Patents

Literature

35results about How to "Restore usability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

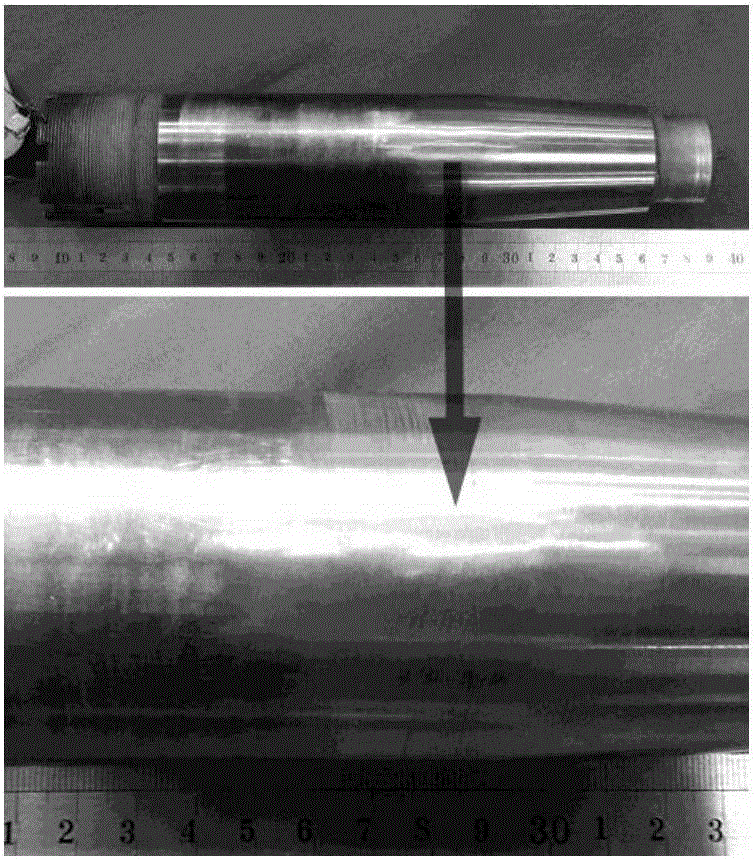

Laser cladding repairing method for aircraft end-journal part surface

InactiveCN105256249AShorten maintenance timeReduce maintenance costsMetallic material coating processesHeat-affected zoneSlag

The invention belongs to the technical field of laser cladding, relates to a laser cladding repairing method for aircraft end-journal part surface, particularly to a method for repairing the mechanical wear and scrape malfunction of an aircraft end-journal part after long-time service by adopting the laser fused deposition technology. The method aims at mechanical wear, scrape and other defects on the surface of the part, selects spherical precipitation to harden stainless steel metal dust, adopts reasonable laser cladding technological parameters, and removes residual stress of the part after cladding through the specific heat treatment technology to recover the performance of the aircraft end-journal and realize repairing of lengthening the service life. The repaired end-journal part hardly deforms, and the depth of a heat affected area is no more than 0.5mm; the repairing area does not have the defects of cracks, incomplete fusion and slag inclusion; the serviceability of the repaired end-journal is recovered.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

