Patents

Literature

50results about How to "Same service life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alumina titanate ceramica lift tube preparation method

The invention relates to a preparation method of ceramic materials; the raw materials used in the method comprises alumina powder, titanium oxide powder, synthetic material of aluminium titanate and stabilizing agents, wherein, the stabilizing agents comprise magnesium oxide, silica dioxide, ferric oxide, chromium dioxide and zirconium oxide. The conditions of the preparation process are as follows: firstly, the raw material and water carry out ball milling and pulping by a wet method; secondly, the slurry is granulated and dried into powder with the water content to be less than 2 percent; thirdly, isostatic pressing molding is carried out; fourthly, the powder is sintered into a lift tube of aluminium titanate ceramics under the conditions that the sintering temperature is 1,480 to 1,550 DEG C, the sintering time is 20 to 30 hours and the sintering atmosphere is oxidizing atmosphere; wherein, alumina powder, titanium oxide powder, stabilizing agents and water carry out ball milling and pulping by the wet method and granulation to prepare particle size, then the synthetic material of aluminium titanate is prepared by sintering. The product prepared by the method is characterized by low price, non-infiltration of alumina melt, no reaction, high intensity, strong thermal shock resistant capability, no slag during the using process, long service life, etc.

Owner:DONGYING XINKEXINTETAO

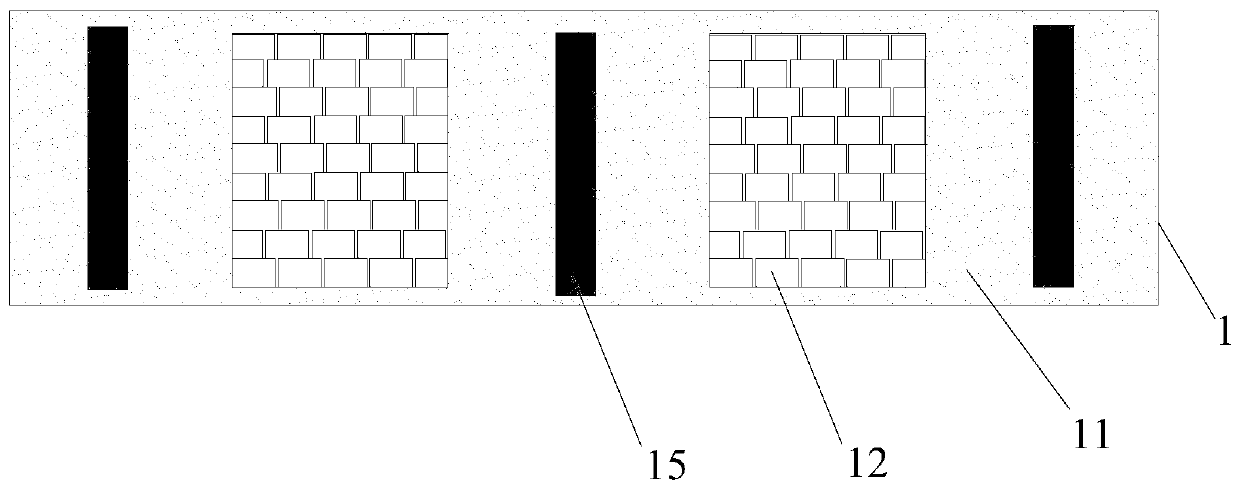

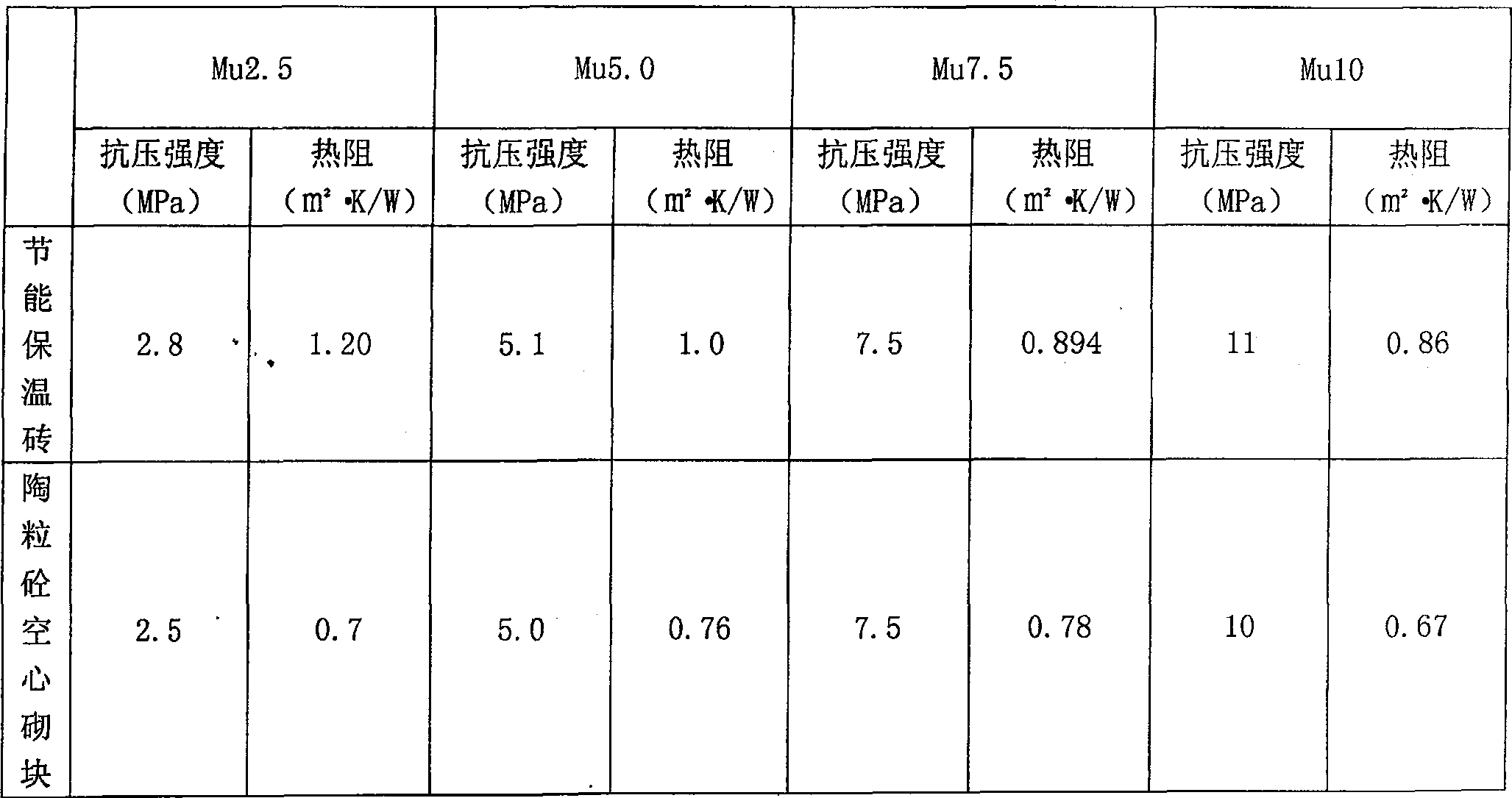

Energy-saving insulating brick

InactiveCN101172831AExcellent heat absorption and heat preservation effectImprove insulation effectSolid waste managementBrickPortland cement

The invention relates to an energy saving heat preserving brick which solves the technical problems that the prior construction wall has cockamamie energy saving and heat preserving measure constructions, long construction period and high cost. The invention comprises the steps as follows: mixing and stirring the raw materials, extruding for shaping and maintaining. The weight ratio of the raw materials is that: 230 to 320 parts of portland cement, 35 to 20 parts of swelling perlite, 430 to 610 parts of general sand, 70 to 15 parts of cinder, 6 to 3 parts of straw, 4 to 2 parts of plant ash, 1.6 to 2 parts of felted wool fibre, and 97 to 135 parts of water. The invention has good energy saving and heat preserving capacities and good compression resisting intensity.

Owner:江苏康顺鼎上节能保温科技股份有限公司

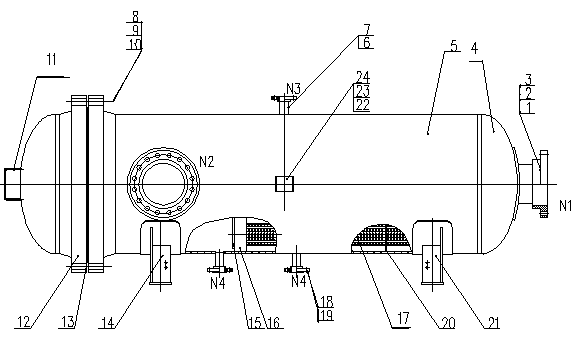

Production process of iron-removing filter

A production process of an iron-removing filter comprises the major machining tools and procedures of a sealing head, a barrel, a filtering element bushing, a flange C, a pore plate, a pipe flange, component assembly, product assembly and pressure test. A product produced with the process is suitable for matched equipment of a water treatment system. The product is simple in machining process, is low in cost, is the same as products of the same type in service life, but is one third lower than the price of the conventional product, and meets user demands. The product quality is consistent with the standards of GB150 Steel Pressure Vessel and Safety Monitoring Specification for Pressure Vessel, JB2932 Manufacturing Technical Conditions for Water Treatment Equipment and SDDZ037 Manufacturing Quality for Power Plant Water Treatment Equipment. The problems of long delivery period and high price for general production enterprises and users to bear due to the adoption of a composite plate as a major material in the conventional iron-removing filter are solved, and great contribution is made to the prevention of environmental pollution.

Owner:NAIR ENERGY EQUIP

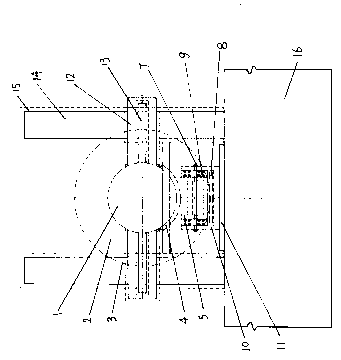

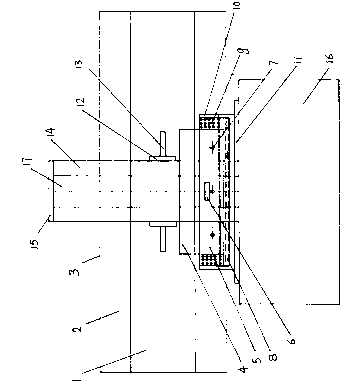

Expanding and extruding connection method for mechanical connection of plastic pipes

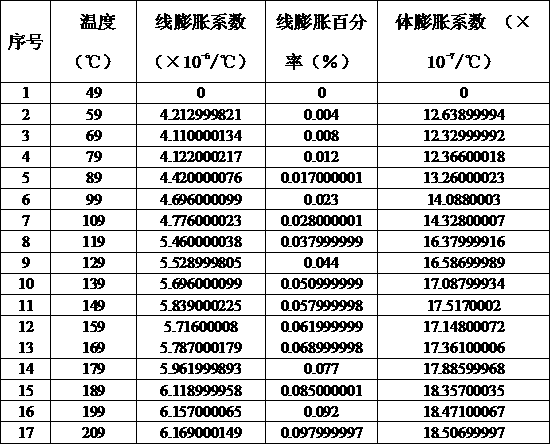

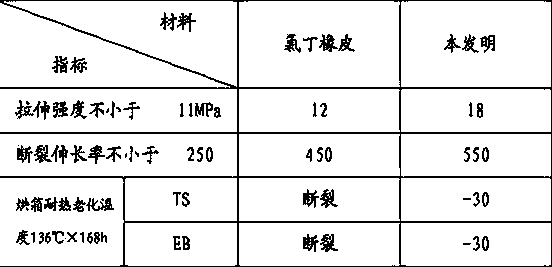

InactiveCN102032413ALifetime SynchronizationFirmly connectedJoints with sealing surfacesPipe connection arrangementsEngineeringTensile ductility

The invention relates to an expanding and extruding connection method for mechanical connection of plastic pipes, specifically comprising the following steps of: (1) expanding the inner diameter of each plastic pipe connection part by 10-25 percent by using a pipe expander and utilizing the stretching ductility of the plastic pipes; and (2) connecting the plastic pipes by adopting a plastic expanding and extruding connector comprising a plastic connector and a plastic nut, sleeving the plastic nut on the plastic pipe, inserting an insertion part of the plastic connector to a connection part of the plastic pipes, fastening the plastic nut on an outer thread of the plastic connector, enabling ribbed edges to clamp the inner wall of the connection part of the plastic pipes, and storing an extruded deformation part of the plastic pipeline into a concave ring. The expanding and extruding connection method of the invention is convenient, concise and reliable to connect various plastic pipelines.

