

the transparent conductive film of the present invention is a transparent conductive film, comprising: an organic polymer film substrate; a first oxide thin film with a high visible-light transmittance formed on the organic polymer film substrate; and a ZnO-based transparent conductive thin film formed on the first oxide thin film, wherein the first oxide thin film has an oxygen content corresponding to 60 to 90% of the stoichiometric value before the ZnO-based transparent conductive thin film is formed. The transparent conductive film exhibits low resistance even when the ZnO-based transparent conductive thin film is relatively thin (particularly 100 nm or less in thickness), and has a low rate of change in resistance value even under a humidification and heating environment.

Owner:NITTO DENKO CORP

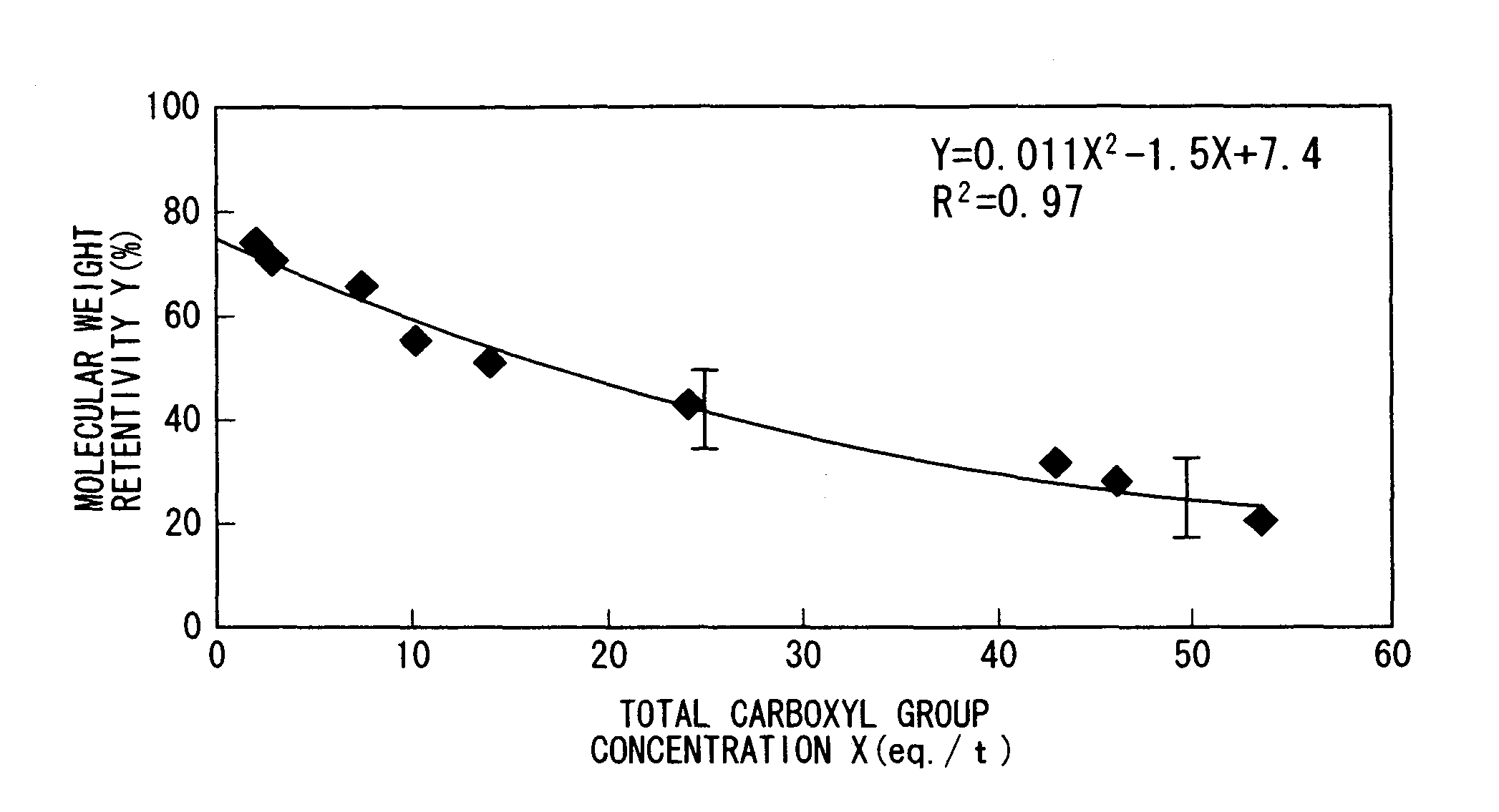

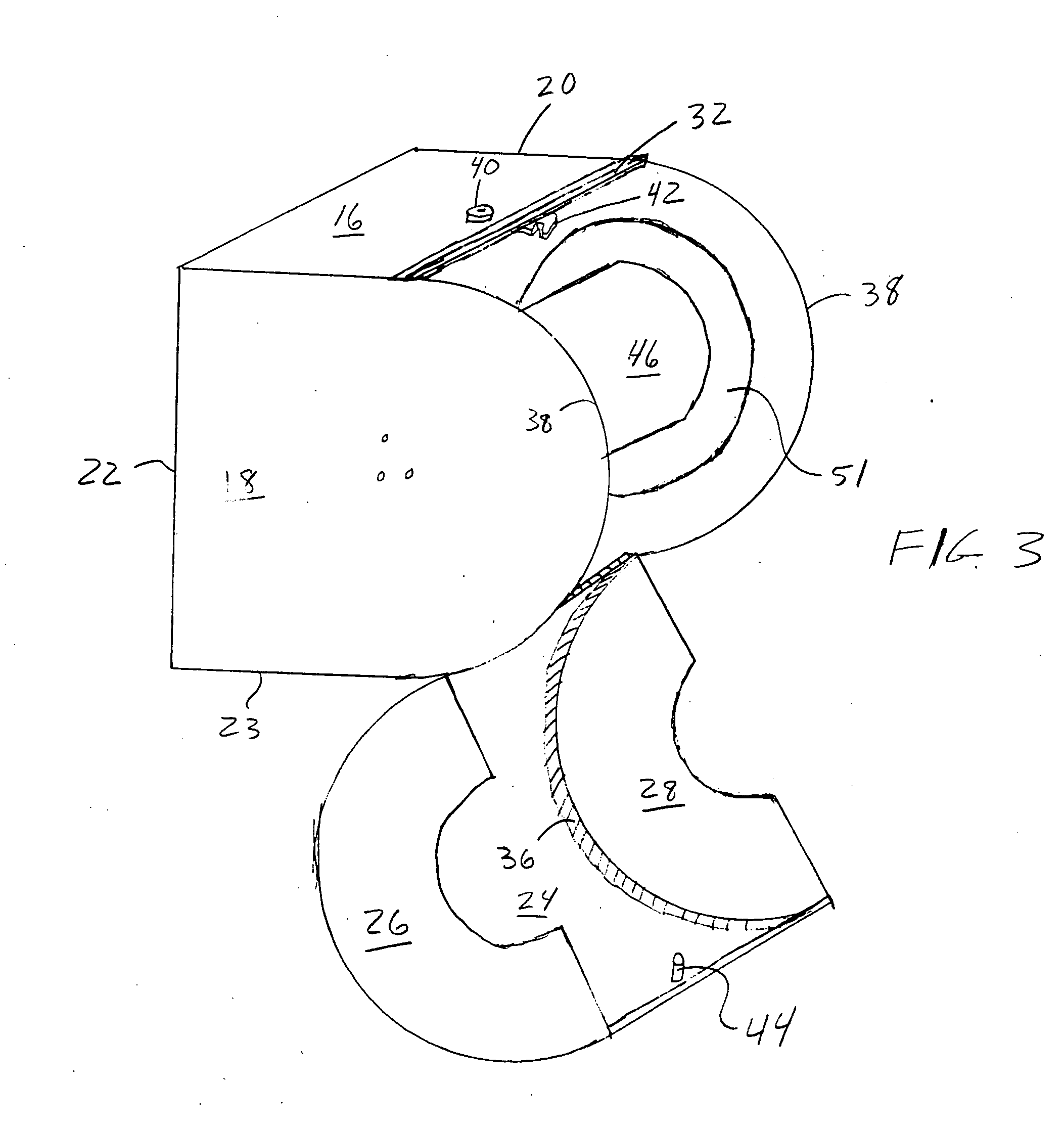

Method for controlling water resistance of polyglycolic acid resin

InactiveUS8318837B2Improve accuracyMoisture resistancePlastic/resin/waxes insulatorsDyeing processMoisture resistanceChemistry

A method of controlling a moisture resistance of polyglycolic acid resin, by controlling a total carboxyl group-source concentration including a contribution of residual glycolide. As a result, a moisture resistance governing the change of strength with time of the polyglycolic acid resin is controlled at a good accuracy.

Owner:KUREHA KAGAKU KOGYO KK

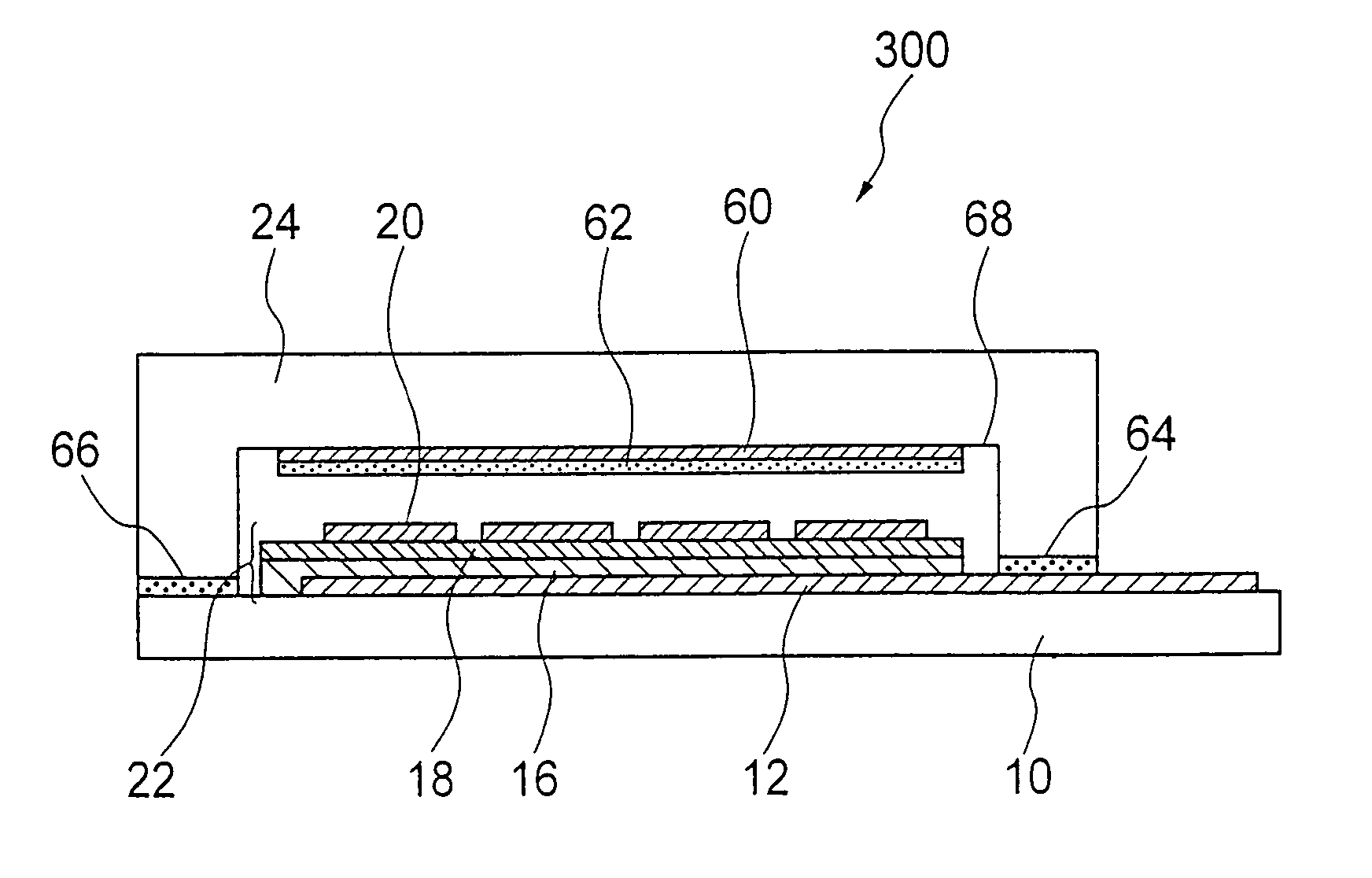

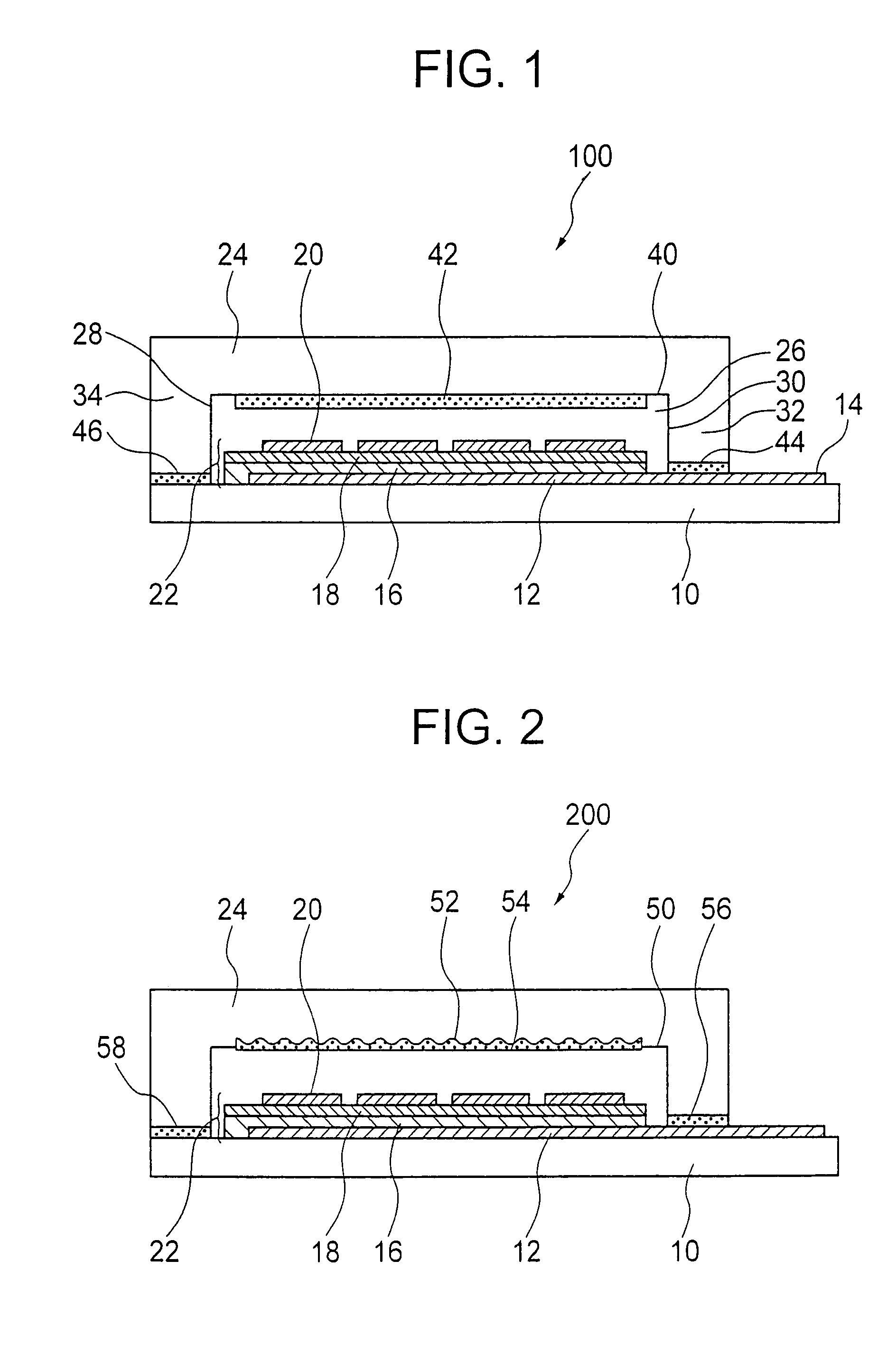

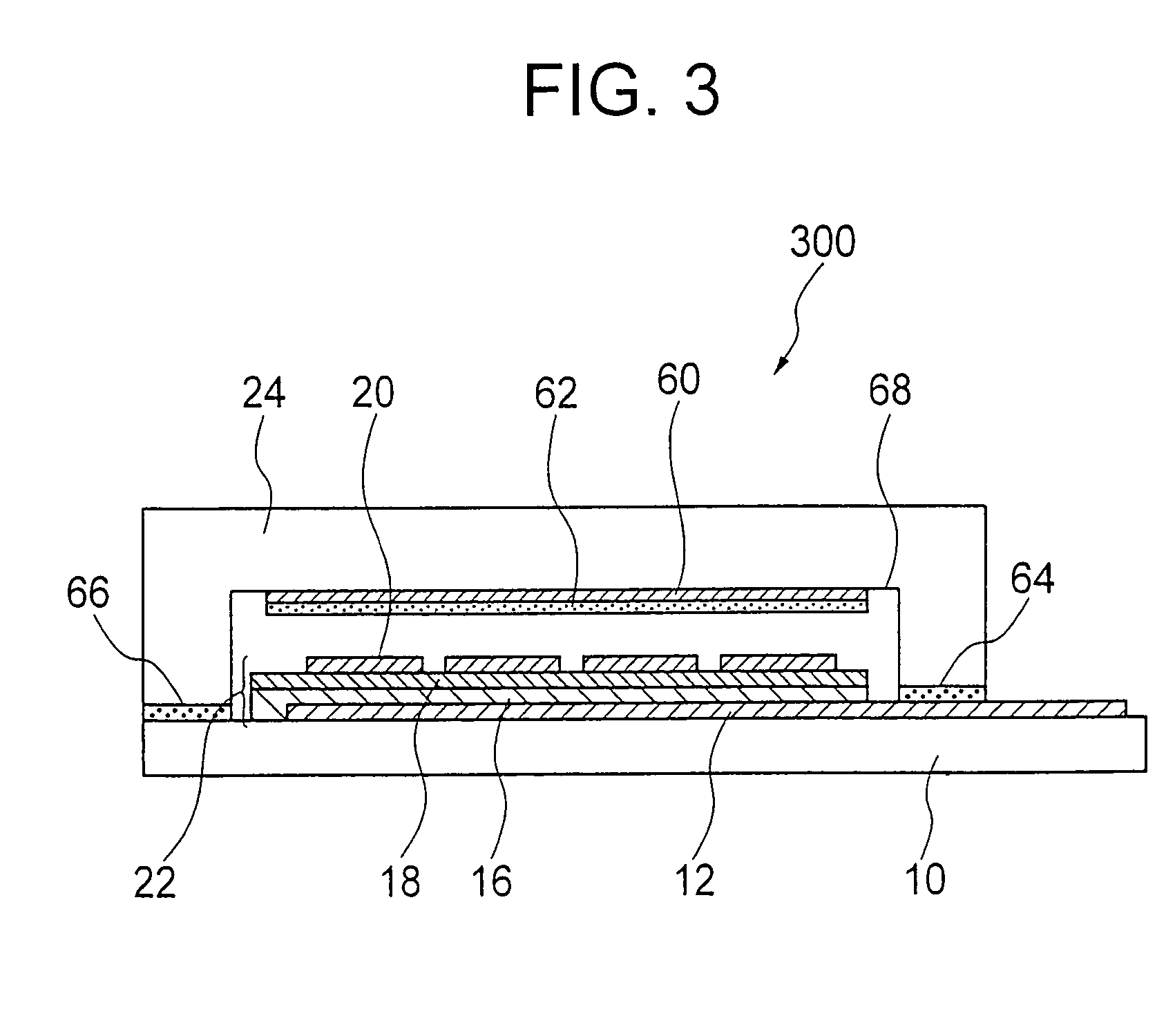

Organic electroluminescent device and method for fabricating same

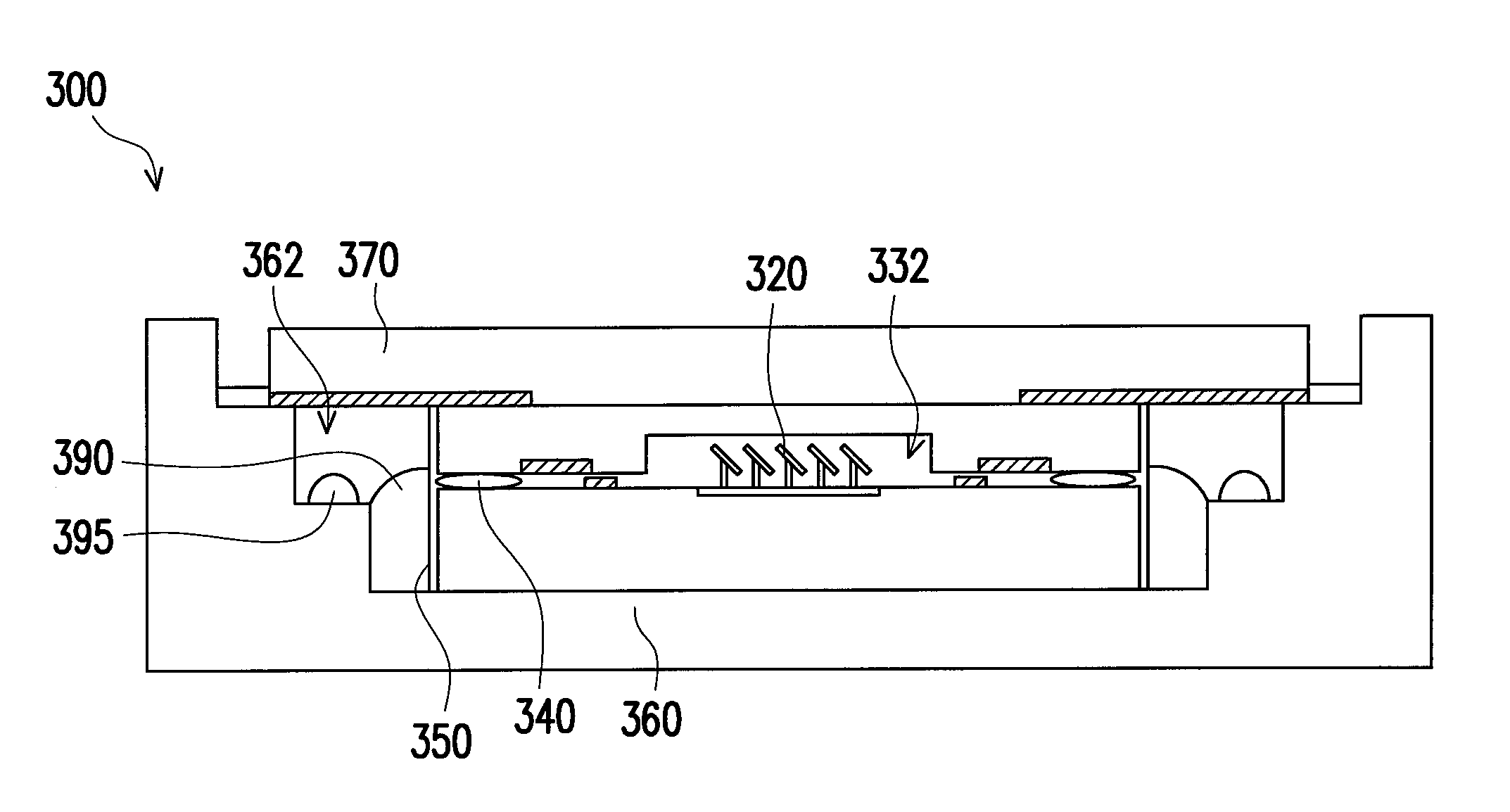

InactiveUS7083866B2Excellent long-term moisture resistanceReduce the numberDischarge tube luminescnet screensElectroluminescent light sourcesDesiccantDark spot

An organic EL device including a stacked structure having an organic luminescent layer positioned between an anode and a cathode; and a sealing can having a desiccant-containing layer on its inner surface. The desiccant in the desiccant-containing layer provides an excellent long-term moisture resistance to the organic EL device, thereby generating no or a few dark spots thereon.