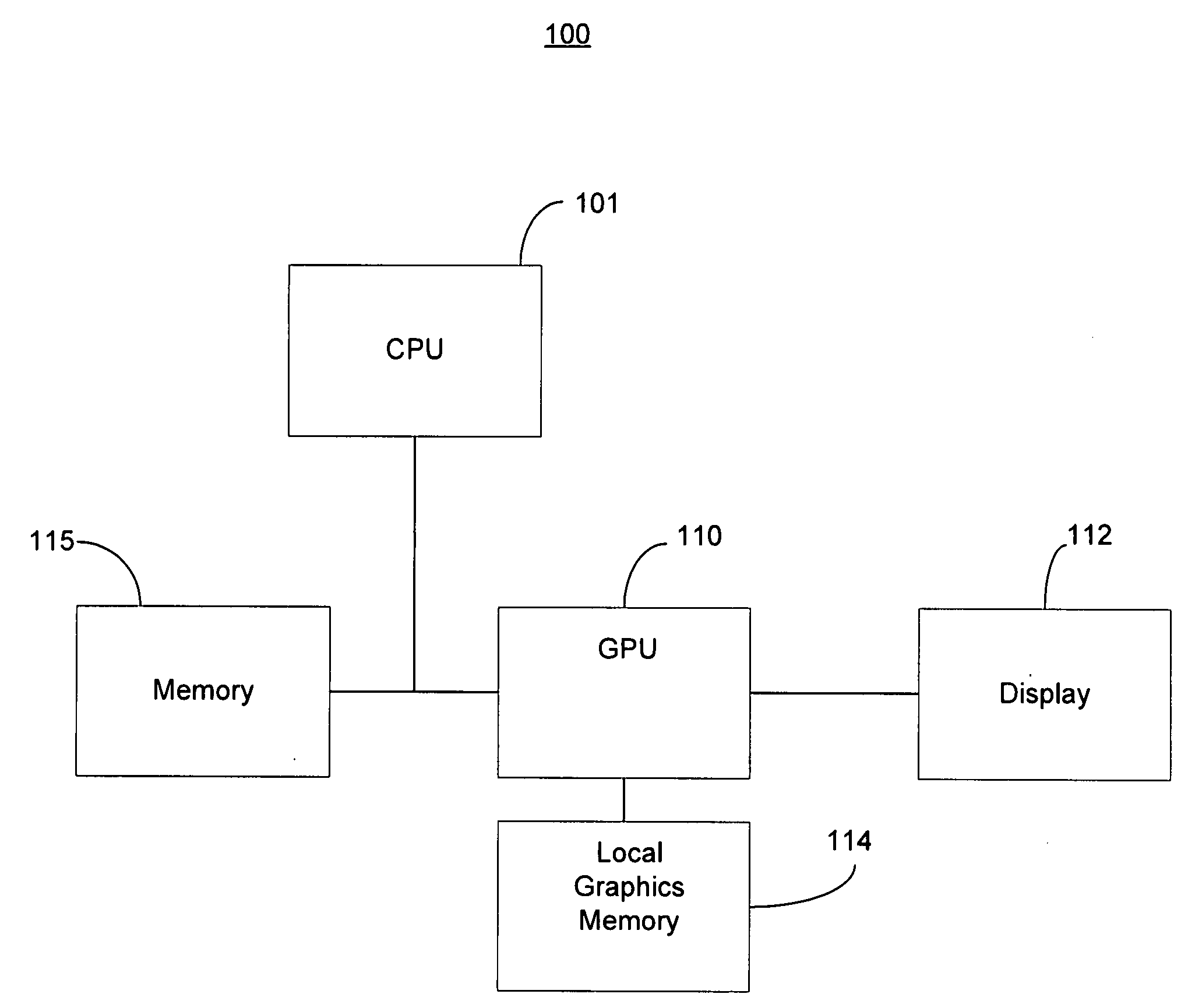

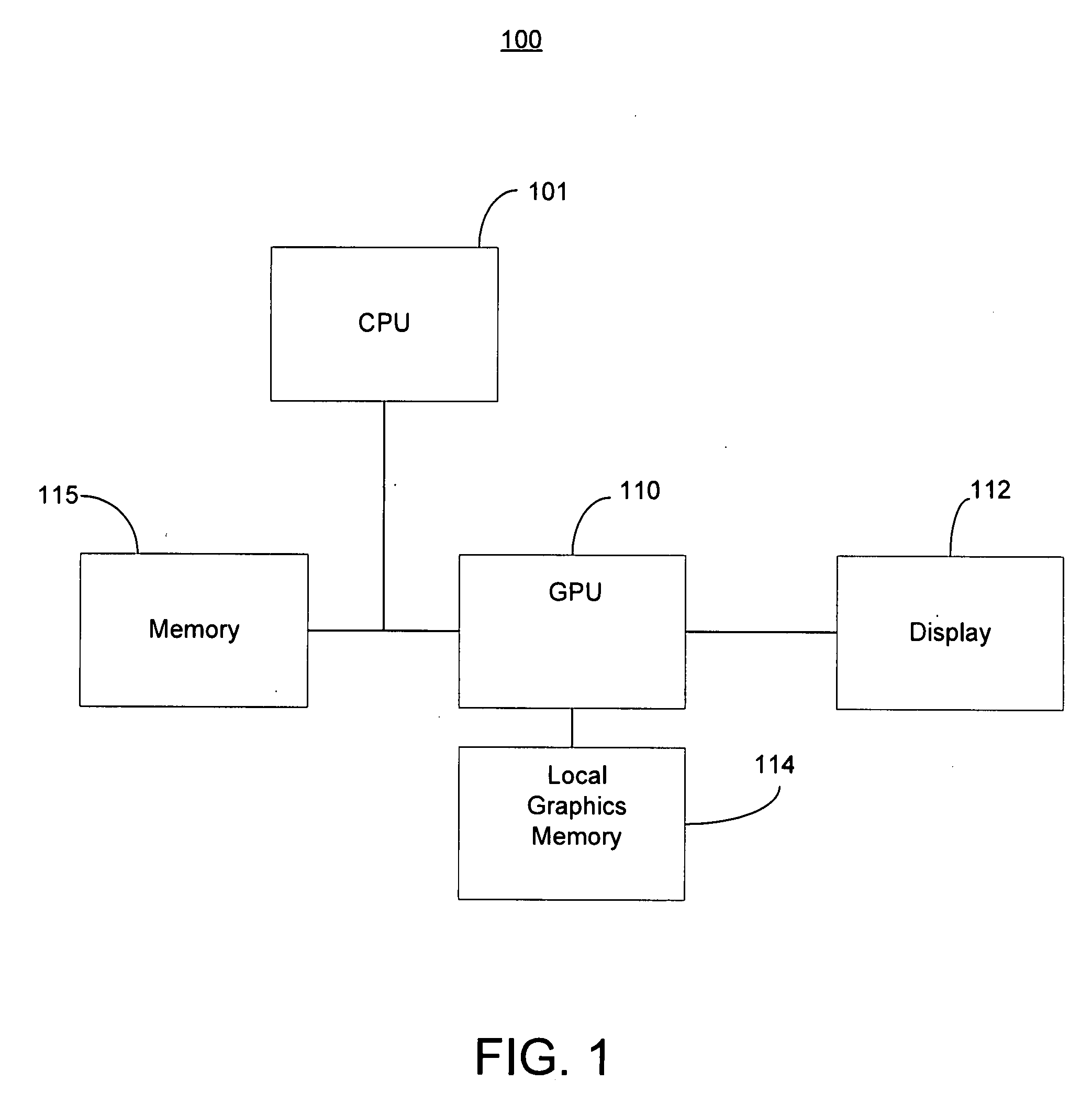

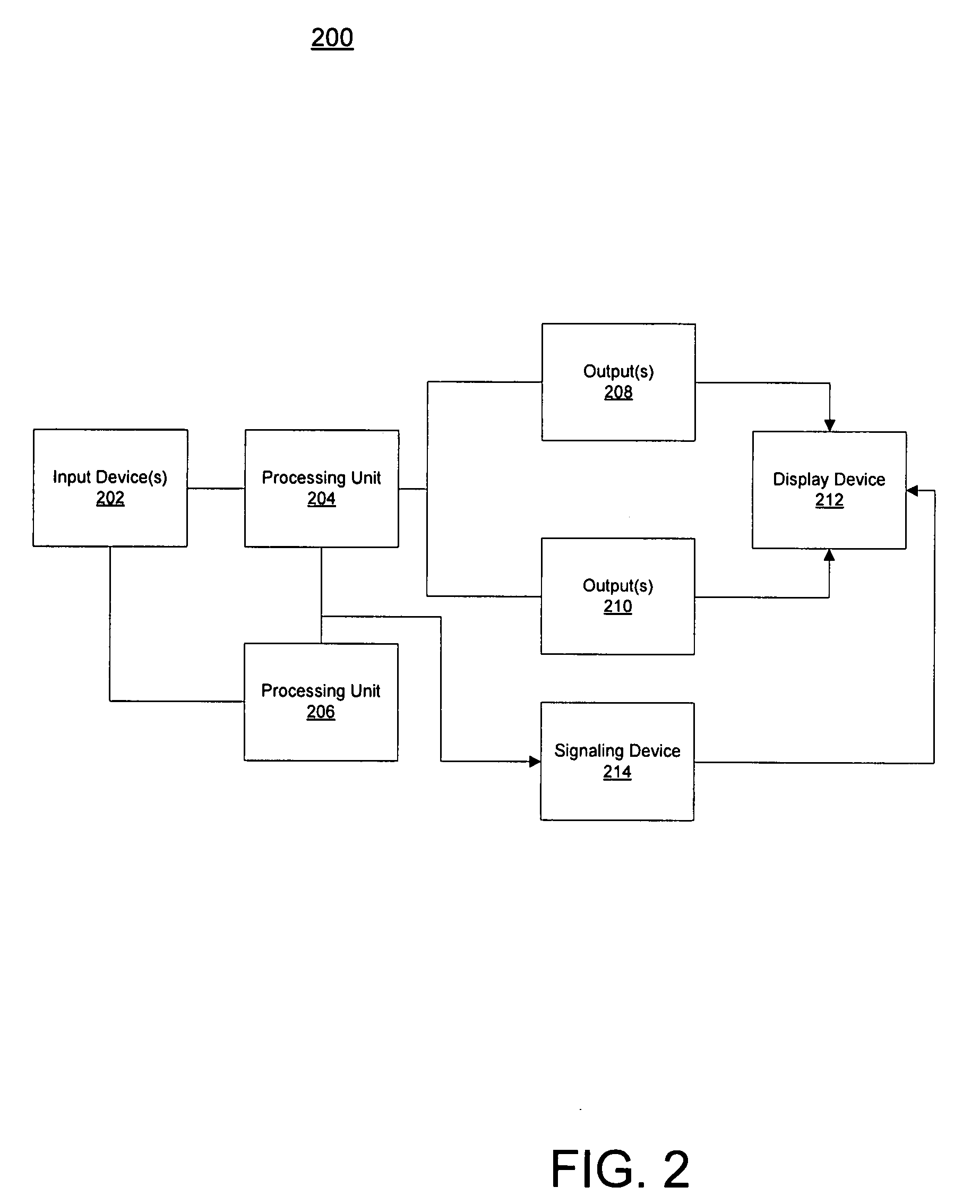

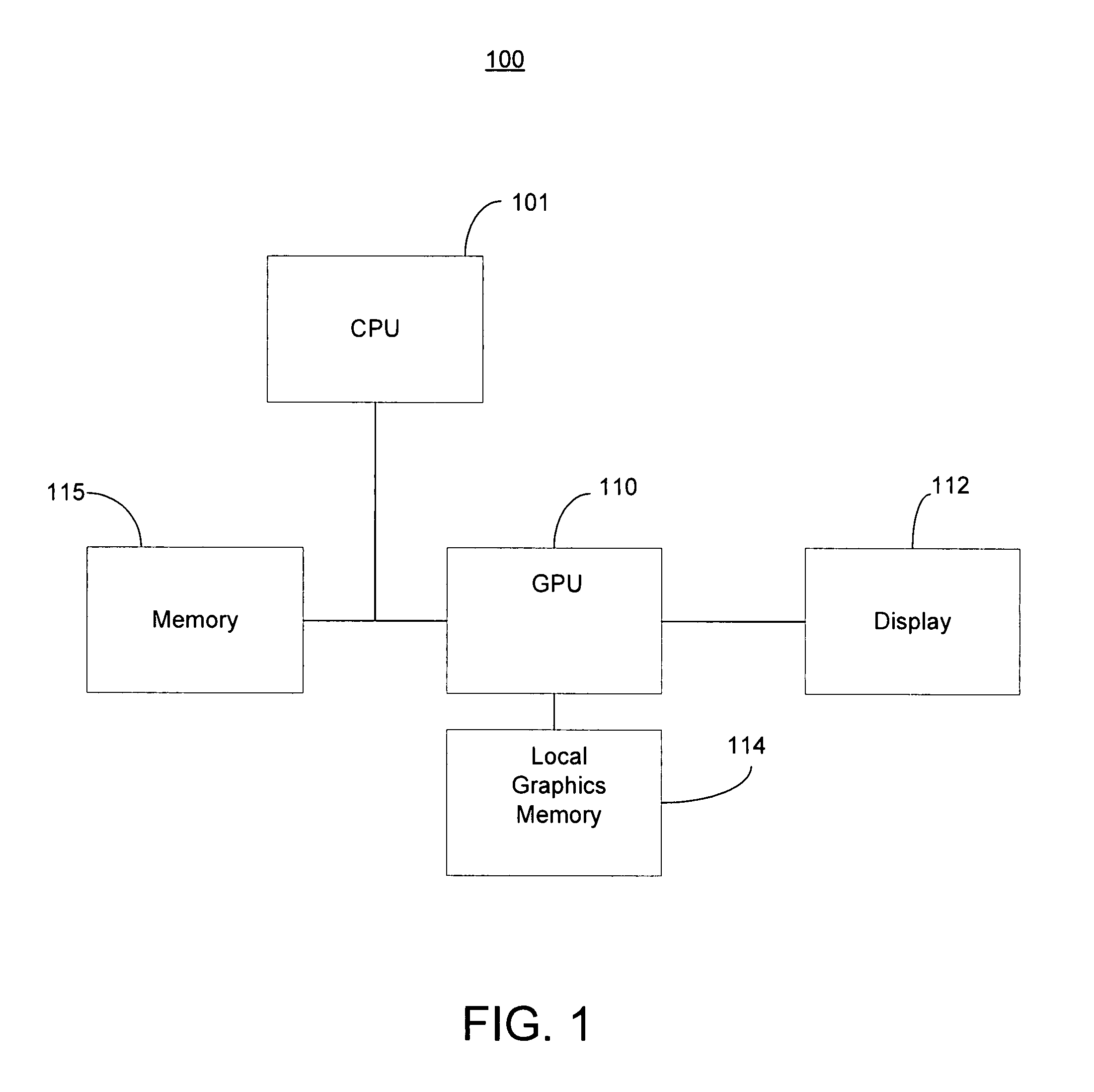

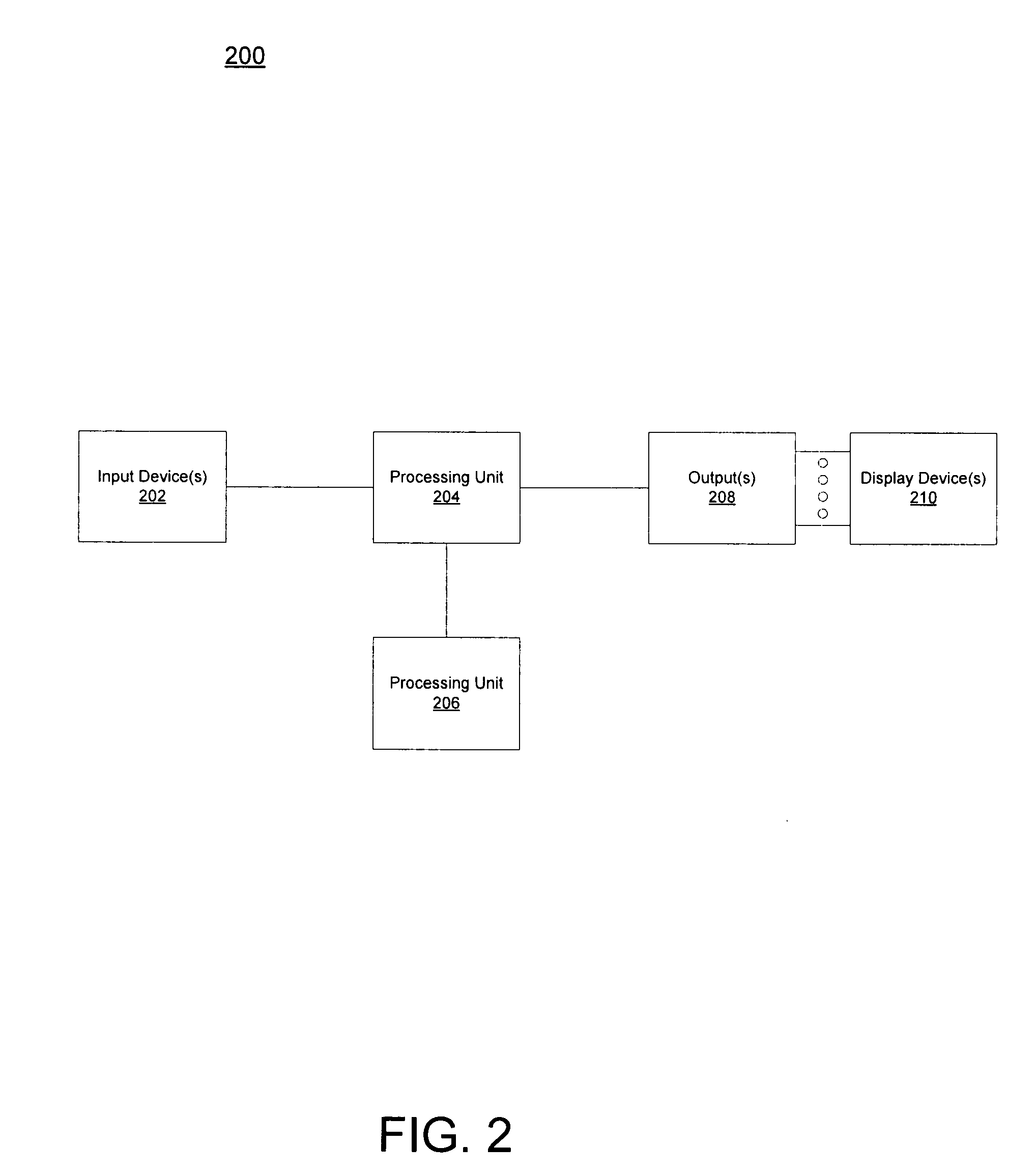

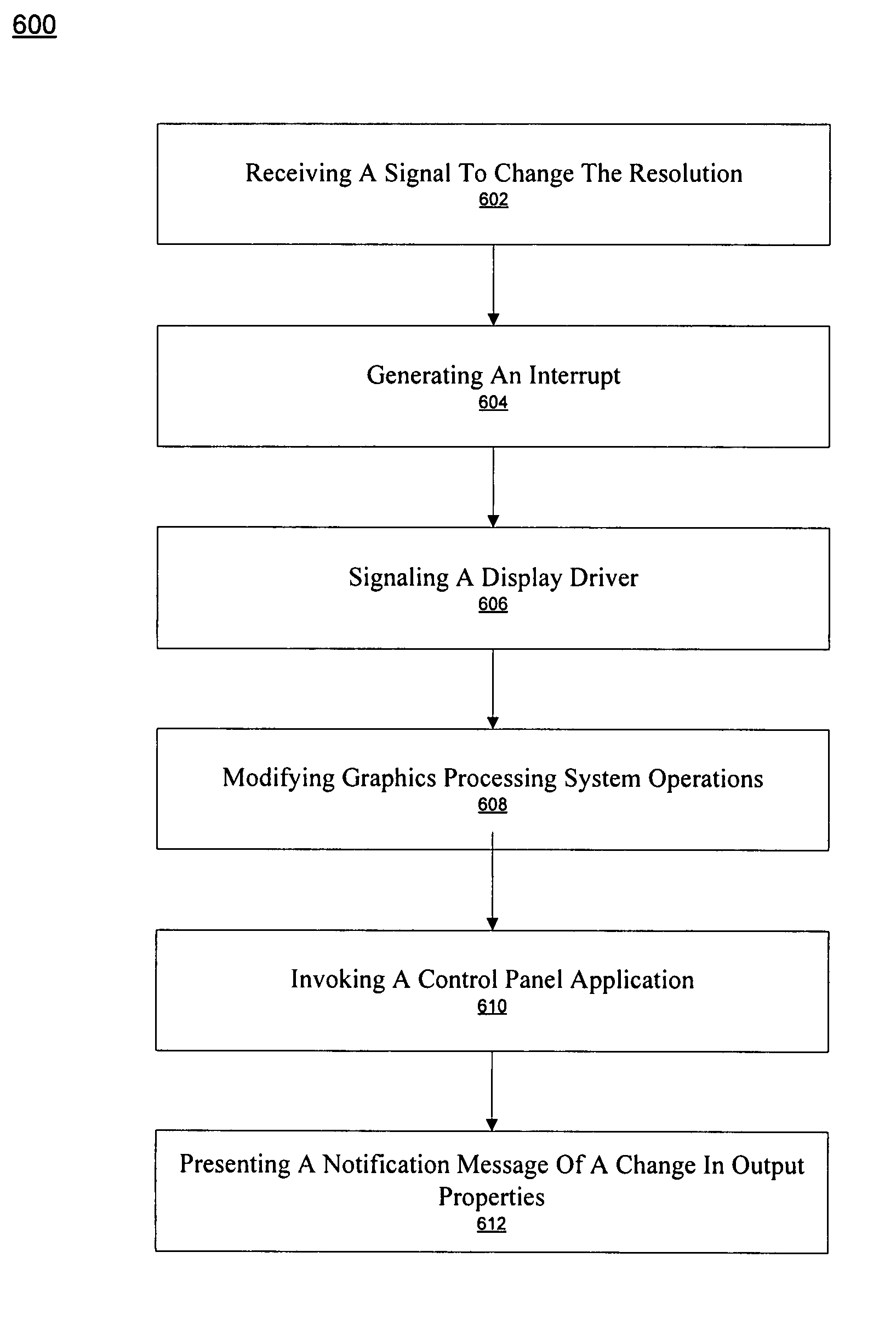

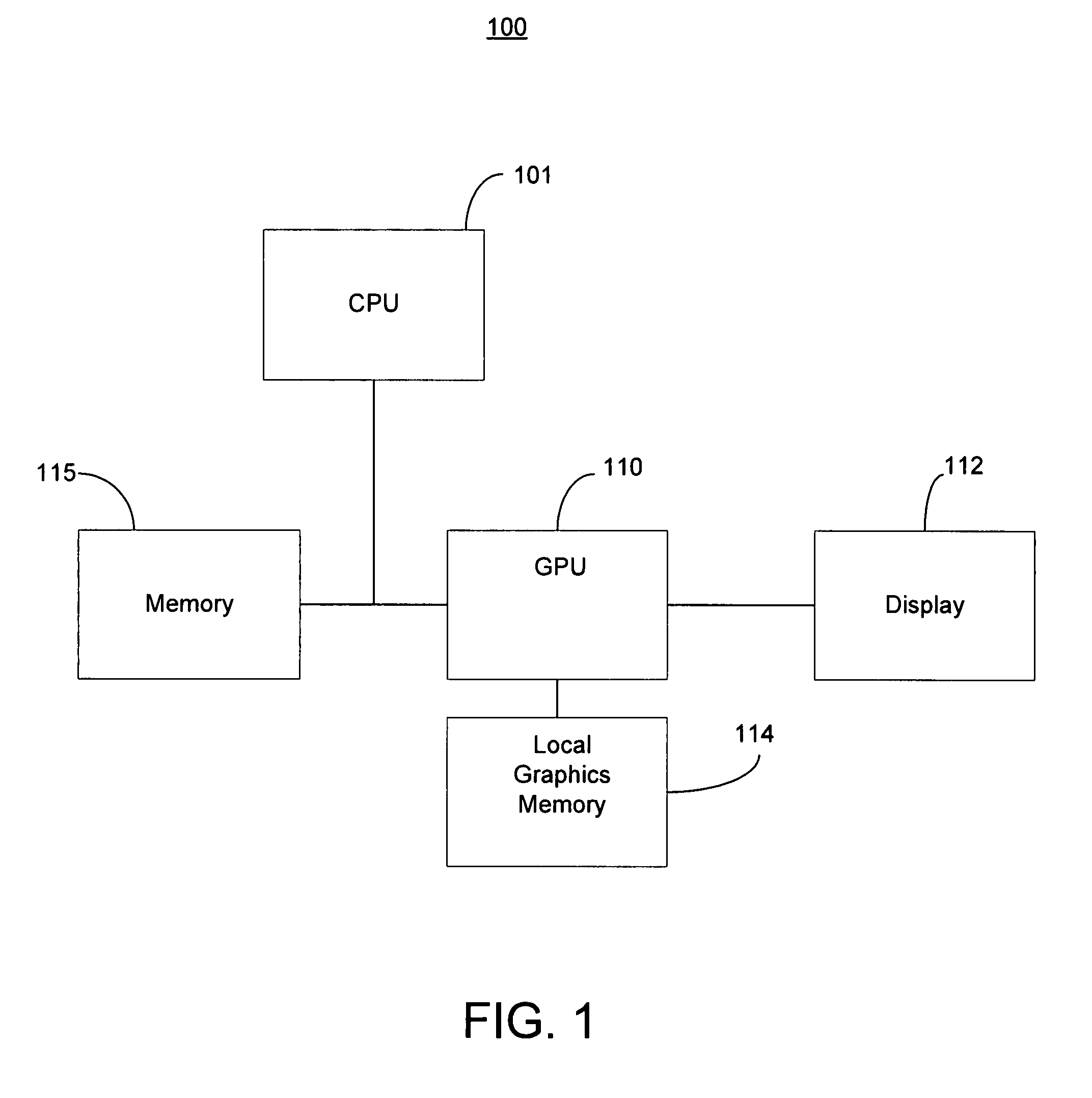

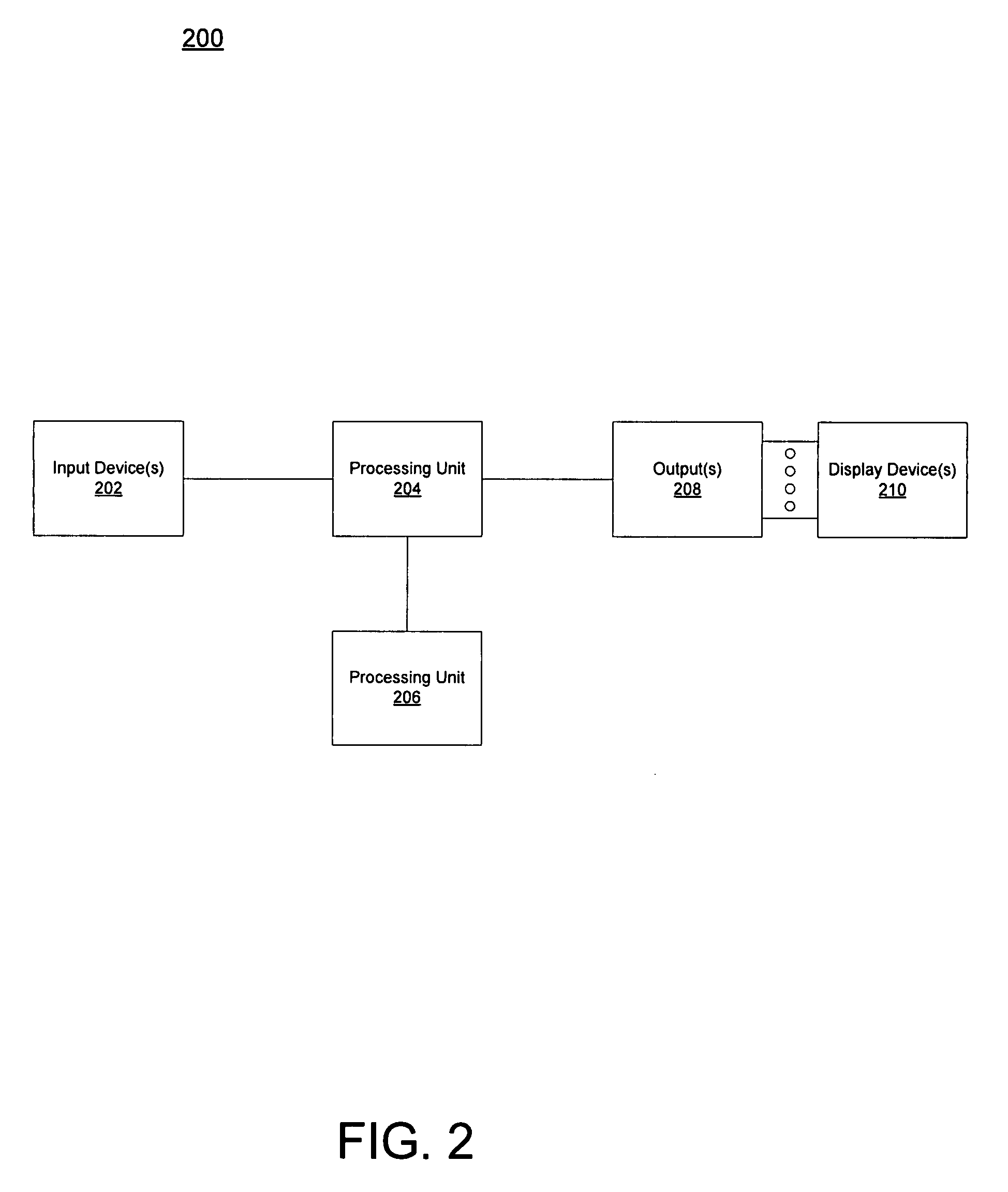

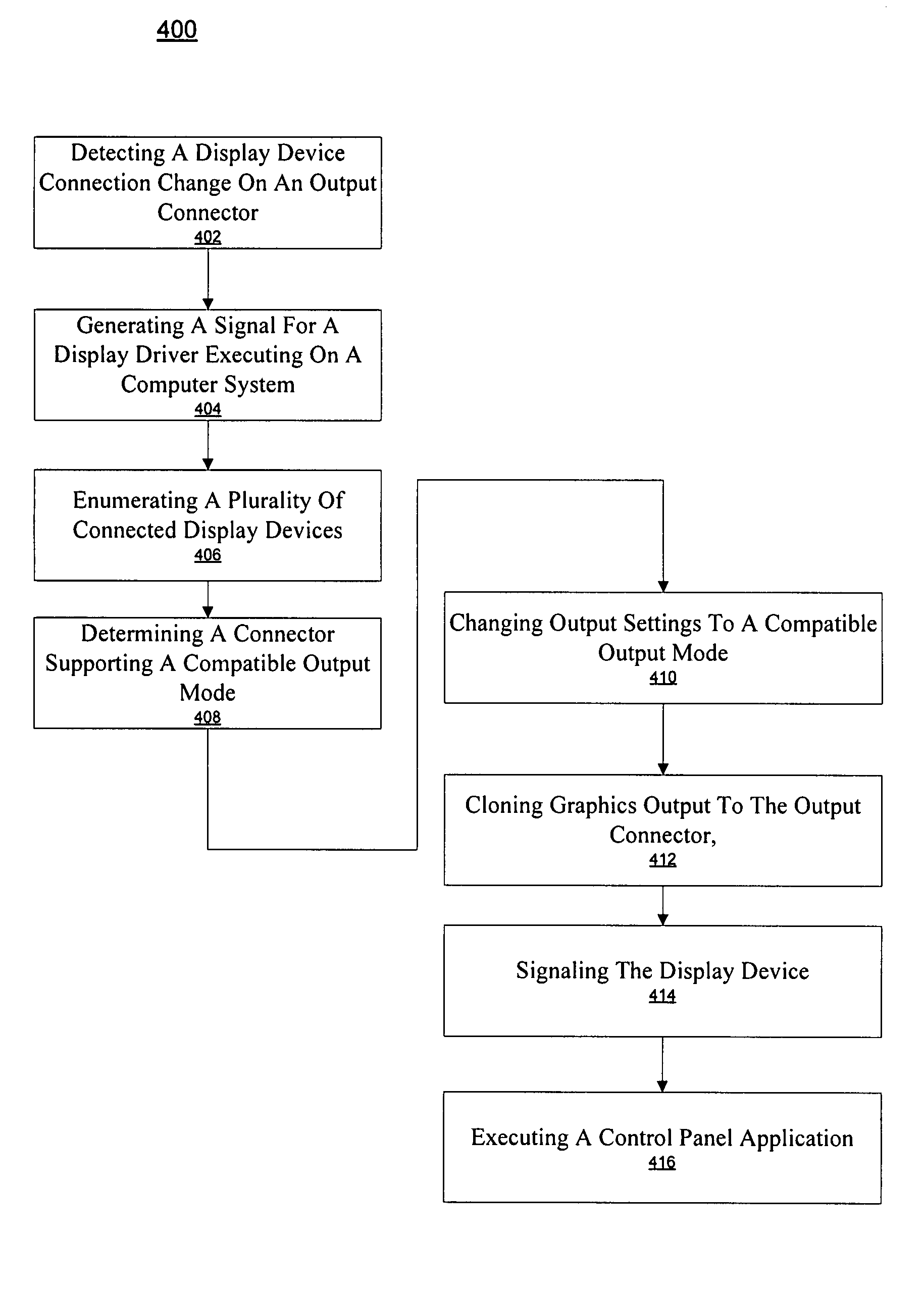

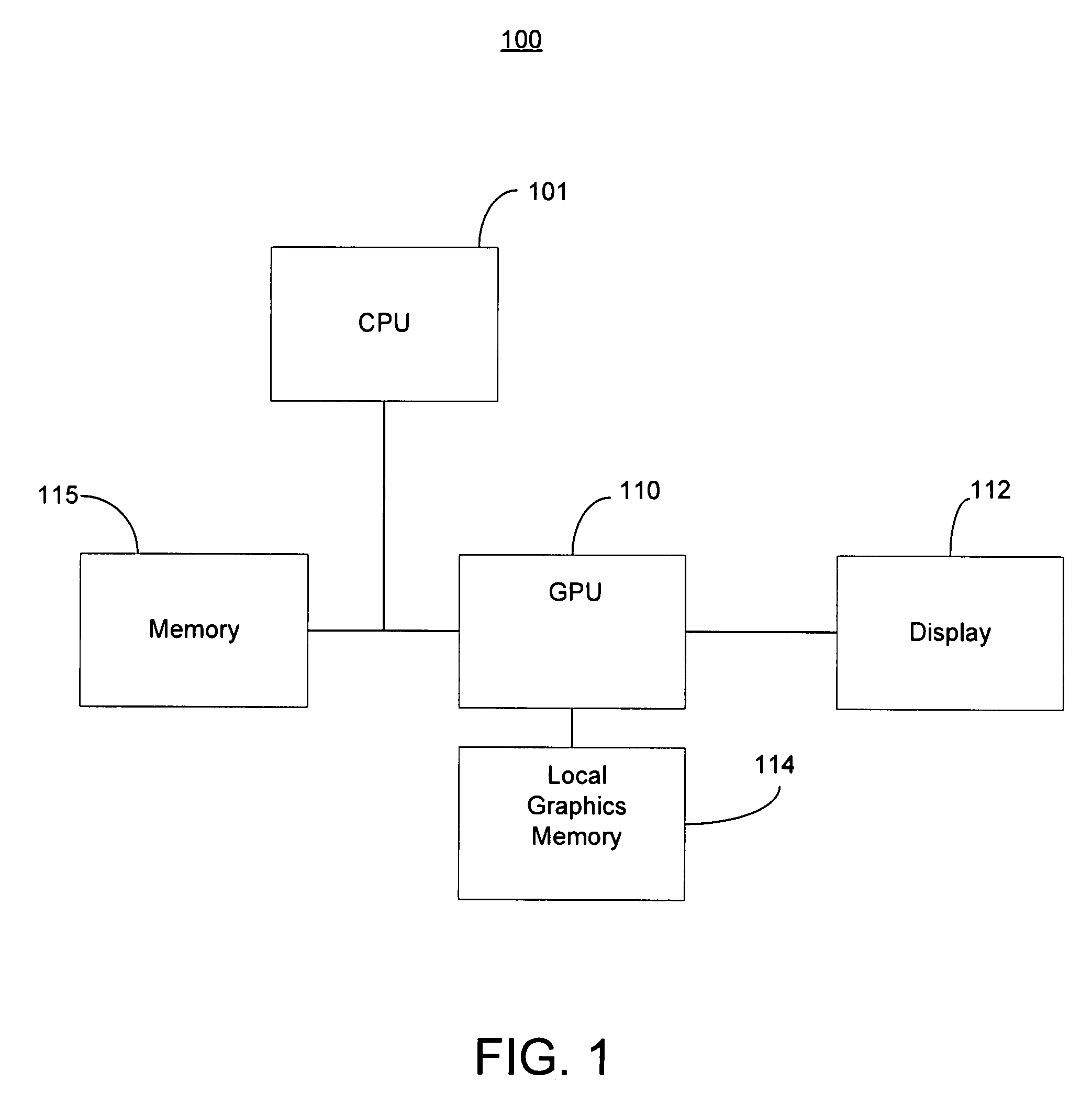

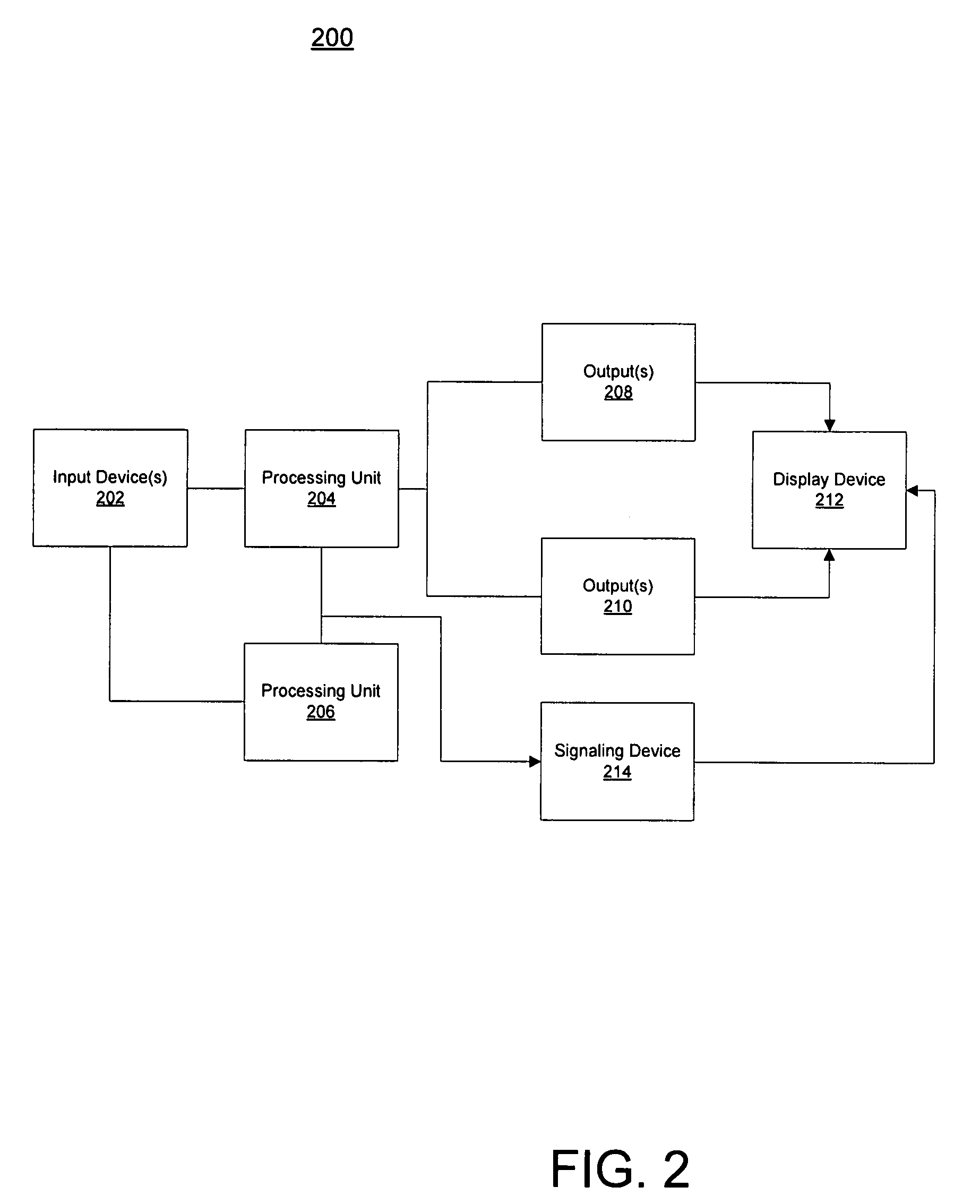

Output restoration with input selection

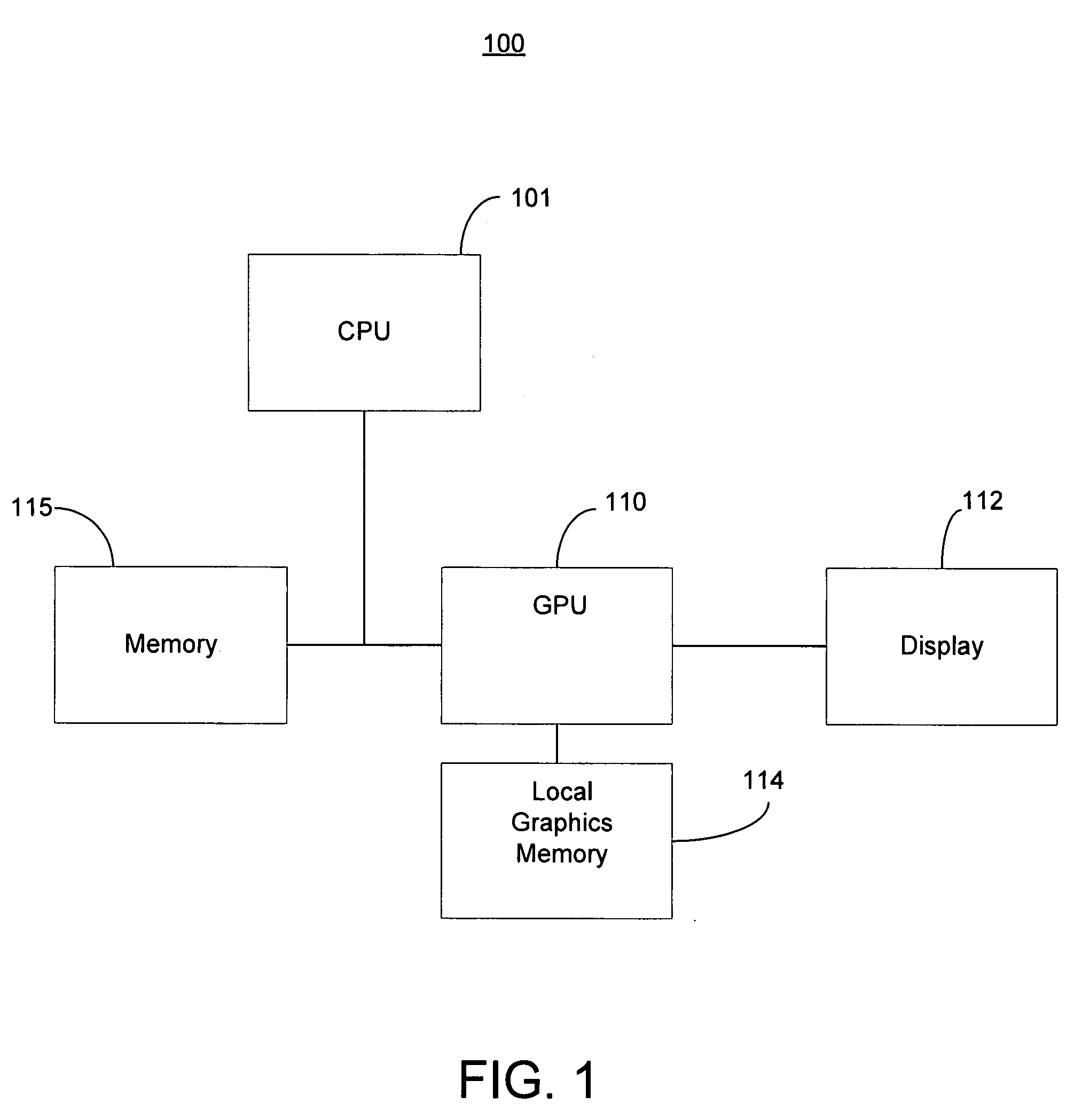

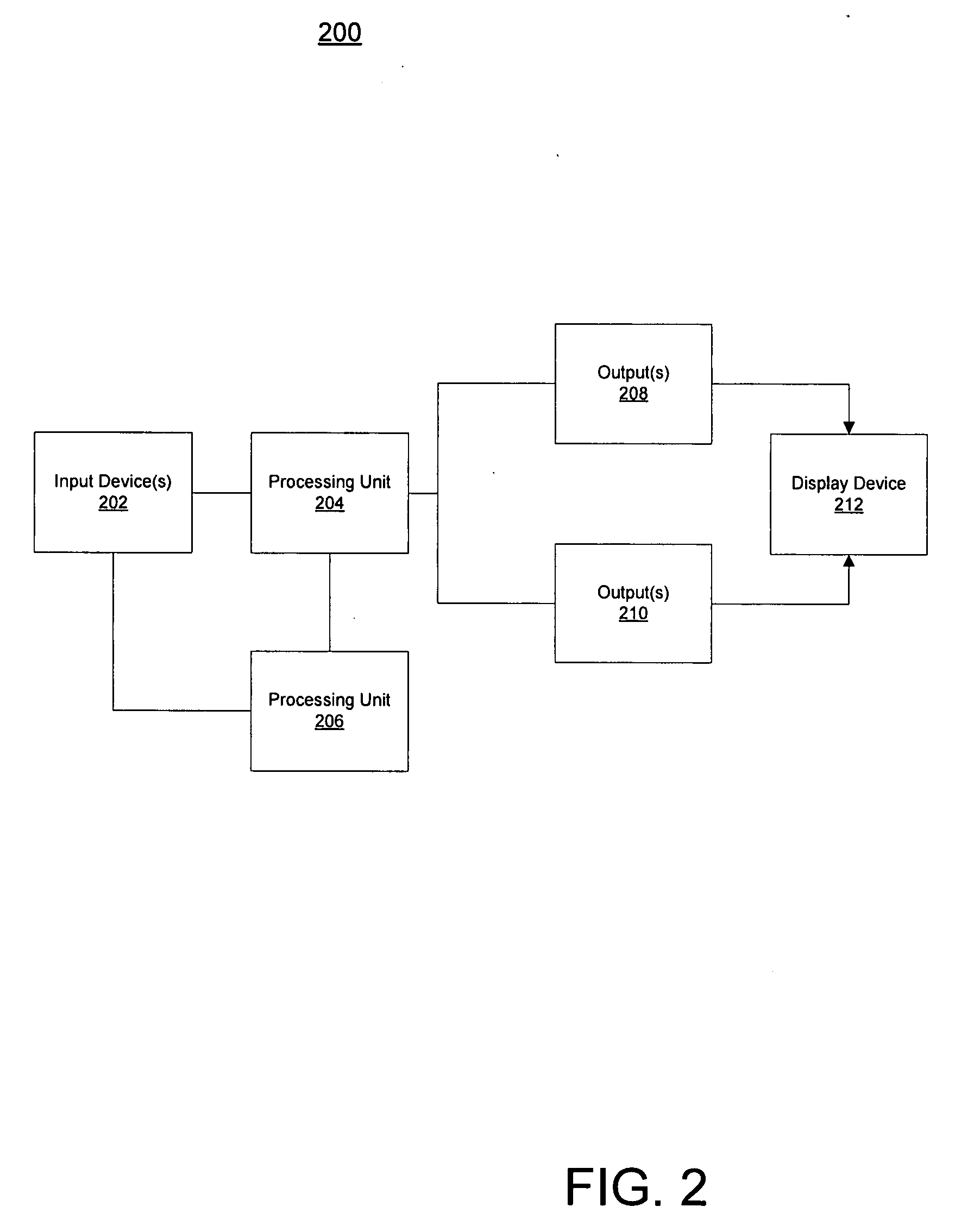

ActiveUS20090079686A1Reliably restoredRestoring output settingCathode-ray tube indicatorsDigital output to display deviceGraphicsInput selection

A method for restoring visual output to a display device. The method includes detecting a display device connection change on an output connector and changing output settings to a compatible output mode on the output connector. The method further includes cloning graphics output to the output connector. The graphics output is modified for display on the output connector. The display device is signaled to change the input source to correspond to the output connector. Subsequently, a control panel application is executed to present an on-display control for changing the output mode of the first output connector.

Owner:NVIDIA CORP

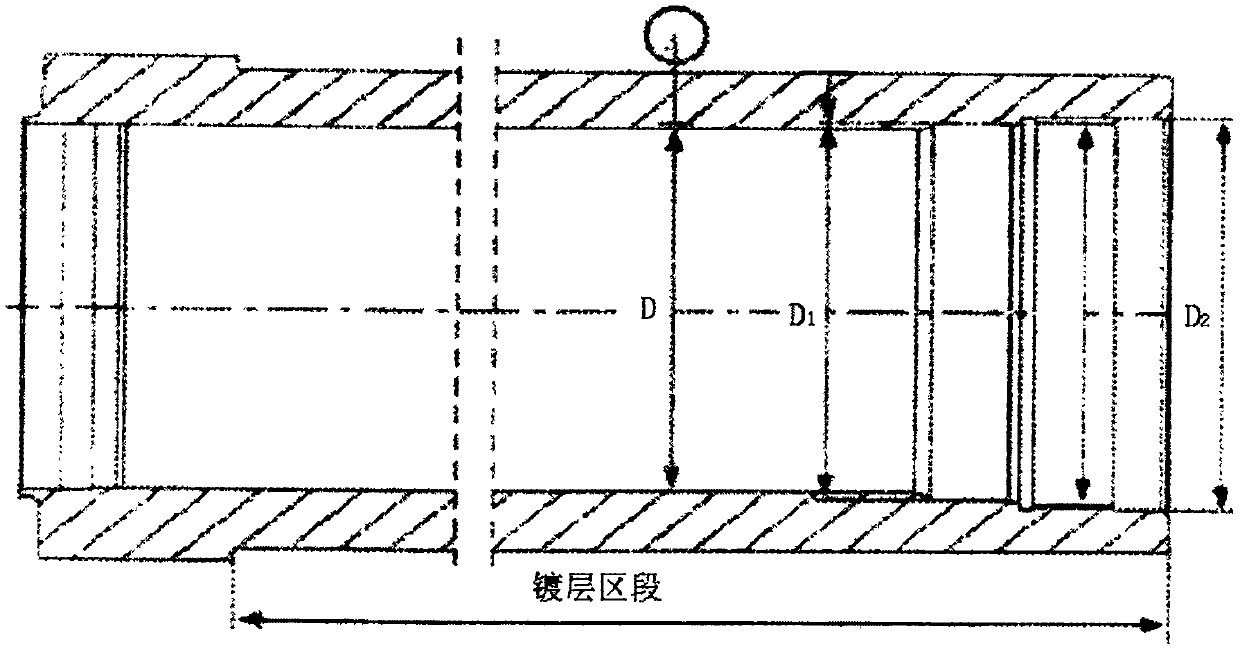

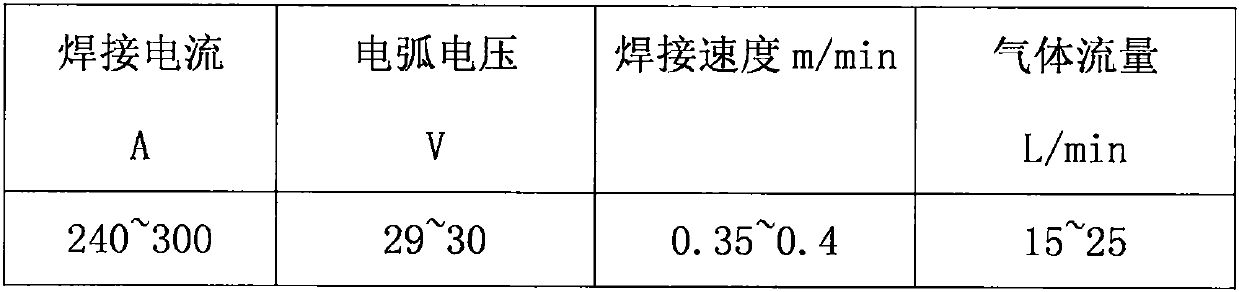

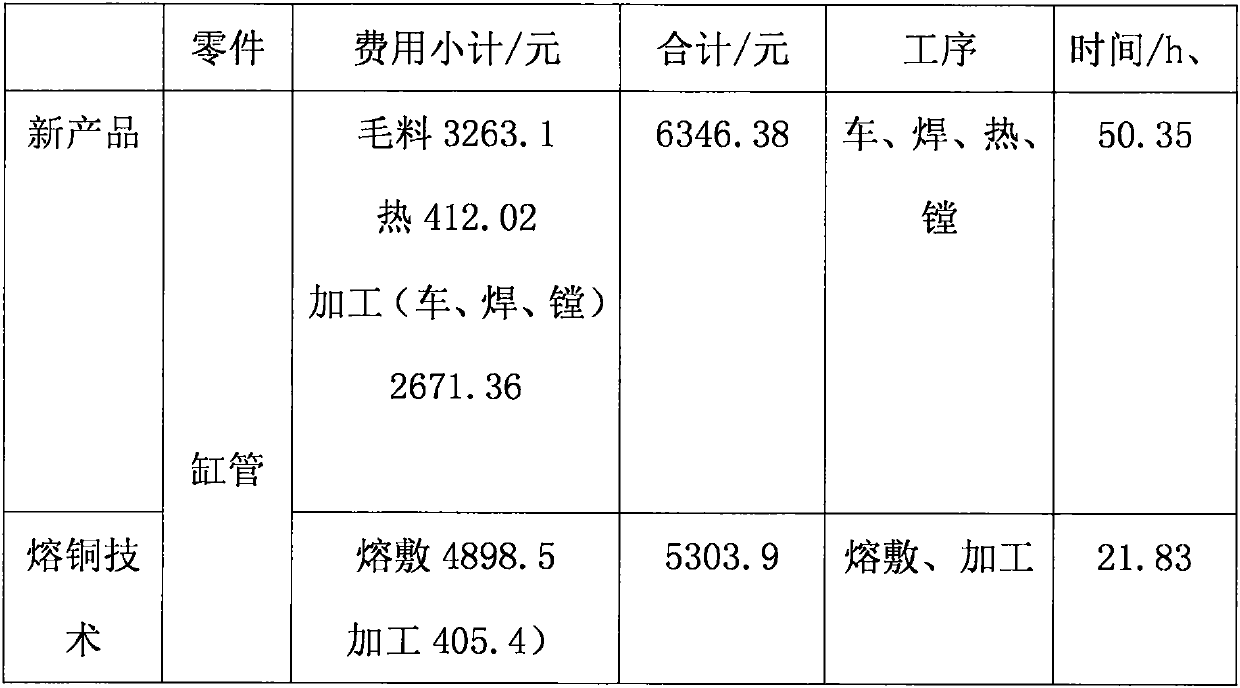

Technology of carrying out surfacing of aluminum bronze on inner surface of coal mine hydraulic bracket 27SiMn oil cylinder

InactiveCN111318785ARestore usabilityAchieve remanufacturingArc welding apparatusCoalMaterials science

The invention relates to the technical field of welding and discloses a technology of carrying out surfacing of aluminum bronze on the inner surface of a coal mine hydraulic bracket 27SiMn oil cylinder. The technology comprises the following steps: 1, evaluating the condition of the inner surface of the coal mine hydraulic bracket 27SiMn oil cylinder; 2, removing an accessory, rust and dirt; 3, boring the corrosion layer on the inner surface of the oil cylinder; and 4, adopting a HK 200 aluminium bronze welding wire with the diameter being 1-1.5 mm as the welding material, and adopting inert gas arc welding to weld the inner surface, except a thread, of the oil cylinder through a hot wire nonmelt electrode. With adoption of the technical scheme, the technology has the following benefits: the scrapped or to-be-scrapped hydraulic bracket 27SiMn oil cylinder is recycled, the original using performance of the oil cylinder is recovered through the technology, so that remanufacturing of theoil cylinder is reached; and the welding quality is stable, the technology completely replaces the electroplating technology to realize the remanufacturing effect, so that the production cost is greatly reduced, the production efficiency is improved and the service life of the oil cylinder is greatly prolonged.

Owner:TIANJIN YINGYUAN WELDING TECH +1

Load sensing forced mode lock

