Patents

Literature

55results about How to "Improve erosion performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tap hole stemming for large-scale blast furnace and preparation method

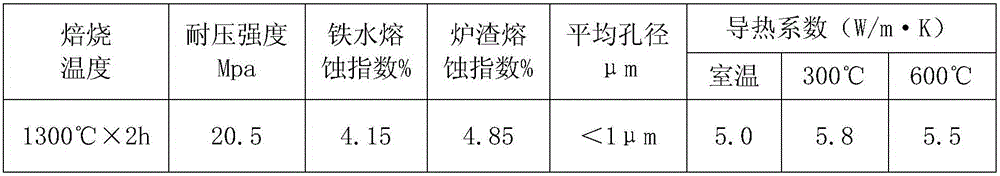

The invention discloses a tap hole stemming for a large-scale blast furnace and a preparation method. The stemming is composed of a binder and the following ingredients: by weight, 40-50 parts of brown aluminum oxide, 8-15 parts of silicon carbide, 6-12 parts of ferro-silicon nitride, 10-15 parts of clay, 6-9 parts of silicon powder, 2-5 parts of alpha-Al2O3, 6-10 parts of coke powder, 1-3 parts of graphite, and 4-6 parts of high-temperature pitch. The binder is tar. The preparation method comprises steps: according to the above ingredients and weight parts, raw materials are prepared, and mixed uniformly, then tar is added into the raw materials, the mixture is subjected to roller compaction and mixing to form a stemming material. The addition amount of the tar is controlled to make the Marshall value of the stemming material be 1100-1400 KPa, the stemming material is then subjected to pressing and molding to obtain final products. The prepared stemming is advantaged by good integrated performances, high intensity, small average hole size, good heat conductivity coefficient and good performances of resistance to slag and iron, corrosion and washing.