Owner:SAMSUNG DISPLAY CO LTD

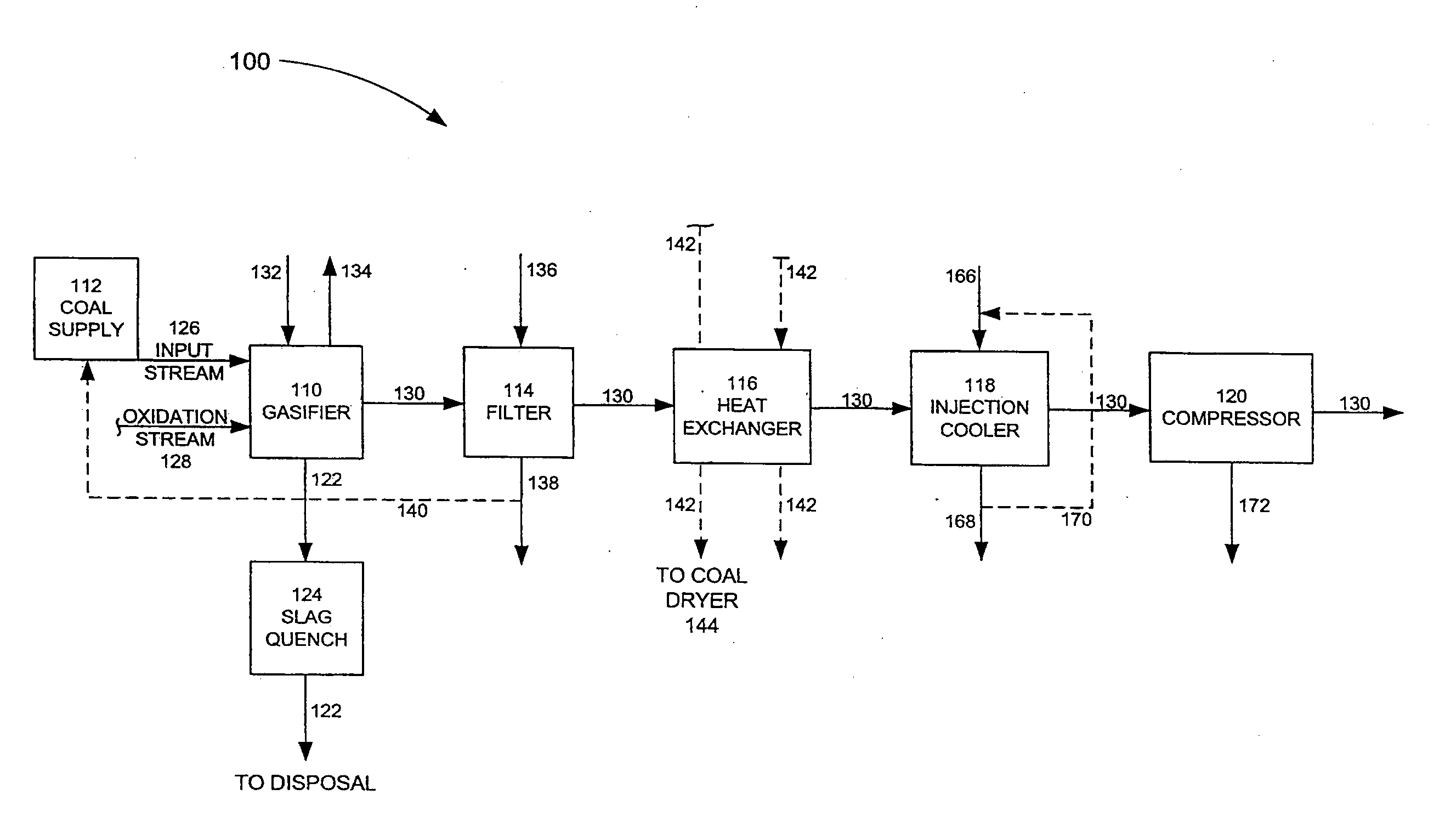

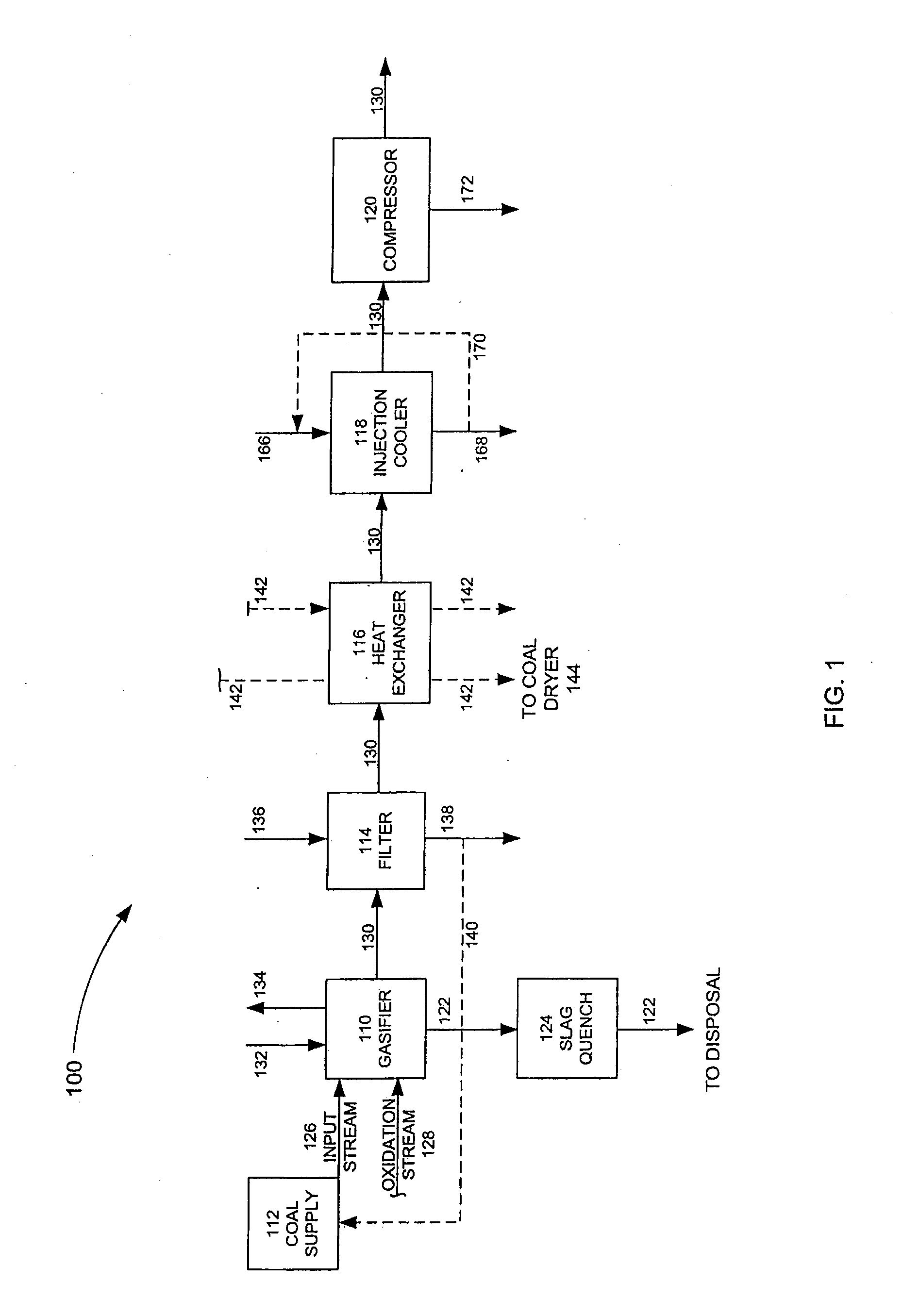

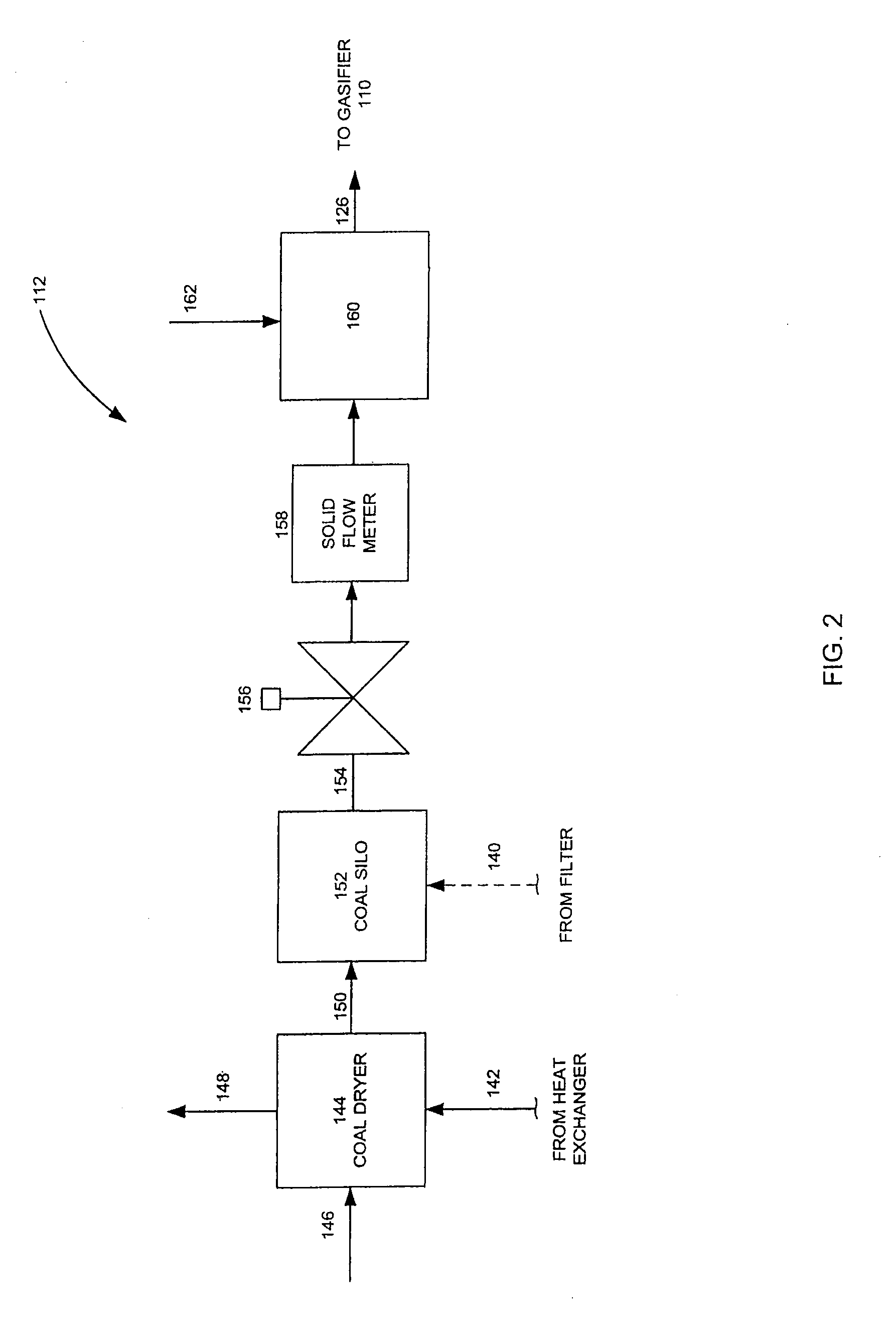

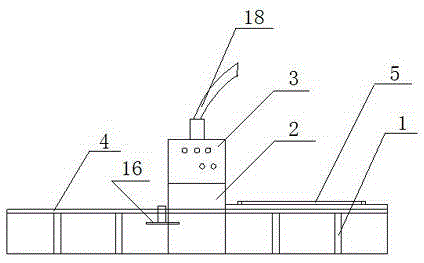

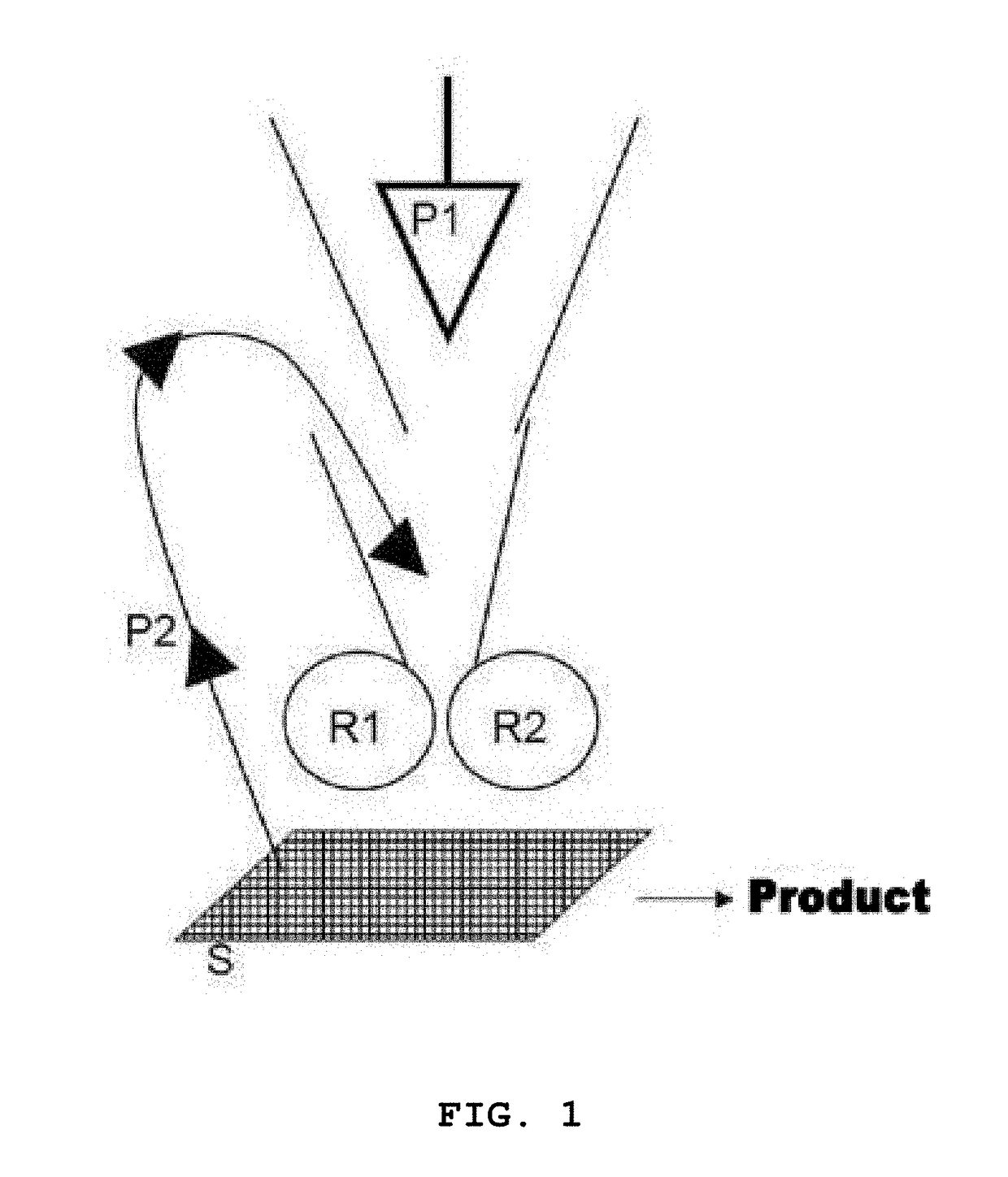

Atmospheric pressure gasification process and system

InactiveUS20110173885A1Reduce and prevent leakage of gasImprove efficiencyGasifier feeding meansGas generation devicesCombustorFuel distribution

A fuel supply system for supplying pulverized feedstock to a gasifier includes a feedstock storage apparatus for storing pulverized feedstock. The feedstock storage apparatus operates at a first pressure. The fuel supply system also includes a mechanical conveyance apparatus linking the feedstock storage apparatus to a fuel distribution apparatus. The mechanical conveyance apparatus is operable to continuously convey the pulverized feedstock from the feedstock storage apparatus to the fuel distribution apparatus at a first flow rate. The fuel distribution apparatus operates at a second pressure that is greater than the first pressure. The fuel distribution apparatus includes at least one outlet communicably connected to at least one burner on the gasifier for transferring pulverized feedstock from the fuel distribution apparatus to the at least one burner.

Owner:HATCH LTD

Curable perfluoropolyether compositions and rubber or gel articles comprising the same

Perfluoropolyether compositions are provided comprising: (A) a linear perfluoropolyether compound containing at least two alkenyl groups, having a perfluoropolyether structure comprising recurring units —CaF2aO— in its backbone, and having a molecular weight of 10,000 to 100,000; (B) an organosilicon compound containing at least two silicon atom-bonded hydrogen atoms; (C) a reinforcing filler; (D) a hydrosilylation catalyst; and (E) a polyfluoromonoalkenyl compound containing one alkenyl group and having a perfluoropolyether structure in its backbone. The compositions cure into rubber or gel products having improved acid resistance.

Owner:SHIN ETSU CHEM IND CO LTD

Humidity control system

ActiveUS9616382B2Moisture resistanceEliminate oxygenGas treatmentFlexible coversControl systemOxygen

Owner:DESICCARE

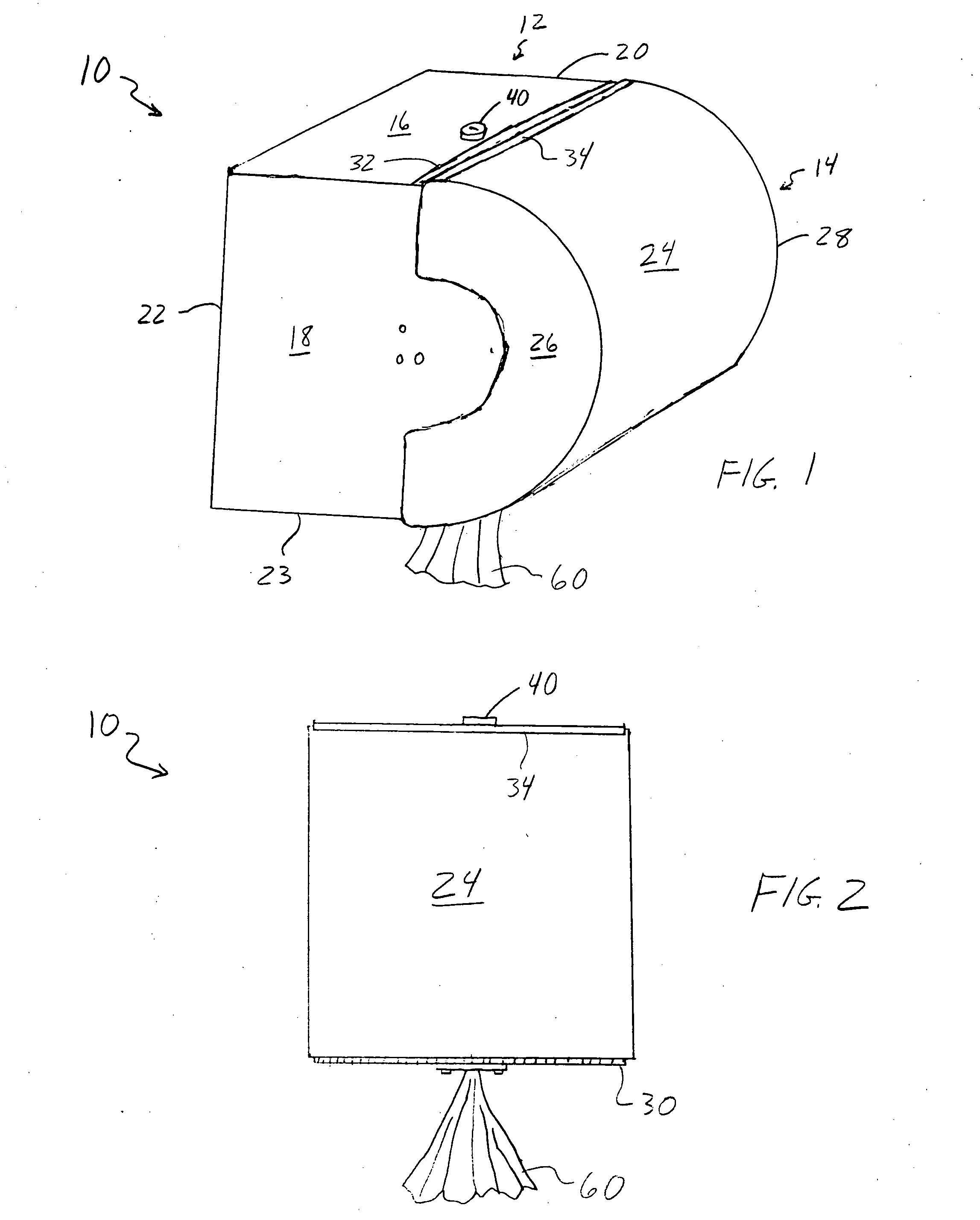

Pre-moistened towelette dispenser

InactiveUS20060208130A1Simple loadingSimple to useFilament handlingDomestic applicationsTowelettesEngineering

The pre-moistened towelette dispenser of the present invention includes a substantially sealed housing to retain moisture within the housing. A roll of pre-moistened, perforated towelettes wound about a cylindrical core is supported within the housing on an axle to allow rotation of the roll of towelettes about the axle to dispense towelettes from the roll. A nipple located in the housing provides a restricted point opening that allows towelettes to exit the housing. The nipple is preferably located in the bottom of the housing to dispense towelettes from the bottom of the housing. An adjustable roll tension system is also provided within the housing. The roll tension system preferably includes a roller that is in contact with and biased against an end cap attached to the cylindrical core at one end of the roll of towelettes. The roll tension system provides resistance to the rotation of the roll of towelettes. The roll tension system is also preferably adjustable so that the dispenser may be adjusted and adapted to accommodate perforated towelettes with different perforation characteristics and tear resistances.

Owner:CASTOR SCOTT +1

Method for Controlling Water Resistance of Polyglycolid Acid Resin

InactiveUS20090298979A1Good accuracyControl moisture resistancePlastic/resin/waxes insulatorsDyeing processChemistryWater resistance

A method of controlling a moisture resistance of polyglycolic acid resin, by controlling a total carboxyl group-source concentration including a contribution of residual glycolide. As a result, a moisture resistance governing the change of strength with time of the polyglycolic acid resin is controlled at a good accuracy.