InactiveUS20090079687A1Reliably restoredRestoring settingCathode-ray tube indicatorsDigital output to display deviceGraphicsLoad sensing

A method for restoring visual output to a display device. The method includes detecting a display device connection change on an output connector and changing output settings to a compatible output mode on the output connector. The method further includes cloning graphics output to the output connector. The graphics output is modified for display on the second output connector. Subsequently, a control panel application is executed to present an on-display control for changing the output mode of the first output connector.

Owner:NVIDIA CORP

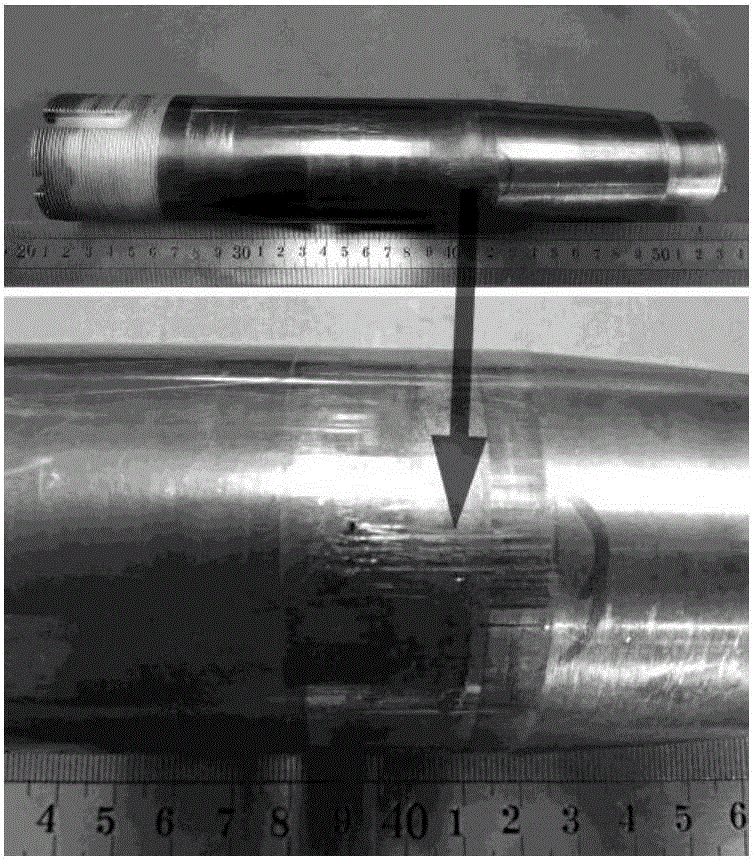

Surface strengthening method of natural gas reciprocating compressor piston rod

InactiveCN108265290ASolving Surface Hardening ProblemsEasy to useMetallic material coating processesHeat-affected zoneEngineering

The invention provides a surface strengthening method of a natural gas reciprocating compressor piston rod. The method comprises the steps that (1) the thickness of a surface strengthening layer of the piston rod is designed and computed; (2) an adopted laser cladding material, cladding parameters and technique conditions are subjected to technique evaluation test verification; (3) according to the evaluation test conclusions, the surface of the piston rod is subjected to laser cladding, a cladding powder material comprises less than or equal to 0.2% of C, less than or equal to 0.5% of Si, less than or equal to 1.2% of Mn, 17-19% of Cr and 1.5-2.5% of Ni; (4) nondestructive testing is conducted; (5) machining is conducted; and (6) final inspection is conducted and comprises size inspection, precision and roughness inspection, hardness inspection and nondestructive inspection. The strengthening layer, treated through the surface strengthening method, of the piston rod surface is combined with a base material in a metallurgical mode, the strength is high, the hardness value is higher than 52 HRC, the width of a heat affected zone is smaller than 0.8 mm, in addition, the mechanical performance of the base material is not affected, and thus the method is suitable for surface strengthening treatment of the piston rod, can also be used for remanufacturing of waste pistons and is widein application prospects.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

Software driven display restore mechanism

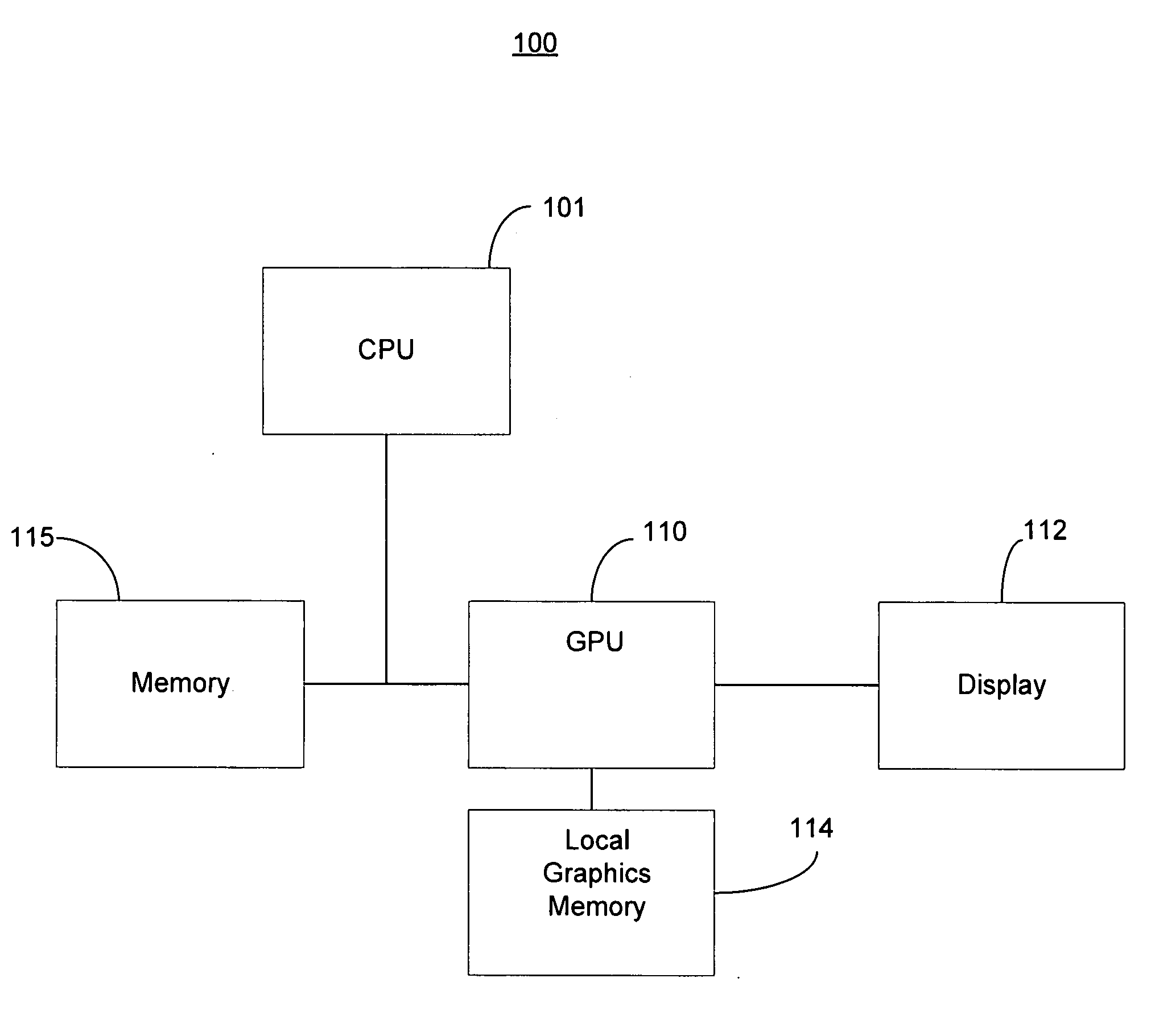

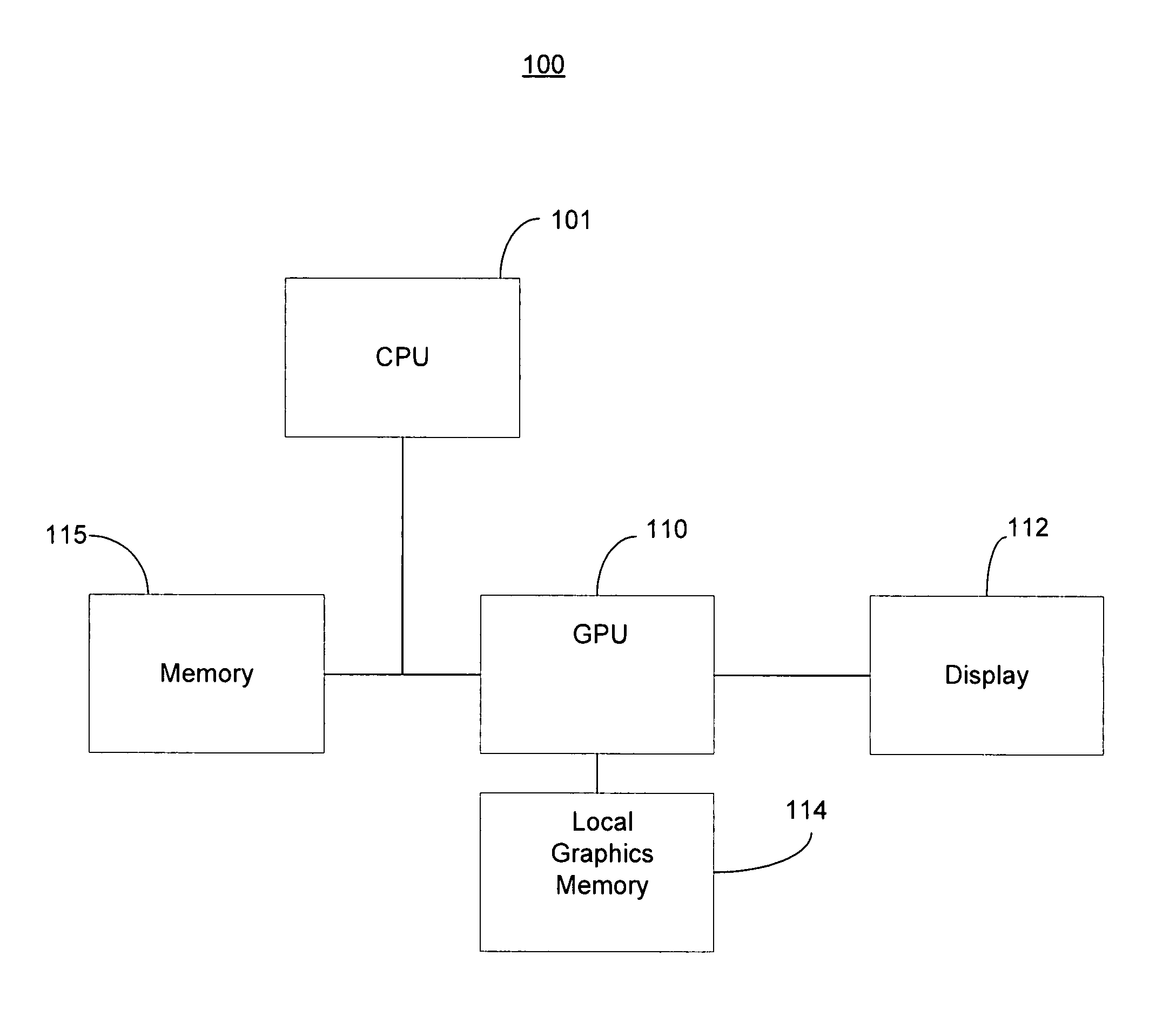

InactiveUS20090073101A1Reliably restoredRestoring settingStatic indicating devicesDigital output to display deviceComputer hardwareDisplay device

A method and system for restoring output to a display device. The method includes receiving a request to restore the output, modifying output settings so output is visible on a display device, and invoking an output configuration application. The method and system allow a user to restore the output on a display device after the output has been configured to settings which exceed the capabilities of the display device.

