Vale blade sealing structure and air valve

A technology of valve blades and sealing structures, which is applied in the direction of valve lifts, valve devices, engine components, etc., can solve problems such as difficulty in guaranteeing straightness and flatness machining accuracy, inability to completely block fire or smoke, and gaps in the closing of valve blades, etc. Achieve good acid and alkali corrosion resistance, light weight and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

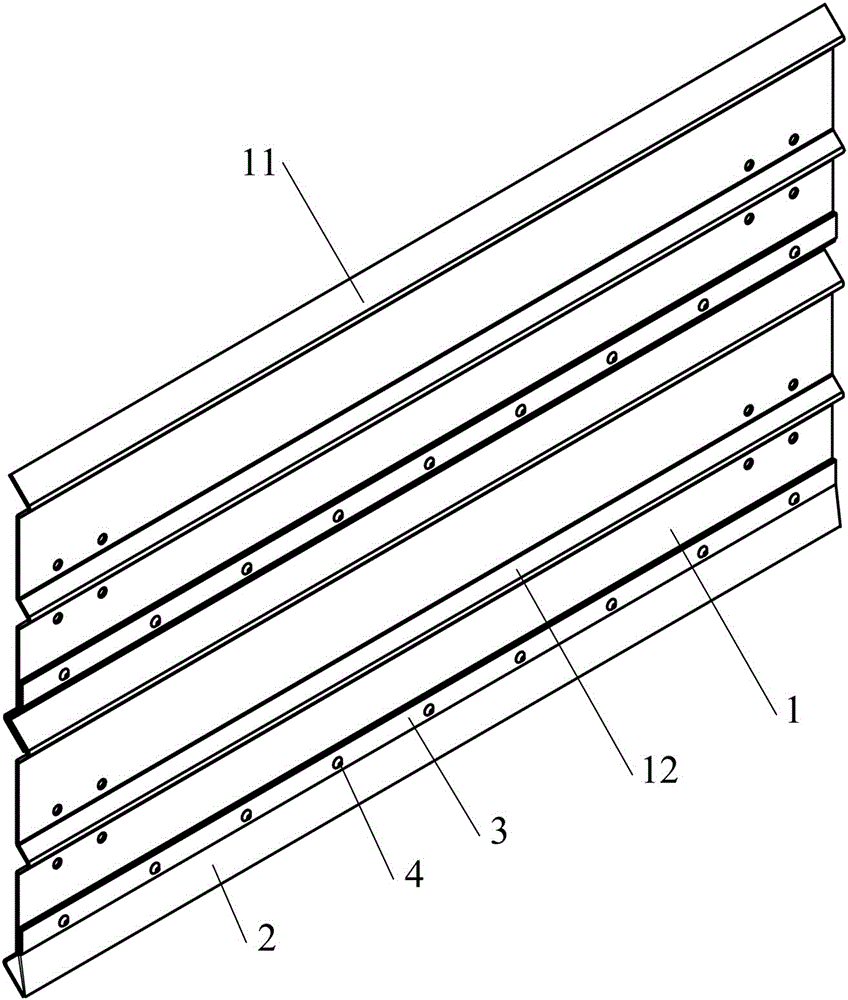

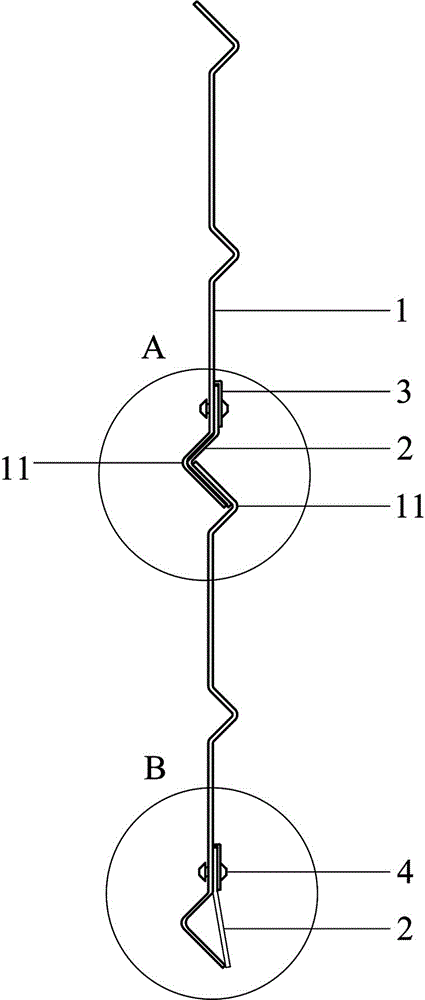

[0020] See figure 1 and figure 2 , a valve blade sealing structure designed in a preferred embodiment of the present invention, including: valve blade 1 and sealing strip 2, the