Multi-scale boride reinforced high-temperature-resistant molten aluminum erosion-resistant iron-based material and preparation method thereof

A technology of iron-based materials and borides, which is applied in the field of multi-scale boride-reinforced high-temperature-resistant molten aluminum corrosion-resistant iron-based materials and its preparation, can solve the problems of poor uniformity of the surface infiltration layer, difficulty in processing and forming, and melting of the modified layer. Corrosion and perforation and other problems, to achieve the effect of excellent resistance to molten aluminum corrosion, good mechanical properties, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the high temperature resistant molten aluminum erosion wear material described in this embodiment specifically includes the following steps:

[0031] (1) Mix and heat scrap steel, pig iron, ferrochrome, ferromolybdenum, ferroboron, ferrotitanium, ferromanganese, ferrosilicon, and high-purity aluminum ingots, and adjust the composition (wt.%) to: C:0.1, B:3.5 , Cr: 12.0, Mo: 1.5, Si: 3.5, Al: 3.5, Mn: 0.5, Ti: 0.5, the balance is Fe;

[0032] (2) Heating the temperature of the alloy melt to 1520°C, and then pouring it into the mold at a pouring temperature of 1450°C, cooling and solidifying to obtain a casting, that is, the high-temperature-resistant molten aluminum erosion wear material (multi-scale boride-enhanced resistant High-temperature molten aluminum corrodes iron-based materials).

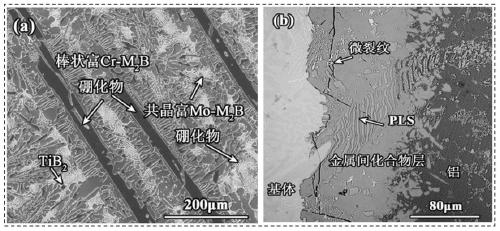

[0033] The structure of the multi-scale boride-reinforced high-temperature-resistant molten aluminum corrosion-resistant iron-based material prepared in th...

Embodiment 2

[0035] The preparation method of the high temperature resistant molten aluminum erosion wear material described in this embodiment specifically includes the following steps:

[0036] 1) Mix and heat scrap steel, pig iron, ferrochrome, ferromolybdenum, ferroboron, ferrotitanium, ferromanganese, ferrosilicon, and high-purity aluminum ingots, and adjust the composition (wt.%) to: C:0.2, B:8.5, Cr: 15.5, Mo: 3.0, Si: 0.5, Al: 6.0, Mn: 1.5, Ti: 6.5, the balance is Fe;

[0037] (2) Heating the temperature of the molten alloy to 1540°C, and then pouring it into the mold at a pouring temperature of 1460°C, cooling and solidifying to obtain a casting, that is, the high-temperature-resistant molten aluminum erosion wear material (multi-scale boride-enhanced resistant High-temperature molten aluminum corrodes iron-based materials).

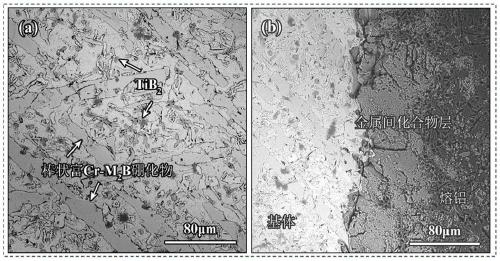

[0038] The structure of the multi-scale boride-reinforced high-temperature-resistant molten aluminum corrosion-resistant iron-based material prepared in this...

Embodiment 3

[0040] The preparation method of the high temperature resistant molten aluminum erosion wear material described in this embodiment comprises the following steps:

[0041] (1) Mix and heat scrap steel, pig iron, ferrochrome, ferromolybdenum, ferroboron, ferrotitanium, ferromanganese, ferrosilicon, and high-purity aluminum ingots, and adjust the composition (wt.%) to: C:0.5, B:5.5 , Cr:20.0, Mo:8.5, Si:1.5, Al:2.5, Mn:2.0, Ti:3.5, the balance is Fe;

[0042] (2) Heating the temperature of the alloy melt to 1560°C, and then pouring it into the mold at a pouring temperature of 1470°C, cooling and solidifying to obtain a casting, that is, the high-temperature-resistant molten aluminum erosion wear material (multi-scale boride-reinforced wear-resistant High-temperature molten aluminum corrodes iron-based materials).

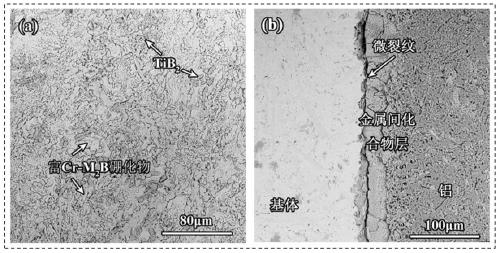

[0043] The microstructure of the multi-scale boride-reinforced high-temperature-resistant molten aluminum corrosion-resistant iron-based material prepared in this exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com