Owner:NVIDIA CORP

Method for regenerating waste rolling oil

InactiveCN105754706AEfficient removalRestore usabilityLubricant compositionEnvironmental resistanceEngineering

The invention belongs to the technical field of petroleum energy resources, and particularly relates to a method for regenerating waste rolling oil.The method comprises the following steps that firstly, the waste rolling oil is pretreated, a polyacrylamide solution, an alkali solution and a poly(diallyldimethylammonium chloride) solution are sequentially added into the waste rolling oil, stirring under heating and centrifugal separating are sequentially performed, and supernatant oil liquid is obtained; meanwhile, silica gel is modified through high-temperature roasting and a method of doping metal elements; lastly, column chromatography is performed on the supernatant oil liquid through the modified silica gel, wherein the supernatant oil liquid is poured into an assembled chromatographic column, the oil acceleratedly passes through the chromatographic column through a vacuum pump, and then regenerated base oil is obtained.The method has the advantages of being easy to operate, low in energy consumption, free of pollution, clean, environmentally friendly, high in recovery rate and the like, and secondary pollution caused by a traditional process technology is thoroughly abandoned; by adopting the method to treat the waste rolling oil, the physical and chemical properties and the using property of the waste oil can be effectively recovered, and the good social benefit and economic benefit are achieved.

Owner:SHANGHAI INST OF TECH

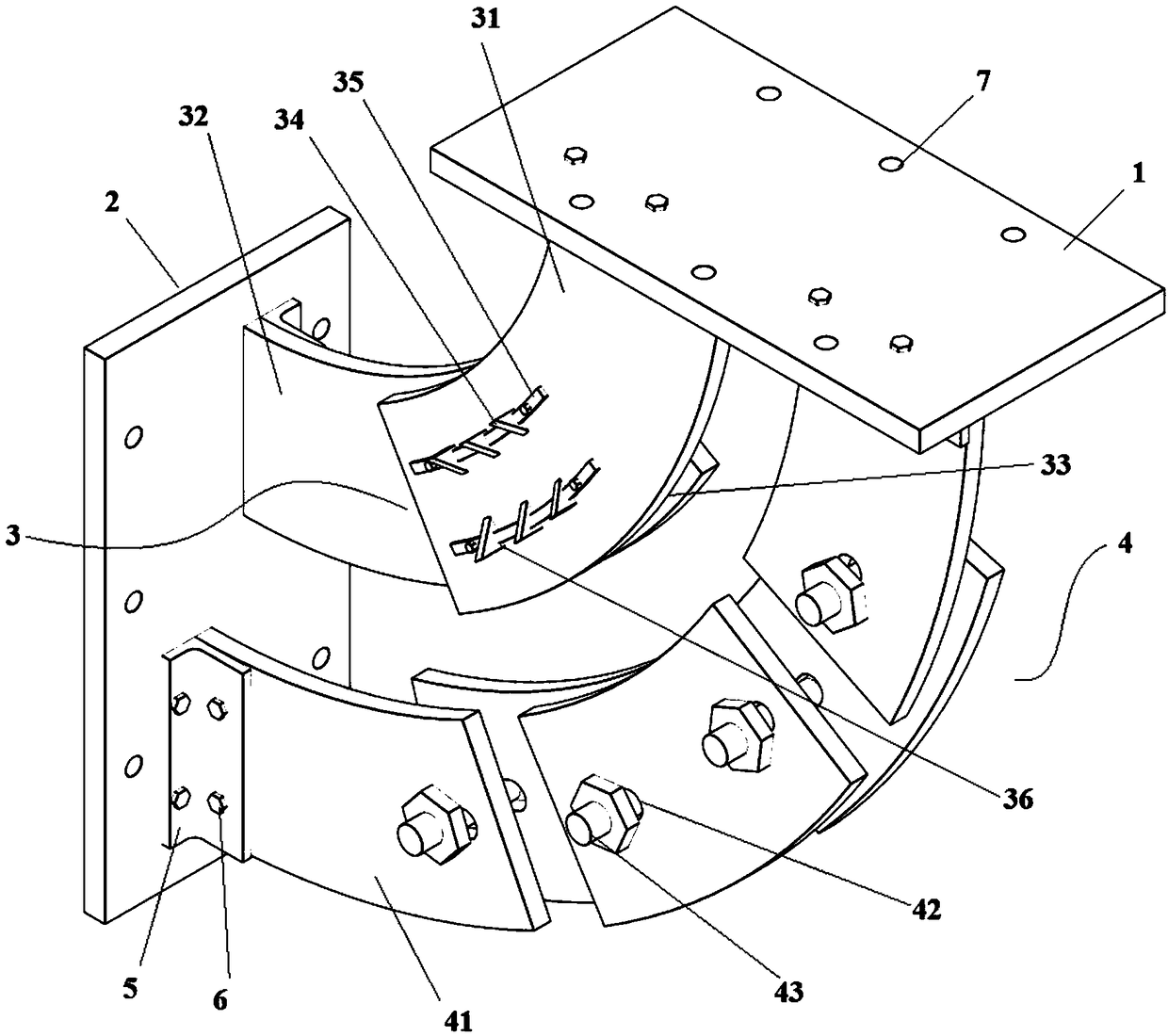

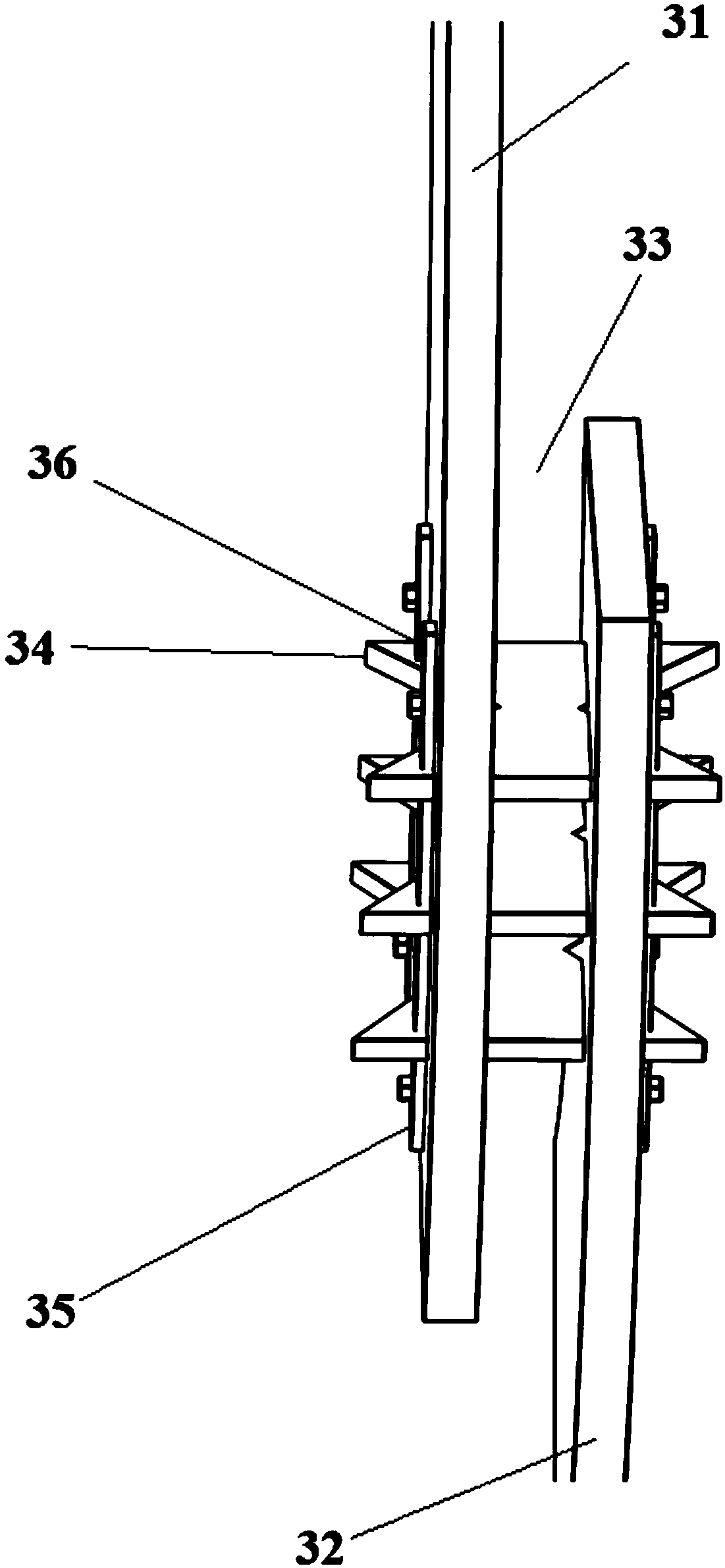

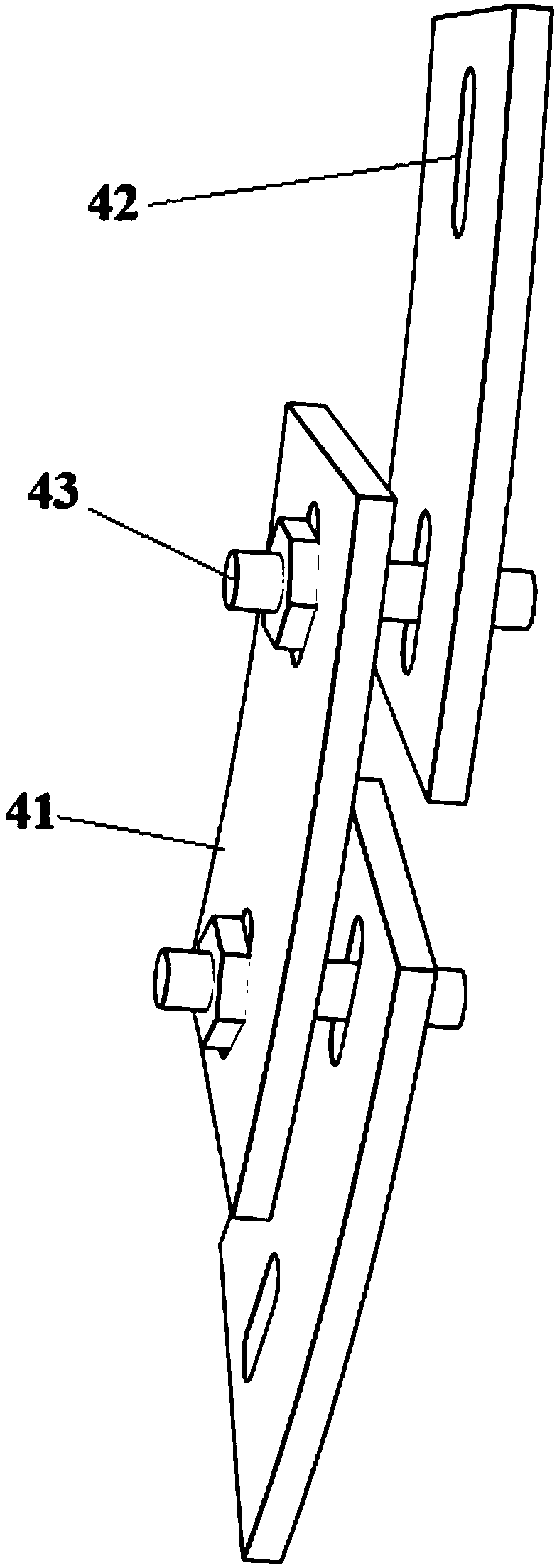

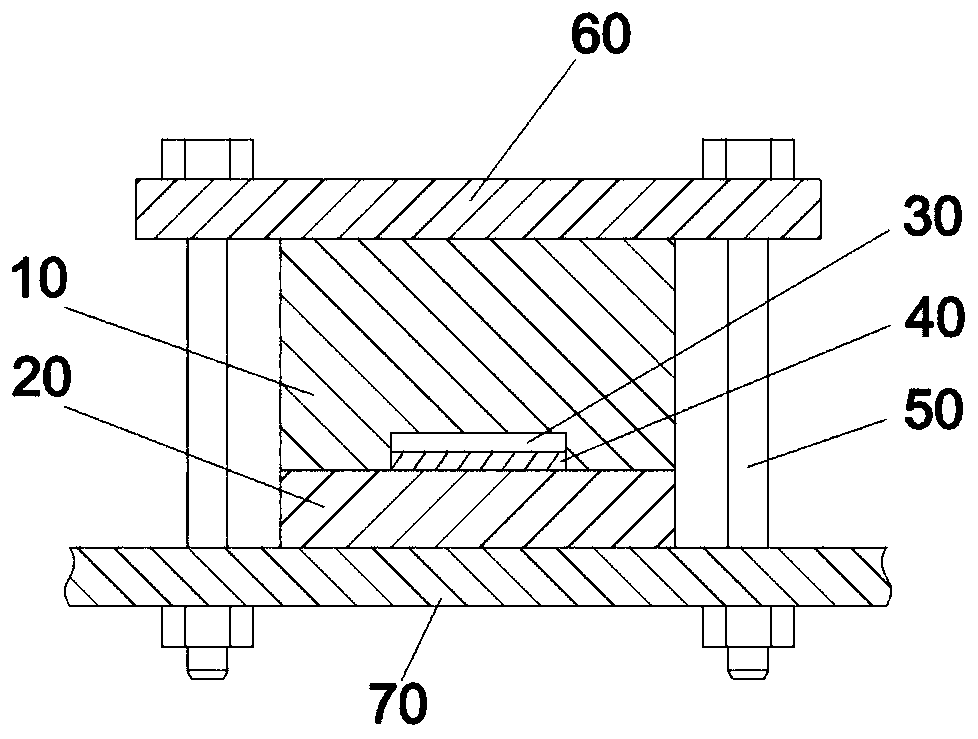

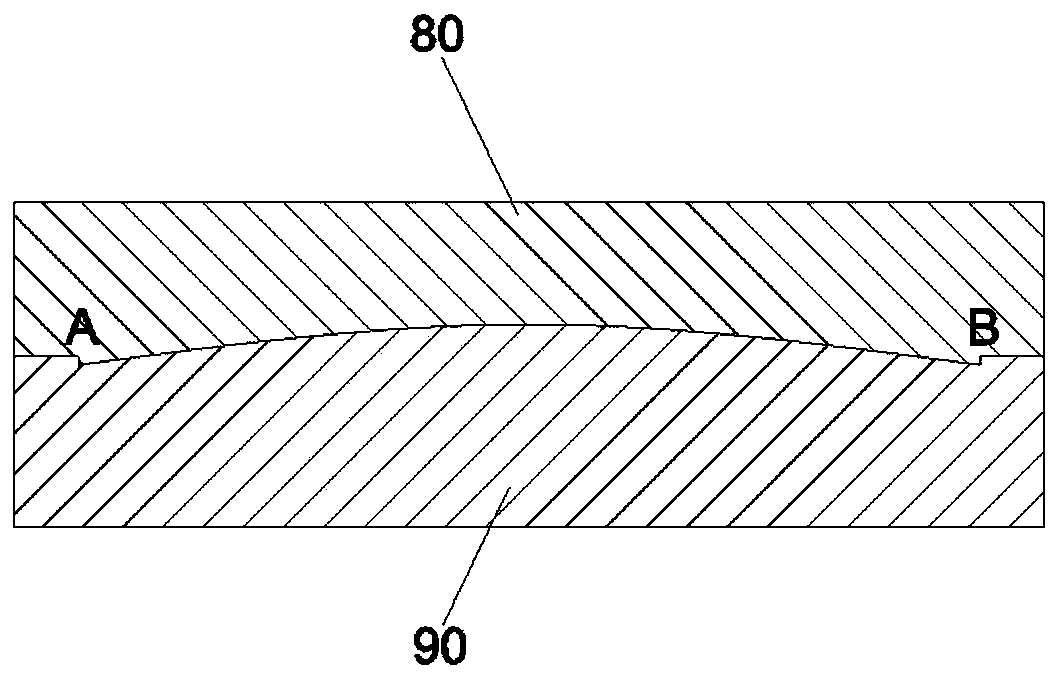

Replaceable arc-shaped soft steel plate combined energy dissipation damper for beam-column joints

PendingCN108442796AReduce plastic deformationRestore usabilityProtective buildings/sheltersShock proofingEngineeringArc energy

The invention provides a replaceable arc-shaped soft steel plate combined energy dissipation damper for beam-column joints. The replaceable arc-shaped soft steel plate combined energy dissipation damper comprises an upper end plate and a lower end plate, wherein an inner arc energy dissipation mechanism and an outer arc energy dissipation mechanism are arranged between the upper end plate and thelower end plate; in the inner arc energy dissipation mechanism, an upper arc plate and a lower arc plate are fixedly connected through a plurality of groups of energy dissipation plates vertically penetrating through the upper arc plate and the lower arc plate, and the parts of each group of energy dissipation plates extending out of the outer side of the upper arc plate and the outer side of thelower arc plate are connected together through connecting pieces; and in the outer arc energy dissipation mechanism, a plurality of outer arc plates are fixed together in series by deformation bolts penetrating through arc grooves. According to the replaceable arc-shaped soft steel plate combined energy dissipation damper, the energy dissipation plates and the deformation bolts jointly bear the energy dissipation, and under the action of an earthquake, the energy dissipation plates and the deformation bolts are bent and deformed, so that the plastic deformation at the beam-column joint is reduced to ensure that a frame beam-column can still maintain good ductility after the earthquake, and the function of dissipating earthquake energy is achieved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