Owner:KUREHA KAGAKU KOGYO KK

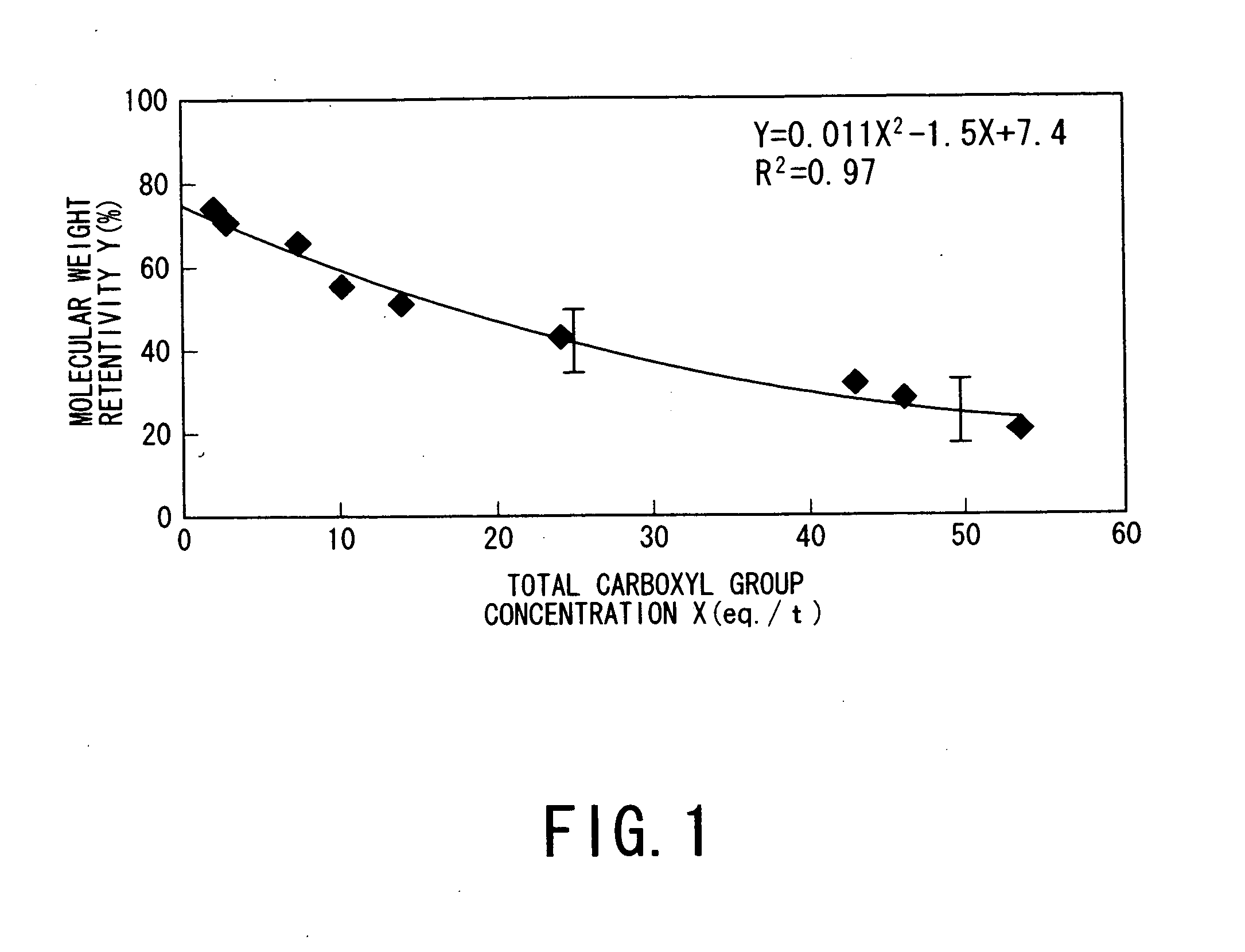

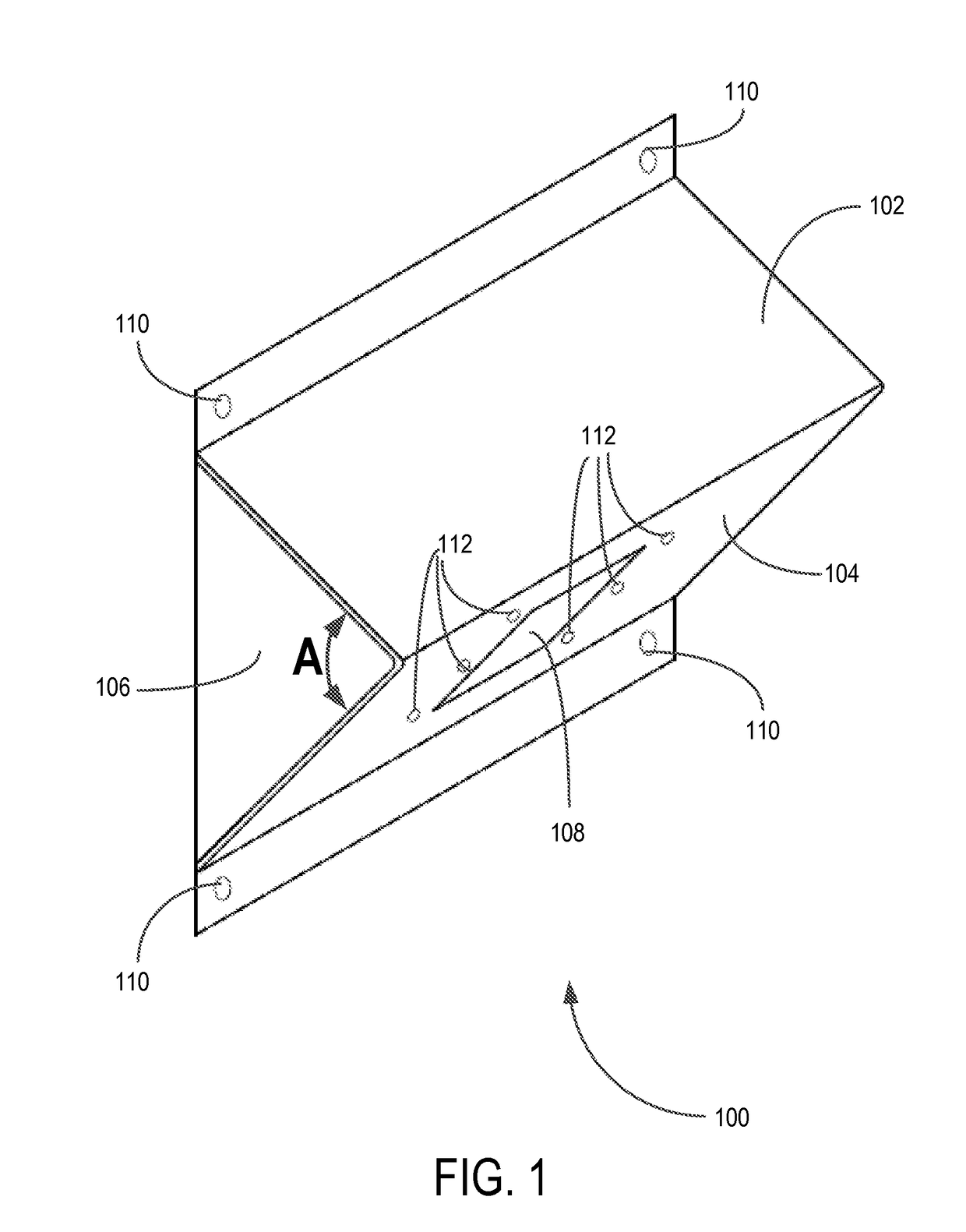

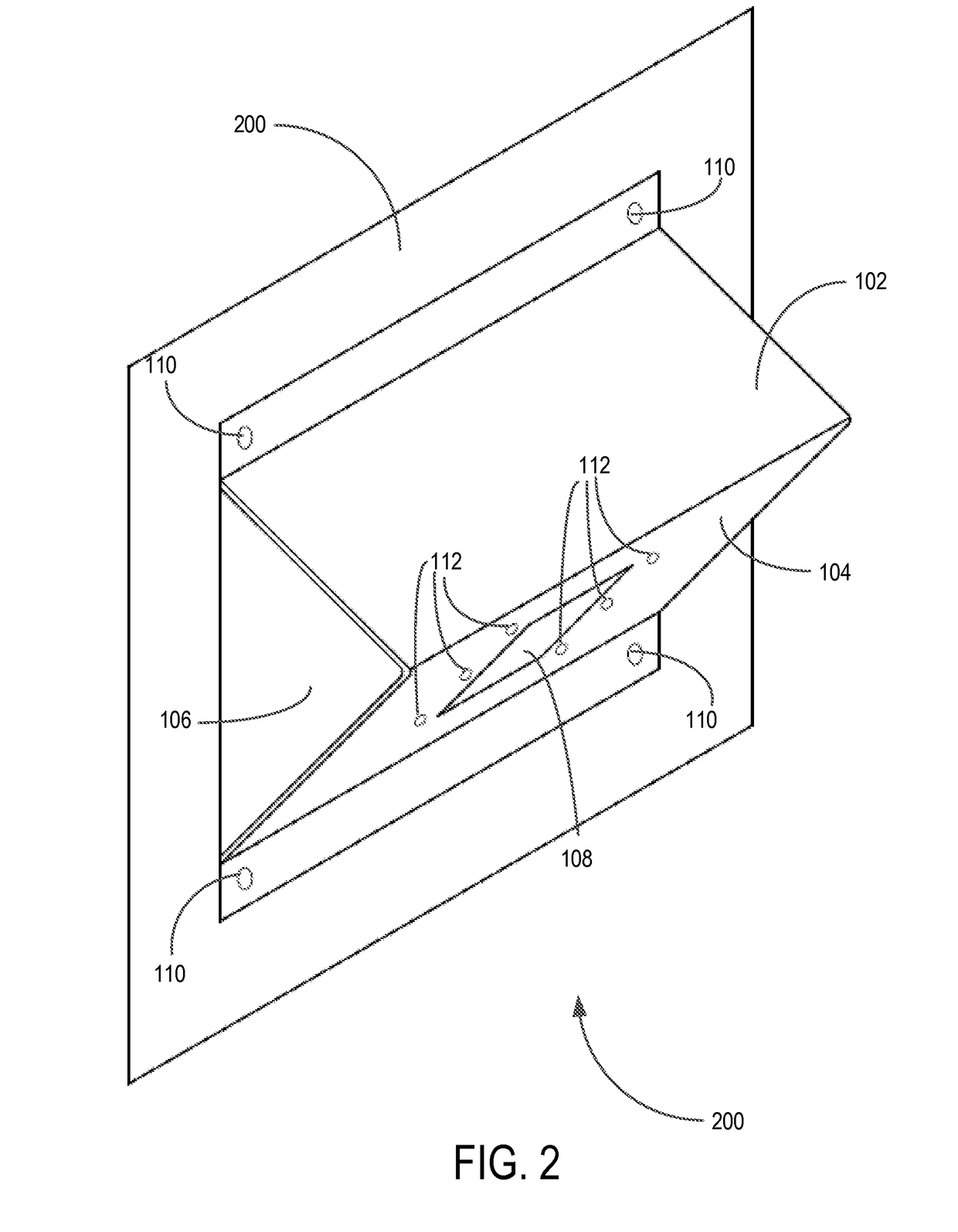

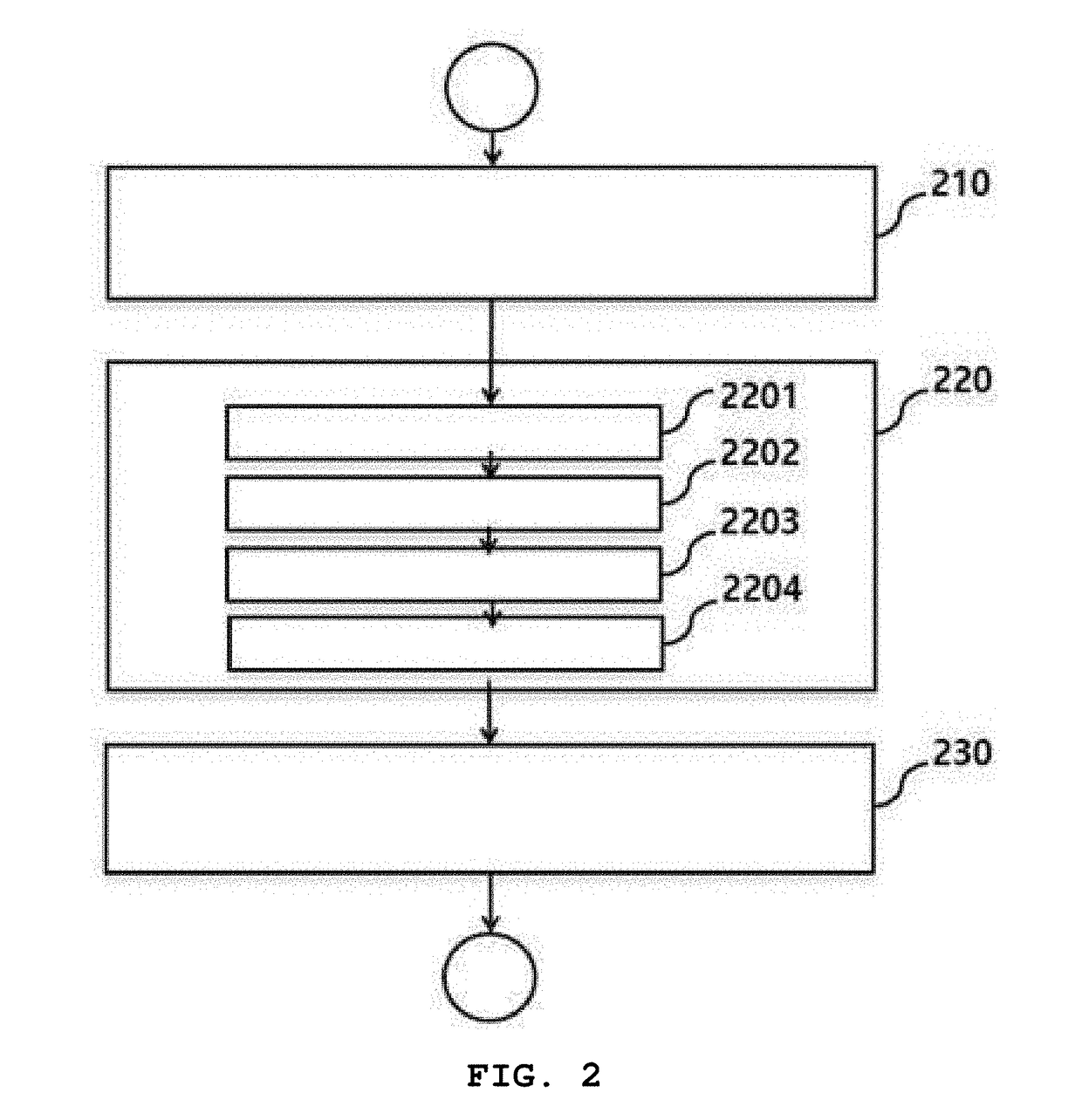

Apparatus for a Plant Growth Medium

InactiveUS20120090235A1Maximize surface areaMoisture resistanceGrowth substratesCulture mediaGrowth plantEngineering

An apparatus comprises a backing sheet comprising a pH neutral material. The backing sheet is configured for supporting at least one plant in a hydroponics system. A plurality of protrusions comprises a pH neutral material. The plurality of protrusions is joined to the backing sheet. The plurality of protrusions is configured for extending away from a surface of the backing sheet for supporting the roots of the at least one plant in which the at least one plant is supported in a growing position and damage to the at least one plant is mitigated during removal of the roots from the protrusions.

