Online repairing structure of double-shaft humidifying stirrer of dust remover

A technology for repairing structures and mixers, applied to mixer accessories, mixers with rotating agitation devices, mixers, etc., can solve the problems of poor humidification effect of dry ash, waste of spare parts costs, waste of humidifiers, etc., to save spare parts, save Maintenance time and improvement of maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

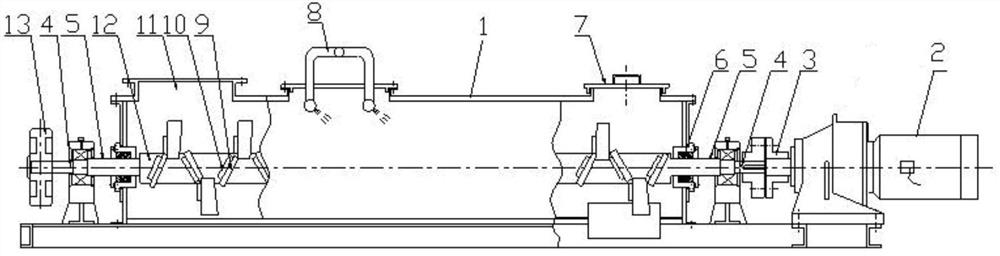

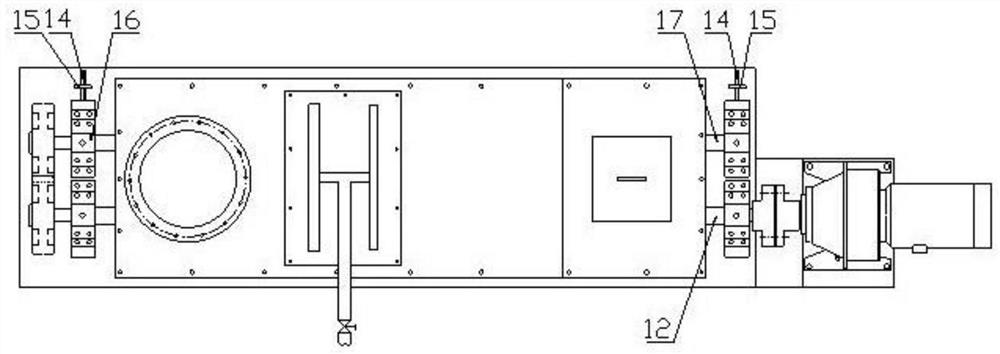

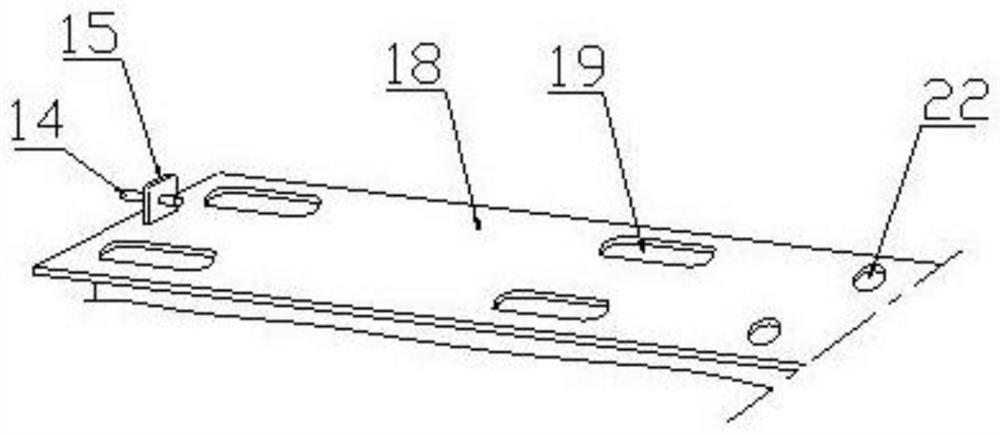

[0023] The present invention consists of a box body 1, a motor and a reducer 2, a shaft coupling 3, a driving shaft 12, a driven shaft 17, a bearing seat 16, a bearing 28, a blade 9, a cutter head 10, a pair of meshing spur gears 13, a seal Baffle plate 6 is formed.

[0024] As shown in the figure, the driving shaft 12 and the driven shaft 17 are installed in parallel in the casing 1 of the humidifier. There is a sealing baffle 6 at the end of the casing 1, and two bearing seats 16 are respectively arranged at both ends of the casing 1. The bearing seats 16 is a split four-screw bearing seat, wherein bearing 28 is installed. Motor and speed reducer 2, shaft coupling 3 are connected with the front end of drive shaft 12, and the rear end of drive shaft 12 and driven shaft 17 is equipped with spur gear 13 respectively, and the spur gear 13 of drive shaft 12 and driven shaft 17 rear end Mesh. The lower part of the blade 9 is welded on the driving shaft 12 and the driven shaft 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com