Patents

Literature

41results about How to "Achieve remanufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

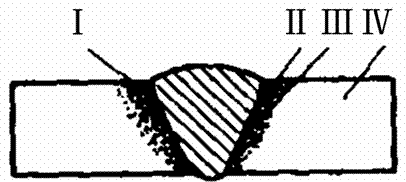

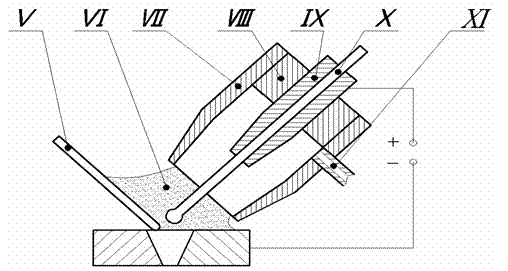

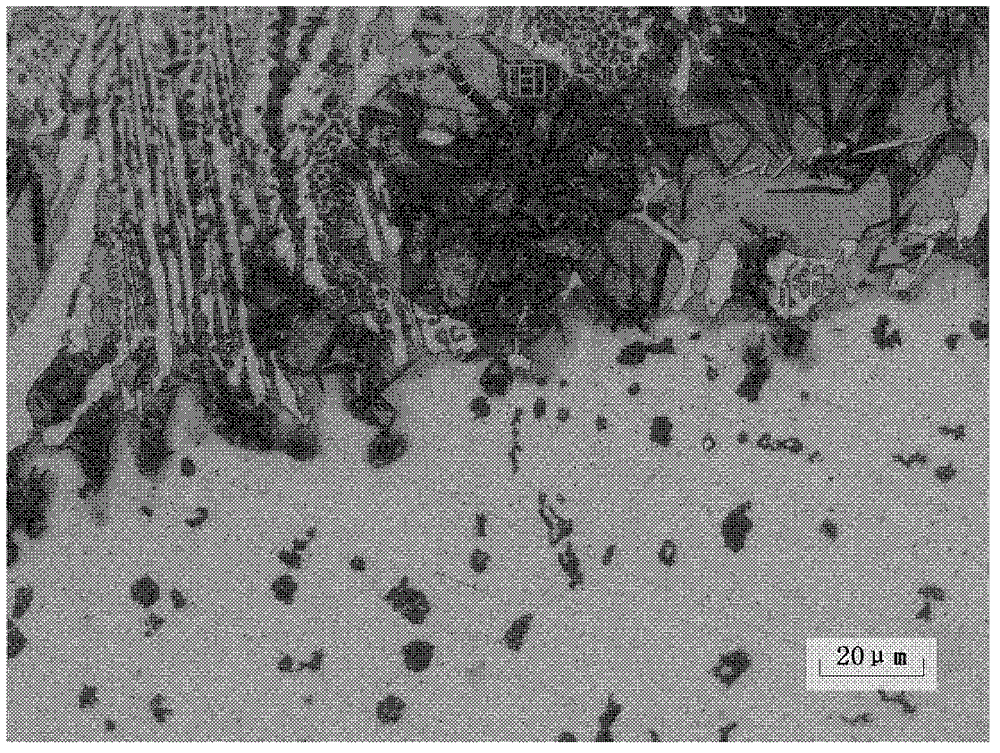

Method and device for remanufacturing sheet metal welding piece by utilizing laser

InactiveCN102886606AAchieve remanufacturingAccelerated microstructure movementWelding/soldering/cutting articlesMetal working apparatusMetal sheetCw laser

The invention discloses a method and a device for remanufacturing a sheet metal welding piece by utilizing laser and relates to the field of non-traditional machining. The method comprises the following steps of: closing cracks by employing continuous laser re-molten cracks and neighboring area; then heating the surface of the joint of the sheet welding piece in a dynamic strain ageing temperature area; and performing laser shock processing on the surface of the joint of the sheet welding piece by utilizing a double-sided laser impact method. According to the device, the sheet welding piece can be compositely strengthened and remanufactured, the cracks on the surface of the welding line are closed, the air holes inside the welding line are eliminated, the tensile strength of the joint of the sheet welding piece is improved, and the service life of the sheet welding piece is prolonged.

Owner:JIANGSU UNIV

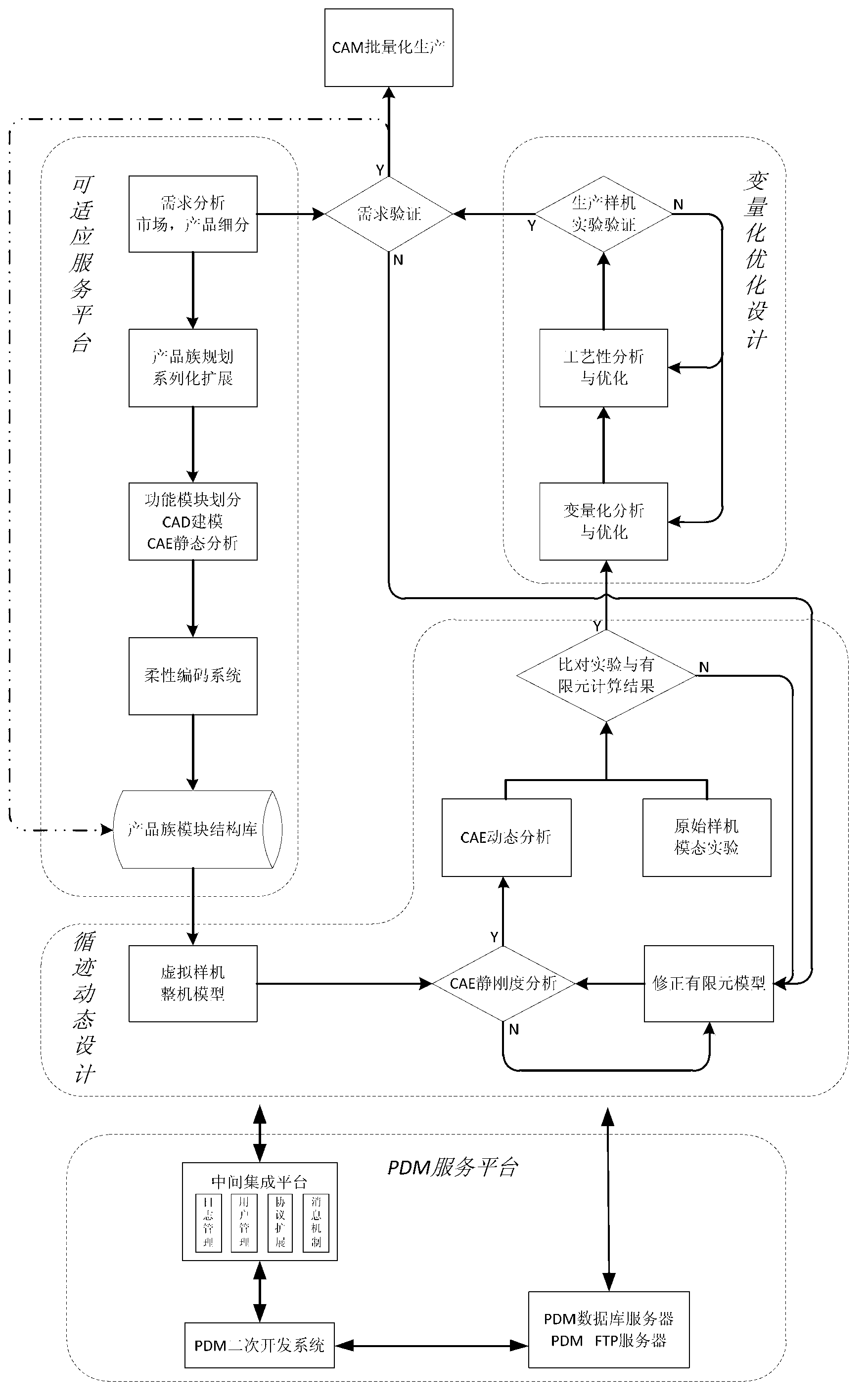

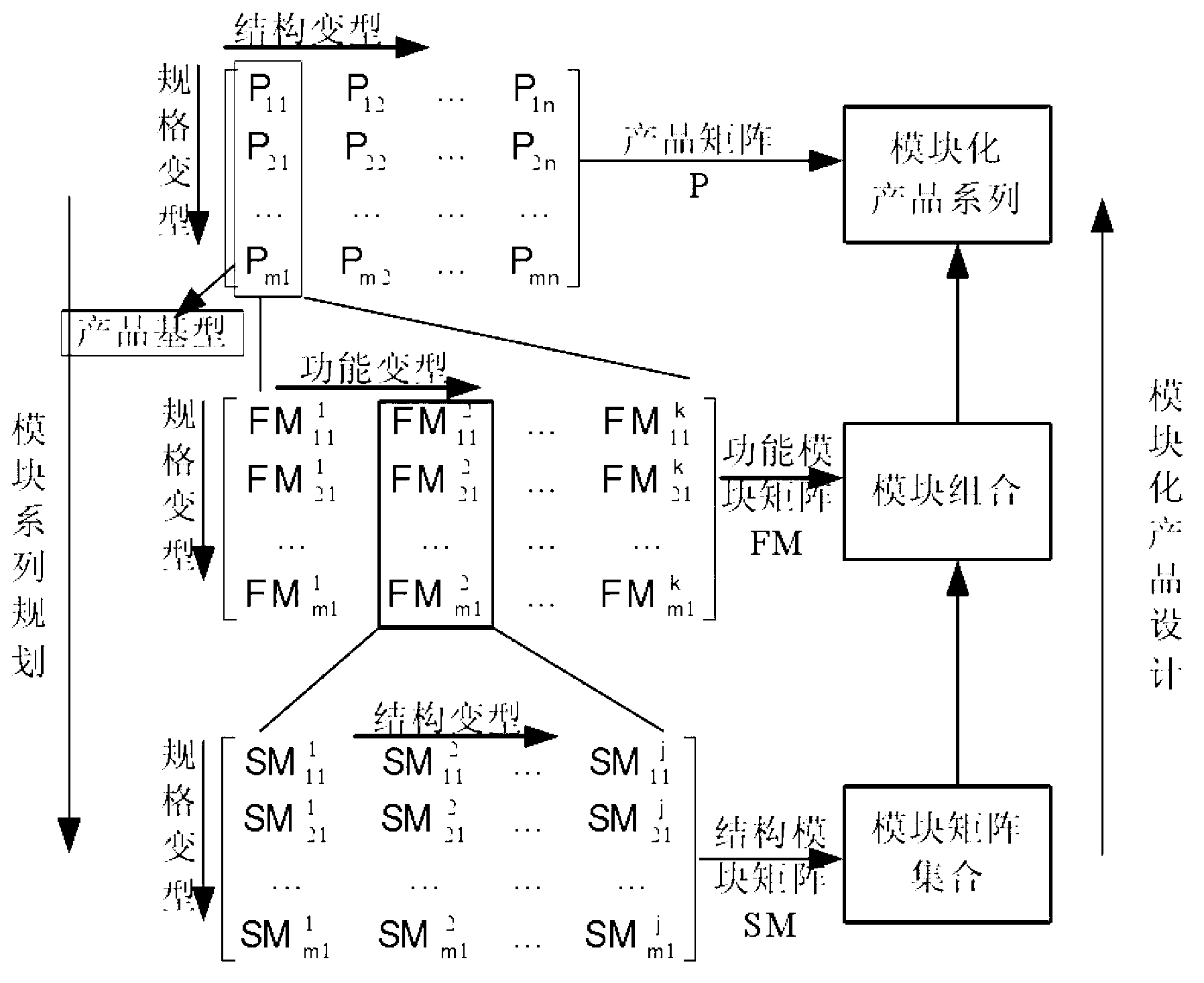

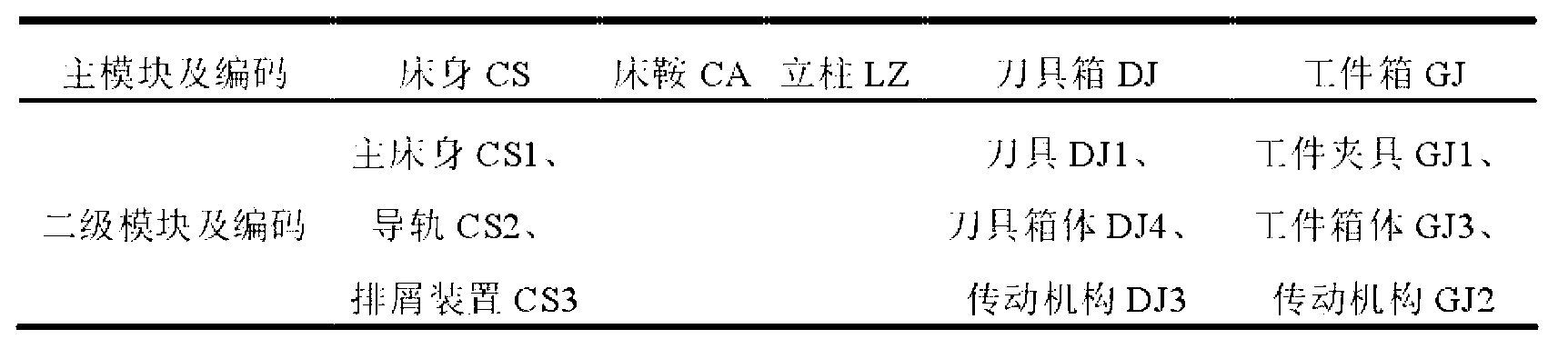

Construction method of adaptive dynamic design platform aiming at mechanical device

ActiveCN103020358AImprove customizabilityQuickly respond to user needsSpecial data processing applicationsRemanufacturingDynamic design

The invention discloses a construction method of an adaptive dynamic design platform aiming at a mechanical device. The construction method mainly comprises the steps of: erecting an adaptive service platform suitable for a target mechanical device, performing tracking dynamic design on a target product, and performing variable optimization design on a target model machine; and erecting a PDM (product data management) service platform as a link of the innovative service integration platform to couple the adaptive service platform, the tracking dynamic design and the variable design into a whole. The construction method can be promoted in other design and manufacturing industries, the prevailing significant problems such as long cycle of design and production, instable design quality, large amount of repeated work of personnel and high cost can be solved, experience of design and manufacturing can be accumulated and repeatedly used, reconstruction and remanufacturing can be realized, waste of resources can be reduced, seamless integration of demand conversion, product design, analysis, simulation and manufacturing can be realized ultimately, the structure of the target product can be optimized, the performance of the target product can be stabilized, rapid transformation can be realized, and the core competitiveness of enterprises can be enhanced.

Owner:TIANJIN UNIV

Composite reinforcement method for TiC/TiB2 base metal ceramic on surface of roller

ActiveCN102618867AImprove performanceImprove surface qualityMolten spray coatingSuperimposed coating processOperabilityAlloy

The invention discloses a composite reinforcement method for TiC / TiB2 base metal ceramic on the surface of a roller, and belongs to the technical field of metallurgical machinery. The composite reinforcement method comprises the processing steps of: cleaning the roller; performing plasma spraying of nickel base alloy or overlaying the nickel base alloy on the cleaned roller; turning the roller according to requirements of a steel groove rolling system to meet the technical requirements; and cladding on the surface of the roller by using an electric spark deposition process to form the TiB2 / TiC base metal ceramic by using a TiB2 / TiC base metal ceramic electrode. The composite reinforcement method has the advantages that: the roller performance is greatly improved and fixed-roller-diameter rolling can be guaranteed, so that the process stability in a rolling process is guaranteed, meanwhile, the service life of the roller is greatly prolonged, the roller consumption is reduced, and the steel rolling operability and the steel surface quality are improved. Compared with processes such as overlaying and laser, the composite reinforcement method can be used for repairing of primary and intermediate rolling roller, and most importantly, the composite reinforcement method can be directly used for surface treatment of the roller of a finishing mill group, so that remanufacturing of thesurface of the roller is realized.

Owner:HUNAN 3T NEW MATERIAL

In-situ spraying reparation method of horizontal aluminum busbar in electrolytic plant

InactiveCN102676970ASimple processing methodUnique process methodMolten spray coatingCoated surfaceElectrolysis

The invention relates to a reparation method of an aluminum busbar, in particular to an in-situ spraying reparation method of a horizontal aluminum busbar in an electrolytic plant. The method comprises firstly checking conditions of the busbar, performing leveling processing on the surface of the busbar, then performing preprocessing on the surface of the busbar to enable the preprocessed matrix surface to reach Sa 2.5-3.0 grade and to expose uniform metal natural color, performing rough processing on the surface of the busbar to enable roughness or riveting line depth of the surface to reach 40-80mu m, utilizing the electric arc spraying technology to spray a base layer and a working layer on the surface of the damaged busbar, finally utilizing a movable suspension milling cutter to mill the coating surface, and performing clean and smooth processing to complete the reparation of the horizontal aluminum busbar. The method can be achieved in the electrolytic plant, can effectively avoid interference of a strong magnetic field, reduces labor strength, has less consumption of labor and materials and simple and fast operation, can repair surface defects of the horizontal busbar serving as the upper structure of an aluminum cell, and can reproduce a repairing layer with excellent abrasion performance.

