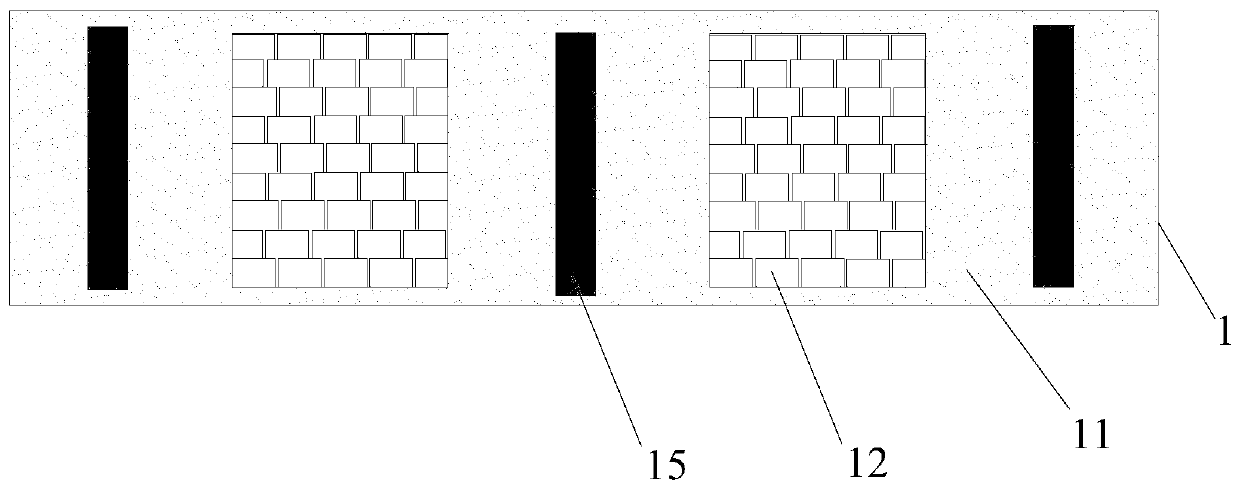

A green building self-insulation structure system

A green building, self-insulation technology, applied in building components, building structure, insulation and other directions, can solve the problems of poor insulation performance and short service life, and achieve the effects of improving safety, reducing self-weight and reducing load-bearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

