Novel ash cleaning apparatus

A ash cleaning device and a new type of technology, which are used in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, etc., can solve the problems of insufficient cleaning strength, reduce the service life of the dust collector, and accelerate the clogging of the filter bag. The time and injection interval are satisfied, the control part is simple and reliable, and the effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

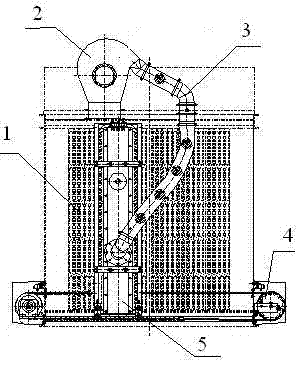

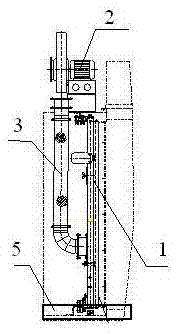

[0018] refer to figure 1 with figure 2 As shown, the present invention is provided with mobile trolley 5, and described mobile trolley 5 is provided with trolley steering mechanism 4, is provided with blowing gas box 1 on described mobile trolley 5, is provided with anti The blower 2 is provided with a pipeline opening at the bottom of the blowing air box 1, and the reverse blower 2 is airtightly communicated with the pipeline opening through a ventilation pipeline, and a fan pulse valve 3 is arranged on the ventilation pipeline.

[0019] The working principle is as follows: the function of the present invention is to remove the dust layer formed on the filter bag inside the dust collector. After the dust-containing gas is evenly distributed through the airflow of the intake hood, it passes through the dust collector from top to bottom, and enters the clean air after being filtered by the flat bag. During this process, the dust is intercepted by the filter bag and forms a du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com