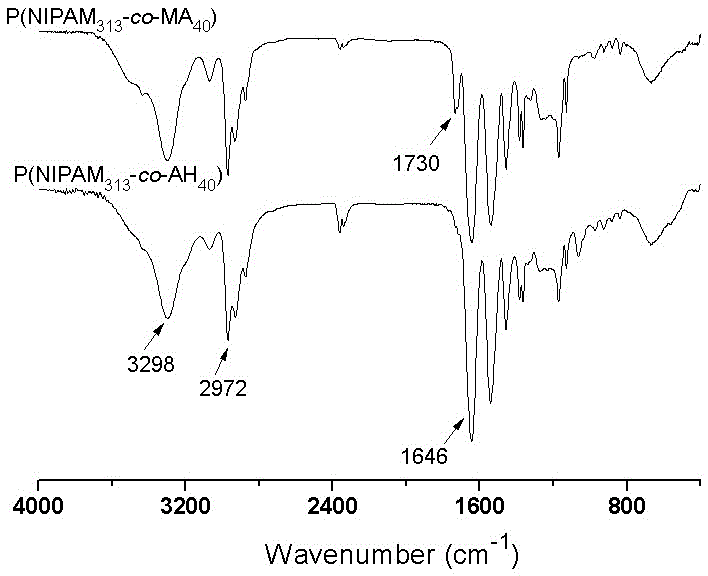

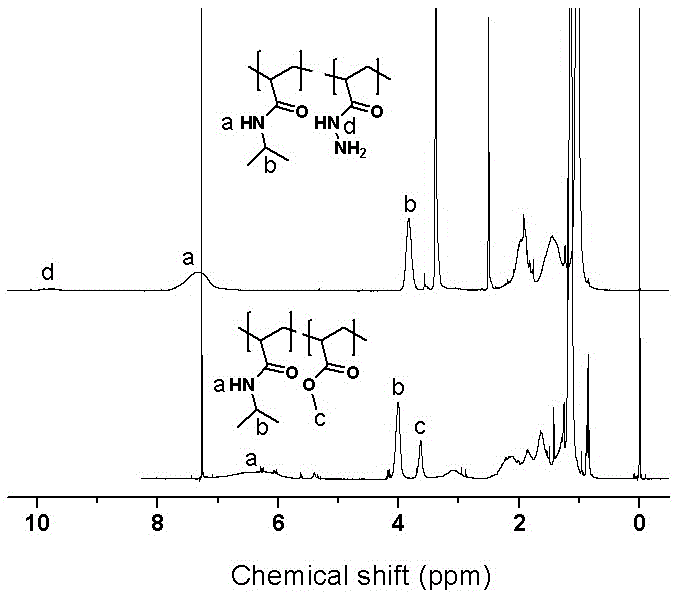

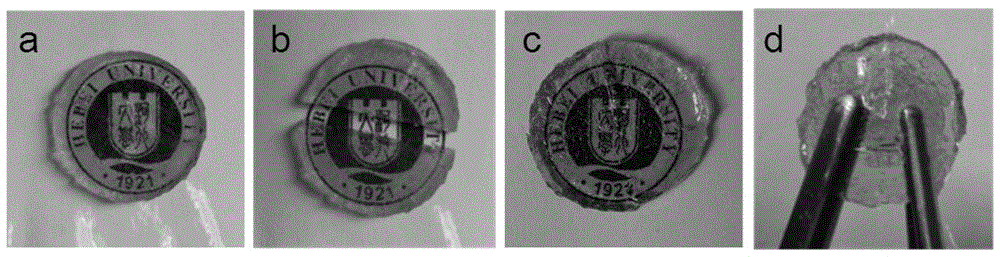

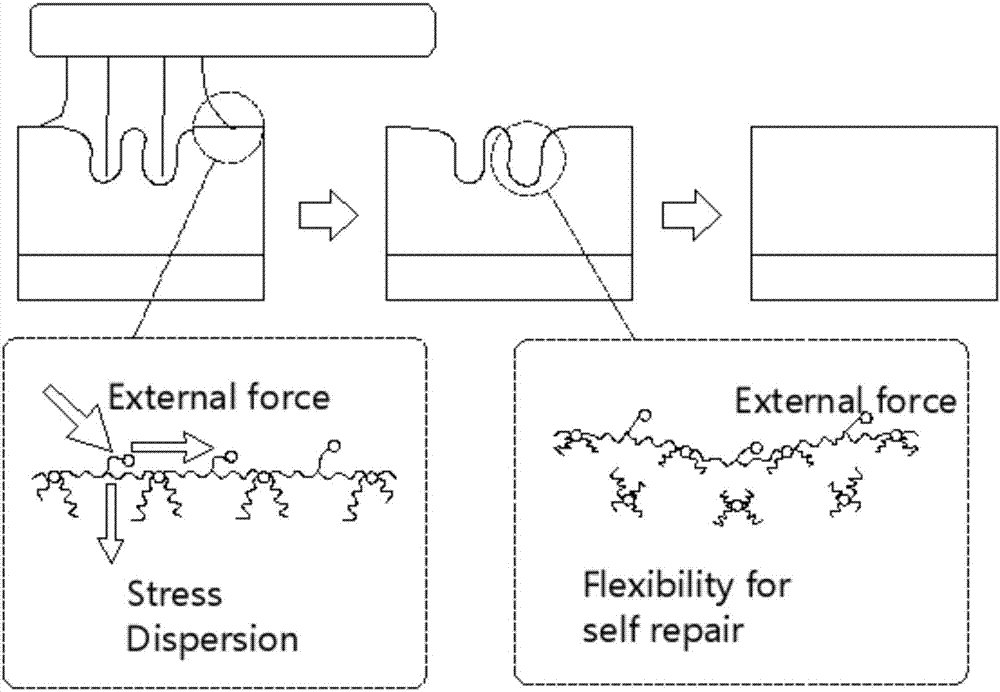

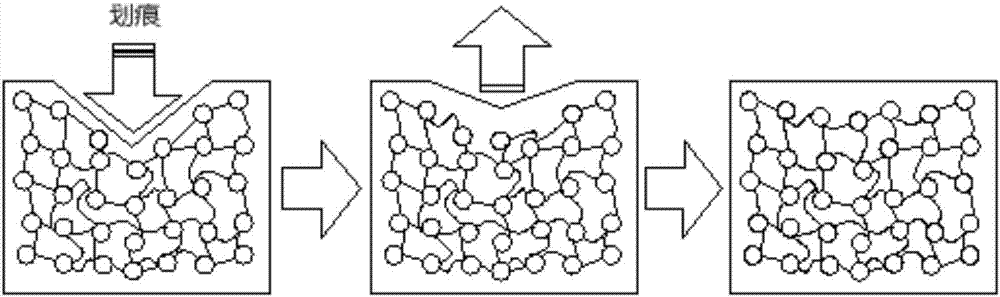

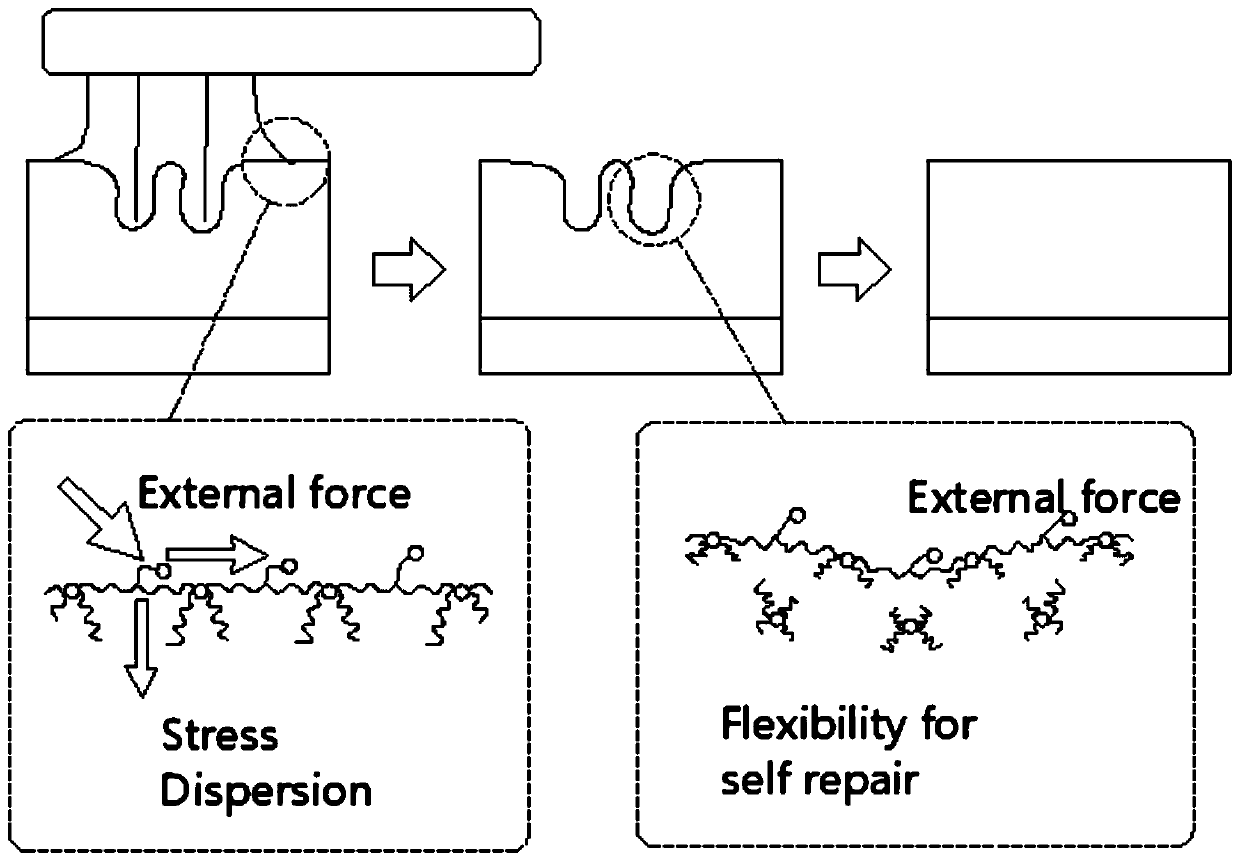

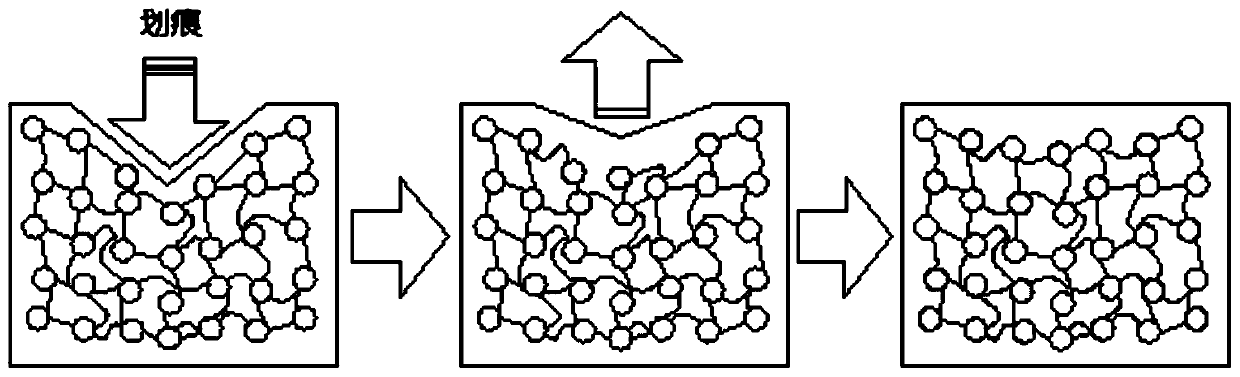

Temperature-sensitive self-repairing hydrogel and preparation method and application thereof

The invention provides temperature-sensitive self-repairing hydrogel and a preparation method and application thereof. The temperature-sensitive self-repairing hydrogel is formed by means of reaction of (N-isopropylacrylamide)-acrylhydrazine copolymer and a compound containing multiple carbonyl groups in an aqueous solution under the action of a catalyst, wherein the catalyst is a weak acid catalyst or an aniline catalyst, the (N-isopropylacrylamide)-acrylhydrazine copolymer comprises repetitive units A and repetitive units B, and the repetitive units A account for 20%-95% of the total mass of the copolymer. The hydrogel has temperature sensitivity and self repairability simultaneously and is good in stability, drug sustained release at different temperatures can be achieved, the hydrogel can achieve self repairing when subjected to damage, the self-repairing process is similar to that of a life body, and the hydrogel has very wide application prospects in biological medicine related fields such as artificial organs and biological indication and drug controlled release. Please see the formula in the description.

Owner:HANDAN WARREN MORE TECHNICAL DEV CO LTD

Cleaning agent for treating oily waste water tubular ceramic membrane and cleaning method

InactiveCN108114608ARestore usabilitySemi-permeable membranesSpecific water treatment objectivesStrong acidsCleansing Agents

The invention relates to a cleaning agent for treating an oily waste water tubular ceramic membrane and a cleaning method. The cleaning agent comprises an acidic cleaning agent and an alkaline cleaning agent, wherein the acidic cleaning agent is a strong acid solution; and the alkaline cleaning agent is composed of NaOH, EDTA and sodium dodecyl benzene sulfonate. The chemical cleaning agent is relatively poor in activity at low temperature, the activity of the chemical cleaning agent is not improved obviously as the temperature exceeds a certain degree, and the energy consumption of the equipment is too great. Experiments verify that the cleaning effect is relatively good when the alkaline washing temperature is about 60 DEG C and the pickling temperature is about 30 DEG C, and the energyconsumption is moderate. According to the technical scheme, blockage caused by oily substances of the ceramic membrane can be eliminated effectively through the formula and the cleaning method of thecleaning agent, and the using ability of the equipment is recovered.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

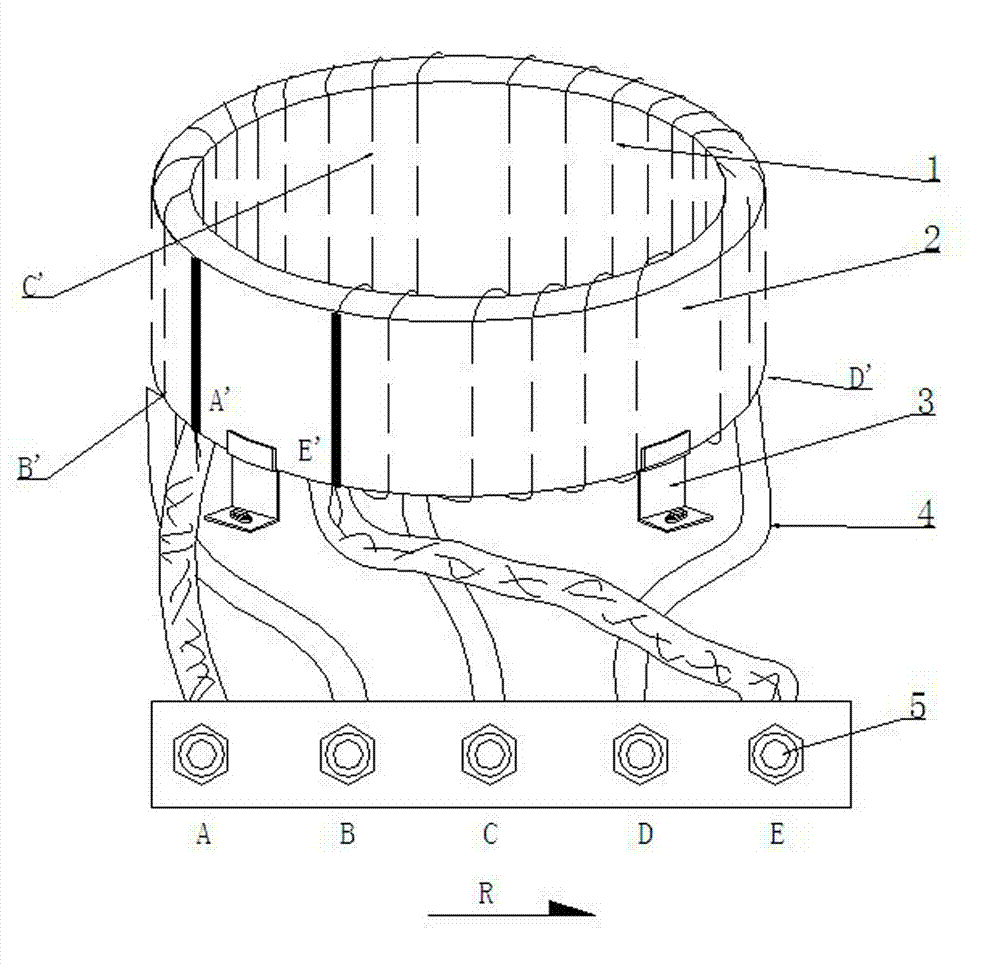

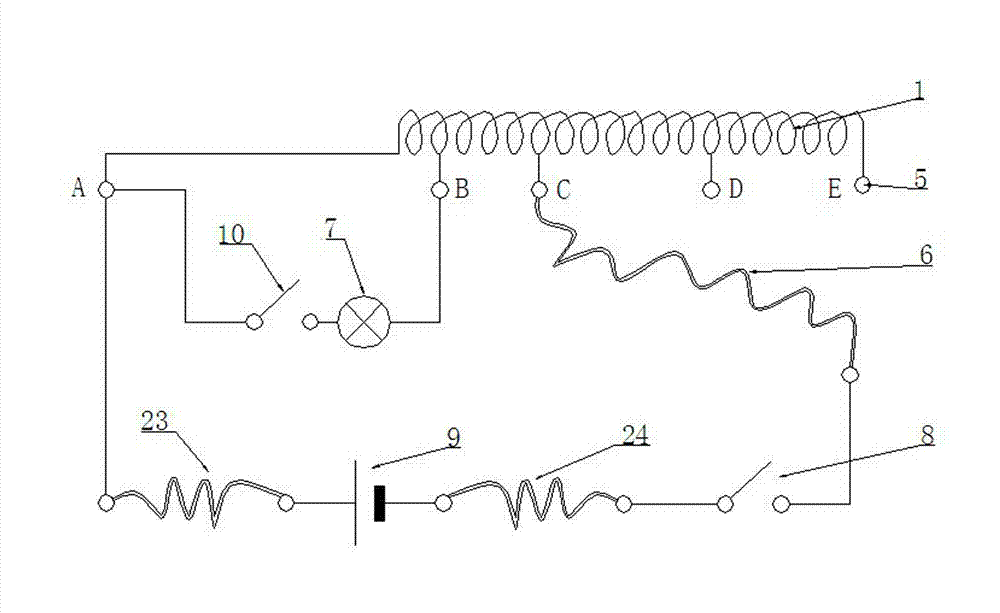

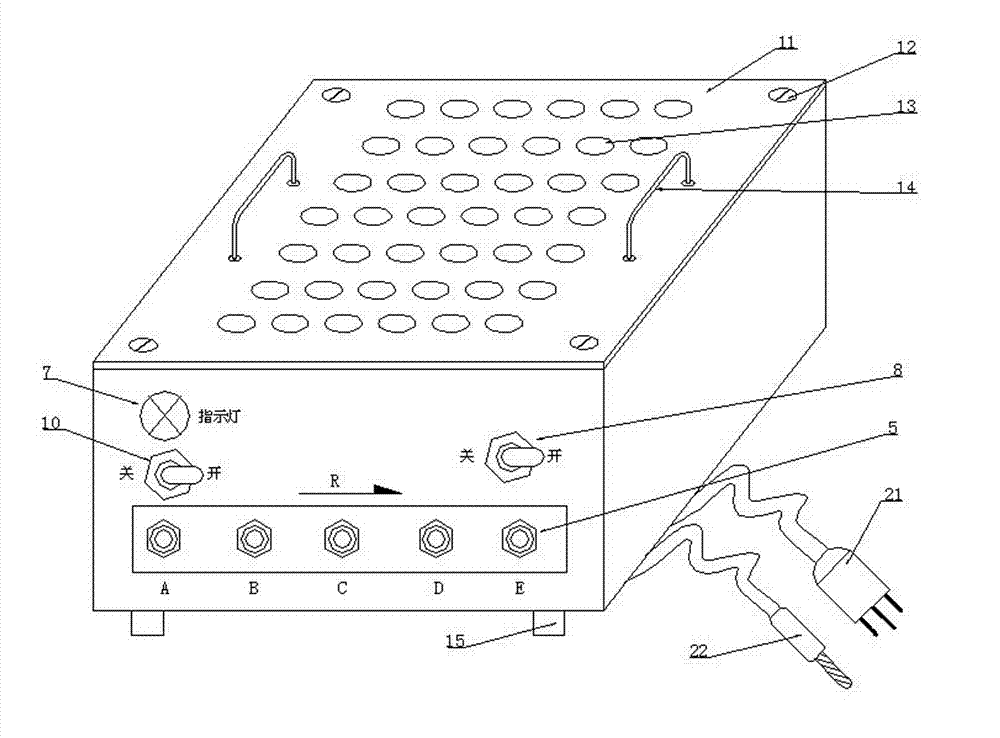

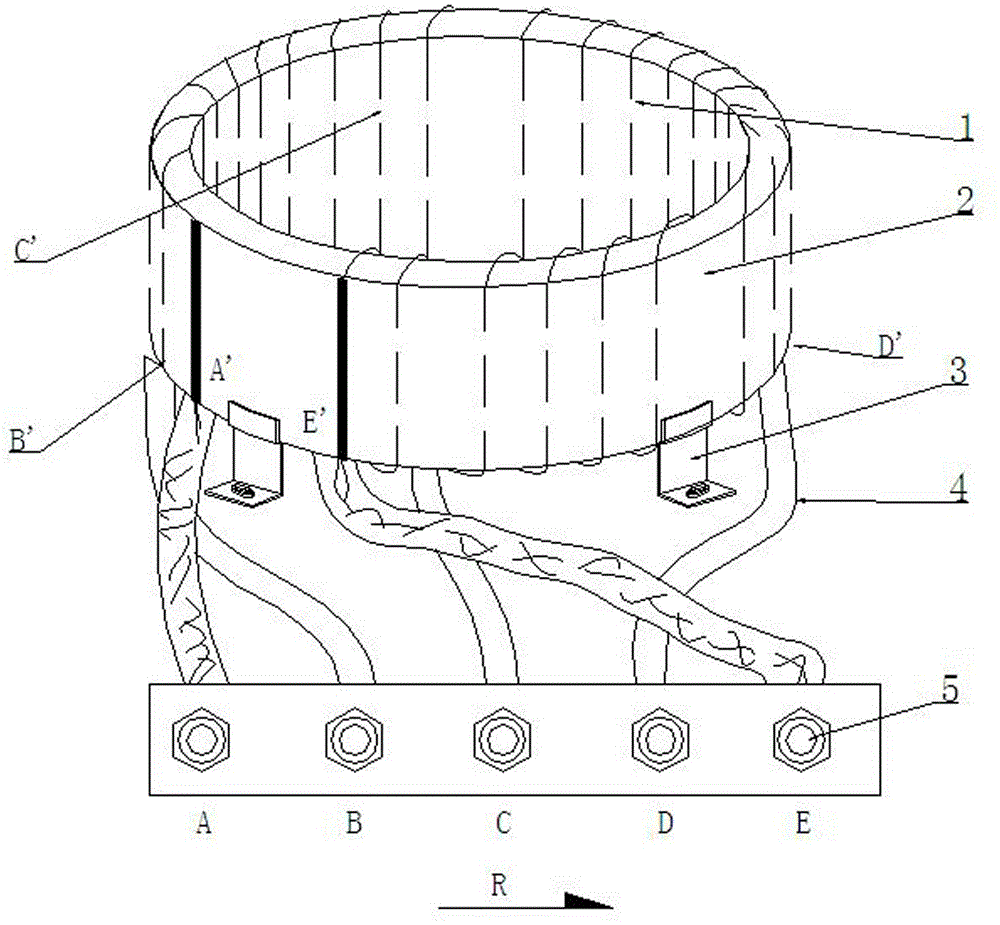

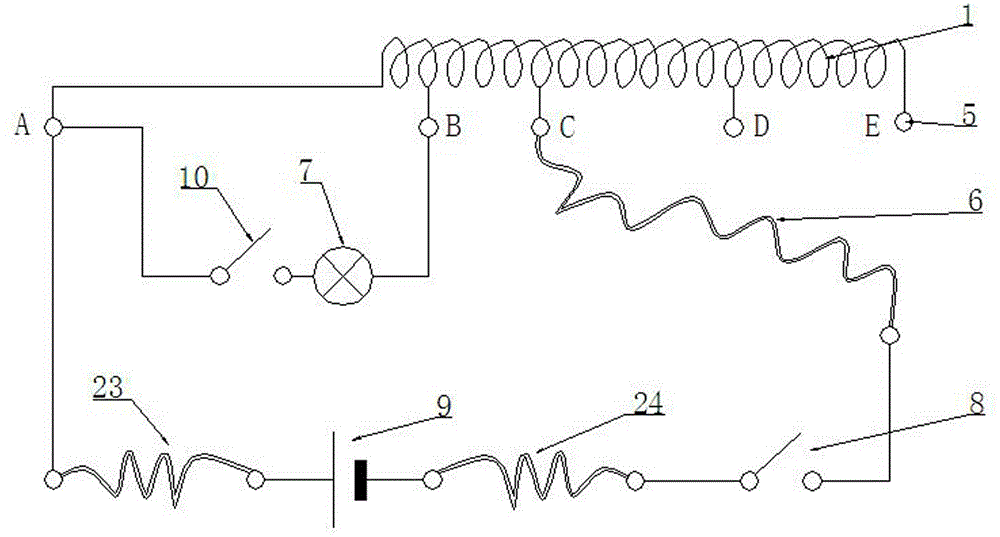

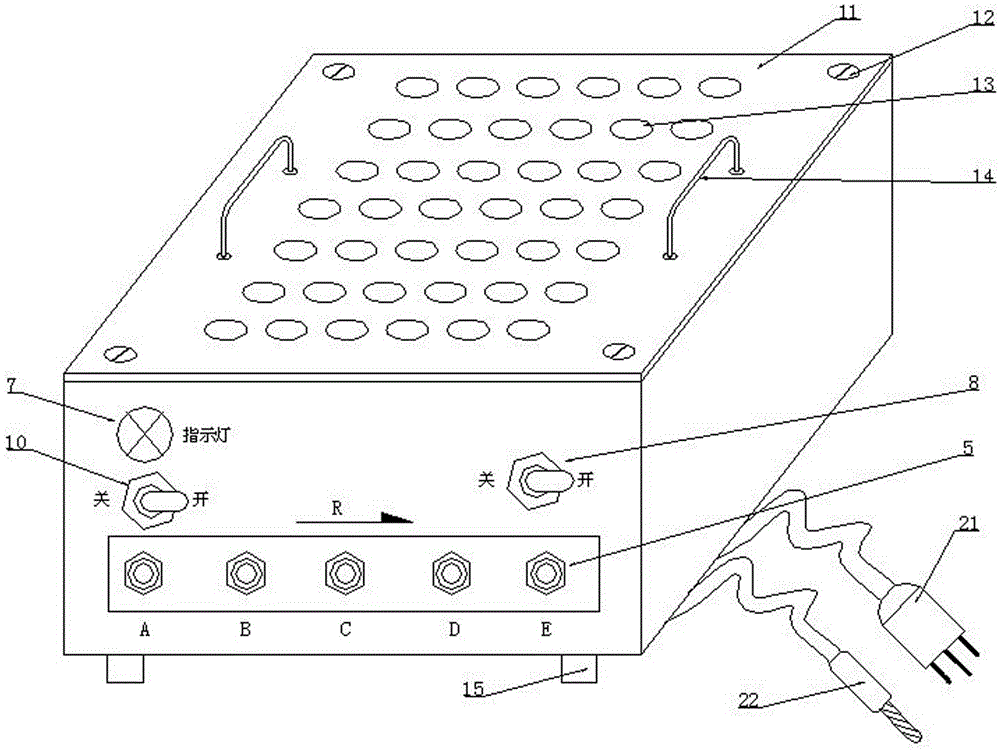

Lead storage battery regeneration apparatus and regeneration method thereof

InactiveCN104332671APrevent dehydrationInhibitory activityWaste accumulators reclaimingBattery recyclingElectrical batteryProcess engineering

The invention relates to the electrical energy storage field, and concretely relates to a lead storage battery regeneration apparatus and a regeneration method thereof. The apparatus adopts a resistance-variable resistance wire provided with an indicating lamp, and the resistance can be changed as needed to completely discharge a lead battery and can effectively avoid the generation of large granule lead sulfate caused by difficult reduction of large granule lead dioxide to lead sulfate due to small discharge current in the later stage of discharge; and the discharge depth can be momentarily observed through the indicating lamp to effectively avoid the sulfate formation of the lead battery and greatly prolong the life of the processed lead battery. The lead storage battery regeneration method has the advantages of non-strict operating conditions, simplicity, use convenience, and realization of good regeneration ability and multiplied service life of the processed lead battery.