Owner:QINGTONGXIA ALUMINUM GRP +1

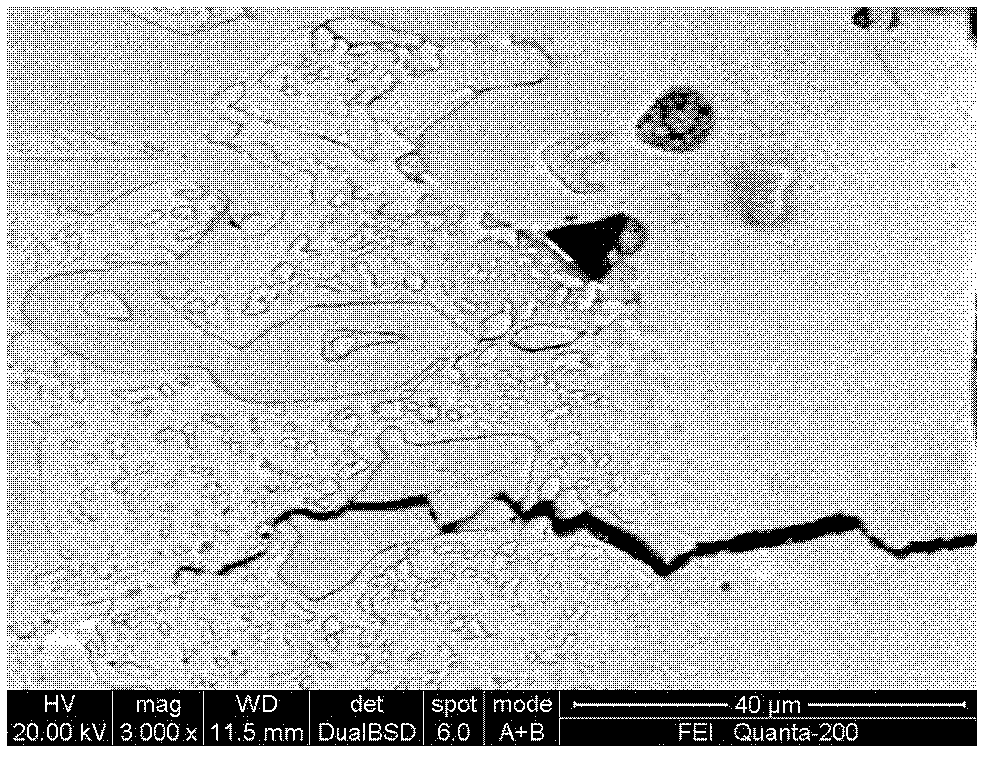

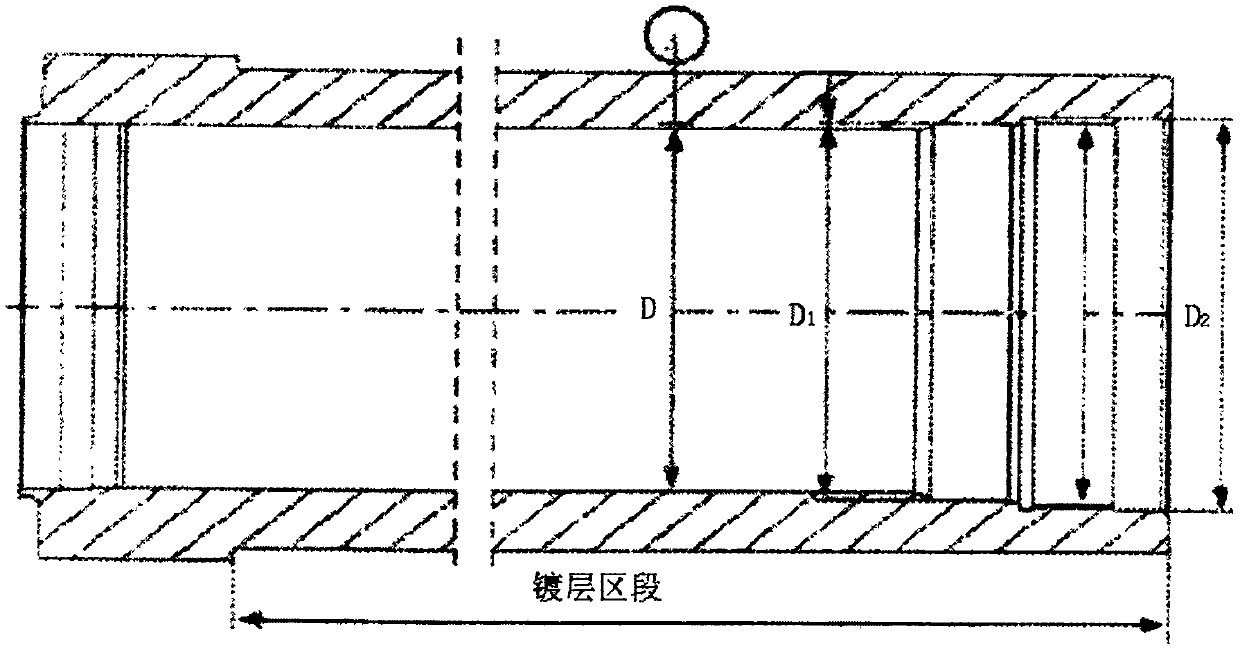

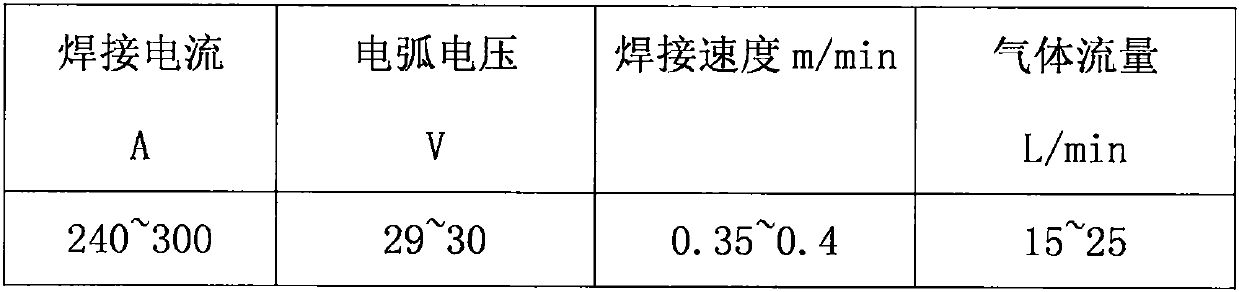

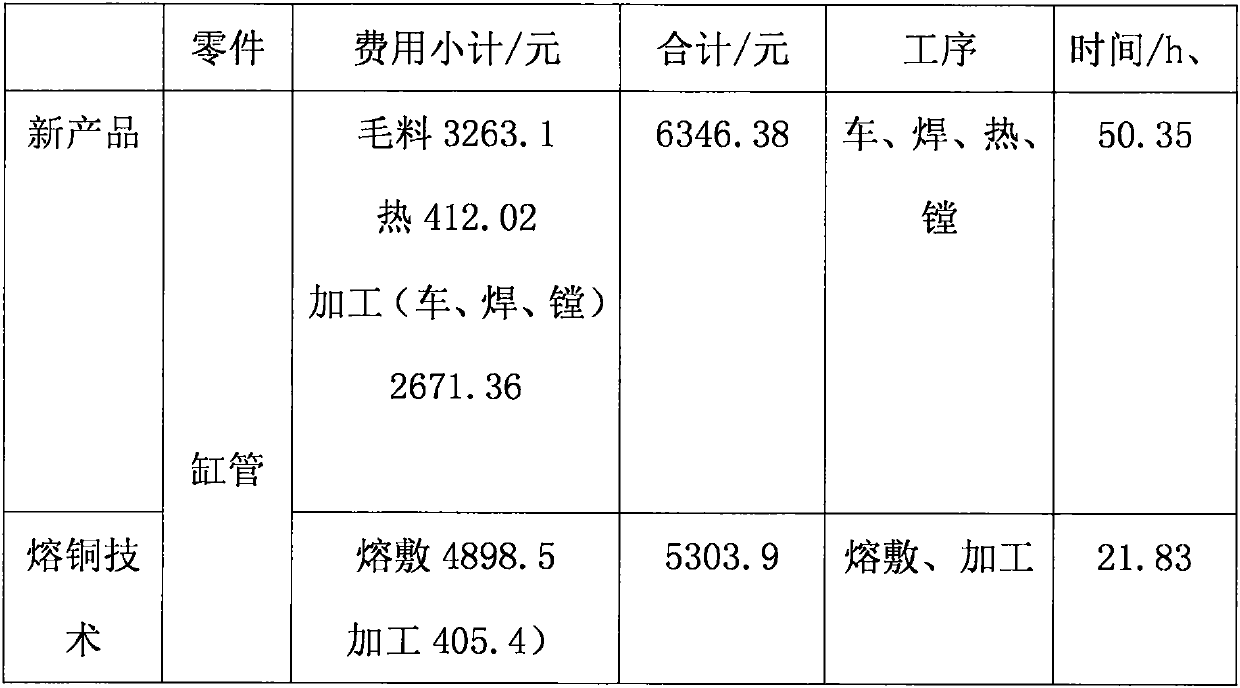

Technology of carrying out surfacing of aluminum bronze on inner surface of coal mine hydraulic bracket 27SiMn oil cylinder

InactiveCN111318785ARestore usabilityAchieve remanufacturingArc welding apparatusCoalMaterials science

The invention relates to the technical field of welding and discloses a technology of carrying out surfacing of aluminum bronze on the inner surface of a coal mine hydraulic bracket 27SiMn oil cylinder. The technology comprises the following steps: 1, evaluating the condition of the inner surface of the coal mine hydraulic bracket 27SiMn oil cylinder; 2, removing an accessory, rust and dirt; 3, boring the corrosion layer on the inner surface of the oil cylinder; and 4, adopting a HK 200 aluminium bronze welding wire with the diameter being 1-1.5 mm as the welding material, and adopting inert gas arc welding to weld the inner surface, except a thread, of the oil cylinder through a hot wire nonmelt electrode. With adoption of the technical scheme, the technology has the following benefits: the scrapped or to-be-scrapped hydraulic bracket 27SiMn oil cylinder is recycled, the original using performance of the oil cylinder is recovered through the technology, so that remanufacturing of theoil cylinder is reached; and the welding quality is stable, the technology completely replaces the electroplating technology to realize the remanufacturing effect, so that the production cost is greatly reduced, the production efficiency is improved and the service life of the oil cylinder is greatly prolonged.

Owner:TIANJIN YINGYUAN WELDING TECH +1

Chlorine-free acid etching solution regeneration and copper recovery device and method thereof

InactiveCN109628936AAchieve remanufacturingEfficient recyclingPhotography auxillary processesProcess efficiency improvementLiquid wasteAcid etching

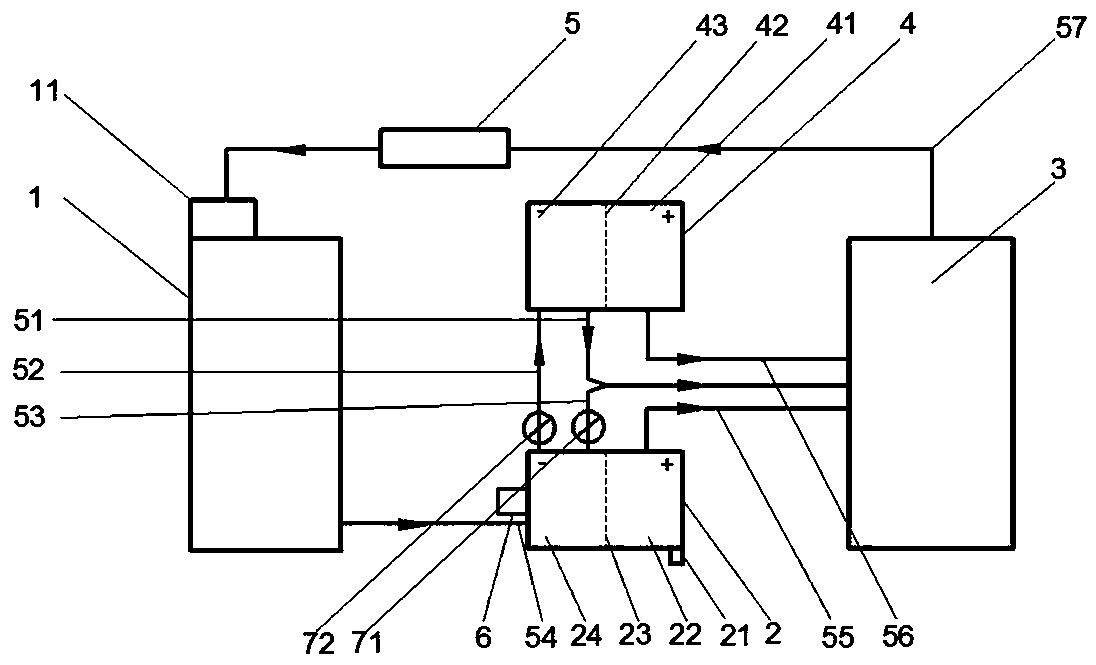

The invention discloses a chlorine-free acid etching solution regeneration and copper recovery device and a method thereof. The regeneration and copper recovery device comprises an etching tank (1), an electrolytic tank (2), a regeneration cylinder (3) and a secondary electrolytic tank (4), wherein the electrolytic tank (2) and the secondary electrolytic tank (4) are respectively provided with ananode area and a cathode area, the anode area and the cathode area are connected with the regeneration cylinder (3) through a pipeline, cuprous ions in etching waste liquid can be oxidized and used asetching liquid to return to the etching tank (1), and when oxygen in the regeneration cylinder (3) is insufficient to completely oxidize the copper oxide ions, the secondary electrolytic tank can bestarted to realize supplementary electrolysis regeneration on the etching liquid in the regeneration cylinder (3). The regeneration and copper recovery device has the beneficial effects that the electrolytic etching waste liquid can be recycled, chlorine is not generated in the working process, and the etching waste liquid can be regenerated and recycled while elemental copper is recycled.