Owner:武钢集团有限公司

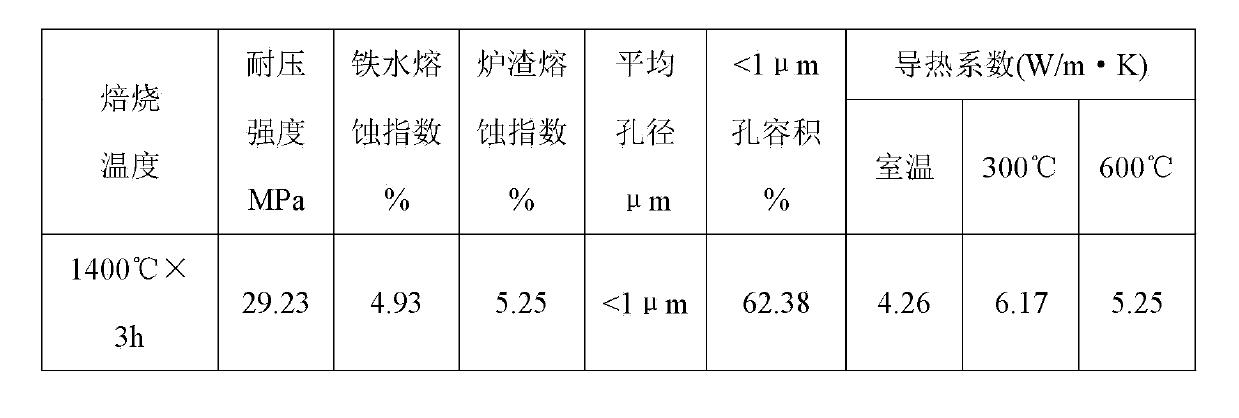

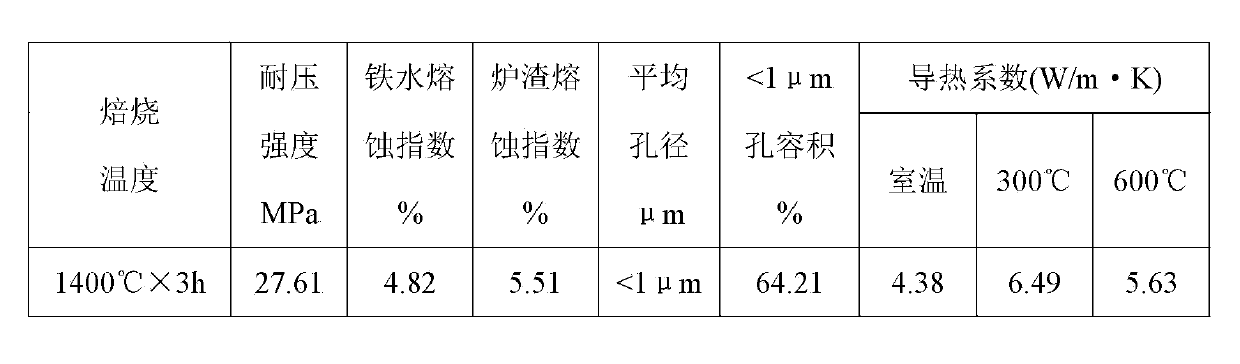

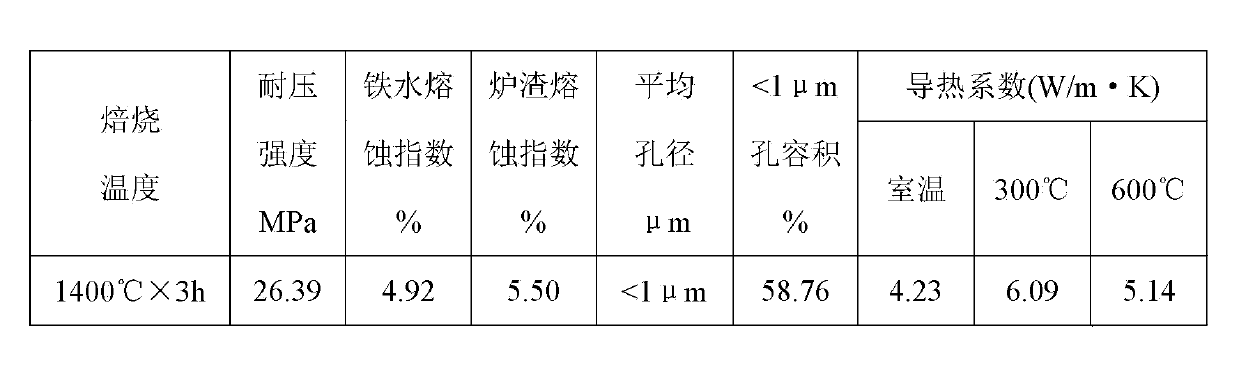

Tapping channel casting material with good oxidation resistance

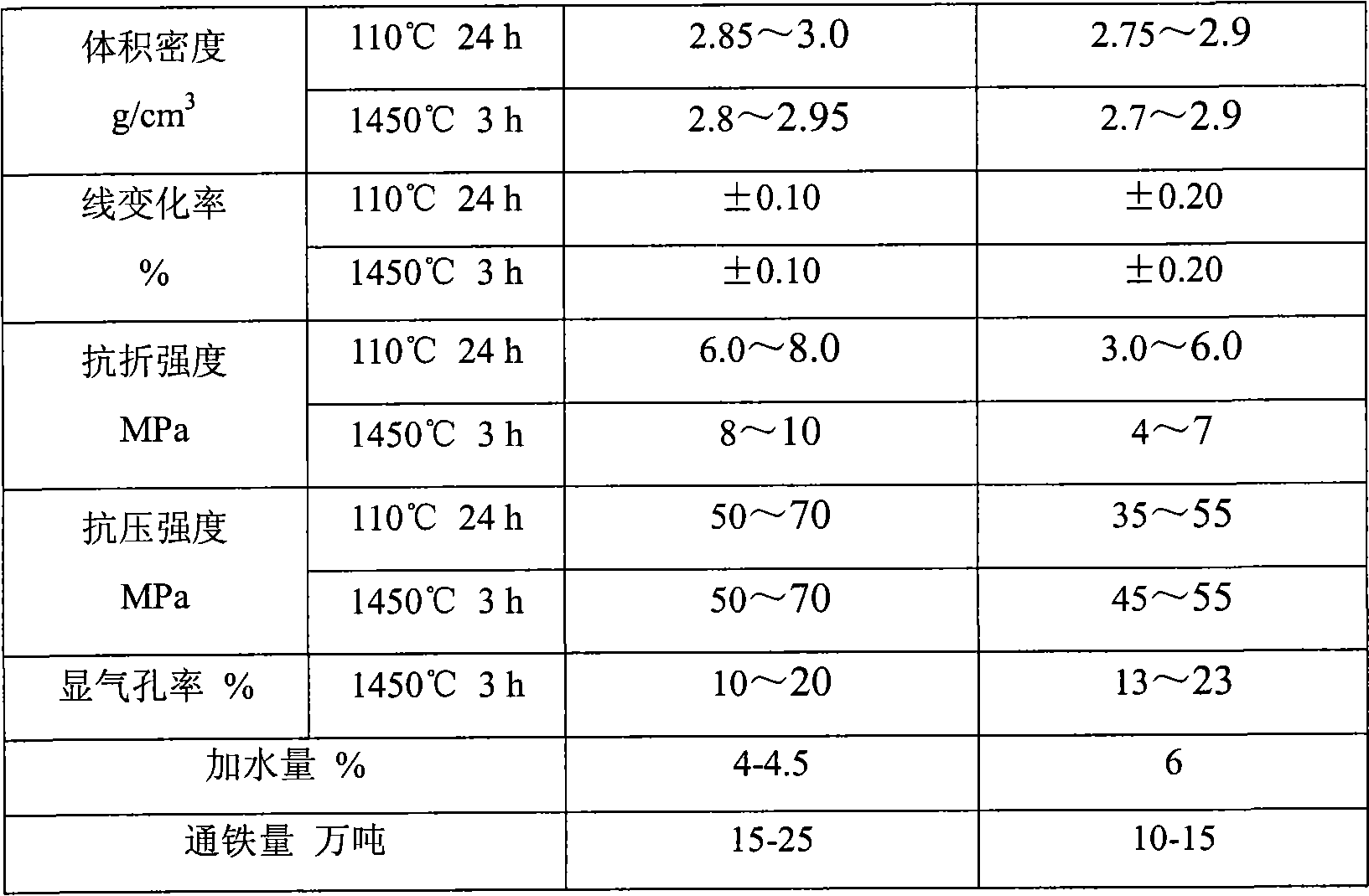

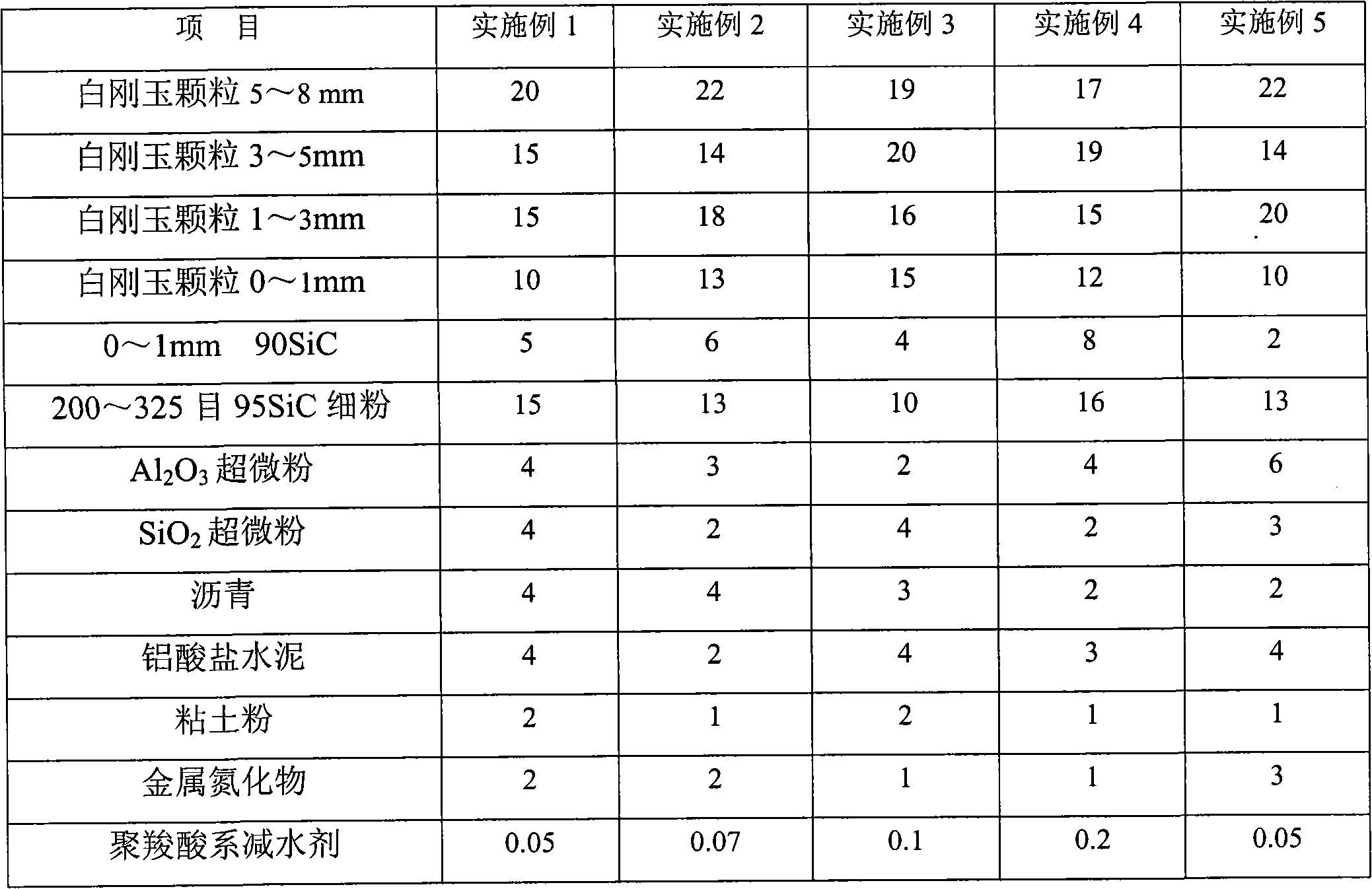

The invention provides a tapping channel casting material with good oxidation resistance. The casting material comprises the following raw materials in percentage by mass: 60 to 70 percent of white corundum granules with a diameter of 0 to 8 millimeters, 2 to 8 percent of silicon carbide with a diameter of 0 to 1 millimeter, 10 to 16 percent of fine silicon carbide powder of 200 to 325 meshes, 2 to 6 percent of Al2O3 super-micro powder, 2 to 4 percent of SiO2 super-micro powder, 2 to 4 percent of asphalt, 2 to 4 percent of aluminate cement, 1 to 2 percent of clay powder, 1 to 3 percent of metal nitride, and 0.05 to 0.2 percent of polycarboxylic acid water reducing agent. The tapping channel casting material has the advantages that: the water consumption of the casting material is obviously reduced, the porosity of the casting material is reduced, the compactness and the strength of the casting material are improved, the flowing property of the casting material is improved, and the constructability of the casting material is improved; the casting material has excellent oxidation resistance and corrosion resistance to molten slag and molten iron; and the service life of the casting material is greatly improved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