Owner:NANYANG NORMAL UNIV

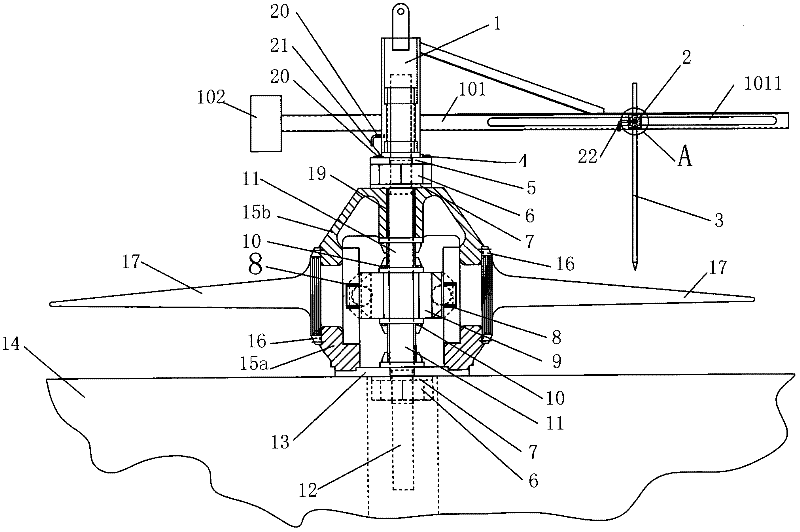

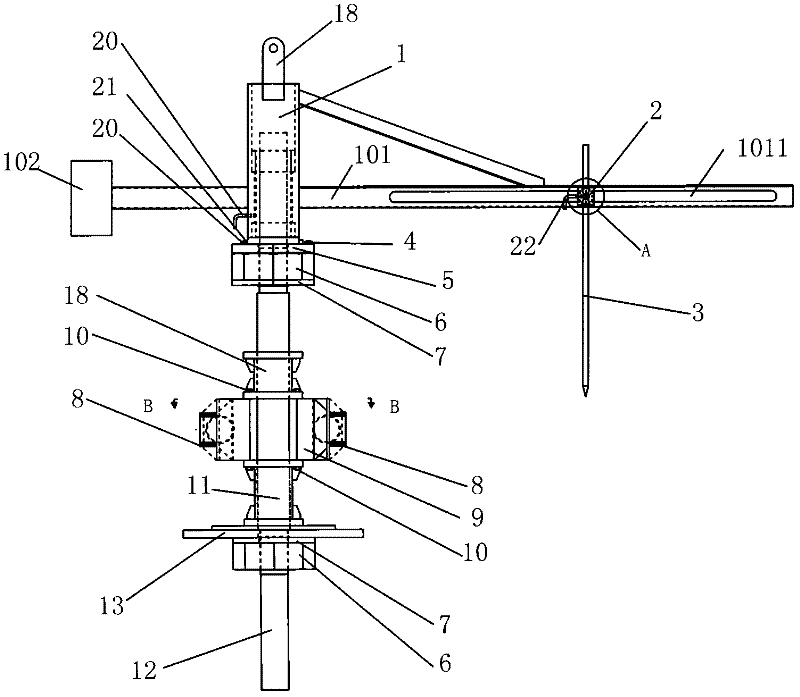

Method for repairing propeller blades of ship

The invention discloses a method for repairing propeller blades of a ship, and belongs to the field of maintenance and repair of main parts used on ships. For a worn blade, the worn part of the guideedge of the blade can be subjected to surfacing through gas welding, and the texture of a used welding wire material is required to be the same as the texture of the propeller, and then the surface ofthe surfacing position is polished. For a defective blade caused by being collided with a hard object, a slightly larger piece of casting material having the same texture as that of the propeller canbe cast in advance according to the shape of the defective part, then match working is conducted through a manual method, a suitable weld chamfer needs to be machined at the weld joint, and then manually welded by using oxygen-acetylene; and finally grinding and trimming are conducted so that the use efficiency of the propeller can be recovered. At the same time, the repairing method is simple and practical, and the repaired blade bodies have the same service life as original blade bodies.

Owner:南通如港船舶配套机械有限公司

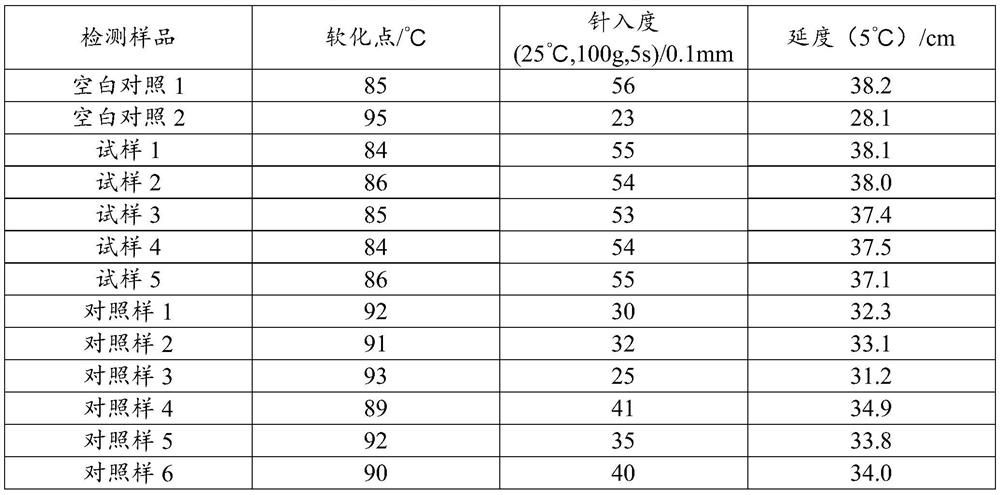

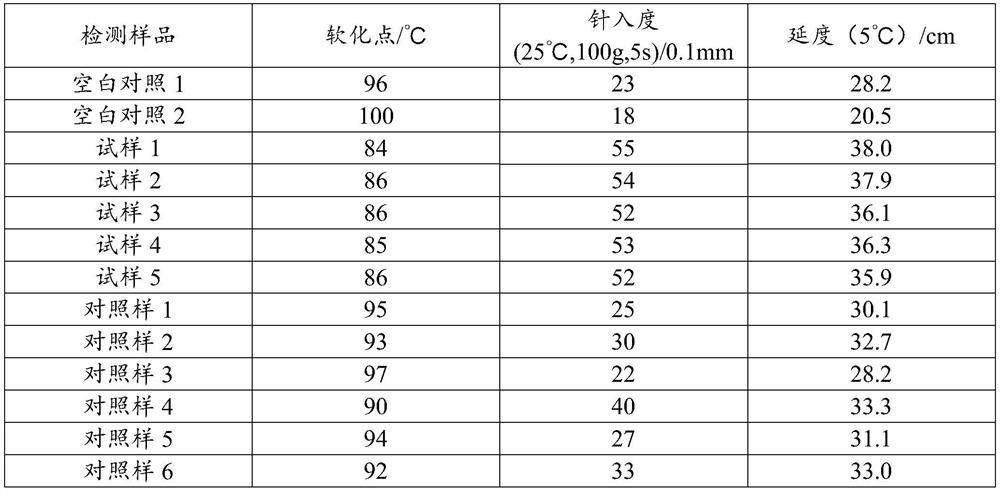

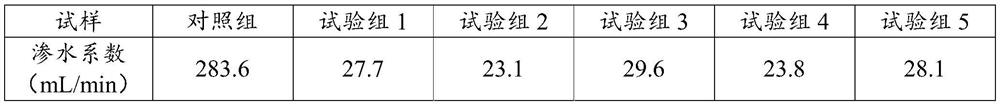

Asphalt pavement regeneration preventive maintenance material as well as preparation method and application thereof

ActiveCN112778907AImprove maintenance effectPrevent agingPaving detailsEpoxy resin coatingsTriethoxysilaneFirming agent

The invention belongs to the technical field of road building materials and engineering, and particularly relates to an asphalt pavement regeneration preventive maintenance material as well as a preparation method and application thereof. The asphalt pavement regeneration preventive maintenance material comprises an asphalt regeneration agent, an asphalt mortar emulsion and a waterproof curing liquid. The asphalt mortar emulsion comprises 38-45 wt% of asphalt, 5-10 wt% of epoxy mortar, 25-31 wt% of an aromatic hydrocarbon solution, 0.5-1 wt% of basalt ore powder, 10-15 wt% of an activator, 2-5 wt% of an emulsifier and 1-2 wt% of a stabilizer. The waterproof curing liquid is prepared from 35-40 wt% of quartz sand, 10-17 wt% of tridecafluorooctyltriethoxysilane, 30-35 wt% of epoxy resin, 8-15 wt% of asphalt and 5-10 wt% of a curing agent. The asphalt regeneration agent, the asphalt mortar emulsion and the waterproof curing liquid are sequentially sprayed on an asphalt pavement to form three protective layers on the asphalt pavement, regeneration of aged asphalt can be promoted, aging of the recycled asphalt can be delayed, and the maintenance effect of the asphalt pavement can be comprehensively improved.

Owner:河南省公路工程试验检测中心有限公司 +1

Hardware driven display restore mechanism

ActiveUS9001016B2Reliably restoredRestoring settingStatic indicating devicesDigital output to display deviceComputer hardwareDisplay device

Owner:NVIDIA CORP

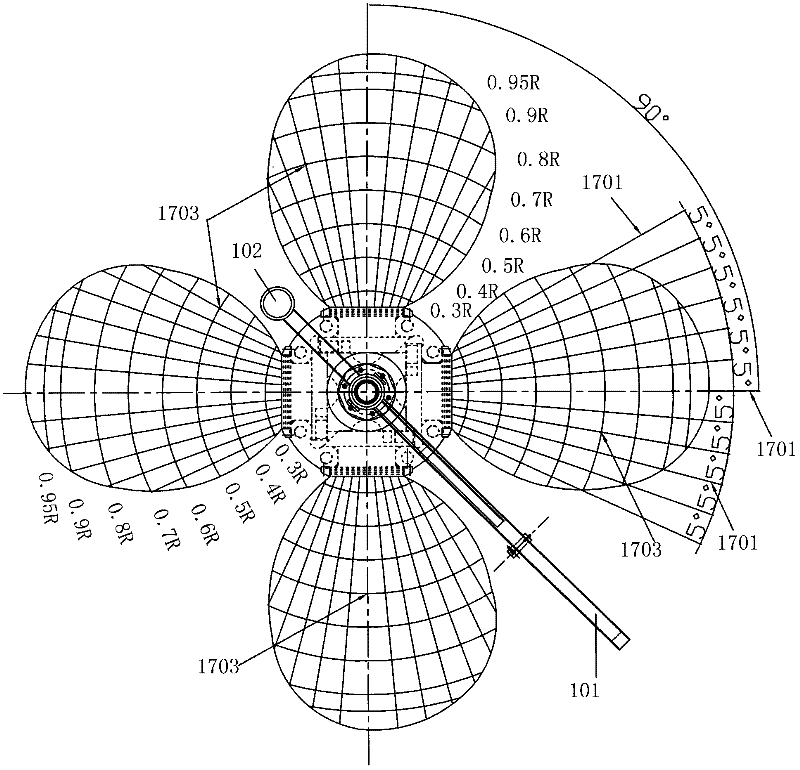

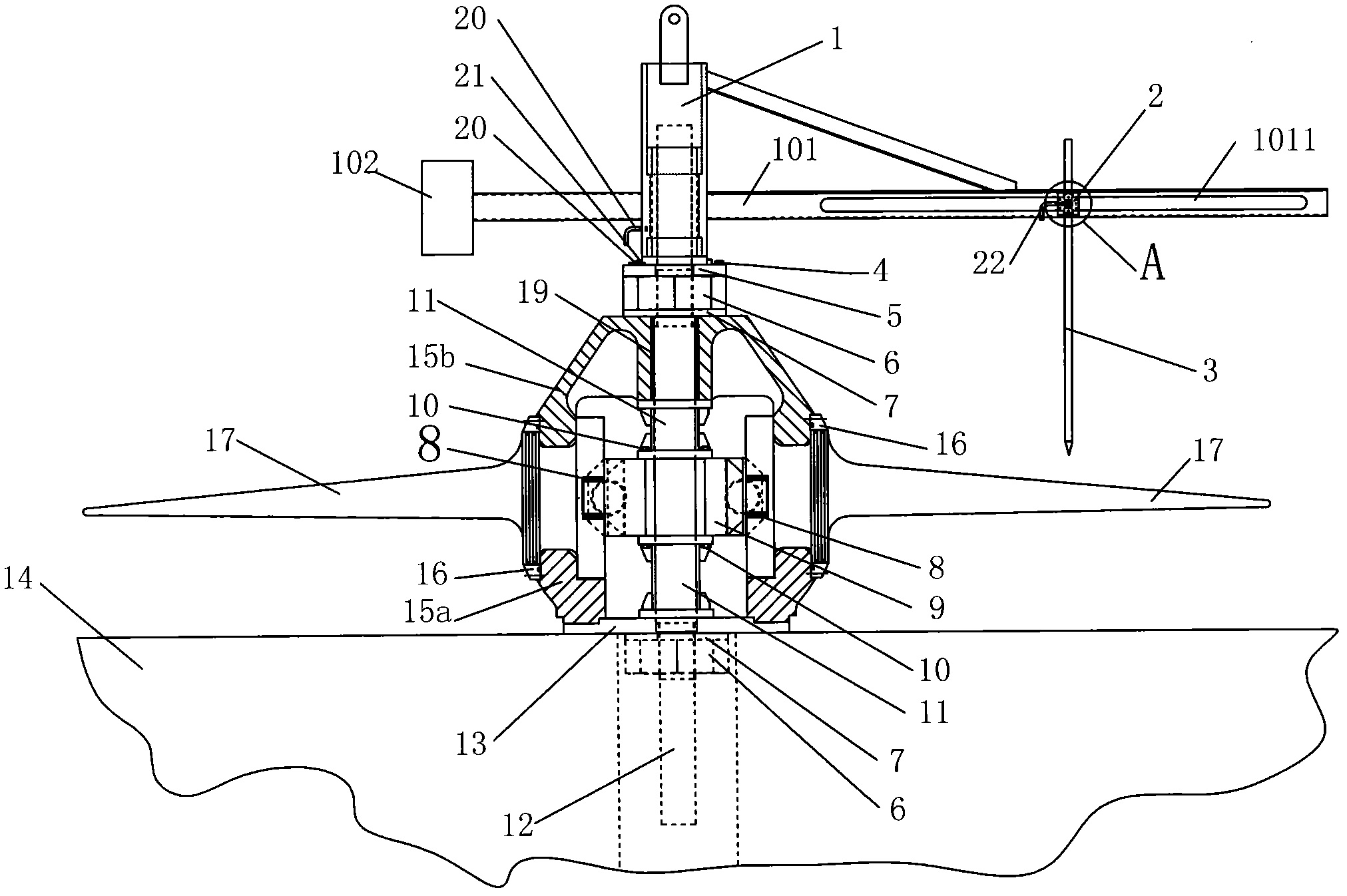

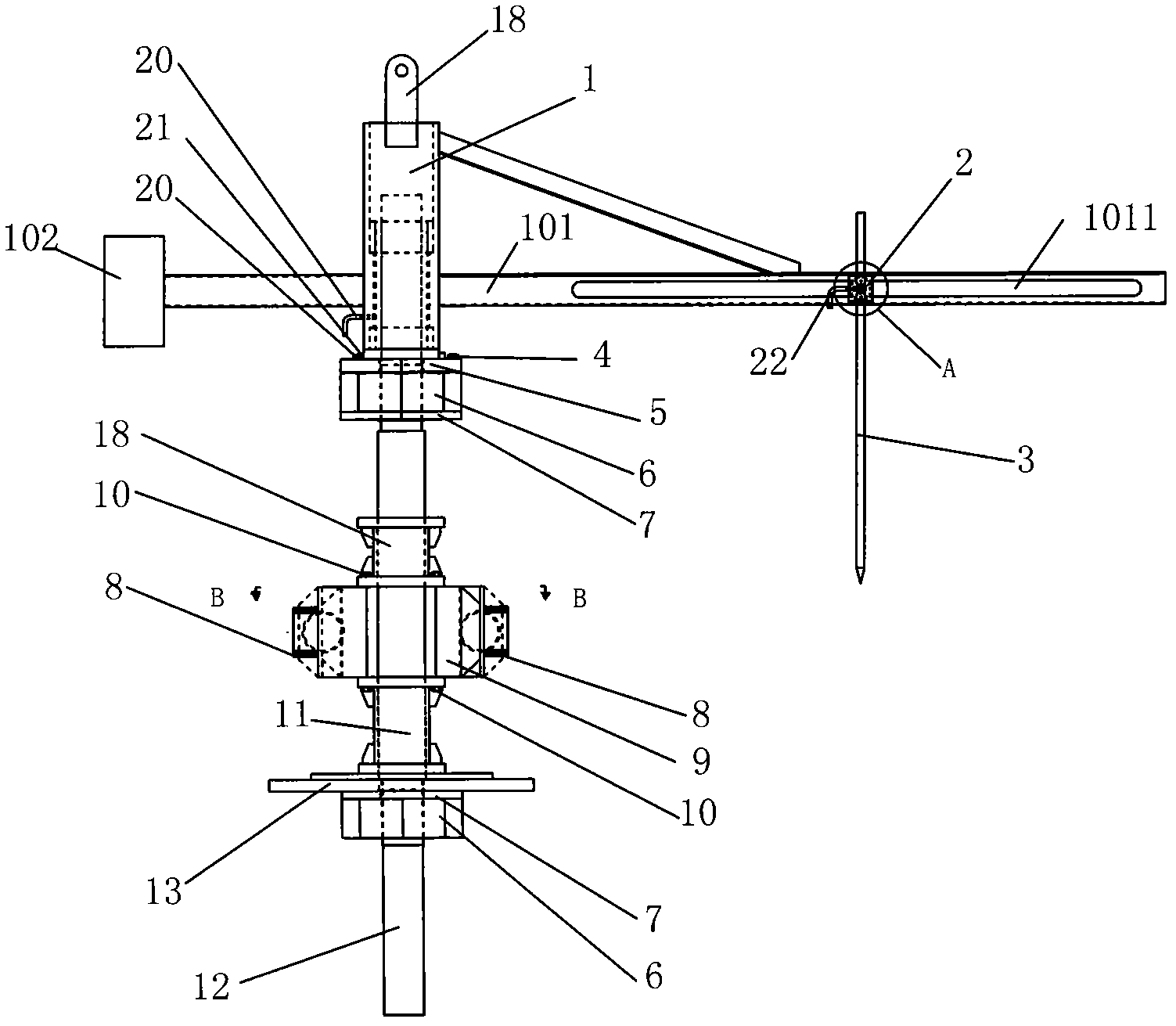

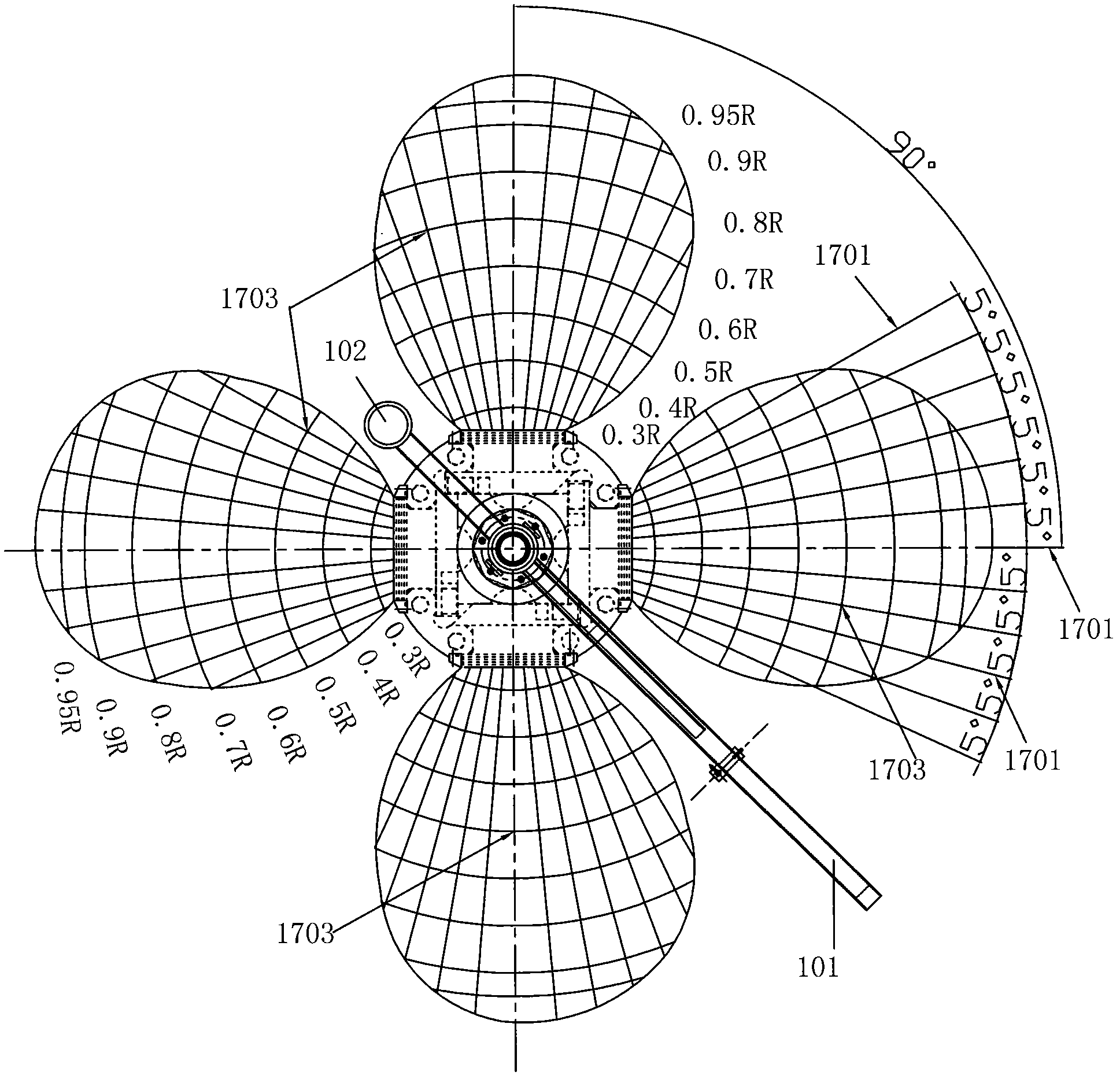

Device and method for repairing marine adjustable pitch oar

The invention discloses a device and a method for repairing a marine adjustable pitch oar. The device comprises an oar blade pitch measuring device and an oar blade locking device, wherein the oar blade pitch measuring device comprises a hollow fixed shaft and a measuring arm frame which is vertically and fixedly arranged with the hollow fixed shaft; the oar blade locking device comprises a rotating shaft; and the hollow fixed shaft is fixedly connected with the rotating shaft, so that the measuring arm frame can make circumferential rotation around the hollow fixed shaft. The invention also discloses a method for repairing the marine adjustable pitch oar on the basis of the repair device. By the repair device and the repair method, after four oar blades, the locking device of the device for repairing the adjustable pitch oar and the like are assembled integrally, the four oar blades are subjected to the measurement of screw pitches on a circular arc in the same circumferential direction, so the measuring accuracy is high. In addition, the oar blade locking device in the repair device can also be used for the static balancing tests of the adjustable pitch oar to eliminate imbalanced weight error formed after the oar blades are welded and repaired.