Owner:HORN BRIAR +1

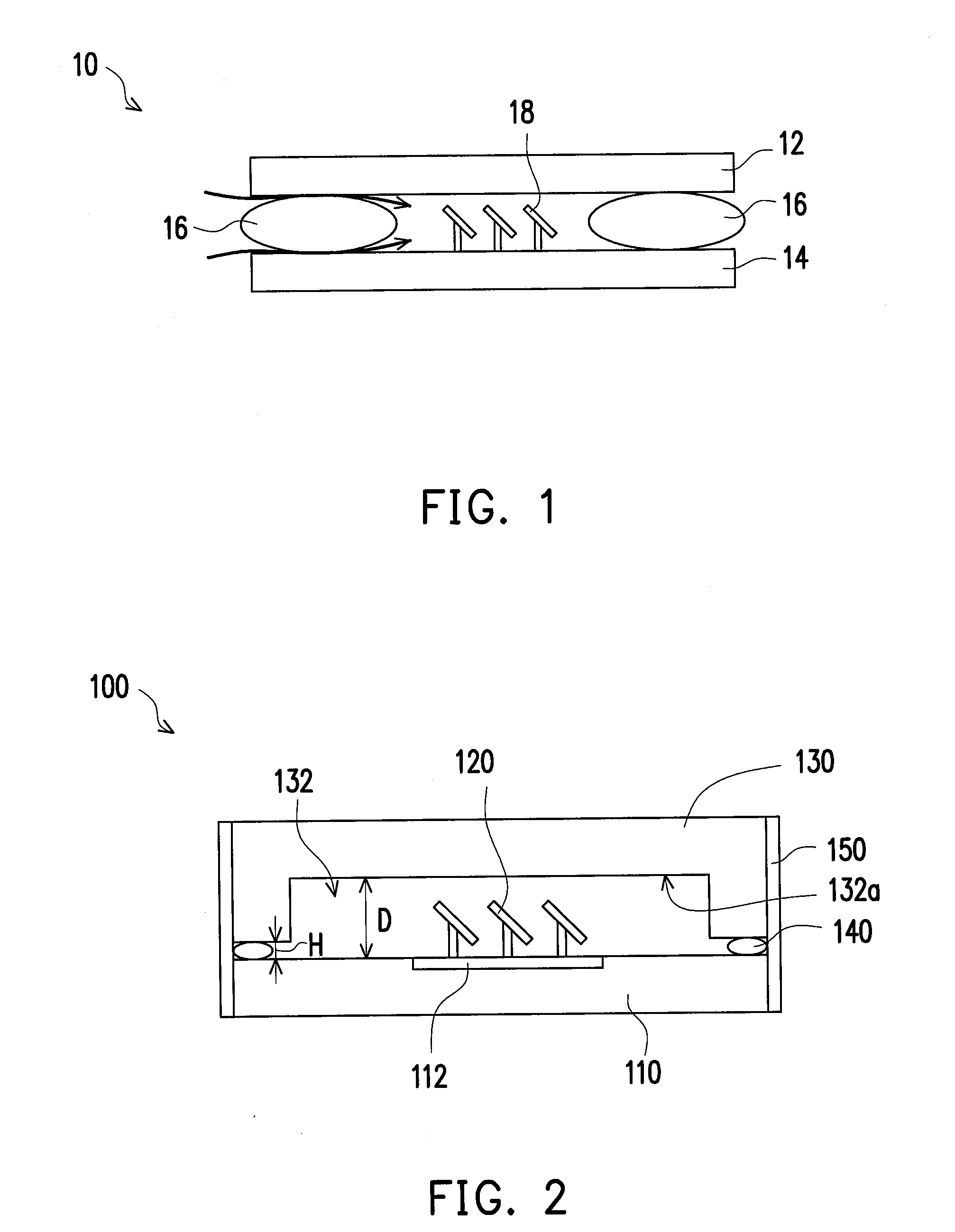

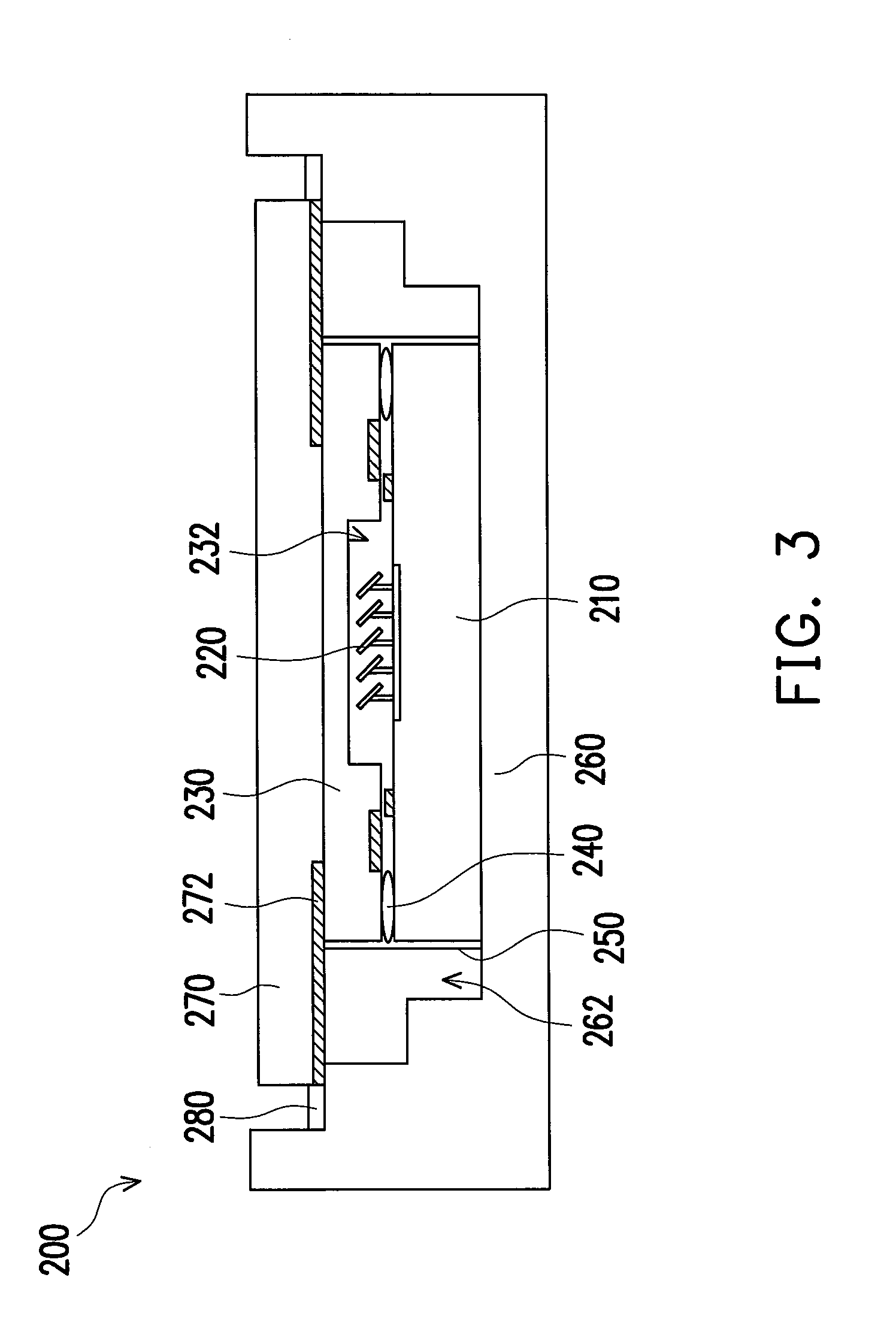

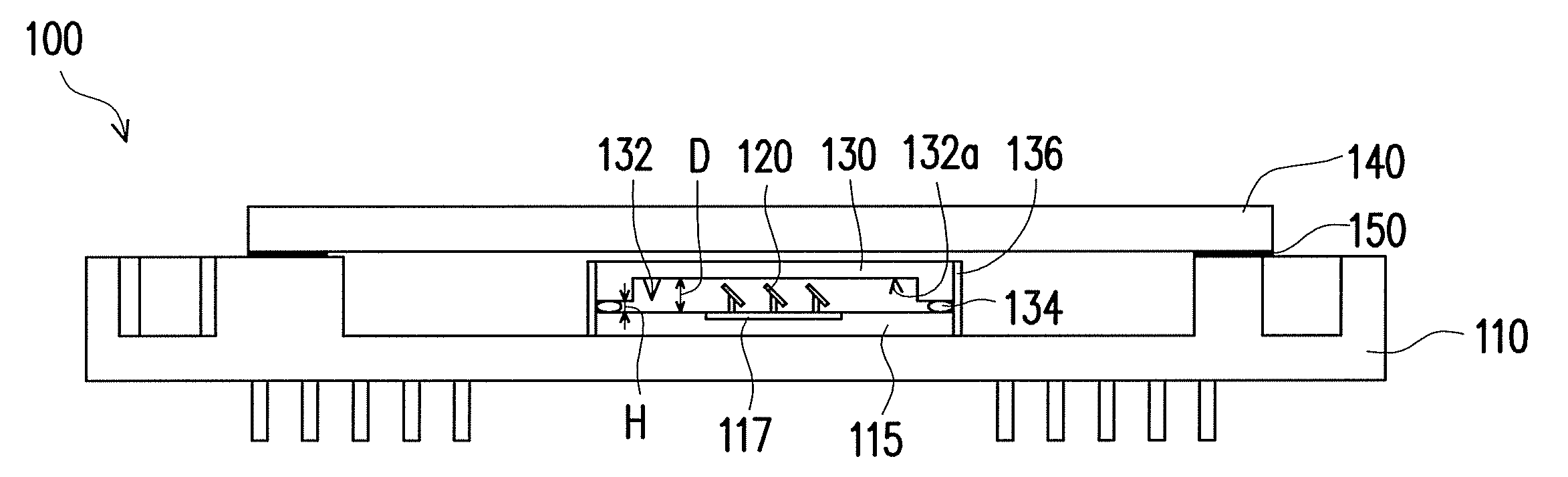

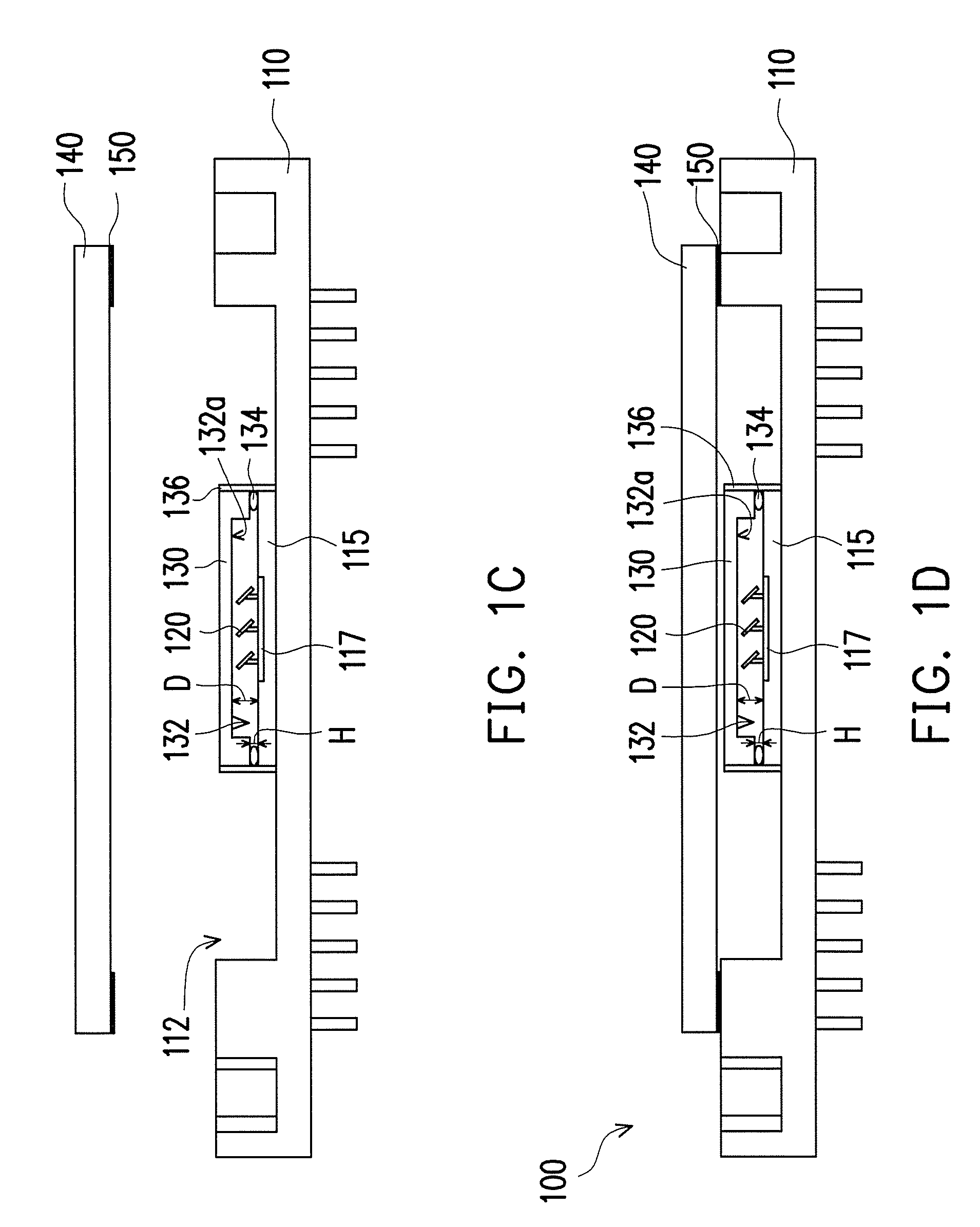

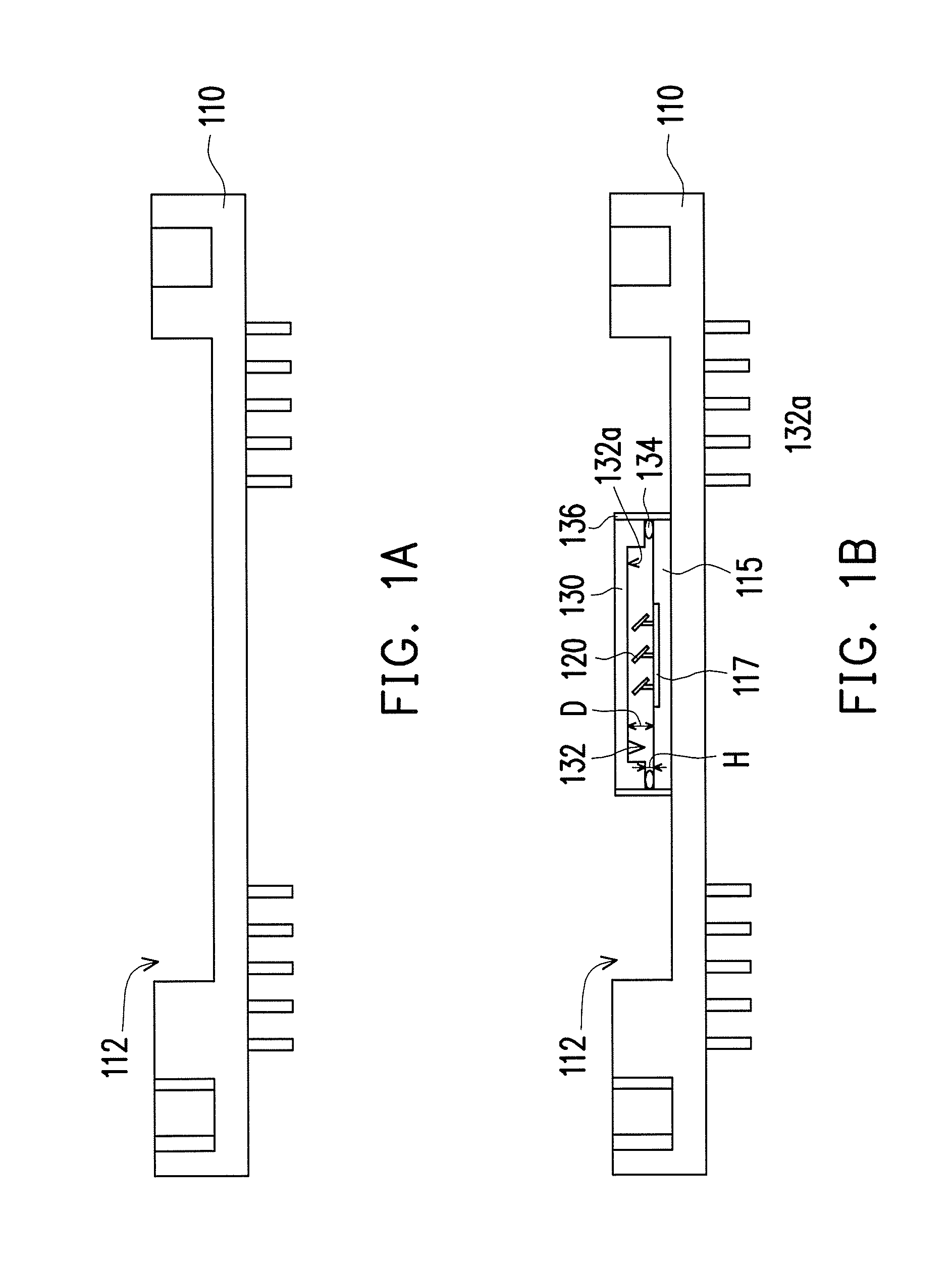

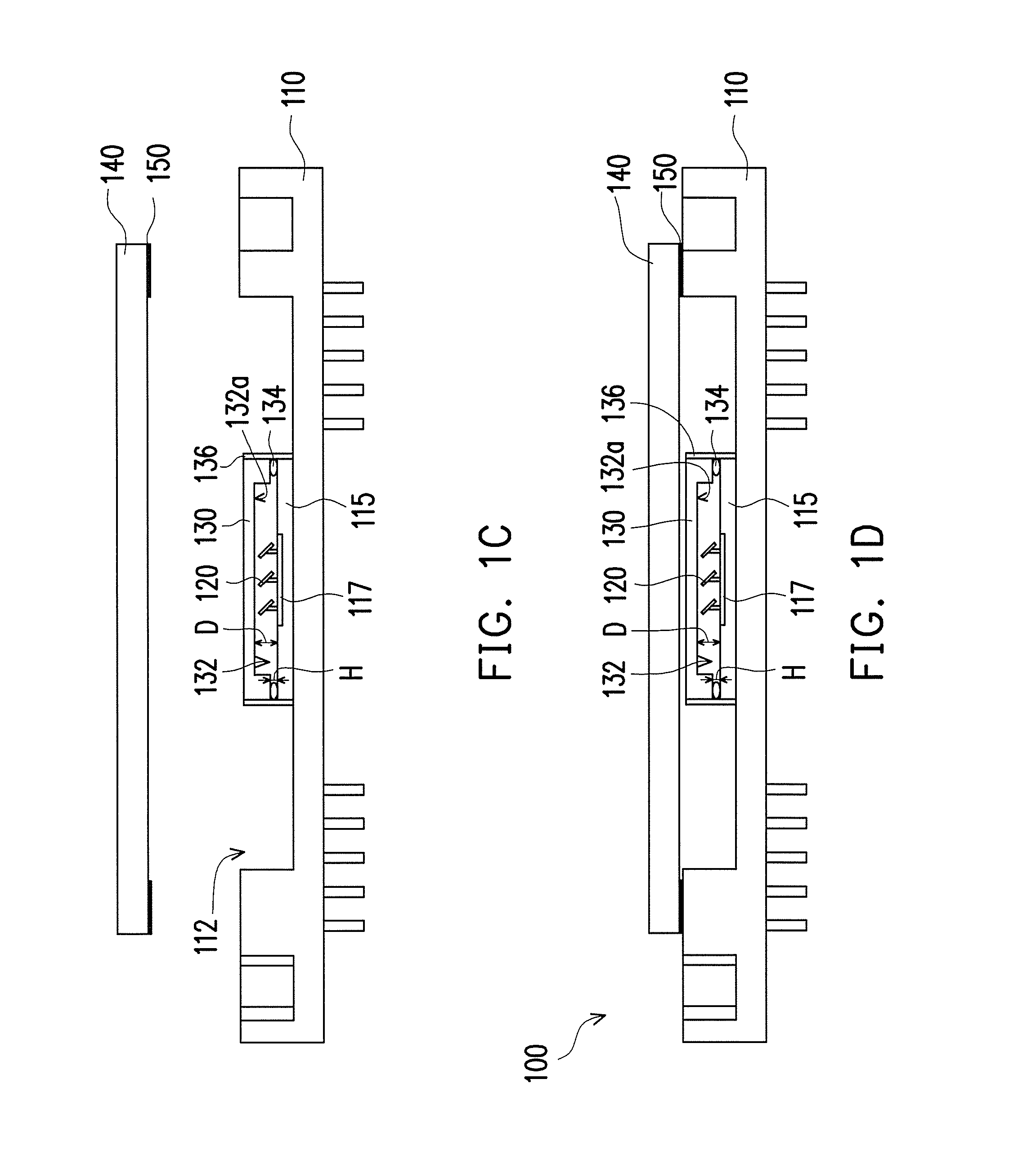

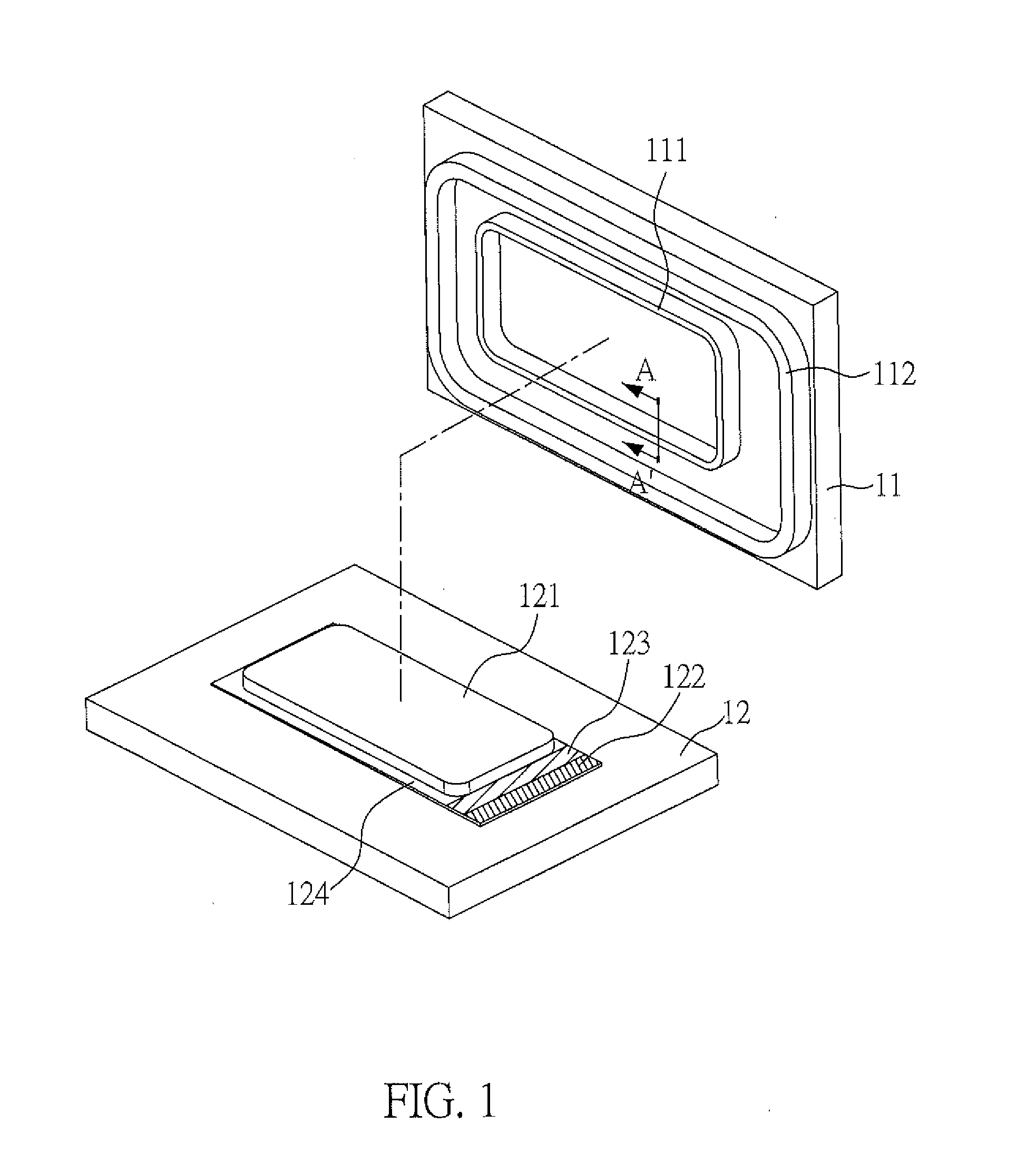

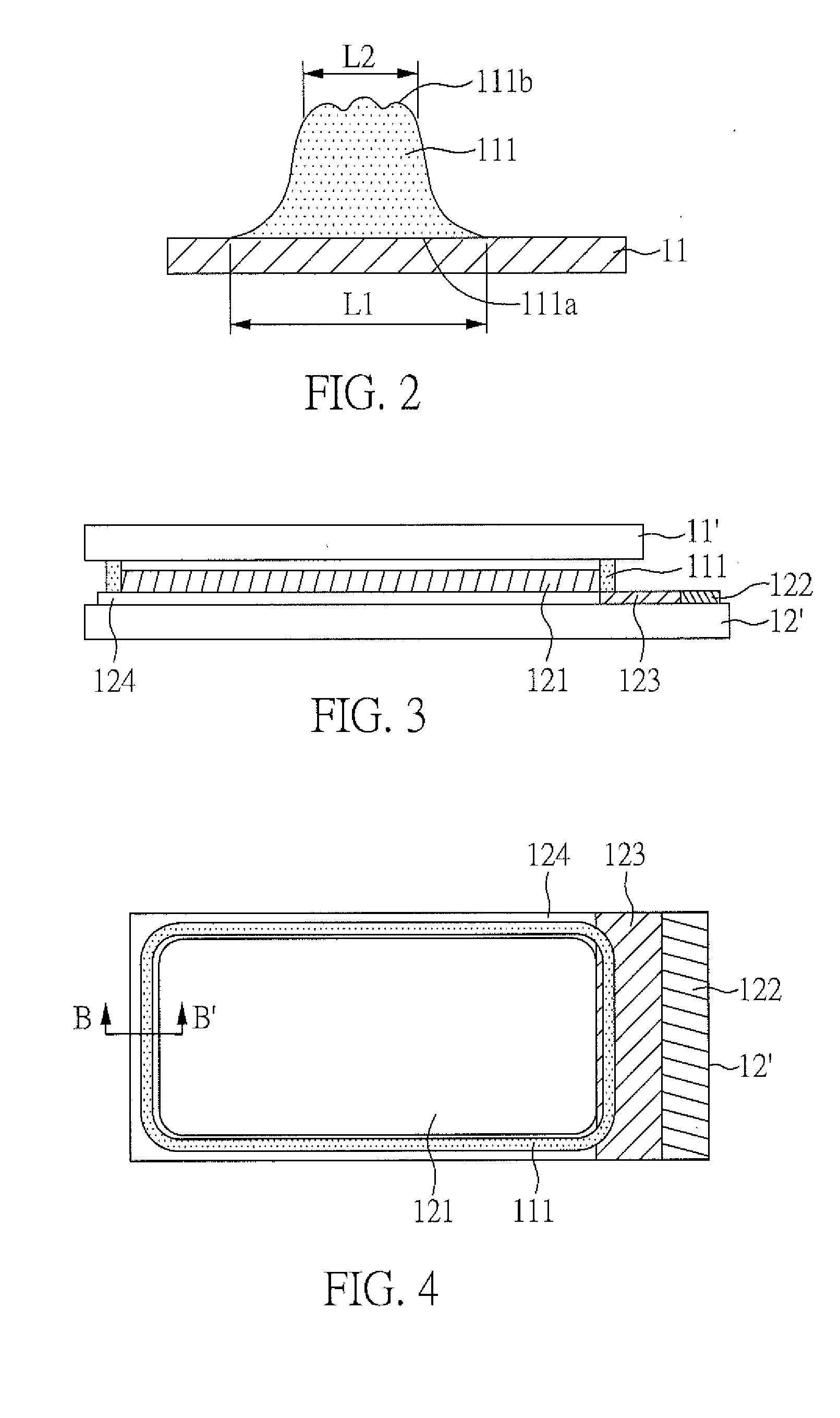

MEMS package structure

ActiveUS20150210538A1Reduce the overall heightMoisture resistanceMirrorsSemiconductor/solid-state device detailsEngineeringMoisture barrier

A MEMS package structure including a chip, a MEMS device, a lid, a sealant and a first moisture barrier is provided. The chip comprises an active surface. The MEMS system device is disposed on the active surface. The lid is covered on the chip and comprising a recess, wherein the MEMS device is in the recess. The sealant is disposed between the chip and the lid so as to seal the recess, wherein a thickness of the sealant is less than a height of the MEMS device. The first moisture barrier is sealed around the chip, the sealant and the lid.

Owner:HIMAX DISPLAY INC

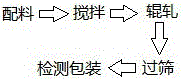

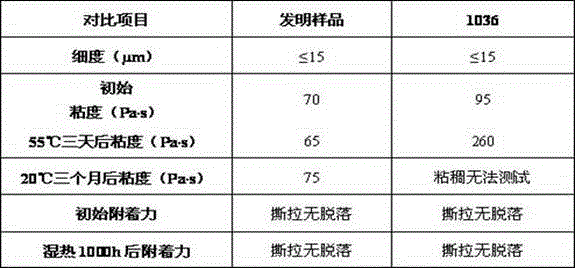

Organic secondary encapsulation slurry for sheet-type resistors, and preparation method thereof

InactiveCN106560489AImprove bindingMoisture resistanceNon-adjustable resistorsOrganic solventRoom temperature

The invention relates to an organic secondary encapsulation slurry for sheet-type resistors, and a preparation method thereof, wherein the organic secondary encapsulation slurry at least contains, by weight, 10-30% of a black pigment, 30-50% of an oxide, 5-10% of an organic resin, and 30-50% of an organic resin, and mixing stirring and rolling with a three-roller grinder are performed to obtain the product. According to the present invention, the organic encapsulation slurry has advantages of good adhesion, good chemical stability, good stability, room temperature storage, and strong competitiveness and broad market prospects in the sheet-type resistor industry.

Owner:西安英诺维特新材料有限公司

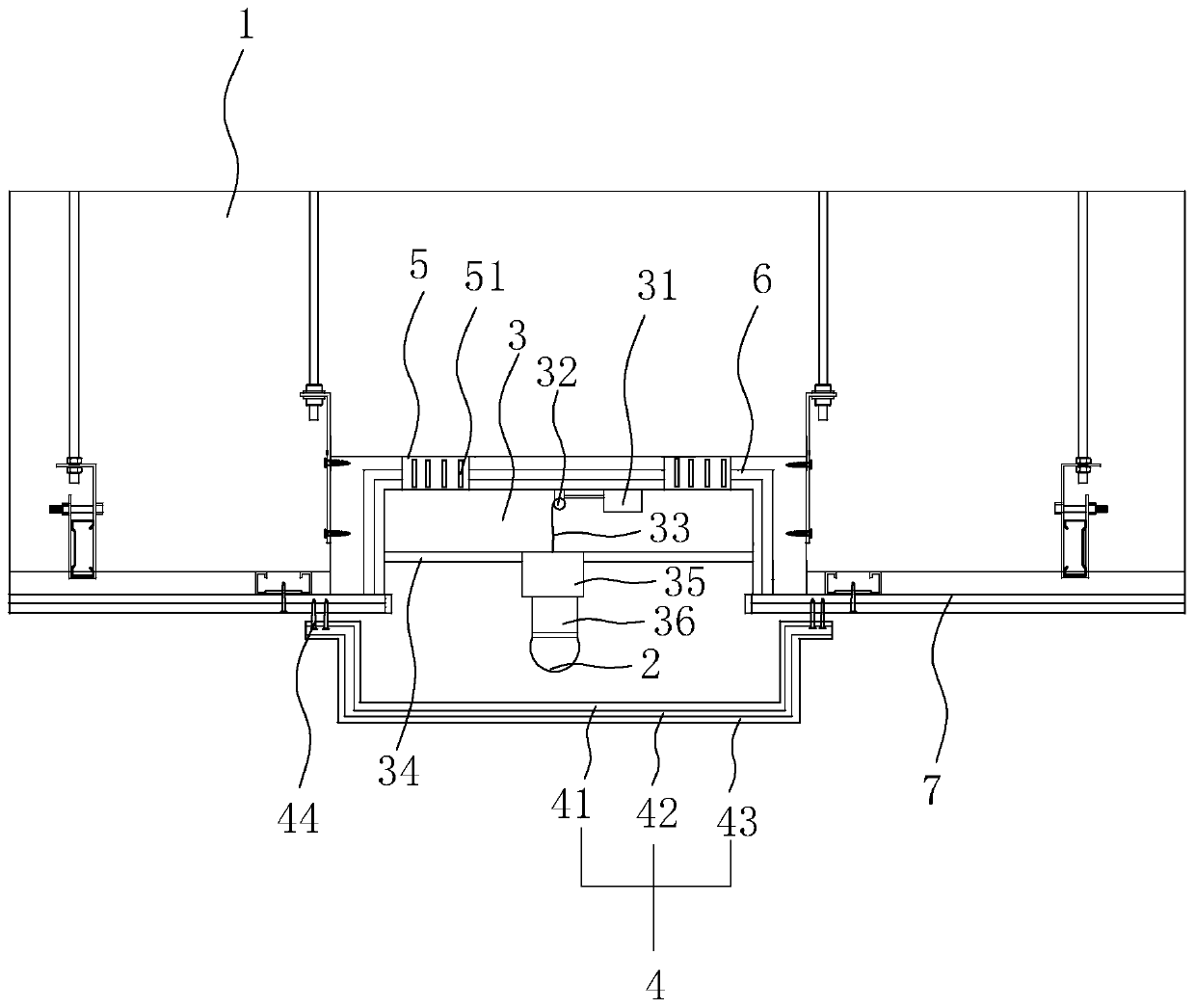

Lamp

ActiveCN109798469APlay a protective effectExtended service lifeLighting support devicesLighting heating/cooling arrangementsDrive wheelEngineering

The invention relates to a lamp which comprises a ceiling and a lamp body. A lamp groove is formed in the ceiling, an opening of the lamp groove is downward, a driving mechanism is arranged at the topof the lamp groove, an output shaft of the driving mechanism is connected with a driving wheel which is connected with the lamp body through a steel rope, a supporting rod is arranged on the inner wall of the lamp groove and positioned right below the driving wheel, an outer sleeve is fixed on the supporting rod, an inner sleeve is axially connected in the outer sleeve in a clamped manner, the bottom of the inner sleeve is connected with the top of the lamp body, diameter of the inner sleeve is identical with that of the lamp body, the steel rope is penetratingly arranged inside the inner sleeve and the outer sleeve, the end of the steel rope is connected with the top of the inner sleeve, and a light transmitting plate covers an opening of the lamp groove and is sequentially connected with a light transmitting faceplate, light transmitting yarn and a light transmitting baseplate from top to bottom. The lamp has lighting effect, and color and brightness of lamplight can be changed while lifting and lowering of the lamp are realized.

