Device for manufacturing or repairing cylinder cover by novel composite corpuscle nickel base alloy

A technology of composite particles and nickel-based alloys, which is applied in metal material coating technology, solid-state chemical plating, coating, etc., can solve the problems of accelerated solution decomposition, solution failure to work normally for a long time, and inability to enter industrial applications. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

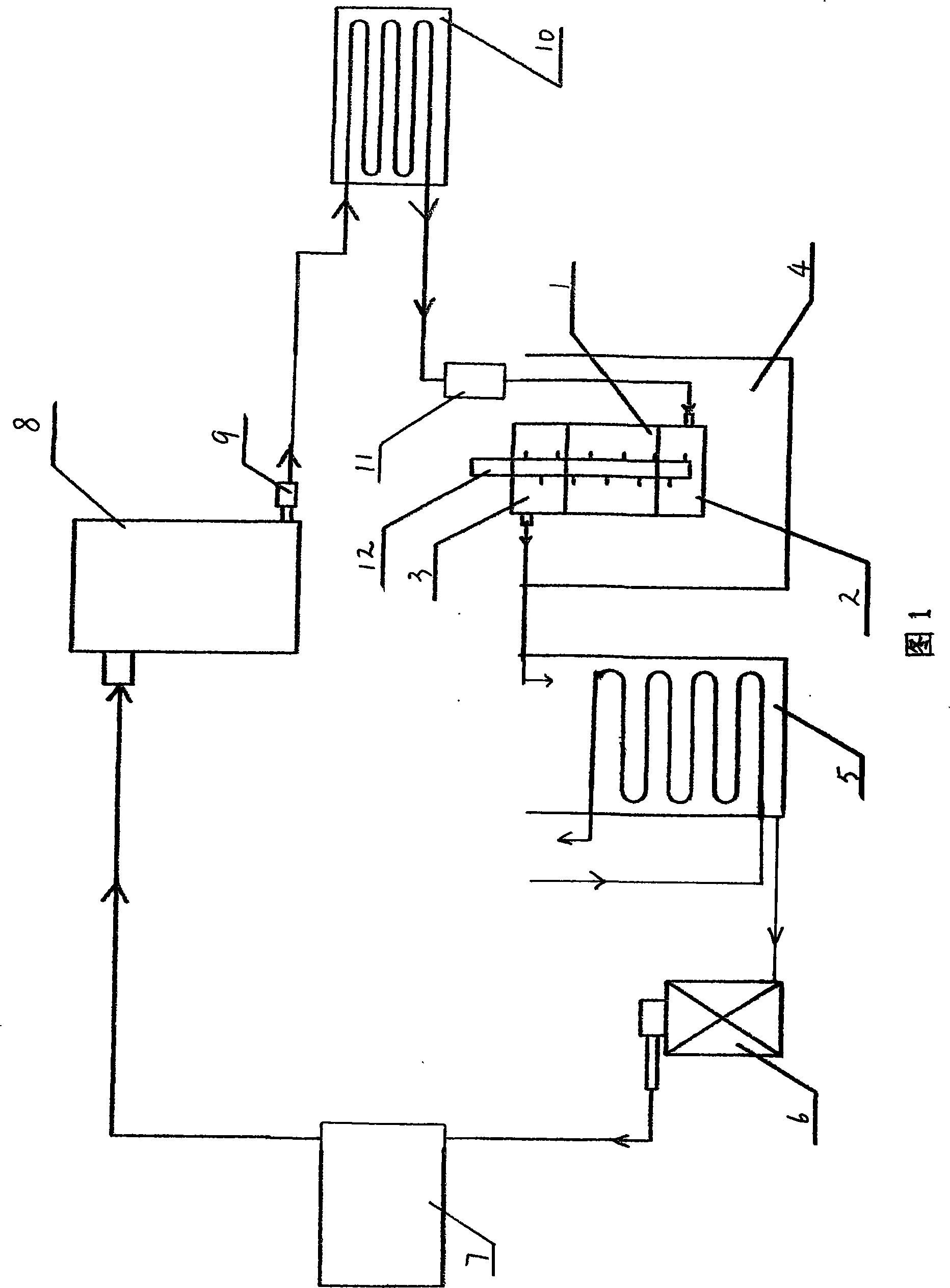

[0011] Referring to Figure 1, the device for manufacturing or repairing cylinder liners with the new type of composite particulate nickel-based alloy of the present invention is mainly composed of the cylinder liner to be processed 1, the lower water cap 2, the upper water cap 3, the stirring rod 12, the incubator 4, and the condenser 5. Filter pump 6, liquid mixing tank 7, liquid storage tank 8, heater 10, granulator 11 and stirring rod 12. The processing part of the cylinder liner 1 to be processed, that is, the inner surface of the cylinder liner, is clean, and the reaction process of the composite particle silicon carbide nickel-based alloy is completed here. The lower part of the cylinder liner 1 to be processed is connected to the lower water cap 2 in a sealed manner, and the upper part of the cylinder liner 1 to be processed is connected to the upper water cap 3 in a sealed manner. The stirring rod 12 is arranged in the cylinder liner 1, the lower water cap 2 and the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com