Owner:上海三山信邦科技有限公司

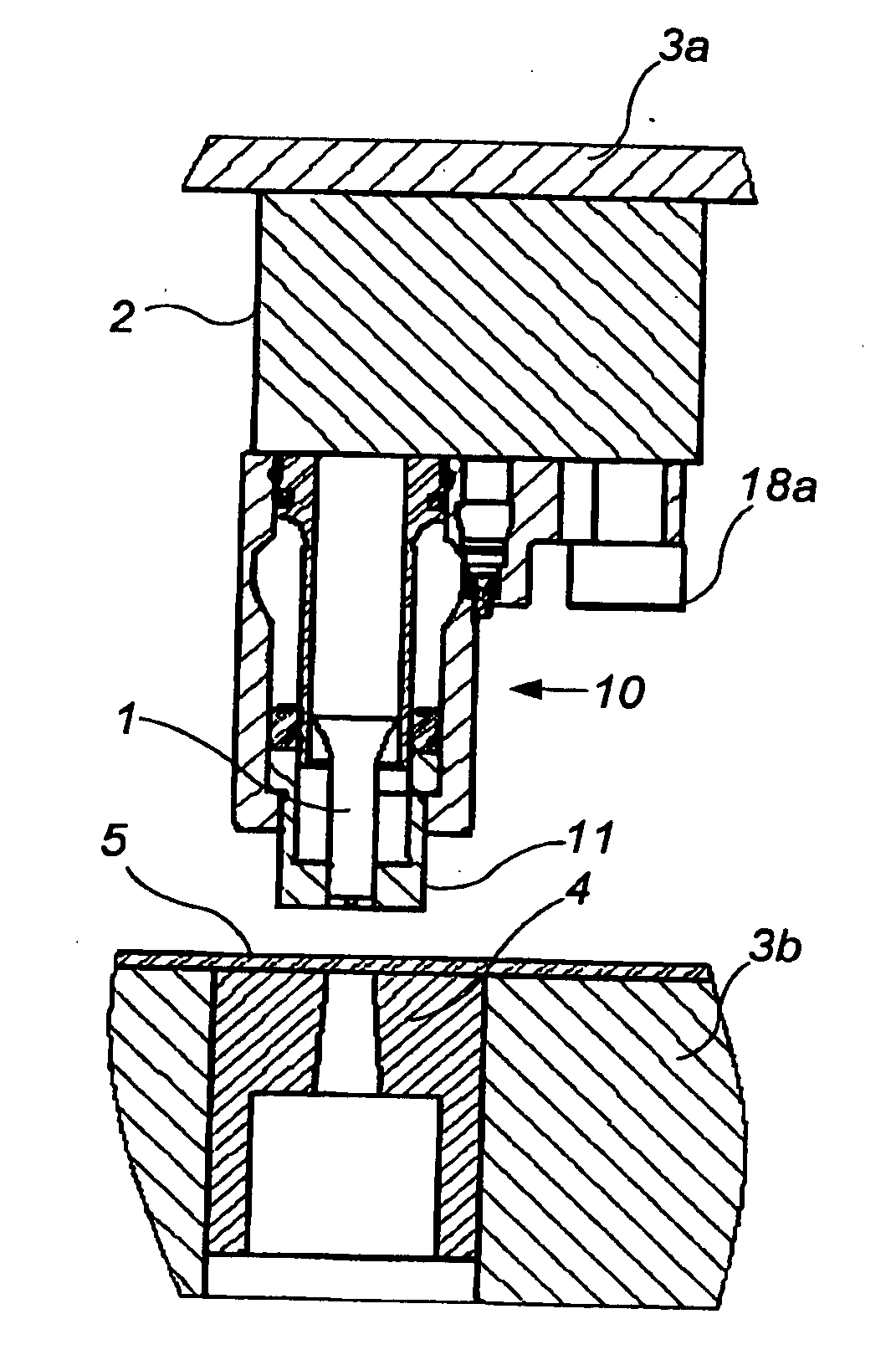

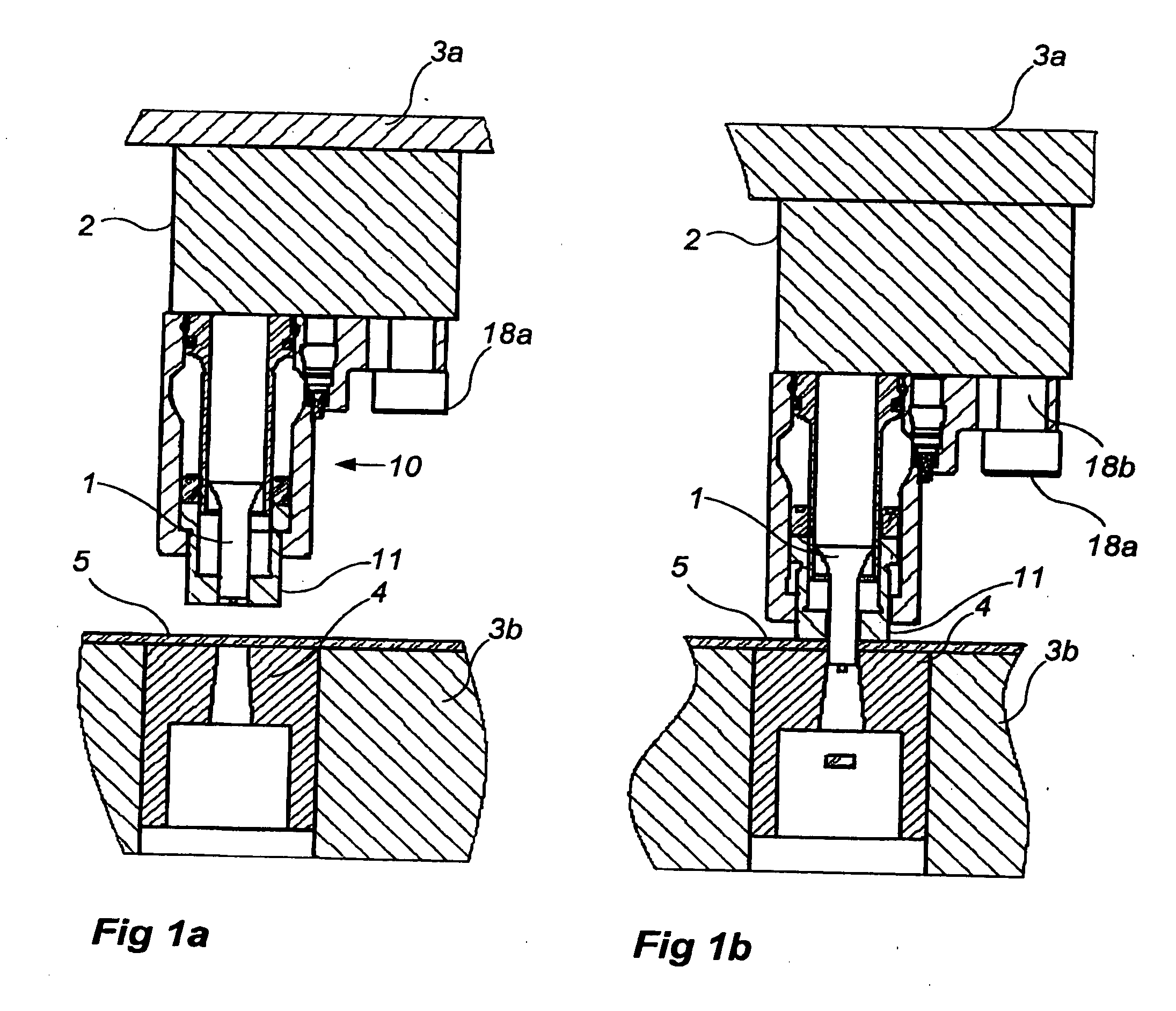

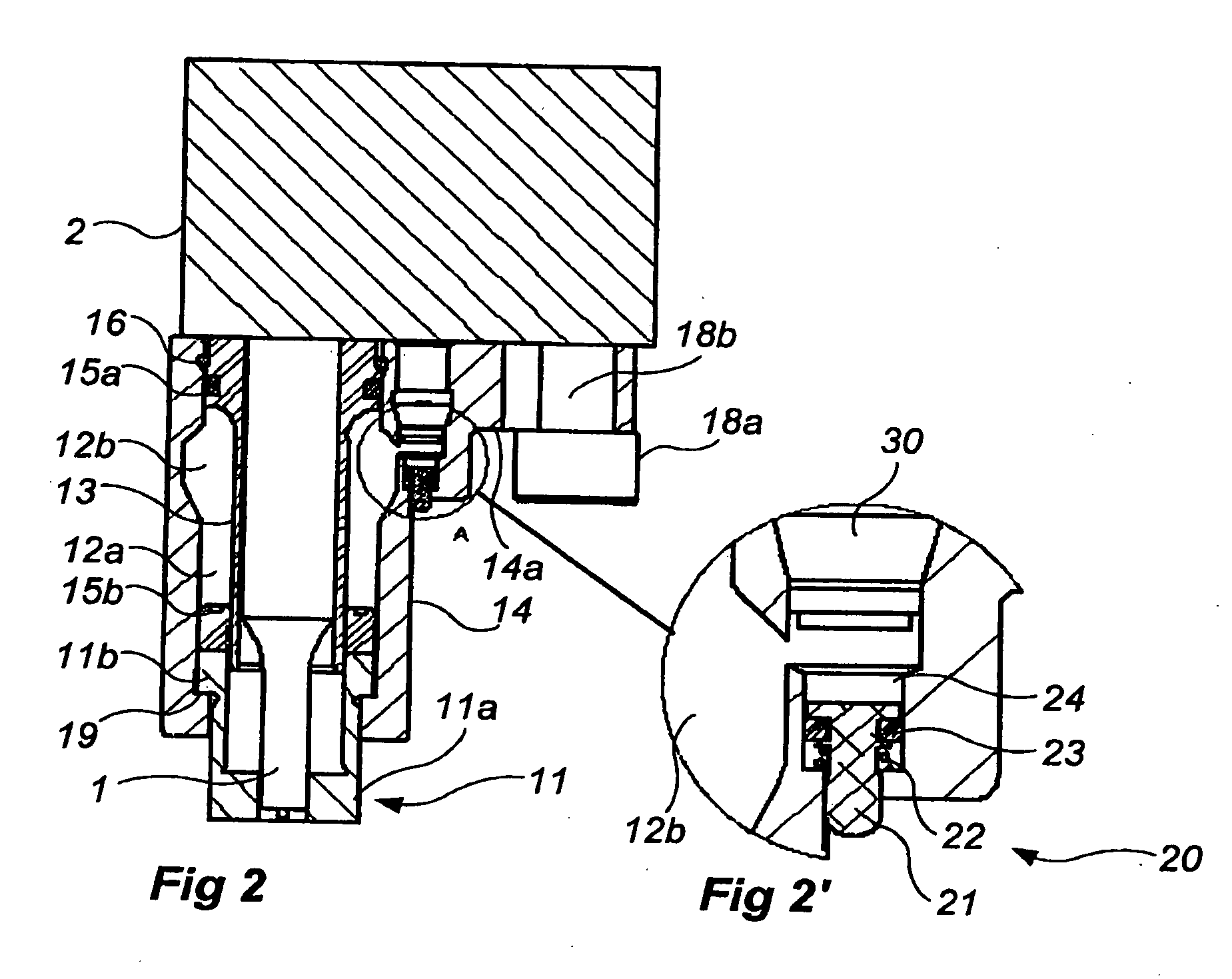

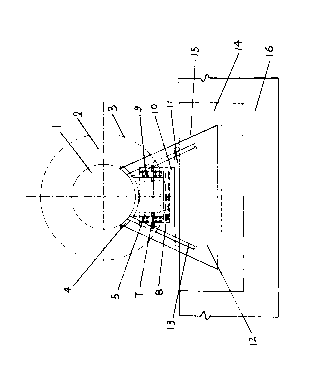

Punch stripper and press tool

InactiveUS20080105095A1Stripping force required can be easilyPromote absorptionStripping-off devicesMetal working apparatusEngineeringMechanical engineering

A punch stripper is adapted to be fastened to a punch retainer of a press tool, and to retain a work piece as the piece is being machined by a punch. The punch stripper includes a punch stripper piston and a pressure chamber adapted to spring-load the punch stripper piston. The pressure chamber is at least partially defined by a gap between an inner sleeve and an outer sleeve. The punch stripper piston has a portion that is axially displaceable in the gap.

Owner:STROMSHOLMEN

Light-weight partition wall board and manufacturing method thereof

InactiveCN103449783AImprove flame retardant performanceImprove sound absorptionCeramicwareFiberFoaming agent

The invention provides a light-weight partition wall board and a manufacturing method thereof. The light-weight partition wall board contains the following components by weight: 350-400kg of cement, 100-180kg of ceramsite, 108-240kg of secondary coal ash, 5kg of monofilament fibers, 0.2-0.3kg of an SY-F60 composite foaming agent, 20ml of triethanolamine and 460-520kg of water. The light-weight partition wall board has the advantages that production investment is low, raw materials can be purchased nearby and production efficiency is high; moreover, the partition wall board also has the advantages of high quality, light weight, high strength, long service life, heat preservation, sound insulation, fire prevention, environment friendliness and the like.