Owner:深圳市水平线室内设计有限公司

Preparation method of moisture-proof traditional Chinese medicine coated film

InactiveCN104587481AChemically stableDry fastPharmaceutical delivery mechanismOil/fats/waxes non-active ingredientsSugar Coated TabletMoisture resistance

The invention discloses a preparation method of a moisture-proof traditional Chinese medicine coated film, which relates to a coating technology of the traditional Chinese medicine and belongs to the medicinal preparation field. The moisture-proof traditional Chinese medicine coated film comprises the following components: 30-40 parts of hydroxypropyl methyl cellulose, 5-8 parts of triethyl citrate, 6-10 parts of xylitol, 4-8 parts of castor oil, 4-8 parts of tween-80, 14-18 parts of dextrin, 6-10 parts of aerosol, 6-10 parts of zein, 5-10 parts of 1% of artificial food coloring solution, 350-420 parts of distilled water (40-50 DEG C) and balance of ethanol with 95% of concentration; wherein weight unit of solid is gram, and volume unit of liquid is milliliter. The moisture-proof traditional Chinese medicine coated film has the beneficial effect of stable chemical property of a film forming substance, inertia to an enzyme system, no physiological toxicity and no usage of cane sugar; the coated film has the advantages of moisture resistance, heat resistance, cold resistance and abrasion resistance which are better than that of the sugar coated tablets, so that the stability of the coated film is increased, and storage period is prolonged.

