Fluid mechanical part resistant to slurry erosiveness and fluid machinery having same

A fluid machinery and component technology, which is applied to the components, mechanical equipment, machines/engines, etc. of the pumping device for elastic fluids, and can solve the problem that the corrosion resistance of the slurry is lower than that of the base metal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] Examples for demonstrating the effects of the present invention will be described below, but the present invention is not limited to the embodiments of the examples.

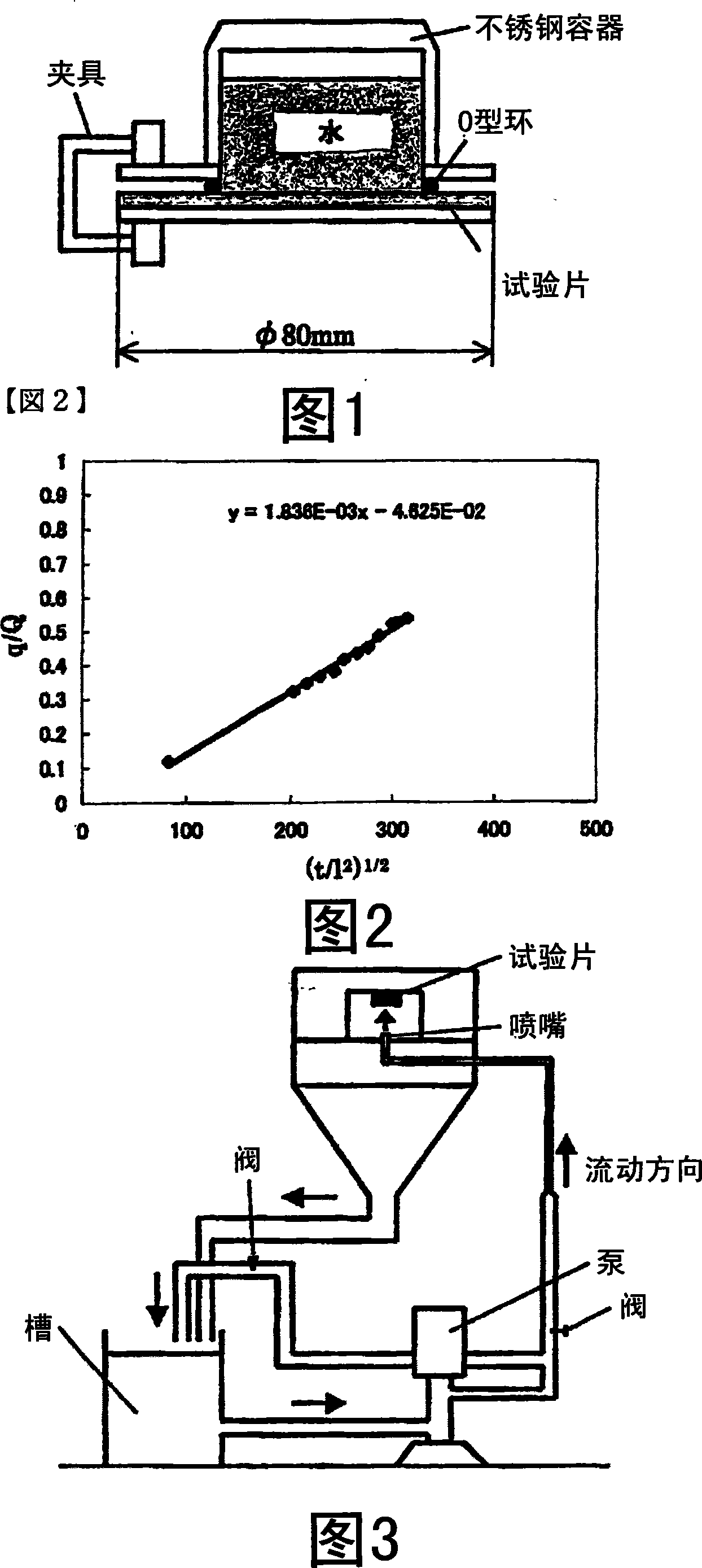

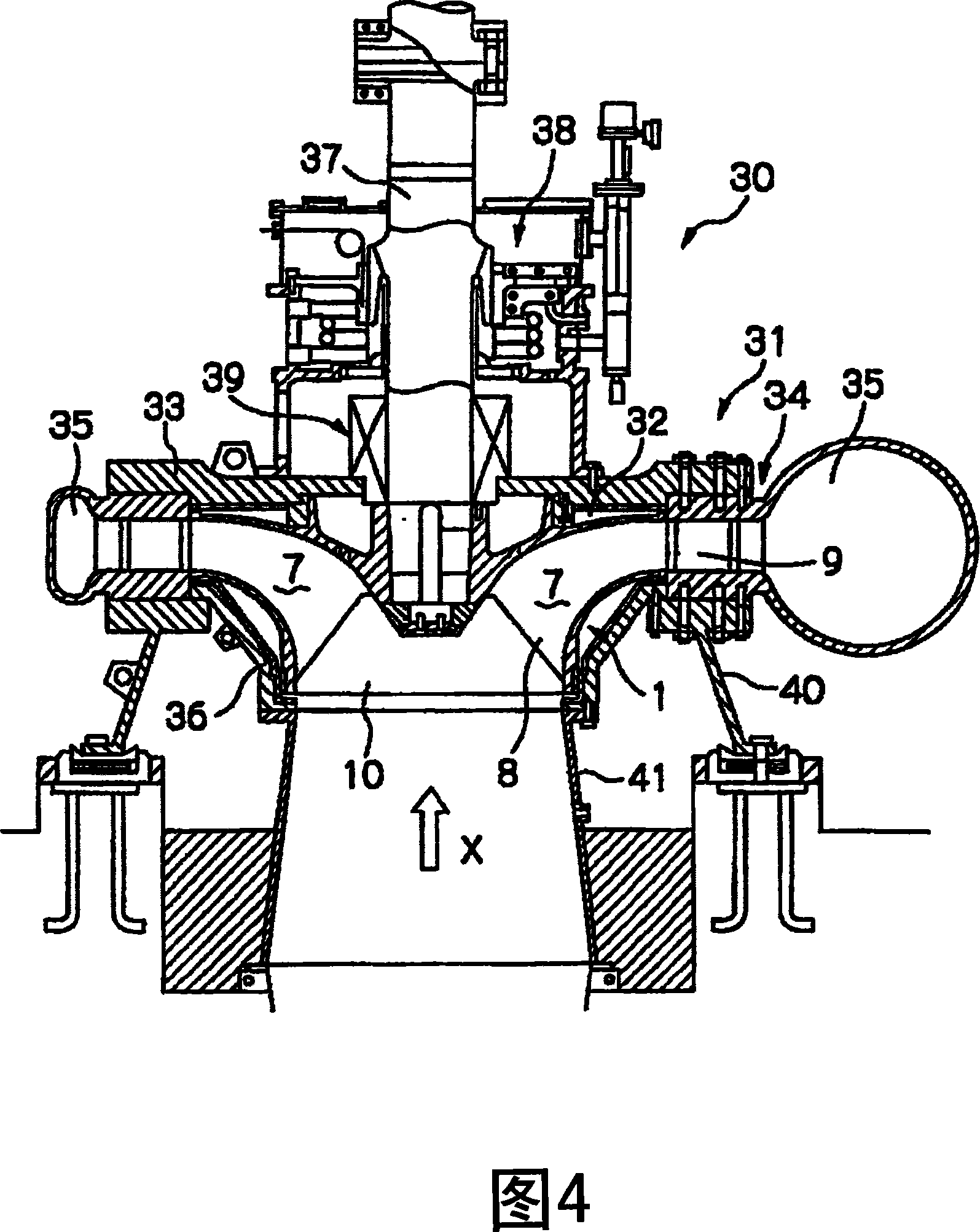

[0044] The immersion test method of the lining material is as described above, according to the immersion test of the lining material at a uniform temperature described in "Corrosion Resistance of Plastics and Its Test and Evaluation" (Author: Okuda Satoshi, Publisher: Nikkan Kogyo Shimbun) method. The test piece was installed in the stainless steel container shown in FIG. 1, it was brought into contact with the water in the container, and this container was kept in the constant temperature bath of 25 degreeC. Observe at predetermined intervals, and continue the test until the lining material expands, cracks, etc., and the base metal corrodes significantly, so that it is confirmed that it cannot be used. The diffusion coefficient was calculated according to the formula described above.

[0045] Determin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com