Owner:CHENGDU HONGHUA ENVIRONMENTAL SCI & TECH CO LTD

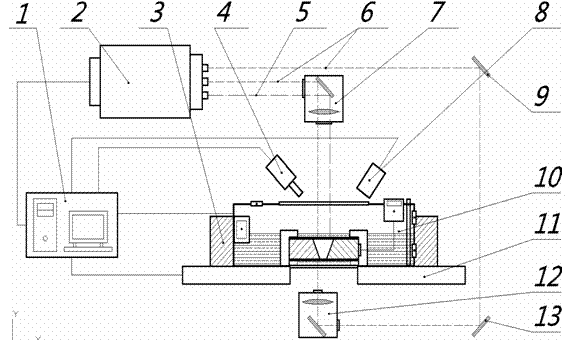

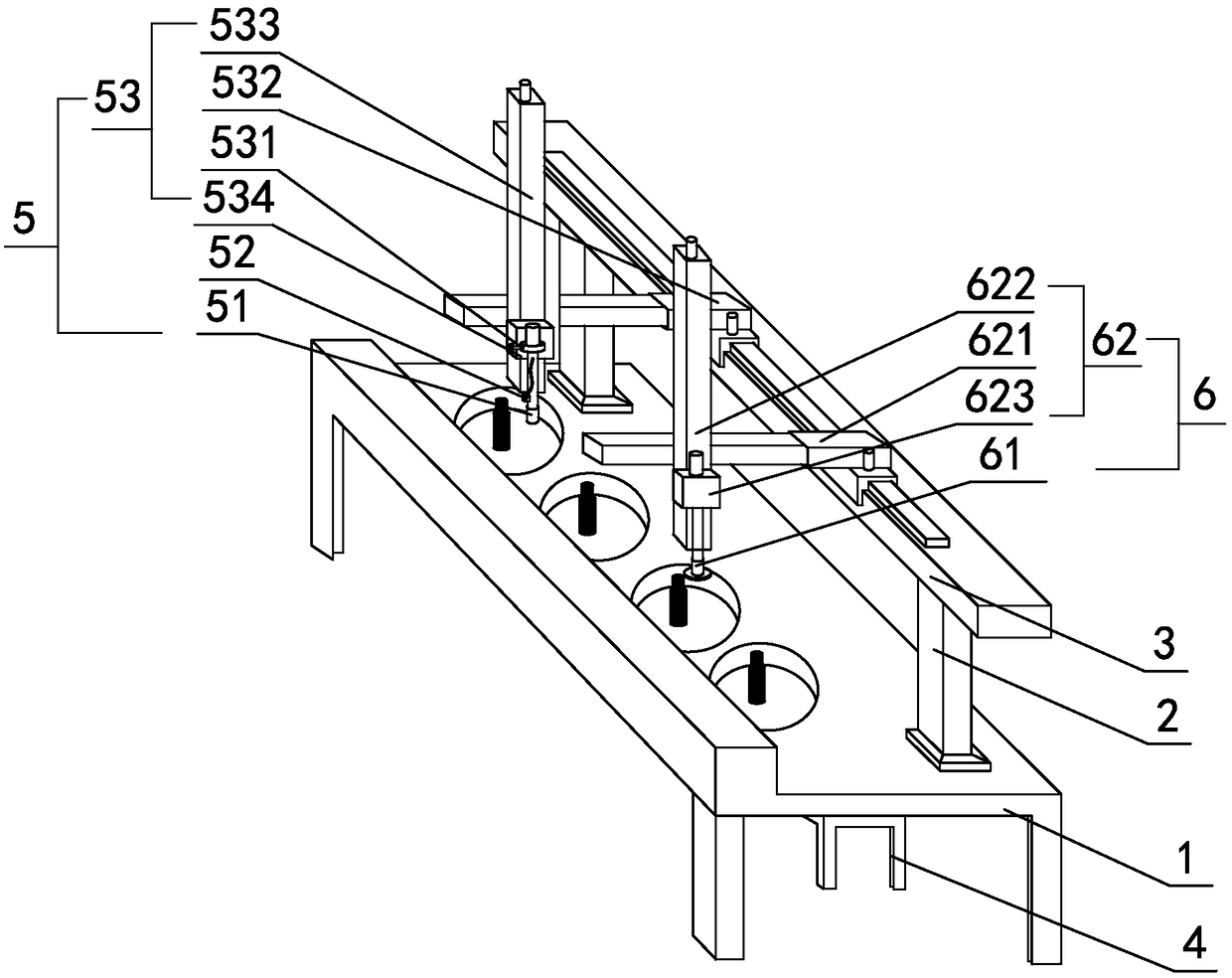

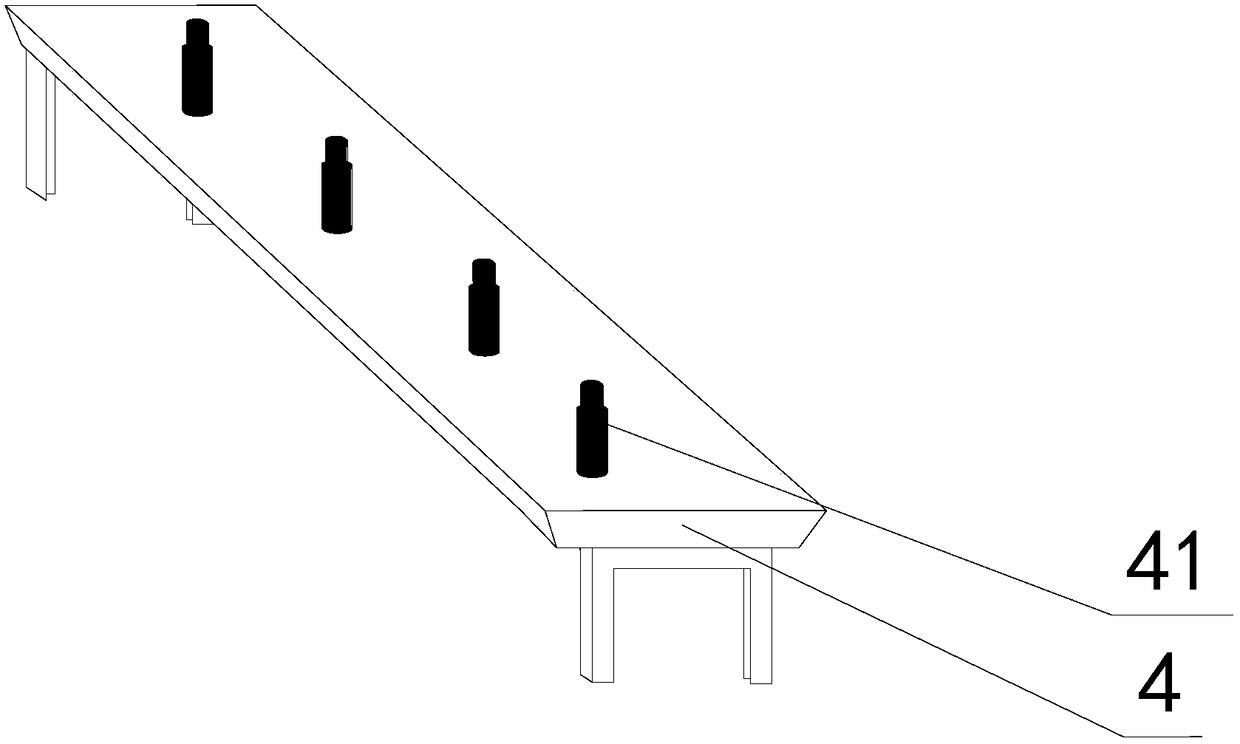

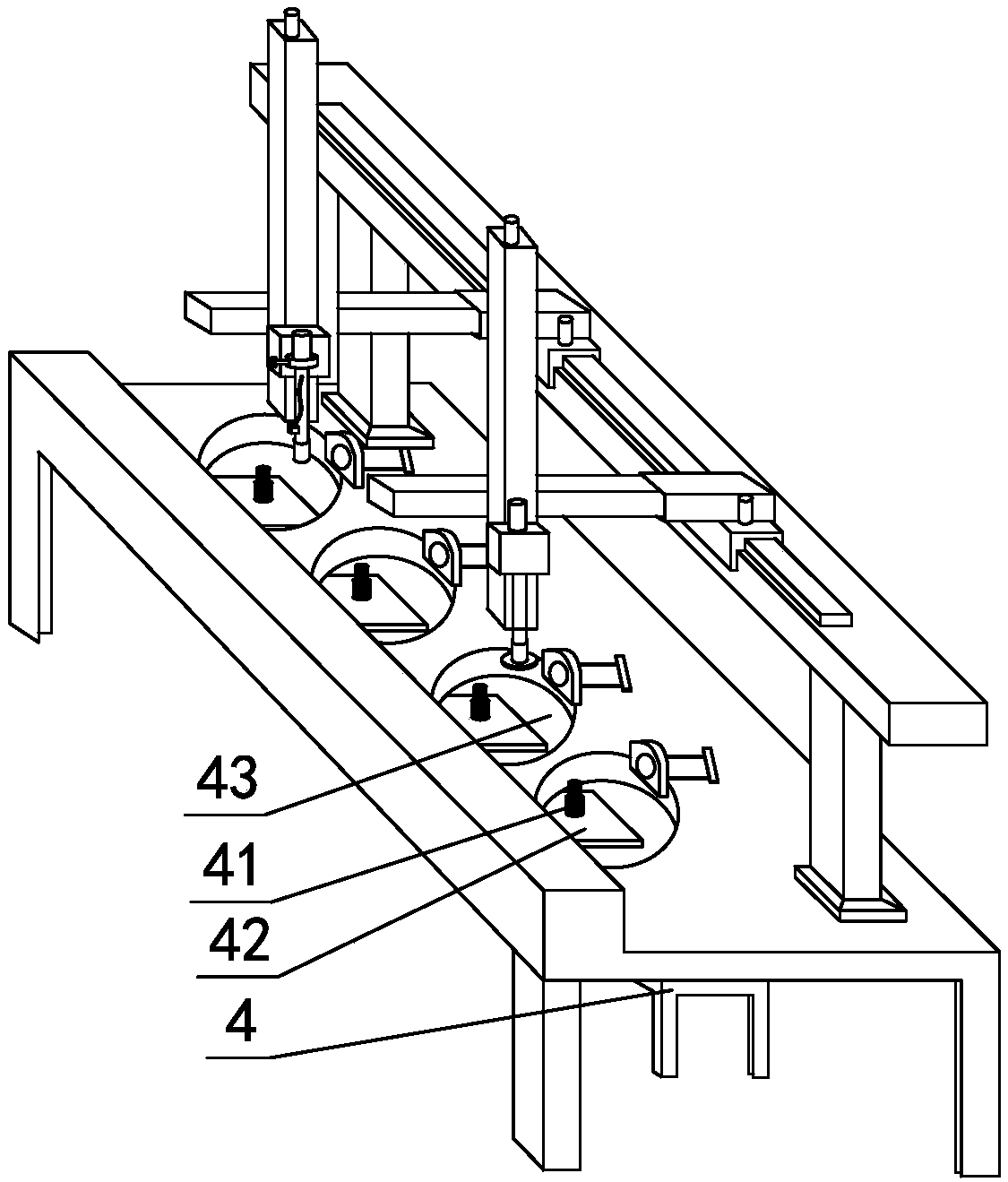

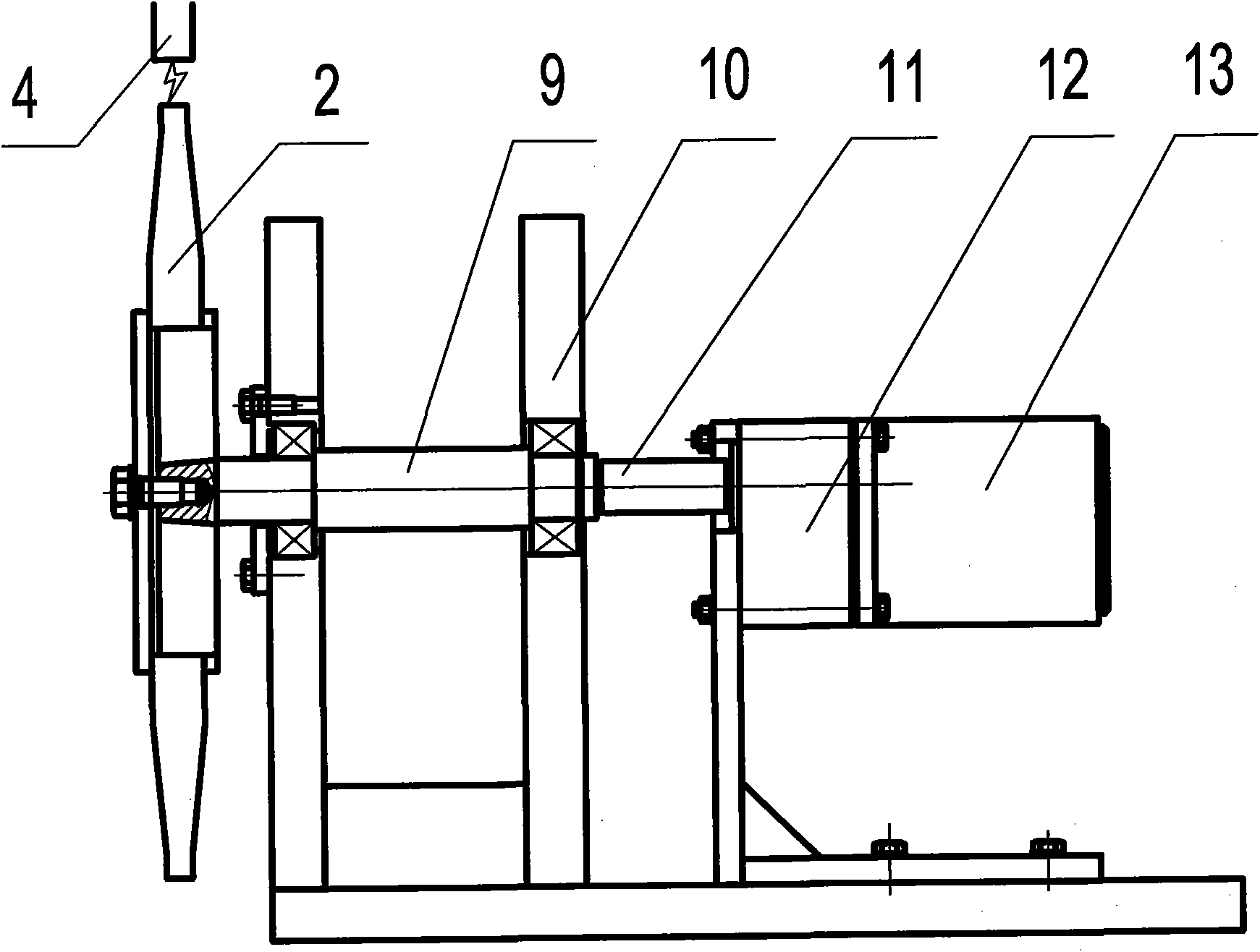

Engine crankshaft circular bead laser cladding repairing device and method

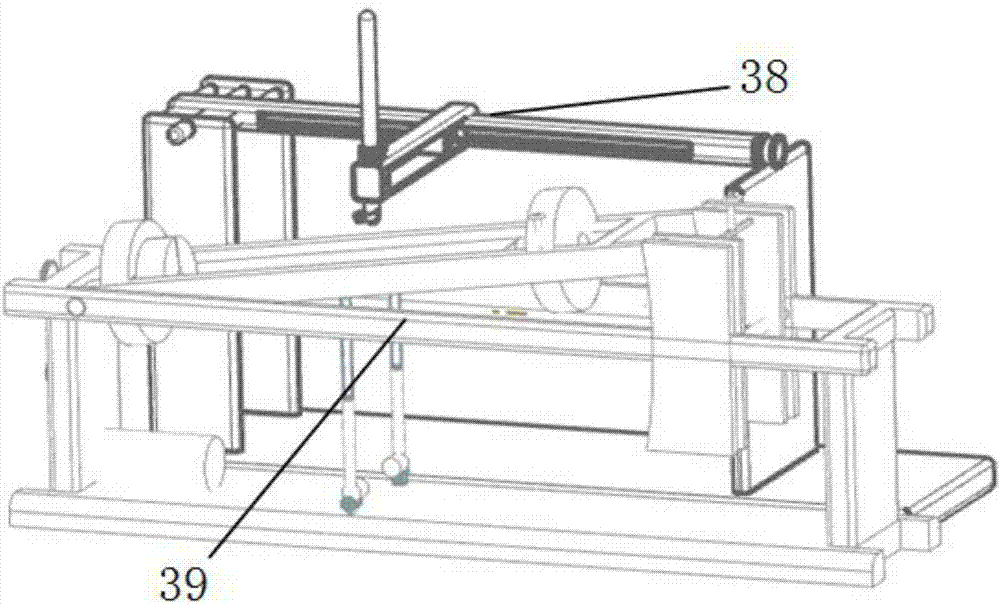

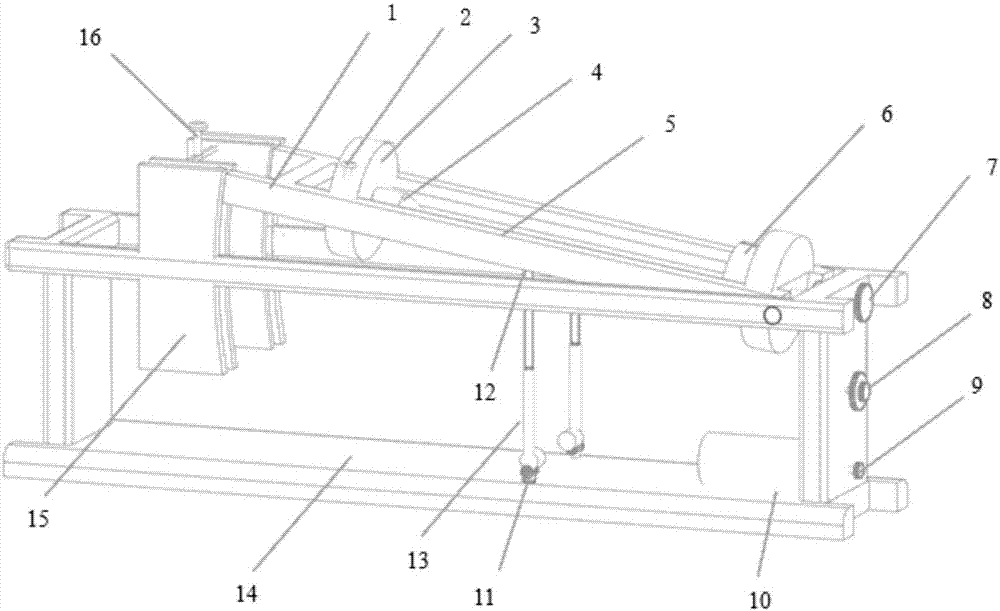

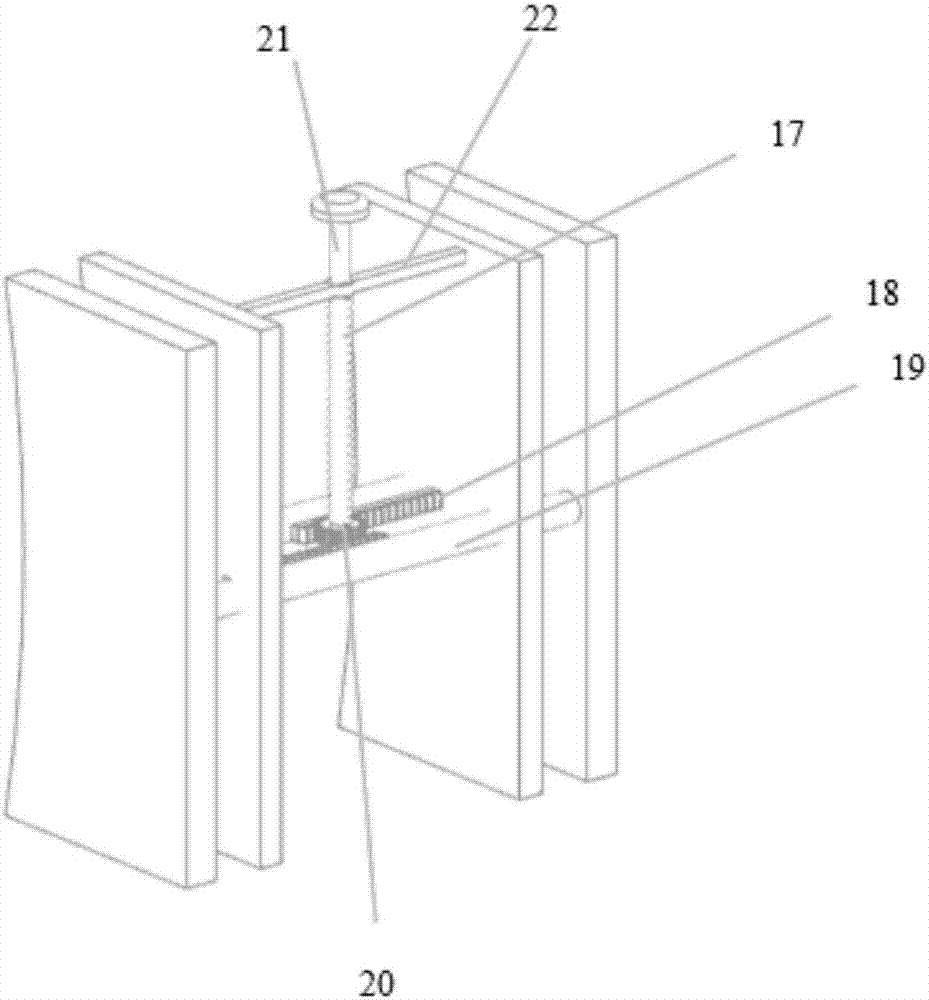

ActiveCN107175403AAchieve remanufacturingAchieve reuseLaser beam welding apparatusCrankshaftSupport plane

The invention discloses an engine crankshaft circular bead laser cladding repairing device and method solving the problem that in the prior art, crankshaft circular bead repairing is limited and having the beneficial effects of being convenient to operate and low in cost. According to the scheme of the engine crankshaft circular bead laser cladding repairing device and method, the engine crankshaft circular bead laser cladding repairing device comprises a crankshaft cladding clamp used for clamping a crankshaft and a three-axis driving mechanism arranged on one side of the clamp support; the crankshaft cladding clamp comprises a chuck used for driving the crankshaft to rotate around the axis of the crankshaft, the chuck is supported through a clamp support, and the crankshaft cladding clamp can ascend and descend so as to drive the crankshaft to incline in the set angle range; the three-axis driving mechanism comprises a supporting frame, the supporting frame supports a first sliding rail, the first sliding rail is provided with an X-direction guide rail capable of moving along the first sliding rail, the X-direction guide rail is provided with a Y-direction connecting rod capable of moving along the X-direction guide rail, the Y-direction connecting rod is provided with a Z-direction lead screw capable of moving up and down relative to the Y-direction connecting rod, and the Z-direction lead screw is fixed to a laser cladding head.

Owner:SHANDONG UNIV

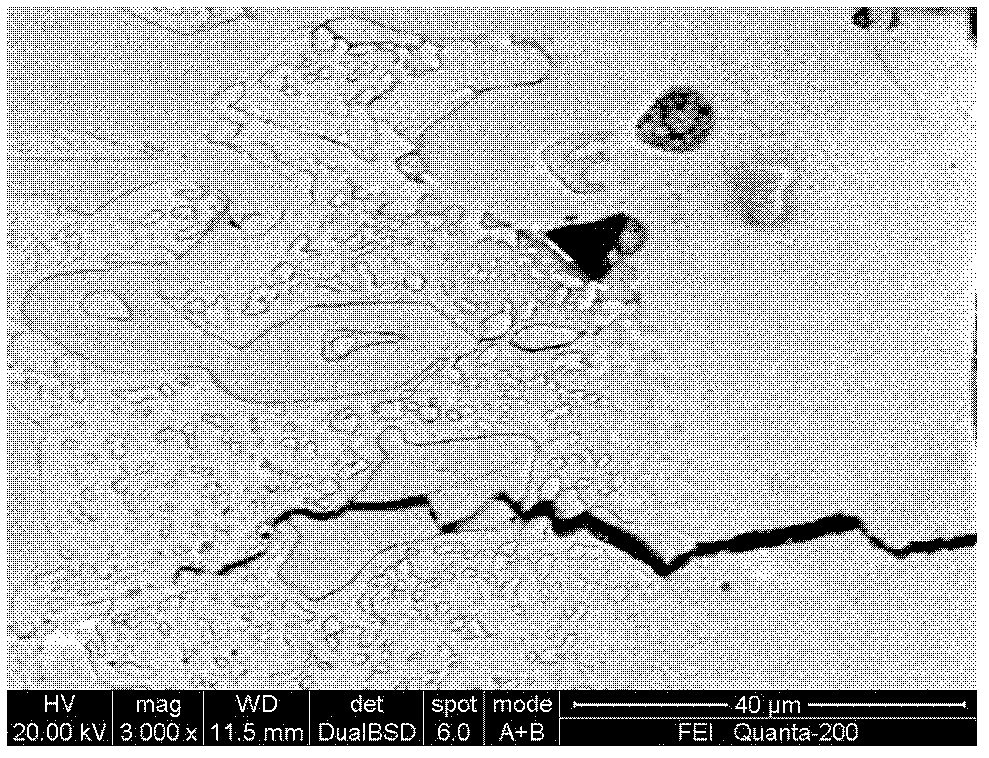

Remanufacturing method of polished rods of oil pumping units and polished rods of oil pumping units

InactiveCN109759689AAchieve remanufacturingChange performanceDrilling rodsDrilling casingsFriction weldingHeat-affected zone

The invention provides a remanufacturing method of polished rods of oil pumping units. The remanufacturing method comprises the steps that step 1, the abrasion section of a polished rod of a certain oil pumping unit is cut off to obtain an intact section of the polished rod of the oil pumping unit; step 2, a connecting section matched with the abrasion section is cut off from the polished rod of another oil pumping unit; step 3, friction welding connection is carried out on the intact section obtained in the step 1 and the connecting section obtained in the step 2; and step 4, post-processingis carried out on the friction welding connection part in the step 3. According to the remanufacturing method, abrasion parts of the polished rods are removed by using existing waste polished rods andadopting a sectional material obtaining method, non-abrasion parts of the polished rods are spliced to the design size by friction welding, and surface processing is carried out to meet the size requirement of the polished rods. The remanufacturing method is characterized in that friction welding is adopted to carry out splicing welding, the bonding part is metallurgical bonding, and through process control, the splicing welding is carried out below the phase change point of a material, so that embrittlement of a heat affected zone is reduced, and the remanufactured polished rods can be recycled by turning waste into treasure.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