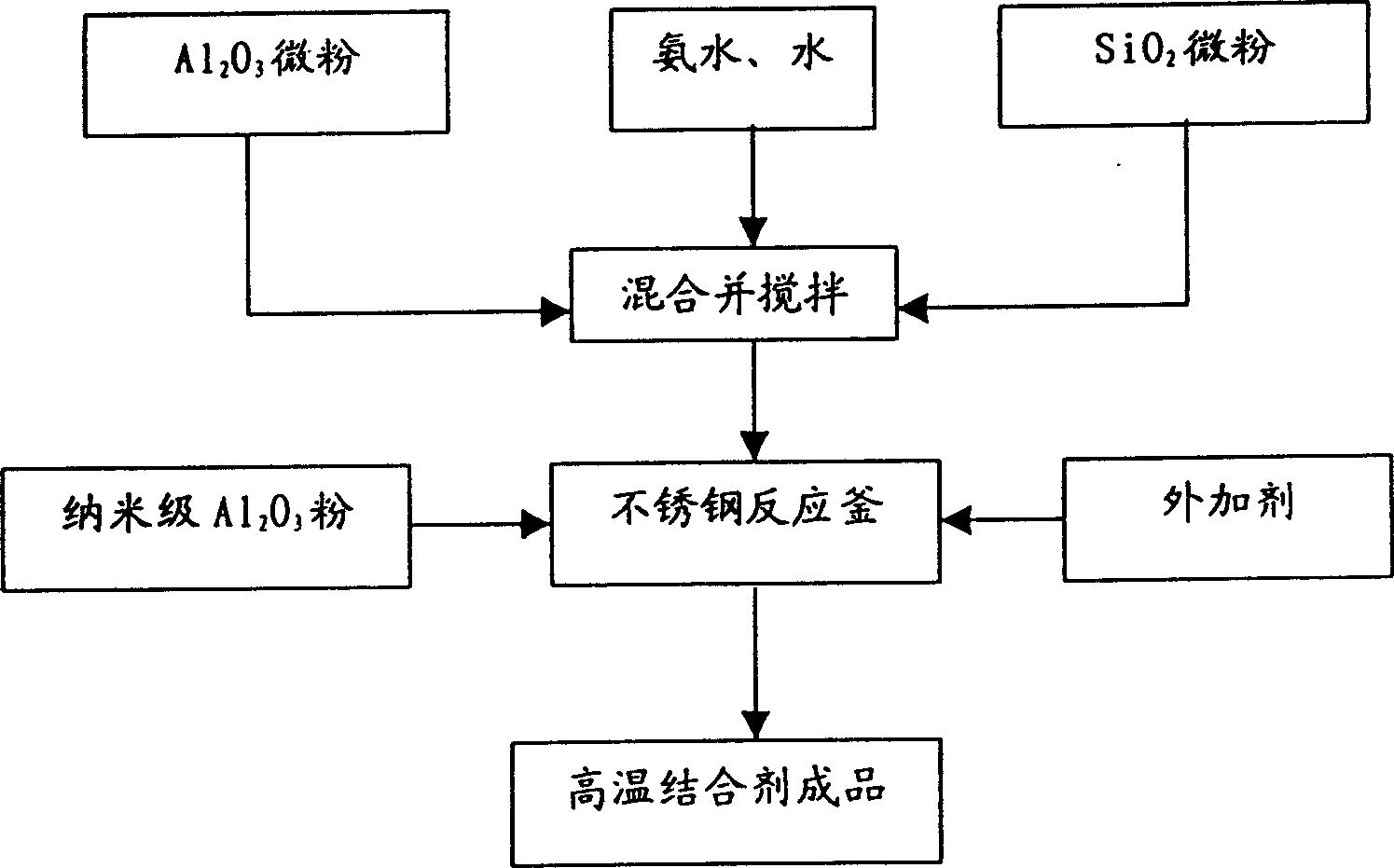

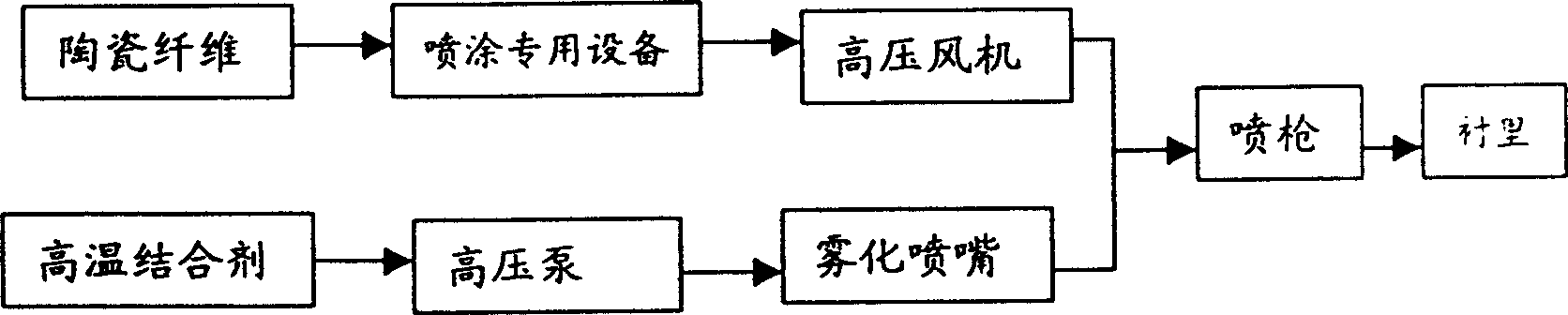

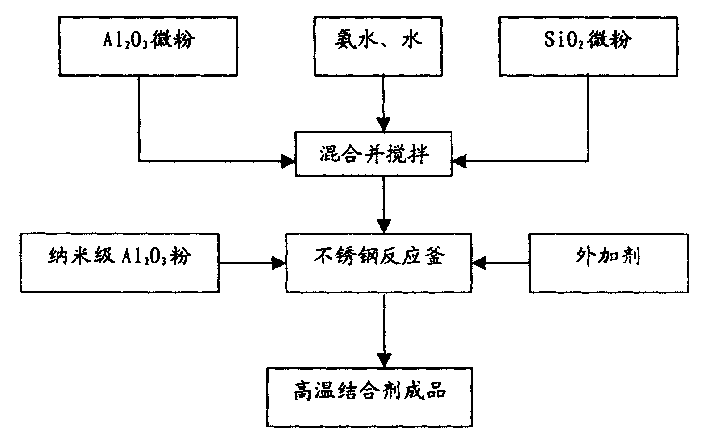

Compact ceramic fiber spraying lining and its working process

InactiveCN1186298CHigh thermal efficiencyExtended service lifeLiquid surface applicatorsFurnace componentsFiberAdditive ingredient

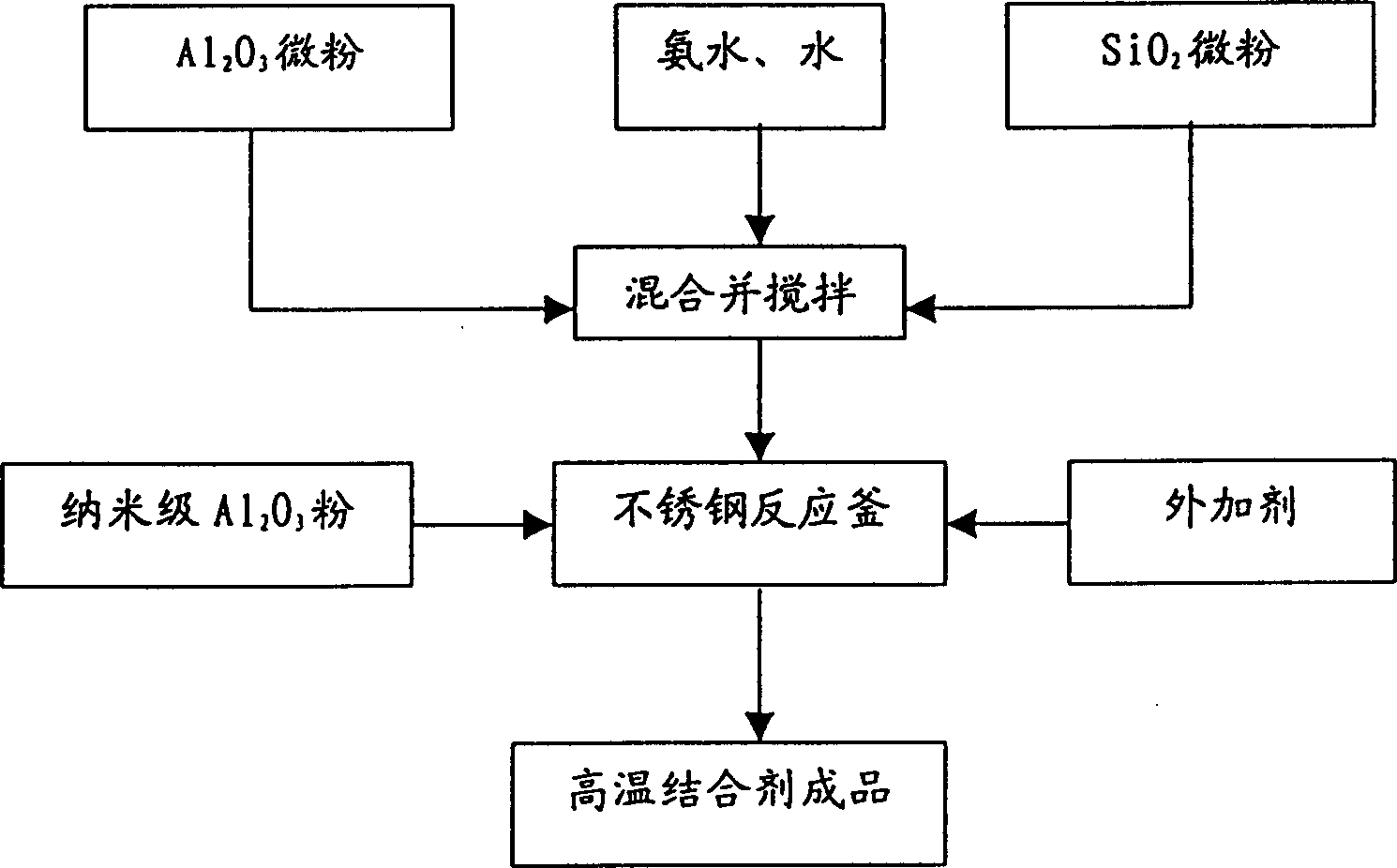

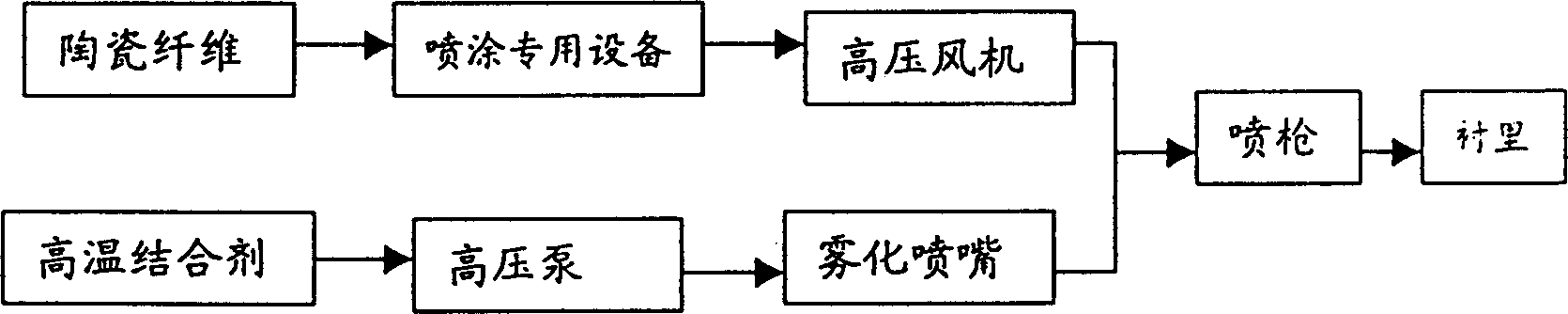

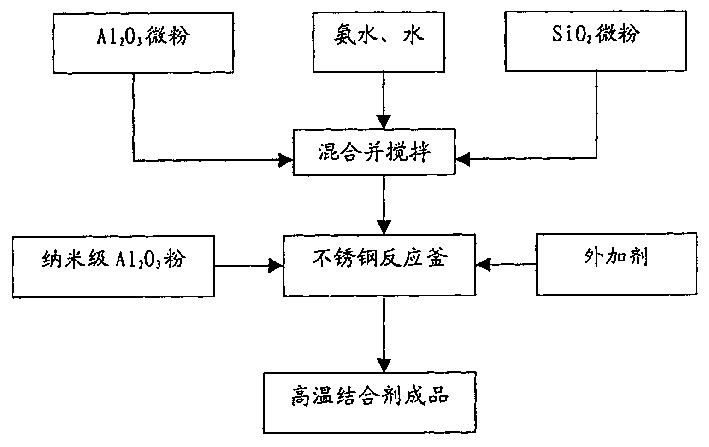

The compact ceramic fiber spraying lining consists of ceramic fiber and high temperature binding agent, and the high temperature binding agent has ingredients including fine alumina powder 2.8-3.2 wt%, fine silica powder 3.3-3.7 wt%, nanometer level alumina powder 0.9-1.1 wt%, and ammonia water 0.9-1.1 wt% except water. During forming ceramic fiber spraying lining, one spray gun with several atomizing nozzles around it is used, the high temperature binding agent is pumped into the atomizing chamber and sprayed via the atomizing nozzles while ceramic fiber is sprayed from the spray gun, and the sprayed binding agent and the ceramic fiber are mixed in the air and the mixture is jetted to the lined surface to form the compact ceramic fiber spraying lining. With high strength, excellent waterproof performance, high heat shock resistance, easy construction and low cost, the sprayed lining is suitable for industrial furnace, tower, cylinder, etc.

Owner:北京嘉邦环保工程技术有限责任公司

Aluminum-plastic separating agent and preparation method thereof

InactiveCN102532592AAchieve separationImprove erosion performancePlastic recyclingProcess efficiency improvementPlastic packagingOrganic solvent

The invention relates to an aluminum-plastic separating agent and a preparation method thereof. The separating agent comprises the following components in part by weight: 1 to 25 parts of water, 5 to 50 parts of acidic compound and 25 to 95 parts of organic solvent. The preparation method comprises the following steps of: weighing corresponding components in the proportion in turn, and properly mixing to obtain a uniform phase; and soaking aluminum-plastic crushed matters in the prepared separating solution, stirring, separating and washing to finally obtain 80 to 90 percent of plastic and 8 to 15 percent of aluminum. The separating agent is difficult to volatilize, has a high speed of separating the aluminum and plastic, and does not have oxidation corrosion on the aluminum. In addition, the separating agent has the advantages of readily available raw materials, low environmental pollution and reuse, production equipment and process are simple, and the cost is low. The product prepared by the invention can be widely applied to aluminum-plastic separation of aluminum-plastic packaging materials such as medicines, foods, cosmetics, daily products, industrial products and the like.

