Semi-automatic corrugated beam guardrail plate mounting machine and working method thereof

A wave beam guardrail, panel installation machine technology, applied in road safety devices, roads, buildings, etc., can solve the troublesome problems of guardrail panels, and achieve the effect of easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

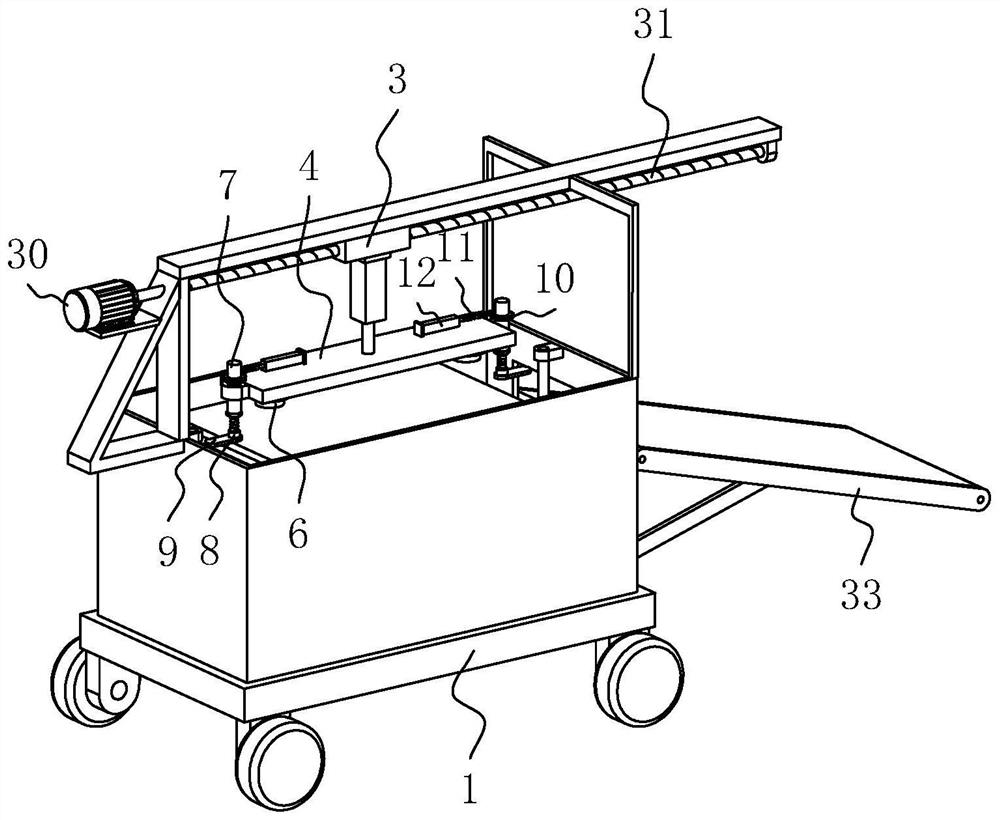

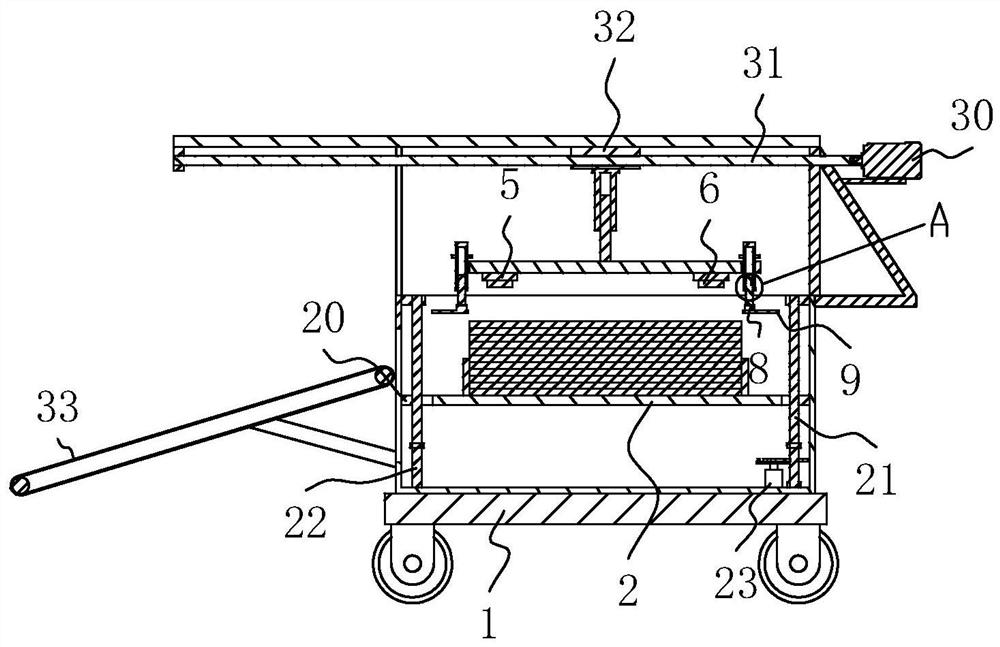

[0042] The embodiment of the present application discloses a semi-automatic corrugated beam guardrail board installation machine and its working method. refer to figure 1 A semi-automatic corrugated beam guardrail panel installation machine and its working method include a delivery vehicle 1, a storage mechanism installed in the delivery vehicle 1, and a transmission mechanism for transmitting the guardrail panel. The transmission mechanism is also located in the delivery vehicle 1, and the transmission mechanism adopts The conveyor belt 33 connected with the delivery car 1 transmission, the conveyor belt 33 is inclined, and the conveyor belt 33 is driven by the driving roller and the driven roller that are connected to the delivery vehicle 1 in rotation. After the guardrail is transported to the conveyor belt 33, the conveyor belt 33 will The guardrail is transported to the location to be processed.