upper and lower ends of a plurality of valve blades 1 overlap each other to form a plane, which is used as a damper valve, and sealing strip 2 By using the bead 3 and the rivet 4 to be fixedly installed on one end of the valve blade 1, it plays the role of making up the connection gap between the valve blades.

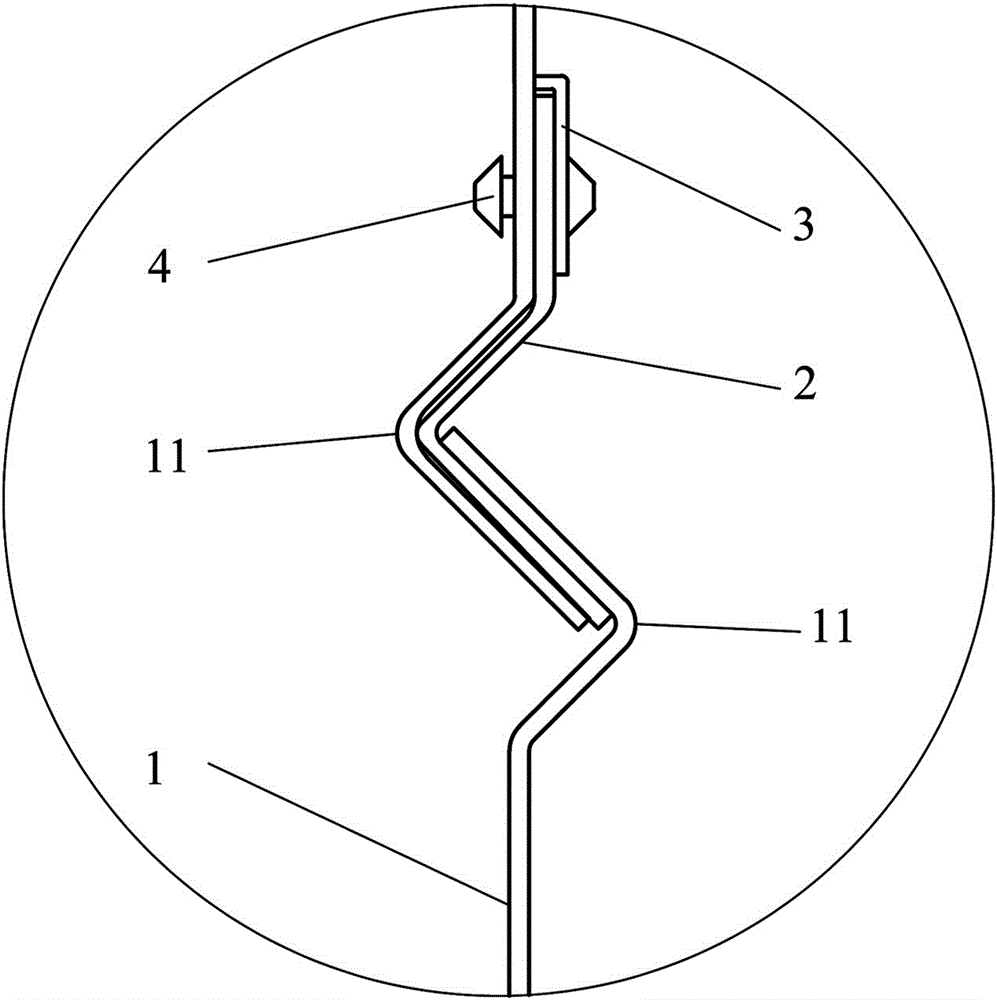

[0021] See image 3 and Figure 4 The upper and lower ends of the valve blade 1 are bent and extended to form an overlapping portion 11. The overlapping portion 11 is composed of an obliquely protruding starting folding surface and a reversely folded final folding surface. The two adjacent valve blades 1 The bending directions of the overlapping parts 11 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com