Owner:CHANGZHOU INST OF CHEM

Periclase-magnesium aluminate spinel refractory material for rotary cement kiln and preparation method thereof

The invention relates to a periclase-magnesium aluminate spinel refractory material for a rotary cement kiln and a preparation method thereof. according to the technical scheme, 75-95wt% of periclase-magnesium aluminate spinel composite material, 4-20wt% of magnesite and 0.5-5wt% of magnesium aluminate spinel are mixed together to obtain a mixture; a binder accounting which is 3-8wt% of the mixture is added to the mixture and mixed evenly, and then the final mixture is mechanically pressed and formed; the formed blank is dried at 110 DEG C for 8-36 hours and then fired at 1500-1650 DEG C, and furthermore, heat is preserved for 4-15 hours, and finally, the periclase-magnesium aluminate spinel refractory material for the rotary cement kiln is obtained. The preparation method of the periclase-magnesium aluminate spinel refractory material for the rotary cement kiln is simple; the periclase-magnesium aluminate spinel refractory material prepared has the characteristic of controllable distribution of magnesium aluminate spinel, and also the characteristics of good coating formation property, good thermal shock resistance and high medium erosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Alumina-carbon-based flow distributing opening and preparing method thereof

InactiveCN105819880AImprove high temperature resistanceImprove erosion abilityPolymer scienceLiquid metal

The invention relates to an alumina-carbon-based flow distributing opening and a preparing method thereof. According to the technical scheme, the preparing method includes the steps that 45wt%-55wt% of large high-aluminum raw particles, 15wt%-25wt% of small high-aluminum raw particles, 22wt%-28wt% of fine high-aluminum raw powder and 6wt%-12wt% of crystalline flake graphite serve as mixing materials, phenolic resin of 4wt%-8wt% of the mixing materials is additionally added, and then the mixing material and the phenolic resin are added into a mixer to be mixed to obtain mixed mud materials; the mixed mud materials are added into a mold and mechanically molded, and an alumina-carbon-based flow distributing opening blank is prepared; the alumina-carbon-based flow distributing opening blank is subjected to heat preservation for 8 hours to 12 hours at the temperature of 180 DEG C to 240 DEG C, and the alumina-carbon-based flow distributing opening is prepared. The alumina-carbon-based flow distributing opening has the advantages of being good in high temperature resistance, excellent in thermal shock resistance and high-temperature-liquid-metal erosion resistance and good in flow distributing effect, and the prepared alumina-carbon-based flow distributing opening meets the use requirement of the twin-roll thin-strip-blank continuous casting technology.

Owner:WUHAN UNIV OF SCI & TECH

Tap hole medium-temperature-sintering environment-friendly stemming for large- and medium-sized blast furnaces and preparation method of tap hole medium-temperature-sintering environment-friendly stemming

The invention relates to tap hole medium-temperature-sintering environment-friendly stemming for large- and medium-sized blast furnaces and a preparation method of the tap hole medium-temperature-sintering environment-friendly stemming.The spreading drying material of the stemming is reasonable in composition and combination and is characterized in that the spreading drying material uses high-aluminum clinker and coke powder as aggregate and brown aluminum oxide, clay and silicon carbide as powder, ferro-silicon nitride content is adjusted, micro-powder such as silicon powder and alpha-aluminum oxide and anti-burst fibers are added, and the binder is the mixture of 9-11 parts of tar, 2-5 parts of resin and 1-3 parts of anthracene oil.The tap hole medium-temperature-sintering environment-friendly stemming has the advantages that the anti-burst fibers are added, so that the heat conduction ability of the stemming is increased, combustion carbonization of the tap hole stemming can be achieved during high-temperature exhausting, and the opening performance of the stemming is improved; the small amount of fire-resistant materials such as the brown aluminum oxide, the silicon carbide and the ferro-silicon nitride with excellent slag iron corrosion resistance are combined with the anti-burst fibers which can exhaust and combust fast and the high-aluminum clinker which is low in cost, the molten iron and slag corrosion resistance of the stemming is increased greatly, and the tapping time of the stemming is guaranteed, and environment pollution is reduced.

Owner:HEBI RONGMING TECH CO LTD

Arc sprayed cored wire suitable for re-melting

ActiveCN103173711AImprove wear resistanceImprove erosion performanceMolten spray coatingPorosityThermal spraying

The invention belongs to the field of hot spraying, and discloses an arc sprayed cored wire suitable for re-melting. The powder core comprises the components of, by mass, 6-15% of Ni, 5-13% of Cr, 4-8% of Al, 5% of B, 3% of Nb, and 1-3% of mixed rare earth nickel powder. The mixed rare earth nickel powder component is composed of, by mass, 60% of Ni and 40% of mixed RE. The mixed RE is composed of, by mass, 25-28% of La; 48-52% of Ce, 14-17% of Nb, and 4-6% of Pu. The balance of the powder core is Fe. An arc sprayed coating provided by the invention has an average Vickers hardness of 530HV0.1, an average bonding strength of 38MPa, an average porosity of 14.2%, and an oxide content of 8.72%. After a re-melting treatment upon the sprayed coating, an average Vickers hardness of the re-melted layer is improved to 770HV0.1, and the layer substantially forms metallurgical bonding with a substrate. After re-melting treatment, the wire material coating has good wear resistance, erosion resistance, and loading resistance. The cored wire provided by the invention can be used in surface treatments of parts with requirements on high impact resistance, large alternating load, and high bonding strength in the fields of engineering machinery, mining machinery, and automobile industry.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Automatic repairing and remanufacturing method of turbine blade

The invention discloses an automatic repairing and remanufacturing method of a turbine blade and relates to the technical field of repairing and remanufacturing of turbine blades. The automatic repairing and remanufacturing method comprises the technological steps of scanning an original blade, establishing a three-dimensional model, conducting reverse modeling through a computer, planning a cutting area and a cutting path, conducting cutting, scanning a gap, conducting reverse modeling, conducting gap overlaying planning, conducting printing overlaying, conducting heat treatment, conducting nondestructive examination, conducting machining and conducting scanning. The determined blade is scanned through a robot 3D scanning system, the 3D model of the blade is obtained through software treatment, the to-be-cut area and the cutting path are defined on the model, and then the damaged portion is completely removed or an area to be manufactured is established. By the adoption of the technical scheme, the problems of water erosion damage repair of the blade, repair and upgrading of the blade and the like can be rapidly and efficiently solved at a high quality; and compared with traditional machining, the automatic repairing and remanufacturing method simplifies the machining technology, greatly improves the on-site machining efficiency of the blade and determines a new direction forefficient and intelligent repairing and remanufacturing for the damage of the turbine rotor blade.

Owner:DONGFANG ELECTRIC WUHAN NUCLEAR EQUIP

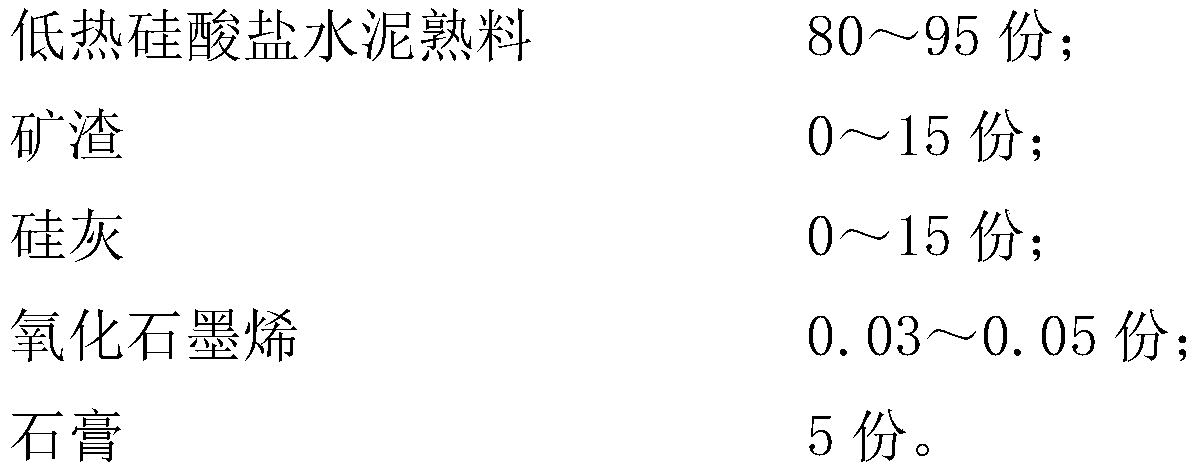

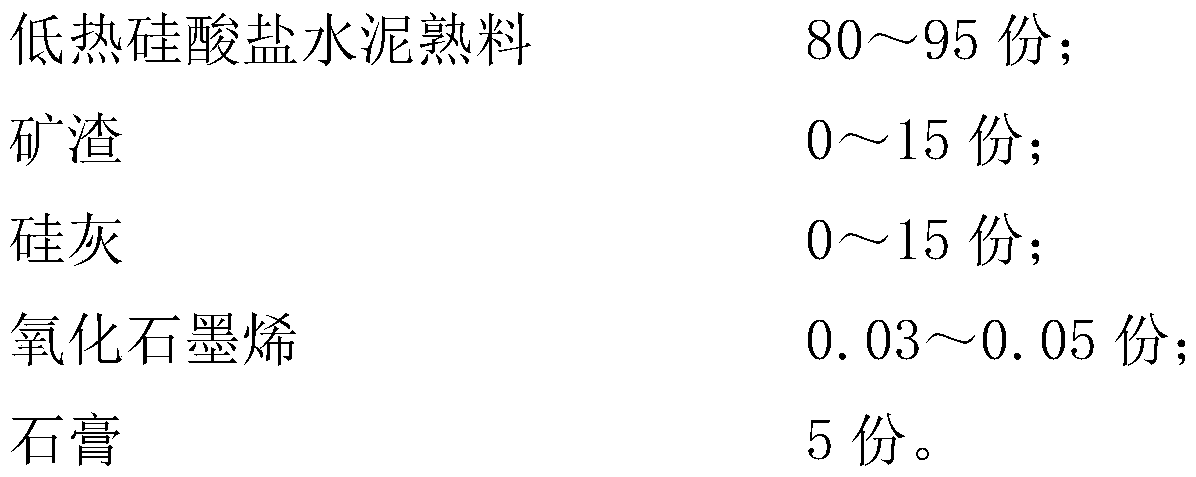

Low-heat Portland cement with high early strength and preparation method and application thereof