Owner:SHIYAN YIFU NEW BUILDING MATERIAL CO LTD

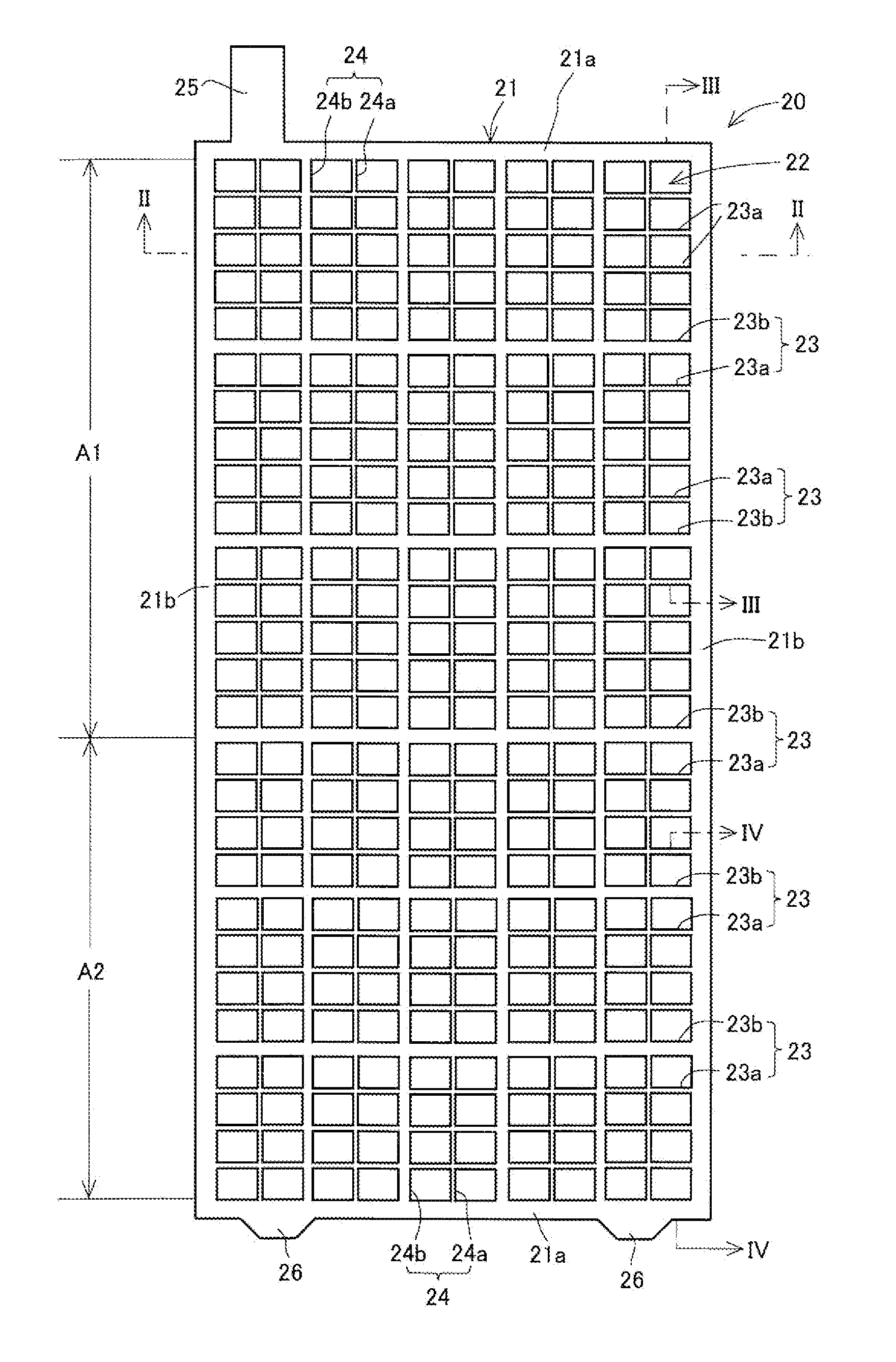

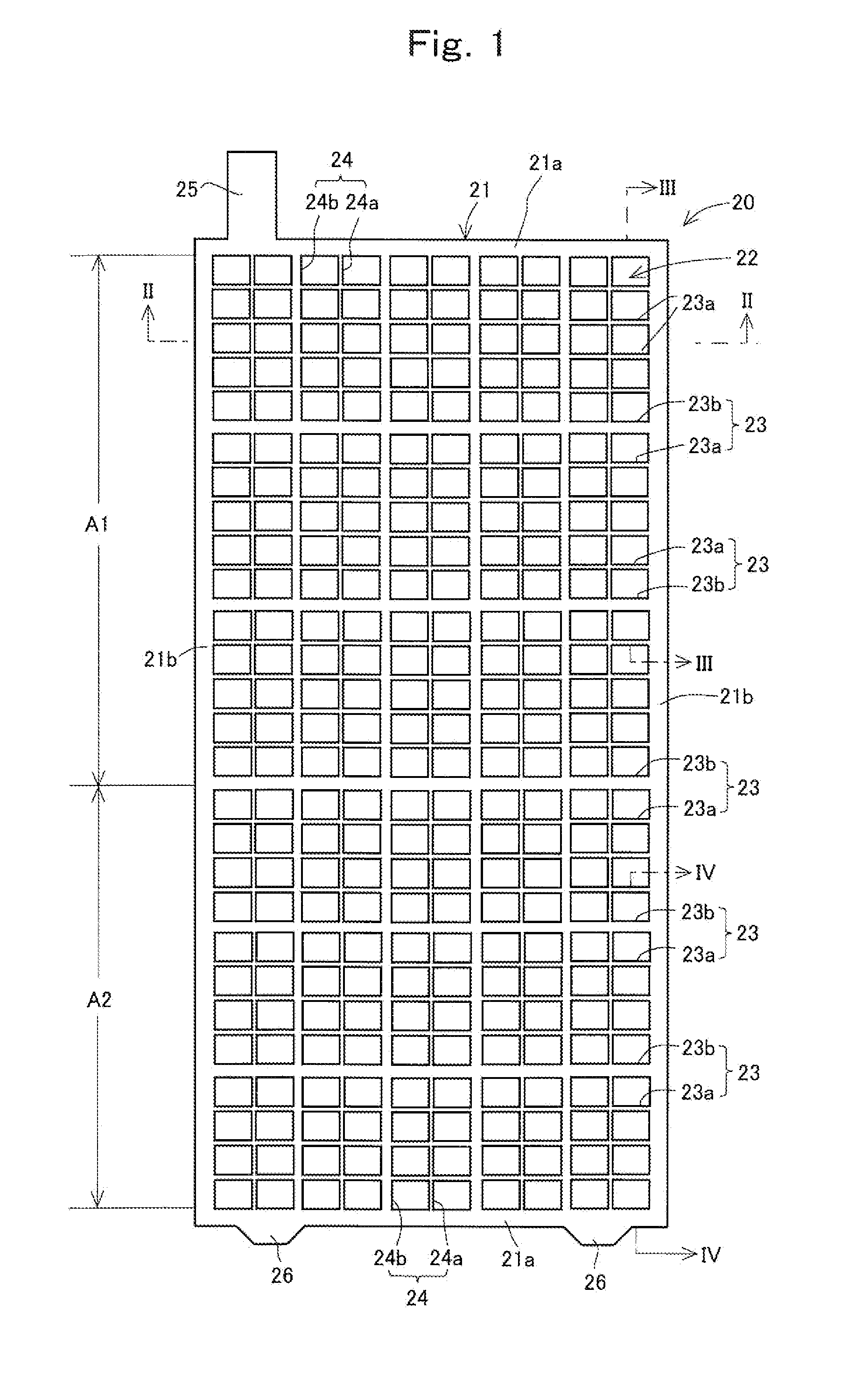

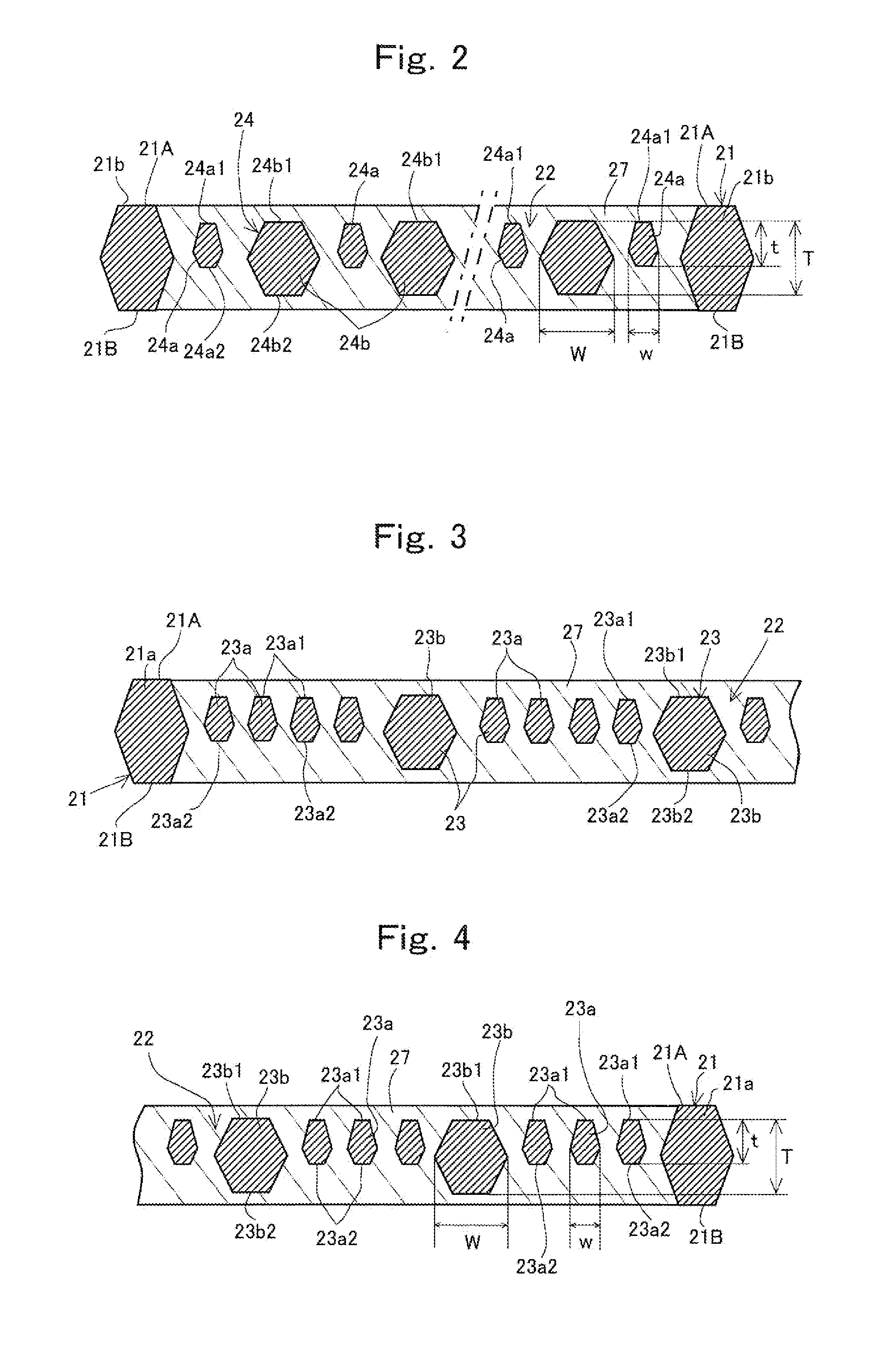

Grid plate for lead acid storage battery, plate, and lead acid storage battery provided with same plate

ActiveUS20110305957A1Low mechanical strengthStay in shapeElectrode carriers/collectorsLead-acid accumulator electrodesEngineeringThin line

Owner:SHIN KOBE ELECTRIC MASCH CO LTD

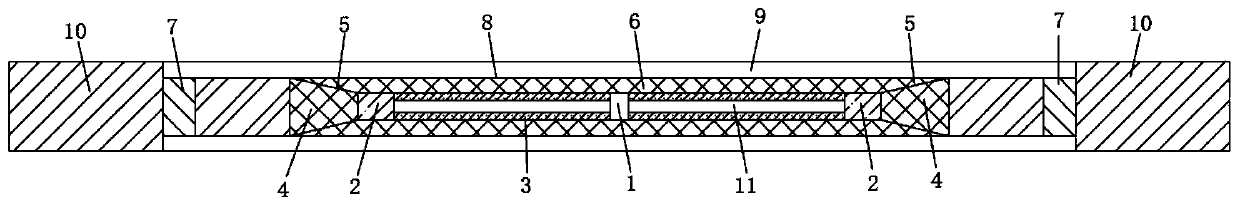

Ultrahigh-voltage submarine cable flexible joint and manufacturing method thereof

InactiveCN110993154AHigh bonding strengthSame electrical performanceLine/current collector detailsApparatus for heat treatmentStructural engineeringElectrical conductor

The invention discloses an ultrahigh-voltage submarine cable flexible joint. The flexible joint comprises a conductor welding segment, a conductor shielding recovery layer, an insulation recovery layer, an insulation shielding recovery layer, a metal sheath recovery layer and an outer sheath recovery layer. The conductor welding segment is arranged at the conductor end parts of the two sections ofsubmarine cables to connect the two sections of submarine cable conductors to form a flexible joint conductor part, the conductor shielding recovery layer, the insulation recovery layer, the insulation shielding recovery layer, the metal sheath recovery layer and the outer sheath recovery layer sequentially arranged on the outer side of the conductor part in a surrounding mode, and the conductorshielding recovery layer, and respectively correspond to the conductor shielding layers, the insulation layers, the insulation shielding layers, the metal sheaths and the outer sheaths of the two section of the cables to connect and form an integrated structure. The structural size of the flexible joint is close to that of a submarine cable body, the flexible joint has the same electrical performance, mechanical performance and bending performance as the submarine cable body, the service life of the flexible joint is prolonged, and meanwhile the manufacturing method of the flexible joint can be suitable for manufacturing molded line, compressed circle and split conductor submarine cable flexible joints.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