Owner:SHANGHAI SHIPYARD

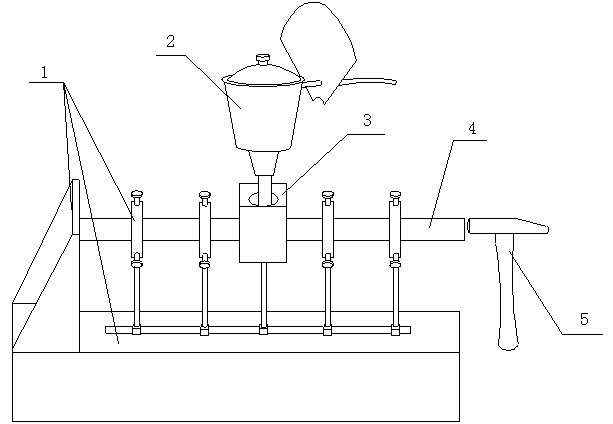

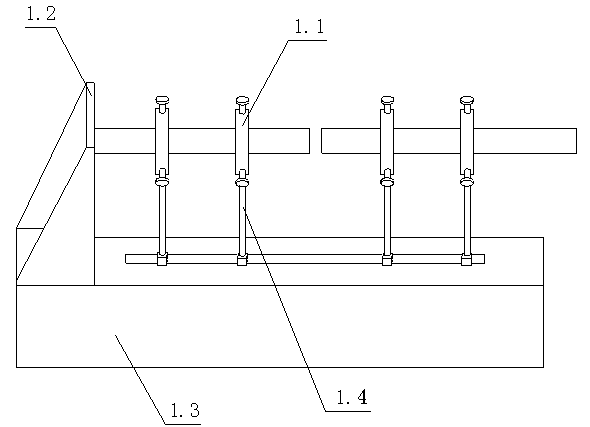

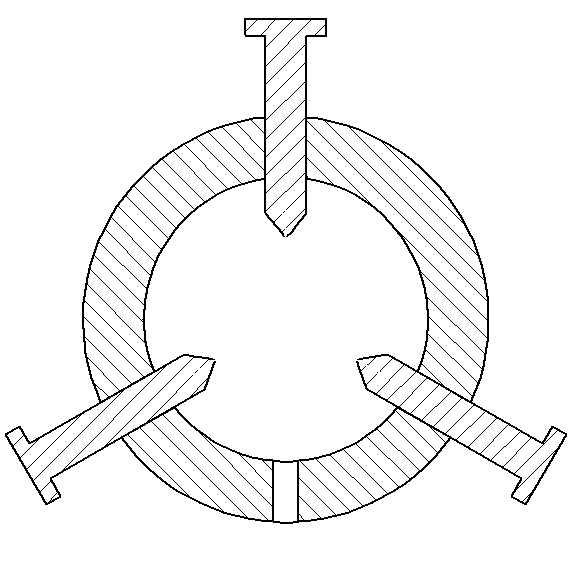

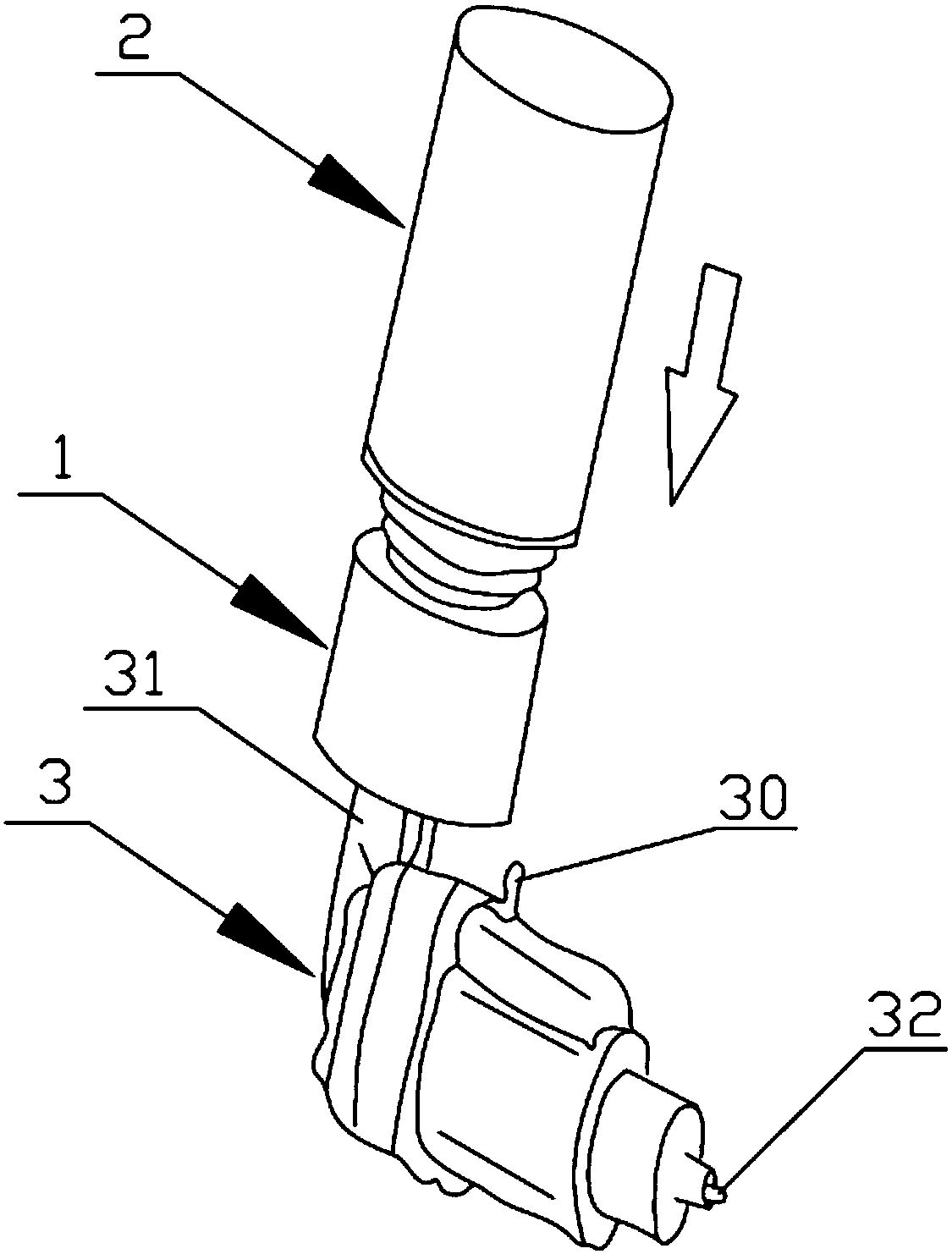

Method for welding shaft of portable exothermic welding shaft welder

InactiveCN102699522AFast repairImprove combat effectivenessAlumino-thermic welding apparatusExothermic weldingBrick

The invention relates to a method for welding a shaft of a portable exothermic welding shaft welder. The problem of fast welding and repairing of broken shafts of military equipments and civilian vehicles is solved. The shaft welder comprises a broken shaft fixer (1), a die (3) and a self-propagating tinker (2), wherein the broken shaft fixer (1) comprises a base (1.3), a supporter (1.4), a baffle plate (1.2) and a ring fixer (1.1); the self-propagating tinker (2) comprises a steel pot (2.5); a bottom refractory brick (2.4) and an upper refractory brick (2.2) are arranged on lining of the steel pot (2.5); a thermit welding flux and an igniter (2.6) are arranged inside the upper refractory brick (2.2); and the thermit welding flux and the igniter (2.6) are pressed together as a whole. The method comprises the following processing steps: treating the surface; filling a die, loading the thermit welding flux and the igniter, casting and pressurizing, stripping the die and polishing. According to the invention, shaft parts of battle-scarred tanks are fast welded and repaired by utilizing an exothermic welding technology, particularly, proper pressure is exerted in the welding process, so that metallographic structure of a welding area is obviously improved and the welding strength is improved.

Owner:江阴东大新材料研究院

Belted layer transplantation technology for all-steel radial tire for heavy vehicle

The invention discloses a belted layer transplantation technology for an all-steel radial tire for a heavy vehicle. The belted layer transplantation technology comprises the following steps: removing steel wires of a damaged protection layer belted layer; lightly grinding inter-layer rubber on a working layer to be fat, coating with mucilage uniformly and airing; after a layer of inter-layer rubber is wound, winding a steel wire of 55-65 degrees and 5*0.35 HT, and provided with proper width and rubber on a tire body precisely, winding steel wires of 0 degree and provided with proper width and the rubber on tire shoulders on the two sides for two circles; sealing with belted layer sealing rubber, paving in a tread with the same width for pad rubber, and winding unvulcanized tread rubber; feeding in a radial parting mold for vulcanizing for 3.5 hours, and taking out of the mold. A novel tire retreading technology is provided by the invention, so that the use value and usability of scrap tires, which cannot retreaded by the conventional retreading technology are recovered again, retreading capacity is recovered, and the phenomenon of shortage of tire bodies is relieved and the difficulties of tire retreading enterprise are solved.

Owner:尹小萍

Device and method for repairing marine adjustable pitch oar

Owner:SHANGHAI SHIPYARD

Output restoration with input selection

ActiveUS9110624B2Reliably restoredRestoring settingDigital computer detailsCathode-ray tube indicatorsGraphicsInput selection

A method for restoring visual output to a display device. The method includes detecting a display device connection change on an output connector and changing output settings to a compatible output mode on the output connector. The method further includes cloning graphics output to the output connector. The graphics output is modified for display on the output connector. The display device is signaled to change the input source to correspond to the output connector. Subsequently, a control panel application is executed to present an on-display control for changing the output mode of the first output connector.

Owner:NVIDIA CORP

A kind of regeneration device and regeneration method of lead storage battery

InactiveCN104332671BRestore usabilityDischarge fullyWaste accumulators reclaimingBattery recyclingElectrical batteryProcess engineering

Owner:NANYANG NORMAL UNIV

The method of cleaning the sticky slag at the bottom of the ladle

The invention discloses a method for cleaning sticky slag at the bottom of a ladle. It includes converter smelting billet rebar, the end point temperature is controlled at ≥ 1630°C, and the end point carbon content is controlled at 0.06% to 0.15%; the steel ladle to be processed is transported to the converter tapping position, and fluorite and silicon carbide are added to the bottom of the ladle. Tapping; during the tapping process of the converter, carbon powder and silicon-manganese alloy are added to control the composition of molten steel: C≥0.2%; Si: 0.2%-0.6%; Mn: 1.2%-1.5%; Alt≤0.0030%; After steel, the ladle is transported to the argon blowing station for argon blowing, and the composition of molten steel top slag is controlled: CaO: 35% ~ 40%, SiO 2 :30%~35%,Al 2 o 3 ≤10%, MgO≤10%; pour out after the argon station leaves the station, the pouring process temperature is ≥1520°C, pour out the pouring slag after casting. The invention aims at the problem that after the slab aluminum-killed molten steel is cast, the bottom of the ladle is more precipitated due to the deposition of high-melting point substances, and provides a method for cleaning the sticky slag at the bottom of the ladle, and the cleaned ladle restores its serviceability, and the method The effect is remarkable, the operation is convenient, and the cost is not increased.

Owner:LIUZHOU IRON & STEEL +1

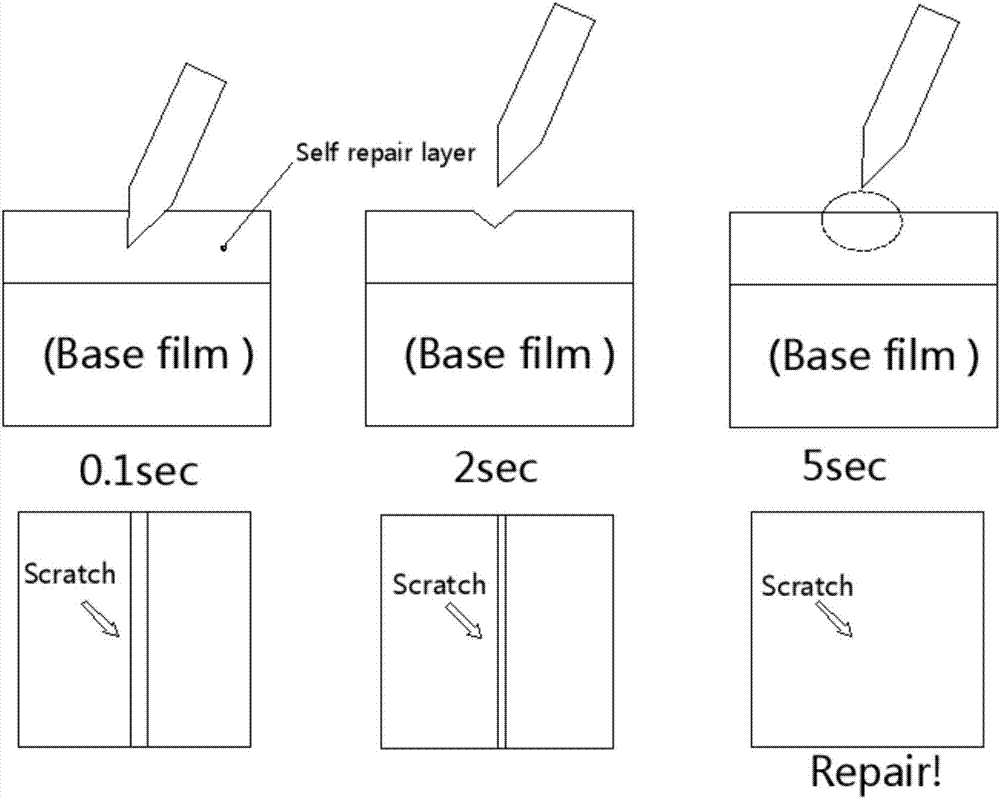

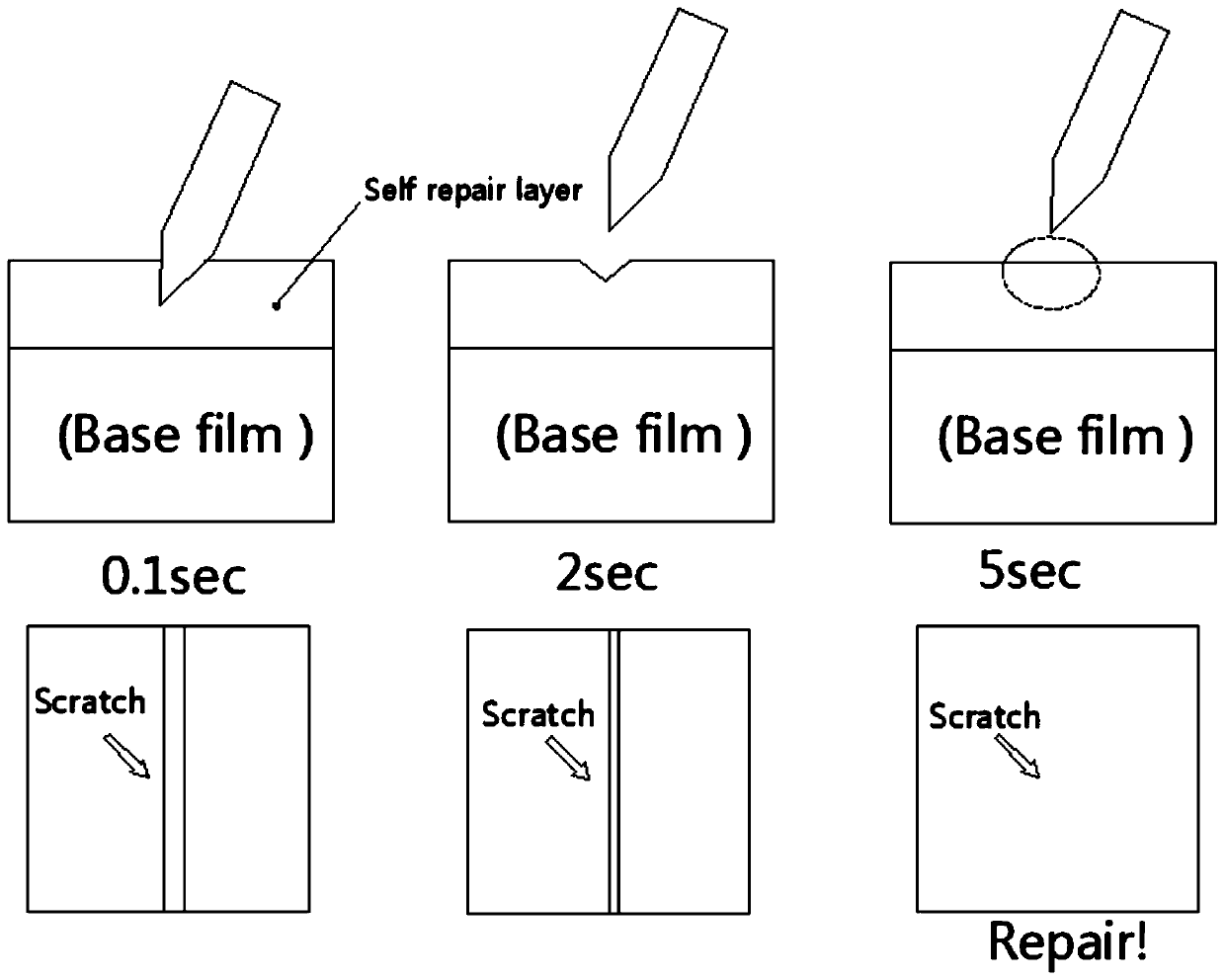

Preparation method and application of self-repaired membrane enhancing liquid

The invention discloses a preparation method and application of a self-repaired membrane enhancing liquid. The self-repaired membrane enhancing liquid comprises the following raw materials in percentage by weight: 55% of acrylate oligomers, 0.7% of leveling agents, 7% of n-butyl acetate, 30% of butanone, 0.5% of a defoaming agent, 5% of an initiator and 1.8% of a surfactant. The invention designs a self-repaired membrane enhancing liquid and a self-repaired membrane for rapidly repairing damage such as collision, scratching and scratching marks on the surface of a product, recovering the use feeling and the attractiveness of the product, prolonging the service life of the product and reducing resource waste, and great application values can be made.

Owner:京钻(厦门)科技有限公司

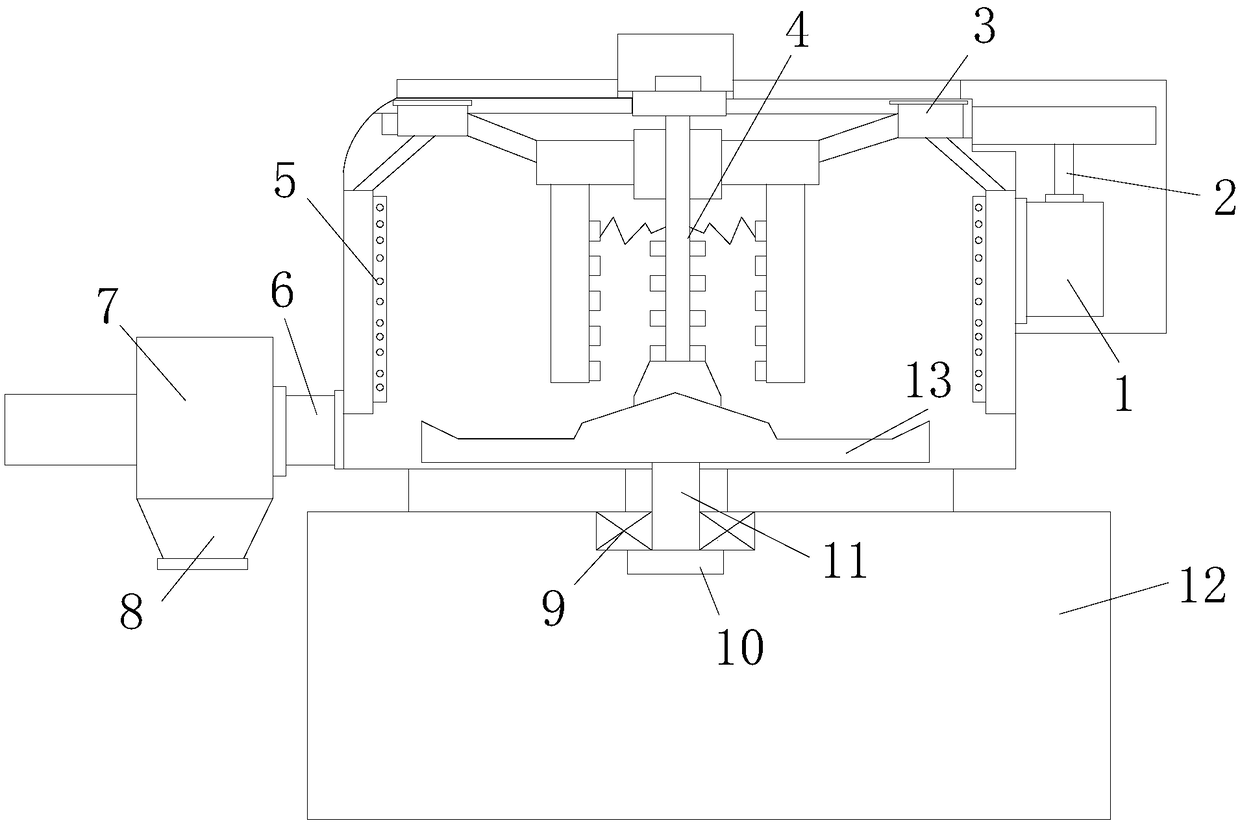

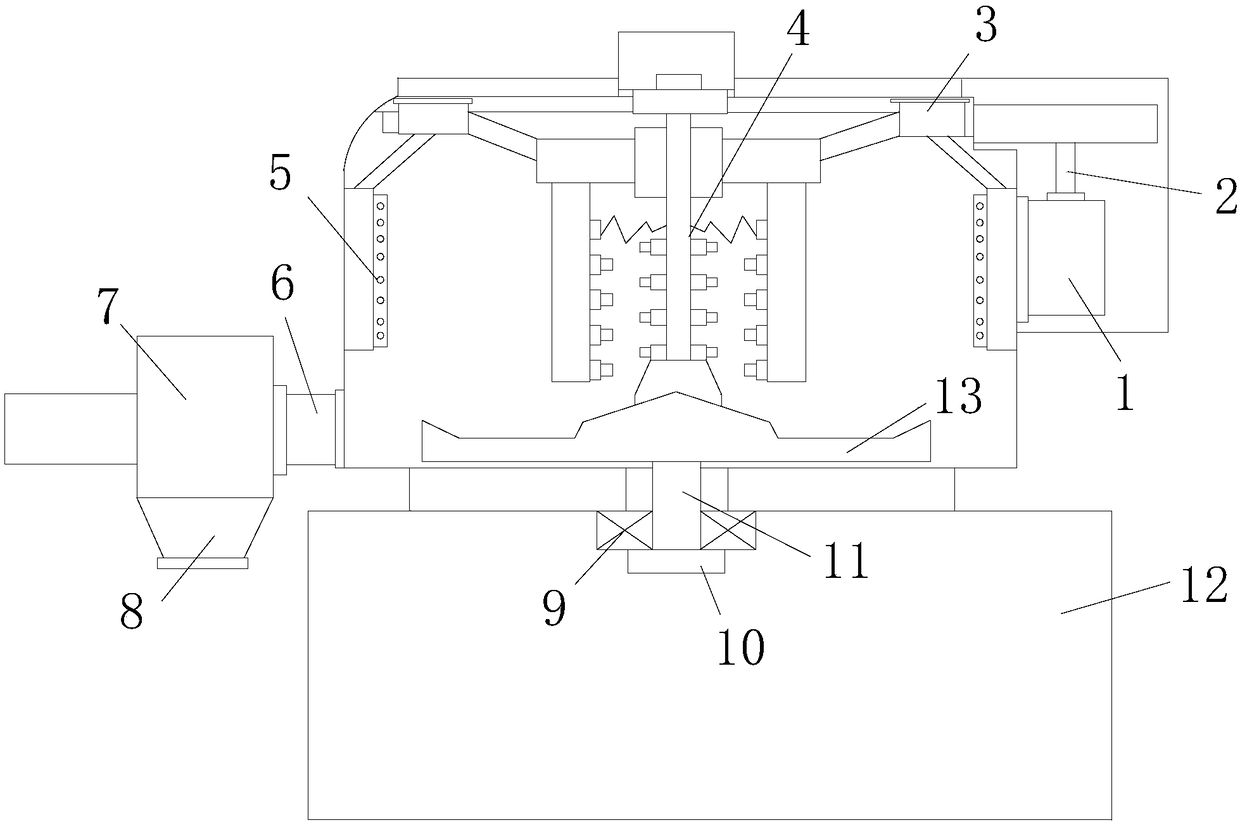

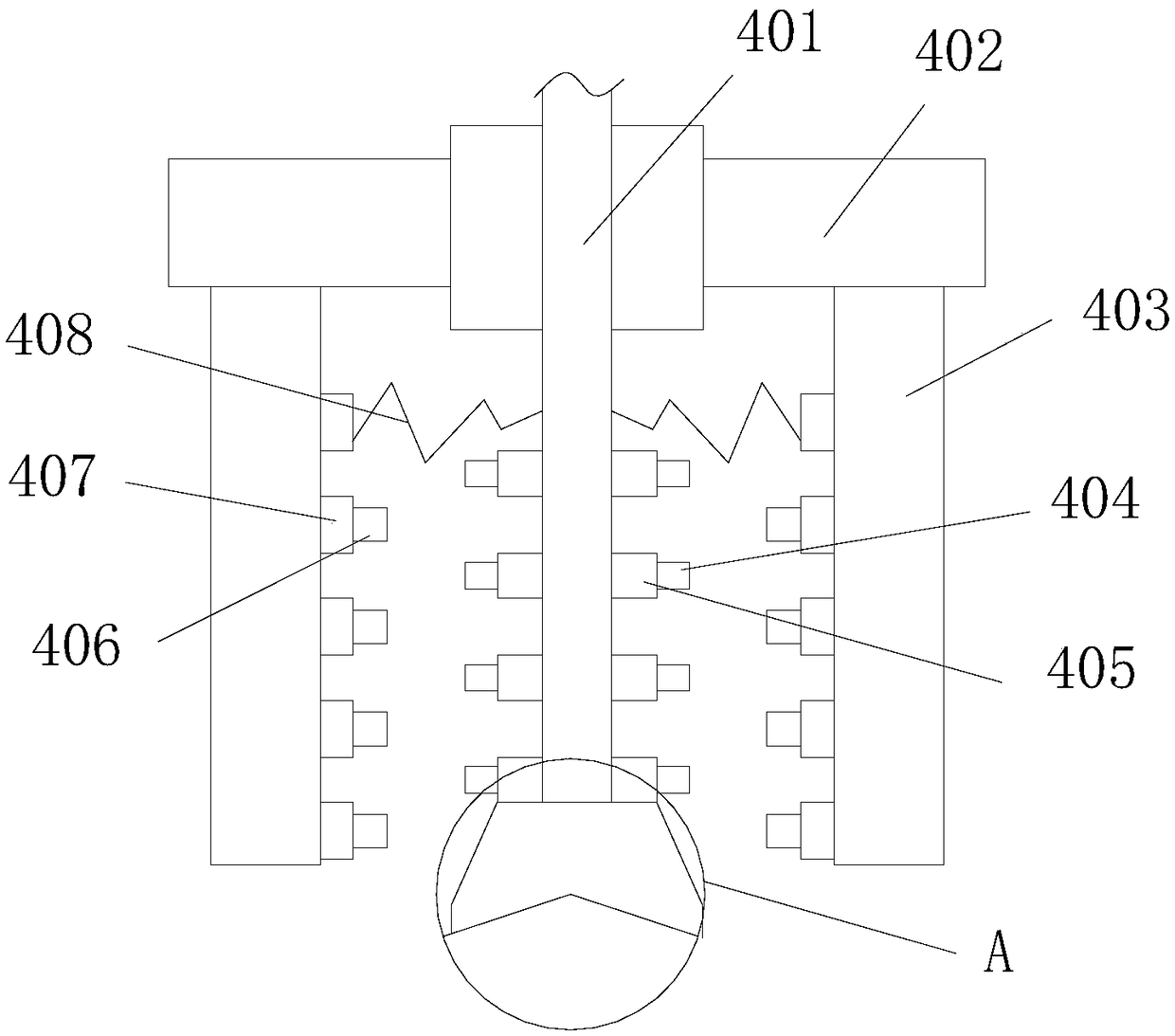

An electromagnetic crushing moisture-proof carbon powder regeneration device for electrophotographic imaging equipment