Owner:刘桐言

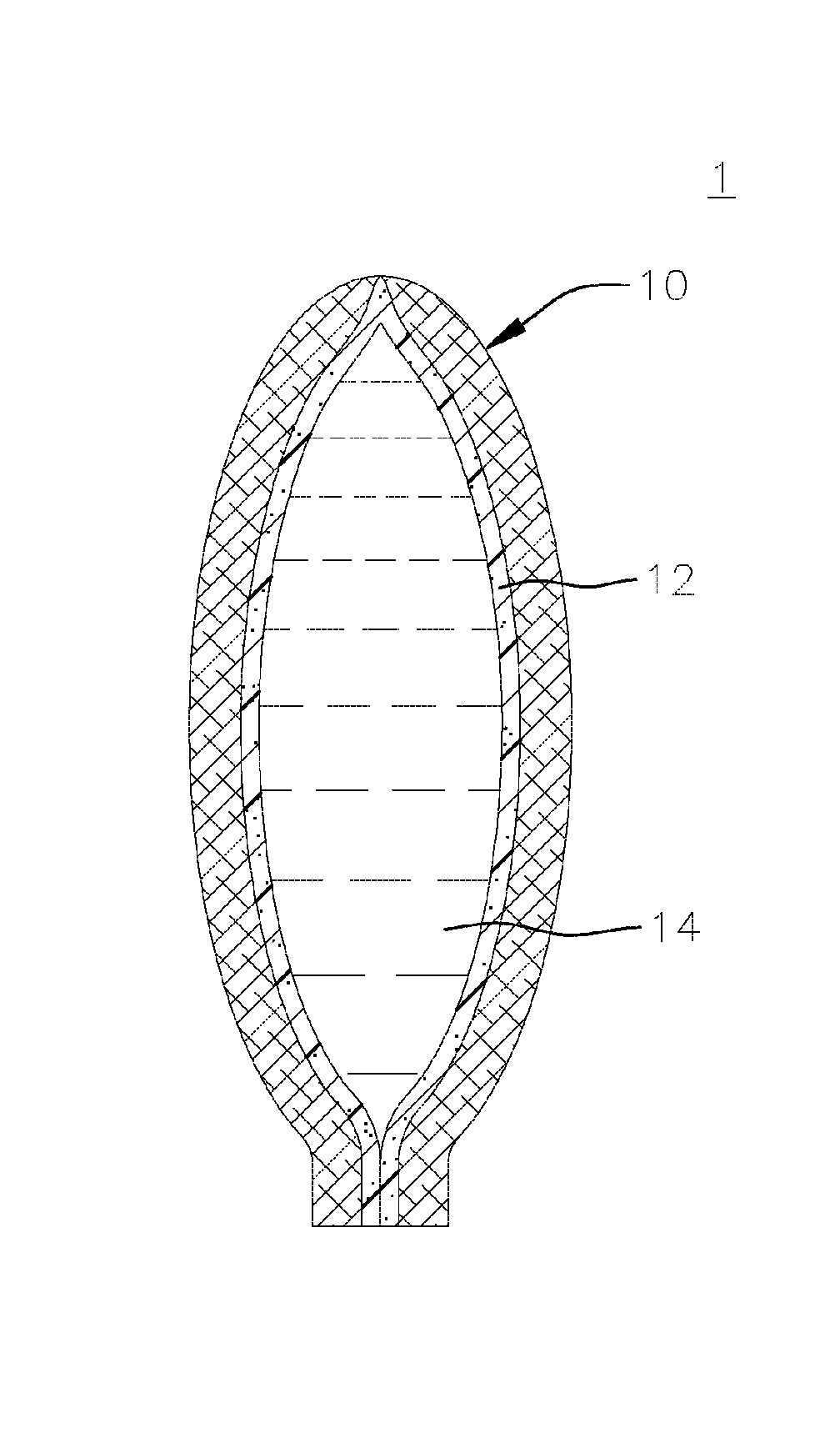

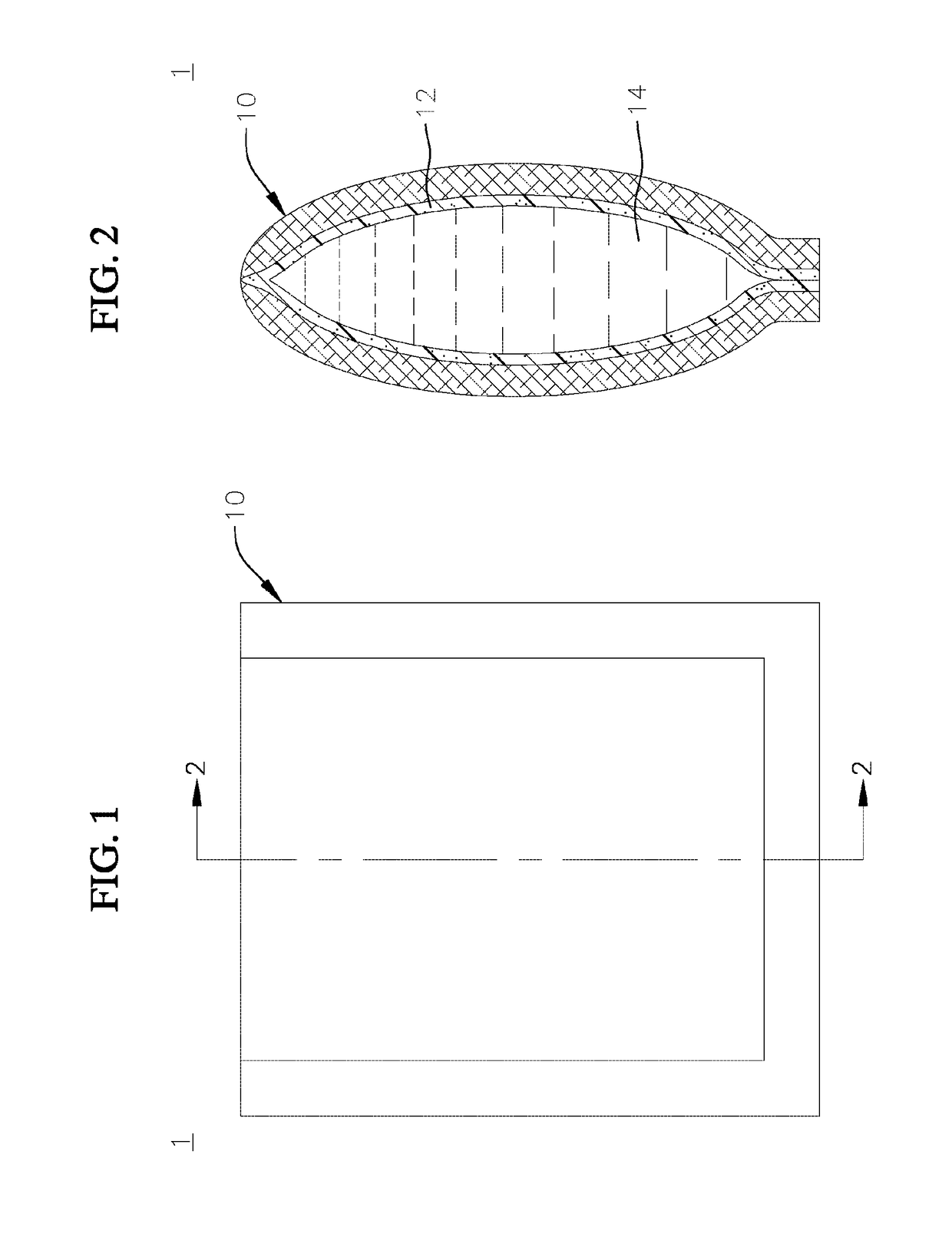

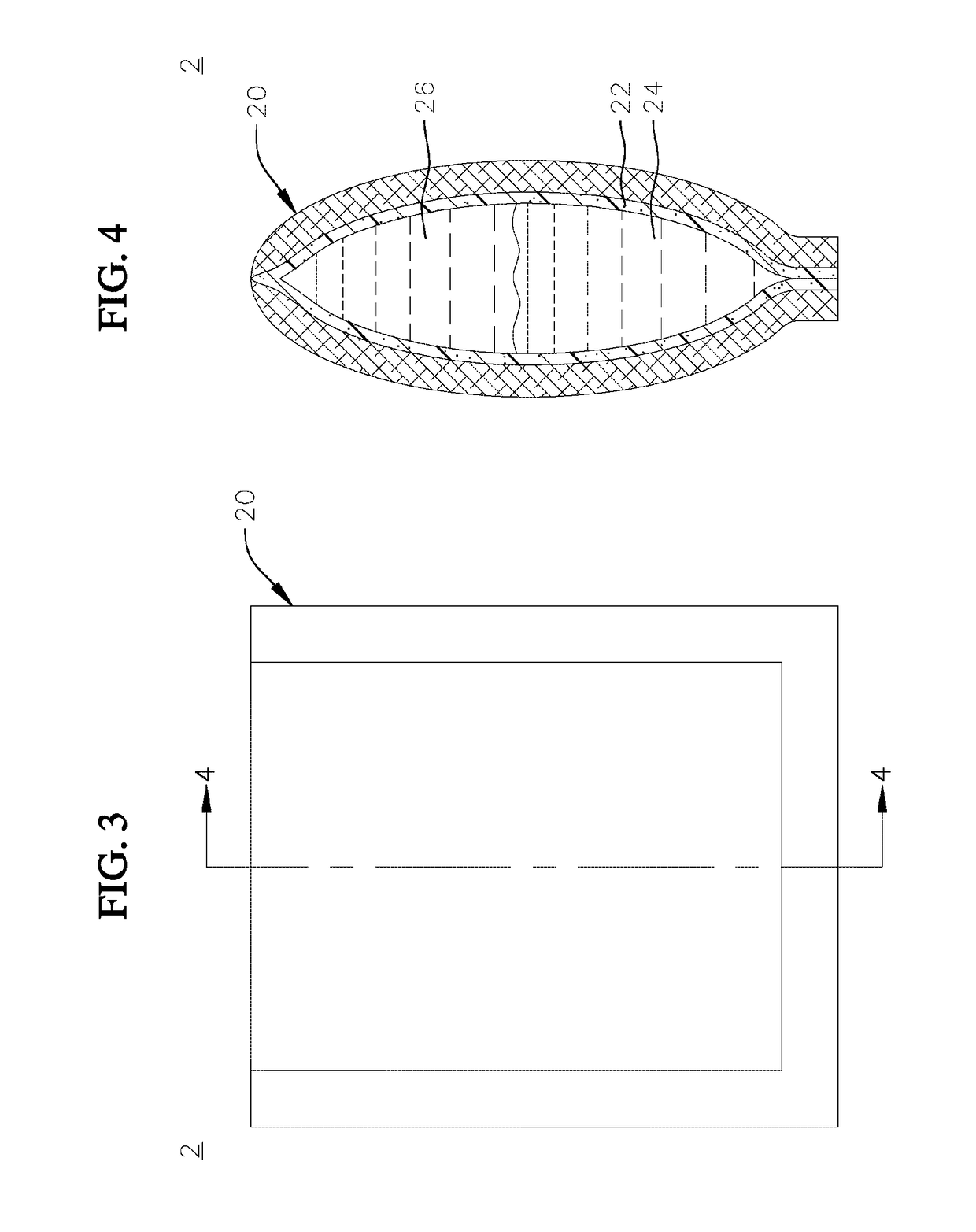

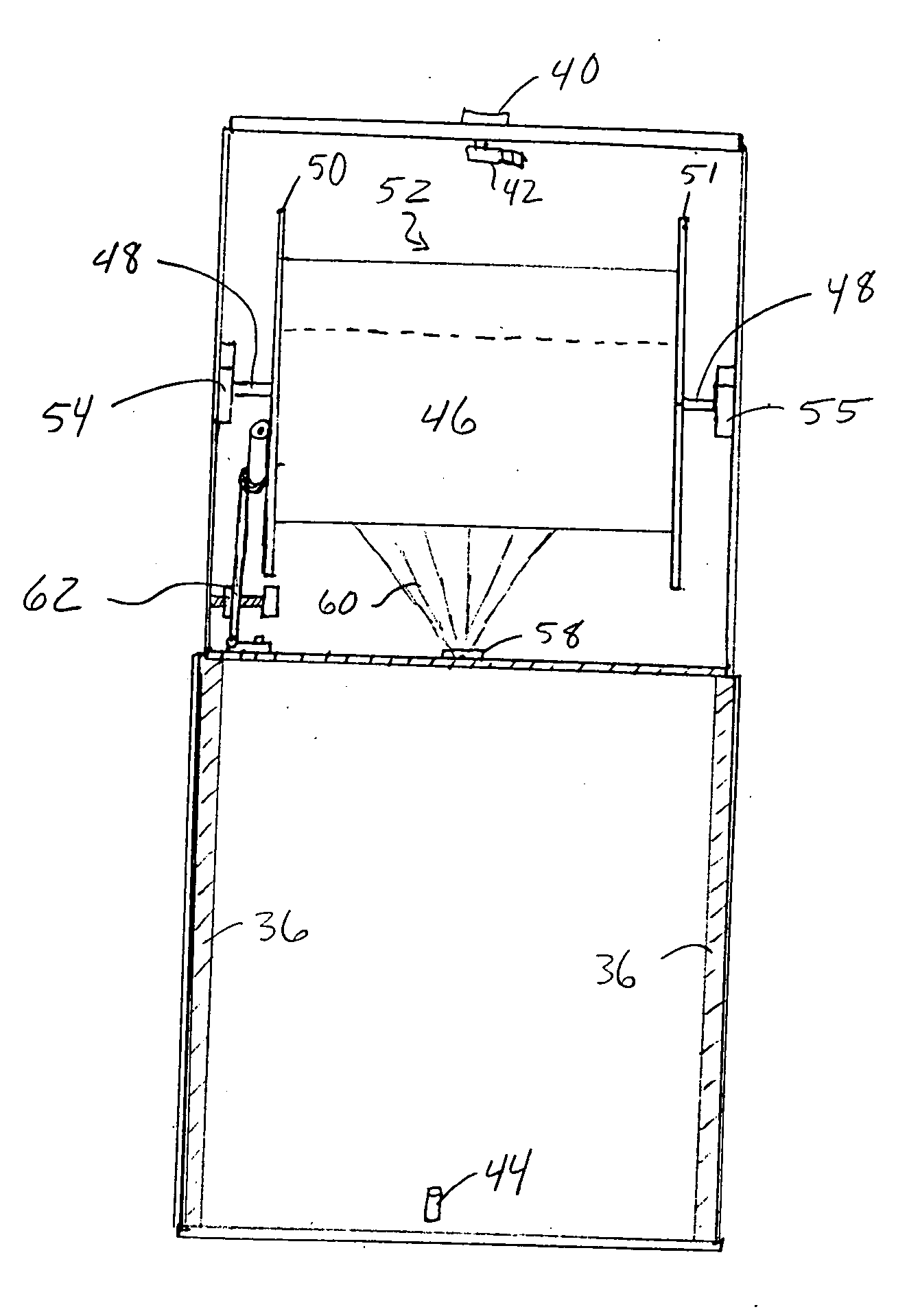

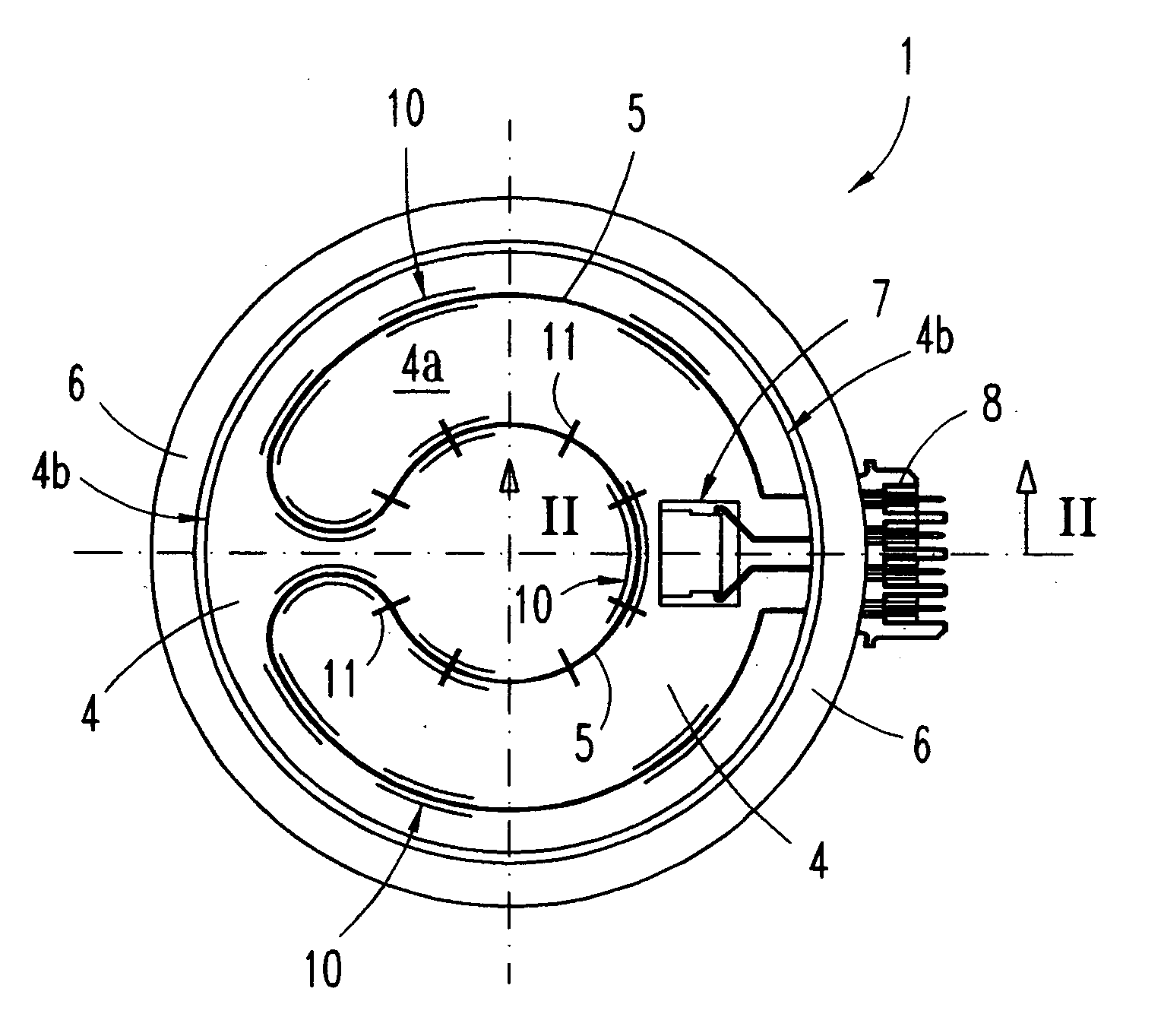

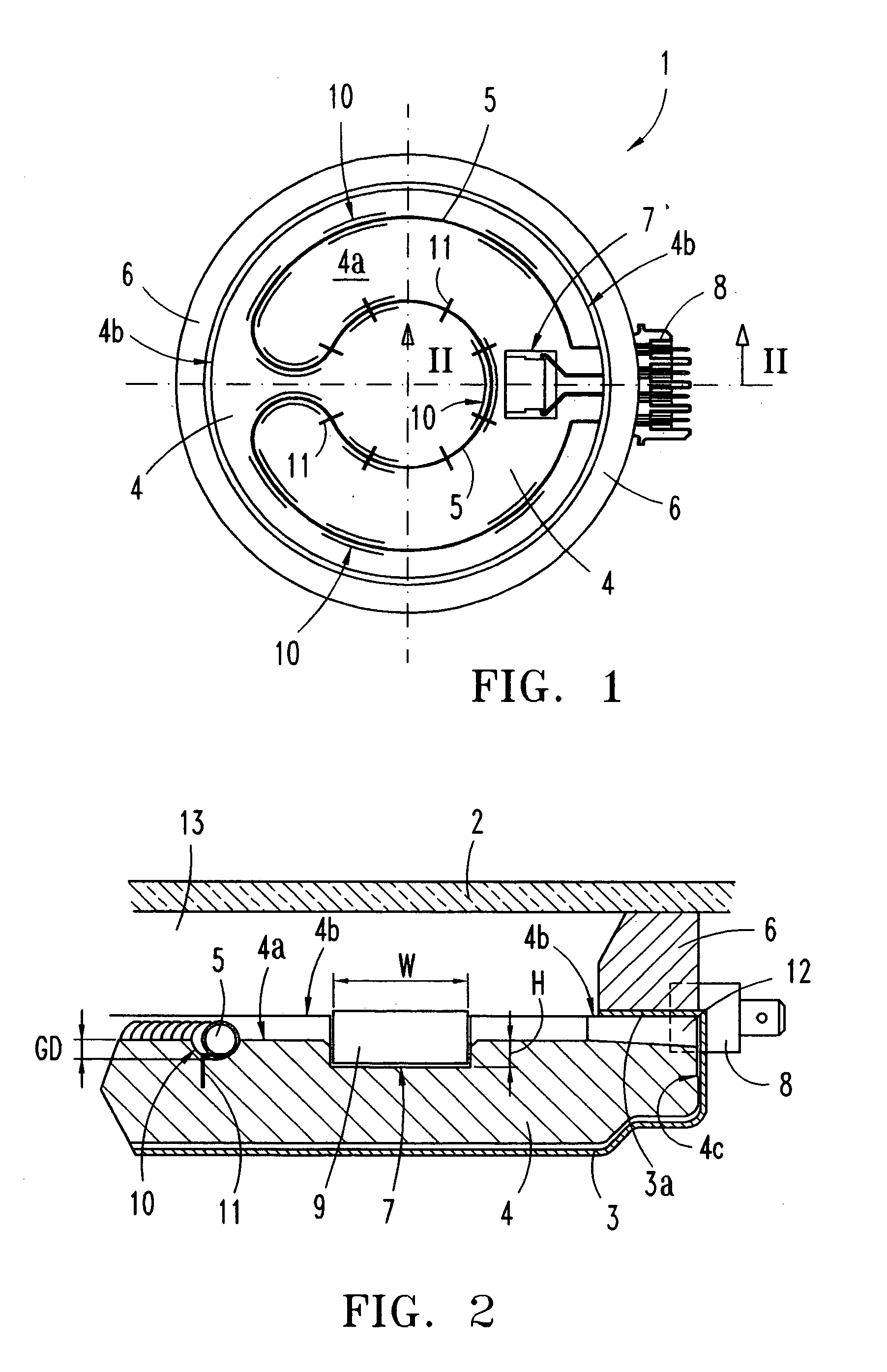

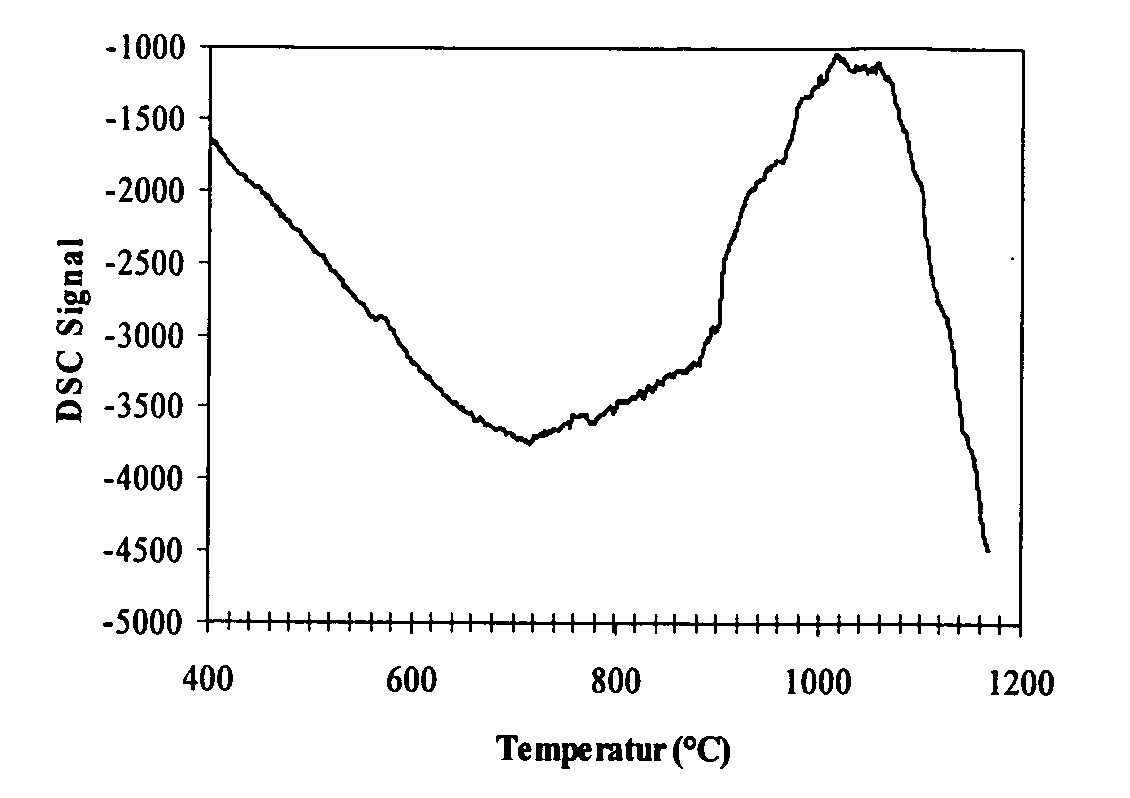

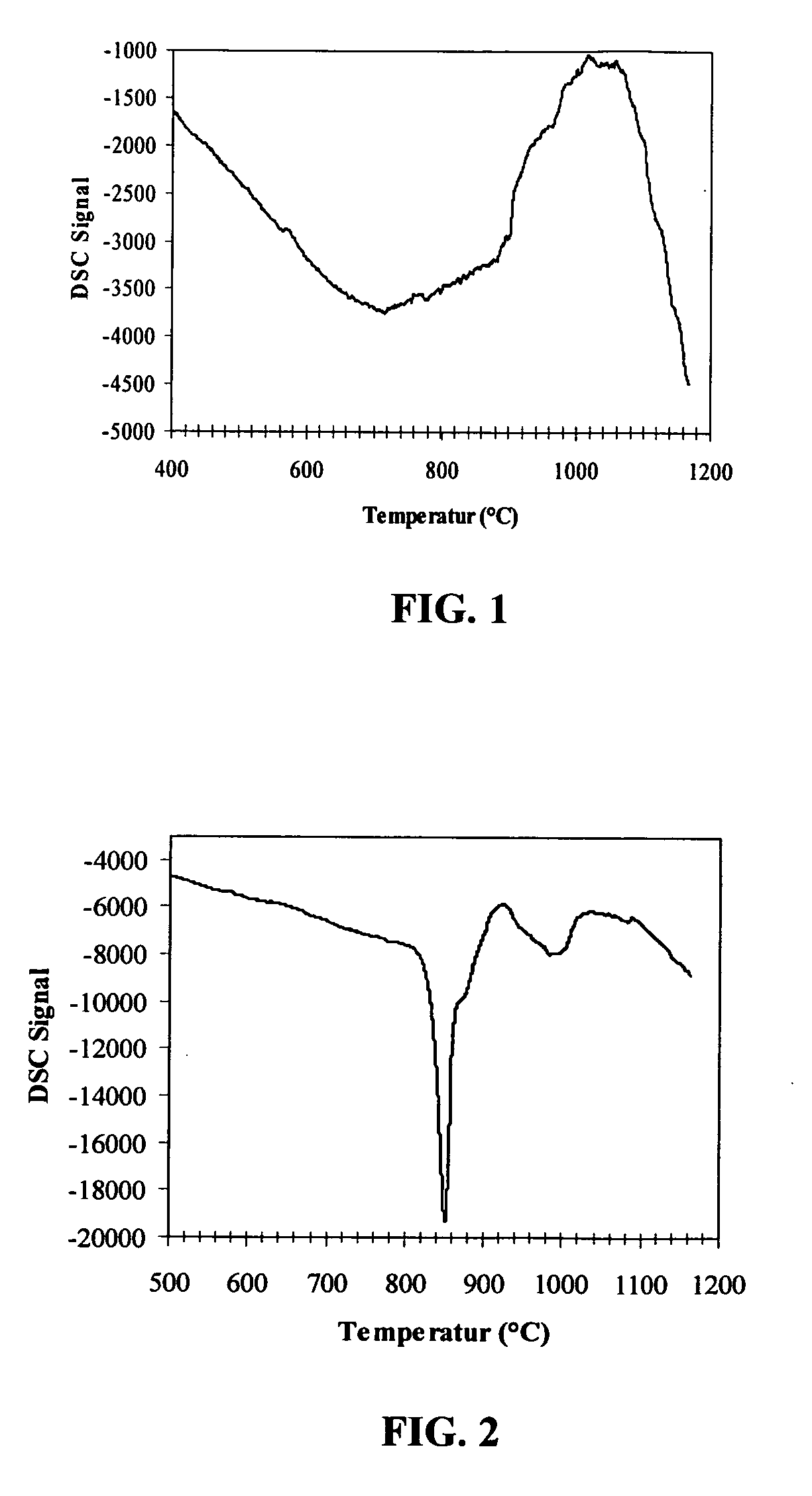

Radiant heater for a cooker, with a moulded insulating base

ActiveUS20060027562A1Improve mechanical propertiesWater absorption capacityHot plates heating arrangementsRadiant heaterEngineering

The radiant heater (1) adapted to a warmer type electric cooking plate (2) comprises an insulating base (4) supporting a heating resistor (5) resting on a central area (4a) fixed by means of metal staples (11) inserted in it, while the insulating base is provided with a guide slot (10) for the heating resistor, a peripheral annular area (4b) for fastening in a metal tray (3), and a vertical annular wall (4c) forming an enclosure below the heated plate area (2), wherein the insulating base is made of a single piece, moulded with a vermiculite mix insulating material and at least one binder compound in an aqueous solution, and a water-repellent additive in a proportion of less than 5%, the density of the resultant insulating moulding after drying being more than 350 Kg / m3.

Owner:EIKA S COOP LTDA +1

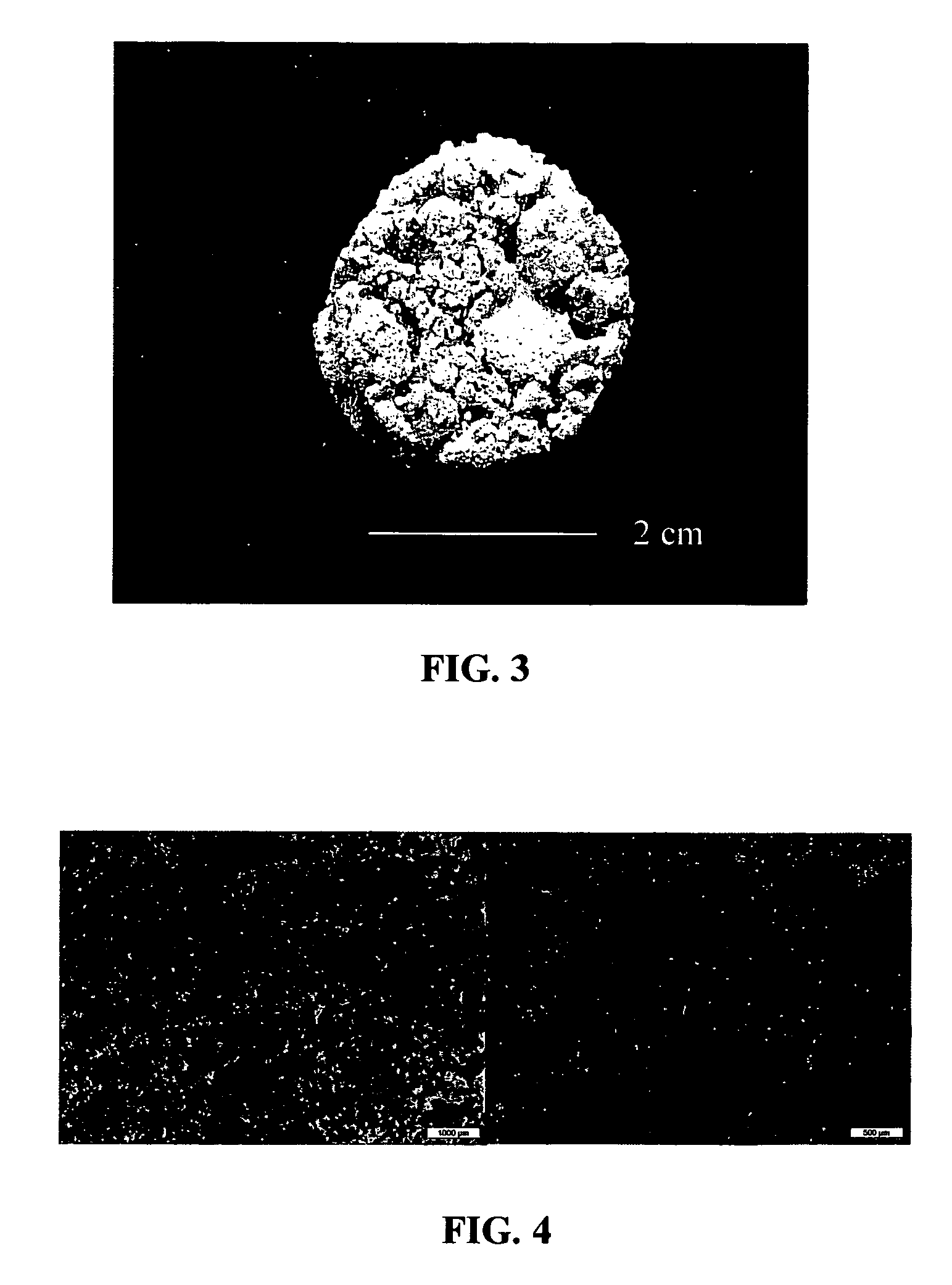

Porous, heat-insulating shaped body, method for producing the shaped body and the use thereof

InactiveUS20070281146A1Low densityMoisture resistanceLayered productsThin material handlingPumice dustSlag

A porous, heat-insulating shaped body, obtained by tempering a material mixture having a weight ratio of 1:1, wherein the mixture includes a silicate such as, for example, natural or expanded perlite, natural or furnace slag pumice, expanding clay, or expanding glass, and an inorganic component selected such that the melting point for the mixture of silicate and inorganic component is in the range of a sintering temperature of the silicate and that a gas is furthermore released from the inorganic component in this temperature range. The porous, heat-insulating shaped body functions to control moisture when used in the form of a heat-insulating board or in the form of an admixture for building materials.

Owner:KERNFORSCHUNGSZENTRUM KARLSRUHE GMBH

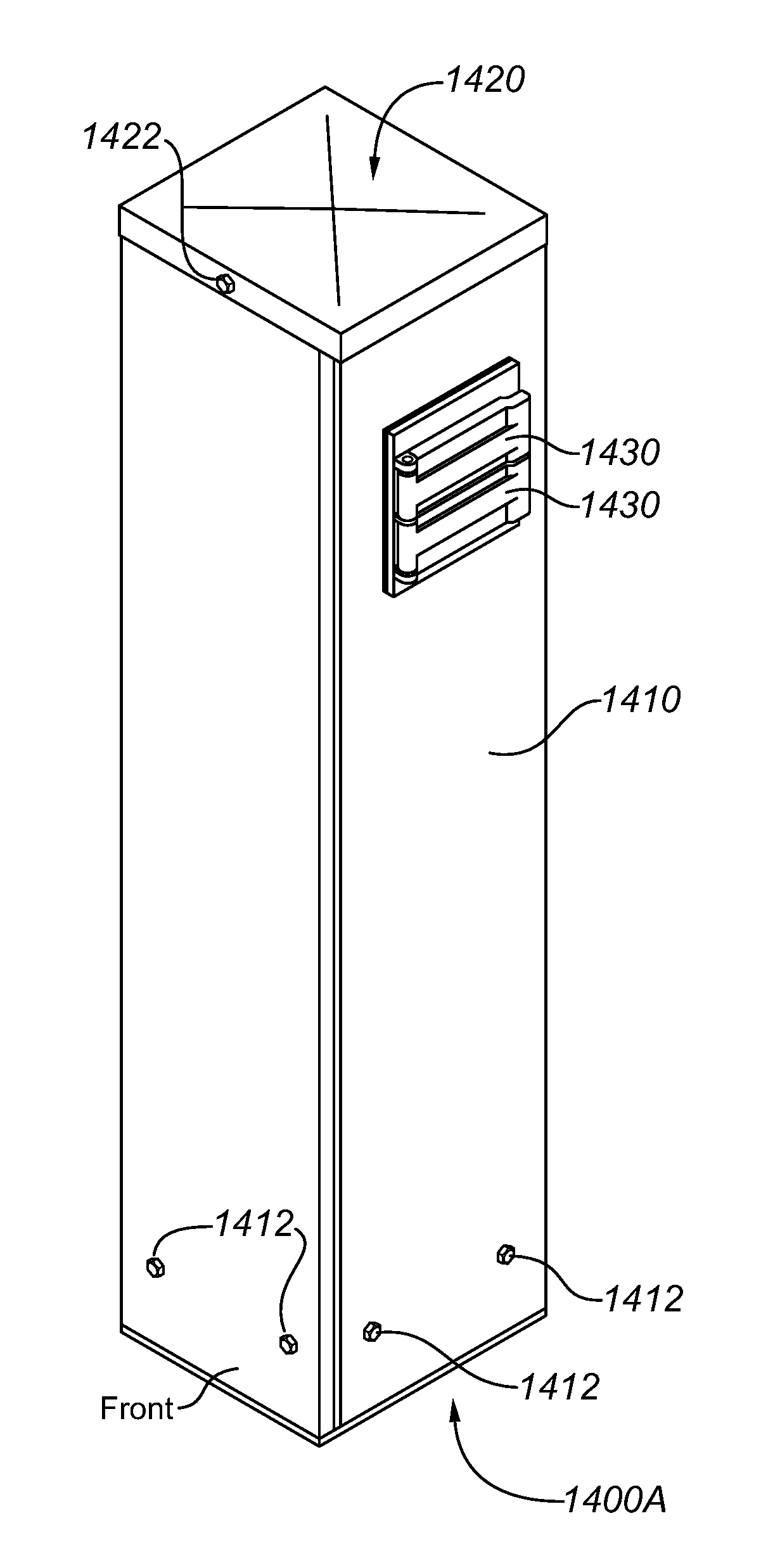

Power pedestal with breakaway pedestal base

InactiveUS20180040995A1Easy to replaceHigh strengthSubstation/switching arrangement detailsCharging stationsStress reliefBreaking point

A power pedestal for electrical outlets is mountable to a mounting surface by means of a pedestal base. The pedestal base incorporates at least one stress relief feature that will allow the power pedestal to break away from the pedestal base in response to an external force acting on the power pedestal so as to induce stresses in the pedestal base exceeding a predetermined breaking point. The power pedestal may then be remounted to the mounting surface using a new pedestal base replacing the broken pedestal base. Optionally, the power pedestal may be provided with protective apparatus for protecting electrical outlets installed in the power pedestal from exposure to weather. The protective apparatus may comprise an angled hood having an angled top surface, at least two side panels, and an angled bottom surface having an aperture.

Owner:A C DANDY PRODS

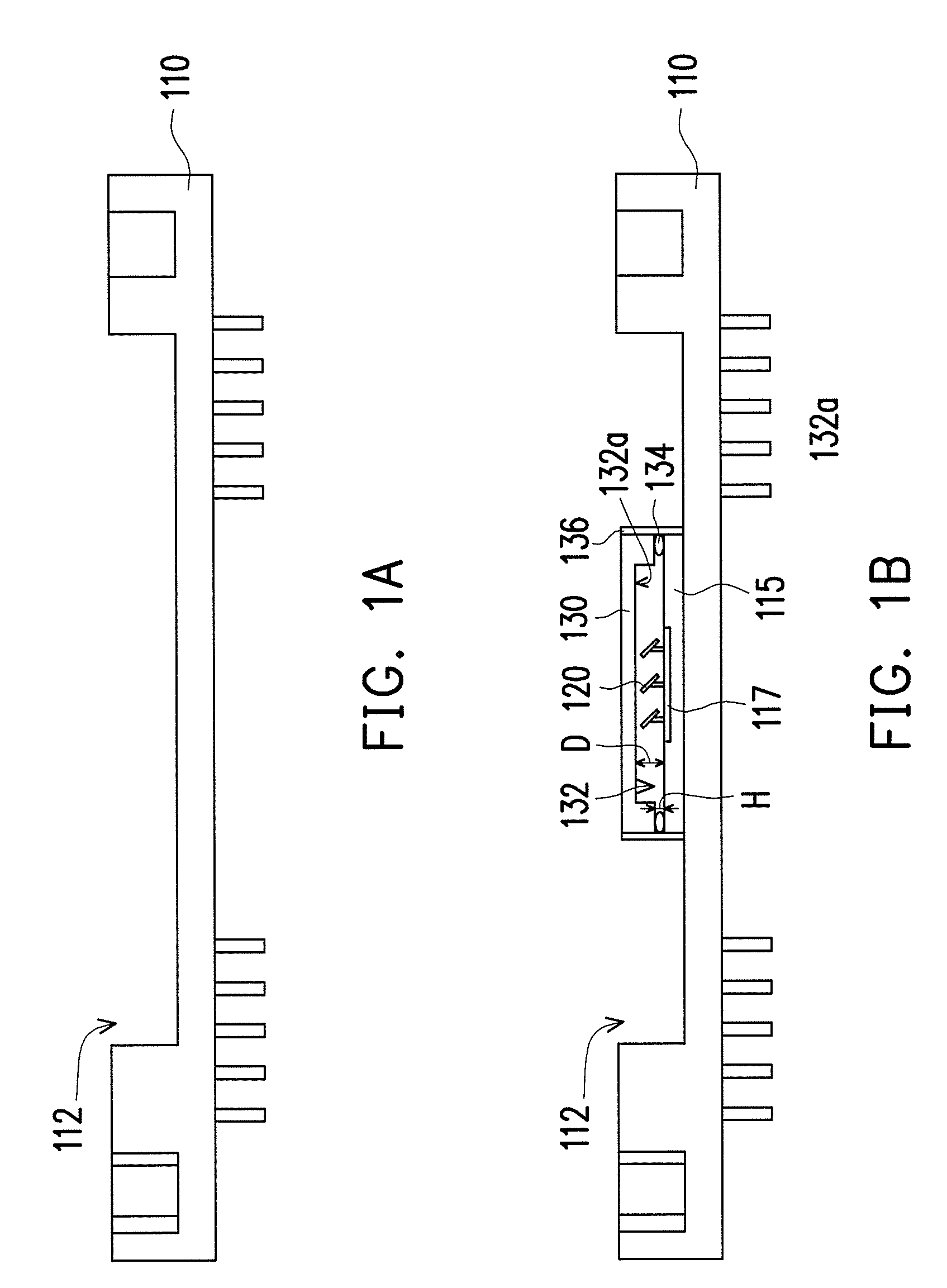

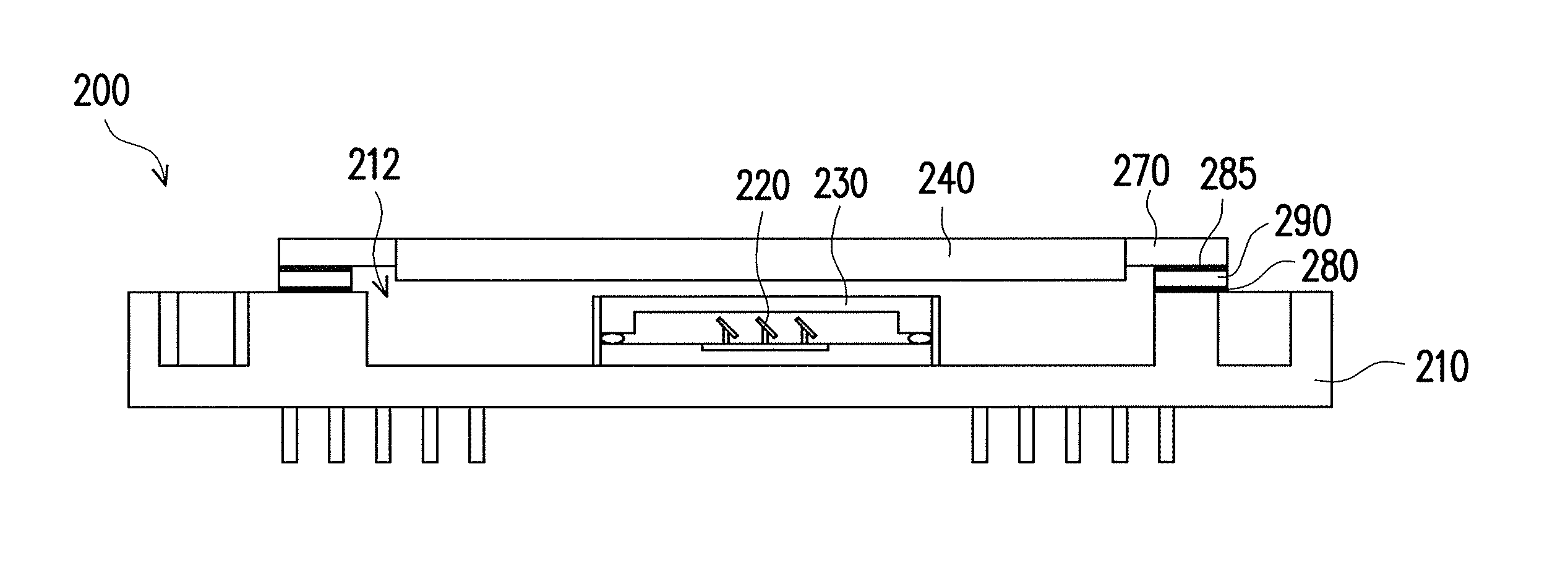

MEMS package structure and manufacturing method thereof

ActiveUS9409766B2Moisture resistanceImprove air tightnessDecorative surface effectsSemiconductor/solid-state device detailsFritEngineering

Owner:HIMAX DISPLAY INC

MEMS package structure and manufacturing method thereof

ActiveUS20150284241A1Moisture resistance propertyImprove air tightnessDecorative surface effectsSemiconductor/solid-state device detailsEngineeringMetal framework

A MEMS package structure includes a base, a MEMS device, a first cover, a second cover and a glass frit. The base includes a recess. The MEMS device is disposed in the recess. The first cover is disposed in the recess and covering the MEMS device. The second cover is disposed on the base and covering the recess. The glass frit is disposed between the base and the second cover. A MEMS package structure includes the base, the MEMS device, the first cover, a second cover, a first metal frame and a first sealing medium. The first metal frame is disposed around the second cover, and the second cover and the first metal frame collectively are disposed on the base and covering the recess. The first sealing medium is disposed between the first metal frame and the base. Manufacturing methods of the MEMS package structures above are further provided.