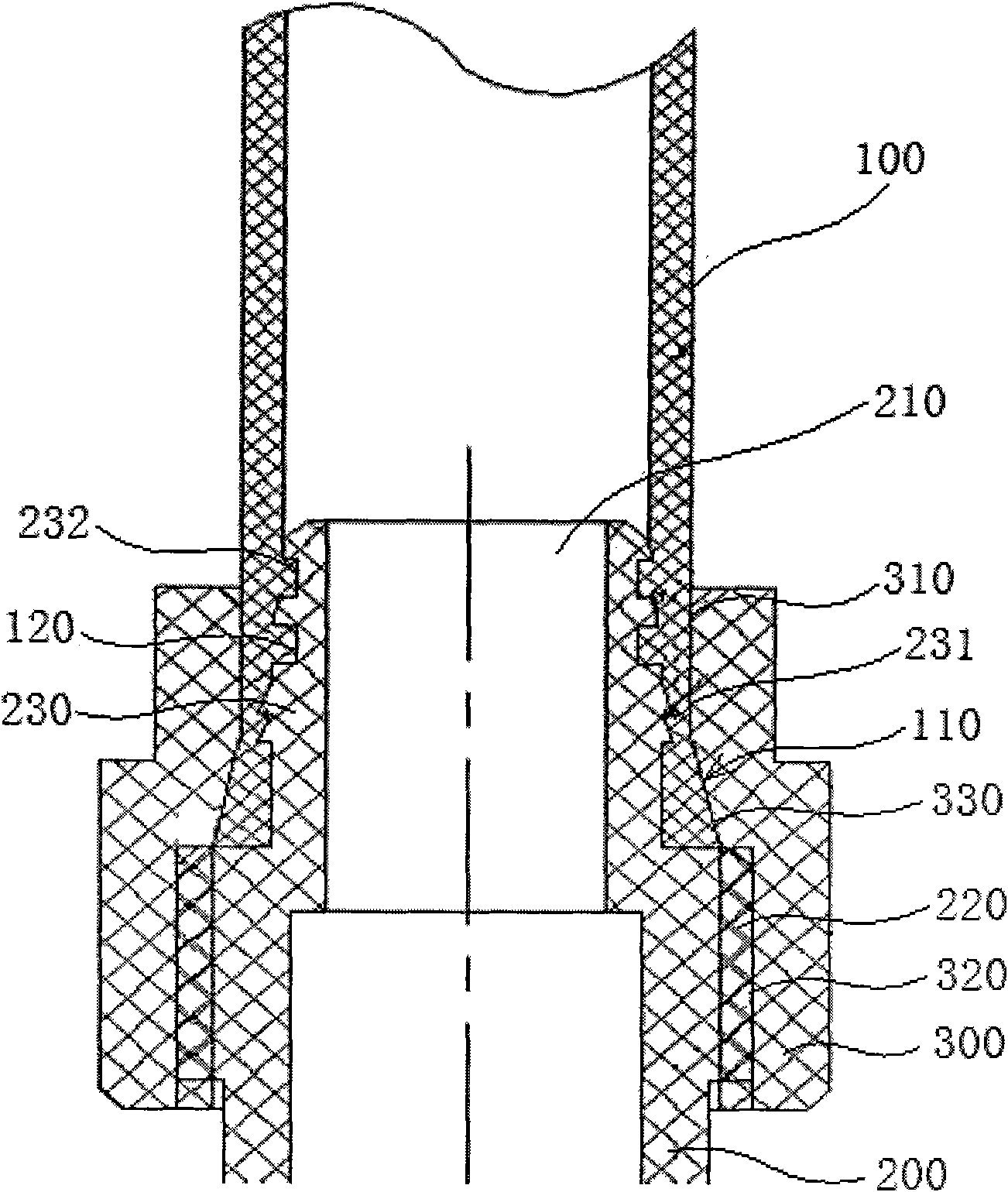

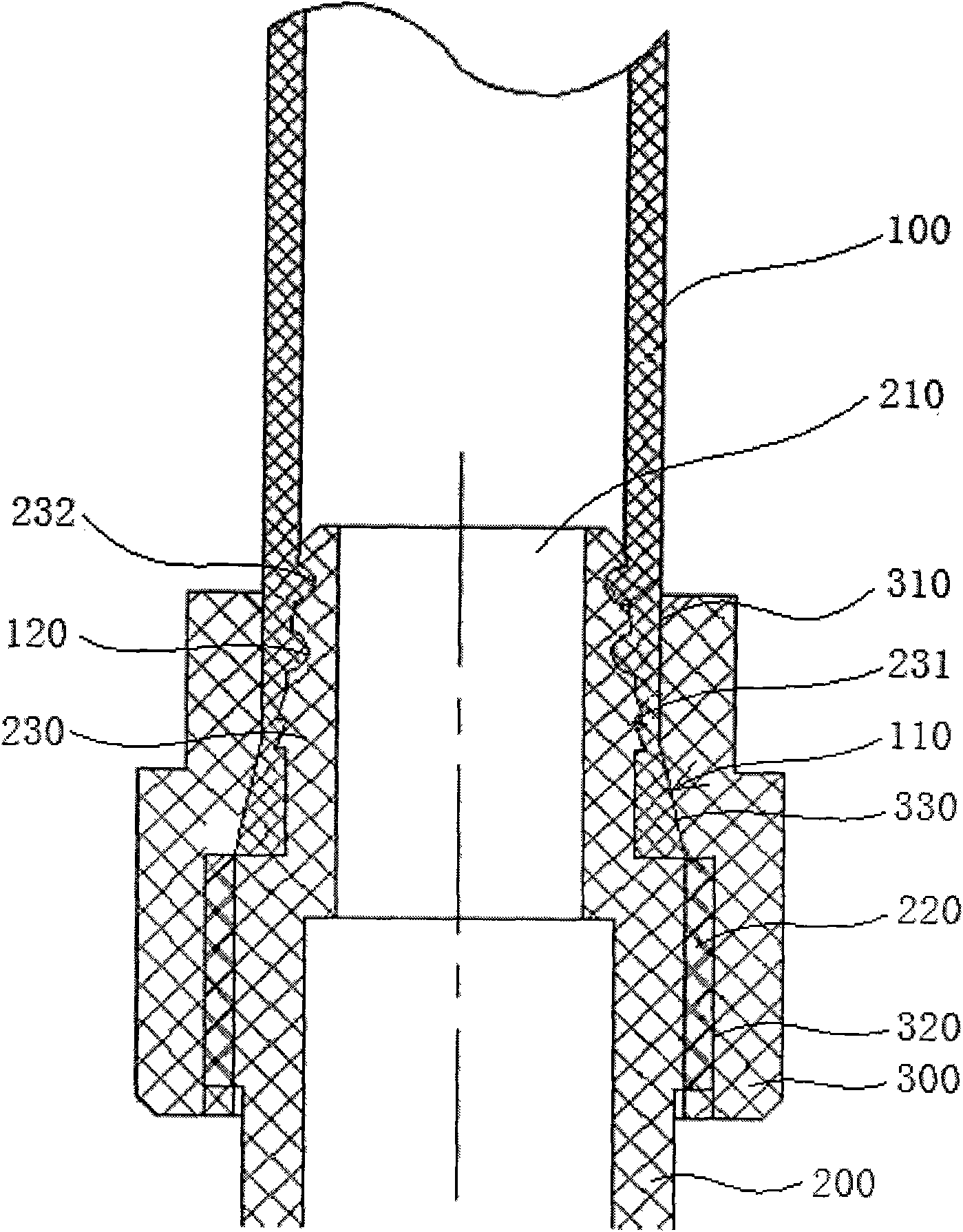

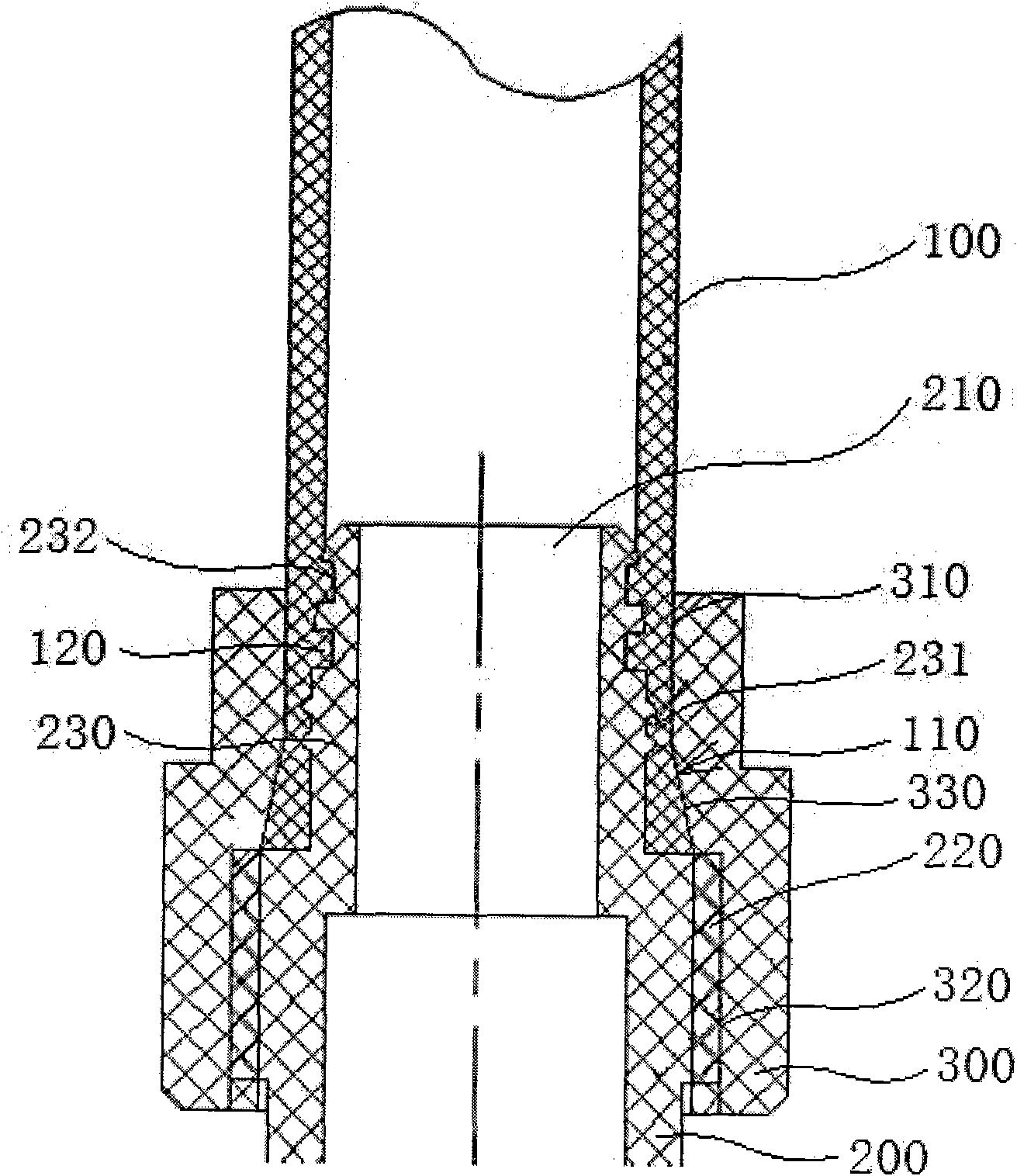

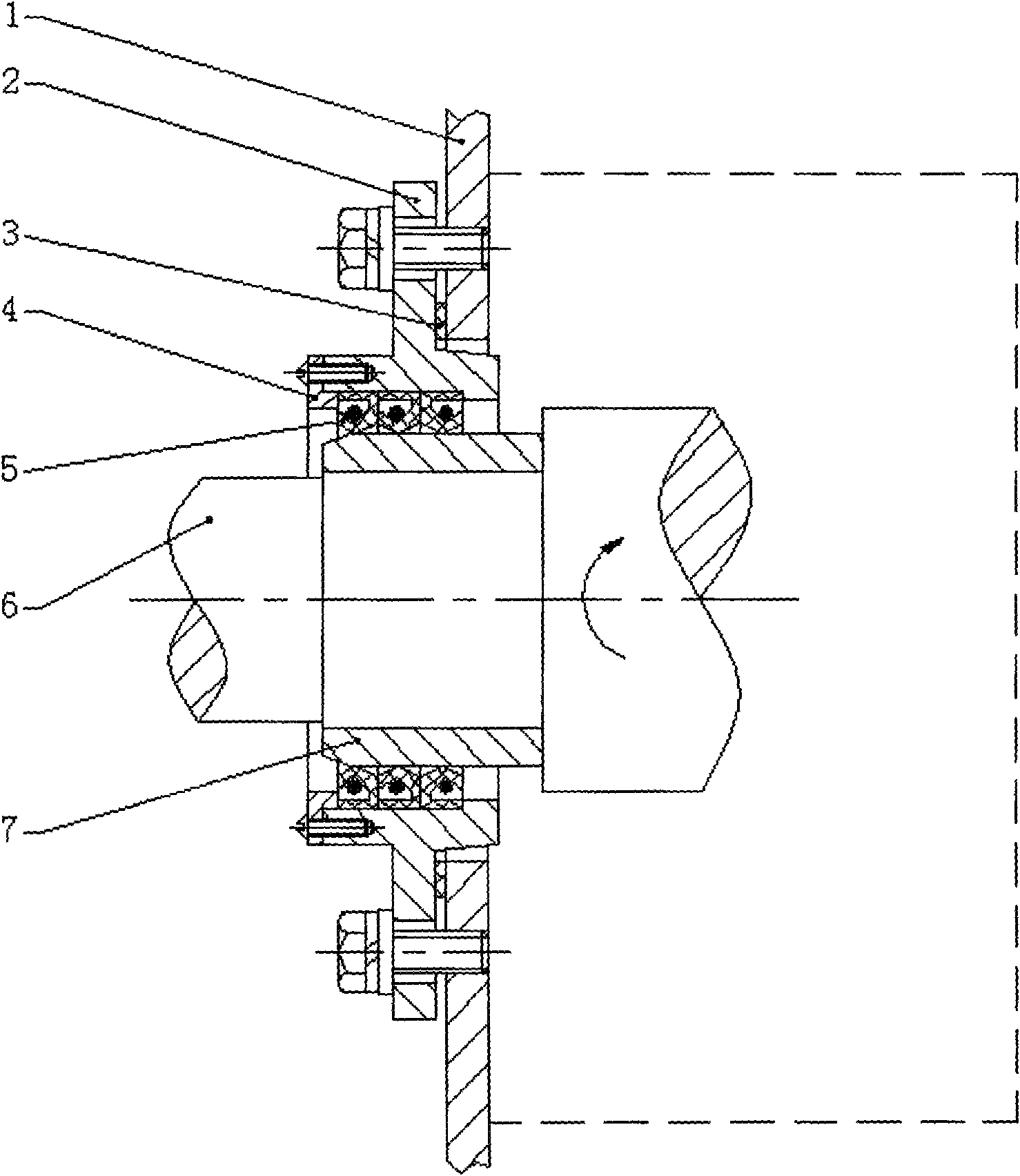

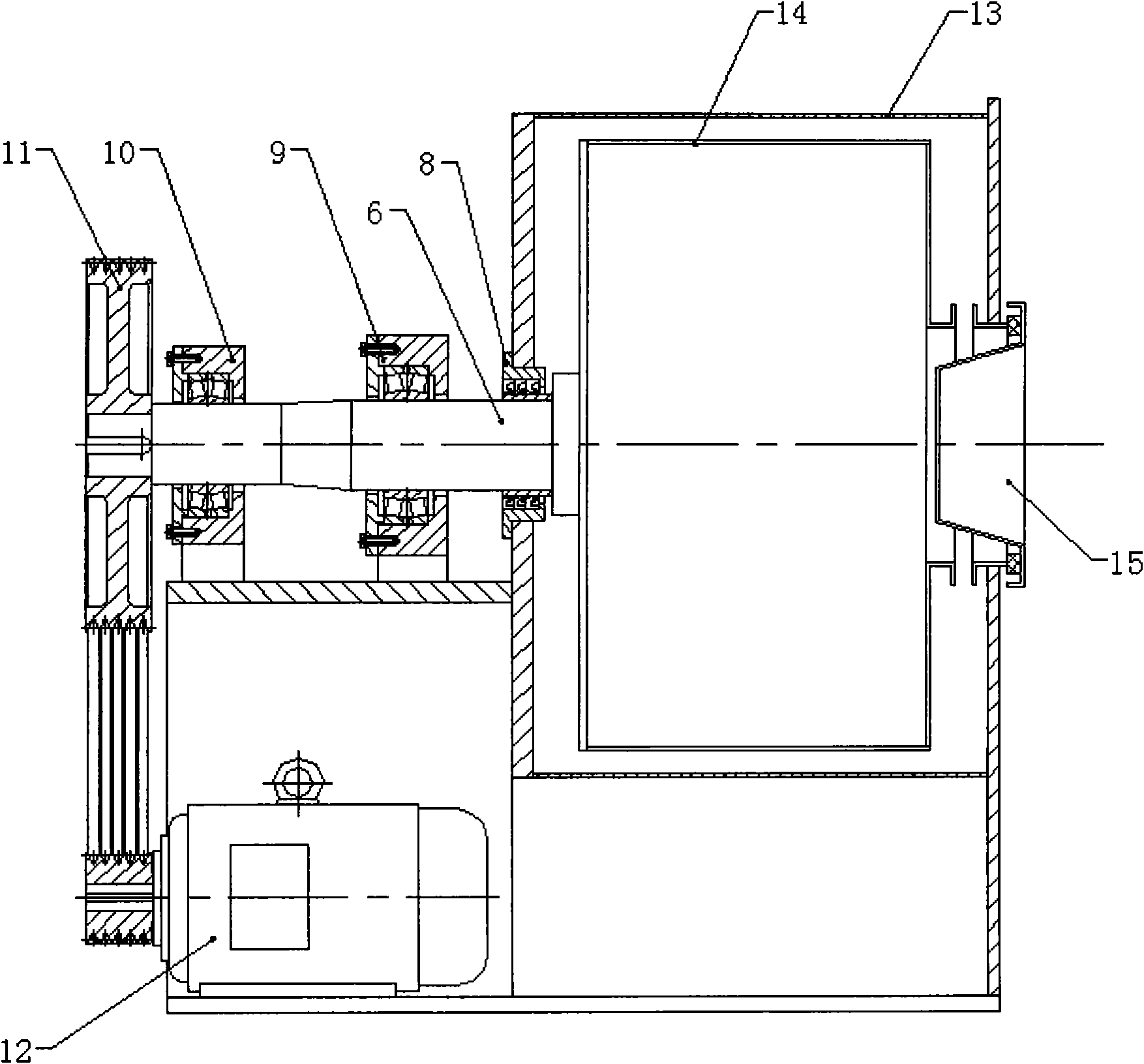

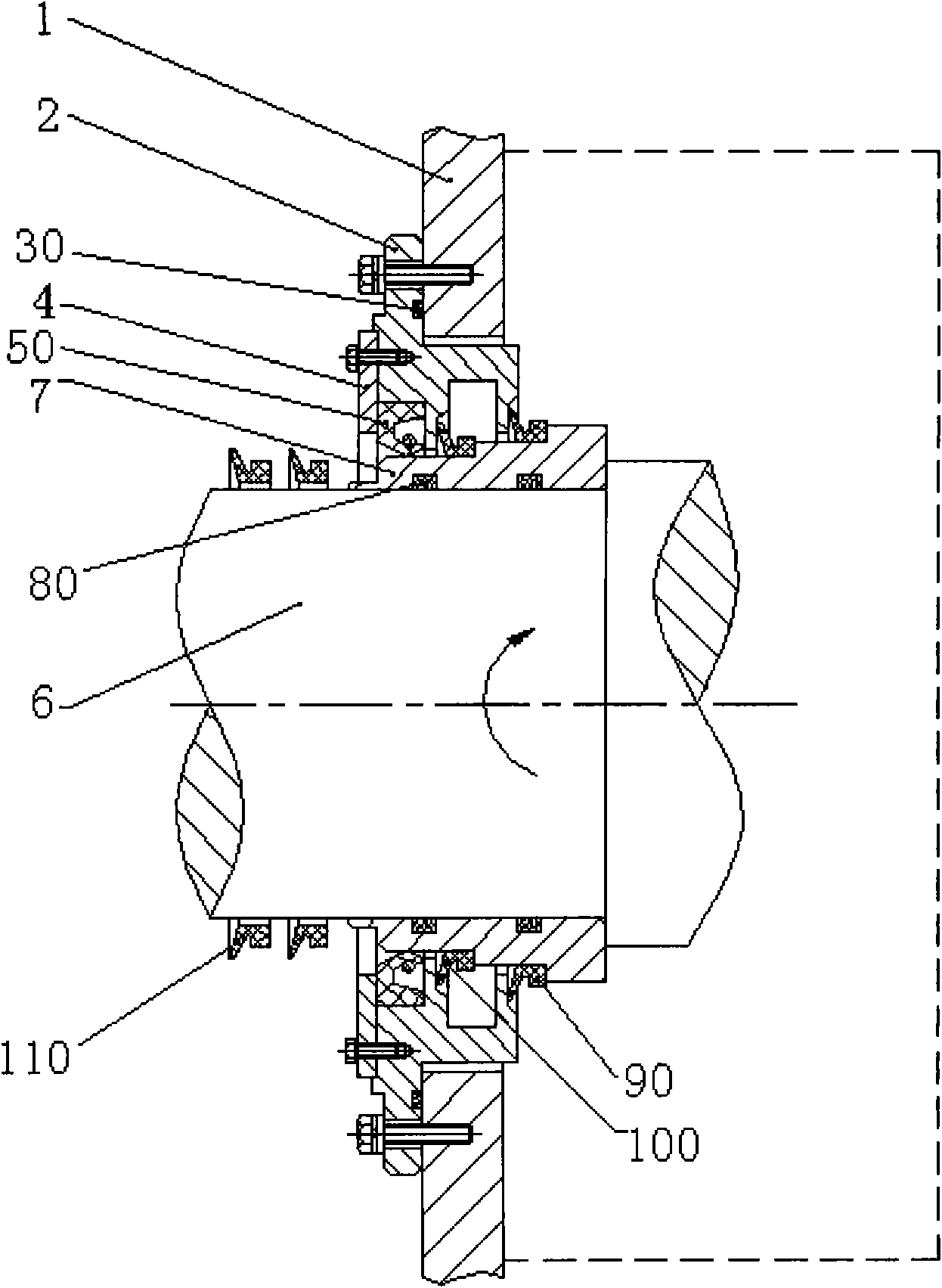

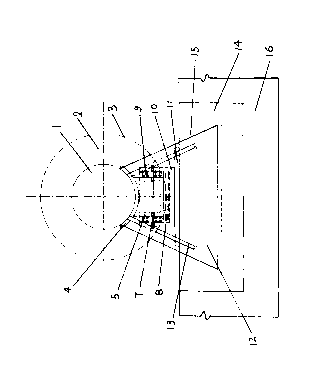

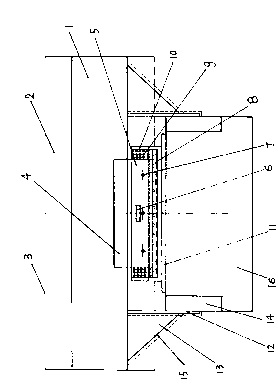

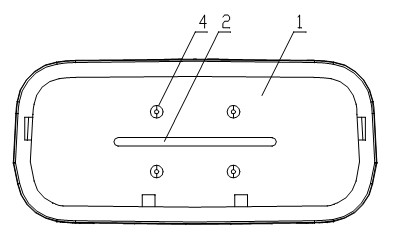

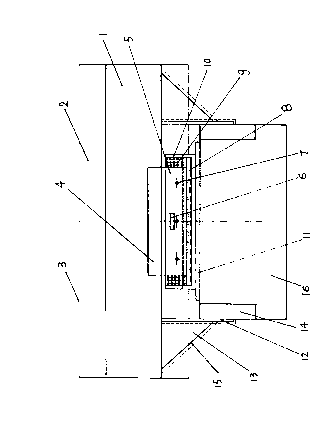

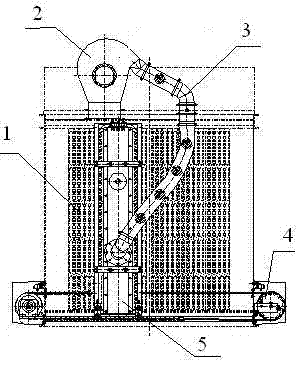

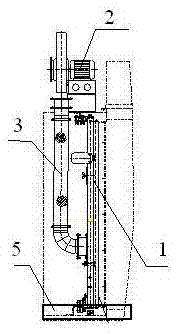

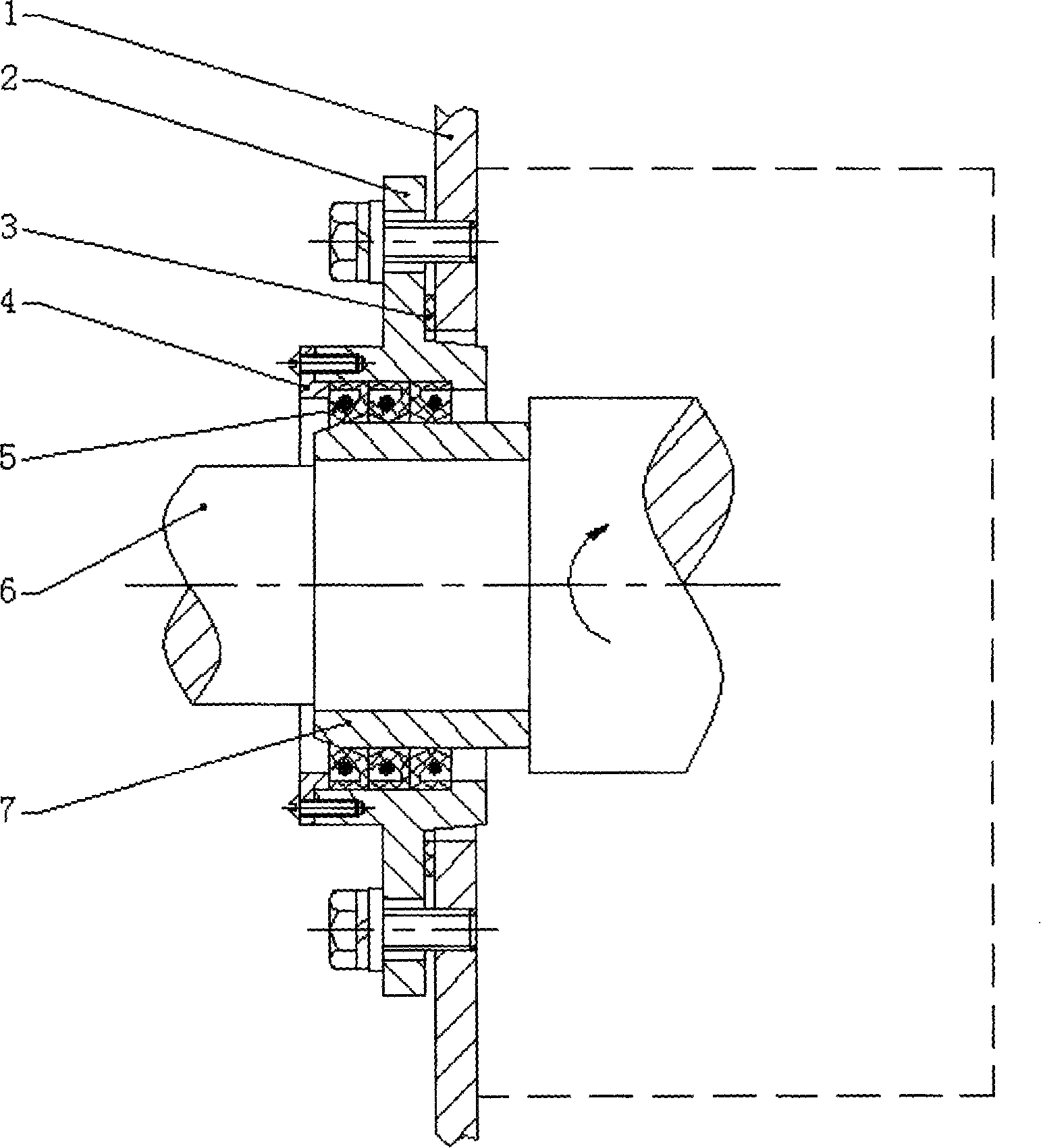

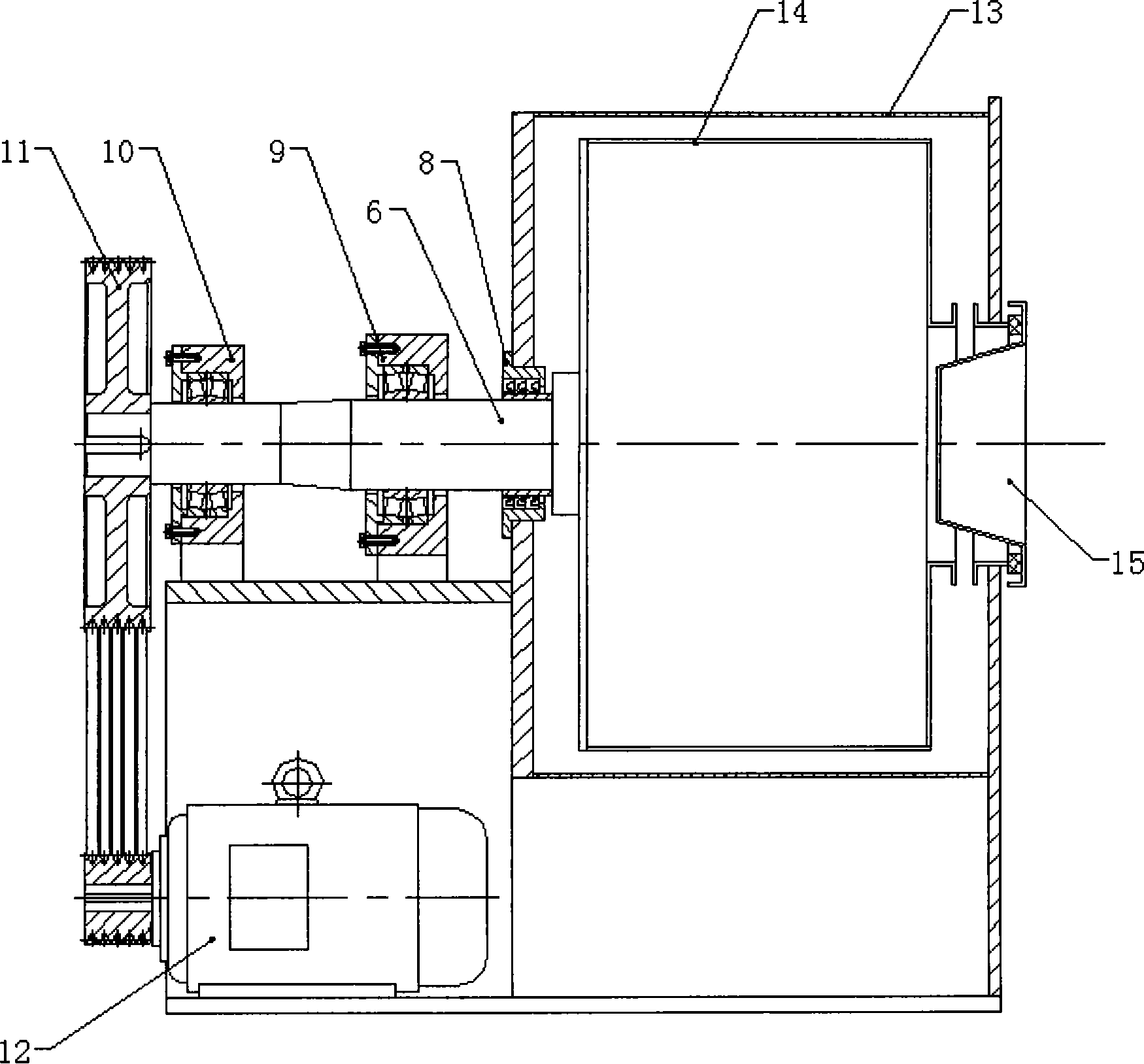

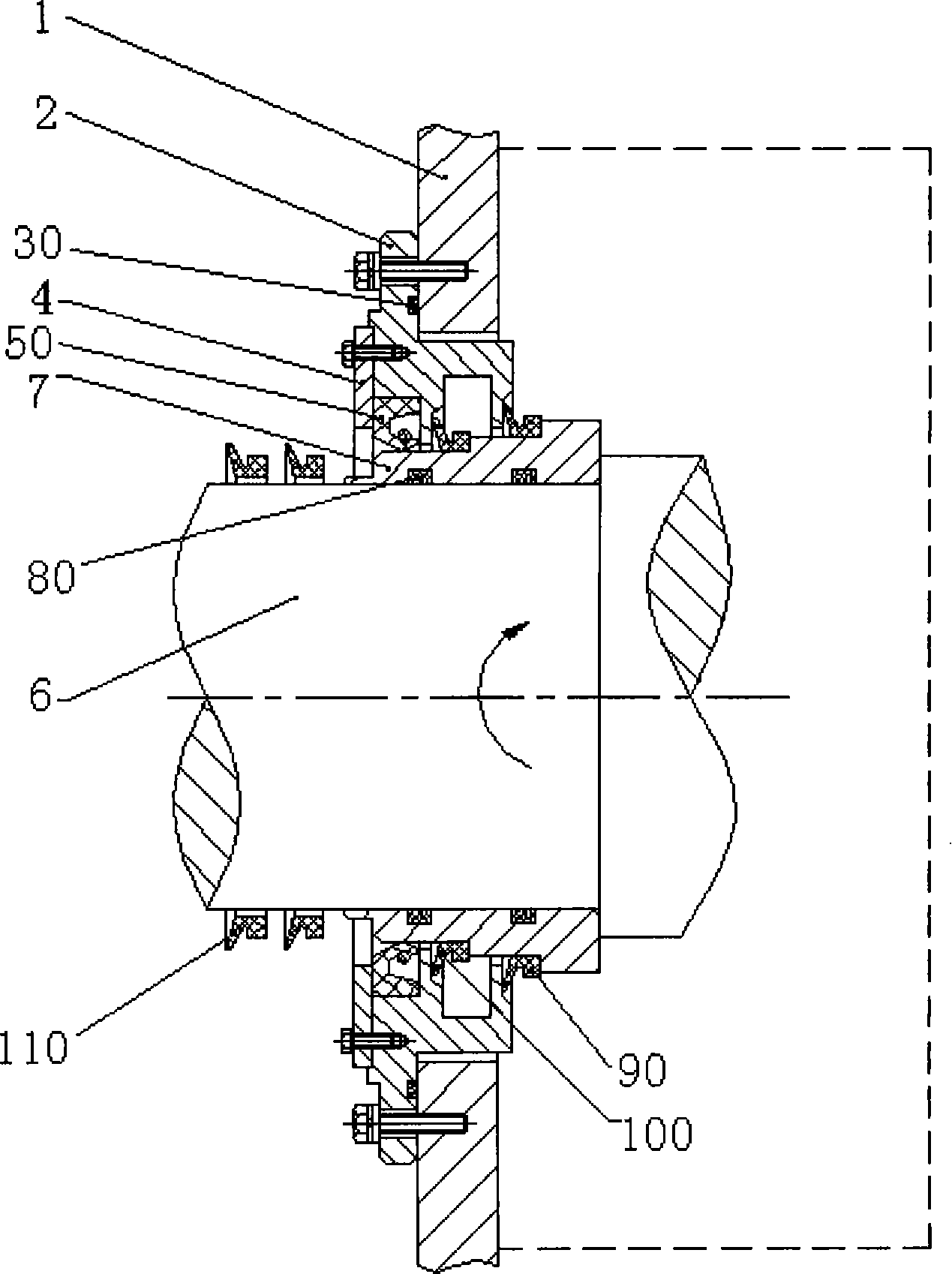

Compound sealing structure with backup function for rotary main shaft of industrial washing machine

InactiveCN101634098AExtended service lifeSame service lifeEngine sealsOther washing machinesState of artCore component

The invention relates to a compound sealing structure with a backup function for a rotary main shaft of an industrial washing machine. The structure of a sealing body, the structure of a framework oil seal press plate and the structure of a shaft housing in the prior art are changed; original three lip framework oil seal are reduced to one; two V-shaped sealing rings and two backup V-shaped sealing rings are provided; and the O-shaped ring seal is applied between the sealing body and a back plate of an outer cylinder body of a washing room and between a shaft housing and a rotary main shaft. The structure has the advantages of greatly improving the service life of the sealing structure, realizing the designed service life of the whole machine, not causing any harmful wear to the core component of the machine-main shaft, avoiding the influence of micro radial run-out of the main shat on the sealing structure when the industrial washing machine works, and greatly simplifying huge workload needed for the maintenance and the replacement of the sealing structure, and prolonging the service life of the whole machine.