InactiveCN110204228AHigh heat of hydrationHigh low heat of hydrationCement productionCrack resistanceSlag

Owner:CHINA BUILDING MATERIALS ACAD

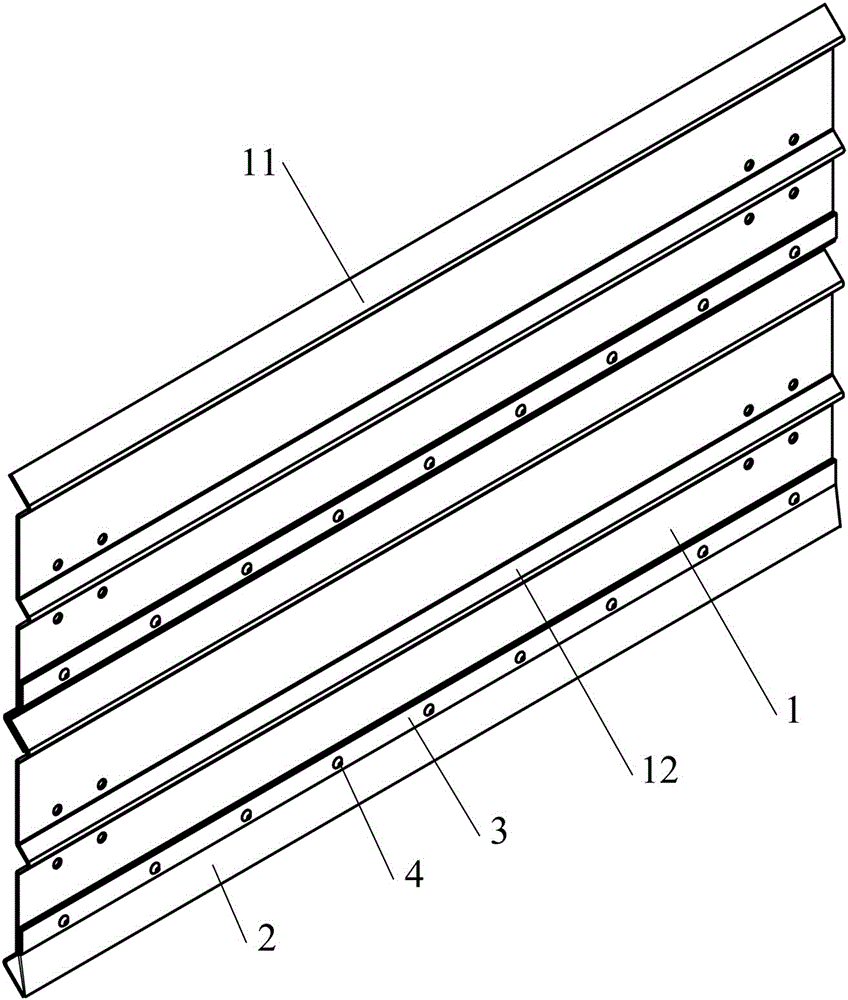

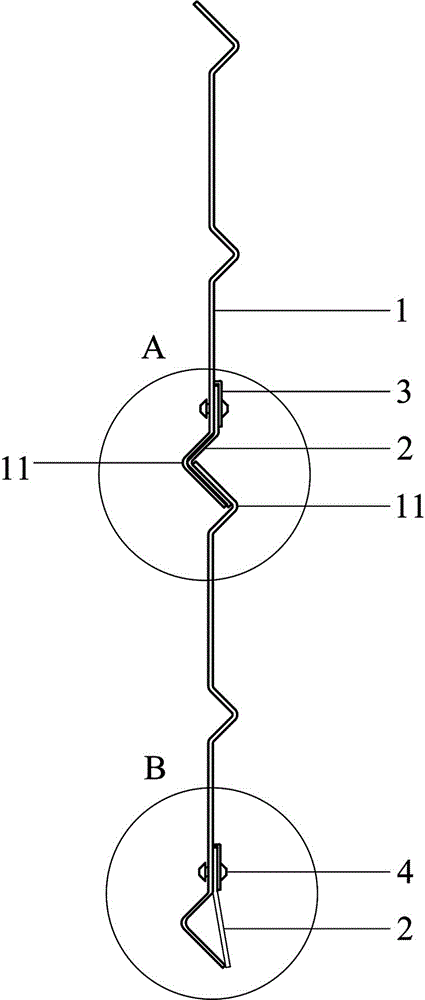

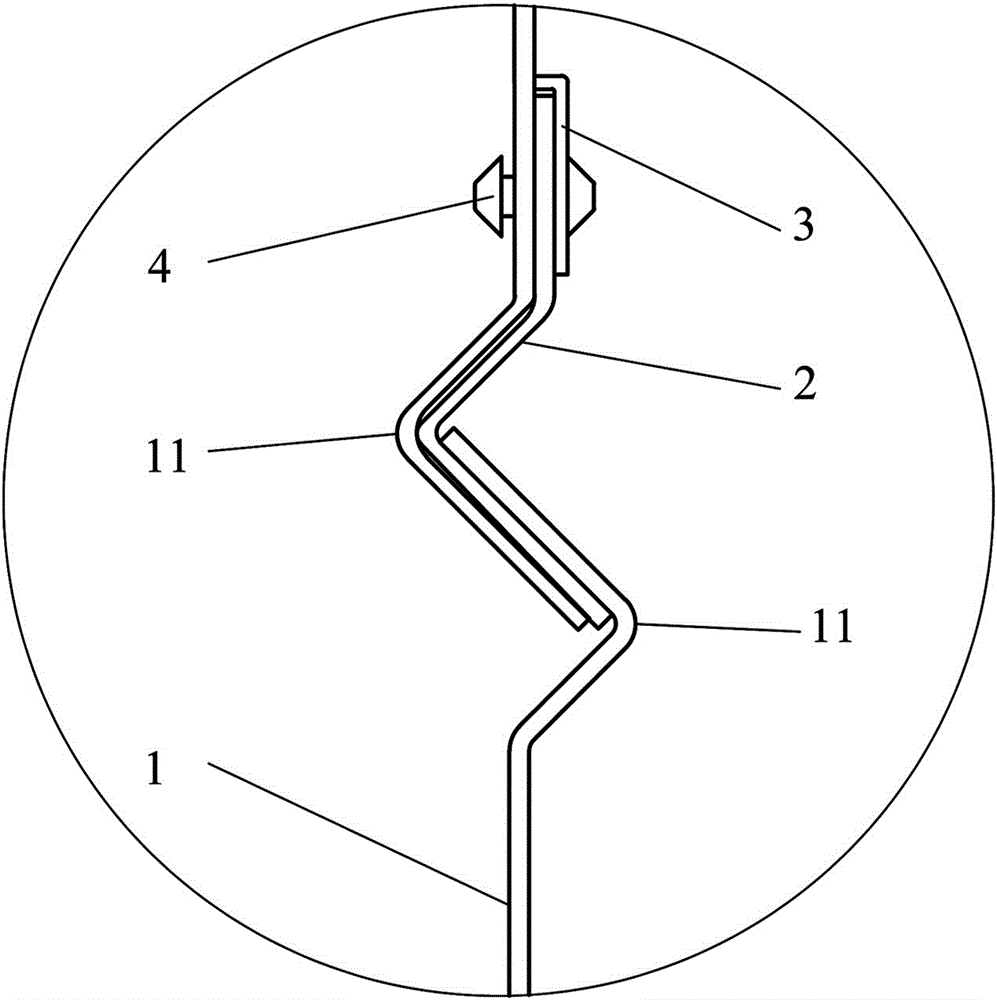

Vale blade sealing structure and air valve

The invention discloses a valve blade sealing structure and an air valve. The valve blade sealing structure comprises valve blades. The upper ends and the lower ends of the valve blades are provided with lap joint parts. The directions of the lap joint parts of every two adjacent valve blades are opposite. Each lap joint part is composed of a folding start face obliquely extending out and a folding stop face reversely folded back. A flexible sealing strip is arranged on one side of one end of the lap joint. A pressing strip is arranged at the upper end of the sealing strip. The pressing strip and the sealing strip are fixed to the valve blades through rivets in an inserting manner. The lower end of the sealing strip is squeezed by and attached to the folding stop faces of the two corresponding adjacent lap joint parts. The valve blade sealing structure is simple and convenient to install; and when the air valve is closed, the flexible sealing strip is deformed under the acting force of the lap joint parts of the valve blades so as to adaptively fill the connecting gaps between the lap joint parts of the valve blades, and therefore the leakage amount of air valves such as an air volume regulating valve, a fire valve, a smoke exhausting fire valve and a smoke exhausting valve is controlled to be reduced as much as possible.

Owner:ZHONGHANG DAJI ENG PRODS SHENZHEN

Novel siliceous nuclear power sacrificial material and preparation method thereof

The invention discloses a novel siliceous nuclear power sacrificial material and a preparation method thereof. The novel sacrificial material is mainly prepared from 325-335 parts of PII.52.5-grade portland cement, 175-190 parts of pulverized fuel ash, 15-25 parts of silicon powder, 1,650-1,750 parts of quartz sand, 145-155 parts of water, 7-10 parts of water reducing agent, 1-1.5 parts of polypropylene fibers and 0.5-1.5 parts of sulfonated graphene. The preparation technology is simple, and a common forcing-type single-horizontal-shaft concrete mixer is adopted for preparing the nuclear power sacrificial material which is excellent in liquidity, strength and corrosion resistance. The prepared novel siliceous iron nuclear power sacrificial material has the advantages of good working performance, high strength, good corrosion resistance and the like, is mainly applied to a current third-generation nuclear power station reactor core catcher and has high engineering application value.