[0043] refer to figure 1 and figure 2 , the storage mechanism includes ...

Embodiment 2

[0057] The embodiment of the present application discloses a working method of a semi-automatic wave beam guardrail installation machine. refer to figure 1 A working method of a semi-automatic corrugated beam guardrail panel installation machine comprises the following steps,

[0058] S1, preparatory work, pile up guardrail plate on storage board 2 in sequence;

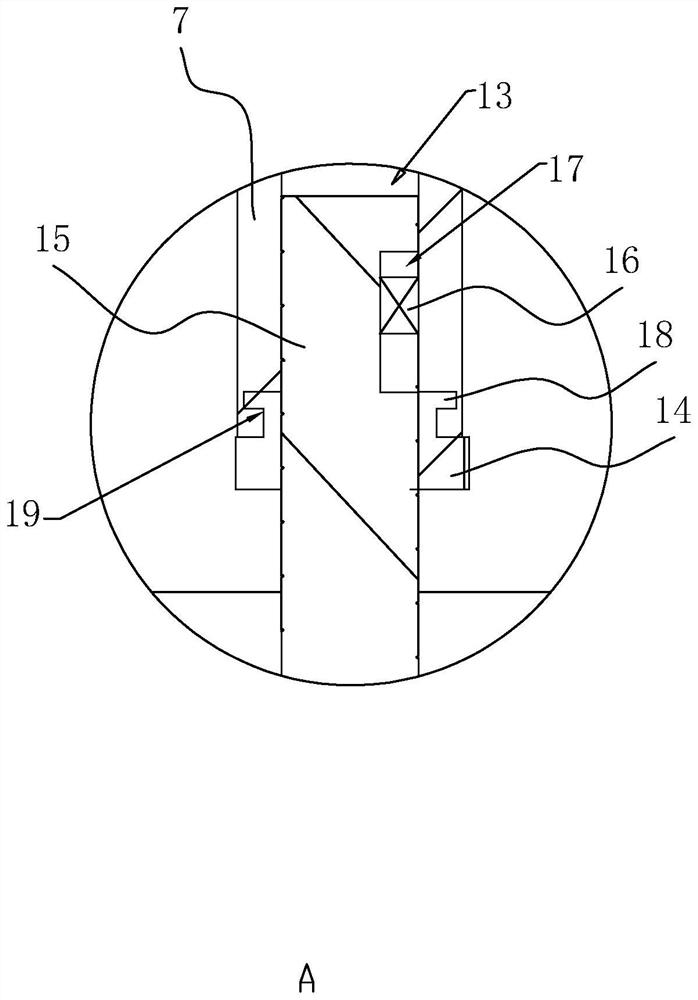

[0059]S2. Adjust the position of the support block 9, drive the nut 14 to rotate, and the screw rod 15 moves together. Under the action of the relative movement between the limit block 16 and the limit groove 17, the screw rod 15 drives the lifting rod 8 to slide in the rotation rod 7 Movement in the hole 13, and then realize the adjustment effect to the position of the support block 9, the distance between the bottom surface of the control electromagnet 6 and the top surface of the support block 9 is equal to the thickness of the guardrail plate;

[0060] S3, the electromagnet 6 is adsorbed, the first oil cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com