Preparation of manganese slag groundmass geopolymer cementing material

A technology of polymer glue and manganese slag, applied in cement production and other directions, can solve the problems of low utilization rate of manganese slag, climate and environment, etc., and achieve the effects of good seawater corrosion resistance, environmental improvement and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

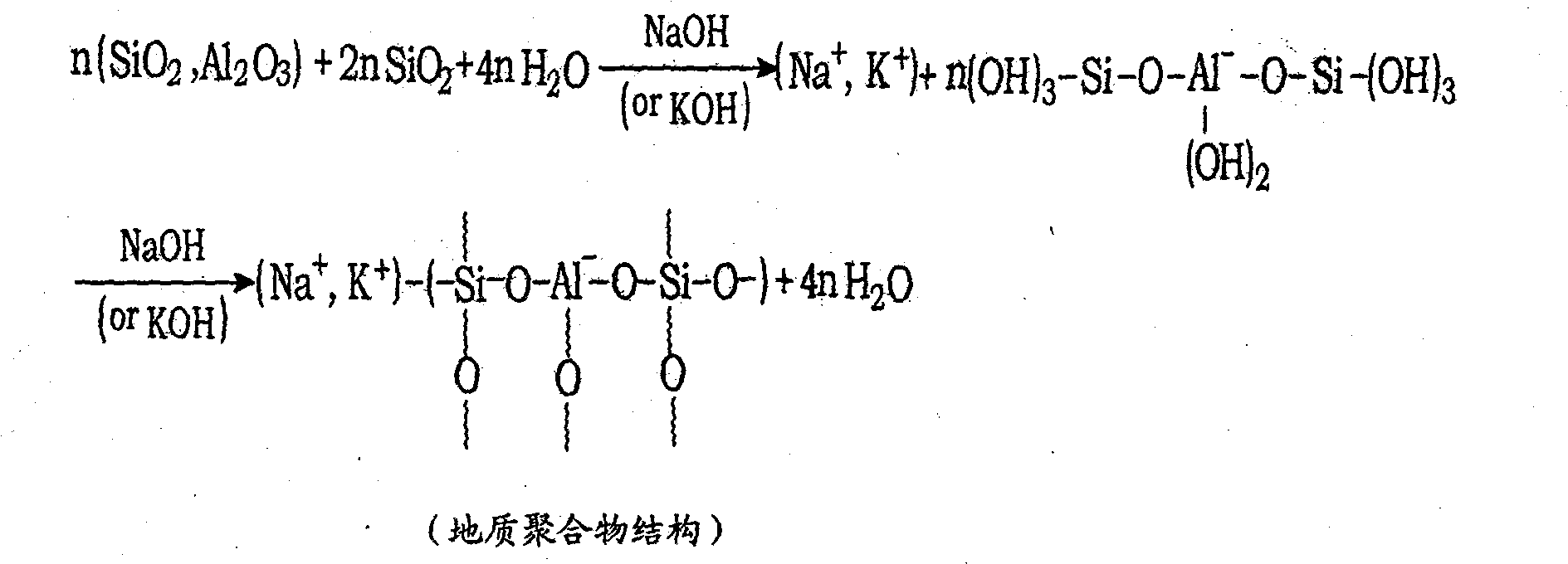

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) The solid component is proportioned by weight percentage, manganese slag 70%, kaolin 30%; the liquid component is proportioned by volume percentage, water glass 40%, water 60%; water-cement ratio 0.45, activator chemically pure KOH is the solid component 4% of sub-mass percentage;

[0021] (2) Dry the manganese slag until the moisture content is less than 1%, put it into a ball mill and grind it until the specific surface area is 450m 2 / Kg; Kaolin is calcined at 650°C to form metakaolin, and ground to a specific surface area of 500m 2 / Kg;

[0022] (3) activator chemically pure KOH is mixed in water glass, and it is mixed with water, obtains the water glass mixed solution of water glass modulus 3.25, Baume degree 40 °;

[0023] (4) Slowly add the mixed solution prepared in step (3) into the mixed powder of manganese slag and metakaolin micropowder, stir for 60 seconds, mix evenly and then form it, and maintain it in an environment with a temperature of 20°C and...

Embodiment 2

[0026] (1) Solid ingredients are proportioned by weight percentage, manganese slag accounts for 90%, kaolin 10%; liquid components are proportioned by volume percentage, water glass 40%, water 60%, water-cement ratio 0.45, and the activator is chemically pure NaOH. 4% of the mass percentage of solid content.

[0027] (2) Dry the manganese slag until the moisture content is less than 1%, put it into a ball mill and grind it until the specific surface area is 600m 2 / Kg; Kaolin is calcined at 900°C to form metakaolin and ground. to a specific surface area of 700m 2 / Kg.

[0028] (3) activator chemically pure NaOH is mixed in the water glass, and it is mixed with water, obtains the water glass modulus that is 3.25, the water glass mixed solution of Baume degree 40 °.

[0029] (4) Slowly add the mixed solution prepared in step (3) into the mixed powder of manganese slag and metakaolin micropowder, stir for 90 seconds, mix evenly and then form it, and maintain it in an environ...

Embodiment 3

[0033] (1) Solid ingredients are proportioned by weight percentage, manganese slag accounts for 80%, kaolin 20%; by volume percentage: water glass accounts for 40%, water accounts for 60%, water-cement ratio is 0.45, and wherein activator is chemically pure KOH accounts for solid 4% of the mass percentage of ingredients;

[0034] (2) Dry the manganese slag with a weight percentage of 90% until the moisture content is less than 1%, put it into a ball mill and grind it until the specific surface area is 600m 2 / Kg; take 10% kaolin by weight, calcinate metakaolin at 900°C, and grind until the specific surface area is 700m 2 / Kg.

[0035] (3) activator chemically pure NaOH is mixed in the water glass, and it is mixed with water, obtains the water glass modulus to be 3.25, the water glass mixed solution of Baume degree 40 °.

[0036] (4) Slowly add the mixed solution prepared in step (3) into the mixed powder of manganese slag and metakaolin micropowder, stir for 90 seconds, mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com