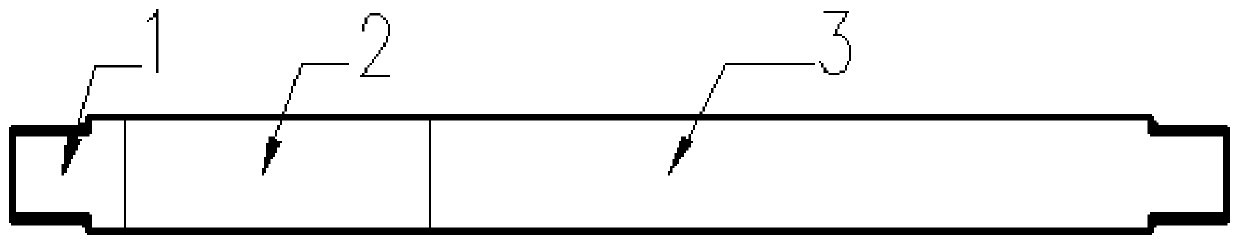

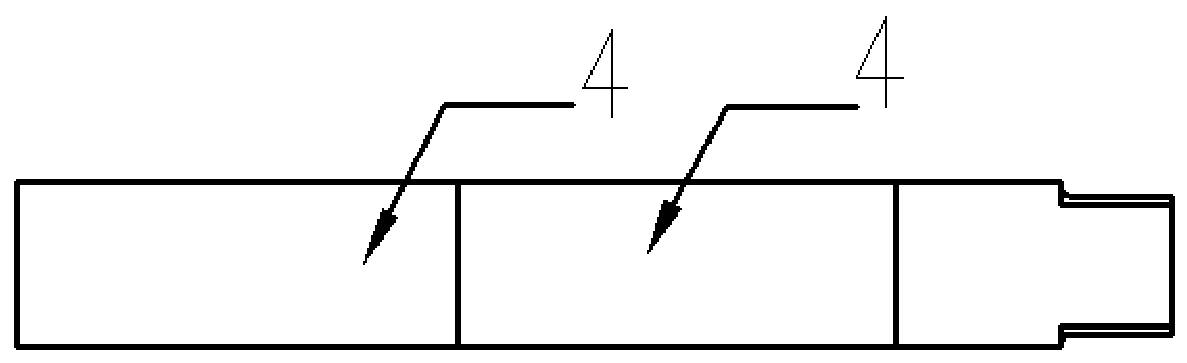

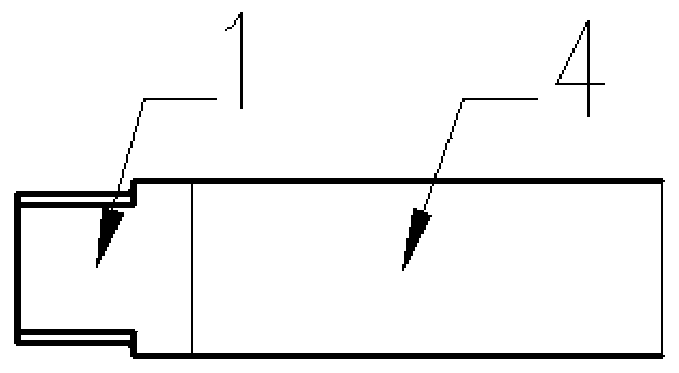

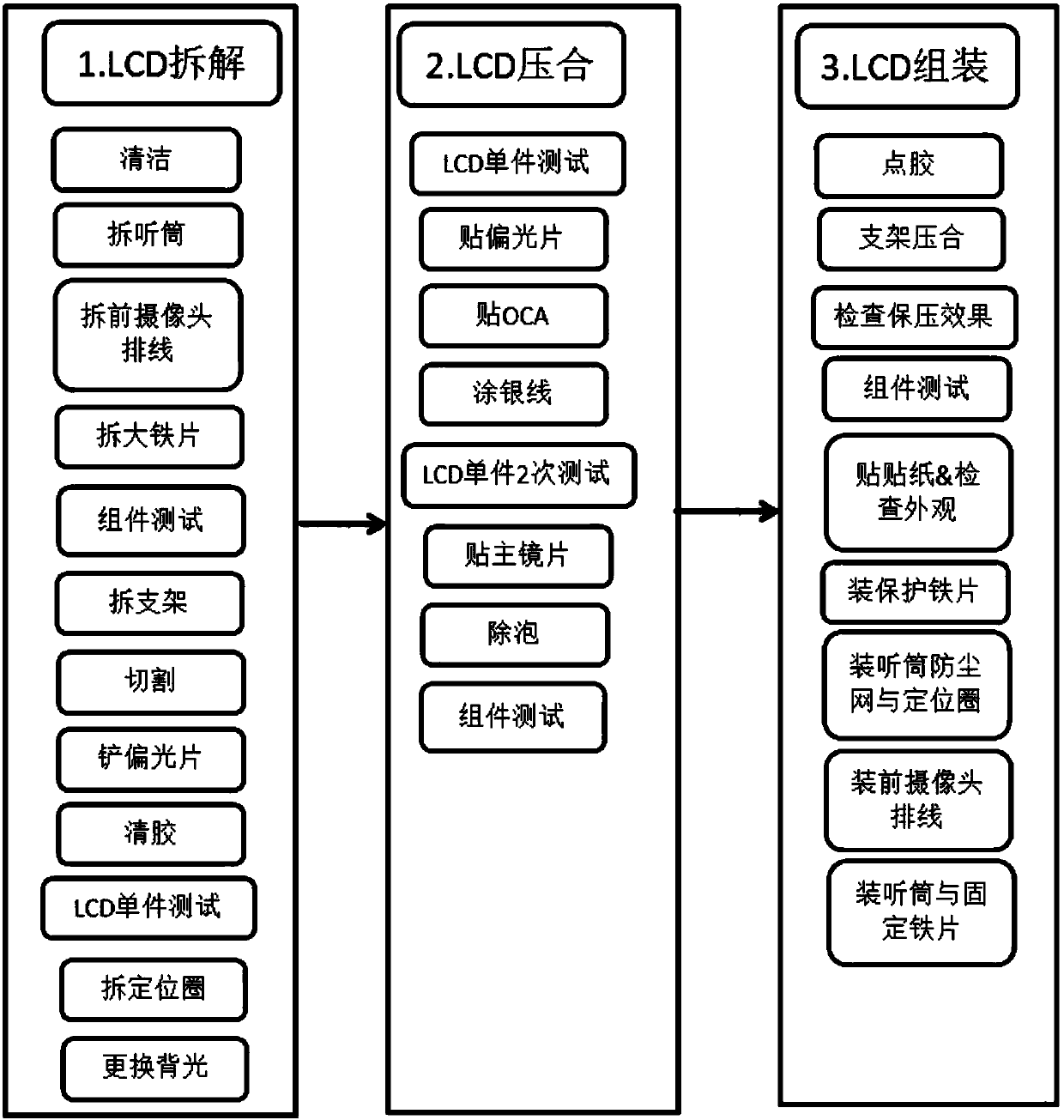

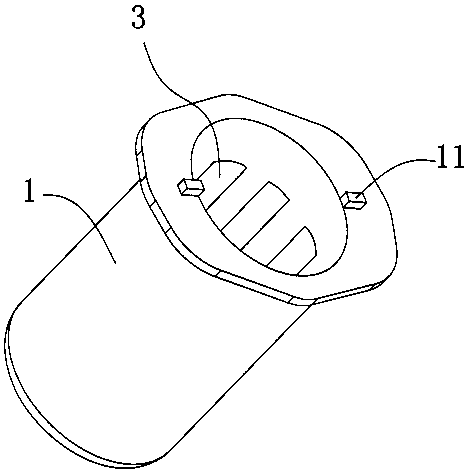

Remanufacturing process of liquid crystal display module

InactiveCN107817623AAchieve remanufacturingSimple and fast operationNon-linear opticsLiquid-crystal displayEngineering

The invention discloses a remanufacturing process of a liquid crystal display module, relating to the technical field of liquid crystal display modules. The remanufacturing process comprises the following process steps: LCD disassembly, LCD press fit and LCD assembly. The remanufacturing process particularly comprises the following process steps: (1) carrying out LCD disassembly, namely cleaning,dismounting a telephone receiver, dismounting a front row of camera flat cable, dismounting a big iron piece, testing assemblies, dismounting a bracket, cutting, shoveling a polaroid, cleaning glue, testing an LCD single component, dismounting a positioning ring, and replacing a back light; (2) carrying out LCD press fit, namely testing the LCD single component, laminating the polaroid, laminatingOCA, coating a silver wire, carrying out secondary testing on the LCD single component, laminating a main lens, removing foams, and testing the assemblies; and (3) carrying out LCD assembly. The remanufacturing process can be used for remanufacturing the liquid crystal display module and is easy and convenient to operate and high in accuracy; and the efficiency is improved.

Owner:俐通电脑科技(深圳)有限公司

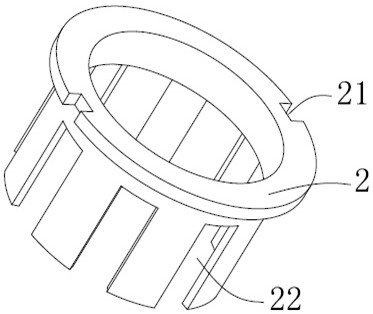

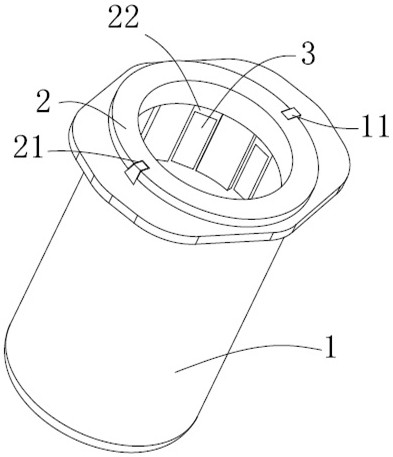

Permanent magnet motor remanufacturing and repairing process with magnetic poles glued and assembly line

ActiveCN110571993AAchieve remanufacturingAchieve recyclingManufacturing stator/rotor bodiesMagnetic polesAssembly line

The invention discloses a permanent magnet motor remanufacturing and repairing process with magnetic poles glued and an assembly line. The process comprises the following steps: firstly, the end coverof a to-be-repaired permanent magnet motor is opened, the outer surface of a stator shell is heated until glue is melted and fails, magnetic poles on the inner side of the stator shell are beaten, and the magnetic poles are separated from the stator shell; the stator shell after being separated is cooled, and glue is adhered to the surface, in contact with the stator shell, of a new magnetic pole; and the surfaces of the positive magnetic pole and the negative magnetic pole which are adhered with the glue are alternately glued to the inner wall of the stator shell. The invention further discloses a permanent magnet motor remanufacturing and repairing assembly line with the magnetic poles glued, which comprises a rotary fixing device, a heating device, a cooling pool, a conveying device and an operation table. The magnetic pole and the stator shell can be completely separated, the magnetic pole is prevented from remaining in the stator shell, the stator shell is not damaged, and the remanufacturing production of the permanent magnet motor is realized.

Owner:三立(厦门)汽车配件有限公司

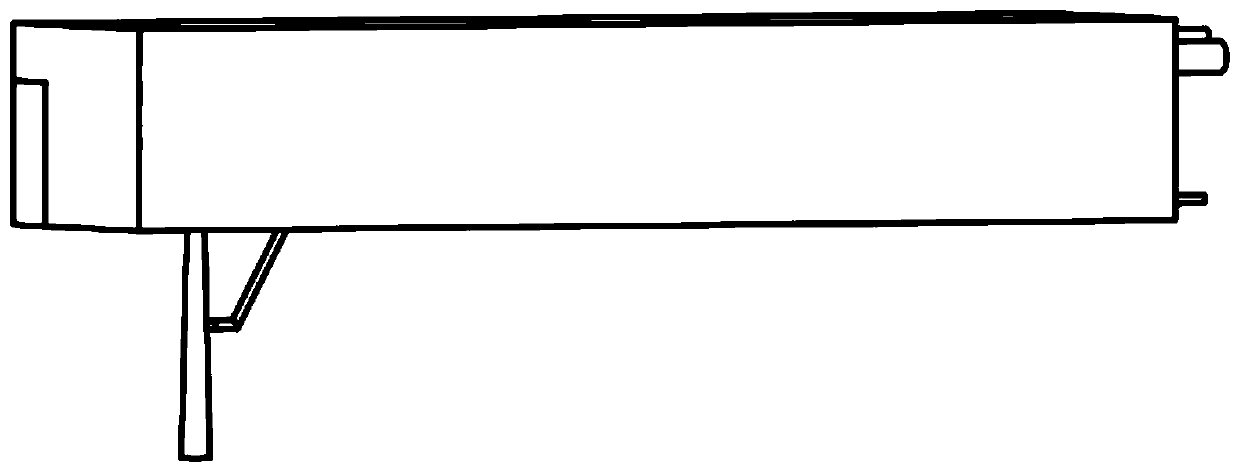

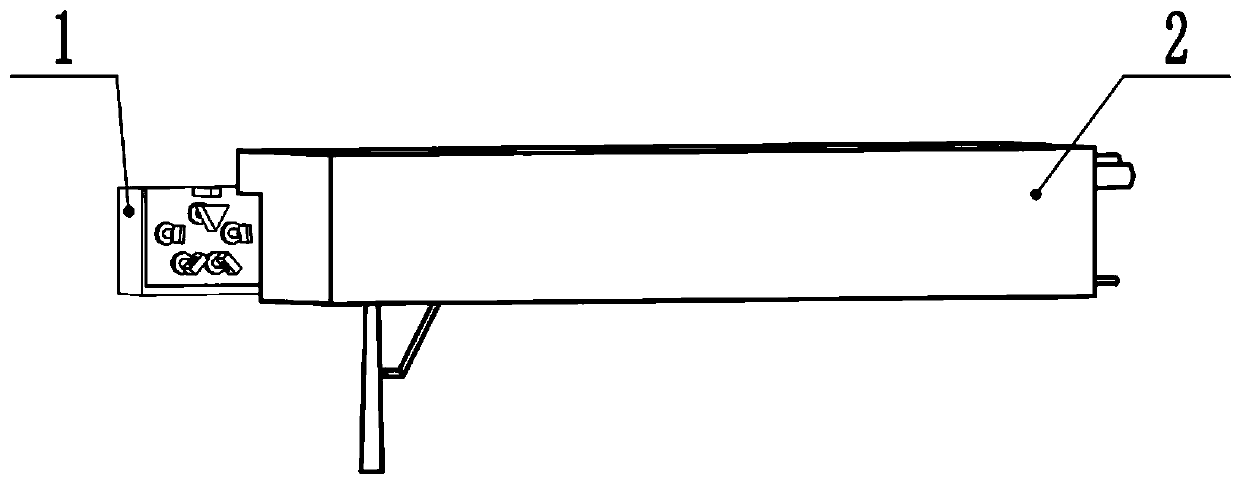

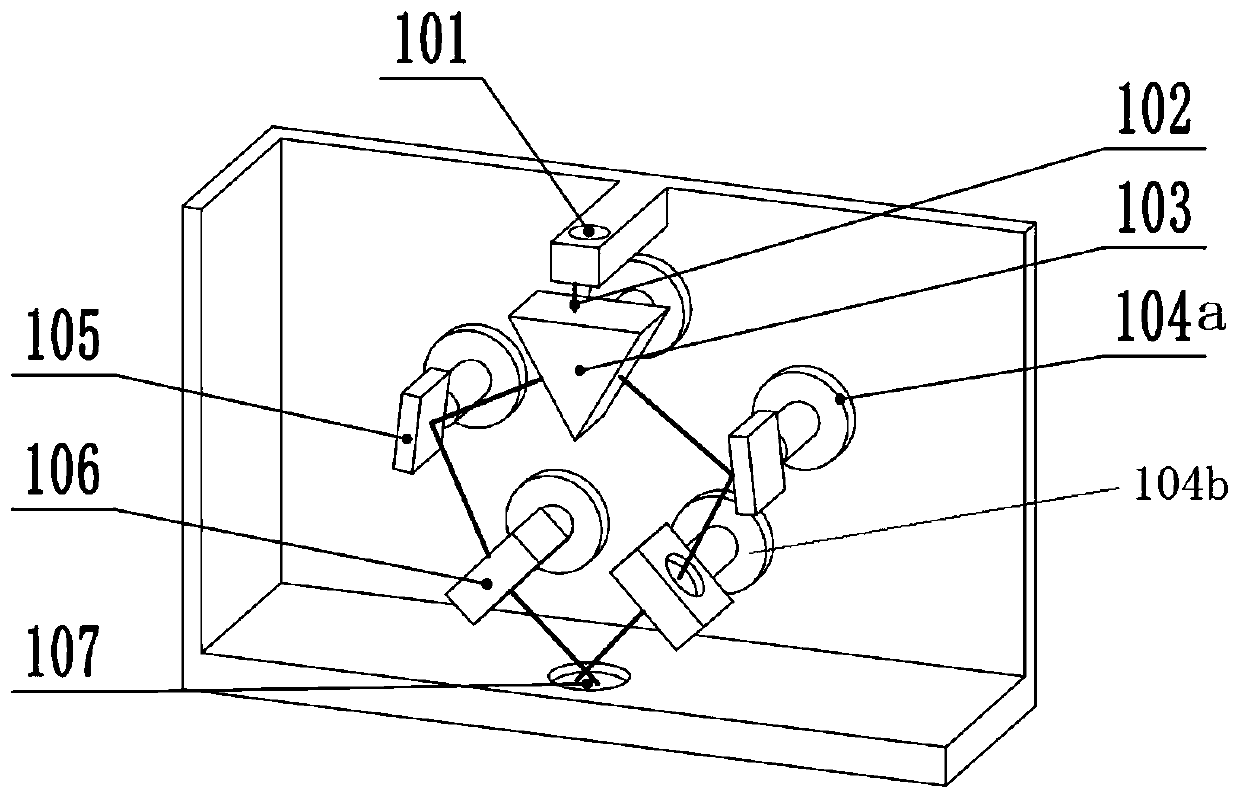

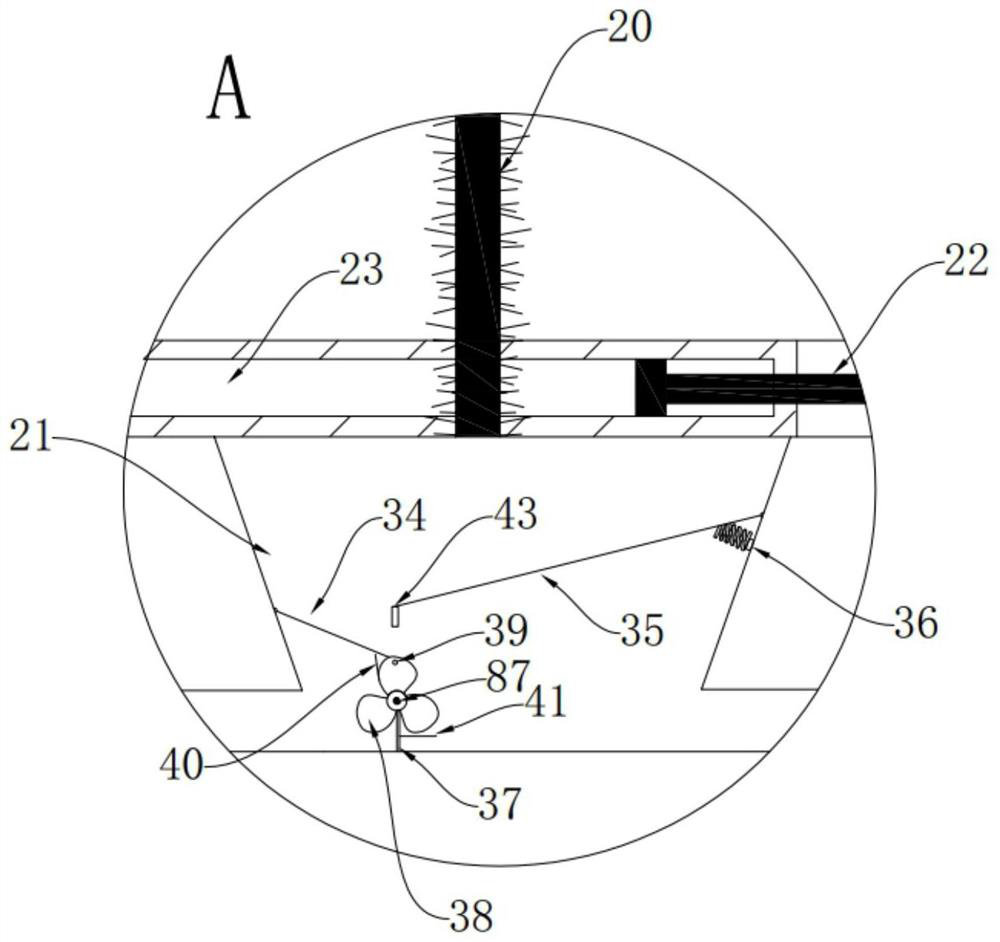

Inner wall supersonic laser composite deposition device

PendingCN110904447AAchieve fixAchieve remanufacturingPressure inorganic powder coatingMetal coatingGalvanometer

The invention discloses an inner wall supersonic laser composite deposition device. The device comprises a galvanometer scanning unit, wherein the galvanometer scanning unit comprises a mounting framebody and a galvanometer scanning device, the mounting frame body is mounted on an inner wall supersonic laser deposition unit, an upper portion of the mounting frame body is provided with a light transmitting opening allowing laser beams to penetrate through, and the bottom of the mounting frame body is provided with a laser outlet allowing the laser beams to penetrate through, the inner wall supersonic laser deposition unit comprises a cylinder body, a nozzle, a laser path, an air supply pipe and a powder supply pipe, the nozzle, the laser path, the air supply pipe and the powder supply pipeare all installed in the cylinder body, a light outlet of the laser path is divided into two parts through an optical splitter, a first path extends to the light transmitting opening of the mountingframe body, and a second path communicates with the upper portion of the nozzle, and a light outlet of a laser device is aligned with a light inlet of the laser path. The device is advantaged in thatpreparation of a metal coating or a composite coating on an inner wall of a hole part is achieved, repairing and remanufacturing of the inner wall can further be achieved, and surface performance of the inner wall is improved.

