Dampproof solid wood floor provided with core plate proper in tightness degree

A solid wood floor and core board technology, applied in the field of floor manufacturing, can solve the problems of expansion and shrinkage with limited margin, moisture resistance, waste of raw material wood, etc., to achieve enhanced moisture-proof effect, simple and convenient operation, and save production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

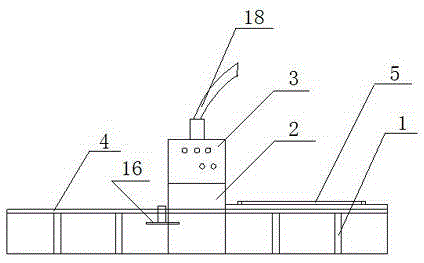

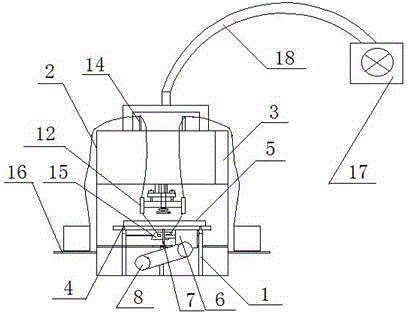

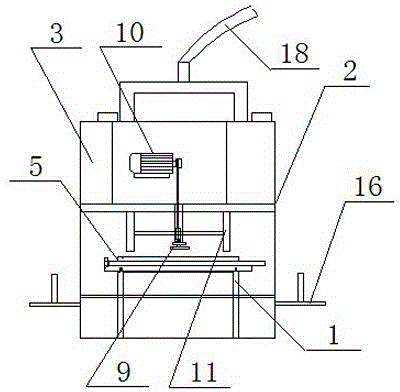

[0023] to combine Figure 1-6 Describe this embodiment, a moisture-proof solid wood floor with a suitable core board, including a front board 25, a core board 26 and a back board 27. The connecting rope 22 of direction setting is connected in series;

[0024] Its manufacturing method comprises the following process: selecting wooden laths 23 of the same size from discarded wooden laths at a temperature of 40 to 60 o After vacuum drying under C, the moisture content is controlled at 5% ~ 8%. The dried wooden laths 23 are aligned, and the grooves 24 are cut on the wooden laths 23 using a rope threading machine. Press the connection rope 22 in the middle, fix the surface plate 25 and the back plate 27 by adhesive 28 respectively on the upper and lower sides of the core board 26 to make a solid wood floor, and make the four sides of the solid wood floor and the solid wood floor The bottom surface of the floor is coated with moisture-proof oil; the ratio of the width of the groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com