Owner:NANJING FORESTRY UNIV

Novel ferrosilicon nuclear power sacrifice material and preparation method thereof

The invention discloses a novel ferrosilicon nuclear power sacrifice material and a preparation method thereof. The novel ferrosilicon nuclear power sacrifice material is primarily composed of 375-400parts of PII.52.5 level silicate cement, 130-145 parts of coal ash, 15-25 parts of silicon powder, 950-1100 parts of quartz sand, 900-1050 parts of hematite iron ores, 175-185 parts of water, 7-10 parts of a water reducer, 1-1.6 parts of polypropylene fibers and 0.5-1.6 parts of sulfonated graphene. The preparation process is simple. The nuclear power sacrifice material which is excellent in flowability, strength and corrosion resistance can be prepared by adopting a conventional forced single horizontal shaft concrete mixer. The prepared novel ferrosilicon nuclear power sacrifice material has the advantages of good working property, high strength, good corrosion resistance, is primarily applied to an existing reactor core trap of a third generation nuclear power plant and has wide engineering application value.

Owner:NANJING FORESTRY UNIV

Compact ceramic fiber spraying lining and its working process

InactiveCN1458126AHigh thermal efficiencyExtended service lifeLiquid surface applicatorsFurnace componentsFiberAdditive ingredient

The compact ceramic fiber spraying lining consists of ceramic fiber and high temperature binding agent, and the high temperature binding agent has ingredients including fine alumina powder 2.8-3.2 wt%, fine silica powder 3.3-3.7 wt%, nanometer level alumina powder 0.9-1.1 wt%, and ammonia water 0.9-1.1 wt% except water. During forming ceramic fiber spraying lining, one spray gun with several atomizing nozzles around it is used, the high temperature binding agent is pumped into the atomizing chamber and sprayed via the atomizing nozzles while ceramic fiber is sprayed from the spray gun, and the sprayed binding agent and the ceramic fiber are mixed in the air and the mixture is jetted to the lined surface to form the compact ceramic fiber spraying lining. With high strength, excellent waterproof performance, high heat shock resistance, easy construction and low cost, the sprayed lining is suitable for industrial furnace, tower, cylinder, etc.

Owner:北京嘉邦环保工程技术有限责任公司

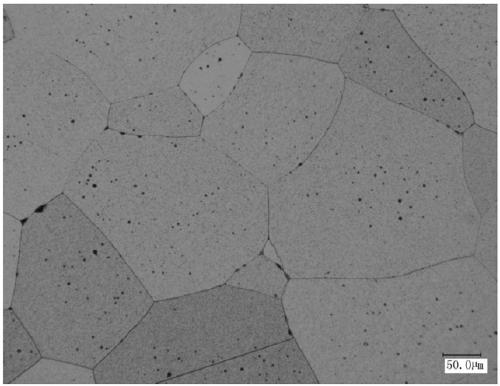

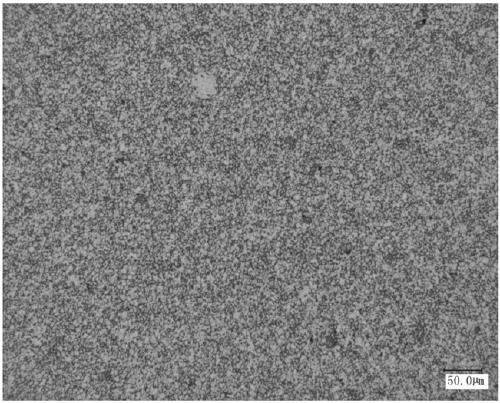

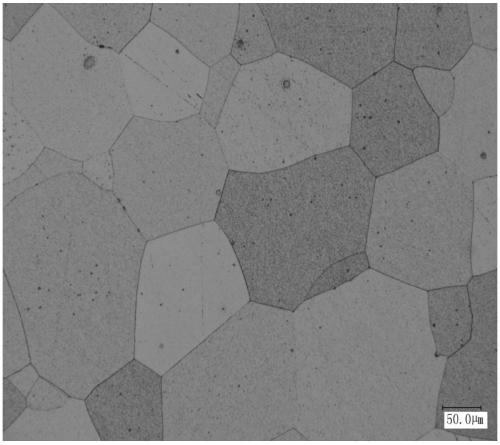

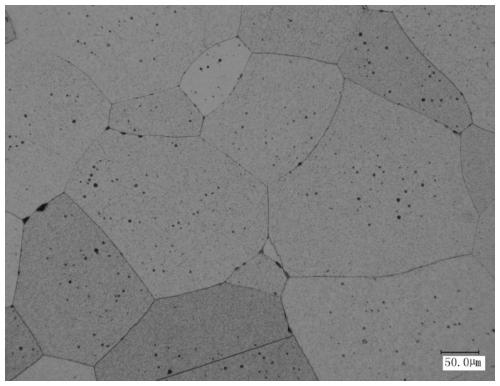

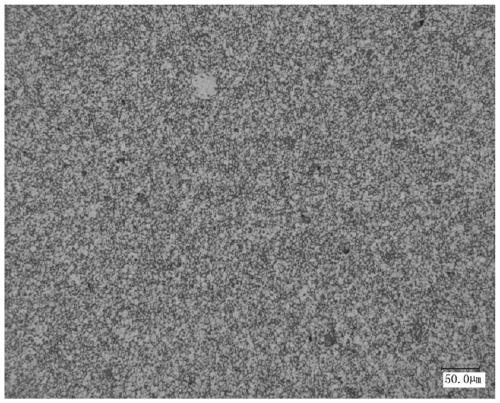

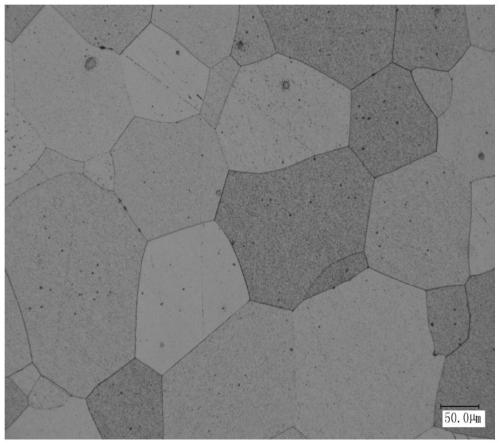

Anti-erosion molybdenum alloy electrode and manufacturing method thereof

ActiveCN109306421AStrong corrosion resistanceRaise the recrystallization temperatureElectric furnaceAlloyImpurity

The invention discloses an anti-erosion molybdenum alloy electrode and a manufacturing method thereof. The anti-erosion molybdenum alloy electrode is prepared by means of solid-liquid doping and multi-element ball-milling doping. The recrystallization temperature of the electrode is higher than 1300 DEG C, the microstructure of the electrode is uniform crystal grains, the dimensions of which are 20-70 [mu]m, and the electrode is prepared from the following components in percent by weight: 3-5wt% of ZrO2, 0.8-1.2wt% of Si, 0.1-0.5wt% of B, 0.001-3wt% of GeO2, 0.001-3wt% of SnO2, 0.001-3wt% of Bi2O3, 0-5wt% of W and 0-4wt% of Al2O3 and the balance of Mo and inevitable impurities. By controlling the content of zirconium oxide and the proportion of silicon and boron in a Mo-Si-B alloy reasonably, the alloy has good anti-erosion capacity, high recrystallization temperature and high-temperature behavior and also has good processing capacity. In addition, other targeted microelements are alsodoped in the molybdenum alloy electrode, so that the anti-erosion capacity to different molten glass is improved.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD +1

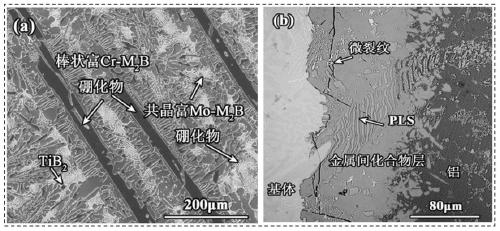

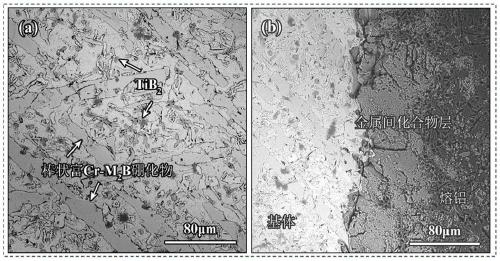

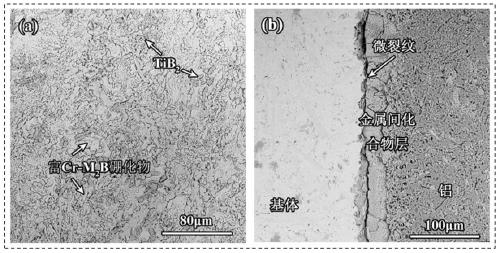

Multi-scale boride reinforced high-temperature-resistant molten aluminum erosion-resistant iron-based material and preparation method thereof

The invention discloses a multi-scale boride reinforced high-temperature-resistant and molten aluminum erosion-resistant iron-based material and a preparation method thereof. The multi-scale boride reinforced iron-based material prepared by the method is smelted by using an electric furnace, and a formed casting structure consists of a matrix ferrite phase, a rod-shaped Cr-rich M2B (M=Fe, Cr, Mo)boride phase, a net-shaped eutectic Mo-rich M2B boride and a dispersed granular TiB2 phase, so that the multi-scale boride reinforced iron-based material has good molten aluminum erosion resistance and strong toughness. The high temperature hardness at 750 DEG C reaches 300.0-450.0 HV, the room temperature impact toughness is greater than 4.0 J / cm2, and the high temperature molten aluminum erosionrate is reduced by 50%-80% compared with H13 steel. The prepared molten aluminum erosion-resistant iron-based material can greatly prolong the service life of parts and has high economic benefit.

