Patents

Literature

67results about How to "Ensure support stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Excavation method for tunnel passing through high-angle thrust water-rich and sand-rich fault

ActiveCN109209398ASimple structureReasonable designUnderground chambersTunnel liningHigh angleStep method

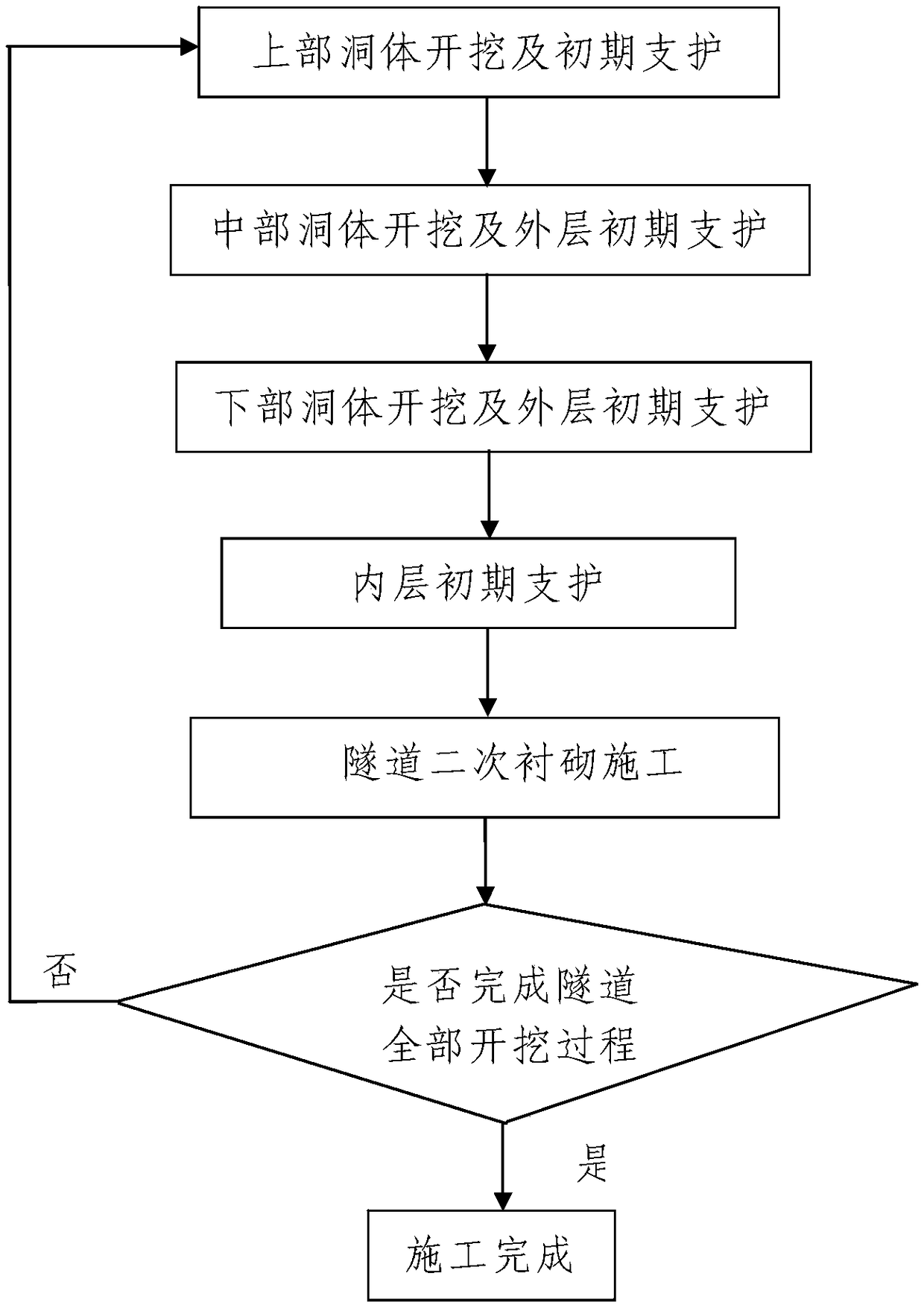

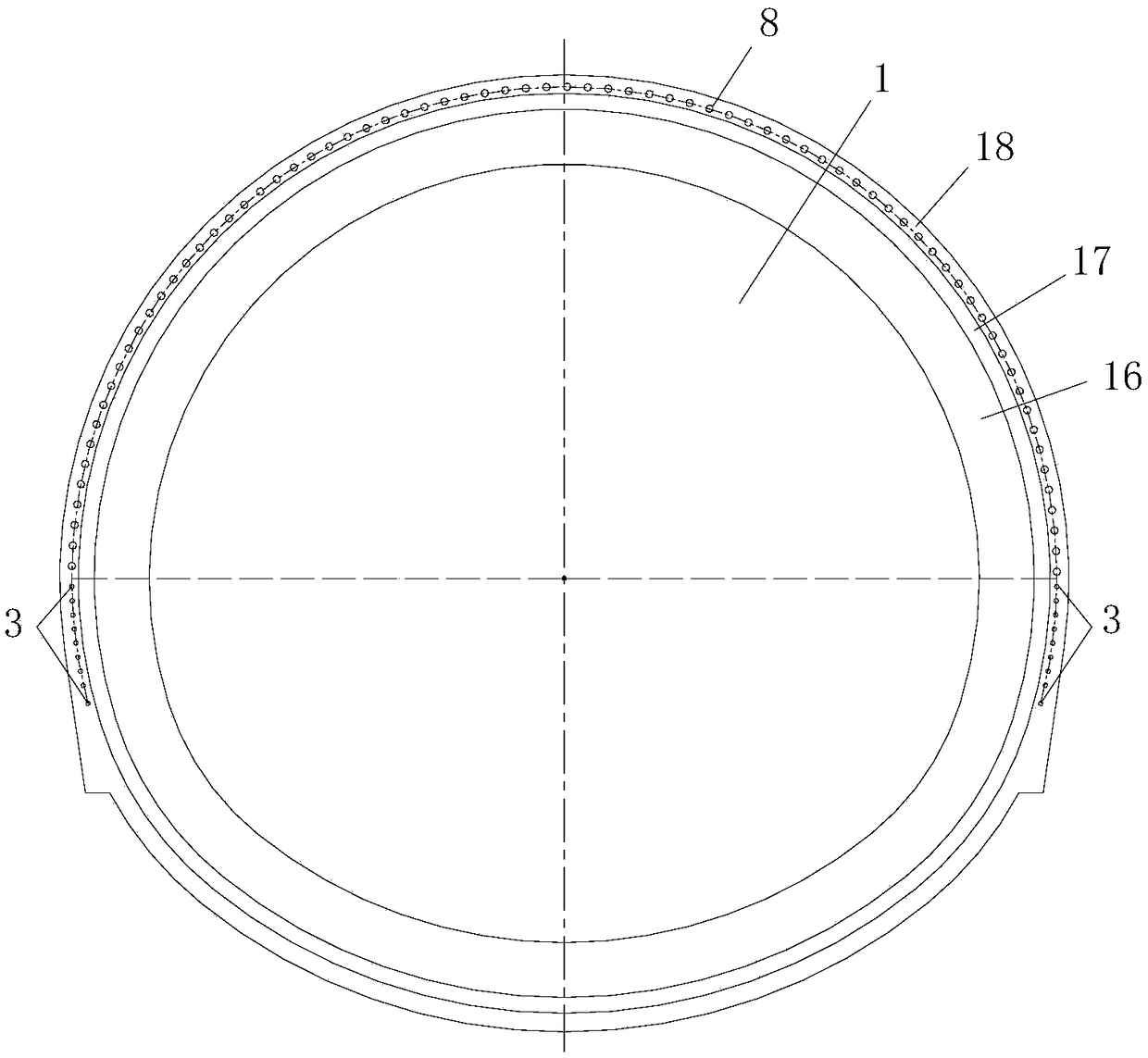

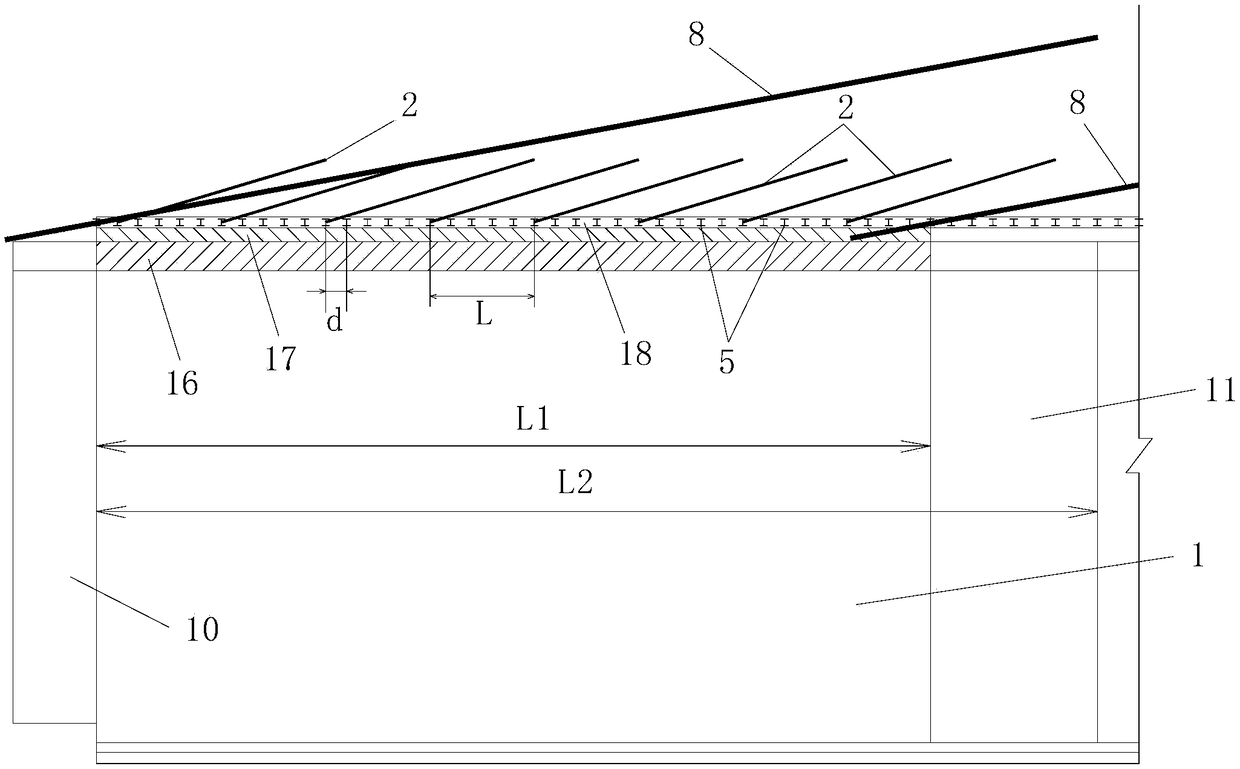

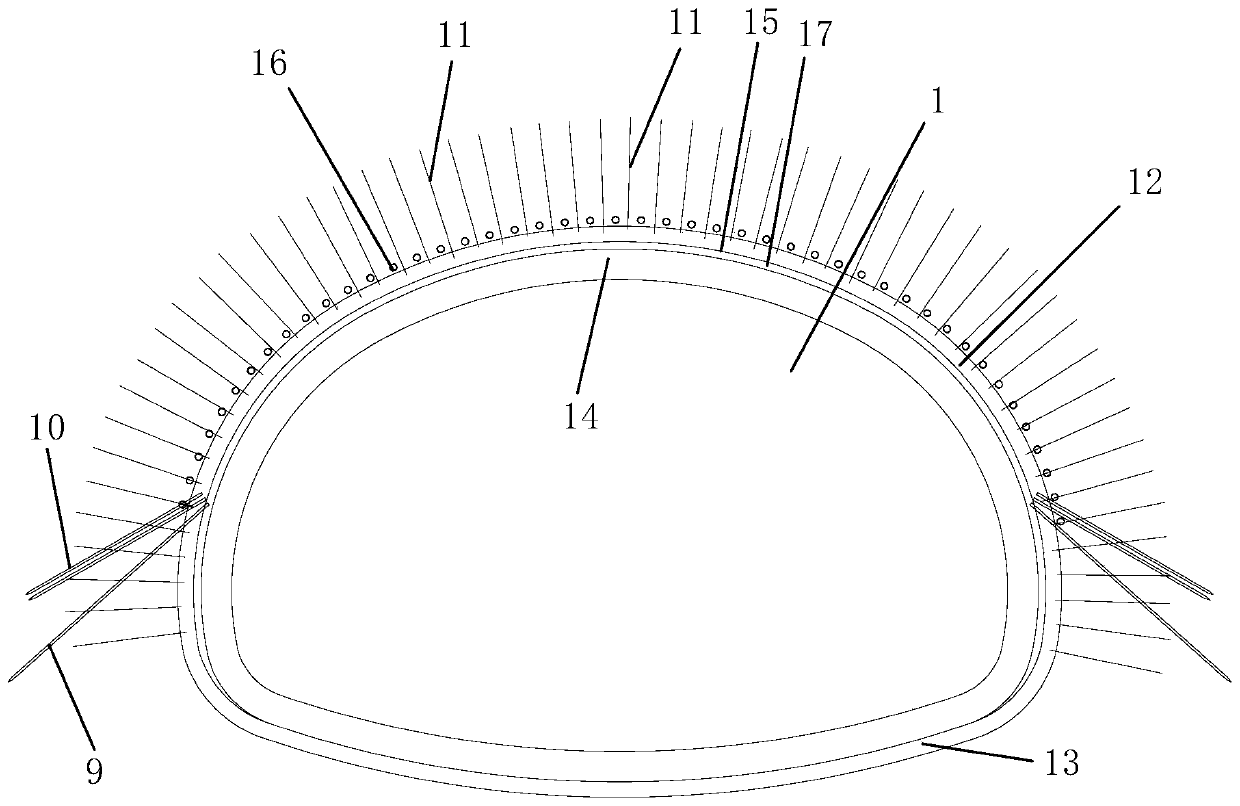

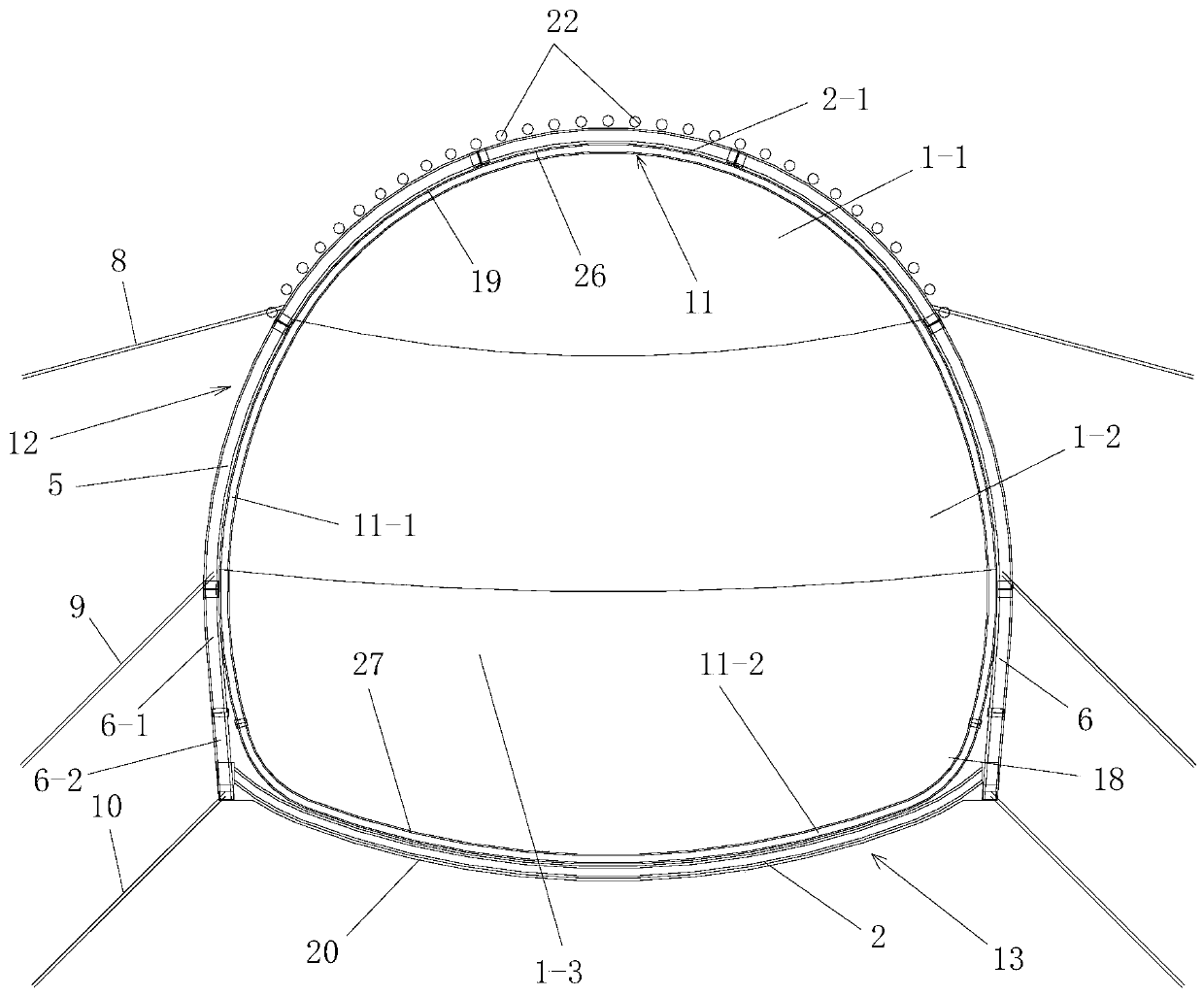

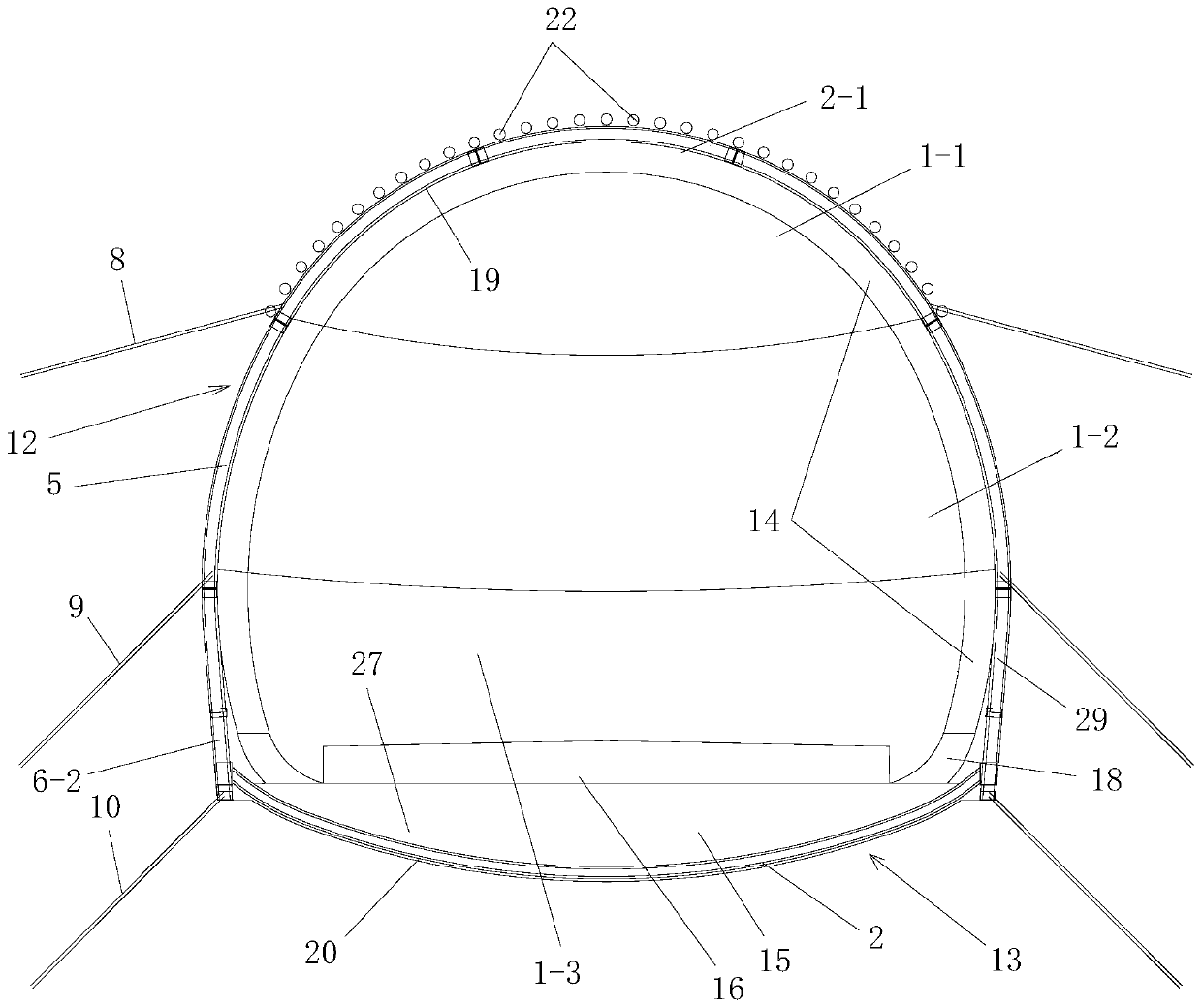

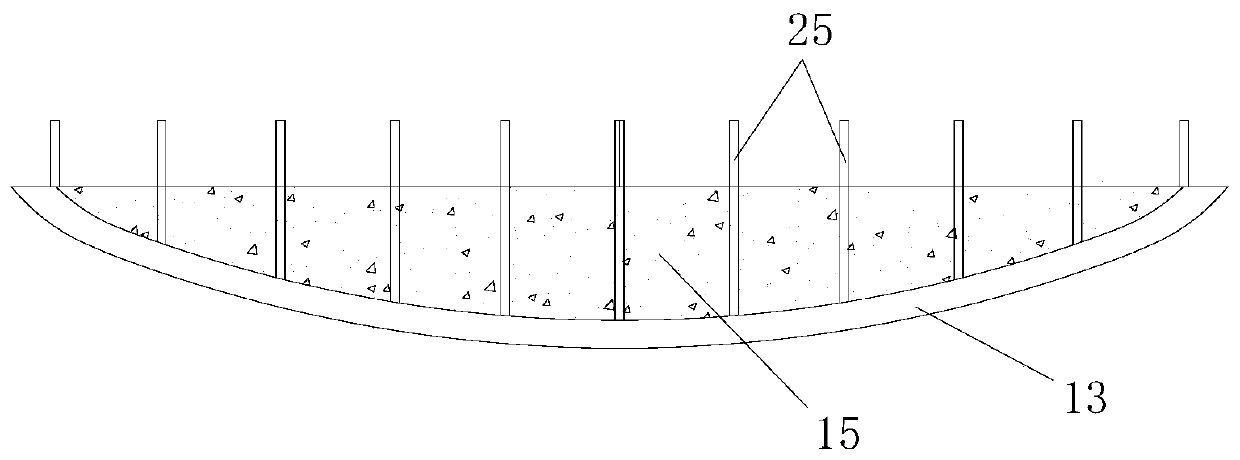

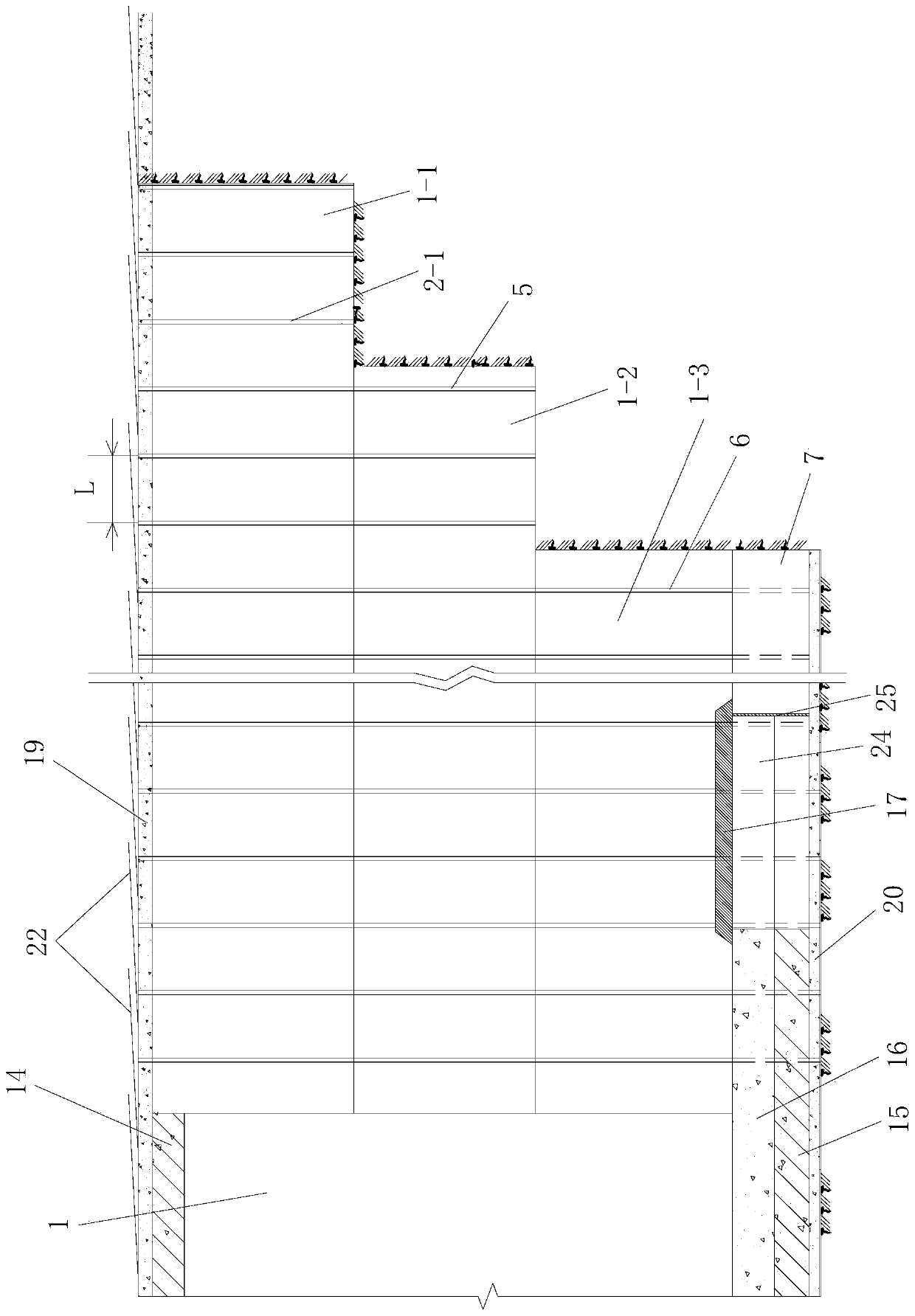

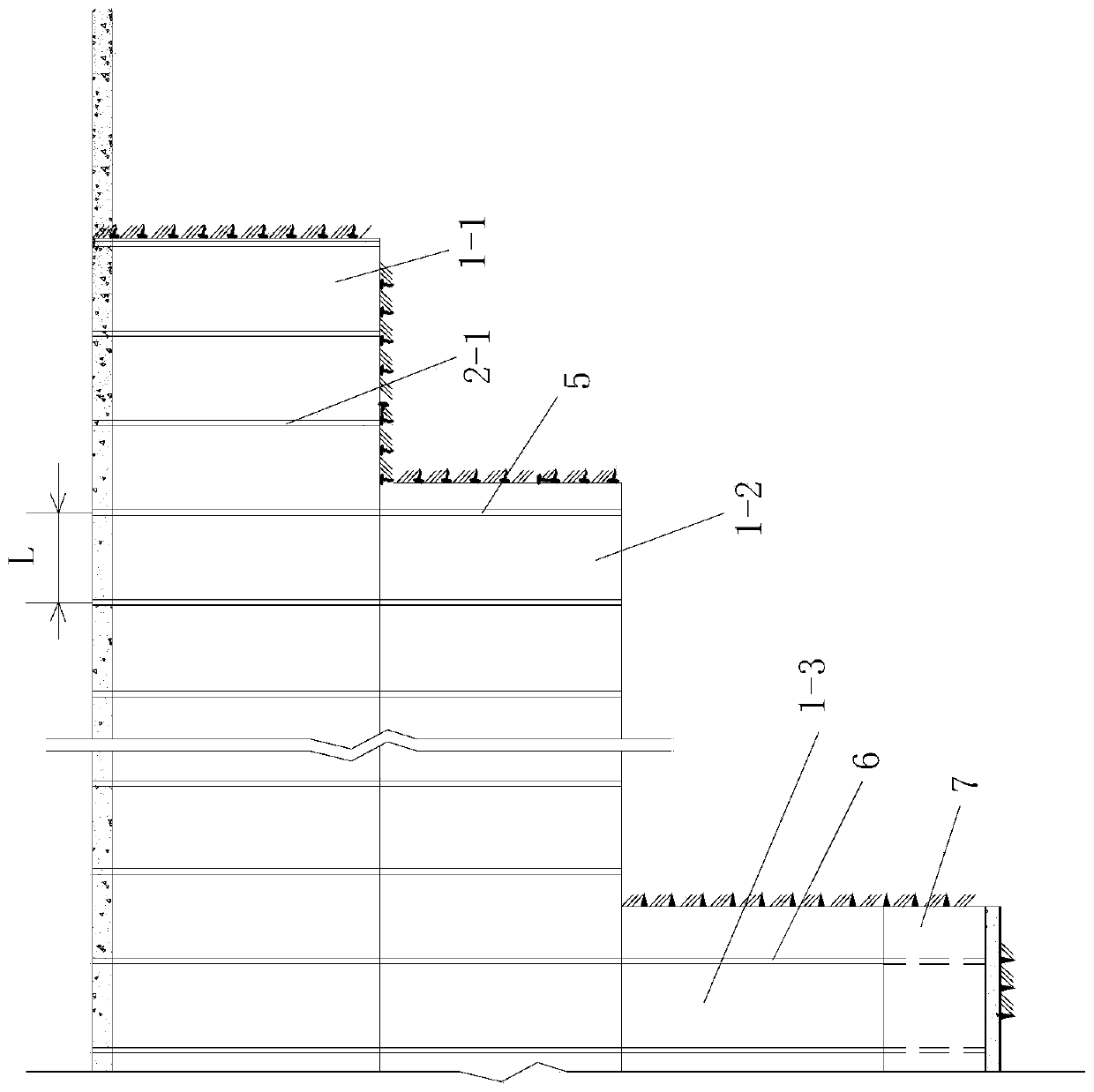

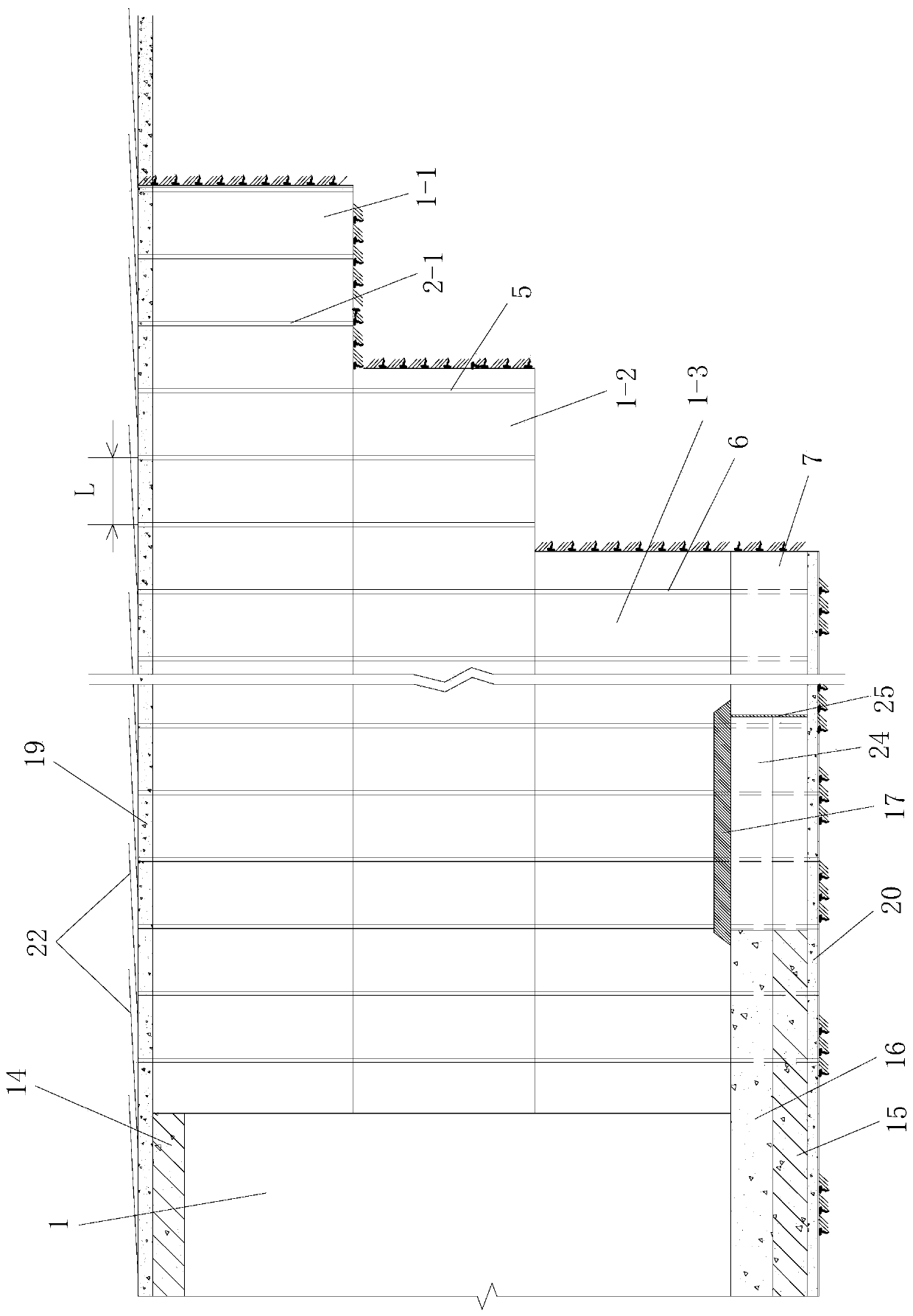

The invention discloses an excavation method for a tunnel passing through a high-angle thrust water-rich and sand-rich fault. A construction tunnel hole is divided from the top to the bottom into an upper hole body, a central hole body, and a lower hole body, wherein the upper hole body is divided into a left guide hole and a right guide hole. A primary support structure of the tunnel hole is a double-layer primary support structure. During the excavation of the construction tunnel, the construction tunnel is divided into a plurality of tunnel segments from the back to the front for excavation. During the excavation of any one tunnel segment, the method comprises the steps: 1, performing the excavation of the upper hole body and the primary supporting; 2, performing the excavation of the central hole body and the primary supporting of an outer layer; 3, performing the excavation of the lower hole body and the primary supporting of the outer layer; 4, performing the primary supporting of an inner layer; 5, repeatedly performing the steps 1-4 for many times, and completing the excavation of the tunnel. The method is simple in step, is reasonable in design, is convenient for construction, is good in use effect, employs a three-step method for the excavation of the tunnel hole, employs double primary support structure for the full-section support of the tunnel hole after excavation, and can guarantee the safety of the tunnel structure later.