Owner:上海雅森洗涤设备有限公司

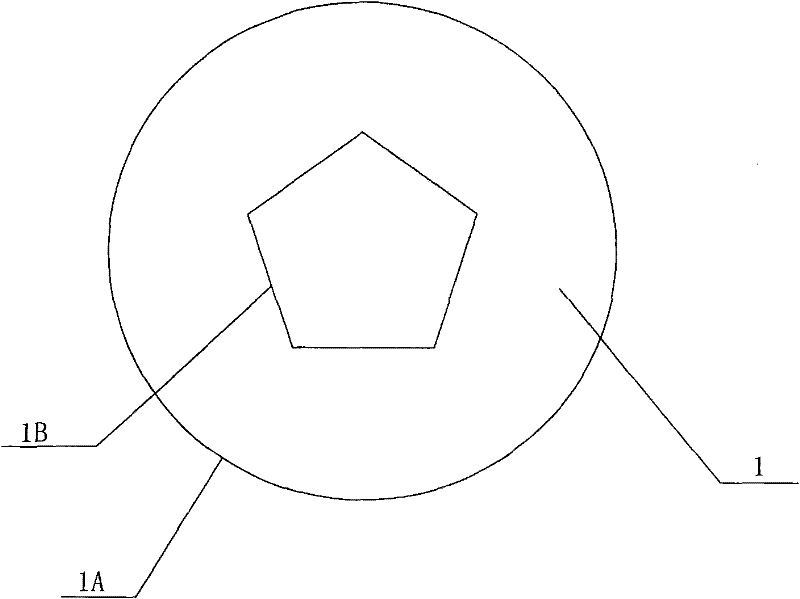

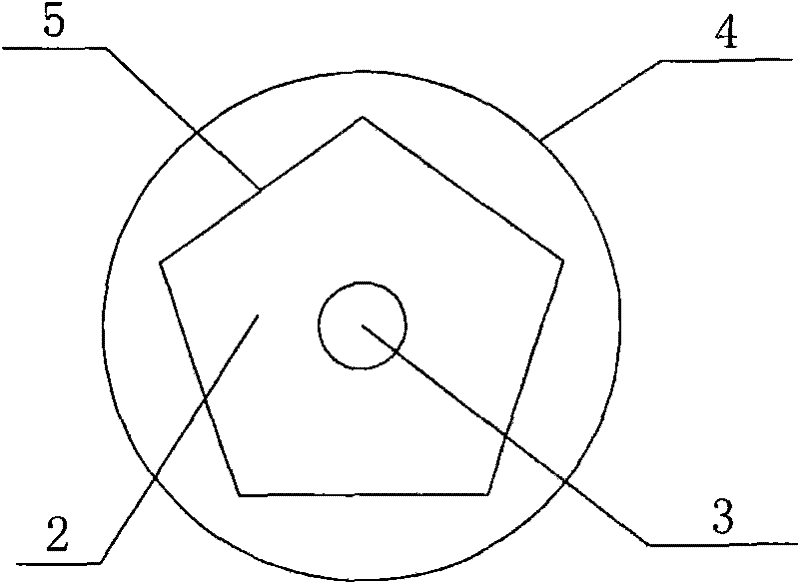

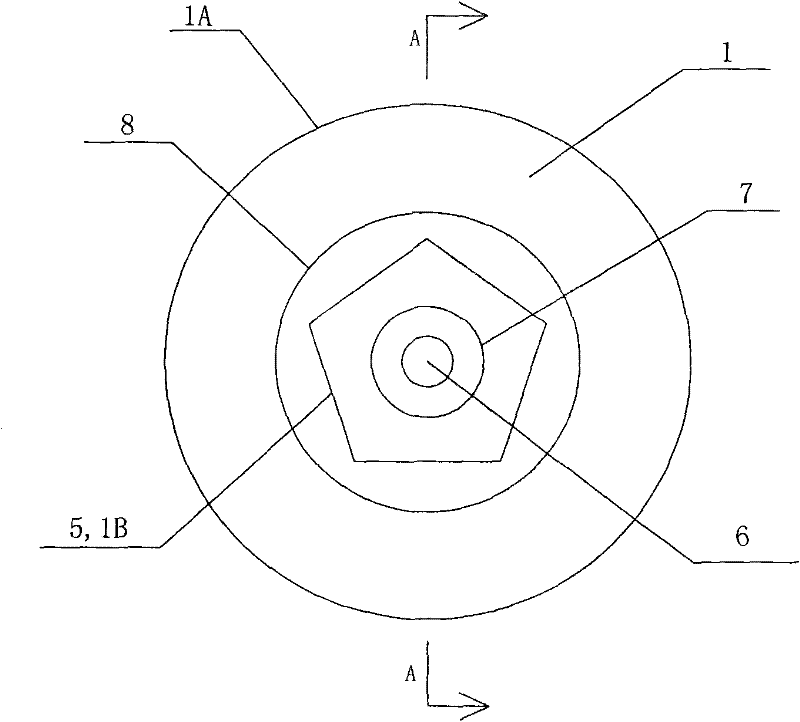

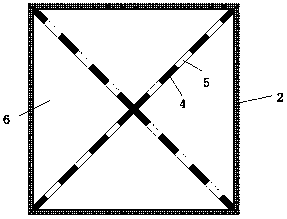

Grinding wheel and fixing disc thereof

InactiveCN102218710AAvailable portion not reducedSame service lifeBonded abrasive wheelsEngineeringGrinding wheel

The invention discloses a grinding wheel. The grinding wheel comprises a circular base sheet, wherein the shape of the outer edge of the circular base sheet is circular and the shape of the inner edge of the circular base sheet is noncircular. The grinding wheel is simple in structure and convenient to manufacture; compared with the conventional disc-shaped grinding wheel, the circular grinding wheel provided by the invention greatly saves raw materials during manufacturing, so that cost is reduced; and since a large quantity of grinding wheel materials near a central installing hole of the conventional grinding wheel are not used actually, the grinding wheel provided by the invention has the same service life with the conventional grinding wheel and has lower cost than that of the conventional grinding wheel. The invention further discloses a fixing disc for installing the grinding wheel. The fixing disc comprises a disc body, wherein the installing hole is formed in the center of the disc body; one side of the outer edge of the disc body radially protrudes so as to form a shoulder-shaped lug boss on the disc body; the protruding part of the shoulder-shaped lug boss is a circular base sheet installing part and is matched with the inner edge of the circular base sheet in shape. The fixing disc provided by the invention is simple in structure and convenient to install and detach the grinding wheel.