Owner:SOUTH CHINA UNIV OF TECH

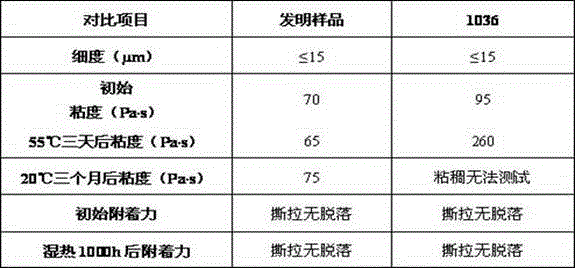

Organic secondary encapsulation slurry for sheet-type resistors, and preparation method thereof

InactiveCN106560489AImprove bindingMoisture resistanceNon-adjustable resistorsOrganic solventRoom temperature

The invention relates to an organic secondary encapsulation slurry for sheet-type resistors, and a preparation method thereof, wherein the organic secondary encapsulation slurry at least contains, by weight, 10-30% of a black pigment, 30-50% of an oxide, 5-10% of an organic resin, and 30-50% of an organic resin, and mixing stirring and rolling with a three-roller grinder are performed to obtain the product. According to the present invention, the organic encapsulation slurry has advantages of good adhesion, good chemical stability, good stability, room temperature storage, and strong competitiveness and broad market prospects in the sheet-type resistor industry.

Owner:西安英诺维特新材料有限公司

Calcium-zirconium refractory material and preparation method thereof

InactiveCN108164274AImprove high temperature mechanical propertiesImproves hydration resistanceRefractoryZirconium

The invention relates to a calcium-zirconium refractory material and a preparation method thereof. According to a technical scheme of the invention, the preparation method comprises the following steps: with 60 to 80 wt% of calcium oxide particles, 10 to 30 wt% of calcium oxide micropowder and 2 to 20 wt% of zirconium oxide micropowder as raw materials, adding 2 to 7 wt% of phenolic resin into theraw materials, carrying out stirring for 3 to 30 minutes, and carrying out press molding; and placing a molded green body into a high-temperature furnace, carrying out sintering under the condition of 1500 to 1800 DEG C for 3 to 6 hours, and carrying out cooling so as to obtain the calcium-zirconium refractory material. The preparation method provided by the invention has the characteristics of simple process and high production efficiency; and the calcium-zirconium refractory material prepared by using the preparation method provided by the invention has the advantages of high melting point,good thermodynamic stability, excellent vacuum stability, excellent melt erosion resistance and strong high-temperature melt purifying capacity, can be used as a lining of a metallurgical furnace anda container, and specifically meets the needs of clean steel production and vacuum melting.

Owner:WUHAN UNIV OF SCI & TECH

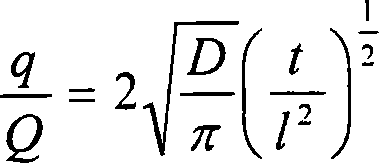

Fluid mechanical part resistant to slurry erosiveness and fluid machinery having same

InactiveCN101096765AImprove erosion performanceImprove erosion abilityPump componentsHydro energy generationSlurrySteel casting

The present invention provides a fluid machinery component exerted with carbamide resin lining and the fluid machinery provided with the component, and the slurry erosion resistance of the fluid machinery component exceeds the base metal, the construction can be executed near the ordinary temperature and it will not accompany with the deterioration or deformation of the base metal. The fluid machinery is the fluid machinery which comprises a surface that at least contacts with the fluid is composed of steel, steel plate, cast iron or cast steel, and it is characterized in that the fluid contact surface is exerted with a carbamide resin lining.

Owner:EBARA CORP

Preparation method of continuous-casting tundish working lining slag line coating material

The invention discloses a continuous casting tundish working lining slag line coating and a preparation method thereof. The continuous casting tundish working lining slag line coating comprises the following components in percentage by mass: 33-37wt% of dead-burnt magnesia with a particle size of 1-3 mm, 47-53wt% of dead-burnt magnesia with a particle size of 0.3-1 mm, 9-11wt% of dead-burnt magnesia with a particle size of 0.088 mm, 2.3-2.7wt% of silica micropowder, 0.1-0.2wt% of sodium tripolyphosphate, 0.6-0.7wt% of calcium lignosulphonate, 0.1-0.3wt% of industrial salt, 0.8-1.2wt% of wood fiber, and 0.4-0.6wt% of alumina powder. The continuous casting tundish working lining slag line coating disclosed by the invention not only saves the cost, but also is relatively high in strength, thermal shock resistance and spalling resistance, excellent in melt or gas erosion resistance, good in coating property and adhesion property of protected materials, and not cracked, peeled off or subjected to chemical reaction with parent materials in the process of application.

Owner:浙江攀盛冶金材料有限公司

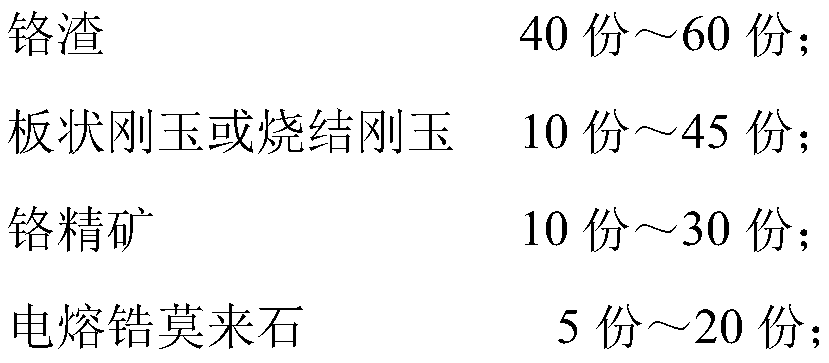

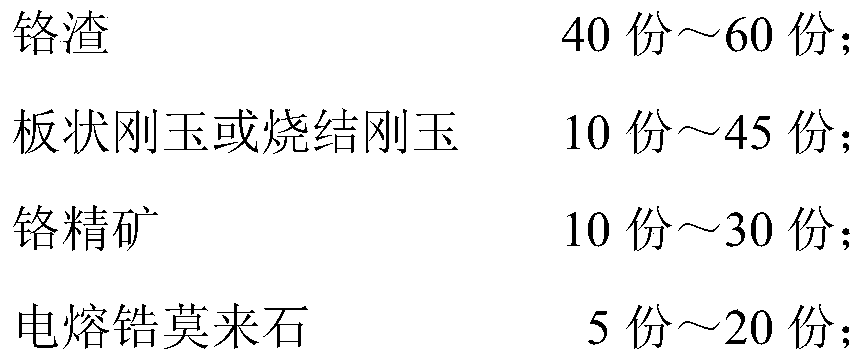

Production method of chromium corundum brick with reduction reaction resistance and thermal shock resistance for non-ferrous metal smelting fuming furnace or side-blown furnace

InactiveCN111423222APromote densificationImprove erosion performanceCrucible furnacesCeramicwareAluminiumPhosphate

The invention relates to a production method of chromium corundum bricks with reduction reaction resistance and thermal shock resistance for a non-ferrous metal smelting fuming furnace or a side-blownfurnace. The method includes uniformly mixing the crushed chromium slag, sintered corundum and chromium concentrate; adding into a three-phase electric arc furnace for smelting; smelting to obtain achromium corundum material; crushing, grinding, screening and grading the chromium corundum material to obtain particles with the particle sizes of 5-3mm, 3-1mm and 1-0mm and powder with the particlesizes of 180-mesh and 325-mesh respectively, adding 3-1mm fused zirconium mullite to obtain a mixed premix, adding a binding agent phosphoric acid, uniformly stirring, and standing for more than or equal to 48h; and adding a binding agent aluminum dihydrogen phosphate, mixing, carrying out compression molding, and carrying out high-temperature firing to obtain the chromium corundum brick. The invention has the advantages that the raw material cost is low, the cost performance is high, and the produced chromium corundum brick not only has scouring resistance, erosion resistance and high temperature resistance, but also has reduction reaction resistance and thermal shock resistance, and can be used for furnace slag line parts, bottoms and reaction zones for smelting lead, zinc, tin and othernonferrous metals.

Owner:锦州集信高温材料有限公司

Continuous casting tundish working lining slag line coating material

The invention discloses a continuous casting tundish working lining slag line coating and a preparation method thereof. The continuous casting tundish working lining slag line coating comprises the following components in percentage by mass: 33-37wt% of dead-burnt magnesia with a particle size of 1-3 mm, 47-53wt% of dead-burnt magnesia with a particle size of 0.3-1 mm, 9-11wt% of dead-burnt magnesia with a particle size of 0.088 mm, 2.3-2.7wt% of silica micropowder, 0.1-0.2wt% of sodium tripolyphosphate, 0.6-0.7wt% of calcium lignosulphonate, 0.1-0.3wt% of industrial salt, 0.8-1.2wt% of wood fiber, and 0.4-0.6wt% of alumina powder. The continuous casting tundish working lining slag line coating disclosed by the invention not only saves the cost, but also is relatively high in strength, thermal shock resistance and spalling resistance, excellent in melt or gas erosion resistance, good in coating property and adhesion property of protected materials, and not cracked, peeled off or subjected to chemical reaction with parent materials in the process of application.