Owner:CHINA RAILWAY 20 BUREAU GRP

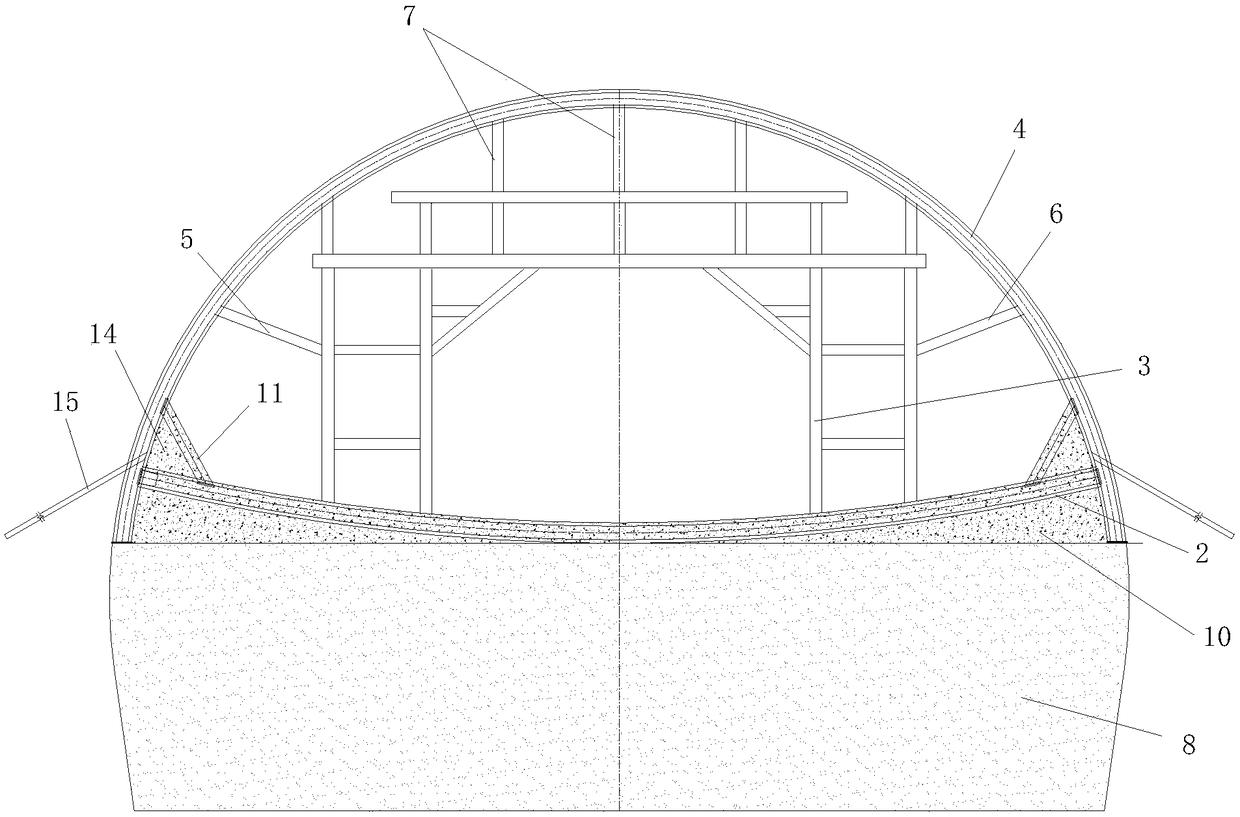

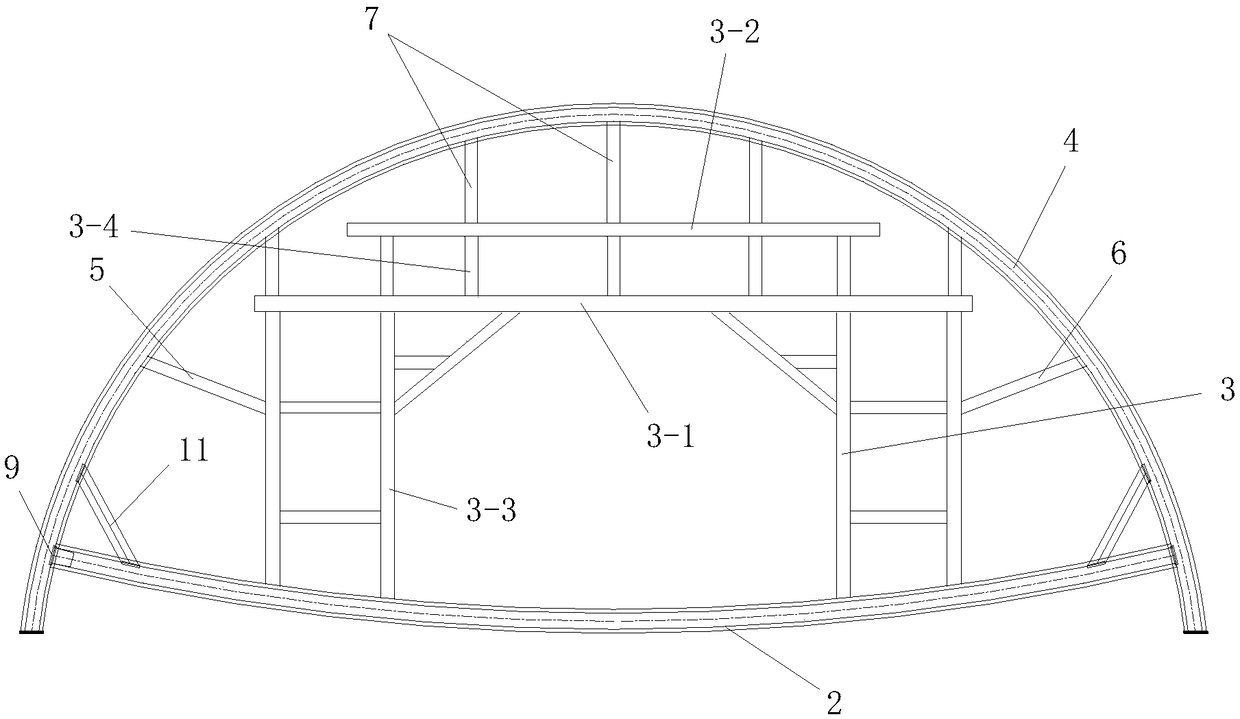

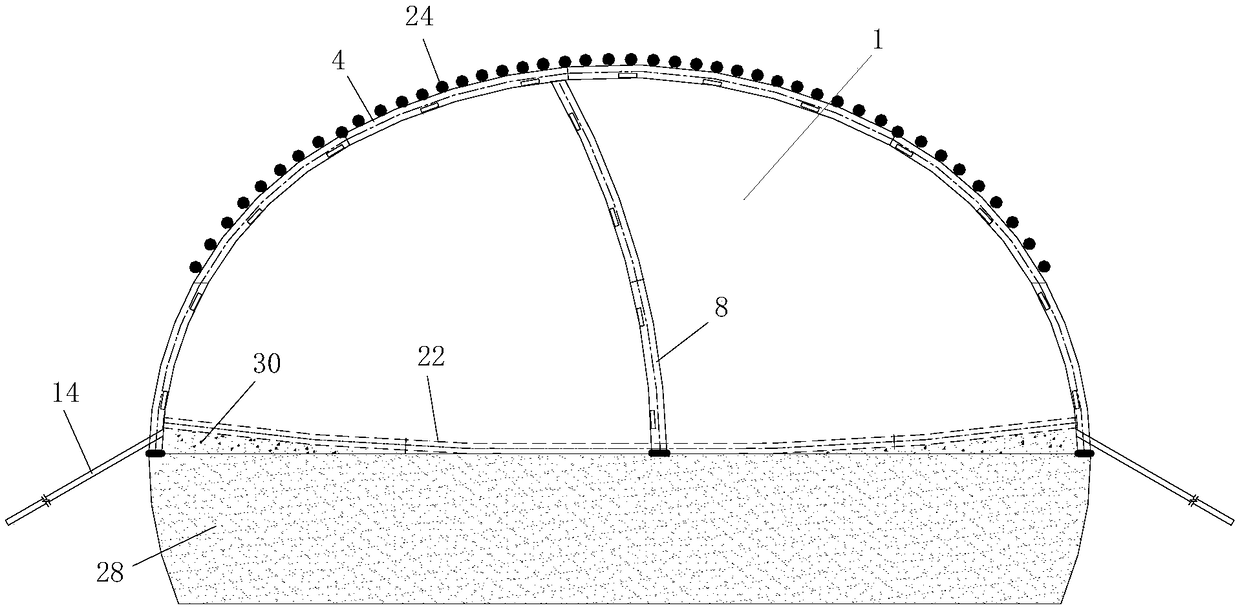

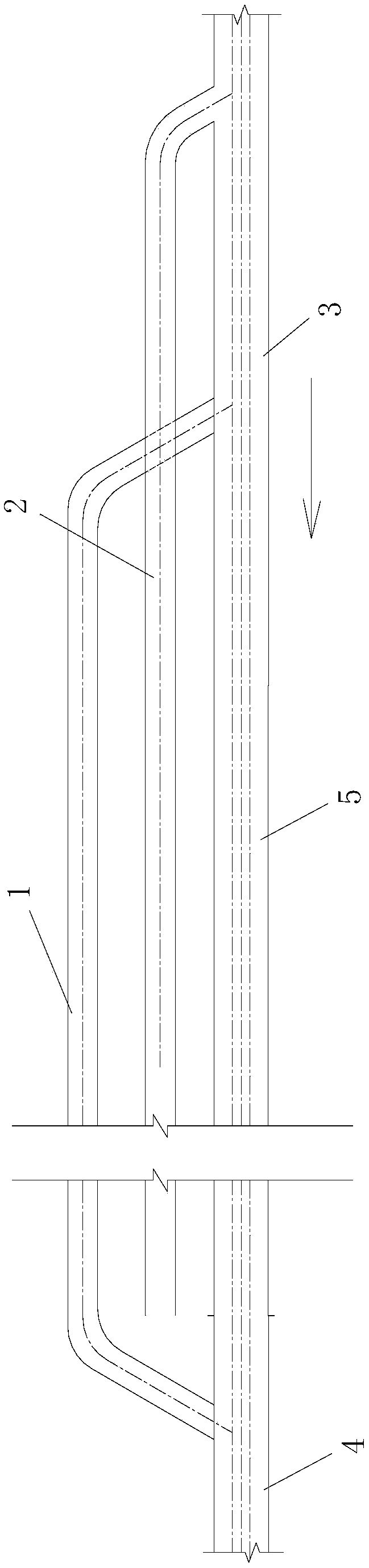

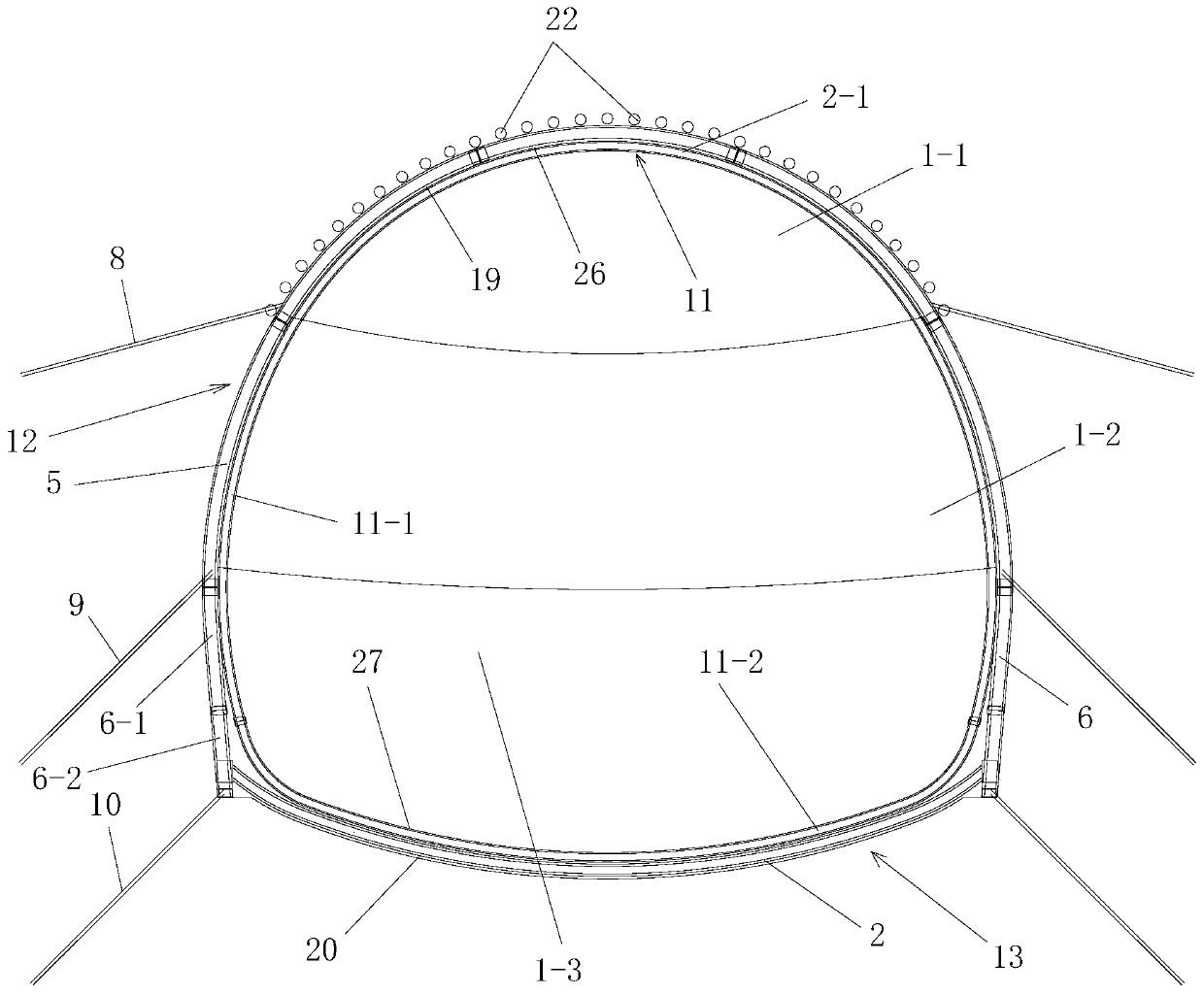

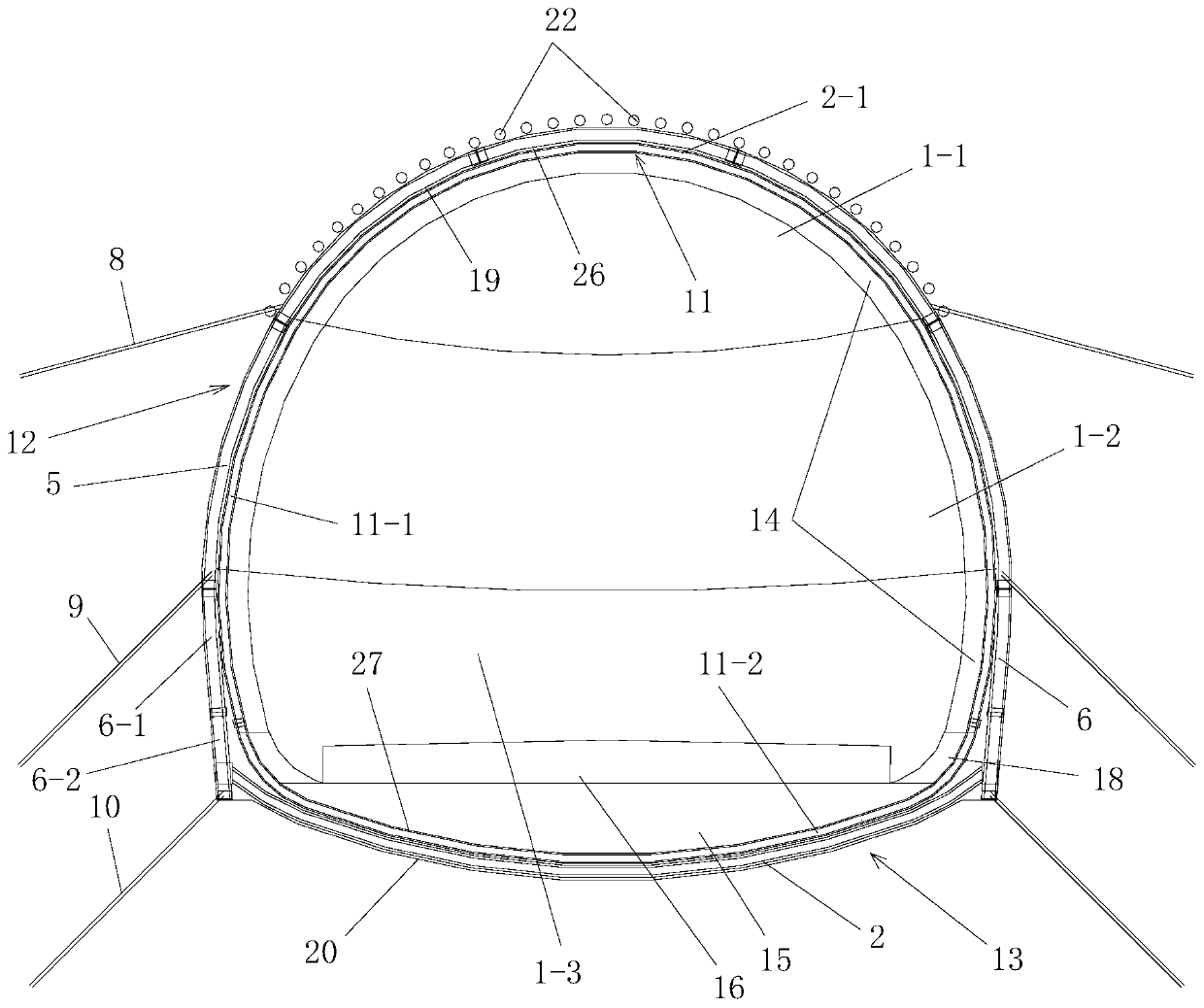

Excavation and support method of large cross-section tunnel through fault fracture zone

ActiveCN108843332AThe method steps are simpleReasonable designUnderground chambersTunnel liningSupporting systemFracture zone