Owner:邢志胜

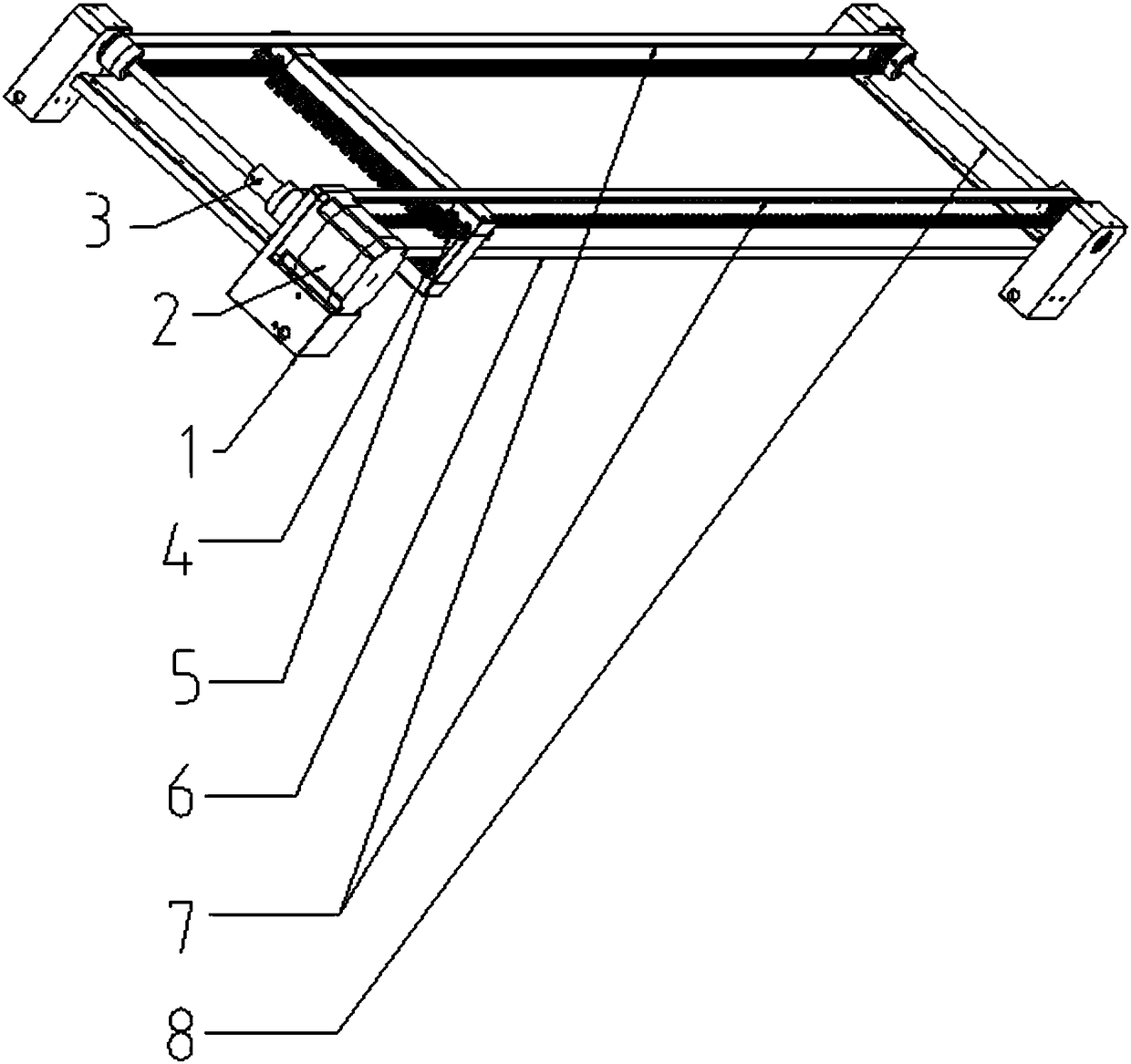

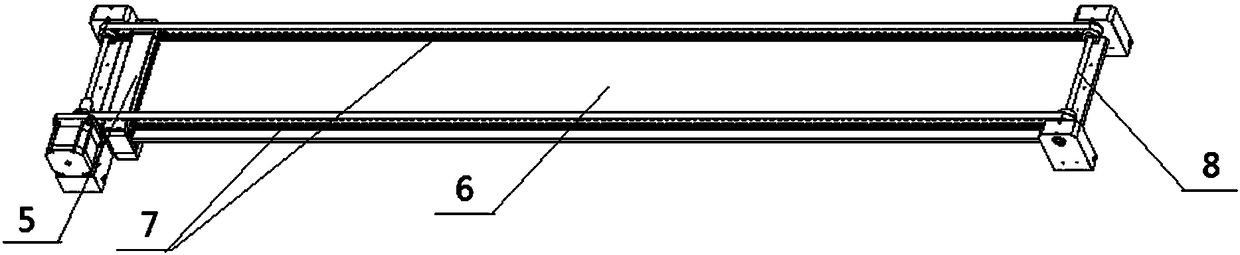

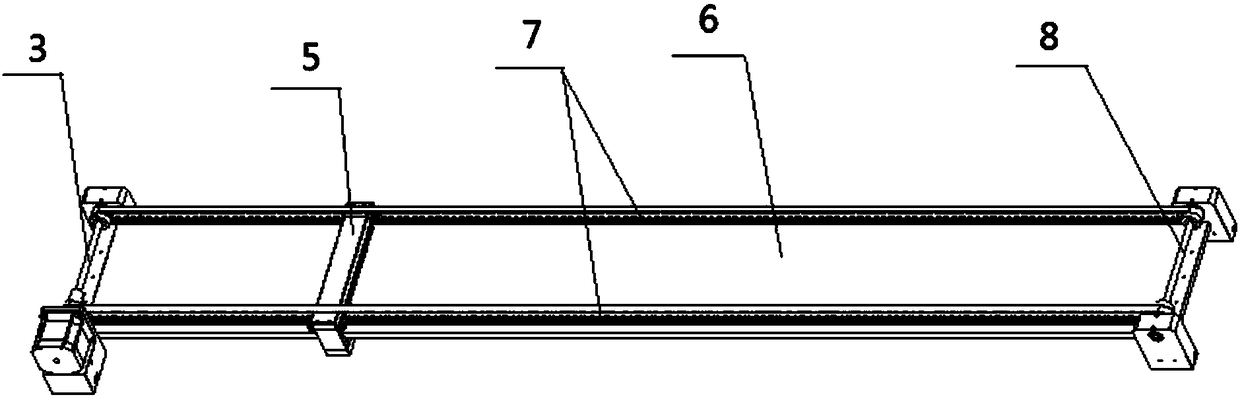

Dust removal device for dustproof net

PendingCN108453065ASame service lifeReal-time maintenanceFouling preventionDispersed particle filtrationBristleEngineering

The invention provides a dust removal device for a dustproof net. The device is arranged on the dustproof net, the dust removal device for the dustproof net is characterized by comprising a first brush, a second brush and a driving device, wherein the first brush penetrates through the two sides of the front side of the dustproof net, and the second brush penetrates through the two sides of the back side of the dustproof net; and brush bristles of the first brush and the brush bristles of the second brush are both in contact with the dust-proof net net surface; the driving device drives the first brush and the second brush to move along the dustproof net net surface. According to the device, the driving device is adopted to drive the two brushes to repeatedly brush from the two faces of the dustproof net to brush away the dust on the dustproof net.

Owner:SHENZHEN GOLD POWER TECH

Method for repairing propeller blades of ship

The invention discloses a method for repairing propeller blades of a ship, and belongs to the field of maintenance and repair of main parts used on ships. For a worn blade, the worn part of the guideedge of the blade can be subjected to surfacing through gas welding, and the texture of a used welding wire material is required to be the same as the texture of the propeller, and then the surface ofthe surfacing position is polished. For a defective blade caused by being collided with a hard object, a slightly larger piece of casting material having the same texture as that of the propeller canbe cast in advance according to the shape of the defective part, then match working is conducted through a manual method, a suitable weld chamfer needs to be machined at the weld joint, and then manually welded by using oxygen-acetylene; and finally grinding and trimming are conducted so that the use efficiency of the propeller can be recovered. At the same time, the repairing method is simple and practical, and the repaired blade bodies have the same service life as original blade bodies.

Owner:南通如港船舶配套机械有限公司

Additive composition for bituminous conglomerates with high mechanical performances

ActiveUS20200062648A1Improve mechanical propertiesDecrease of rutting phenomenonSolid waste managementPolymer sciencePolyvinyl alcohol

Additive composition compositions intended to be mixed into bituminous conglomerates for road paving, comprising containing a thermoplastic polymer, a polymeric compound selected from the group consisting of polyvinylbutyral (PVB), polyethylacrylate (PEA) polymethylacrylate (PMA), polybutylacrilate (PBA), lignin and mixtures thereof, and graphene are disclosed. preferably wherein The graphene is contained in a quantity between 0.005 and 1% by weight based on the total weight of the composition. A bituminous conglomerate suitable for making a road paving, containing comprising aggregates, filler, bitumen and said the additive is also disclosed.

Owner:ITERCHIM SRL

Patterning process for rotationally-molded product

InactiveCN102773954BImprove bindingThe joint is smooth and smoothCoatingsRotational moldingIndustrial engineering

The invention relates to the technical field of manufacture of plastic products, in particular to a patterning process for a rotationally-molded product. The process is based on a rotational molding process, and comprises the following steps of: attaching a layer of colored solvent to a part to be patterned according to the shape and size of a pattern in a mold, closing the mold, feeding raw materials for producing the rotationally-molded product, and patterning the rotationally-molded product by using the rotational molding process to integrate the colored solvent with the rotationally-molded product. The obtained pattern can be more firmly combined with the product, difficultly falls, and is fadeless, bright, durable, long in service life and attractive and elegant in appearance, and the combined part of the pattern and the product is flat and smooth; moreover, the patterning process is simpler, low in investment cost, in line with industrial production and utilization and favorable for industrial upgrading, and the production efficiency and the quality are greatly improved; and the patterning process is applied to the manufacture of multicolor and multiform patterns, the service life of the pattern is the same as that of the rotationally-molded product, and the pattern is high in cost performance.

Owner:东莞市启民环保科技有限公司

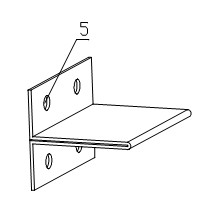

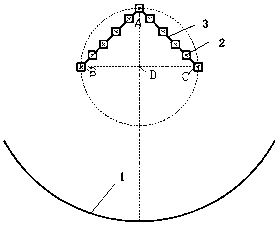

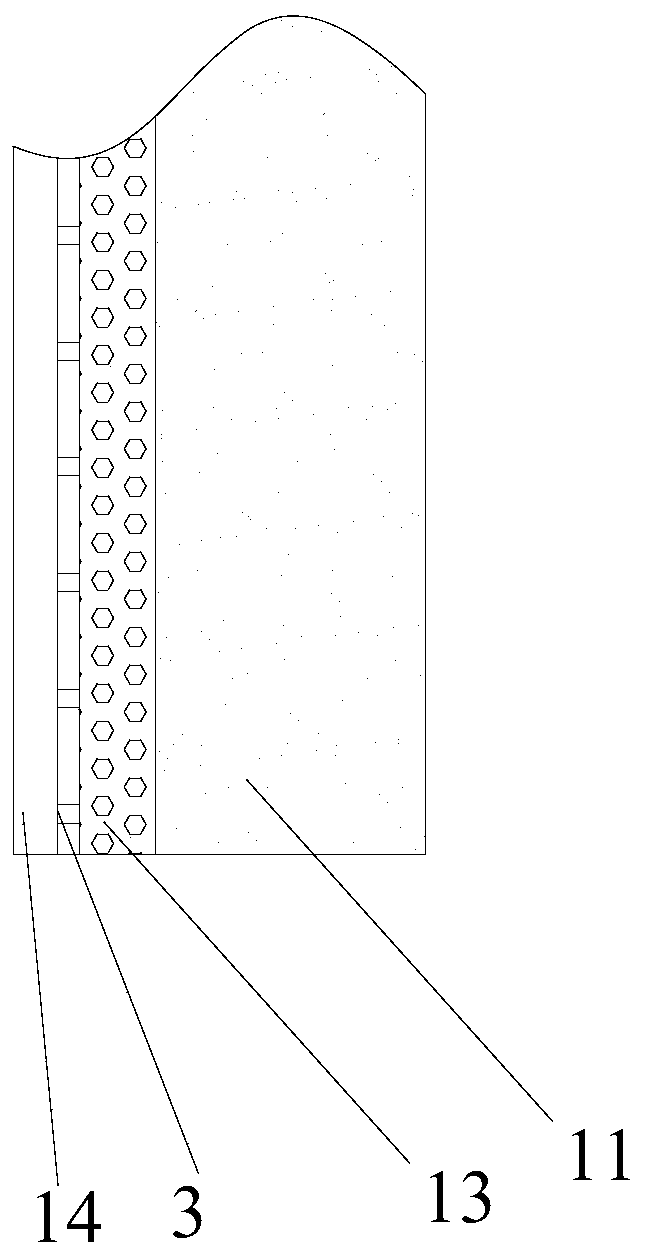

Single face baffle fixing support arranged on 200 DEG C overhead heat supply pipeline and used for preventing heat bridge from transferring heat

InactiveCN103104786ABlocking lossReduce the temperatureThermal insulationPipe protection by thermal insulationEpoxyThermal bridge

The invention discloses a single face baffle fixing support arranged on a 200 DEG C overhead heat supply pipeline and used for preventing a heat bridge from transferring heat. The problem that a heat bridge effect easily happens in an existing device is solved. An arc-shaped top face bracket (5) is placed inside a pit of a high-strength heat insulation novolac epoxy bracket (10), a glass wool insulating layer (9) is arranged between the outer side face of the arc-shaped top face bracket (5) and the inner side face of the high-strength heat insulation novolac epoxy bracket (10), a high-strength heat insulation novolac epoxy baffle (14) is placed on the side face of a pipeline support frame (16), an aluminum foil reflecting film is arranged between the high-strength heat insulation novolac epoxy baffle (14) and a steel single face baffle (12), and the steel single face baffle (12) is movably connected with the high-strength heat insulation novolac epoxy baffle (14) in an abutted mode. The single face baffle fixing support has the advantage that heat bridge loss between a heat transferring steel pipe and the pipeline support frame is cut off.