Owner:HIMAX DISPLAY INC

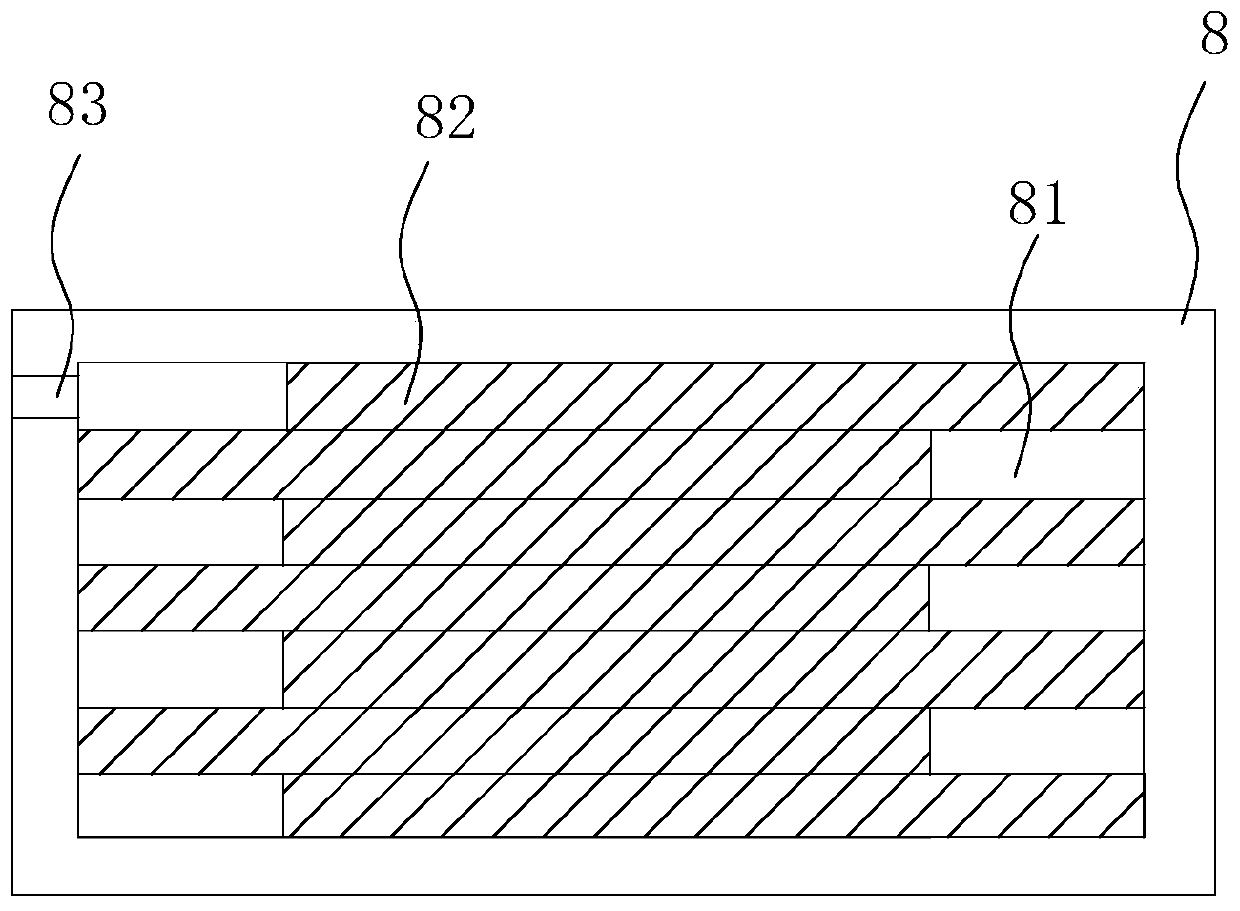

Dampproof solid wood floor provided with core plate proper in tightness degree

The invention discloses a dampproof solid wood floor provided with a core plate proper in tightness degree. The floor comprises a surface plate, the core plate and a back plate, wherein the core plate is formed by series connection of multiple wood laths through at least two connecting ropes arranged in the long-side direction of the core plate. The method for manufacturing the floor comprises the steps of selecting two wood laths in the same size, conducting vacuum drying on the wood laths at a temperature ranging from 40 DEG C to 60 DEG C, and controlling the moisture content of the wood laths to be 5-8%; placing the dried wood laths in order, cutting the wood laths with a rope threading machine to obtain grooves, and pressing the connecting ropes into the grooves during cutting; fixing the surface plate and the back plate to the upper side and lower side of the manufactured core plate through adhesives respectively to obtain the solid wood floor, and applying dampproof oil to the four sides and bottom surface of the manufactured solid wood floor. Through the cooperation of a grooving device, a rope pressing device and a press-aligning plate, mechanical rope threading is achieved, grooving and rope threading are achieved synchronously, the size ratio of the grooves to the connecting ropes is proper, the tightness degree of the manufactured core plate is proper, certain redundancy is available under a damp condition, and moisture resistance is realized.

Owner:于桂菊

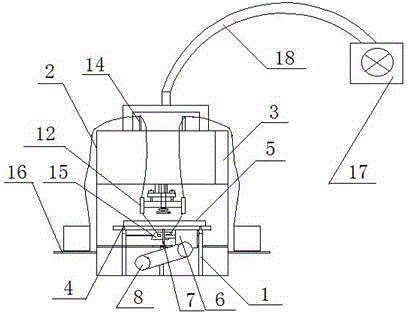

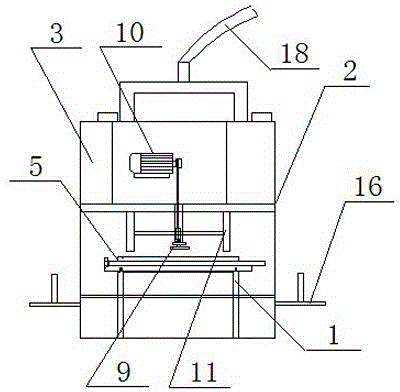

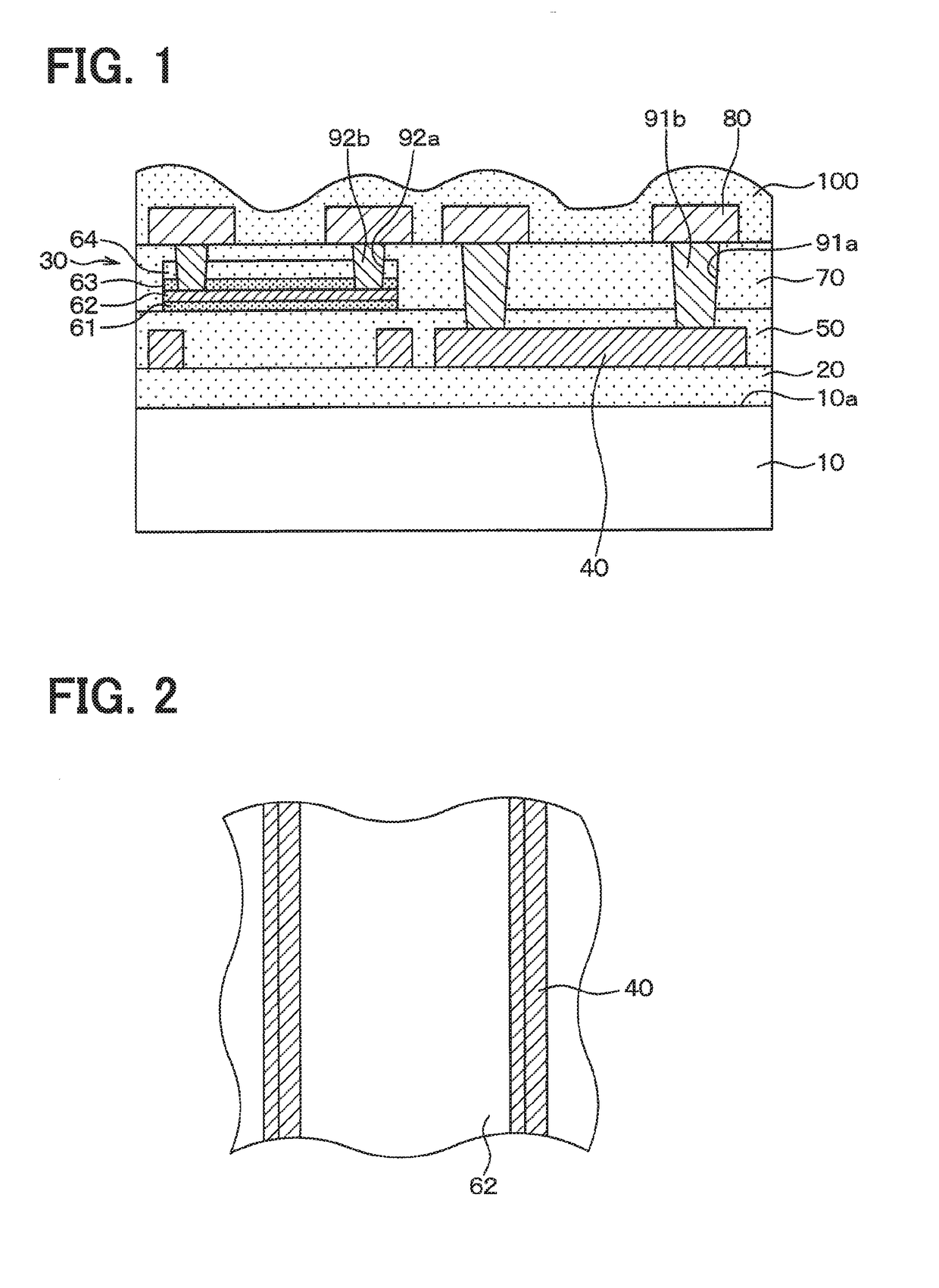

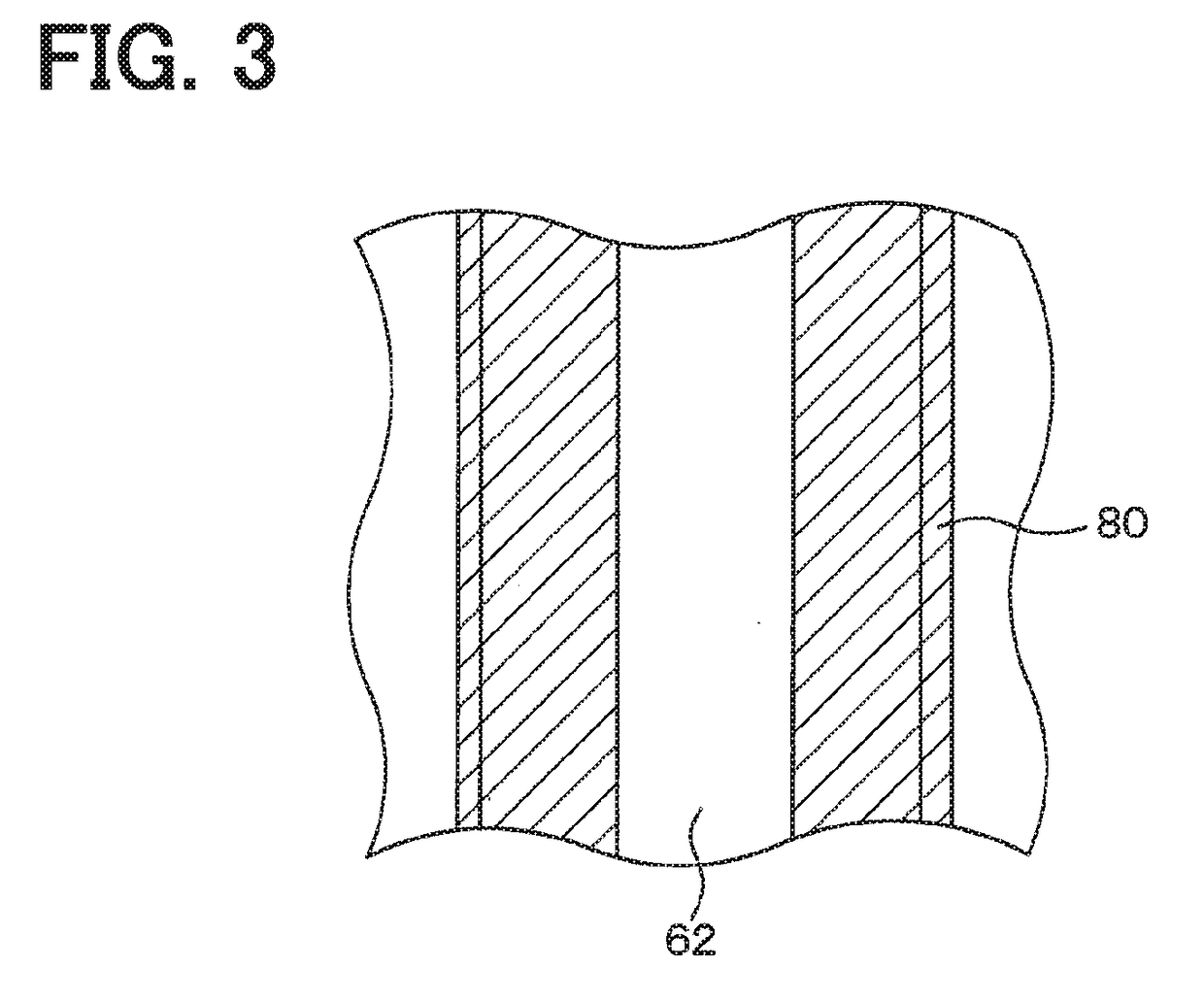

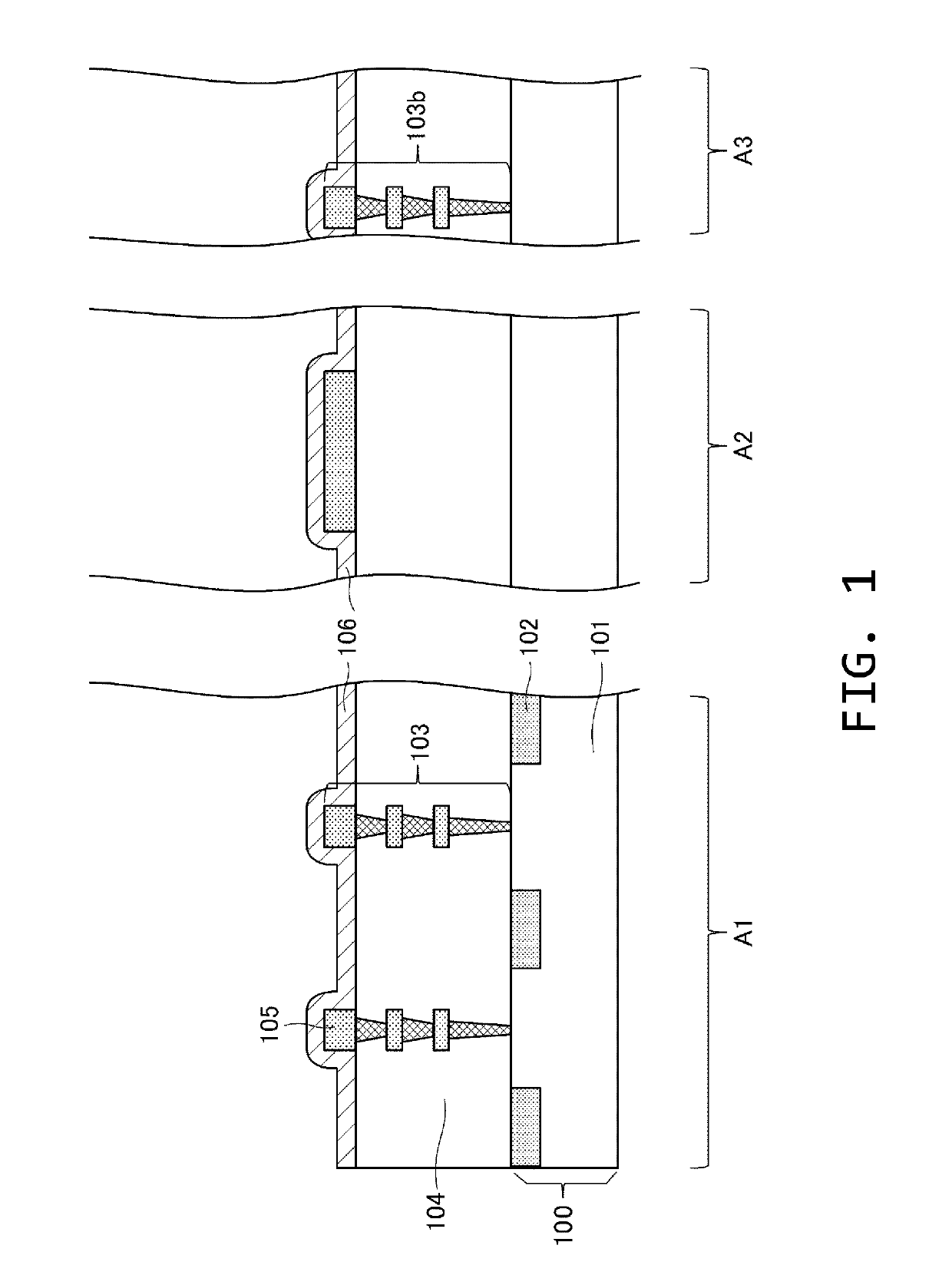

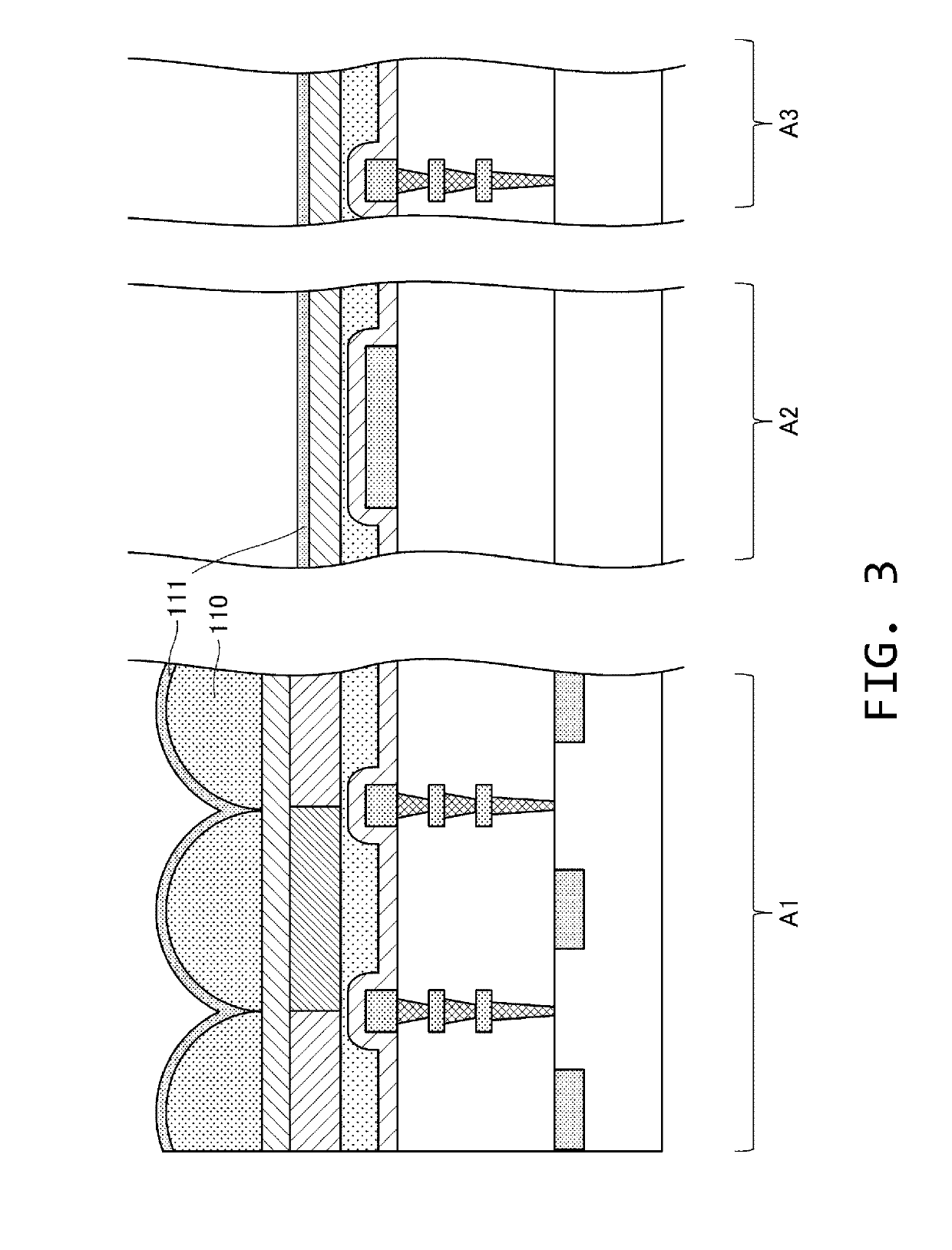

Semiconductor device and manufacturing method therefor

ActiveUS20170256505A1Without increase number of step and complexityOxidation be restrictSemiconductor/solid-state device detailsSolid-state devicesSheet resistanceEngineering

A semiconductor device includes: a substrate; a first wiring layer arranged above the substrate; a first insulating film covering the first wiring layer; a lower oxidation preventing film arranged on the first insulating film; at least one thin-film resistor arranged on the lower oxidation preventing film; an upper oxidation preventing film arranged on the at least one thin-film resistor; a second insulating film covering the lower oxidation preventing film, the at least one thin-film resistor, and the upper oxidation preventing film; a second wiring layer arranged on the second insulating film; and a third insulating film covering the second wiring layer. The first wiring layer overlaps an end portion of the at least one thin-film resistor when viewed in a normal direction of one surface of the substrate.

