Technology of carrying out surfacing of aluminum bronze on inner surface of coal mine hydraulic bracket 27SiMn oil cylinder

An inner surface, aluminum bronze technology, applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., can solve problems such as scratches, affecting the sealing effect, high environmental pollution, etc., achieve stable welding quality, improve production efficiency, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: The material of the oil cylinder in the column of the coal mine hydraulic support is 27SiMn. The inner surface of the steel is surfacing with aluminum bronze, and the technical level of the surfacing of the copper layer is very important to the internal quality of the copper layer and the bonding performance of the steel matrix. The impact; due to the high carbon content of 27SiMn, the content of alloying elements is also high. Therefore, the main problem of welding is to avoid welding cracks, reduce the hardenability of the heat-affected zone, reduce the content of diffusible hydrogen before welding, and reduce the binding force of the welding zone.

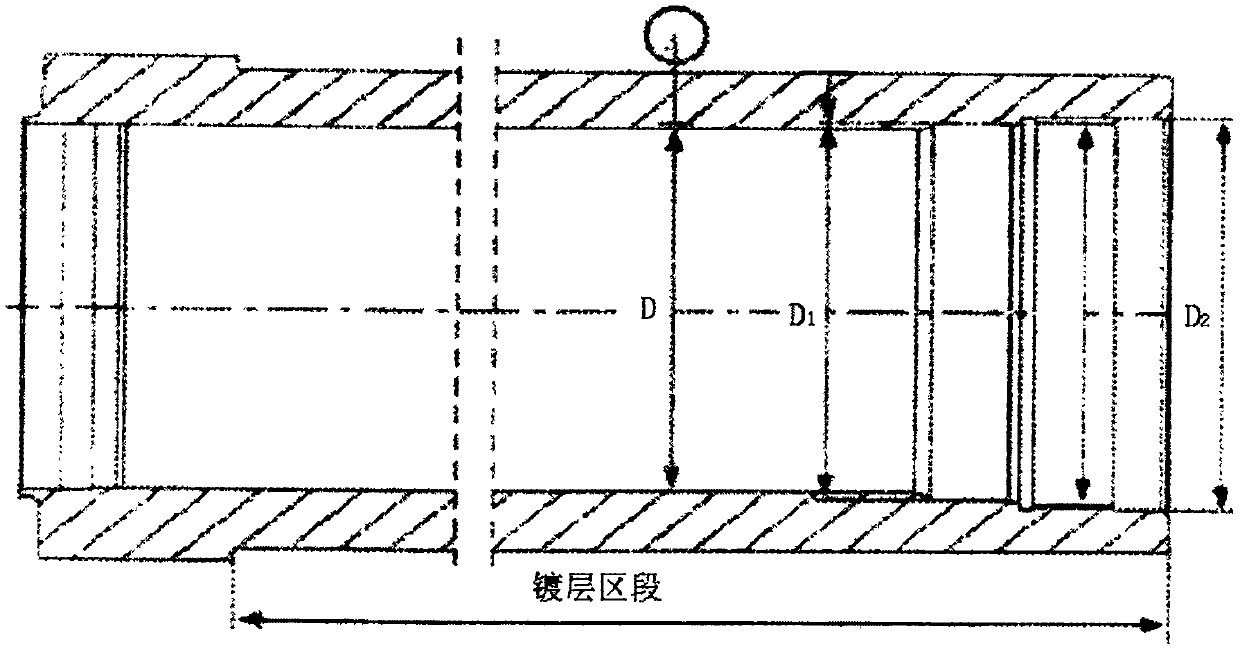

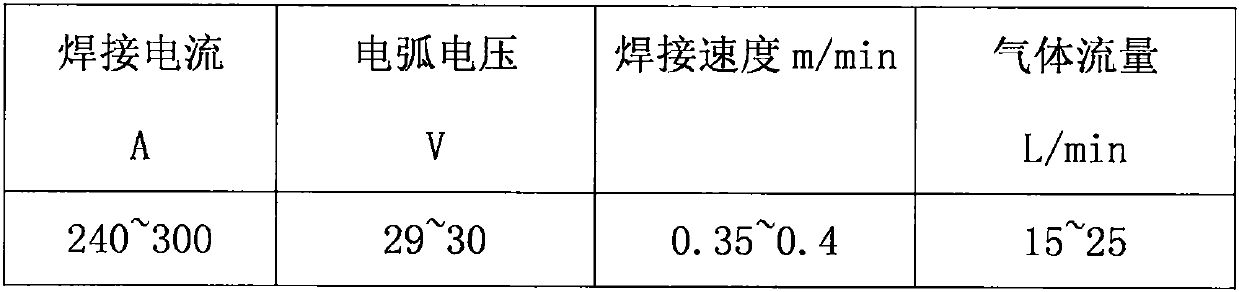