Owner:CEEC SHANXI ELECTRIC POWER EXPLORATION & DESIGN INST

Thermoplastic elastomer composition for crane cable sheath

InactiveCN103540046AMeet the requirementsSimple processPlastic/resin/waxes insulatorsInsulated cablesWaxThermoplastic elastomer

The invention relates to a crane cable, particularly a composition for a crane cable sheath. The thermoplastic elastomer for a crane cable sheath comprises the following components in parts by weight: 30-35 parts of PVC (polyvinyl chloride) resin, 8-10 parts of light calcium carbonate, 28-30 parts of TOTM (trioctyl trimellitate), 2-3 parts of DOS (dioctyl sebacate), 1-1.5 parts of epoxy soybean oil, 2-2.5 parts of environment-friendly calcium zinc stabilizer and 0.2-0.5 part of low-molecular polyethylene wax. The components are subjected to extrusion molding to obtain the cable sheath. The composition saves the cost, simplifies the technique, enhances the production efficiency, and satisfies the operational requirements of the customers.

Owner:SHANGHAI QIFAN CABLE CO LTD

Double-faced baffle fixing support arranged on 200 DEG C overhead heat supply pipeline and used for preventing heat bridge from transferring heat

InactiveCN103104783ABlocking lossReduce the temperatureThermal insulationPipe protection by thermal insulationCalcium silicateEpoxy

The invention discloses a double-faced baffle fixing support arranged on a 200 DEG C overhead heat supply pipeline and used for preventing a heat bridge from transferring heat. The problem that a heat bridge effect easily happens in an existing device is solved. An arc-shaped top face bracket (5) is placed inside a pit of a high-strength heat insulation novolac epoxy bracket (10), a glass wool insulating layer (9) is arranged between the outer side face of the arc-shaped top face bracket (5) and the inner side face of the high-strength heat insulation novolac epoxy bracket (10), a calcium silicate hard insulation board (8) is placed on the pit bottom of the high-strength heat insulation novolac epoxy bracket (10) and the outer bottom of the arc-shaped top face bracket (5), an aluminum foil reflecting film is arranged between the high-strength heat insulation novolac epoxy baffle (14) and a steel double-faced baffle (12), and the steel double-faced baffle (12) is movably connected with the high-strength heat insulation novolac epoxy baffle (14) in an abutted mode. The double-faced baffle fixing support has the advantage that heat bridge loss between a heat transferring steel pipe and a pipeline support frame is cut off.

Owner:CEEC SHANXI ELECTRIC POWER EXPLORATION & DESIGN INST

Solar heat collector with high corrosion resistance

ActiveCN105737404AImprove corrosion resistanceExtended service lifeSolar heating energySolar heat devicesSolar thermal collectorSolar heat

The invention provides a solar heat collector which comprises two tube plate structures. A certain included angle is formed between the two tube plate structures. The direction of the included angle is opposite to the bending direction of an arc structure of a reflector. The focal point of the reflector is located within the included angle formed by the tube plate structures. Inner fins are arranged in heat collecting tubes and connected with opposite corners of a rectangle. The interiors of the heat collecting tubes are divided into a plurality of small channels through the inner fins. Communicating holes are formed in the inner fins. The outer surfaces of the heat colleting tubes and the outer surfaces of heat collecting plates are coated with anti-corrosion layers. The surface of the heat collector is coated with a corrosion-resisting material, so that the corrosion resistance of the heat collecting tubes is increased, and the service life is prolonged.

Owner:长沙威航新能源技术有限公司

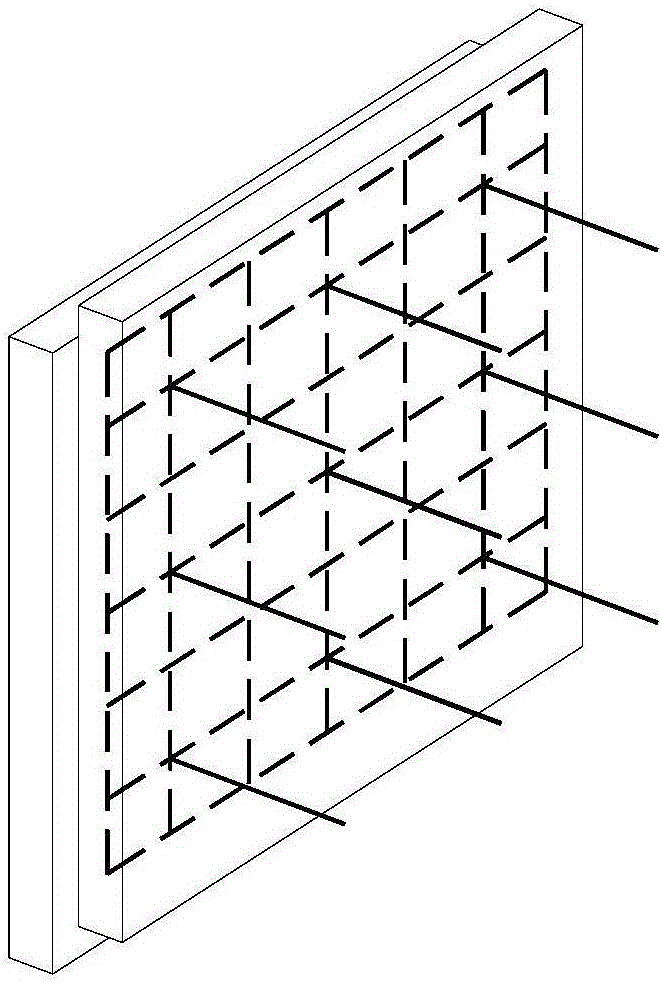

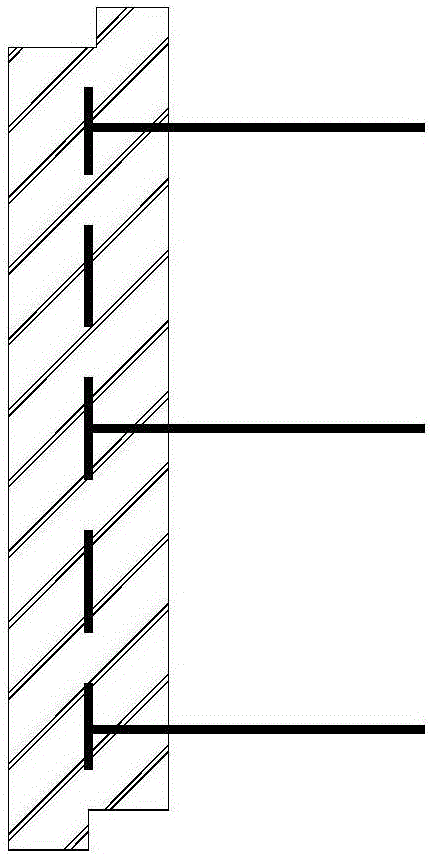

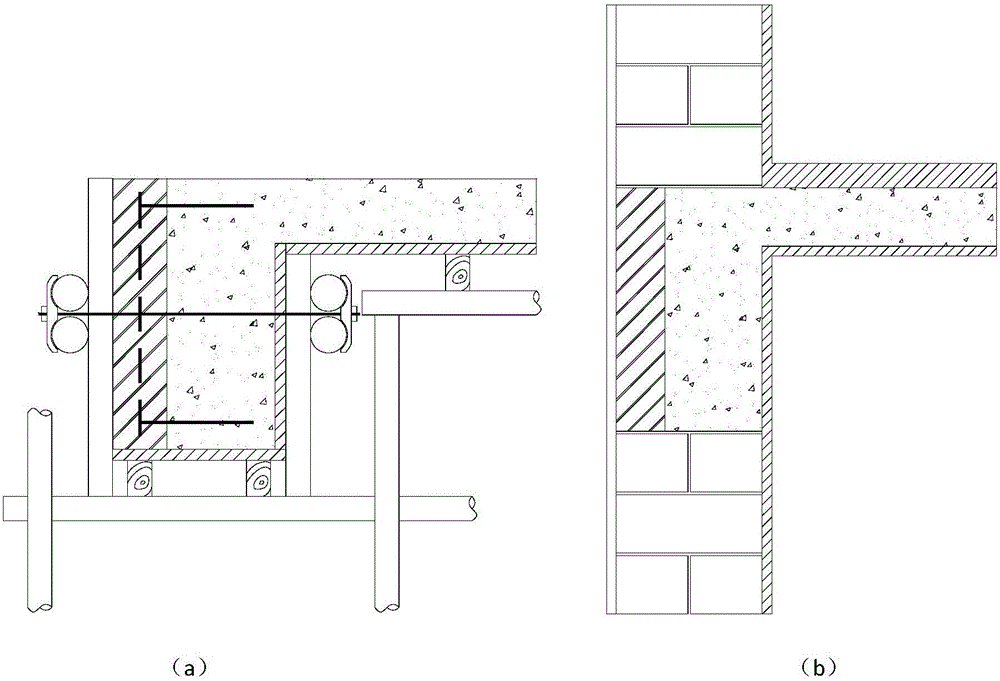

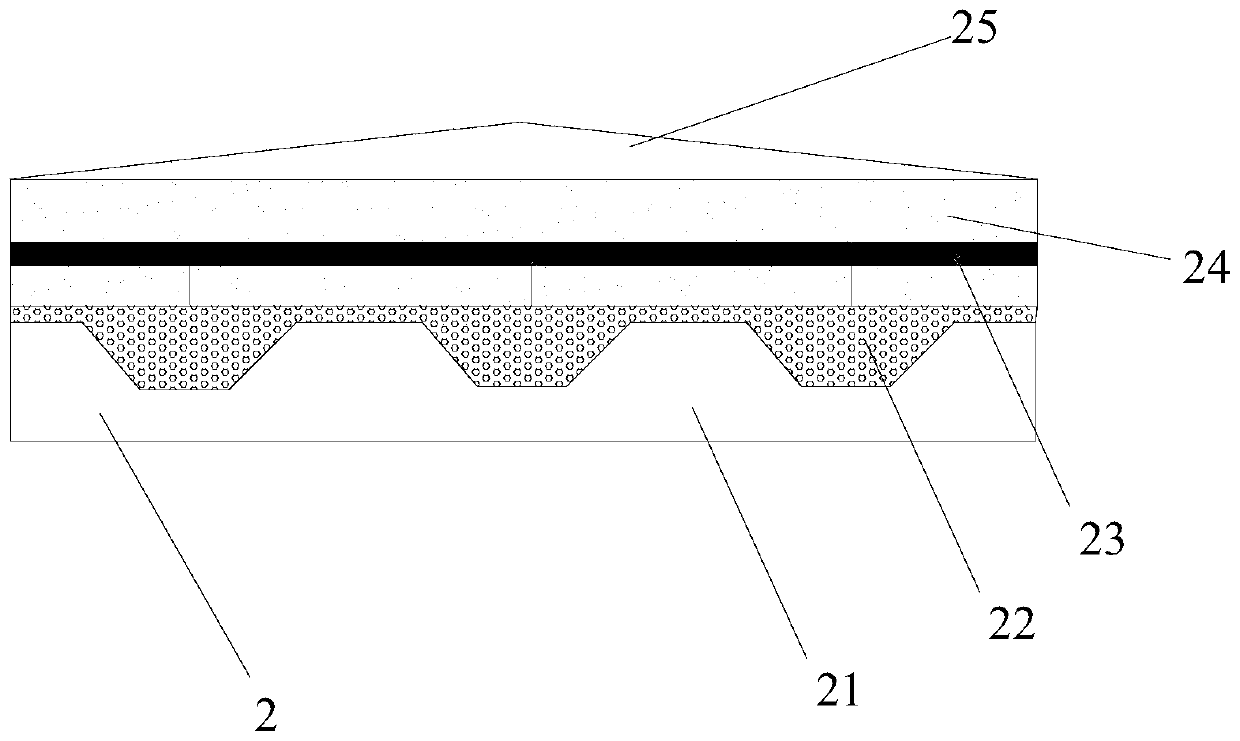

Heat preservation plate with reinforcing bars and heat preservation structure construction method of heat preservation plate with reinforcing bars on outer wall concrete part

PendingCN106759994AImprove fire performanceSame service lifeClimate change adaptationHeat proofingCrack resistanceConcrete beams

The invention discloses a heat preservation plate with reinforcing bars and a heat preservation structure construction method of the heat preservation plate with the reinforcing bars on the outer wall concrete part. The heat preservation plate with the reinforcing bars comprises a heat preservation plate body and reinforcement bar net pieces laid in the heat preservation plate; wherein nodes of the multiple reinforcement bar net pieces extend out of connection reinforcing bars. According to the heat preservation structure construction method of the heat preservation plate with the reinforcing bars on the outer wall concrete part, the outer wall concrete part comprises a concrete beam, a concrete shear wall, a construction outer wall balcony, the position of an outdoor air conditioner partition, the position of a bay window and the position of a parapet. During the construction process, the heat preservation plates with the reinforcing bars are connected in a groove and tongue mode, construction sealants are provided for assisting, and it is ensured that no water or slurry leaks in connection positions. According to the heat preservation plate with the reinforcing bars, self-strength, crack resistance and impact ductility of the heat preservation plate can be remarkably improved, and the heat preservation plate can bear certain vertical loads and horizontal loads besides bearing self gravity loads.

Owner:THE ARCHITECTURAL DESIGN & RES INST OF ZHEJIANG UNIV

Remote controller battery bin cloth strip mounting device and mounting method thereof

ActiveCN102610766AEasy to fixWon't break the bondCell component detailsSignsElectrical batteryElectrical and Electronics engineering