Owner:浙江攀盛冶金材料有限公司

Carbon metal compound composite material

The invention discloses a carbon metal compound composite material which comprises the following main components: SiC, C, Si3N4 and Si. The preparation method of the carbon metal compound composite material comprises the following steps: (1), weighting, burdening and mixing SiC, C, Si3N4 and Si in proportion, and shaping; (2) nitriding and sintering at the sintering temperature of 1380-1560DEG C for 100-200 hours; (3) dipping in an asphalt impregnation liquid for 8-60 hours; and (4) roasting in nitrogen or storage carbon at 200-1500DEG C for 48-200 hours. By utilizing the carbon metal compound composite material disclosed by the invention, the aluminum liquid flowing state can be effectively improved, and the power consumption of the aluminium refining industry is lowered.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP

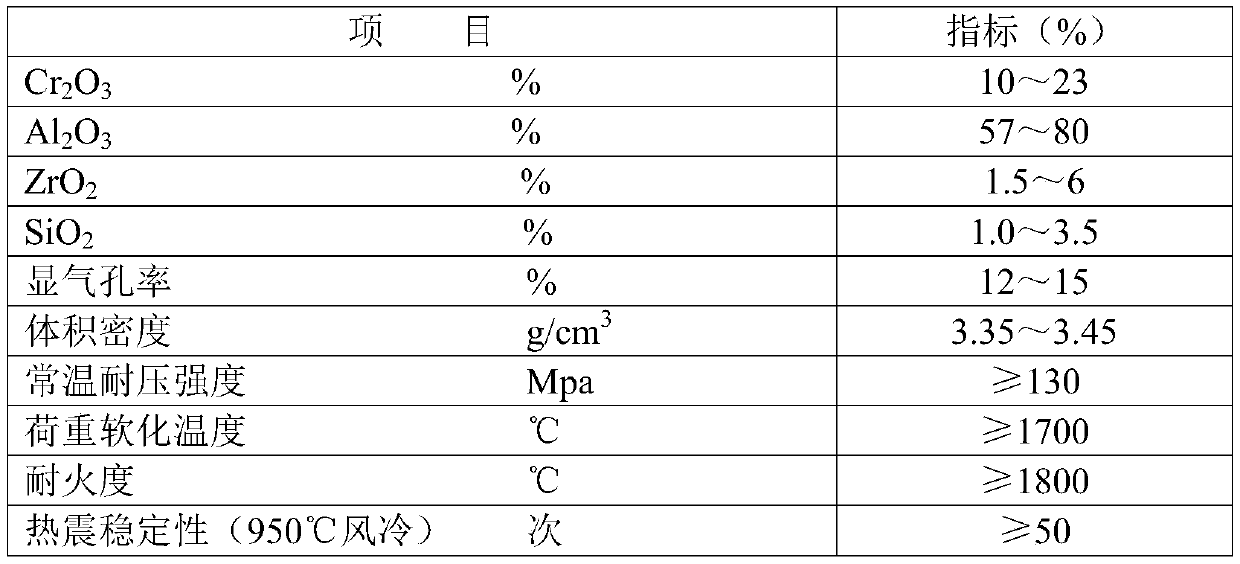

Preparation of manganese slag groundmass geopolymer cementing material

The invention discloses a method for preparing a manganese slag-based geological polymer binder comprising: (1) the solid components of the materials are manganese slag and kaolin; the liquid components are water glass, water and activator. (2) the manganese slag is dried till the moisture content is less than 1%, and is milled in a ball mill till the specific surface is 400-600m<2> / kg, the kaolin is calcined at 900 DEG C till the kaolin becomes metakaolin, and is milled till the specific surface is 500-700<2> / kg. (3) the activator is added into the water glass solution and is mixed uniformlywith water to get a water glass solution with a water glass modulus value of 1.5-3.5 and a water glass baume of 35-45 degrees. (4) the mixed solution prepared by the step (3) is added into the mixed powder of managese and metakaolin micropowder, is stirred and moulded after uniform mixture and maintenance. The preparation method has advantages of simple technology, no pollution during the preparation process, good gelling property and strong anti-seawater erosion property using industrial waste residue.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Marine antifouling paint as well as preparation method and application thereof

ActiveCN109266172AImprove erosion performanceImprove performanceAntifouling/underwater paintsPaints with biocidesEpoxySolvent

The invention provides marine antifouling paint. The marine antifouling paint comprises a component A and a component B, wherein the component A comprises the following components in parts by weight:15 to 30 parts of epoxy resin, 1 to 5 parts of pigment, 5 to 8 parts of a silane coupling agent, 2 to 5 parts of an aid, 3 to 6 parts of a filler, and 15 to 25 parts of a solvent; the component B comprises the following components in parts by weight: 20 to 40 parts of an epoxy resin curing agent, 5 to 10 parts of an antifouling agent, and 10 to 20 parts of a solvent; and a mass ratio of the component A to the component B is (2.5 to 4): 1, and the antifouling agent is a combination of a compound I and a compound II. The marine antifouling paint provided by the invention is high in marine bioerosion resistance and high in storage stability, still uniform by virtue of stirring after being stored for 12 months, free from the phenomenon such as coarse particles, hard or colloidal precipitates,scaling, hard pigment settling and the like and excellent in performance.

Owner:ZHEJIANG FEIJING PAINT

An anti-corrosion molybdenum alloy electrode and its manufacturing method

ActiveCN109306421BStrong corrosion resistanceRaise the recrystallization temperatureElectric furnaceAlloyImpurity

The invention discloses an anti-erosion molybdenum alloy electrode and a manufacturing method thereof. The anti-erosion molybdenum alloy electrode is prepared by means of solid-liquid doping and multi-element ball-milling doping. The recrystallization temperature of the electrode is higher than 1300 DEG C, the microstructure of the electrode is uniform crystal grains, the dimensions of which are 20-70 [mu]m, and the electrode is prepared from the following components in percent by weight: 3-5wt% of ZrO2, 0.8-1.2wt% of Si, 0.1-0.5wt% of B, 0.001-3wt% of GeO2, 0.001-3wt% of SnO2, 0.001-3wt% of Bi2O3, 0-5wt% of W and 0-4wt% of Al2O3 and the balance of Mo and inevitable impurities. By controlling the content of zirconium oxide and the proportion of silicon and boron in a Mo-Si-B alloy reasonably, the alloy has good anti-erosion capacity, high recrystallization temperature and high-temperature behavior and also has good processing capacity. In addition, other targeted microelements are alsodoped in the molybdenum alloy electrode, so that the anti-erosion capacity to different molten glass is improved.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD +1

Evanescent mode base paint for producing grate bar, and preparation technology of evanescent mode base paint

InactiveCN104325069AImprove permeabilityImprove erosion performanceFoundry mouldsFoundry coresCarboxymethyl celluloseHeat stability

The invention relates to an evanescent mode base paint for producing a grate bar, and a preparation technology of the evanescent mode base paint. The evanescent mode base paint is characterized by mainly comprising quartz powder with the meshes of 8-15, water, starch, white latex, sodium carboxymethyl cellulose and edible trona venenum, wherein the weight ratio of the quartz powder to the water to the starch to the white latex to the sodium carboxymethyl cellulose to the edible trona venenum is 100 to 75 to 40 to (1.8-2.3) to 8 to 2. The preparation technology of the evanescent mode base paint comprises the following steps: (1) fully mixing the quartz powder with the meshes of 8-15 with the water; (2) then feeding the corn starch by weight ratio, and continuously stirring while feeding; (3) then, feeding the white latex and the sodium carboxymethyl cellulose; (4) finally, feeding the edible trona venenum by weight ratio; (5) stirring the mixture obtained in the step (4) for 1 hour at the speed of 50-100 revolutions per minute. The paint prepared by the invention has enough refractoriness, chemical stability and heat stability, is high in adhesive capability and low in gas generation amount, and has good suspension property, brushing property, coating property and rheological property and high air permeability.

Owner:TIANJIN DELIWEI MACHINERY MFG

Method for compositing and producing tundish impact plate through combination of stopper turning material and waste sliding plate

ActiveCN109369147AImprove anti-scourImprove erosion abilityCeramic materials productionClaywaresSocial benefitsBrick

The invention discloses a method for compositing and producing a tundish impact plate through combination of a stopper turning material and a waste sliding plate. According to the method, a waste sliding plate brick and the stopper turning material are introduced into the impact plate, sliding plate granules and stopper granules are obtained through secondary processing, tabular corundum in the recycled sliding plate is taken as an aggregate and is combined with a certain amount of aluminum-rich spinel of the stopper turning material, the high-temperature flushing resistance of corundum particles and the slag corrosion resistance of the aluminum-rich spinel are adequately utilized and effectively combined, and the novel tundish impact plate is produced by virtue of thermoplastic phenolic resin, so that the flushing resistance and corrosion resistance of the impact plate in the high-temperature use process are improved, the safety of the impact plate is substantially improved, and the service life of the impact plate is substantially prolonged; the flushing resistance, corrosion resistance and thermal shock resistance of the produced tundish impact plate are superior to existing products in the use process, the circular and efficient utilization of waste refractory materials is realized, the regeneration of resources is realized, the energy is saved, the environment is protected, and the social benefit is obvious.

Owner:甘肃酒钢集团科力耐火材料股份有限公司

Magnesium calcium RH varnished tube hot spray repair material for smelting silicon steel and formulating method thereof

Owner:上海彭浦特种耐火材料厂有限公司

Ladle castable for smelting of high manganese steel, and preparation method of ladle castable

The invention relates to a ladle castable for smelting of high manganese steel, and a preparation method of the ladle castable. The ladle castable is characterized in that 43-68 wt% of microporous corundum particles and 10-27 wt% of magnesium aluminate spinel particles are taken as aggregate, 5-15 wt% of microporous corundum fine powder, 2-4 wt% of magnesium aluminate spinel micro-powder, 4-8 wt%of pseudo-boehmite, 2-4 wt% of rhop-Al2O3 fine powder, 0.1-1 wt% of monoclinic phase zirconia fine powder and 0.1-1.5 wt% of manganese powder are used as matrix, and the aggregate and the matrix are taken as raw materials; organic fibers with an amount being 0.04-0.08wt% of the weight of the raw materials, a polycarboxylic acid water reducer with an amount being 0.1-0.5wt% of the weight of the rawmaterials, maleic acid with an amount being 0.2-0.5wt% of the weight of the raw materials and a defoaming agent with an amount being 0.01-0.03wt% of the weight of the raw materials are taken as additives. The preparation method comprises the steps of mixing the matrix, the additives and water to obtain a premix; spreading the aggregate into a mould, then pouring the premix into the mould, molding, drying, and demoulding to obtain the ladle castable for the smelting of the high manganese steel. The ladle castable is high in strength, good in thermal shock resistance, scouring-resistant and excellent in steel slag erosion resistance, and can improve the quality of the high manganese steel.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com