[0019] The inner wall of 27SiMn oil steel cylinder is surfacing welded with aluminum bronze, and the process is as follows: the welding method is hot wire non-melting pole inert gas shielded welding, and the welding material is directly 1.2mm HK200 aluminum bronze welding wire, of which the hot wire is non-melti...

Embodiment 3

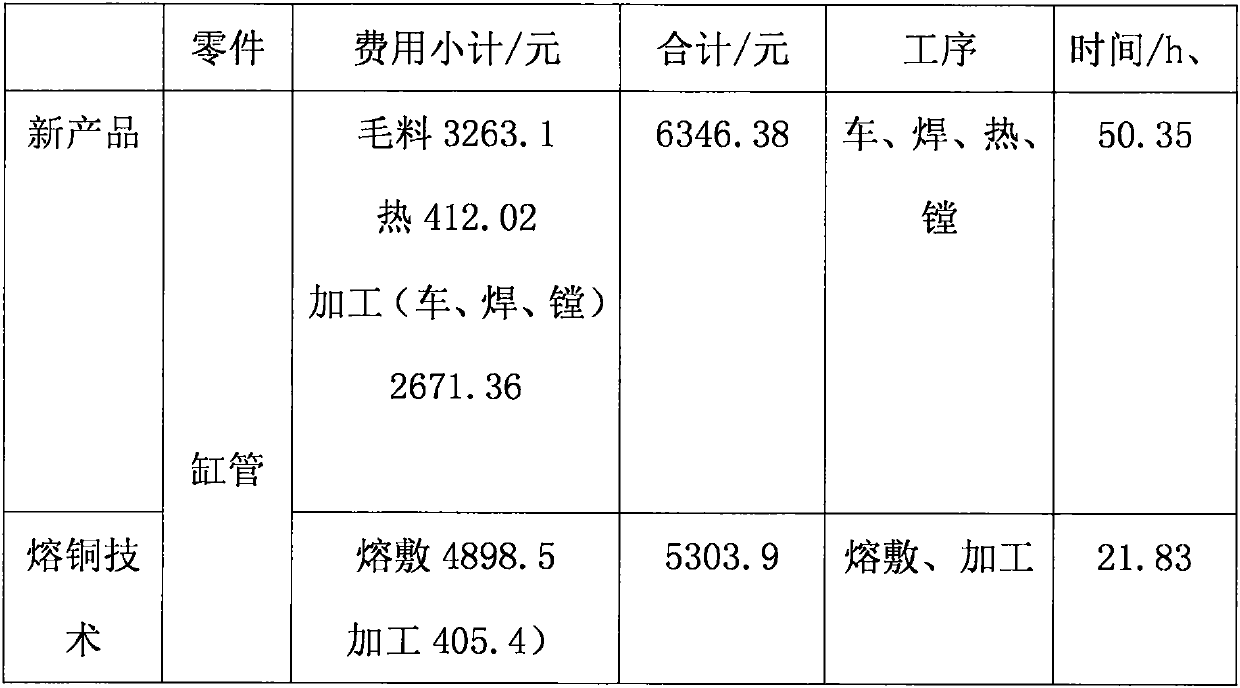

[0027] Embodiment 3: Taking a cylinder tube as an example, the cost and time comparison of newly manufactured products and repairing a cylinder tube with the technology of melting copper in the inner hole:

[0028] 1. New manufacturing process: preparation, turning, welding, heating, turning, boring, etc.;

[0029] 2. The cost of the two and the time it takes are compared as shown in the table below;

[0030]

[0031] Through calculation, it can be concluded that the cost of repairing a cylinder tube by melting copper is 1042.48 yuan compared with the new manufacture of a cylinder tube, and it takes 50.35 hours to manufacture a new cylinder tube, and it takes 21.83 hours to repair a cylinder tube by melting copper, and it takes 21.83 hours to manufacture a new one. The time-consuming is 2.3 times of repairing one root. It can be seen from the above table that the reasonable use of the new copper melting process can effectively shorten the overhaul cycle, and the overall qu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com