Owner:惠州市创荣发实业有限公司

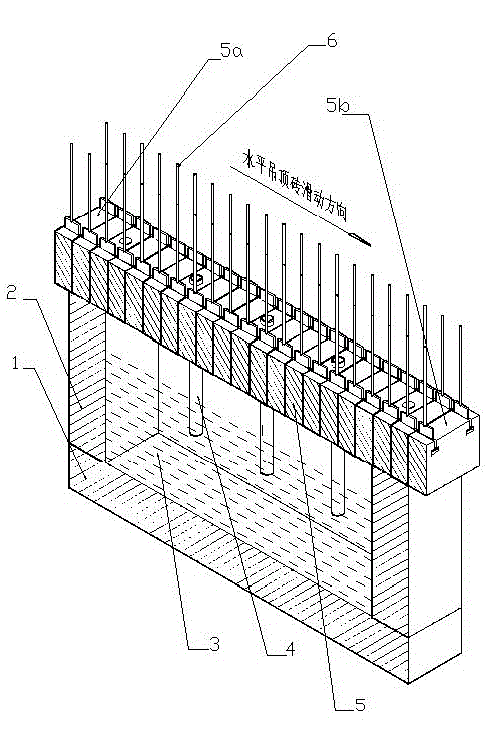

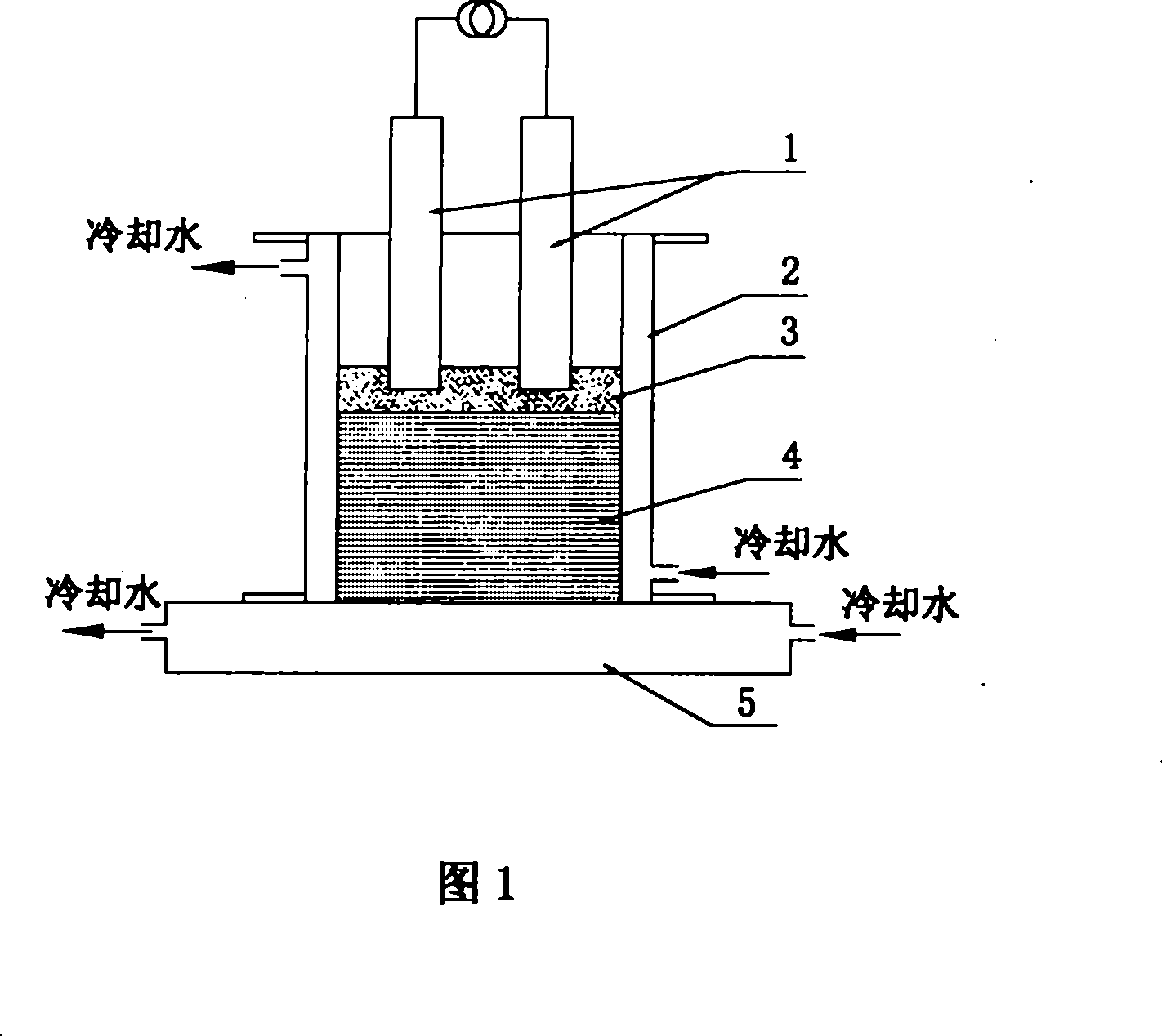

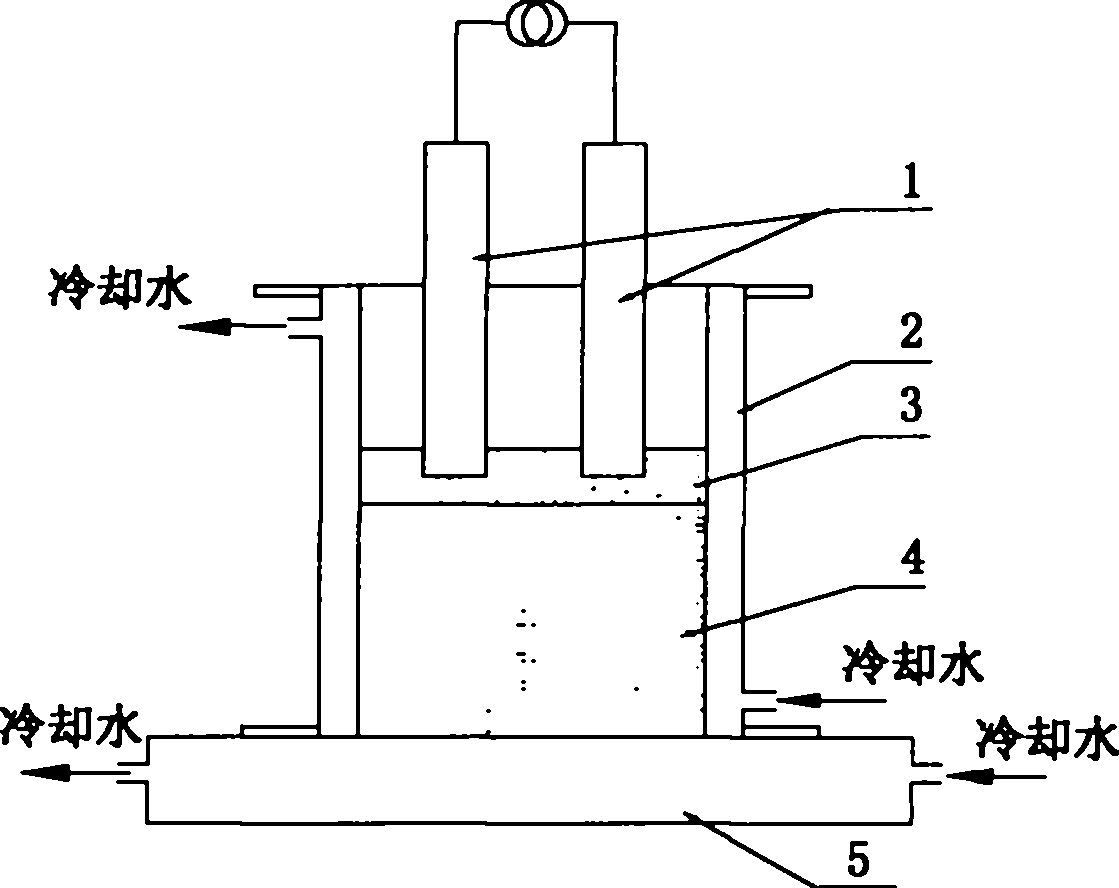

Novel method for melting glass liquid through immersion and combustion on glass liquid by jet pipe of combustor

The invention relates to a novel method for melting glass liquid through immersion and combustion on glass liquid by a jet pipe of a combustor. The method is characterized in that the jet pipe of the combustor is inserted into the glass liquid from an upper part of the glass liquid through a kiln crown, a breast wall or a pool wall, a gaseous fuel and a gas oxidizing agent are respectively injected into the glass liquid through the jet pipe of the combustor or mixed and then injected into the glass liquid, so that the gaseous fuel and the gas oxidizing agent are combusted in the glass liquid, the generated high-temperature gas stirs the glass liquid, and most heat is transferred to the glass liquid and a mixed batch. For preventing severe erosion of the bricks of the kiln crown and preventing usage life shortening, the kiln crown is designed as a continuously updated structure, the structure is characterized in that the bricks of the kiln crown are suspended by a hanging wheel for compositing a movable kiln horizontal suspended ceiling, the bricks are easily and horizontally moved with entire row on the kiln along a transverse direction; new supplementary bricks of the kiln crown are added in the horizontal suspended ceiling from one transverse side of the kiln crown and pushed to the other side, at the same time, the corroded old bricks are pushed from the other side and discharged; so that continuous update of the bricks of the kiln crown can be guaranteed.

Owner:徐林波

Patterning process for rotationally-molded product

InactiveCN102773954AImprove bindingThe joint is smooth and smoothCoatingsRotational moldingIndustrial engineering

The invention relates to the technical field of manufacture of plastic products, in particular to a patterning process for a rotationally-molded product. The process is based on a rotational molding process, and comprises the following steps of: attaching a layer of colored solvent to a part to be patterned according to the shape and size of a pattern in a mold, closing the mold, feeding raw materials for producing the rotationally-molded product, and patterning the rotationally-molded product by using the rotational molding process to integrate the colored solvent with the rotationally-molded product. The obtained pattern can be more firmly combined with the product, difficultly falls, and is fadeless, bright, durable, long in service life and attractive and elegant in appearance, and the combined part of the pattern and the product is flat and smooth; moreover, the patterning process is simpler, low in investment cost, in line with industrial production and utilization and favorable for industrial upgrading, and the production efficiency and the quality are greatly improved; and the patterning process is applied to the manufacture of multicolor and multiform patterns, the service life of the pattern is the same as that of the rotationally-molded product, and the pattern is high in cost performance.

Owner:东莞市启民环保科技有限公司

Single face baffle fixing support arranged on 150 DEG C overhead heat supply pipeline and used for preventing heat bridge from transferring heat

InactiveCN103104787AReduce the temperatureBlock heat lossThermal insulationPipe protection by thermal insulationEpoxyCalcium silicate

The invention discloses a single face baffle fixing support arranged on a 150 DEG C overhead heat supply pipeline and used for preventing a heat bridge from transferring heat. The problem that a heat bridge effect easily happens in an existing device is solved. A steel single face baffle (12) is placed on the outer side wall of a heat transferring steel pipe (1), a pre-buried steel plate (11) is placed on the top face of a pipeline support frame (16), an arc-shaped bracket (4) and an arc-shaped top face bracket (5) are fixed on the outer side face of the bottom arc-shape of the heat transferring steel pipe (1), the arc-shaped top face bracket (5) is placed on a pit of a high-strength heat insulation epoxy resin bracket (10), a calcium silicate hard heat insulation board (8) is placed between the pit bottom of the high-strength heat insulation epoxy resin bracket (10) and the outer bottom of the arc-shaped top face bracket (5), a high-strength heat insulation epoxy resin baffle (14) is placed on the side face of the pipeline support frame (16), and the steel single face baffle (12) is connected with the high-strength heat insulation epoxy resin baffle (14) in an abutted mode. The service life of the support is the same with the service life of the heat transferring steel pipe.

Owner:CEEC SHANXI ELECTRIC POWER EXPLORATION & DESIGN INST

A kind of solar heat collector with changing flow rate of heat collecting tube

ActiveCN105758009BHomogeneous mixingAvoid lostSolar heating energyHeat transfer optimizationEngineeringStreamflow

The invention provides a solar thermal collector. The solar thermal collector comprises two tube plate structures, wherein a certain included angle is formed between the two tube plate structures; the direction of the included angle is opposite to the bending direction of an arc structure of a reflecting mirror; the focus of the reflecting mirror is in the included angle formed by the tube plate structures; inner fins are arranged inside collector tubes, are connected with opposite angles of rectangles and divide the interiors of the collector tubes into a plurality of small channels; communication pores are formed in the inner fins; the flows of fluids in different collector tubes are larger and larger in the extension directions from the collection point of the two tube plate structures to the lowest positions at the two sides. The solar thermal collector has the advantages that the uniform mixedness of fluids is maintained, thus avoiding loss of heat during fluid mixing; the temperatures of the collector tubes are ensured to basically keep the same, thus prolonging the overall service lives of the collector tubes.

Owner:青岛酒店管理职业技术学院

A green building self-insulation structure system

The invention discloses an environment-friendly building self-heat-insulation structure system and belongs to the technical field of building heat-insulation structures. The environment-friendly building self-heat-insulation structure system comprises a self-heat-insulation wall body and a self-heat-insulation floor slab. The self-heat-insulation wall body comprises a reinforced concrete bearing wall, porous foaming concrete building blocks, a first foaming polyurethane plate, heat-resistant mortar layers and elastic columns; the porous foaming concrete building blocks are arranged in first cavities, and the elastic columns are arranged in second cavities; the first foaming polyurethane plate is connected with the porous foaming concrete building blocks, and the first foaming polyurethaneplate and the porous foaming concrete building blocks are both provided with the heat-resistant mortar layers; and the self-heat-insulation floor slab comprises a compression steel plate, a second foaming polyurethane plate, a steel wire net plate, foam concrete and a heat-resistant mortar slope surface layer, and the bottom face of the compression steel plate is connected with the reinforced concrete bearing wall through reinforcements. According to the self-heat-insulation structure system, heat insulation, sound insulation and seismic resistance are integrated, the sources of raw materialsare wide, environmental friendliness is achieved, and heat insulation and safe using performance are both achieved.

Owner:白香鸽

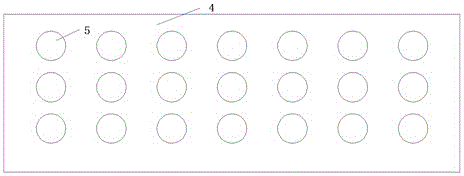

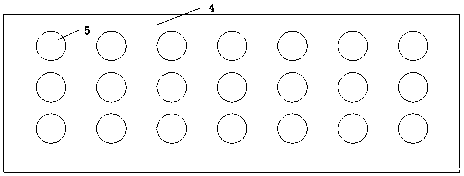

Novel ash cleaning apparatus

InactiveCN106853306ALarge filter areaImprove cleanlinessDispersed particle filtrationEngineeringElectrical and Electronics engineering

The invention relates to a new type of dust cleaning device, which is provided with a moving trolley, an air blowing box is arranged on the moving trolley, a reverse blower is arranged on the top of the blowing air box, and a pipe opening is arranged at the bottom of the blowing air box. The reverse blower is airtightly communicated with the pipe opening through a ventilation pipe, and a blower pulse valve is arranged on the ventilation pipe. The control part of the invention is simple and reliable, the injection positioning is accurate, and the injection time and injection interval period should meet the requirements of different working conditions.

Owner:青岛纵横农业科技有限公司

Compound sealing structure with backup function for rotary main shaft of industrial washing machine

InactiveCN101634098BExtended service lifeSame service lifeEngine sealsOther washing machinesCore componentEngineering

The invention relates to a compound sealing structure with a backup function for a rotary main shaft of an industrial washing machine. The structure of a sealing body, the structure of a framework oil seal press plate and the structure of a shaft housing in the prior art are changed; original three lip framework oil seal are reduced to one; two V-shaped sealing rings and two backup V-shaped sealing rings are provided; and the O-shaped ring seal is applied between the sealing body and a back plate of an outer cylinder body of a washing room and between a shaft housing and a rotary main shaft. The structure has the advantages of greatly improving the service life of the sealing structure, realizing the designed service life of the whole machine, not causing any harmful wear to the core component of the machine-main shaft, avoiding the influence of micro radial run-out of the main shat on the sealing structure when the industrial washing machine works, and greatly simplifying huge workload needed for the maintenance and the replacement of the sealing structure, and prolonging the service life of the whole machine.

Owner:上海雅森洗涤设备有限公司

Energy-saving insulating brick

InactiveCN100542991CExcellent heat absorption and heat preservation effectImprove insulation effectSolid waste managementFiberBrick

The invention relates to an energy-saving thermal insulation brick, which solves the technical problems of cumbersome construction, long construction period and high cost of existing building wall energy-saving thermal insulation measures. In the present invention, the raw materials are mixed, stirred, extruded, and maintained. The weight ratio of the raw materials is: 230-320 parts of Portland cement, 35-20 parts of expanded perlite, 430-610 parts of ordinary sand, and 70-15 parts of cinder. 6-3 parts of straw, 4-2 parts of plant ash, 1.6-2 parts of wool felt fiber, and 97-135 parts of water. The invention has good energy-saving heat preservation performance and compressive strength.

Owner:江苏康顺鼎上节能保温科技股份有限公司

Manufacture method of steel ingot for million multikilowatt nuclear electricity pile core component

The invention discloses a method for manufacturing a steel ingot used for million-kilowatt nuclear power reactor core structural component, austenitic stainless steel ingot that weighs over 25 tons is manufactured by electroslag remelting process: firstly, preparation: a single-phase bipolar series connected or triphase bipolar series connected electroslag remelting furnace is adopted; a copper wall water-cooling crystallizer and a water-cooled base plate are adopted; a consumable electrode is assembled; slag charge is matched; SiGa and Al powder are adopted for deoxidation; secondly, refinement and fusion casting: a graphite electrode is picked up and replaced by the consumable electrode to remelt the fully melted slag charge after slagging and slugging. When the actual weight of the steel ingot is 2 tons less than the preset weight, the electric power is reduced and feeding operation in telophase is carried out; thirdly, the steel ingot is stripped. The steel ingot manufactured by the invention has extremely high purity, extremely fine uniformity, excellent high temperature resistance and tarnish resistance, as well as strong anti neutron radiation embrittlement sensibility.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD +1

Production method of regenerating metal alloy from imperfect fine powder using nickel aluminium alloy catalyst

InactiveCN1295361CSolve the reuse problemSolve resource problemsProcess efficiency improvementVacuum pumpingSlag

The invention relates to an alummel catalyst deficient fine powder recreating metal alloy manufacturing method. It solves the problems of polluting environment, unstable product quality, reducing catalyzing life by electro-slag furnace re-melting process. Its manufacturing method includes the following steps: using 70MPa-90MPa pressure to make the alummel deficient fine powder form; putting the formed fine powder block to sintering furnace; starting vacuum system; heating the block for 1-3 hours; heating up 50-150 centigrade degree; vacuum degree is 0.1Pa-1Pa; stopping vacuum pumping; inputting argon gas as protection gas; furnace pressure is 0.2MPa-0.6MPa; heating the block for 3-12 hours; heating up 500-700 centigrade degree; heating up 800-1200 centigrade degree after 10-15 hours; stopping heating and keeping the temperature for 10-14 hours; then stopping inputting argon; naturally cooling to room temperature to draw a charge. Then the alummel is gained.

Owner:锦州市催化剂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com