Organic secondary encapsulation slurry for sheet-type resistors, and preparation method thereof

A secondary packaging, organic pulp technology, applied in resistors, non-adjustable metal resistors, circuits, etc., can solve the problems of low aging at room temperature, improve production costs and production operations, good resistance to humidity and heat environment erosion, The effect of good adhesion

Inactive Publication Date: 2017-04-12

西安英诺维特新材料有限公司

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

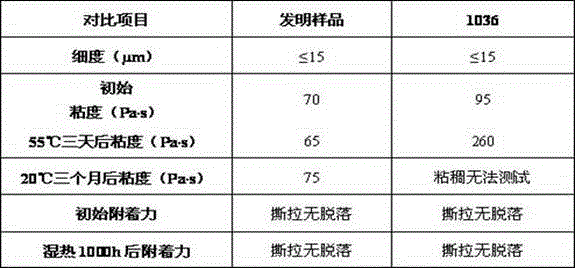

[0006] (1) This product belongs to organic slurry, and its solvent and resin are used at low temperature. Therefore, the product needs to be stored at low temperature. The general storage temperature is -10°C to 0°C, and the aging time at room temperature is low. Therefore, the present invention is aimed at storage temperature for research;

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0032] The present invention will be further explained by specific examples below. It should be understood that the following examples are only used to illustrate the present invention, but not to limit the scope of the present invention.

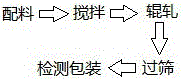

[0033] Attach the above slurry figure 2 The process is prepared into slurry, after testing and packaging, it can be used by customers.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to an organic secondary encapsulation slurry for sheet-type resistors, and a preparation method thereof, wherein the organic secondary encapsulation slurry at least contains, by weight, 10-30% of a black pigment, 30-50% of an oxide, 5-10% of an organic resin, and 30-50% of an organic resin, and mixing stirring and rolling with a three-roller grinder are performed to obtain the product. According to the present invention, the organic encapsulation slurry has advantages of good adhesion, good chemical stability, good stability, room temperature storage, and strong competitiveness and broad market prospects in the sheet-type resistor industry.

Description

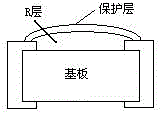

Technical field [0001] The invention belongs to electronic paste and a preparation method, and particularly relates to a secondary encapsulation paste for chip resistors and a preparation method. Background technique [0002] Electronic paste is one of the basic materials of electronic components and the core component of electronic components, which plays a decisive role in the performance of electronic products. Chip resistors are one of the industries that have developed very rapidly since the 21st century. , Due to its light, small and thin characteristics, leading the development of electronic products to the trend of miniaturization, precision and intelligence. [0003] The composition of chip resistors is as figure 1 As shown in the figure, it can be seen that the encapsulation layer protects the core functional layer of the chip resistor-the resistor layer. Therefore, the performance of the product plays a key role in the stability of the chip resistor components. The ea...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L61/06C08L63/00C08K3/04C08K3/36C08K3/22H01C7/00

CPCC08L61/06C08K3/04C08K3/22C08K3/36C08K2003/2227C08L63/00C08L2201/08C08L2203/20H01C7/00

Inventor 邢杰李娟

Owner 西安英诺维特新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com