InactiveCN109001965AAvoid getting wet againImprove moisture resistanceElectrography/magnetographyDrive shaftElectric machinery

The invention discloses an electromagnetic crushing moisture-proof carbon powder regeneration device for electrophotographic imaging equipment, and the structure includes: a starting motor, a drive shaft, an actuator, a forward and backward magnetic crushing device, a moisture-proof guiding-out device, a carbon collection tank, a discharge hopper, a supporting block, a supporting rotating rod, a support body and an outer projection seat. By controlling the forward rotation of the starting motor, the rotation of the forward and backward magnetic crushing device is realized, the carbon powder isimpacted and crushed for the first time under the interaction of an inner magnetic device and an outer magnetic device, and is crushed for the second time under the action of an extrusion spring, sothat that carbon powder is fully crushed, then the starting motor is controlled to rotate reversely, the outer projection seat can be driven to rotate through the forward and backward magnetic crushing device, The carbon powder is pushed onto the moisture-proof guiding-out device, and the carbon powder and a material block are fully rubbed to fill the gap between the carbon powder, so that moisture in the air is prevented from entering the carbon powder, and the carbon powder can be dried at the same time to restore the original use effect, thereby avoiding unclear photographic imaging printing and remaining on the equipment and wasting carbon powder.

Owner:缪宝梅

A kind of preparation method and application of self-healing membrane strengthening liquid

The invention discloses a preparation method and application of a self-repaired membrane enhancing liquid. The self-repaired membrane enhancing liquid comprises the following raw materials in percentage by weight: 55% of acrylate oligomers, 0.7% of leveling agents, 7% of n-butyl acetate, 30% of butanone, 0.5% of a defoaming agent, 5% of an initiator and 1.8% of a surfactant. The invention designs a self-repaired membrane enhancing liquid and a self-repaired membrane for rapidly repairing damage such as collision, scratching and scratching marks on the surface of a product, recovering the use feeling and the attractiveness of the product, prolonging the service life of the product and reducing resource waste, and great application values can be made.

Owner:京钻(厦门)科技有限公司

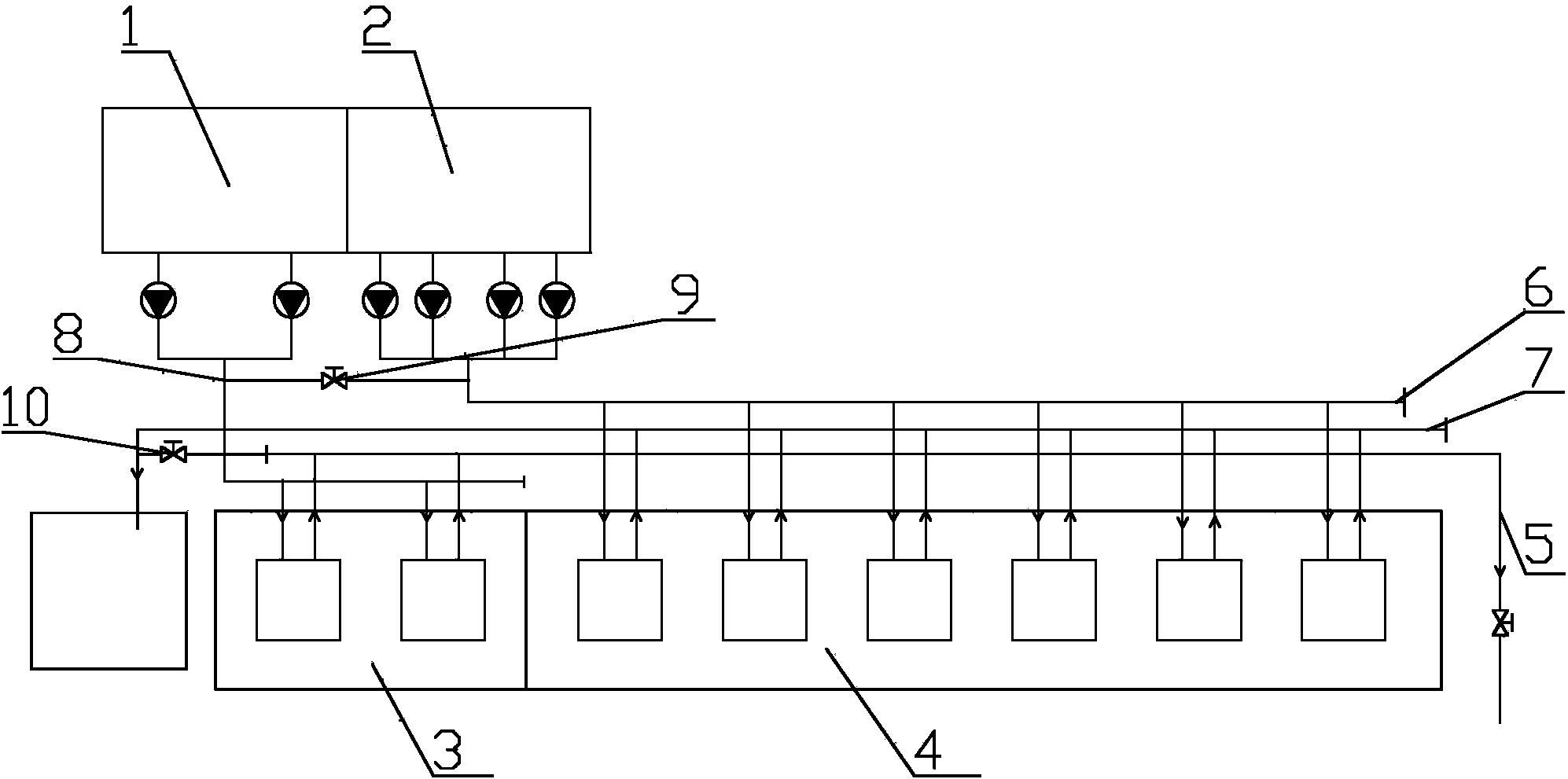

Device for prolonging service life of oil-containing filter cloth of continuous casting plate frame

The invention relates to a device for prolonging the service life of oil-containing filter cloth of a continuous casting plate frame. The device comprises a continuous casting slurry regulating reservoir, a steelmaking slurry regulating reservoir, a continuous casting plate frame and a steelmaking plate frame, wherein the continuous casting slurry regulating reservoir is connected with the continuous casting plate frame through a continuous casting plate frame feeding main pipe and a continuous casting plate frame filtrate water return pipe; the steelmaking slurry regulating reservoir is connected with the steelmaking plate frame through a steelmaking plate frame feeding main pipe and a steelmaking plate frame filtrate water return main pipe; the continuous casting plate frame feeding main pipe is communicated with the steelmaking plate frame feeding main pipe through a pipeline with a feeding branch pipe valve; and the continuous casting filtrate water return pipe is communicated with the steelmaking filtrate water return pipe through the pipeline with a water return branch pipe valve. Revolving furnace dust removing sludge is treated by using the continuous casting plate frame, has the characteristics of high pH and high basicity, and can be used for cleaning oil sludge attached to the continuous casting plate frame, so that the service performance of the filtering cloth is recovered, and the service life of the filter cloth is prolonged.

Owner:LIANFENG STEEL (ZHANGJIAGANG) CO LTD

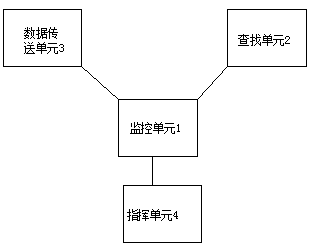

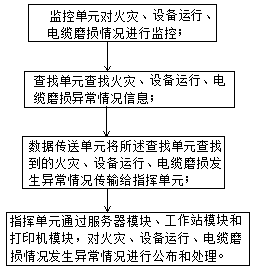

Power safety monitoring system

InactiveCN108303959AAvoid escalationTimely processingTotal factory controlProgramme total factory controlElectricityCommand system

The invention, which belongs to the technical field of monitoring systems, provides a power safety monitoring system comprising a monitoring unit, a searching unit, a data transmitting unit and a command unit,. The monitoring unit, the searching unit, the data transmitting unit and the command unit are electrically connected to each other. The monitoring system is able to monitor fire occurrence,equipment operation and cable wearing in real time. Therefore, emergency measures can be taken timely in case of abnormity, so that accident expanding is avoided. When a fault or abnormity is monitored, the command system can be dispatched quickly and thus the fault can be processed timely, so that normal power supply and usage are recovered.

Owner:HEFEI TONGYOU ELECTRONICS TECH CO LTD

Novel windshield wiper elastic piece and manufacturing method thereof

InactiveCN110654041AWaterproofResistant to salt sprayDomestic articlesMaterials scienceMacromolecule

The invention provides a manufacturing method of a novel windshield wiper elastic piece. The manufacturing method of the novel windshield wiper elastic piece comprises the steps that a continuous fiber assembly serves as a reinforcing body, a thermoplastic high-molecular polymer serves as a basic body, the continuous fiber assembly passes through a mold with a mold cavity through a pultrusion technology, a continuous elastic piece is manufactured under the traction action of a traction device and cut off according to the fixed length required by the design, then the elastic piece is placed ina shape press mold to be subjected to thermal shaping for the second time, and therefore the windshield wiper elastic piece with the arch radian in the length direction is obtained. The manufacturingmethod is simple in technology and good in repeatability, and the performance of the windshield wiper elastic piece is better that that of a stainless steel windshield wiper elastic piece.

Owner:GUANGDONG YATAI NEW MATERIAL TECH CO LTD

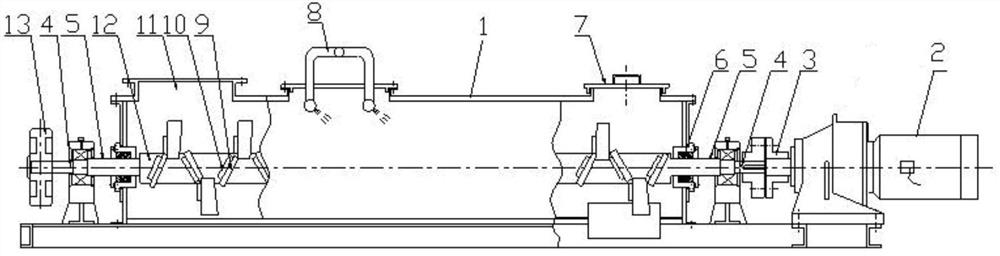

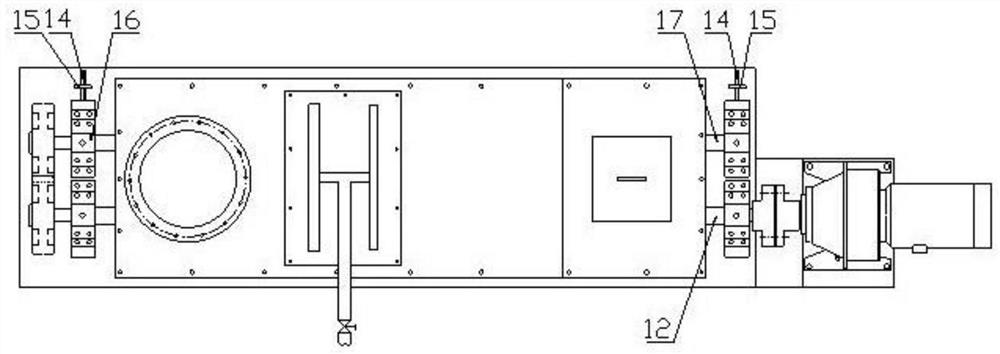

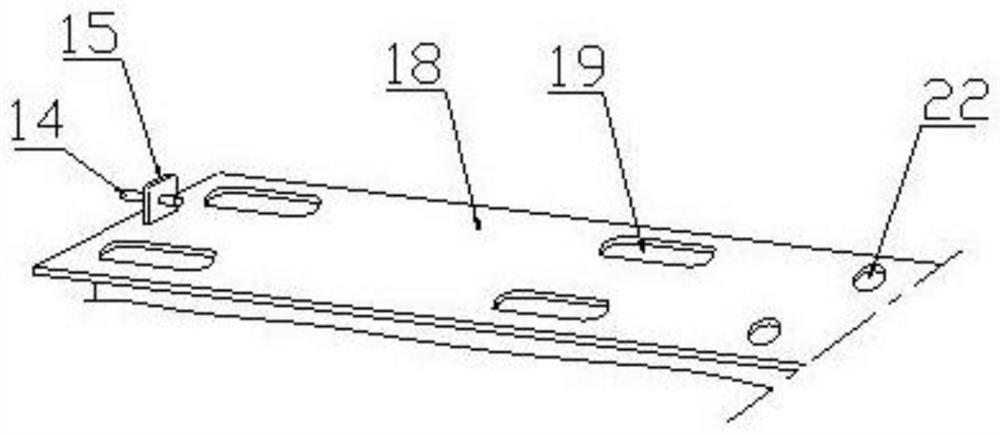

Online repairing structure of double-shaft humidifying stirrer of dust remover

PendingCN113262709AEasy to operateRestore usabilityRotary stirring mixersTransportation and packagingSteel platesTool bit

The utility model discloses an online repairing structure of a double-shaft humidifying stirrer of a dust remover, belongs to the technical field of dust remover stirrer equipment, and is used for repairing the double-shaft humidifying stirrer. According to the technical scheme, an adjusting top plate is vertically welded to the upper surface of a box body bottom plate on the outer side of the rear end of a driven shaft, a lead screw hole is formed in the adjusting top plate, and an adjusting lead screw is screwed in the lead screw hole; when the easily-broken part of the driving shaft is broken, a dummy shaft for repairing is arranged, one end of the driving shaft is matched with the shaft device and the bearing, the end face of the other end is of a sleeve structure, and the maintenance end of the driving shaft is embedded in the end face sleeve of the dummy shaft and fixedly connected; after the blades are abraded, maintenance blades are additionally arranged and are arc-shaped manganese steel plates, the lower ends of the maintenance blades are welded to the upper ends of the abraded blades, and the tool bits are installed on the maintenance blades through fixing bolts. The online repairing structure is simple in structure and convenient to use, the problems of blade clamping, driving shaft breaking and blade abrasion caused by gear abrasion or gear tooth abutting and offside can be rapidly solved, the maintenance time is greatly saved, and the maintenance cost is reduced.

Owner:HEBEI IRON AND STEEL

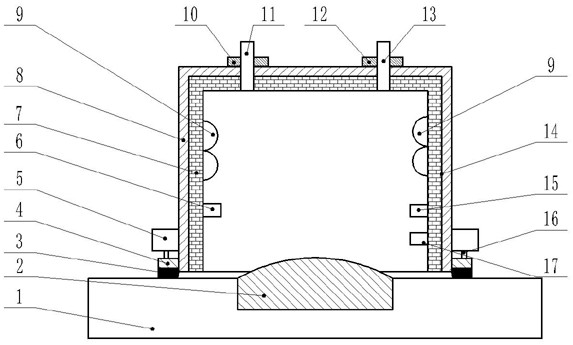

A device and method for performing heat treatment under water

ActiveCN111020120BReduce hardenabilityRestore usabilityFurnace typesHeat treatment furnacesOxygen monitoringMechanical engineering

Owner:SOUTHEAST UNIV

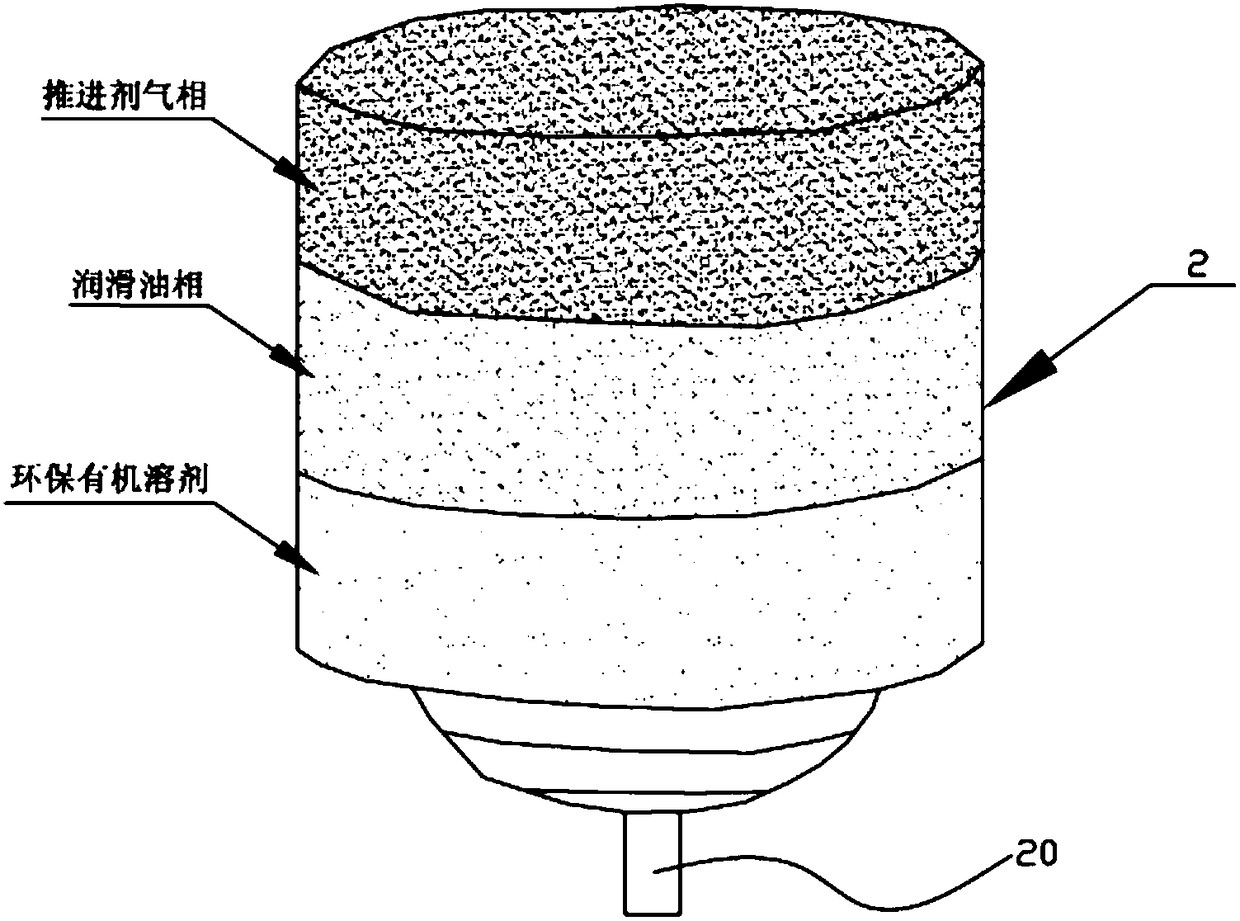

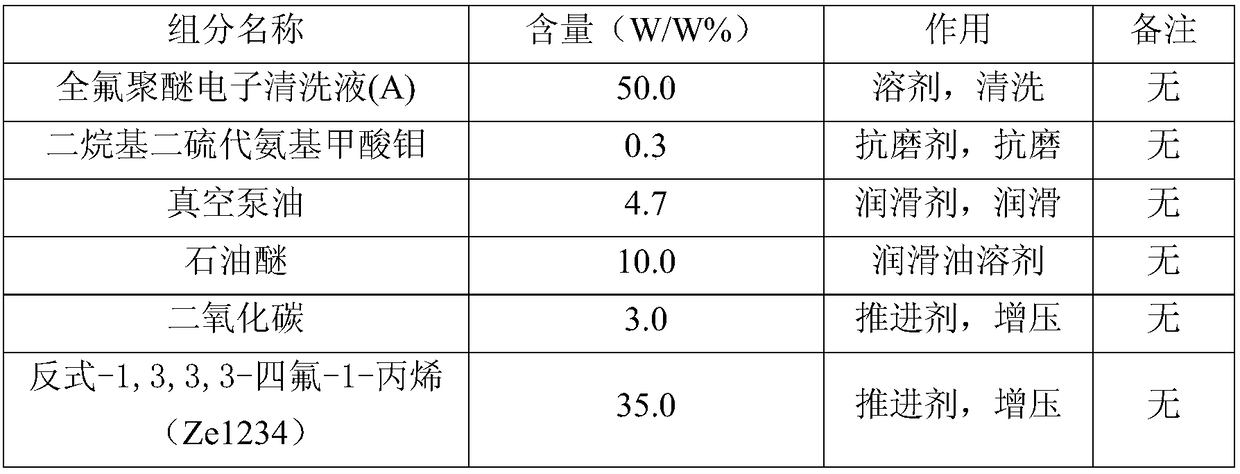

cleaning aerosol

ActiveCN106318702BRestore usabilityReduce use costOrganic non-surface-active detergent compositionsAerosol detergent compositionsOrganic solventPneumatic tool

The invention provides a cleaning aerosol which is used for cleaning multiple pneumatic tools. The cleaning aerosol mainly comprises an environment-friendly organic solvent, lubricating oil, a lubricating oil solvent and a propellant; based on the physicochemical properties of the components, the aerosol is naturally layered in an aerosol tank, wherein the cleaning component stays below, the lubricating component is in the middle, and the propellant stays above to prepare special aerosol. In cooperation with a special actuator, the cleaning aerosol can be propelled into a pneumatic tool without disassembling the pneumatic tool; and during no-load rotation of a pneumatic motor, the cleaning and lubricating of the pneumatic tool are finished once. Therefore, a cleaning effect can be realized without disassembling the pneumatic tool, the operation is simple and quick, the functions of cleaning and lubricating without disassembly are realized, and the time and the labor are saved; and the usability of the pneumatic tool is quickly recovered.

Owner:广东好顺欧迪斯科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com