Novel windshield wiper elastic piece and manufacturing method thereof

A shrapnel and wiper technology, which is applied to other household appliances, household components, household appliances, etc., can solve the problems of stainless steel shrapnel not being resistant to salt spray corrosion, quality consistency, limited service life, etc., to achieve excellent surface quality, Overall low cost and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

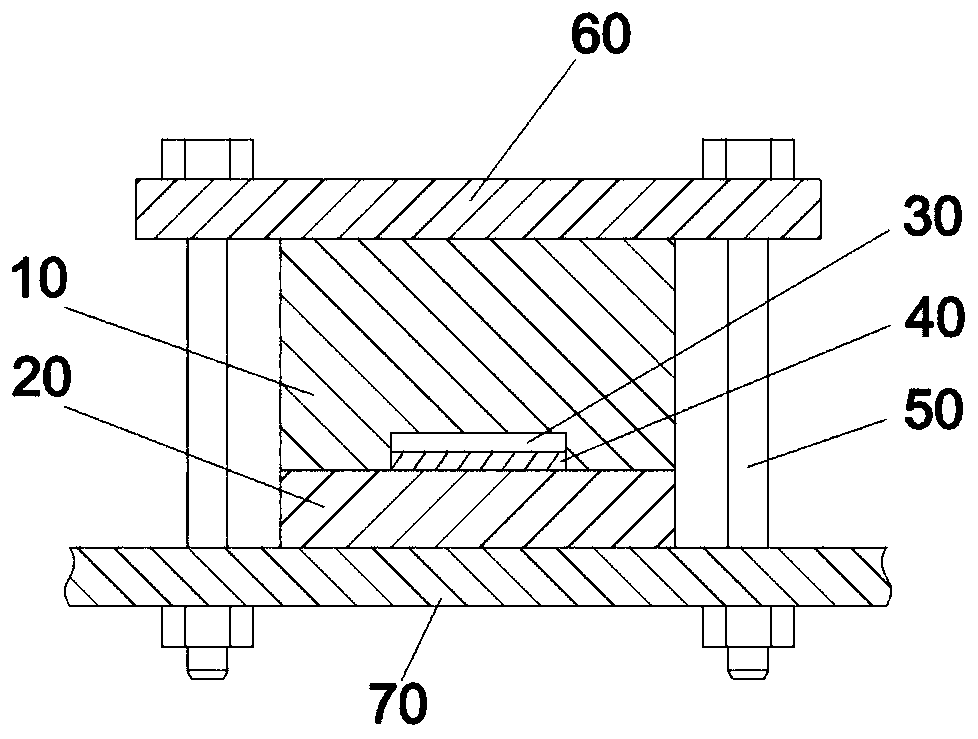

[0025] The embodiment of the present application relates to a preparation method of a novel wiper shrapnel, comprising the following steps:

[0026] S1. Using continuous fiber aggregates as reinforcements and thermoplastic polymers as a matrix, the continuous fiber aggregates are passed through a mold with a cavity through a pultrusion process, and continuous elastic pieces are prepared under the traction of a drafting device;

[0027] S2. The continuous shrapnel is truncated according to the design requirements;

[0028] S3. Carrying out secondary heat setting on the fixed-length truncated shrapnel, placing the shrapnel in a molding die for hot-pressing and shaping, and obtaining a wiper shrapnel with a permanent arch in the length direction;

[0029] Specification parameters such as length, width, thickness and arch height of the shrapnel can be determined according to design requirements;

[0030] The continuous fibers are continuous carbon fibers and / or glass fibers;

[...