Owner:ZHEJIANG UNIV OF TECH

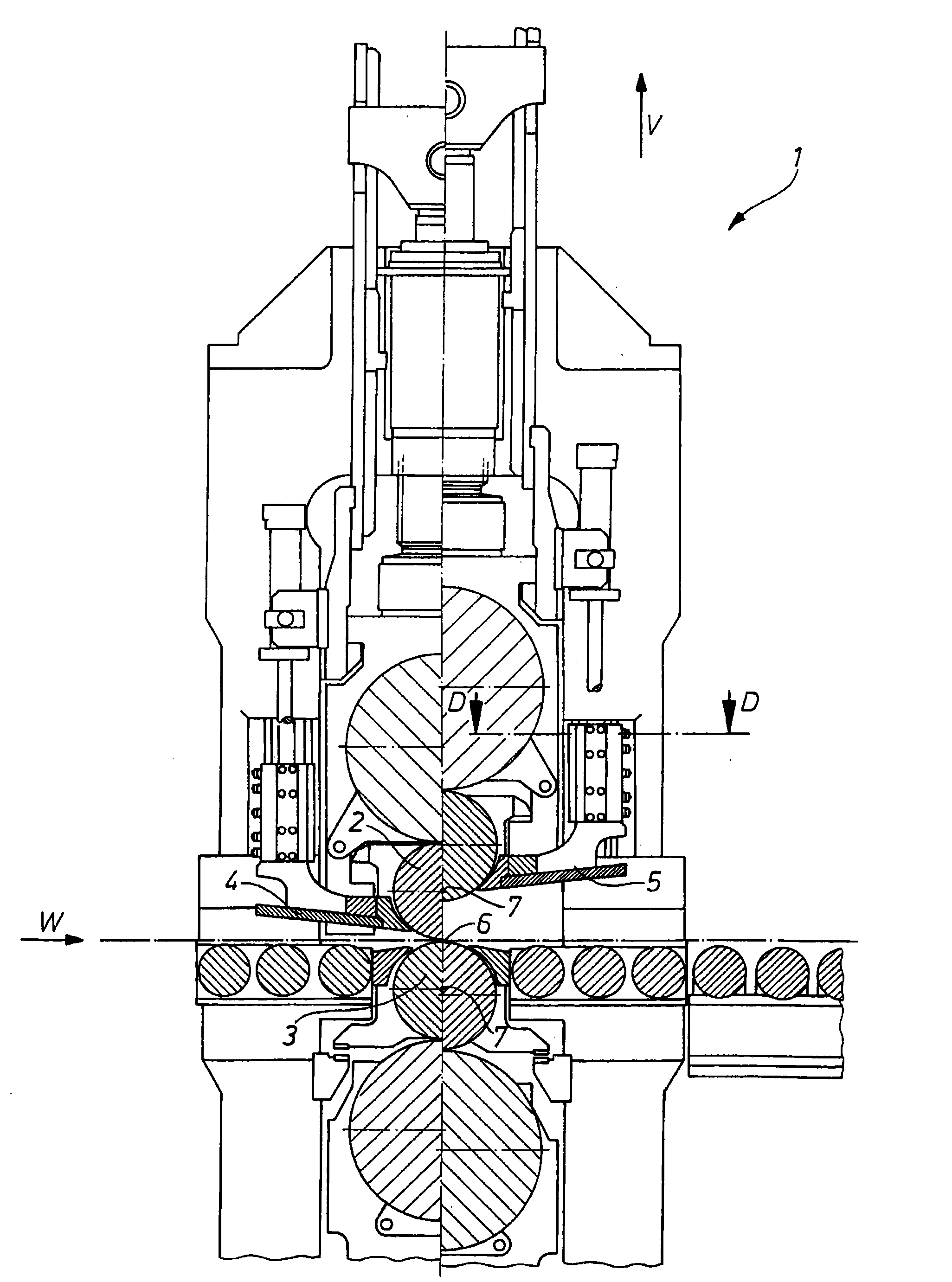

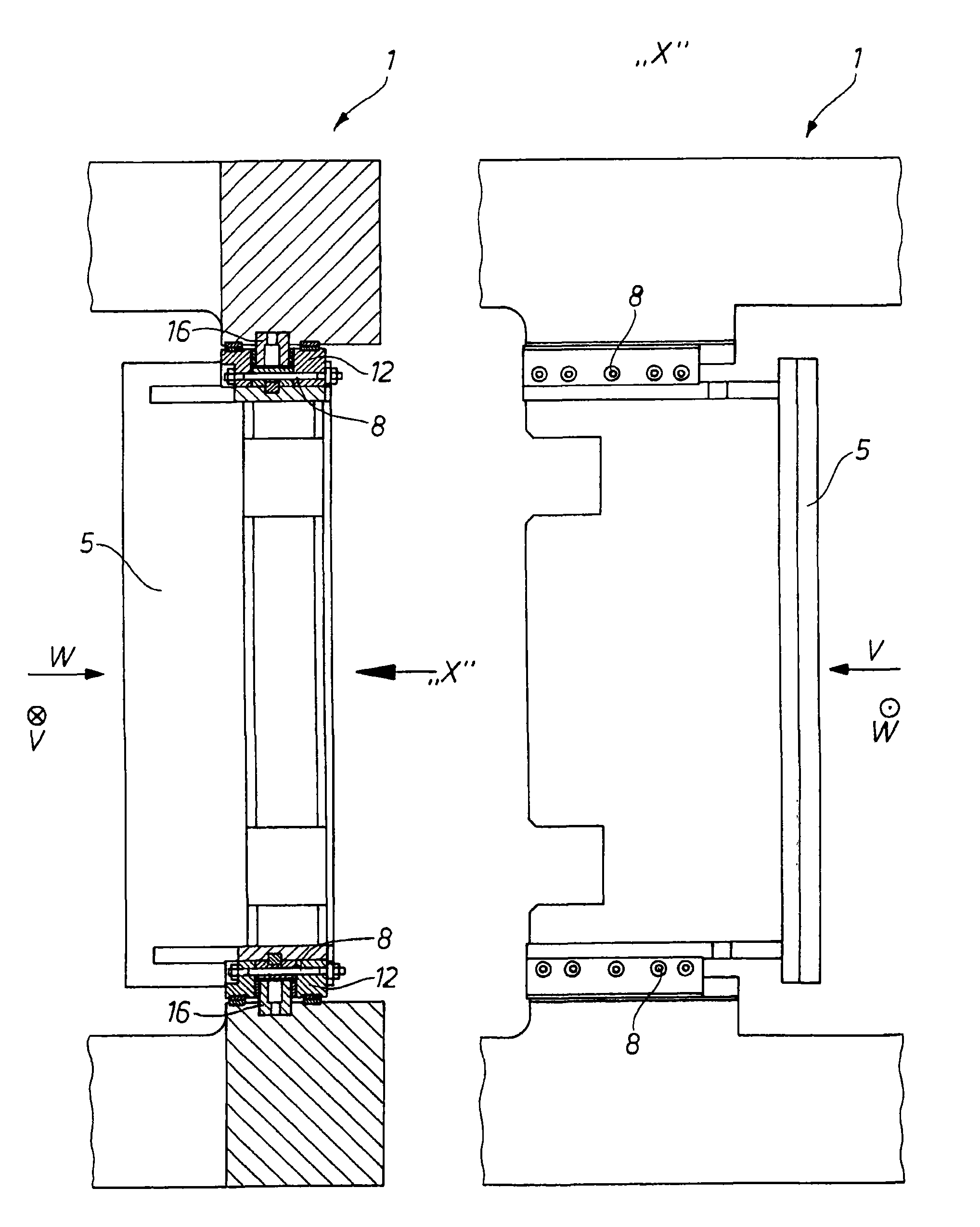

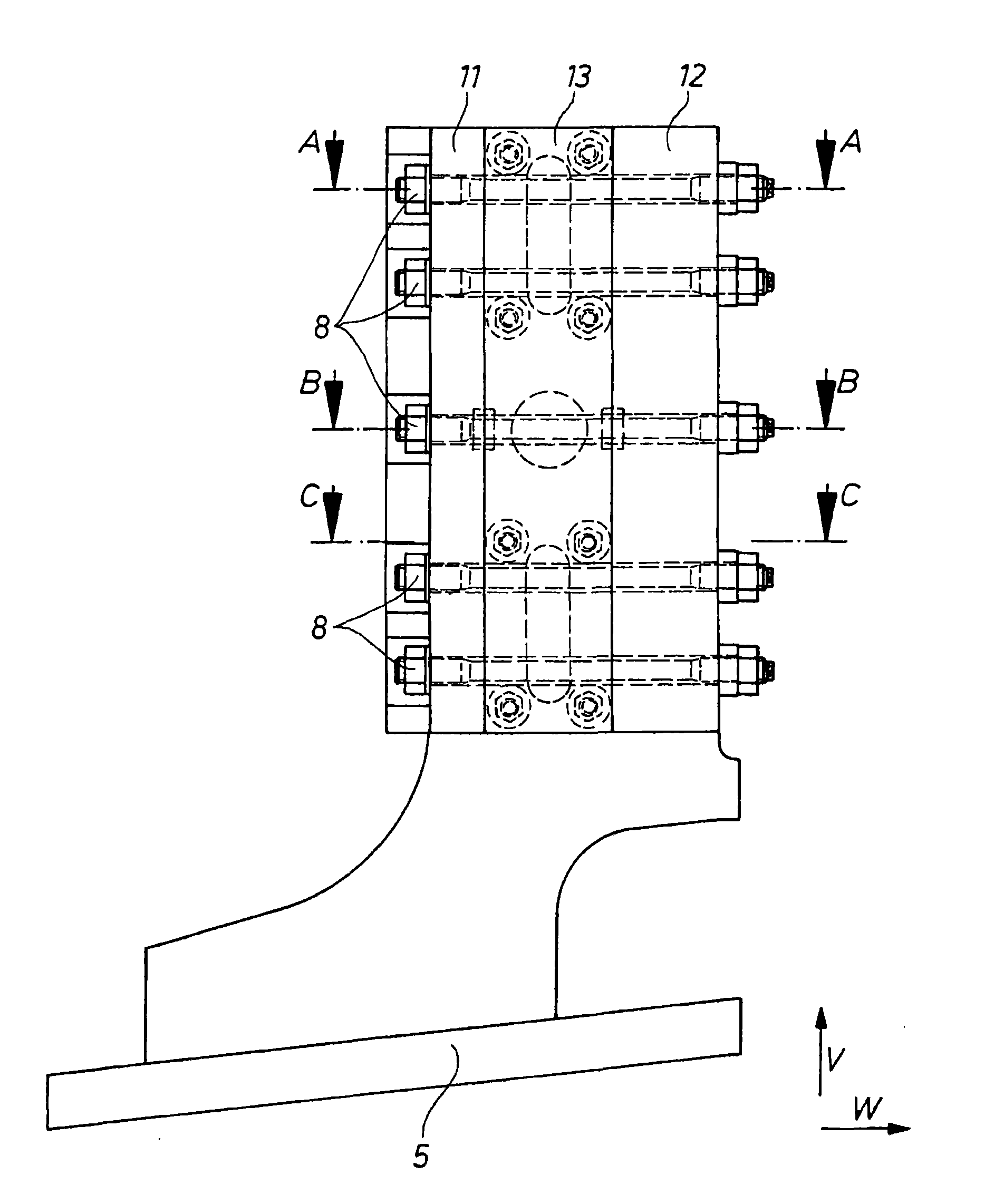

Roll stand

ActiveCN101541445ALee DesignReduce damageGuiding/positioning/aligning arrangementsEngineeringStructural engineering

Owner:SMS DEMAG AG

Method for producing high-temperature resistant composite lining plate through micro-metallurgy

The invention discloses a method for producing a high-temperature resistant composite lining plate through micro-metallurgy, which comprises the steps of removing rust, oil stains and scale impurities from the surface of a metal base material, producing metal-base ceramic particle reinforced alloy powder for mixing according to the metal base material and condition requirements, mixing the mixed alloy powder with white emulsion, then uniformly painting the mixed alloy powder on the surface of the metal base material, blacking the alloy powder layer with Chinese ink after drying, drying again, and allowing the metal-base ceramic particle reinforced alloy powder to conduct rapid micro-metallurgy reaction with the metal on the surface of the base material through high-density energy of semiconductor laser beams so as to obtain a 0.2-0.35 mm-thick high-temperature resistant metal ceramic layer that is positioned on the surface of the metal base material and metallurgically bonded with the base material. The high-temperature resistant composite lining plate is low in cost, stable in quality and suitable for large-scale production, requirements of special conditions of on-site high-temperature abrasion can be met, and the service life of the lining plate is extended effectively.

Owner:QINHUANGDAO GERUIDE ENERGY SAVING TECH SERVICE

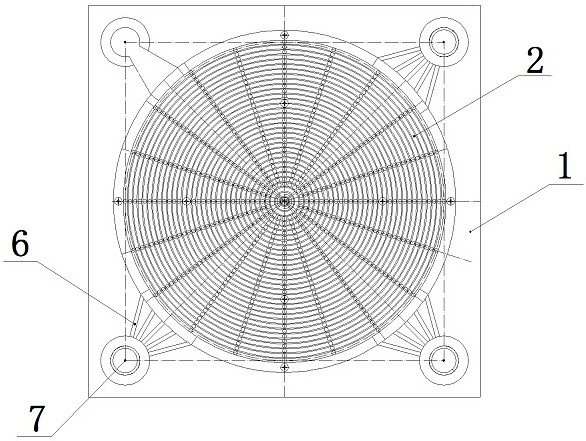

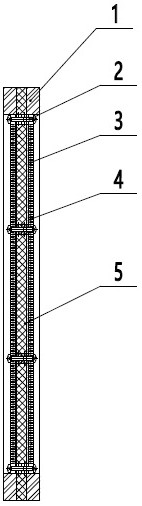

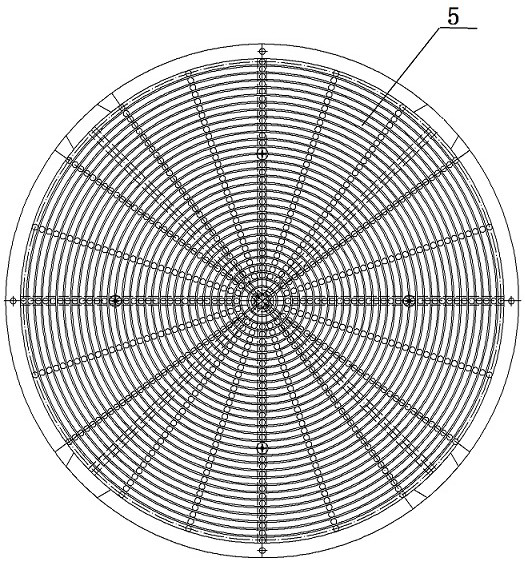

Plate core embedded type stainless steel combined filter plate and corresponding compartment type filter mechanism

PendingCN112138439AFast liquidSave valuable resourcesFiltration separationRemanufacturingStructural engineering

The invention discloses a plate core embedded type stainless steel combined filter plate and a corresponding compartment type filter mechanism. The combined filter plate comprises a square plate frame, a detachable filter disc and a filter disc bracket, has a symmetrical double-sided structure and is made of a stainless steel material; the key points of the innovative scheme are as follows: a filter plate is improved into a cavity overhead type, and a plate core is replaceable; the filter disc support is embedded in a cavity of the square plate frame, the detachable filter disc is installed onthe filter disc support, namely, the filter disc is erected by the support to form a cavity overhead layer, and the flow guide net groove is not blocked any more. When the filter disc is corroded anddamaged, the filter disc can be detached and replaced to prevent the whole filter plate from being scrapped; the invention has the advantages that high temperature resistance and high pressure resistance are achieved, the cavity is overhead and unblocked, liquid discharging is fast, and the plate core is replaceable. The compartment type filter mechanism uses the combined filtering plate, so thatthe technical problems that a stainless steel filtering plate flow guide net groove is easy to block, a plate core cannot be partially replaced, and remanufacturing cannot be realized are solved; theoverhead cavity is formed, so that the filtering efficiency and effect are improved, the plate core is replaceable, precious resources are saved, and the use cost is reduced; and the invention is thedevelopment direction of remanufacturing of the stainless steel filter press.

Owner:JINGJIN ENVIRONMENTAL PROTECTION INC

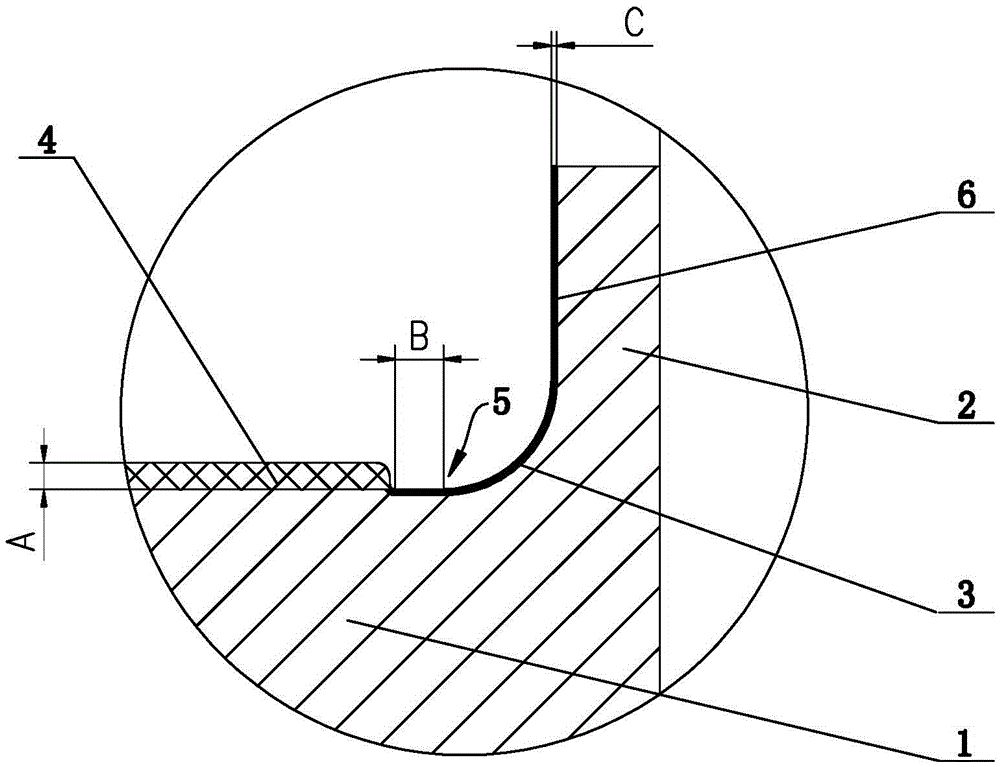

Engine crankshaft and remanufacturing method thereof

The invention discloses an engine crankshaft belonging to the technical field of engine remanufacturing. The engine crankshaft comprises a plurality of shaft necks, wherein each shaft neck comprises a shaft neck body, wherein flanges are arranged at two ends of the shaft neck body, a circular bead is arranged between each flange and the shaft neck body, a laser cladding coating is formed on the outer surface of the shaft neck body, a gap is left between the edge of the laser cladding coating and the corresponding circular bead, and nitriding layers are formed on the end surfaces, close to the shaft neck body, of the flanges, the circular beads and the gaps. The invention also discloses an engine crankshaft remanufacturing method. The remanufacturing method comprises the steps of removing a nitration layer or an oxidation layer on the surface of the shaft neck, forming the laser cladding coating, forming the nitration layer and restoring the product size. By using the remanufacturing method, the engine crankshaft with a defect on the shaft neck can be repaired under conditions of ensuring the safety factor and the whole performance of the crankshaft to meet the using requirements, the precision requirement of the crankshaft neck can be restored and the remanufacturing of the crankshaft of a high-speed engine can be achieved.