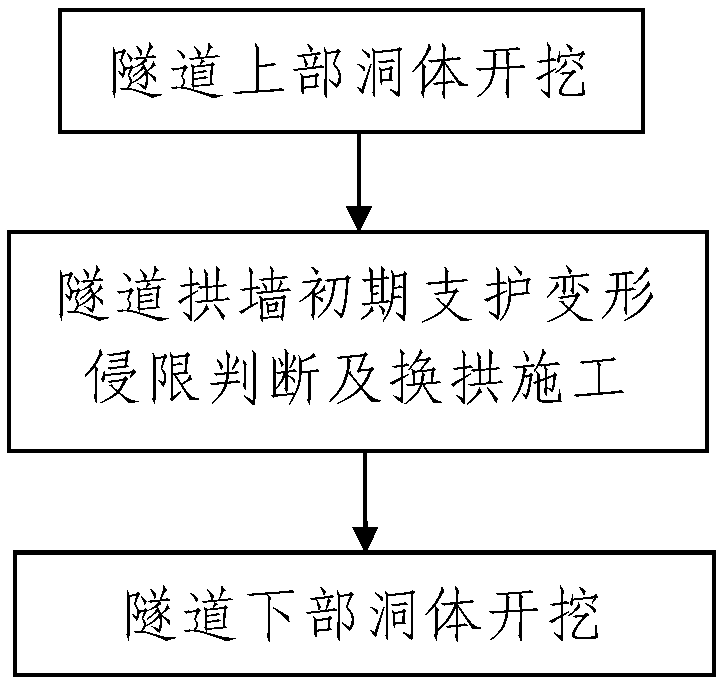

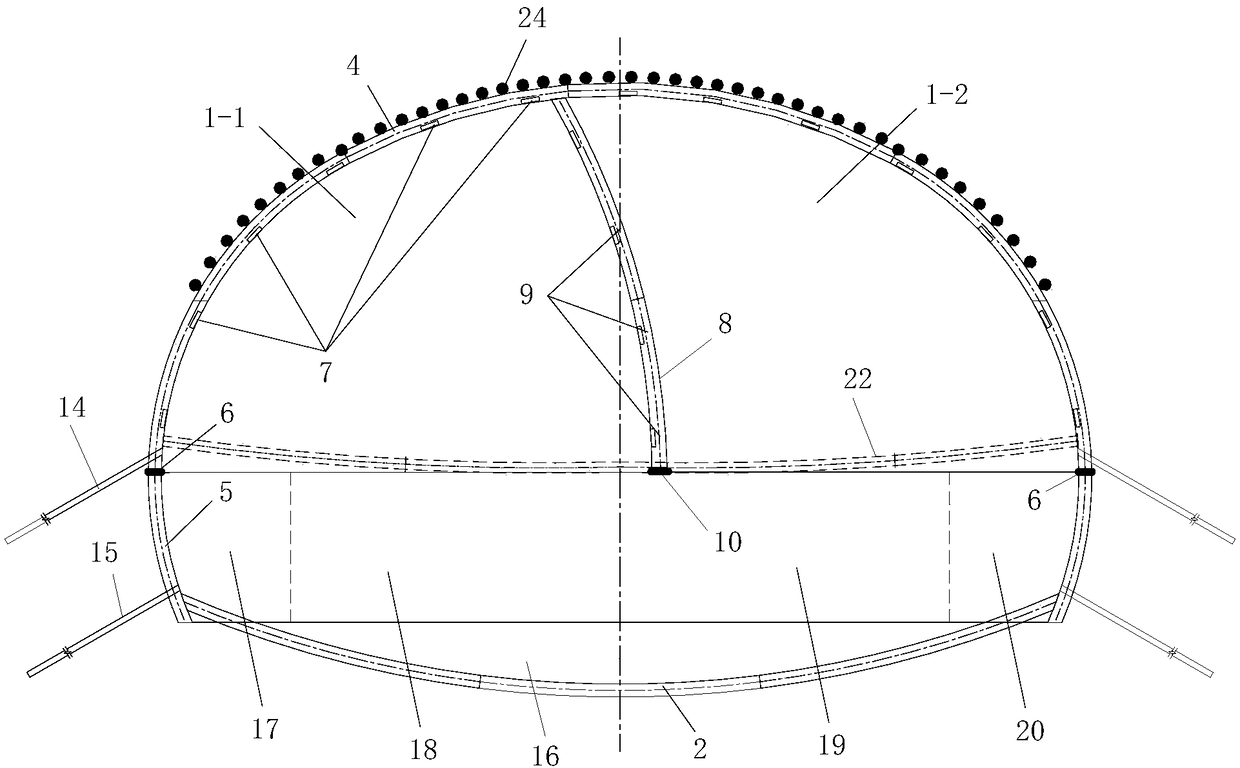

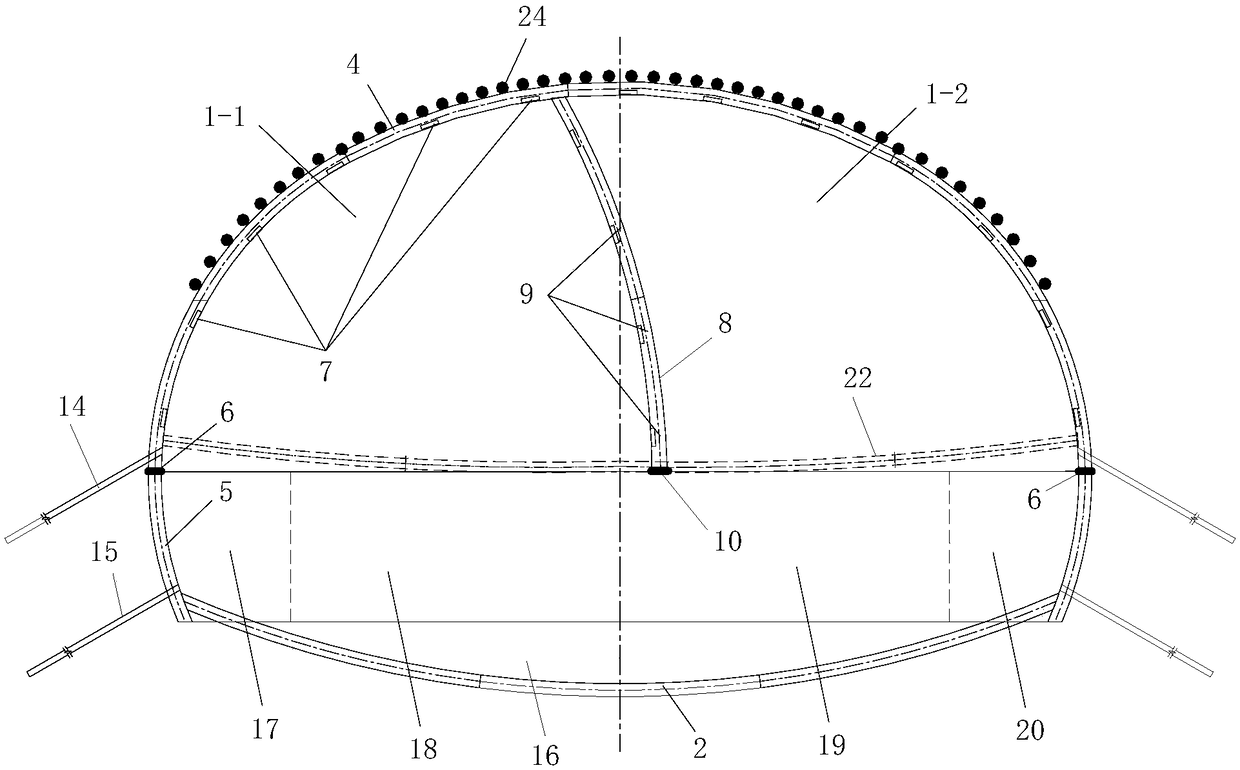

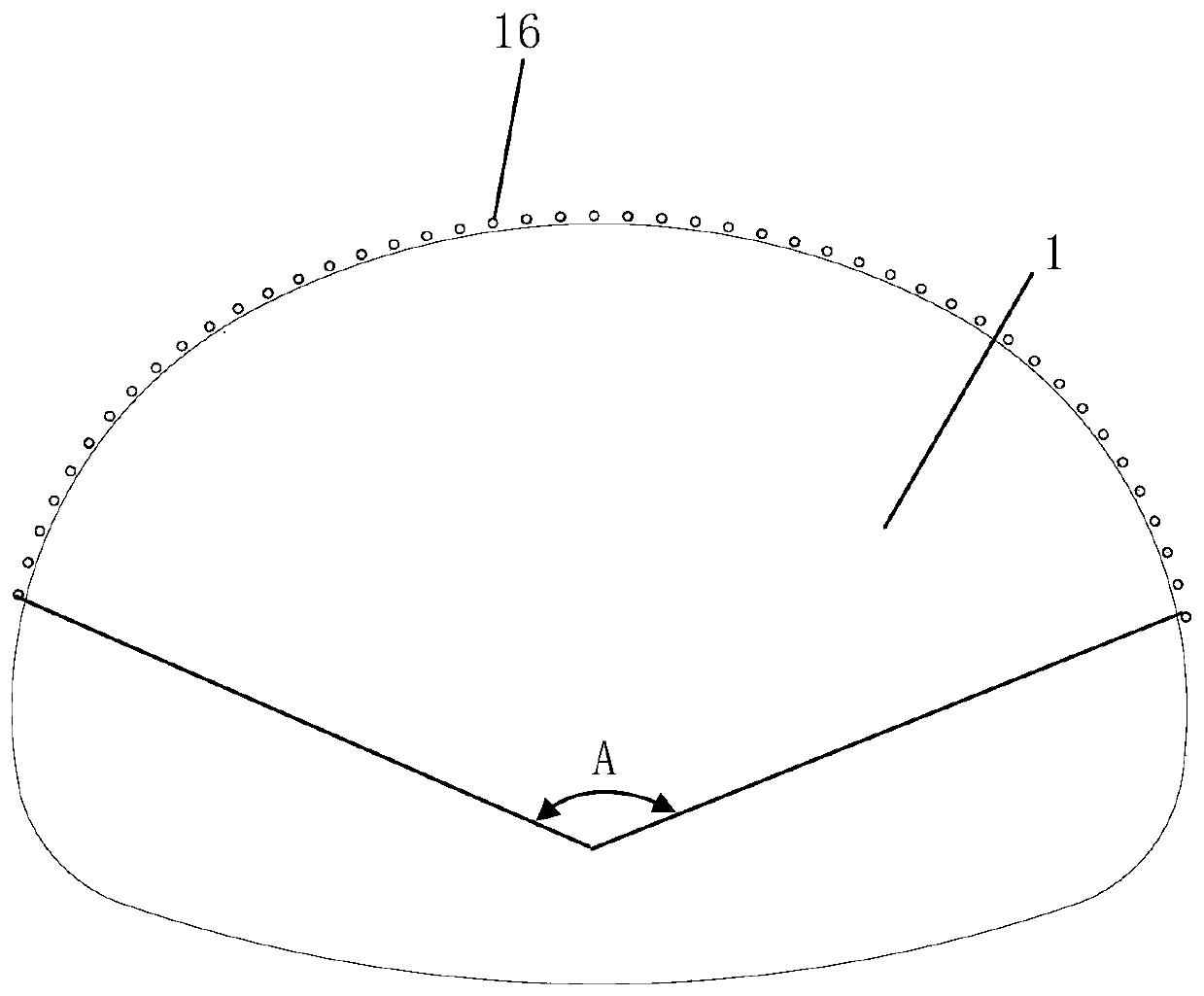

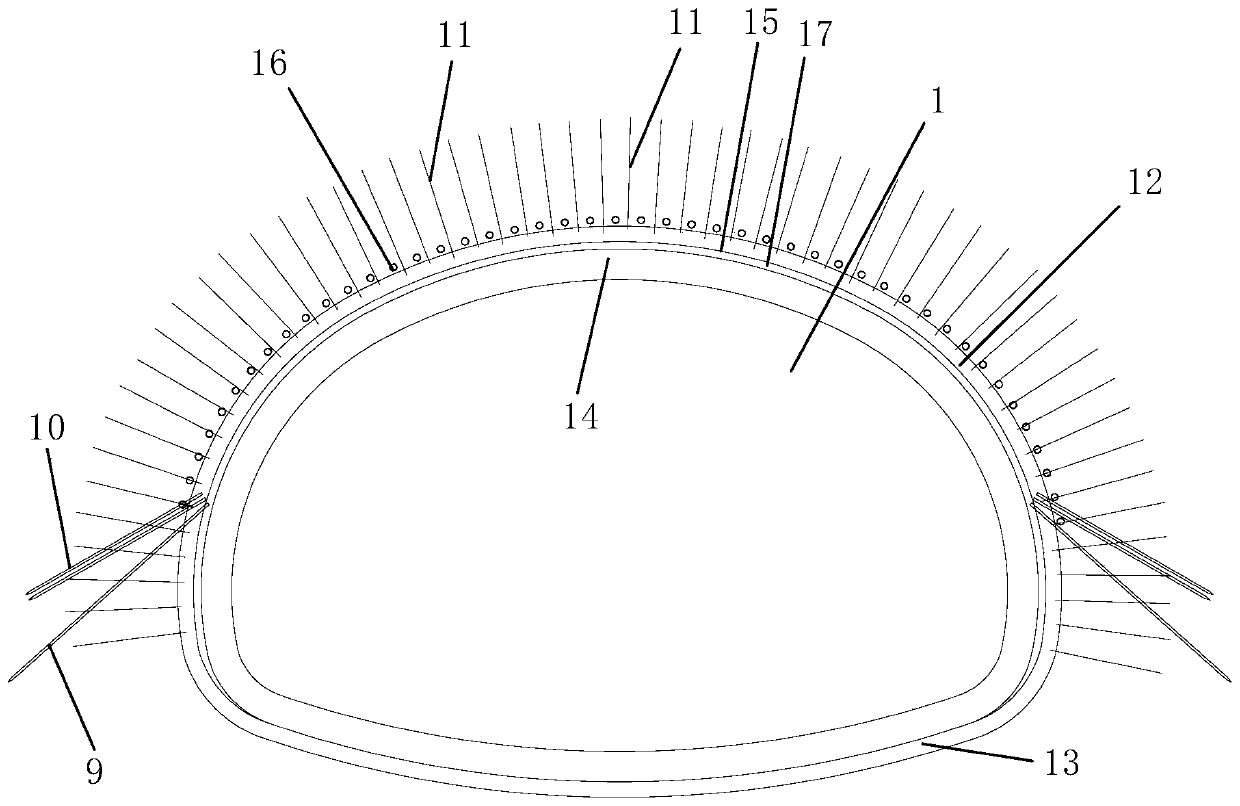

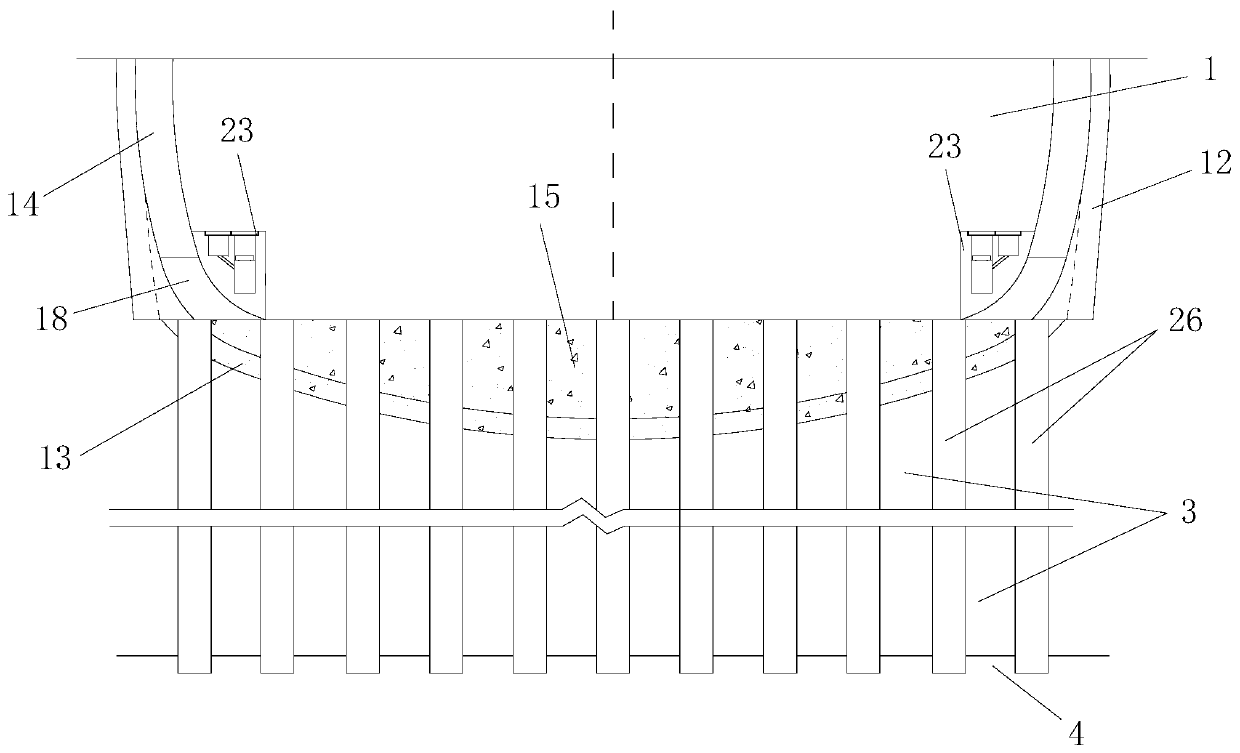

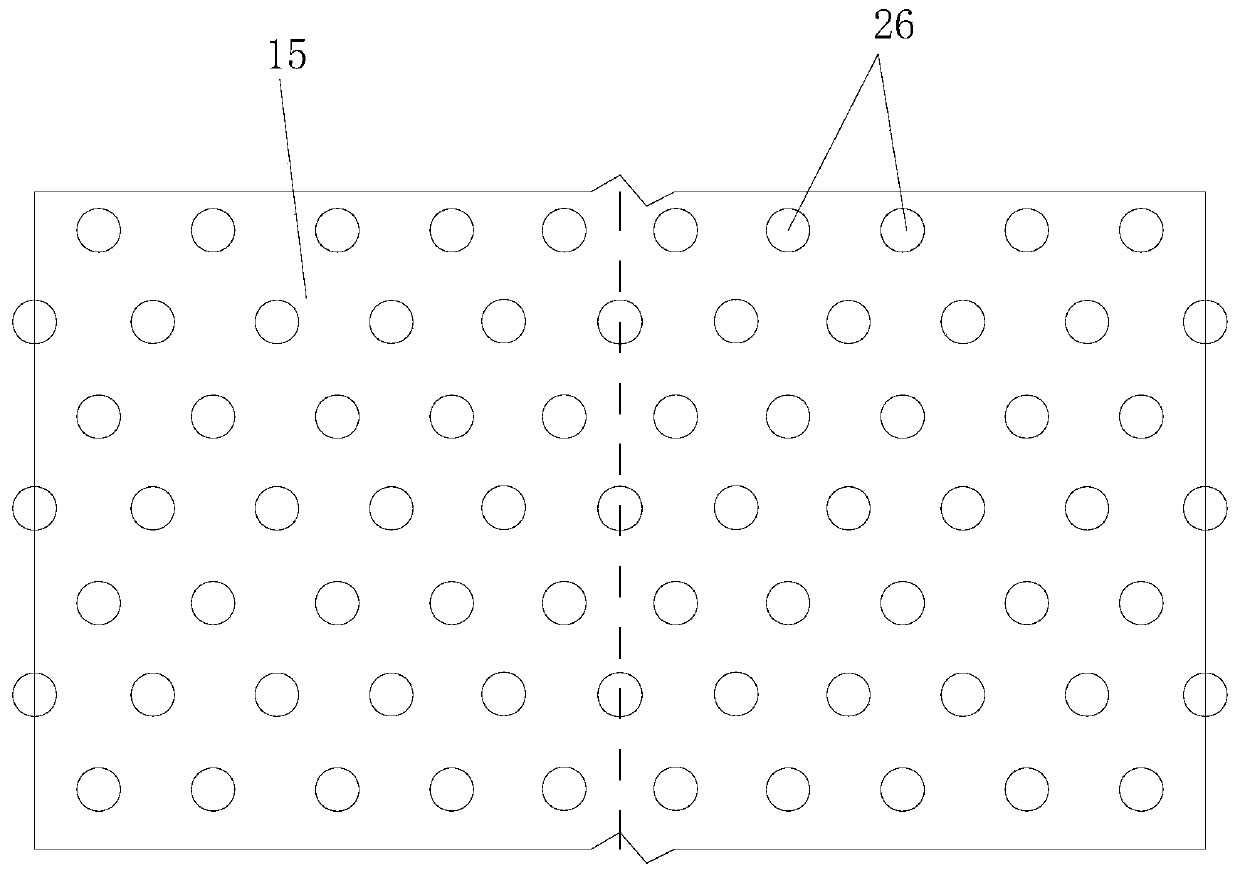

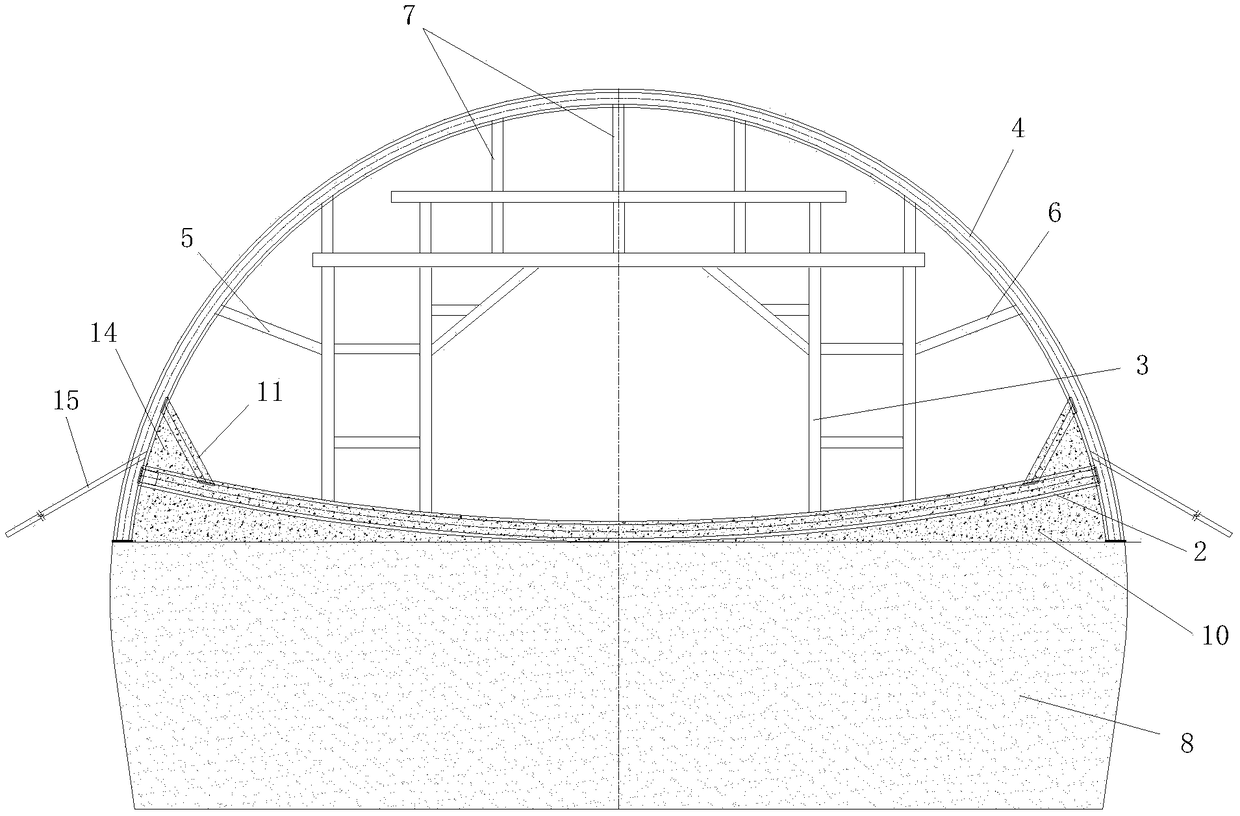

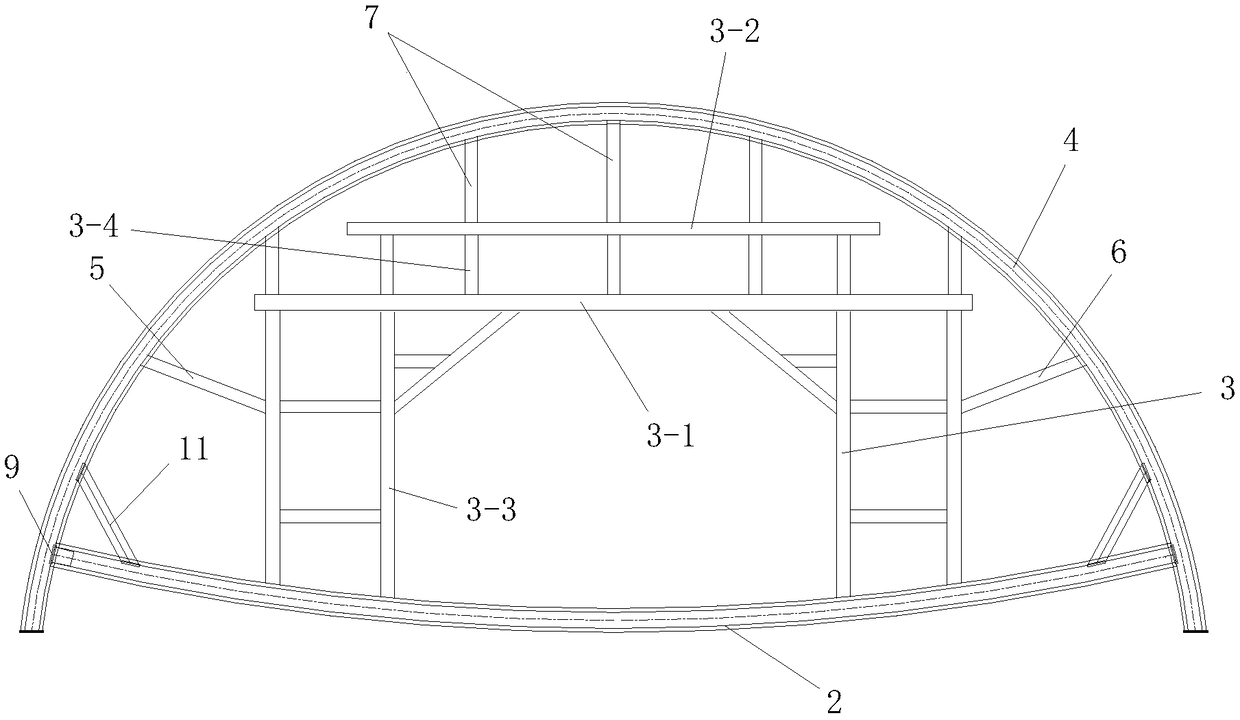

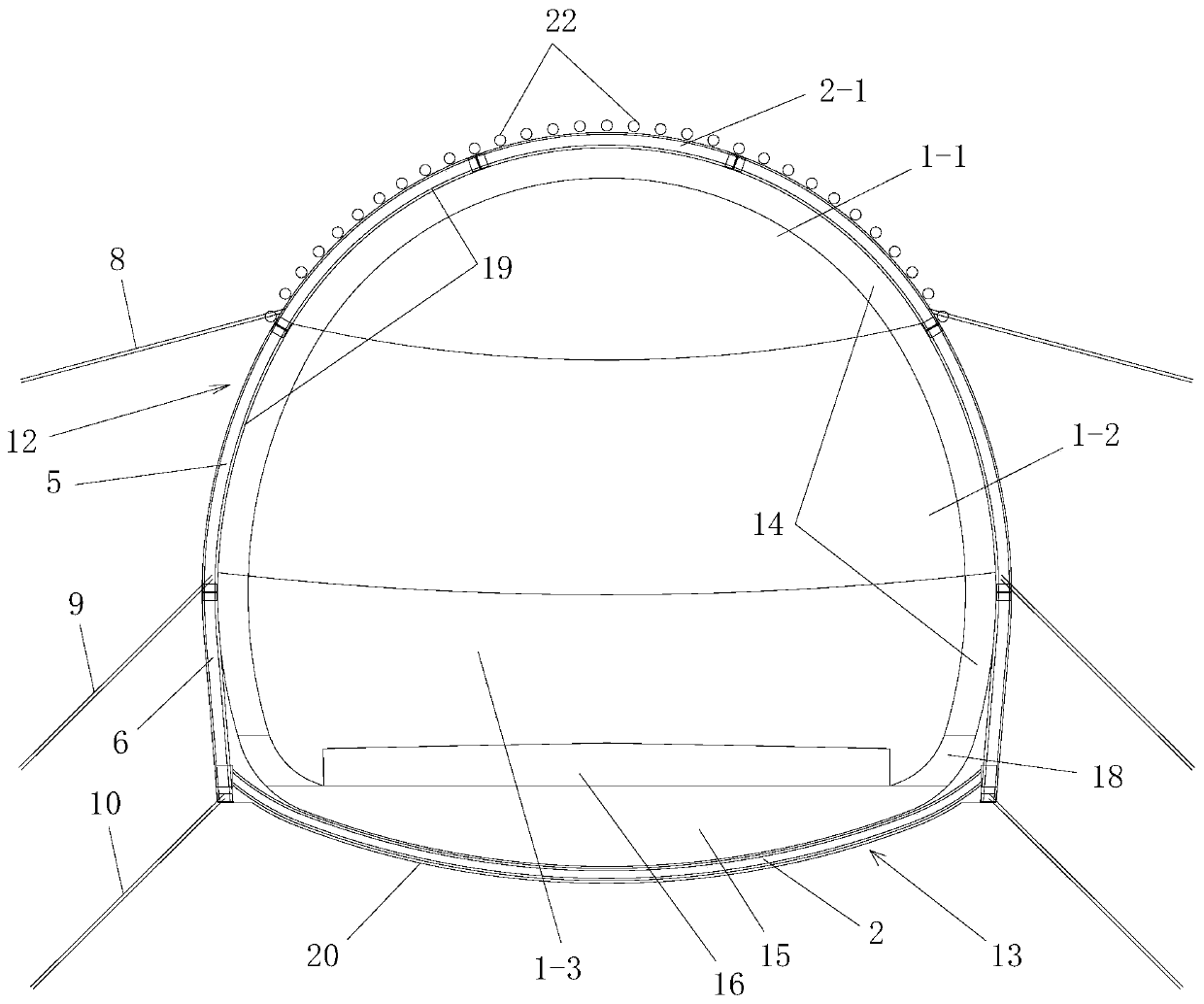

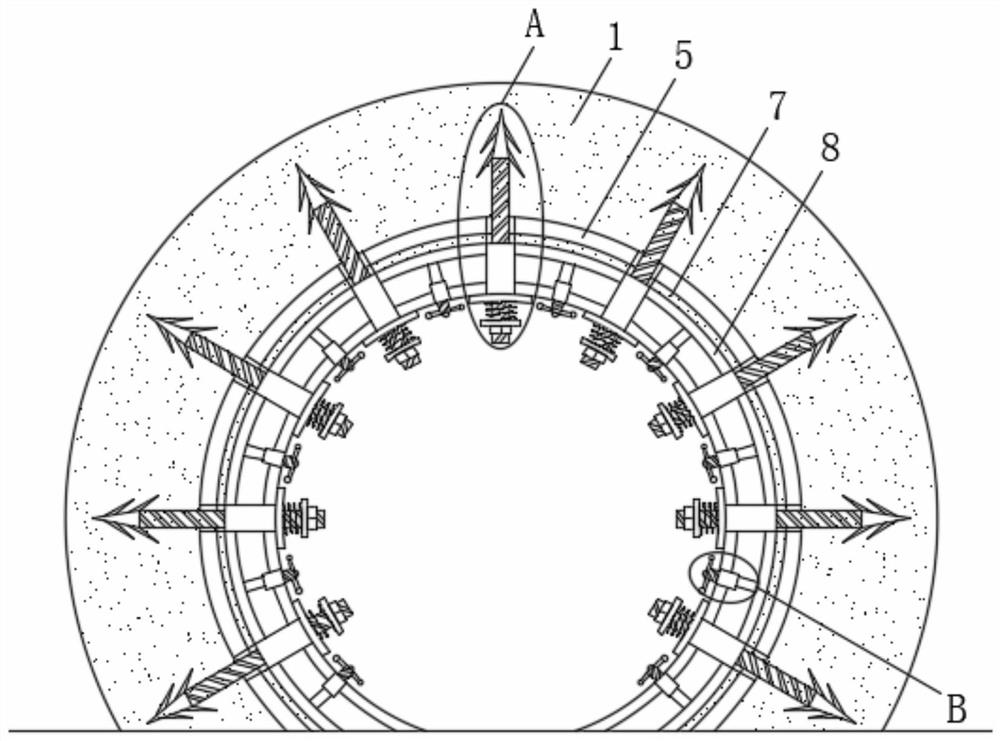

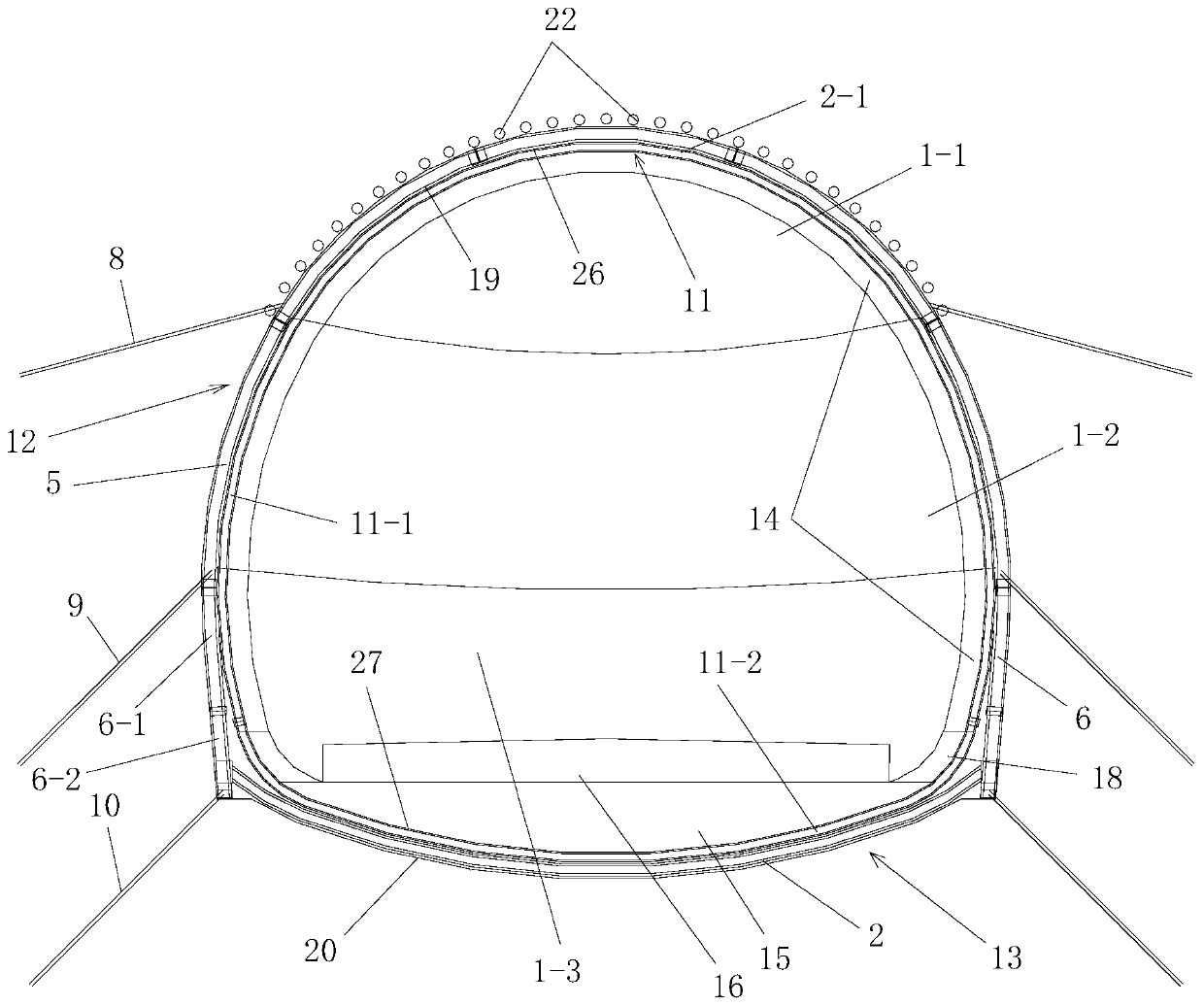

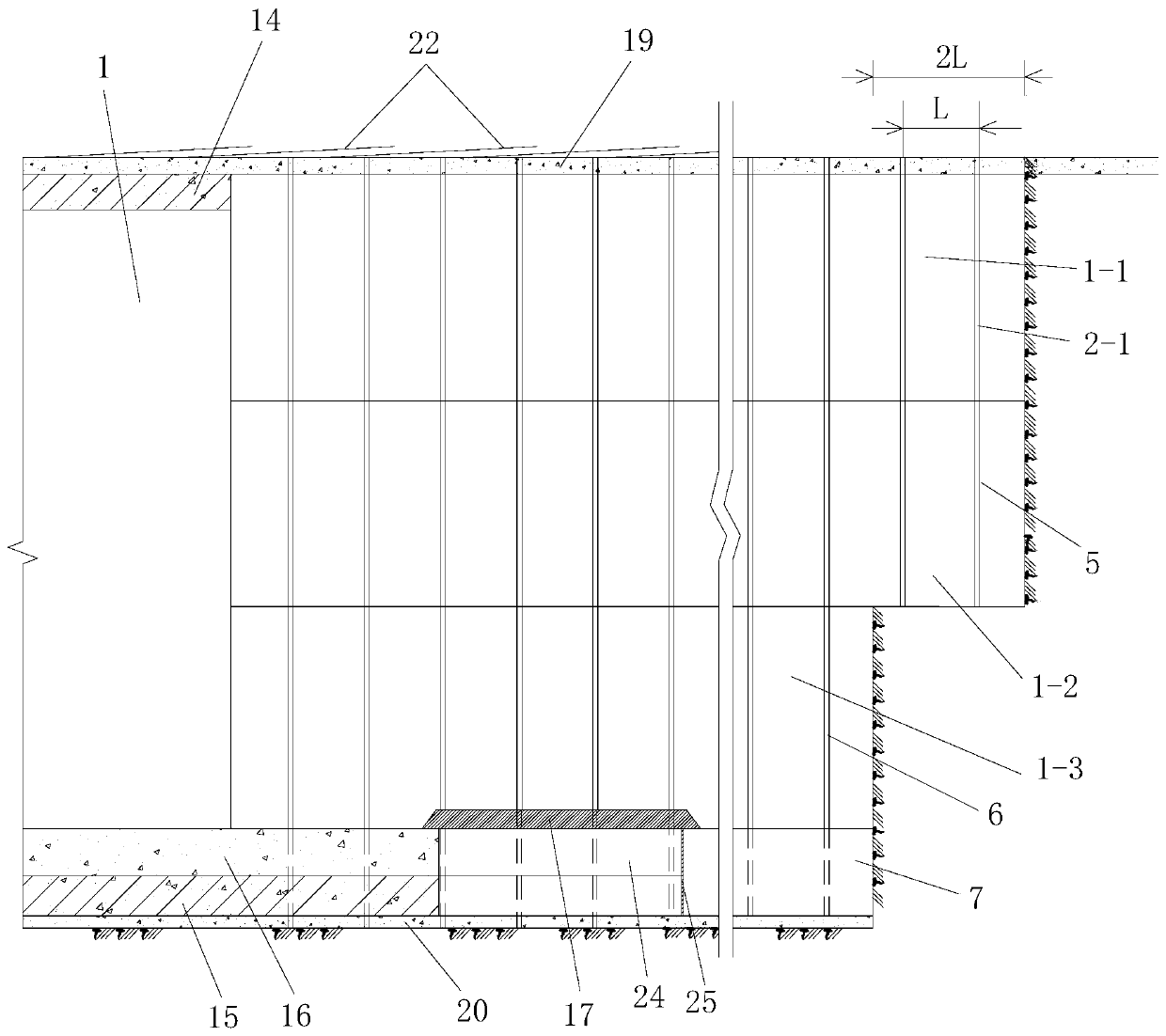

The invention discloses an excavation and support method of large cross-section tunnel through fault fracture zone. The initial support structure of tunnel comprises a whole cross-section support system and the lattice girder and shotcrete support structure of the tunnel. A temporary support structure of middle-partition wall is arranged between a left pilot tunnel and a right pilot tunnel. The actual construction includes the steps: 1, excavation of the upper tunnel body; 2, the judgment of the initial support deformation of the tunnel arch wall and the construction of the replacement arch; 3, excavation of the lower tunnel body. The excavation and support method of large cross-section tunnel through the fault fracture zone has reasonable design, simple construction, and good use effect.Only the upper half section of the tunnel is excavated by the center diaphragm method, and the excavation cross-section is reduced so that the stability of the arch roof is ensured. The whole cross-section support system and the temporary support structure of middle-partition wall are supported by the underpass beam and joined together to form a stable monolithic support system, which can avoid the sinking of the supporting arch and ensure the stability of the initial support effectively. Besides, the construction of replacement arch is conducted on only half cross-section of the tunnel and the cost can be saved, and the construction safety can be ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