Owner:DENSO CORP

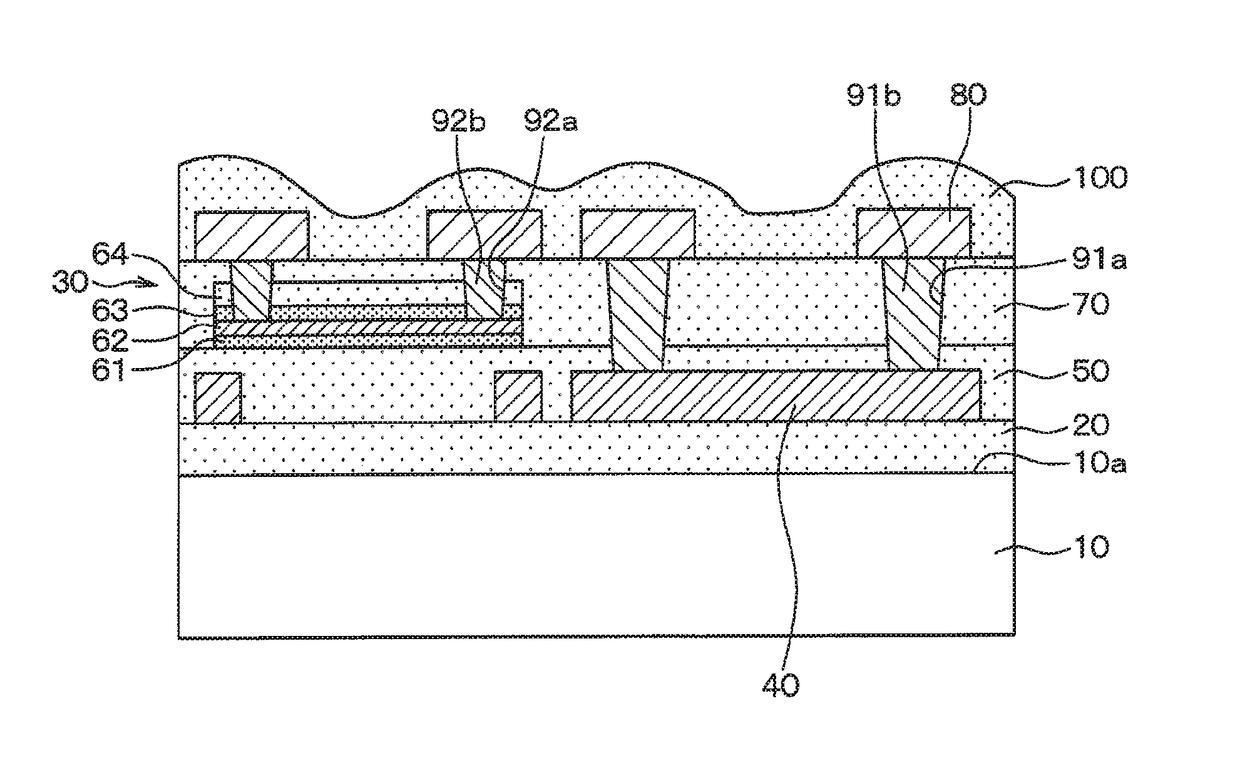

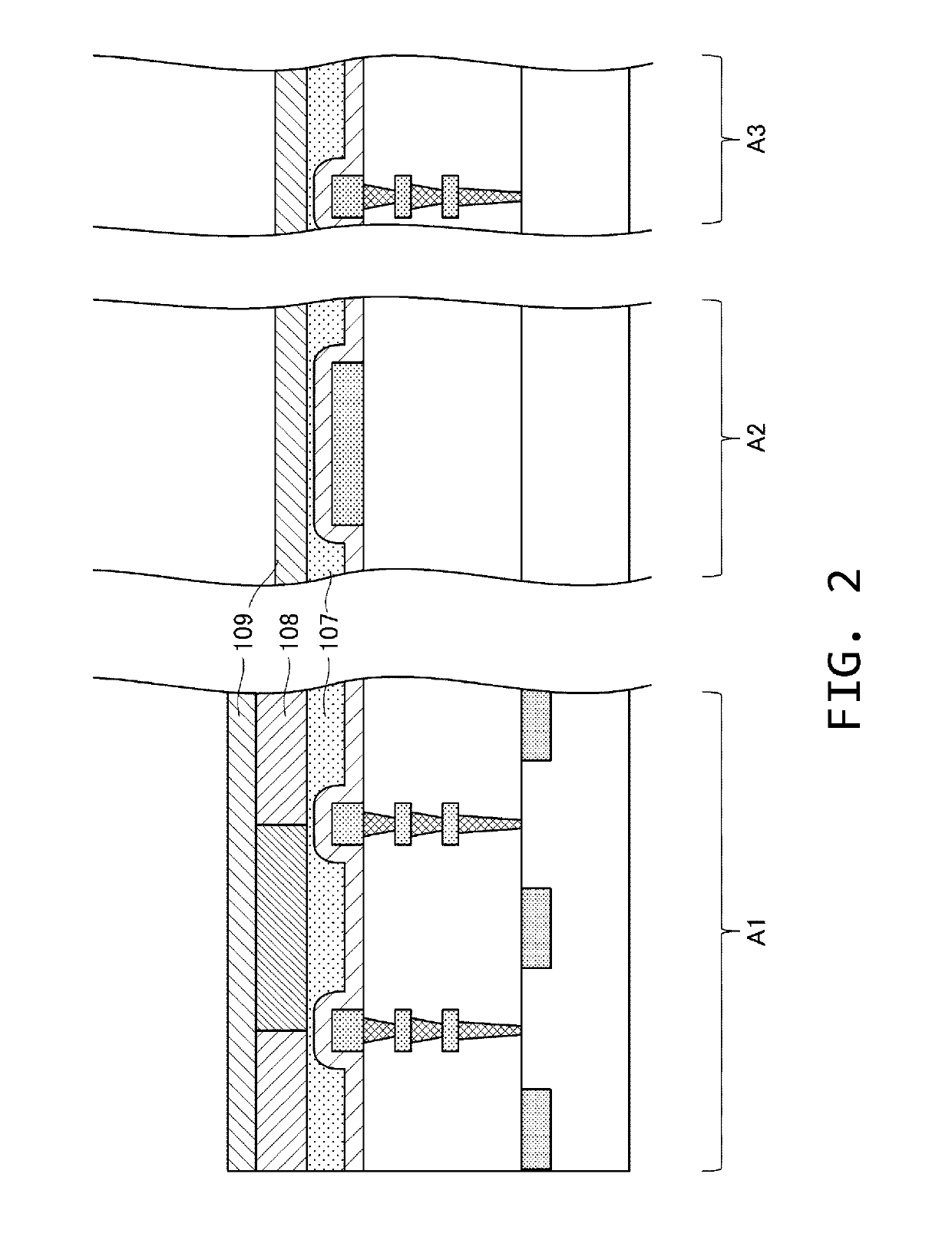

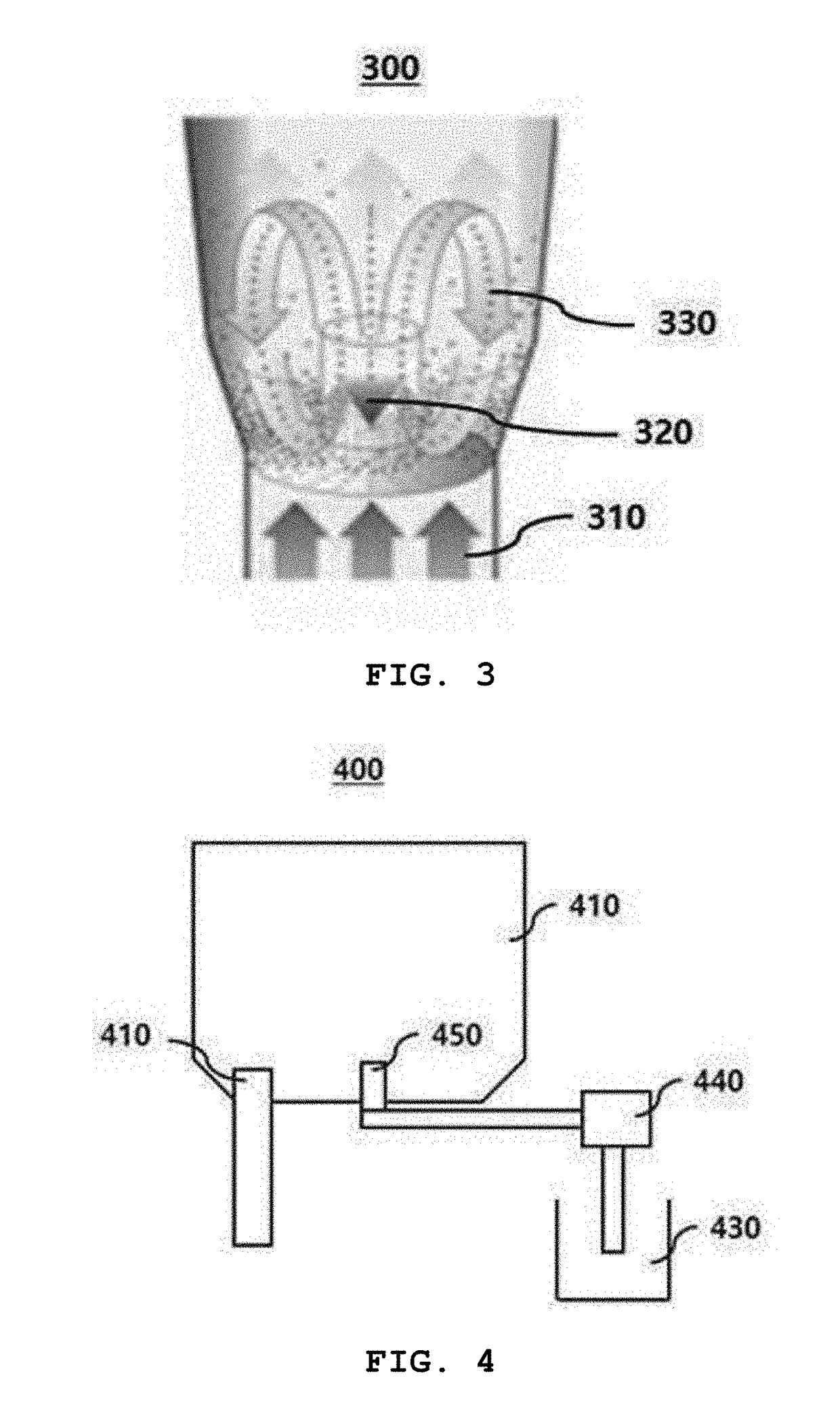

Image pickup device and display device

InactiveUS20190229220A1Improve moisture resistanceWithout deteriorating optical characteristicImage enhancementImage analysisDisplay deviceSemiconductor

Provided is an image pickup device including: a semiconductor substrate including a pixel region in which pixels are arranged and a pad electrode region on which a pad electrode portion is disposed; a wiring layer formed on the semiconductor substrate and including the pad electrode portion; a planarizing layer formed on the wiring layer and formed in a portion upper than the pad electrode portion in the pad electrode region, the planarizing layer including an organic material; and an inorganic film formed on the planarizing layer. An opening having a side wall portion is formed in the planarizing layer and the inorganic film so that an upper surface of the pad electrode portion is exposed. A metal film that covers at least a surface that forms the side wall portion of the planarizing layer is disposed in the opening.

Owner:CANON KK

Wet granulated cell culture medium and preparation method therefor

InactiveUS20170204363A1High strengthUniform shapeBacteriaCell culture mediaSpherical granuleSpray Granulation

Disclosed is a wet granulated cell culture medium which supports the growth of mammalian cells and / or insect cells and / or plant cells and bacteria, and a preparation method therefor. The method for preparation of a cell culture medium includes preparation of an aqueous cell culture medium solution and bottom spray granulation, and collecting spherical granules from the chamber and homogenizing the size of the granules.

Owner:AMBROTHIA

Air regulation valve, air regulation valve device, cabin suspension system and motor vehicle

ActiveCN110608314AOscillatingWith amplitudeCheck valvesValve members for absorbing fluid energyCushioningCoil spring

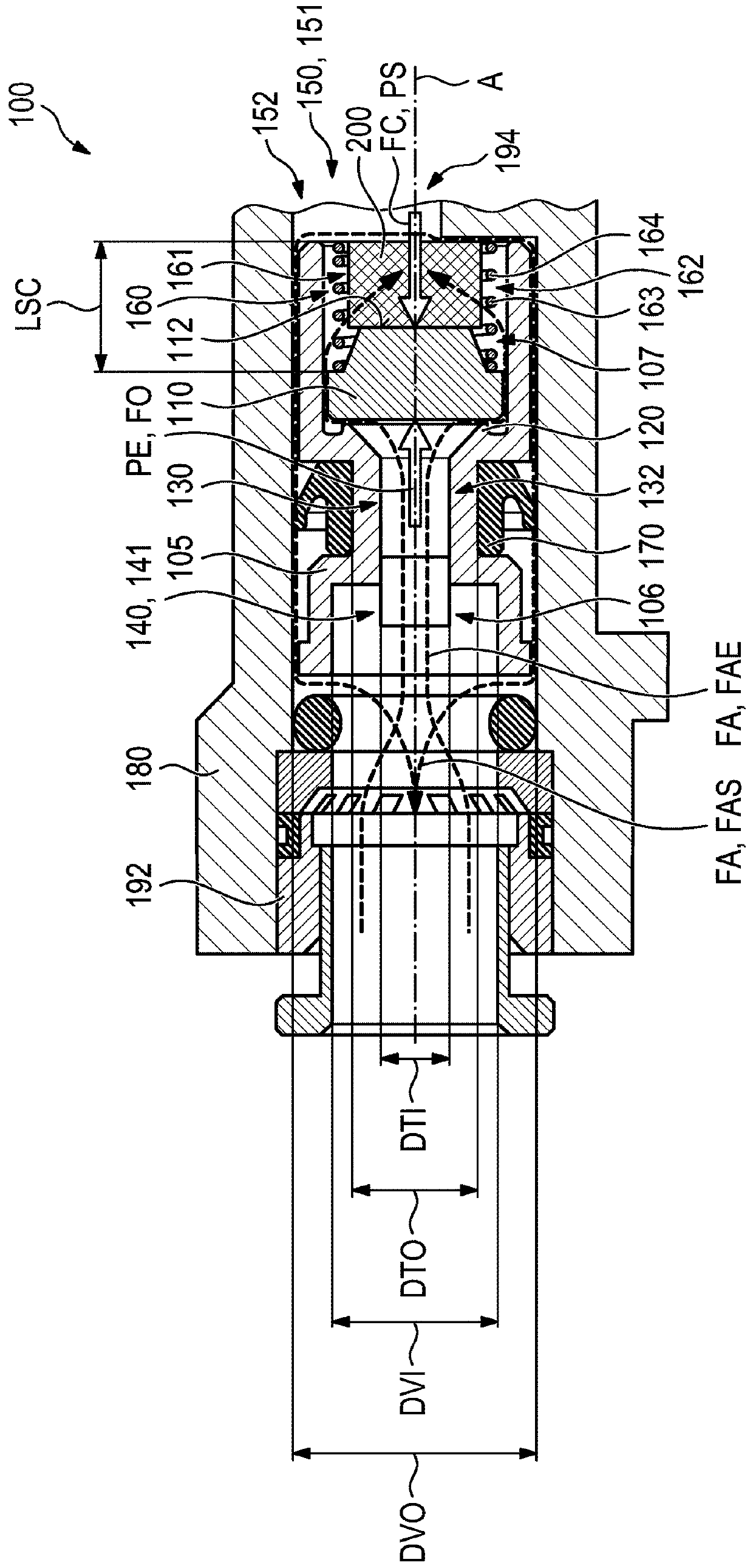

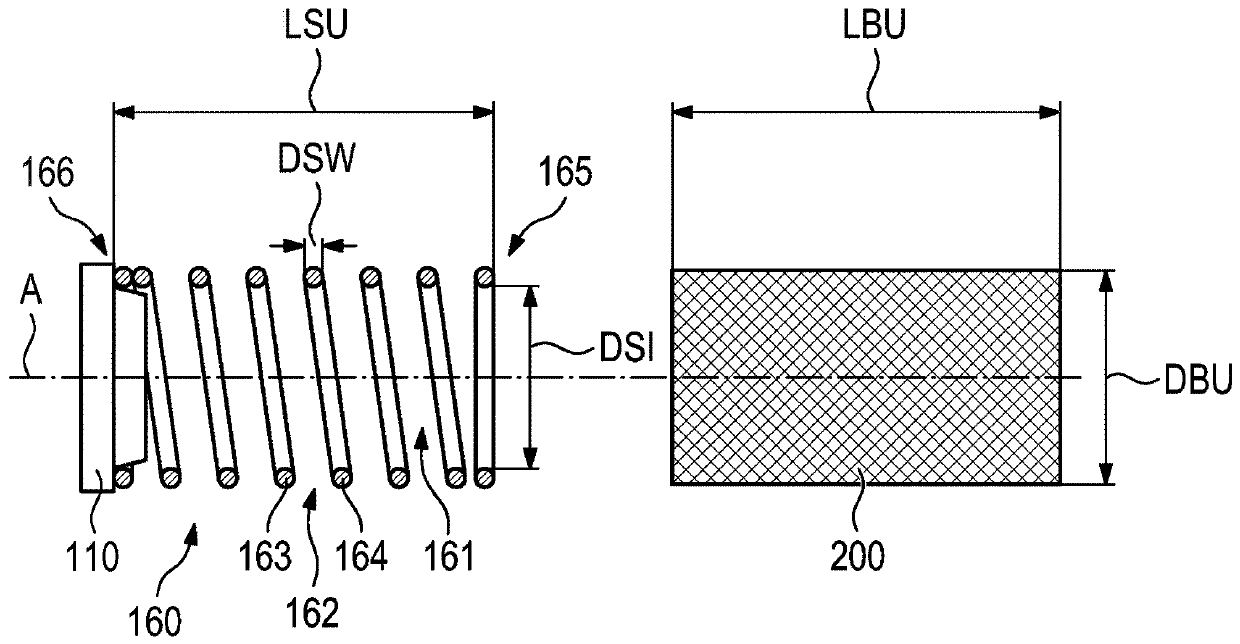

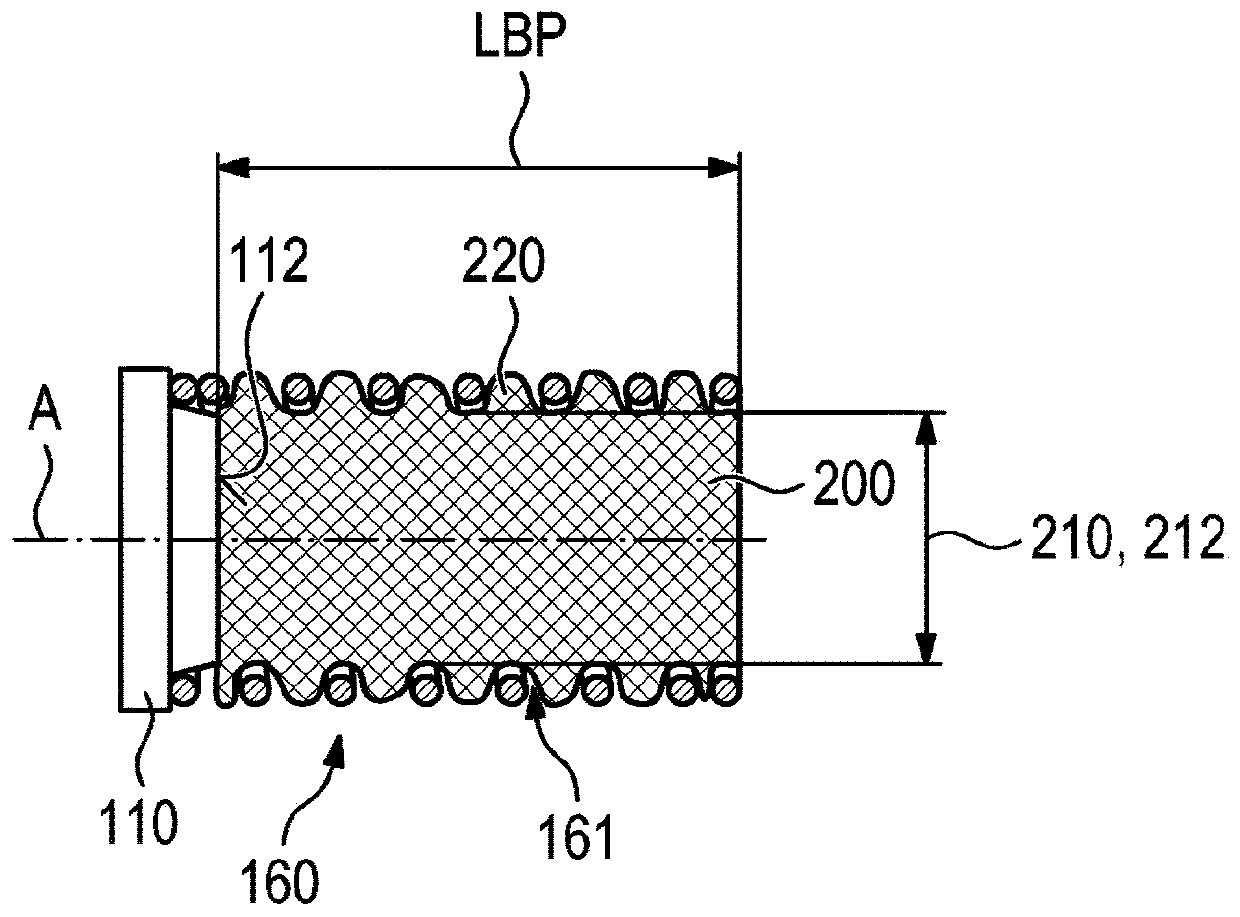

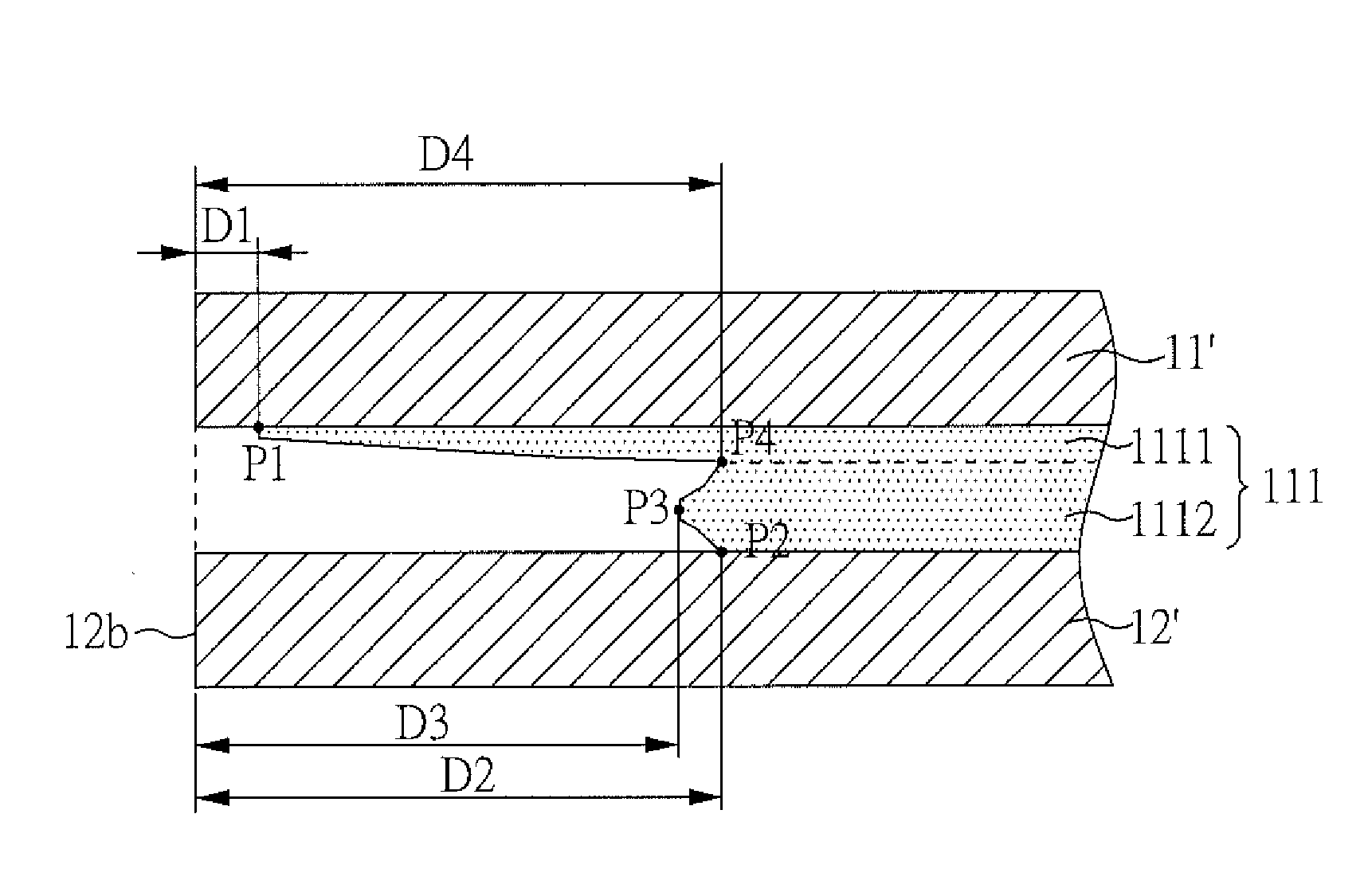

The invention relates to an air regulation valve, an air regulation valve device, a cabin suspension system and a motor vehicle. The air regulation valve is adapted to regulate an air flow (FA) for anair cushioning receptacle (802) in a motor vehicle (1000), wherein the air regulation valve (100) comprises: a valve seat (120), a valve body (110), and a valve passage element (105) with a passage inlet (140) on an inlet side (141) and a passage outlet (150) on an outlet side (151), wherein a coil spring (160) is in contact with the valve body (110) and a valve stop (152) on the outlet side (151), adapted to exert a closing force (FC) to press the valve body (110) to the valve seat (120). According to the invention a damping body (200) is arranged in an inner spring space (161) of the coil spring (160) such that the damping body (200) radially extends in a winding space (162) between a first coil winding (163) and a second coil winding (164) of the coil spring (160).

Owner:WABCO EURO BVBA SPRL

Immediate release film coatings containing medium chain glycerides and substrates coated therewith

ActiveUS9504654B2Good lookingReduce the amount requiredCoatingsDrageesPolyvinyl alcoholImmediate release

The present invention is directed to immediate release film coating compositions for use on oral dosage forms such as compressed tablets and other orally-ingestible substrates which contain medium chain glycerides as detackifiers. The film coating compositions can be applied either directly to a substrate or after the substrate has been coated with a subcoat. In preferred aspects, the polymer is polyvinyl alcohol and the medium chain glycerides are mixtures of caprylic (8 carbon chain) and capric (10 carbon chain) mono- and diesters of glycerin. Aqueous suspensions comprising the inventive film coating compositions, methods of applying the coatings to substrates and the coated substrates themselves are also disclosed.

Owner:BPSI HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com