Owner:WEICHAI POWER CO LTD

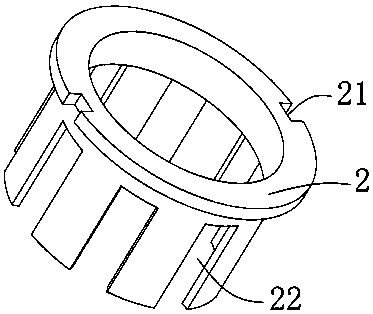

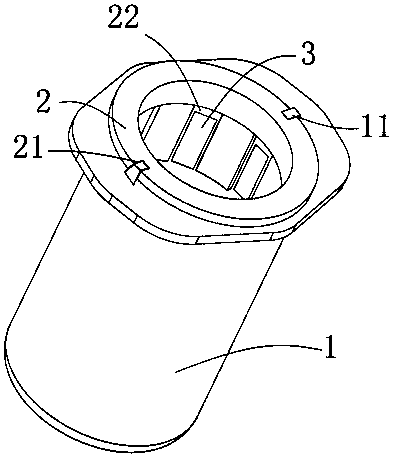

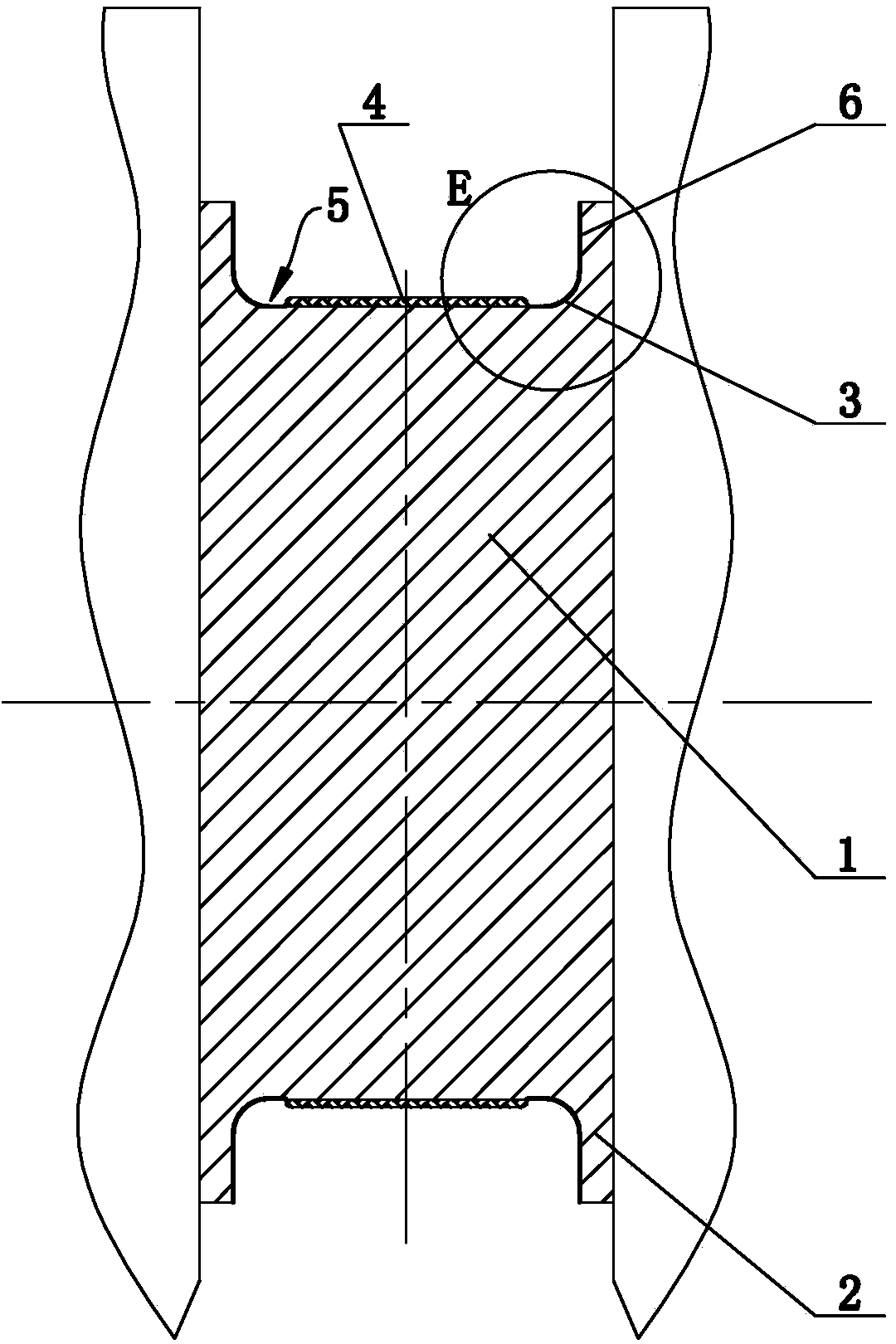

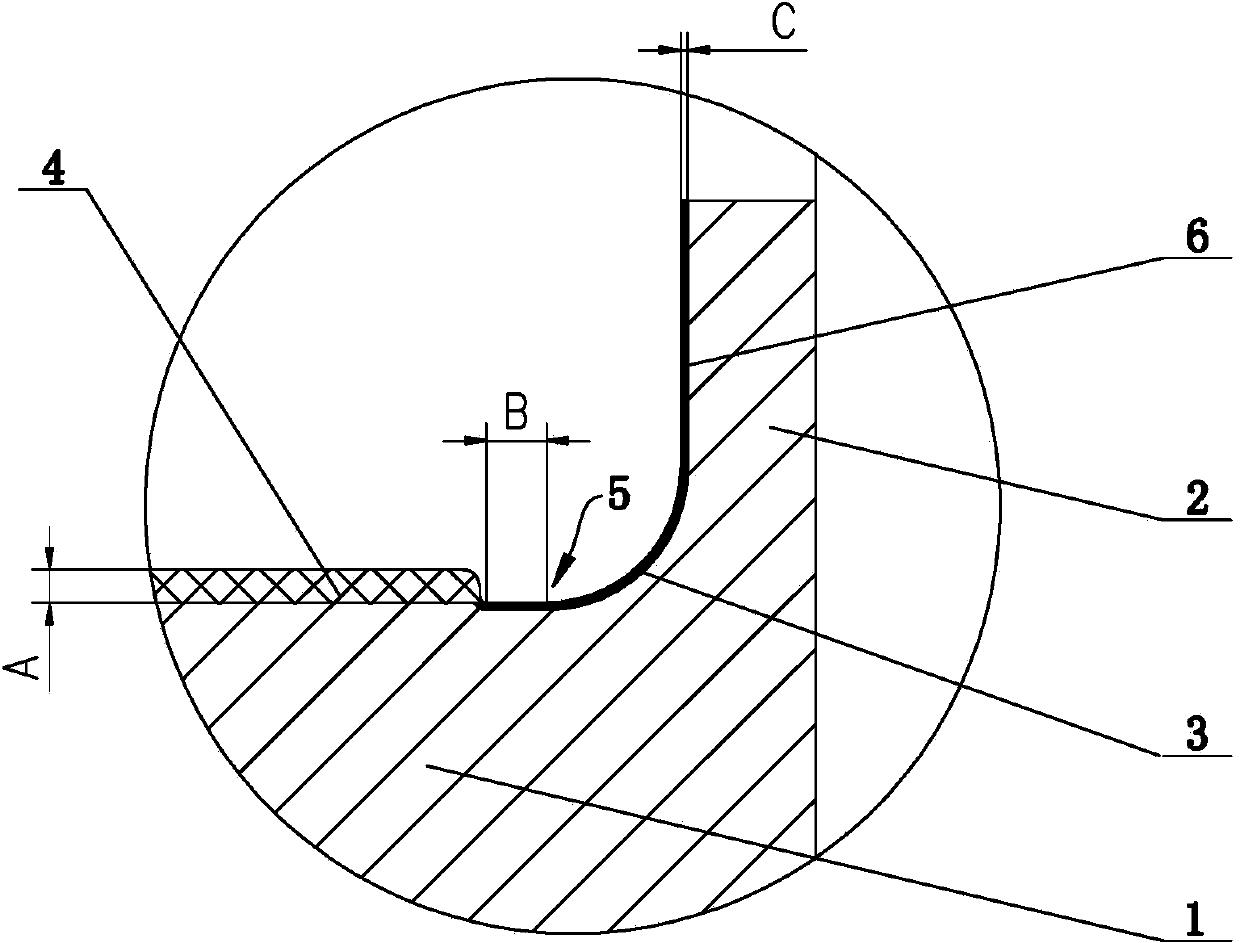

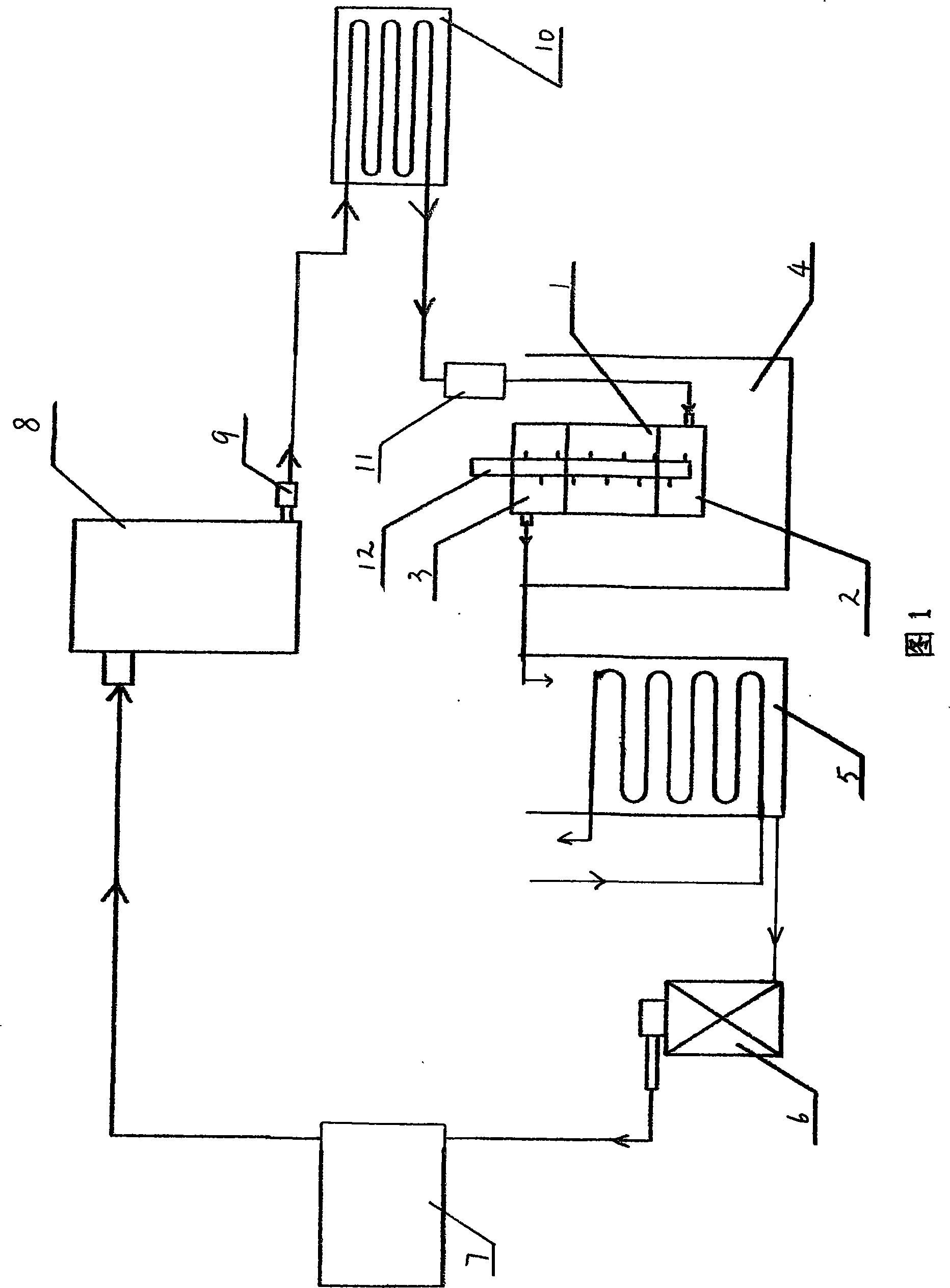

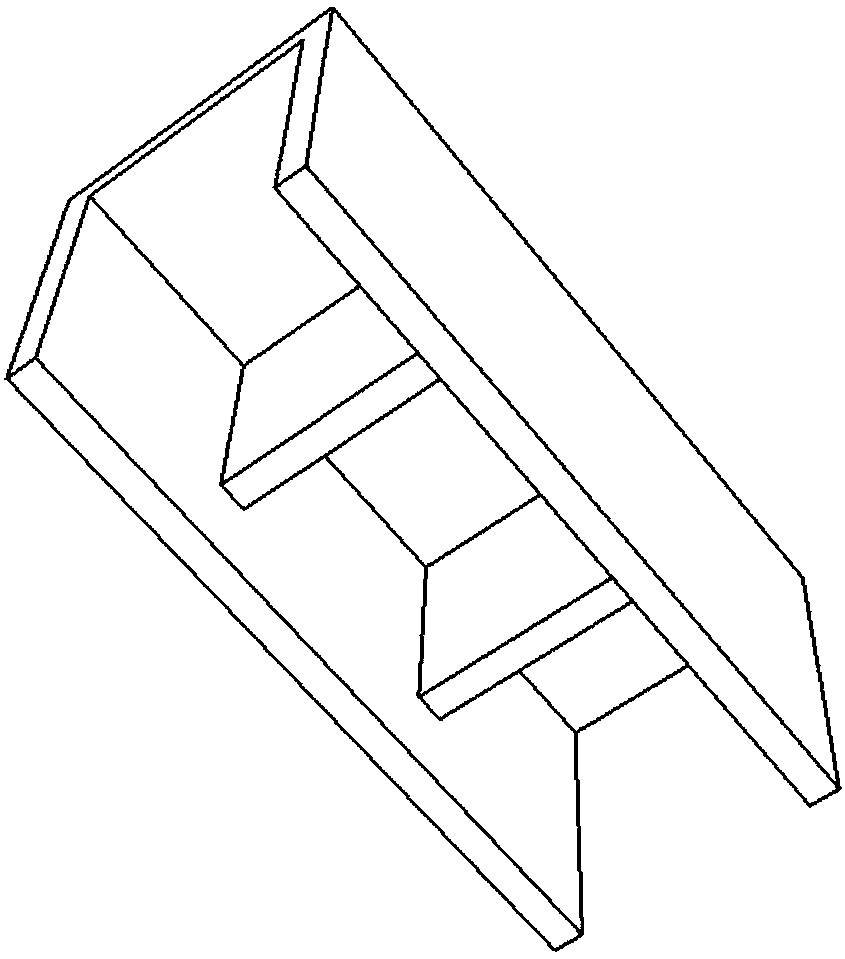

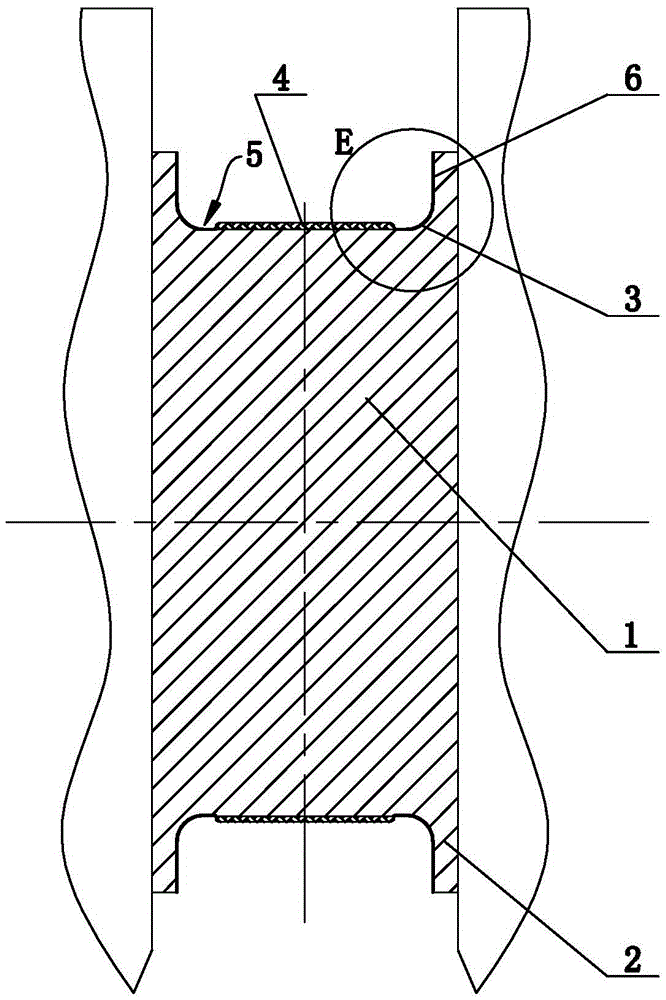

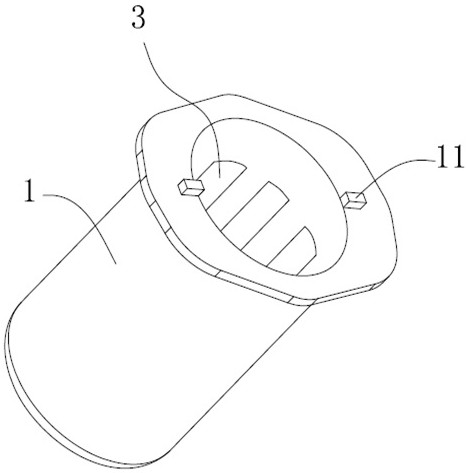

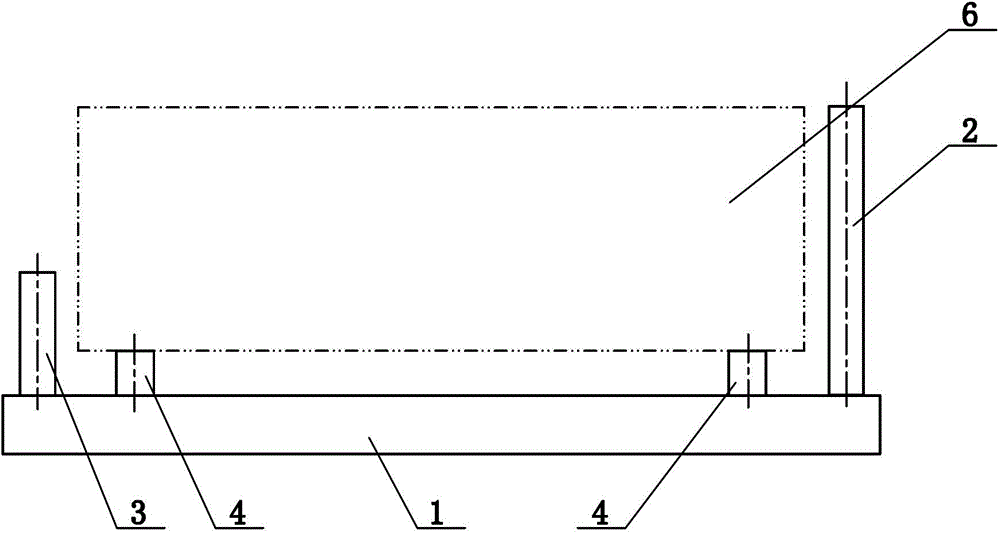

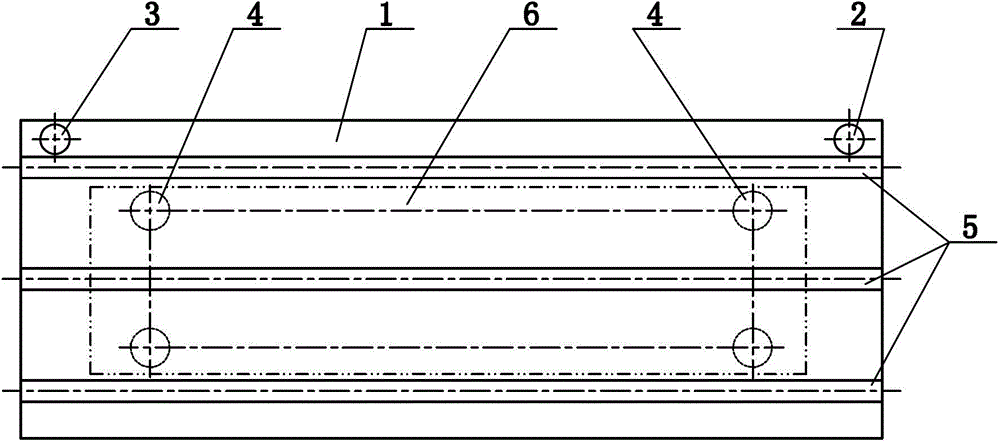

Device for manufacturing or repairing cylinder cover by novel composite corpuscle nickel base alloy

InactiveCN101250697AAchieve remanufacturingImprove performanceSolid/suspension decomposition chemical coatingLiquid storage tankAlloy

The invention relates to a device which uses new composite particle nickel base alloy to manufacture and repair cylinder jackets and is used to repair the inner wall of the cylinder jackets of large power diesel engines after abrasion due to use. The device comprises a cylinder jacket (1) which needs manufacturing, a lower water hat (2), an upper water hat (3), a stirring rod (12), a condenser (5), a filter pump (6), a liquid mixing tank (7), a heater (10), a partial feeding device (11) and the stirring rod (12), wherein the lower portion of the cylinder jacket (1) which needs manufacturing is connected with the lower water hat (2) in a sealed mode, the upper portion is connected with the upper water hat (3) in the sealed mode, the stirring rod (12) is arranged in the cylinder jacket (1) which needs manufacturing, the lower portion of the lower water hat (2) is communicated with an outlet of the partial feeding device (11), the upper portion of the upper water hat (3) is communicated with an inlet of the condenser (5), the outlet of the condenser (5) is connected with the filter pump (6), the filter pump (6) is connected with the liquid mixing tank (7), the liquid mixing tank (7) is connected with a solution inlet of a liquid storage tank (8), a solution outlet of the liquid storage tank (8) is communicated with the solution inlet of the heater (10), and the solution outlet of the heater (10) is communicated with the solution inlet of the partial feeding device (11). The inner wall of the cylinder jackets after abrasion due to use can be repaired to the original size to be used continuously through utilizing the device of the invention.