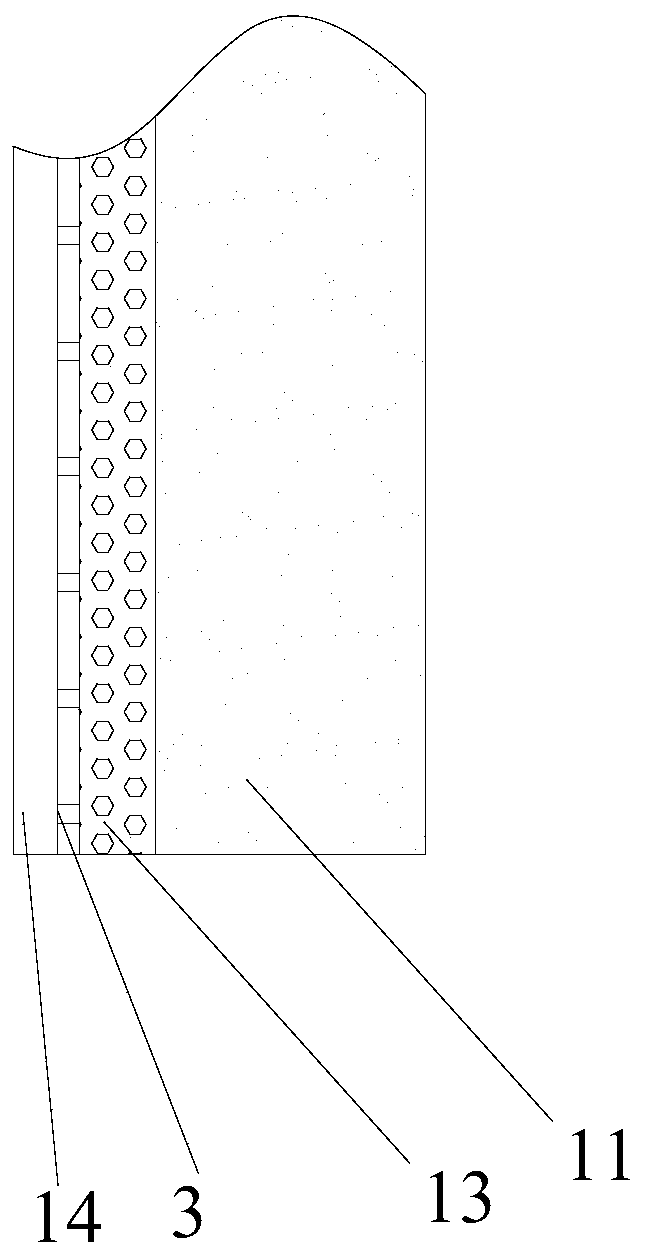

[0023] The raw materials for preparing the heat-resistant mortar layer include the following components in parts by weight: 35 parts of glass sand, 21 parts of ceramic particles, 15 parts of adhesive, 55 parts of cement, 20 parts of sand and 60 parts of water. Glass sand is obtained by crushing and rolling waste glass, and ceramic particles are obtained by crushing and rolling waste ceramic materials. According to the ratio of each raw material, the components are mixed and stirred evenly to obtain a heat-resistant mortar.

Embodiment 2

[0025] The raw materials for preparing the heat-resistant mortar layer include the following components in parts by weight: 76 parts of glass sand, 58 parts of ceramic particles, 20 parts of adhesive, 80 parts of cement, 27 parts of sand and 70 parts of water.

Embodiment 3

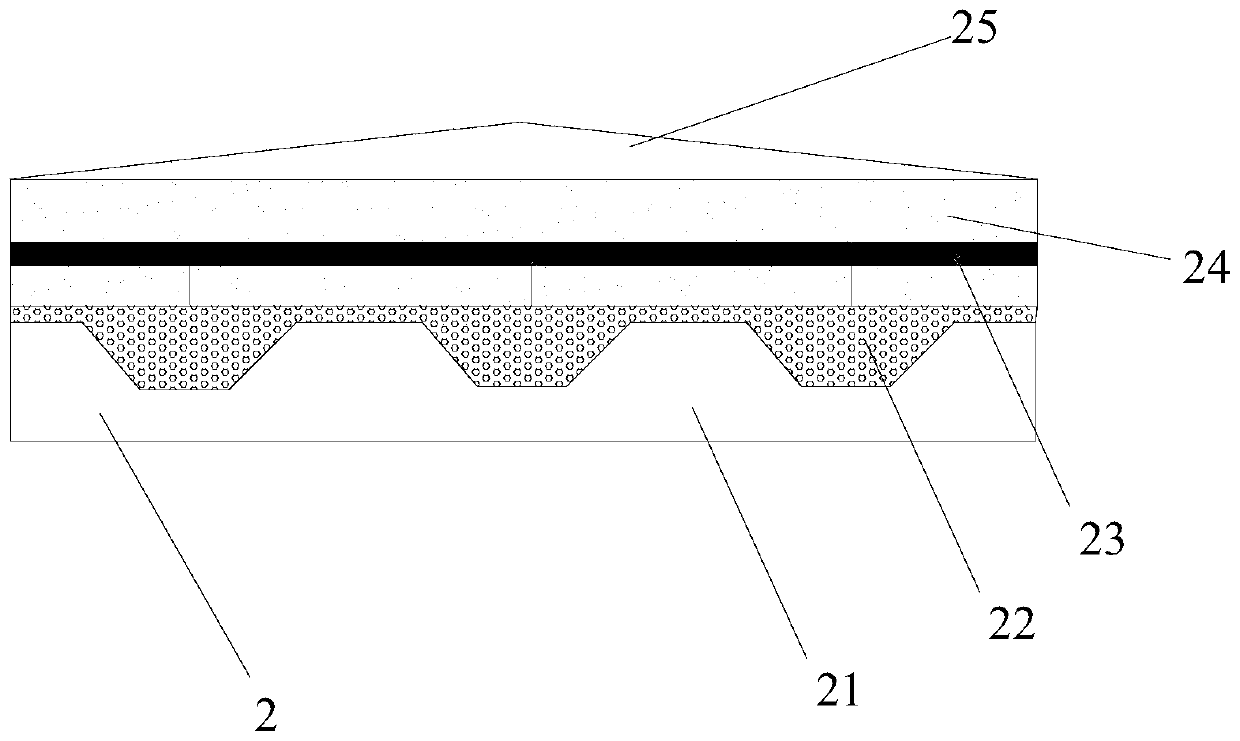

[0027] The raw materials for preparing the fiber layer include the following components in parts by weight: 30 parts of waste fiber, 45 parts of waste asbestos, 20 parts of rubber particles and 12 parts of binder. Mix evenly and apply on the inner side of the polyurethane foam board 13.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com