Embodiment 1

[0040] A preparation method of a novel wiper shrapnel, comprising the following steps:

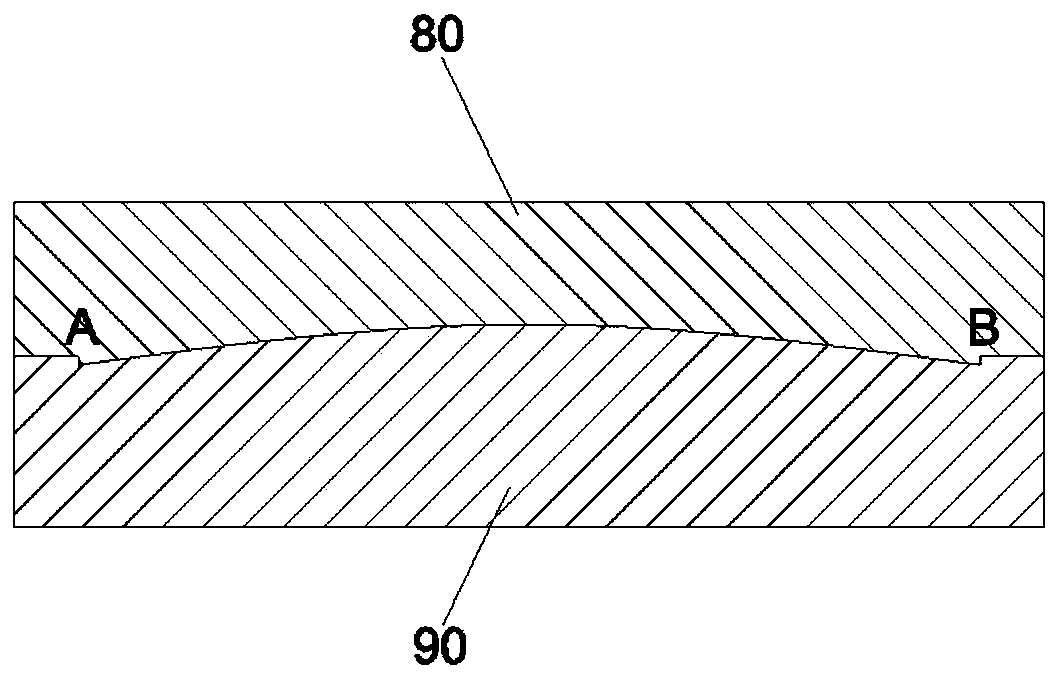

[0041] S1. Continuous carbon fiber is used as reinforcement, thermoplastic polyurethane TPU is used as resin matrix, polyurethane resin is heated and melted in the resin tank, the heating temperature is 100-120°C, continuous carbon fiber passes through the resin tank and is completely impregnated with resin, and is made by pultrusion process The continuous fiber aggregate passes through a heated mold with a cavity (110-130°C), and is released under the traction of the drafting device, and is cooled by high-speed flowing air to prepare continuous shrapnel. The width of the shrapnel is 10mm, and the thickness of the shrapnel is 0.6mm;

[0042] S2. The continuous shrapnel is truncated according to the design requirements, and the length of the shrapnel is 700mm;

[0043] S3. Carry out secondary heat setting on the fixed-length truncated shrapnel, place the shrapnel in a mold with an arched ra...

Embodiment 2

[0045] A preparation method of a novel wiper shrapnel, comprising the following steps:

[0046] S1. Continuous glass fiber is used as reinforcement, thermoplastic polyurethane TPU is used as resin matrix, polyurethane resin is heated and melted in the resin tank, the heating temperature is 100-120°C, continuous glass fiber passes through the resin tank and is completely impregnated by resin, through pultrusion The process makes the continuous fiber aggregate pass through a heated mold with a cavity (130°C), and is released under the traction of the drafting device, and is cooled by high-speed flowing air to prepare continuous shrapnel, the shrapnel width is 6mm, and the thickness of the shrapnel is 0.8mm;

[0047] S2. The continuous shrapnel is truncated according to the design requirements, and the length of the shrapnel is 600mm;

[0048] S3. Carry out secondary heat setting on the fixed-length truncated shrapnel, place the shrapnel in a mold with an arched radian in the mid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com