Owner:JIANGYIN JIANGDONG STAINLESS STEEL MFG

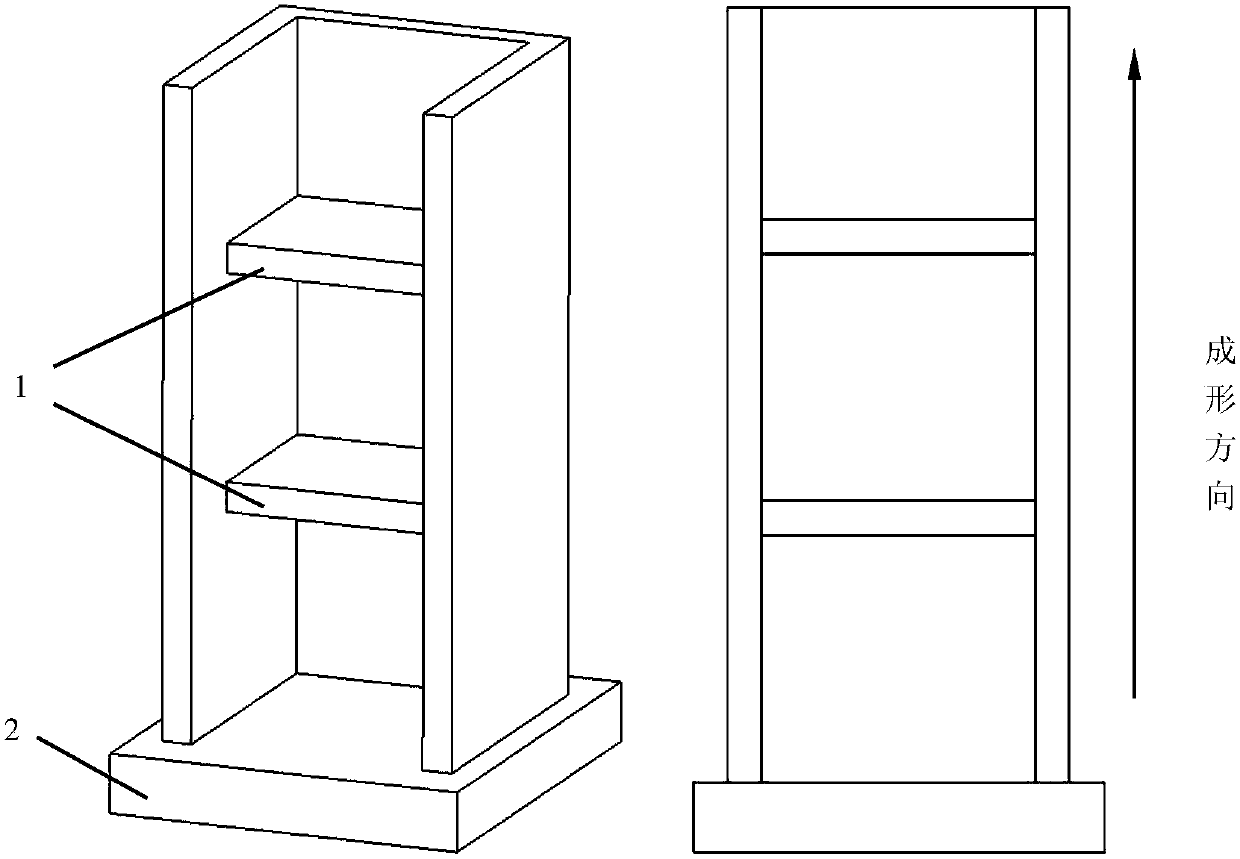

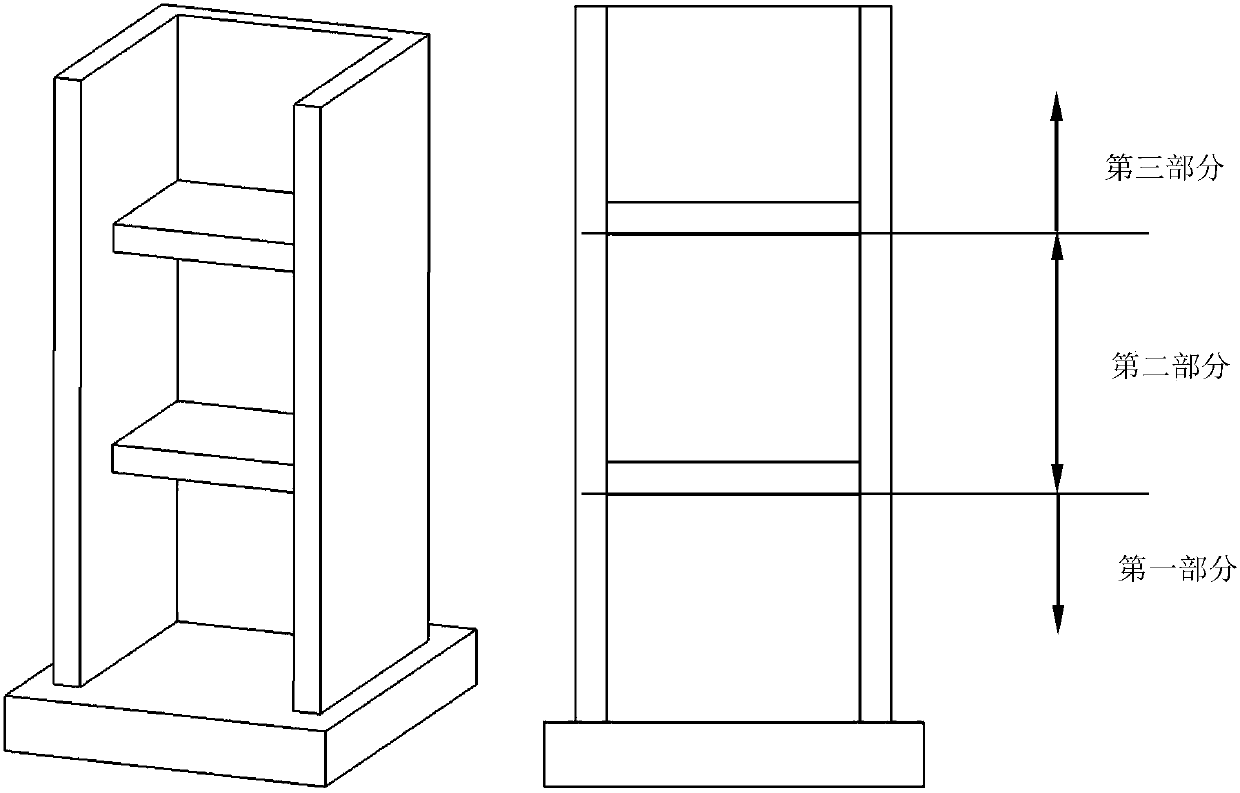

A high energy beam additive manufacturing method for a suspended structure of a metal part

ActiveCN106041075BSolve unformable problemsLarge machining allowanceAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringHigh energy beam

The present invention is a high-energy beam additive manufacturing method for a suspended structure of a metal part, comprising the following steps: step 1: establishing an overall forming process model of the metal part; step 2: splitting the overall forming process model; step 3: determining the forming of each suspended structure The fixed structure, shape and size of the supporting substrate; Step 4: According to the forming direction, first form the first part of the model structure, after the forming is completed, install and fix the first supporting substrate through the fixed structure corresponding to the first suspended structure; then continue to form the second Part of the model structure, while completing the forming of the second part of the model structure, the forming of the first suspended structure is realized based on the first supporting substrate; finally, the subsequent part of the model structure and the forming of the suspended structure are completed in the same way to obtain the whole Metal parts; step 5: heat-treating the formed metal parts and removing the support substrate, base material and spare parts to obtain an all-metal additive manufacturing component with a suspended structure.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Teaching display device for improving understanding ability of old people

PendingCN113910813AImprove participationAchieve remanufacturingBoard cleaning devicesWriting boardsOlder peopleSoftware engineering

The invention discloses a teaching display device for improving the understanding ability of old people. The teaching display device comprises a reverse erasing, collecting, dust-raising preventing and recycling interesting interaction device, a writing and displaying combined device, a multimedia learning interaction screen overturning and storing device, a writing and displaying combined screen rotating device, an automatic height adjusting device and a convenient and intimate auxiliary device. The invention belongs to the technical field of teaching appliances and particularly relates to the teaching display device for improving the understanding ability of the old people, aiming at the technical problems that an existing teaching display device erases chalk dust from the outside and dust flies around after erasing, a reverse thinking method that a blackboard eraser does not move and a blackboard moves is adopted, and according to the asymmetry principle, an automatic opening and closing magnetic dust-raising preventing assembly is creatively arranged, the technical prejudice in tradition that blackboard erasing can be achieved only by moving the blackboard eraser is overcome, and the technical effects that the blackboard is erased internally and chalk dust is conveyed and collected in a raising-preventing mode can be achieved only by moving the blackboard.

Owner:刘晓娟

A kind of ni-cr-al nano welding layer and preparation method

ActiveCN104827206BHard textureImprove wear resistanceArc welding apparatusWelding/cutting media/materialsPorosityWear resistance

Owner:WUHU DINGHENG MATERIAL TECH

A kind of engine crankshaft and its remanufacturing method

The invention discloses an engine crankshaft belonging to the technical field of engine remanufacturing. The engine crankshaft comprises a plurality of shaft necks, wherein each shaft neck comprises a shaft neck body, wherein flanges are arranged at two ends of the shaft neck body, a circular bead is arranged between each flange and the shaft neck body, a laser cladding coating is formed on the outer surface of the shaft neck body, a gap is left between the edge of the laser cladding coating and the corresponding circular bead, and nitriding layers are formed on the end surfaces, close to the shaft neck body, of the flanges, the circular beads and the gaps. The invention also discloses an engine crankshaft remanufacturing method. The remanufacturing method comprises the steps of removing a nitration layer or an oxidation layer on the surface of the shaft neck, forming the laser cladding coating, forming the nitration layer and restoring the product size. By using the remanufacturing method, the engine crankshaft with a defect on the shaft neck can be repaired under conditions of ensuring the safety factor and the whole performance of the crankshaft to meet the using requirements, the precision requirement of the crankshaft neck can be restored and the remanufacturing of the crankshaft of a high-speed engine can be achieved.

Owner:WEICHAI POWER CO LTD

A permanent magnet motor remanufacturing repair process and assembly line with glued magnetic poles

ActiveCN110571993BAchieve remanufacturingAchieve recyclingManufacturing stator/rotor bodiesElectric machineMagnetic poles

The invention discloses a remanufacturing and repairing process and assembly line of a permanent magnet motor with glued magnetic poles, comprising the following steps: firstly, the end cover of the permanent magnet motor to be repaired is opened, and the outer surface of the stator shell is heated until the glue melts and fails, Beat the magnetic pole inside the stator casing to separate the magnetic pole from the stator casing; cool the stator casing after separation, and glue the side where the new magnetic pole is in contact with the stator casing; the positive and negative magnetic poles have been stained with glue alternately glued to the inner wall of the stator housing. The invention also discloses a permanent magnet motor remanufacturing and repairing assembly line with glued magnetic poles, which includes a rotating fixing device, a heating device, a cooling pool, a conveying device and an operating table. The invention can realize the complete detachment of the magnetic pole and the stator shell, prevent the magnetic pole from remaining in the stator shell, and at the same time not damage the stator shell, and realize the remanufacturing production of the permanent magnet motor.

Owner:三立(厦门)汽车配件有限公司

Remanufacturing Method of Main Bearing Hole of Engine Cylinder Block Assembly

ActiveCN103447903BAchieve remanufacturingSimple processHoning machinesPlane surface grinding machinesCrankcaseEngineering

The invention discloses a reproducing method of a main bearing hole of an engine cylinder block assembly, belongs to the field of engine reproducing technologies, and is characterized in that a combination surface of a main bearing seat of a cylinder block is taken as a reference, an amount of finish of 0.02-0.10 mm is eliminated from the combination surface of the main bearing seat of the cylinder block, and requirements of a form and location tolerance of the main bearing seat of the cylinder block are ensured; a combination surface of a main bearing seat of a crankcase is taken as a reference, an amount of finish of 0.02-0.10 mm is eliminated from the combination surface of the main bearing seat of the crankcase; the cylinder block and the crankcase are assembled together through a main bearing bolt so as to form a cylinder block assembly; each main bearing hole of the engine cylinder block assembly is honed, and honing of the main bearing holes needs to be synchronously carried out so as to ensure each technological requirement of the main bearing holes of the engine cylinder block assembly. The reproducting method has the advantages of simple process, no potential hidden trouble of a brush plating manner, and capability of realizing reproduction of the engine cylinder block assembly with the problem of the size out-of-tolerance of the main bearing holes.

Owner:WEICHAI POWER CO LTD

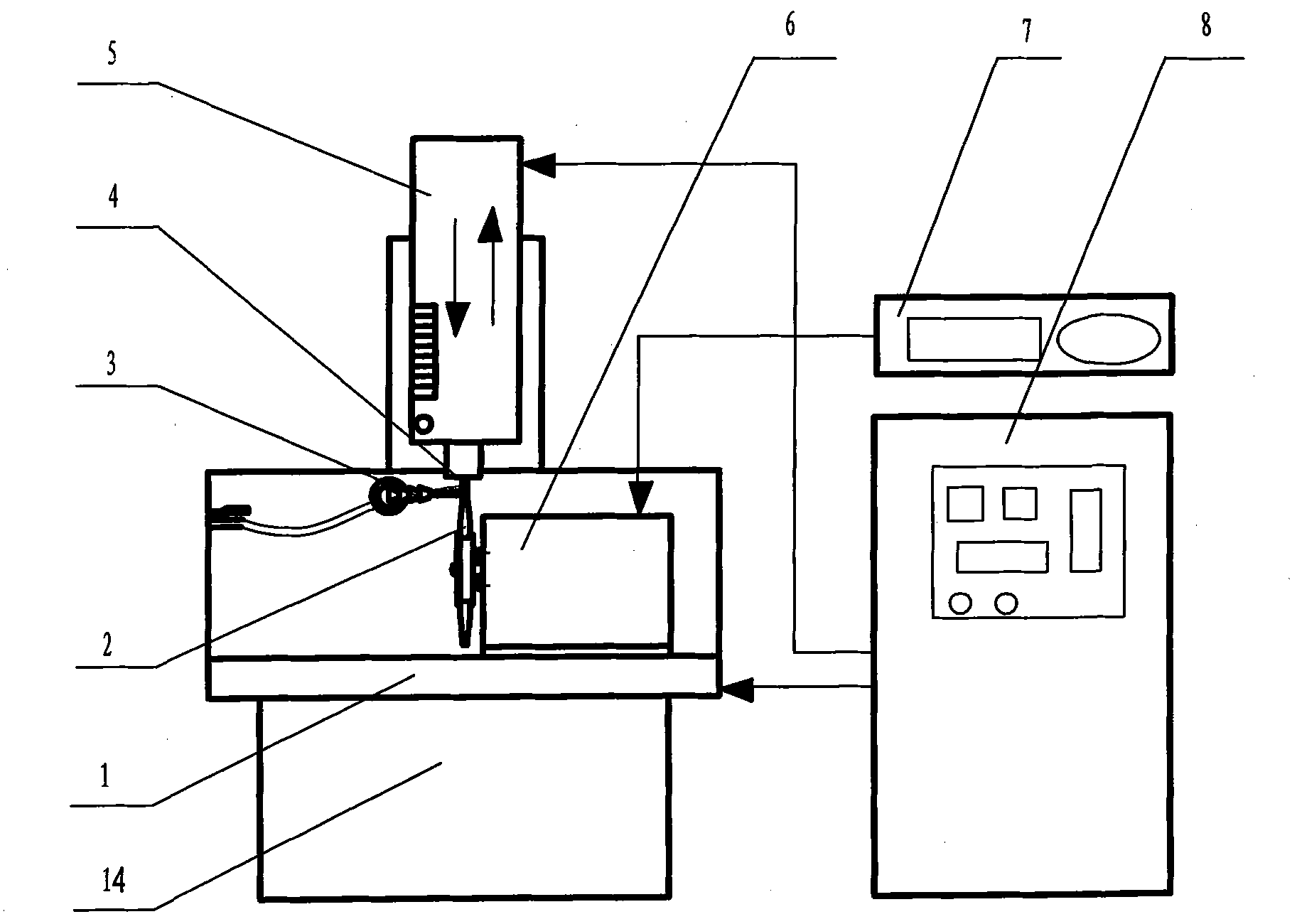

A special aircraft for intelligent repair of railway coupler tongue

ActiveCN106475782BPracticalHigh degree of intelligenceOther manufacturing equipments/toolsControl systemReliability engineering

The invention discloses a special intelligent repair machine for a railway coupler knuckle which comprises a base, stand columns, a slide rail, a coupler knuckle positioning support, a welding assembly, a milling assembly and a control system. The slide rail is installed on the base through the stand columns. The coupler knuckle positioning support is arranged under the base and penetrates out of the base to be used for fixing a coupler knuckle. The special repair machine is high in practicability, high in intelligence degree and high in efficiency, welding repair and milling forming are integrated, and the procedure that the coupler knuckle is machined on a coupler knuckle profiling milling machine special for coupler knuckles after welding repair is completed is omitted, the welded workpiece can be repaired continuously and formed at a time, materials and manpower are saved, welding materials are saved by 70% or over, the maintenance cost is lowered, railway vehicle coupler knuckle detecting and remanufacturing are achieved, and the flexibility of coupler knuckle repair is greatly improved while the intelligence level of coupler knuckle repair is increased.

Owner:张爽

An automatic repair method for steam turbine blades

The invention discloses an automatic repairing method for steam turbine blades, which relates to the technical field of steam turbine blade repairing. →Gap stacking planning→Printing and stacking→Heat treatment→Non-destructive testing→Processing→Scanning, use the robot 3D scanning system to scan the determined blade, and then obtain the 3D model of the blade through software processing, define the area to be cut and path to remove all damaged parts or establish areas to be remanufactured; by implementing this technical solution, problems such as blade water erosion damage repair and blade repair and upgrade can be solved quickly, efficiently and with high quality, which simplifies the processing technology compared to traditional machining. , which greatly improves the on-site processing efficiency of blades, and determines a new direction for efficient and intelligent repair and remanufacturing of turbine rotor blade damage.

Owner:DONGFANG ELECTRIC WUHAN NUCLEAR EQUIP

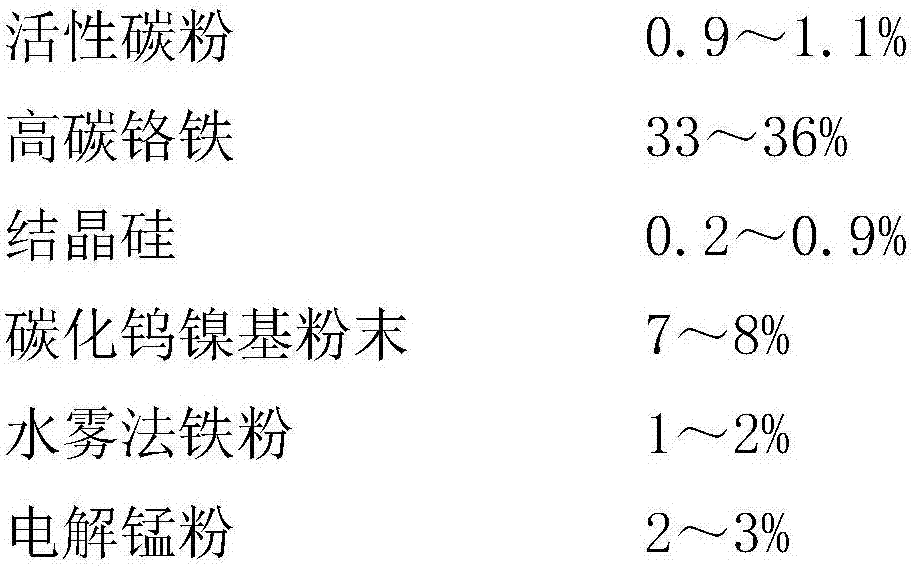

Cobalt-chromium-tungsten alloy powder for valve spraying welding and welding technology thereof

InactiveCN107335940AImprove performanceAchieve remanufacturingWelding/cutting media/materialsSoldering mediaNickel chromium alloyTemperature resistance

The invention relates to cobalt-chromium-tungsten alloy powder for valve spraying welding and a welding technology thereof. The cobalt-chromium-tungsten alloy powder is prepared from, by mass, 0.9%-1.1% of activated carbon powder, 33%-36% of high carbon ferro-chrome, 0.2%-0.9% of silicon metal, 7%-8% of tungsten carbide nickel base powder, 1%-2% of water-mist-method iron powder, 2%-3% of electrolytic manganese powder, 0.1%-0.4% of nano-tantalum powder, 4%-5% of nickel-chromium alloy powder and the balance cobalt powder. The cobalt-chromium-tungsten alloy powder is face-centered cubic solid solution alloy, and is one alloy with the broadest application in an alloy series. The content of carbon and the content of tungsten are moderate, and the tenacity is good. In the wide temperature range of 850 DEG C or below, the cobalt-chromium-tungsten alloy powder has the excellent corrosion resistance, high-temperature resistance, impact resistance and adhesive wear resistance. After the cobalt-chromium-tungsten alloy powder is adopted and spray-welded on the surface of a valve, the size of the valve is repaired, the performance of the valve can be greatly improved, and reproducing of the valve is achieved.

Owner:WUHU DINGHAN REMFR TECH

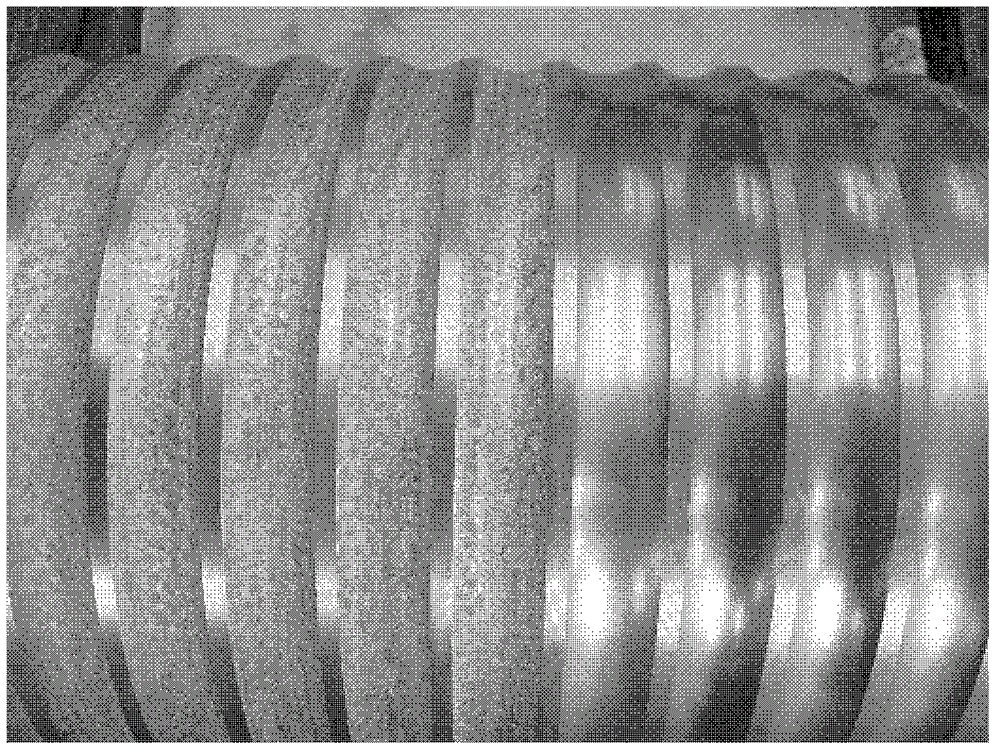

Laser heat treatment process for a steel ring

ActiveCN104846365BAchieve fixExtended service lifeMetallic material coating processesControl systemNitrogen

The invention relates to a laser heat treatment process for a steel ring, comprising the following steps: (1) pretreatment; (2) flaw detection to determine the area; (3) observing and measuring the repaired range of the steel ring surface, and carrying out the process in a control cabinet according to the measurement results Programming, written into the PLC control system; (4) Turn on the gas source to output carbon dioxide, nitrogen, and helium; (5) Turn on the laser, adjust the spot width to 9mm, and use WC‑12Co nanomaterials as cladding materials to lay thickness 0.5mm; (6) post-processing. The invention adopts the method of laser cladding, cladding WC-12Co nano-materials made according to a specific ratio on the surface of the steel ring to form a cladding layer, which improves the mechanical properties of the steel ring while realizing the repair of the steel ring , that is, the hardness, wear resistance, and toughness are all improved, realizing the remanufacturing of the steel ring, avoiding the waste of resources, and saving the maintenance and use costs of equipment.

Owner:WUHU DINGHAN REMFR TECH

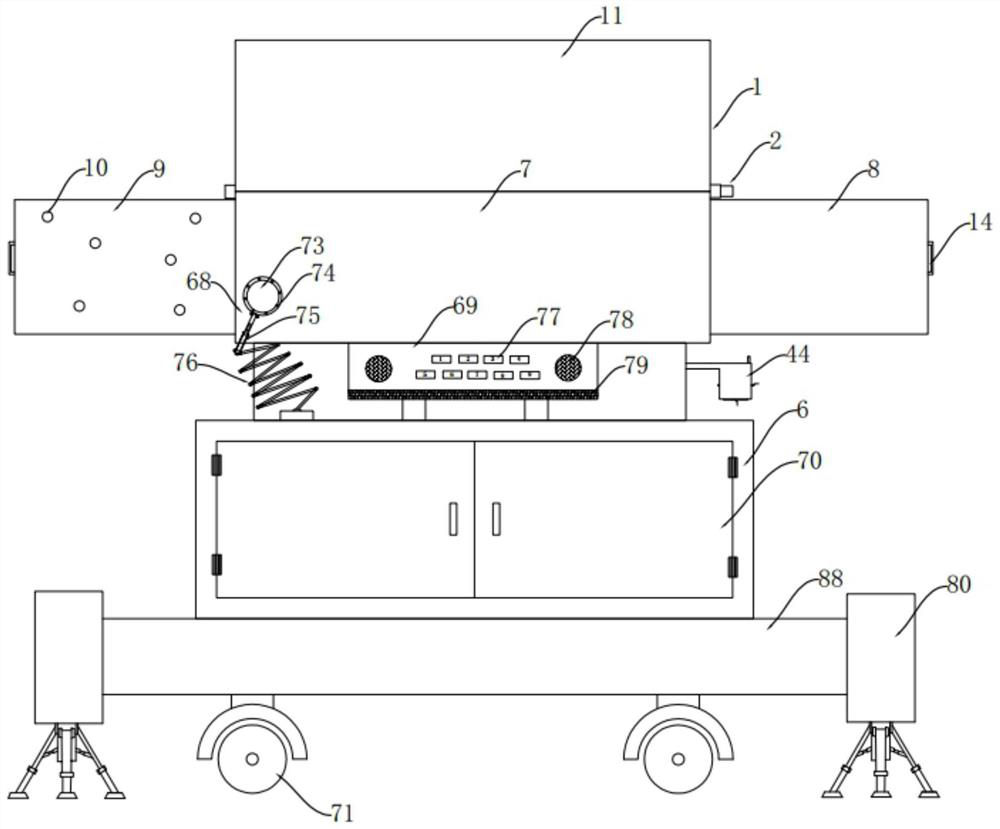

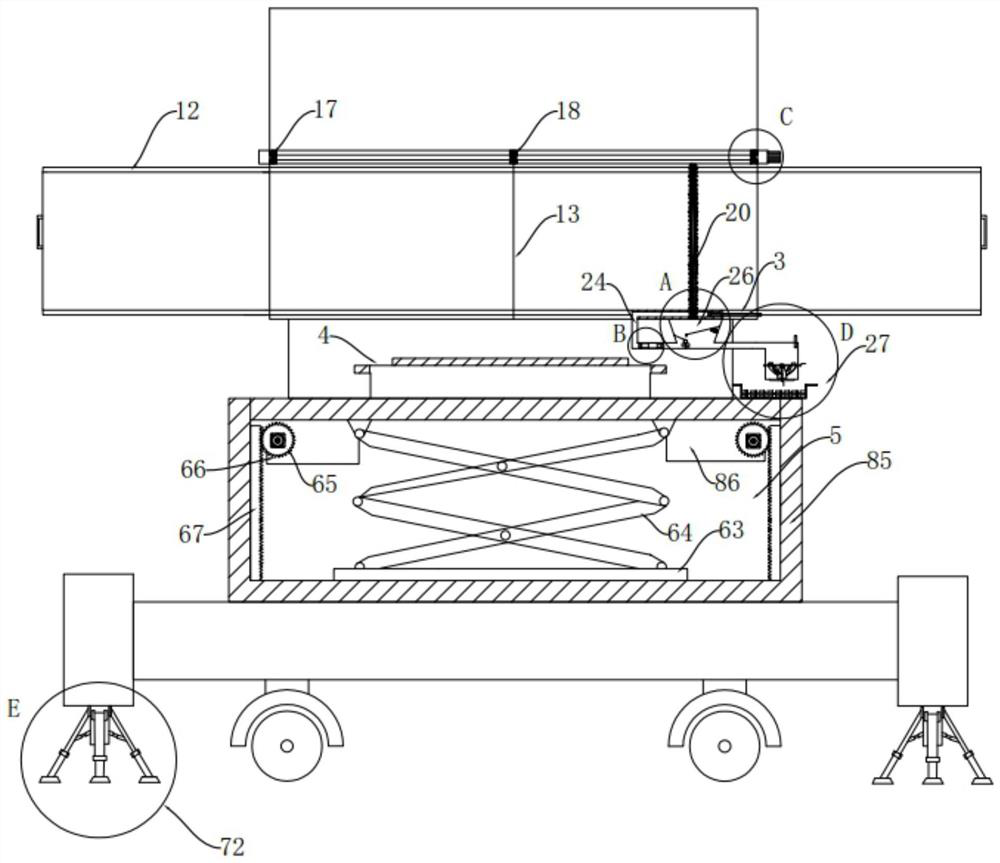

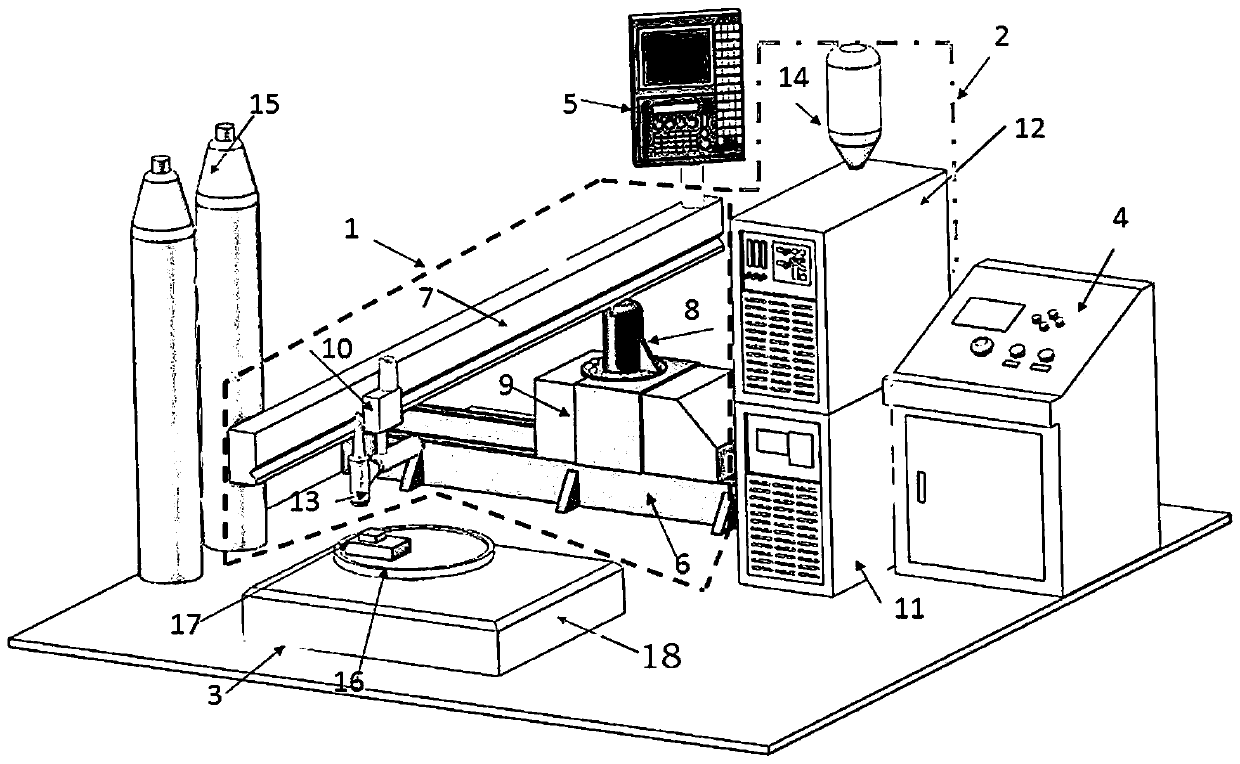

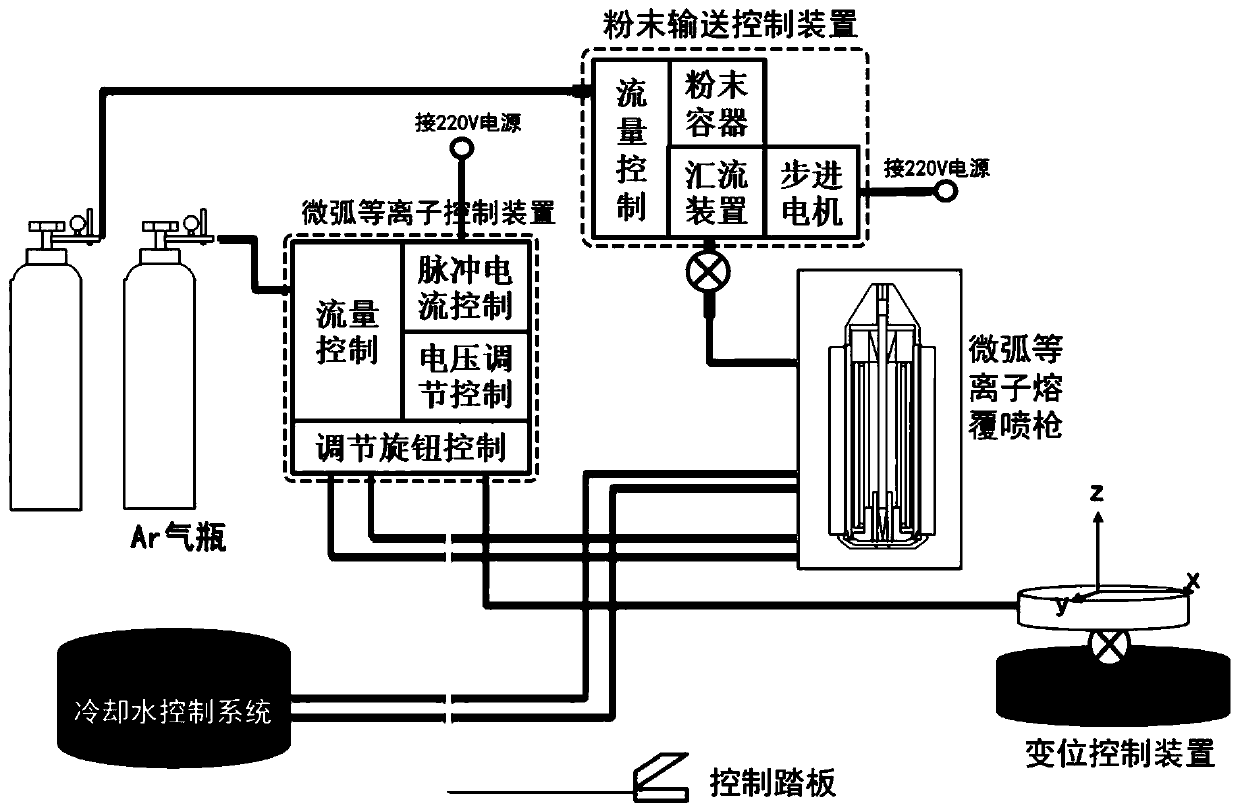

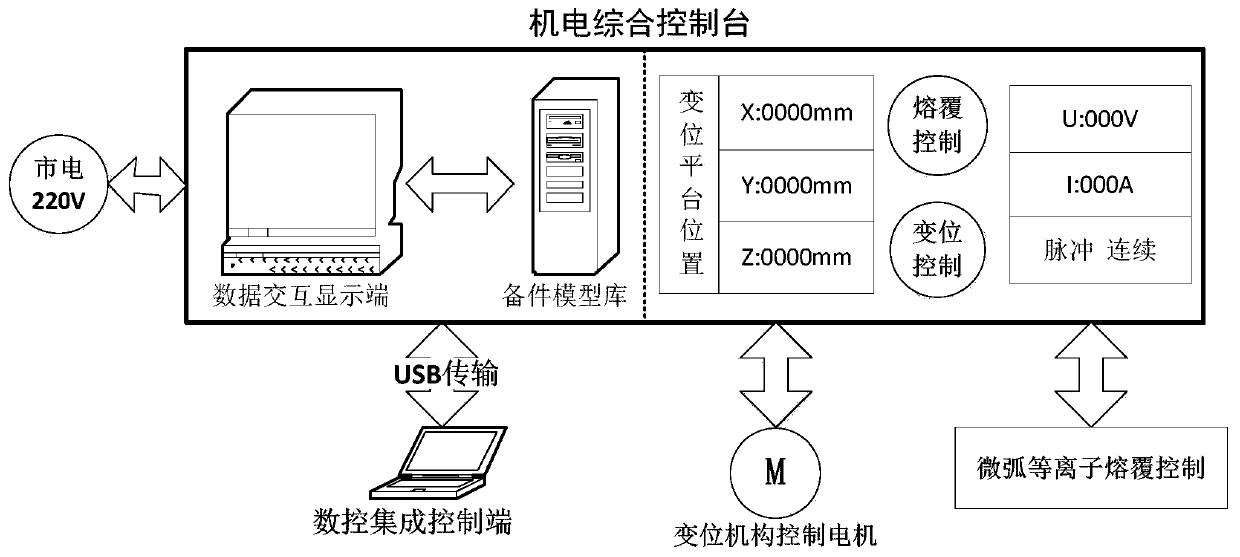

Spare part micro-arc pulse plasma rapid additive manufacturing device and method

ActiveCN111558717AEasy to operateReduce environmental demandsAdditive manufacturing apparatusIncreasing energy efficiencyNumerical controlProcess engineering

The invention discloses a spare part micro-arc pulse plasma rapid additive manufacturing device and method. The rapid additive manufacturing device comprises a spray gun track control mechanism, a pulse micro-arc plasma cladding platform, a displacement mechanism, an electromechanical integrated console and a welding gun path planning numerical control display table. The rapid additive manufacturing device has the advantages of being convenient to operate, high in environment adaptability and capable of achieving large-range and high-temperature-domain part additive manufacturing, the technology can achieve rapid manufacturing of metal parts, the technology is suitable for rapid additive generation of field environment spare parts, the emergency maintenance guarantee capacity is effectively improved, and the technology can also be applied to rapid forming of high-melting-point difficult-to-machine metal parts.

Owner:中国人民解放军火箭军工程大学

Device for preparing ultrahard abrasive particle layer by adopting electric spark deposition method

The invention discloses a device for preparing an ultrahard abrasive particle layer by adopting an electric spark deposition method. The device comprises a working platform, a grinding wheel metal basal body and a grinding wheel basal body driving mechanism, wherein the grinding wheel metal basal body and the grinding wheel basal body driving mechanism are arranged on the working platform, the grinding wheel basal body driving mechanism is used for driving the grinding wheel metal basal body to rotate, a compression powder electrode is arranged at one side of the grinding wheel metal basal body, the compression powder electrode is arranged on a servo mechanism which can linearly move up and down in a reciprocating manner, a working solution nozzle is arranged at the other side of the grinding wheel metal basal body, a deposition power supply and control panel which can produce a discharging pulse is arranged at one side of the compression powder electrode, the anode of the deposition power supply and control panel is connected with the grinding wheel metal basal body, and the cathode of the deposition power supply and control panel is connected with the compression powder electrode. According to the device disclosed by the invention, the ultrahard abrasive layer can be deposited on the surface of the grinding wheel metal basal body, the problem that an old grinding wheel metalbasal body is difficult to recycle and is difficult to reproduce can be solved, and reproducing and green recycling of an ultrahard grinding wheel are realized.

Owner:湖南高创海捷工程技术有限公司

Ni-Cr-Al nanometer welding layer and preparation method

ActiveCN104827206AAchieve remanufacturingImprove performanceArc welding apparatusWelding/cutting media/materialsPorosityWear resistance

The invention relates to a Ni-Cr-Al nanometer welding layer and a preparation method; the Ni-Cr-Al nanometer welding layer comprises the following components in mass percent: 44 to 59% of Ni, 34 to 41% of Cr, 7 to 9% of Al and 1 to 2% of additive; the additive is SiC; the method comprises the following steps: preparing Ni, Cr and Al all into a nanosphere in a gas atomization method, then, uniformly mixing the nanosphere with ground additive to prepare into a NiCrAl nanometer welding wire; at last, welding the NiCrAl nanometer welding wire on the surface of a part to form the NiCrAl nanometer welding layer. According to the Ni-Cr-Al nanometer welding layer and the preparation method, by adopting reasonable materials and proportion, the shortages of poor bonding strength of the welding layer, high porosity, relatively poor wear resistance and corrosion resistance in the prior art are solved; the remanufacturing of the to-be-repaired part is realized and the waste of resources is prevented; meanwhile, the property of the repaired part is improved and the usability of the part is prolonged.

Owner:WUHU DINGHENG MATERIAL TECH

Composite reinforcement method for TiC/TiB2 base metal ceramic on surface of roller

ActiveCN102618867BImprove performanceImprove surface qualityMolten spray coatingSuperimposed coating processOperabilityAlloy

The invention discloses a composite reinforcement method for TiC / TiB2 base metal ceramic on the surface of a roller, and belongs to the technical field of metallurgical machinery. The composite reinforcement method comprises the processing steps of: cleaning the roller; performing plasma spraying of nickel base alloy or overlaying the nickel base alloy on the cleaned roller; turning the roller according to requirements of a steel groove rolling system to meet the technical requirements; and cladding on the surface of the roller by using an electric spark deposition process to form the TiB2 / TiC base metal ceramic by using a TiB2 / TiC base metal ceramic electrode. The composite reinforcement method has the advantages that: the roller performance is greatly improved and fixed-roller-diameter rolling can be guaranteed, so that the process stability in a rolling process is guaranteed, meanwhile, the service life of the roller is greatly prolonged, the roller consumption is reduced, and the steel rolling operability and the steel surface quality are improved. Compared with processes such as overlaying and laser, the composite reinforcement method can be used for repairing of primary and intermediate rolling roller, and most importantly, the composite reinforcement method can be directly used for surface treatment of the roller of a finishing mill group, so that remanufacturing of the surface of the roller is realized.

Owner:HUNAN 3T NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com