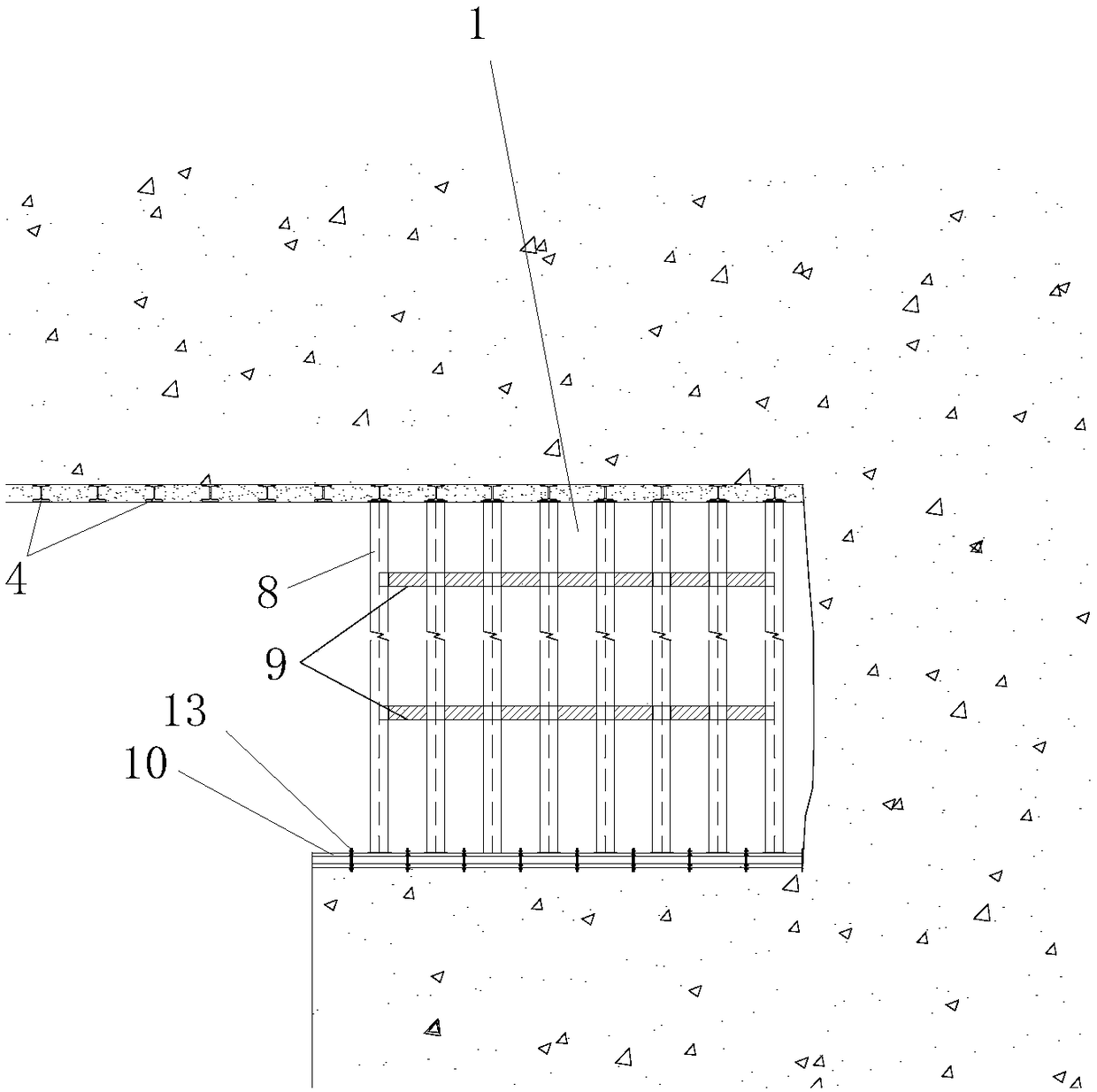

Construction method of large-section tunnel crossing fault fracture zone

ActiveCN108915720AThe method steps are simpleReasonable designUnderground chambersTunnel liningSupporting systemFracture zone

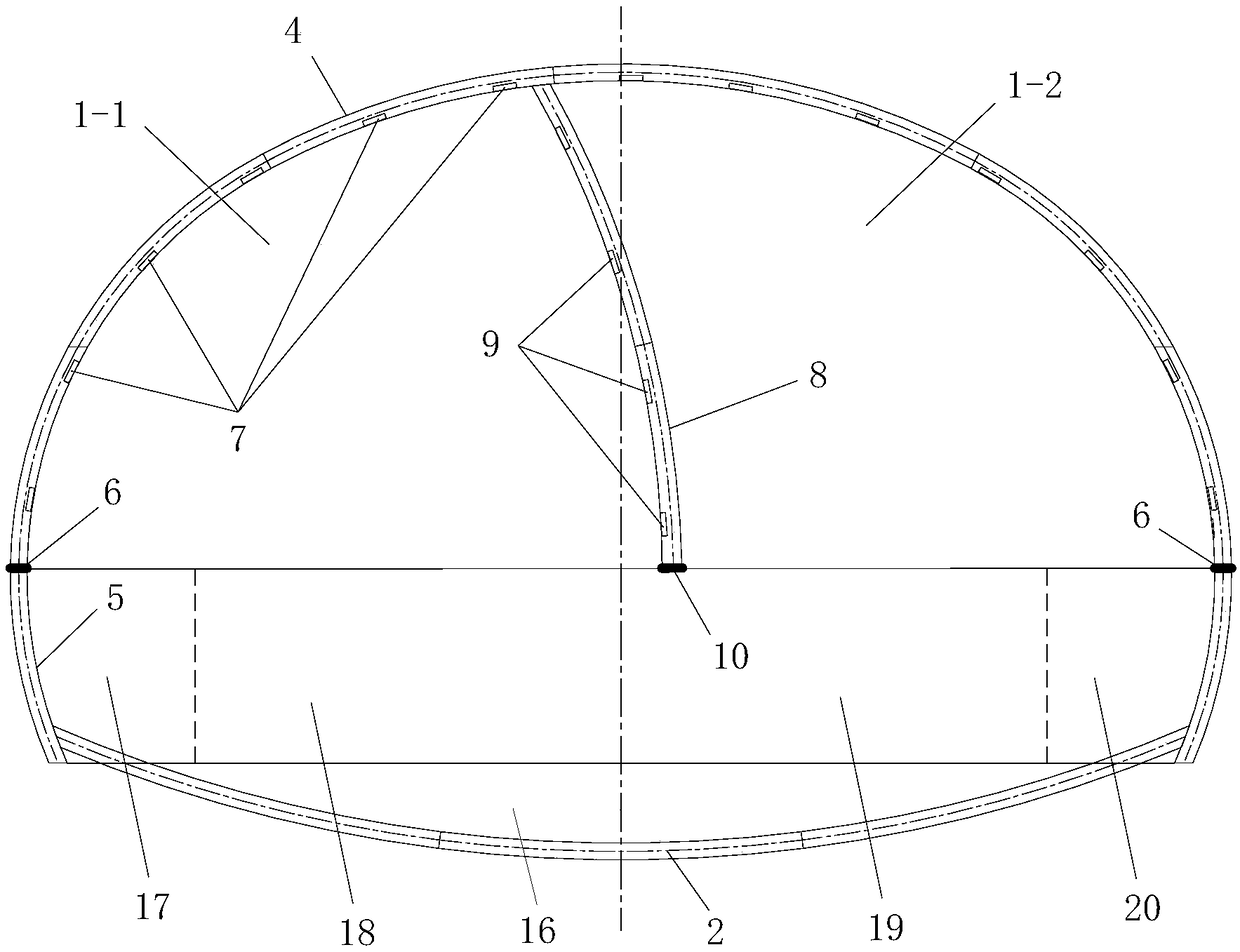

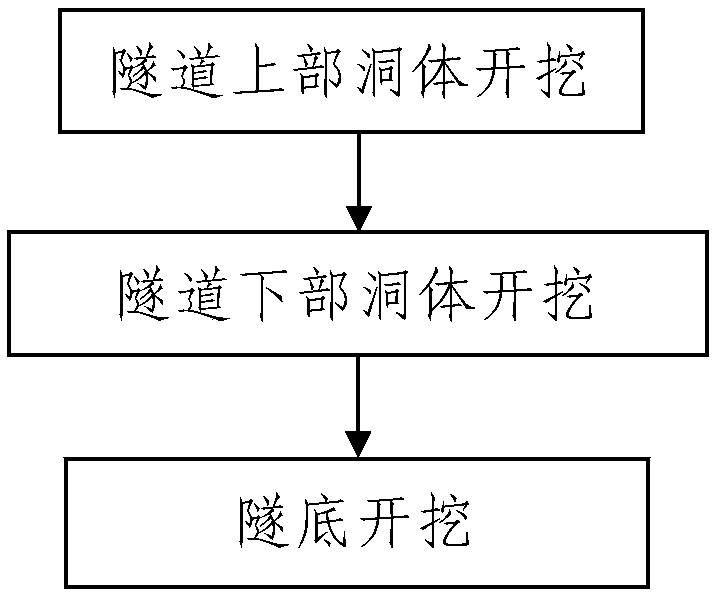

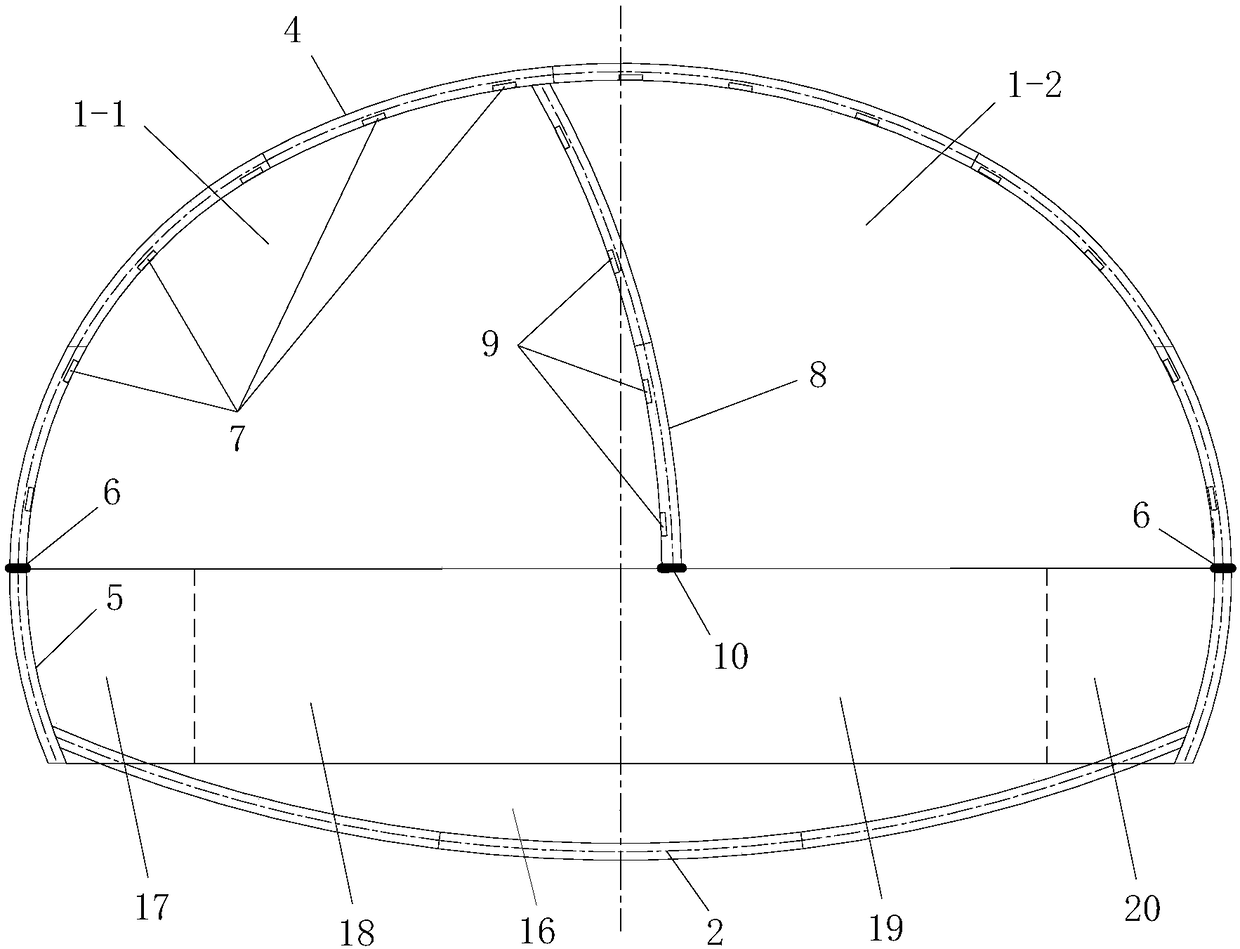

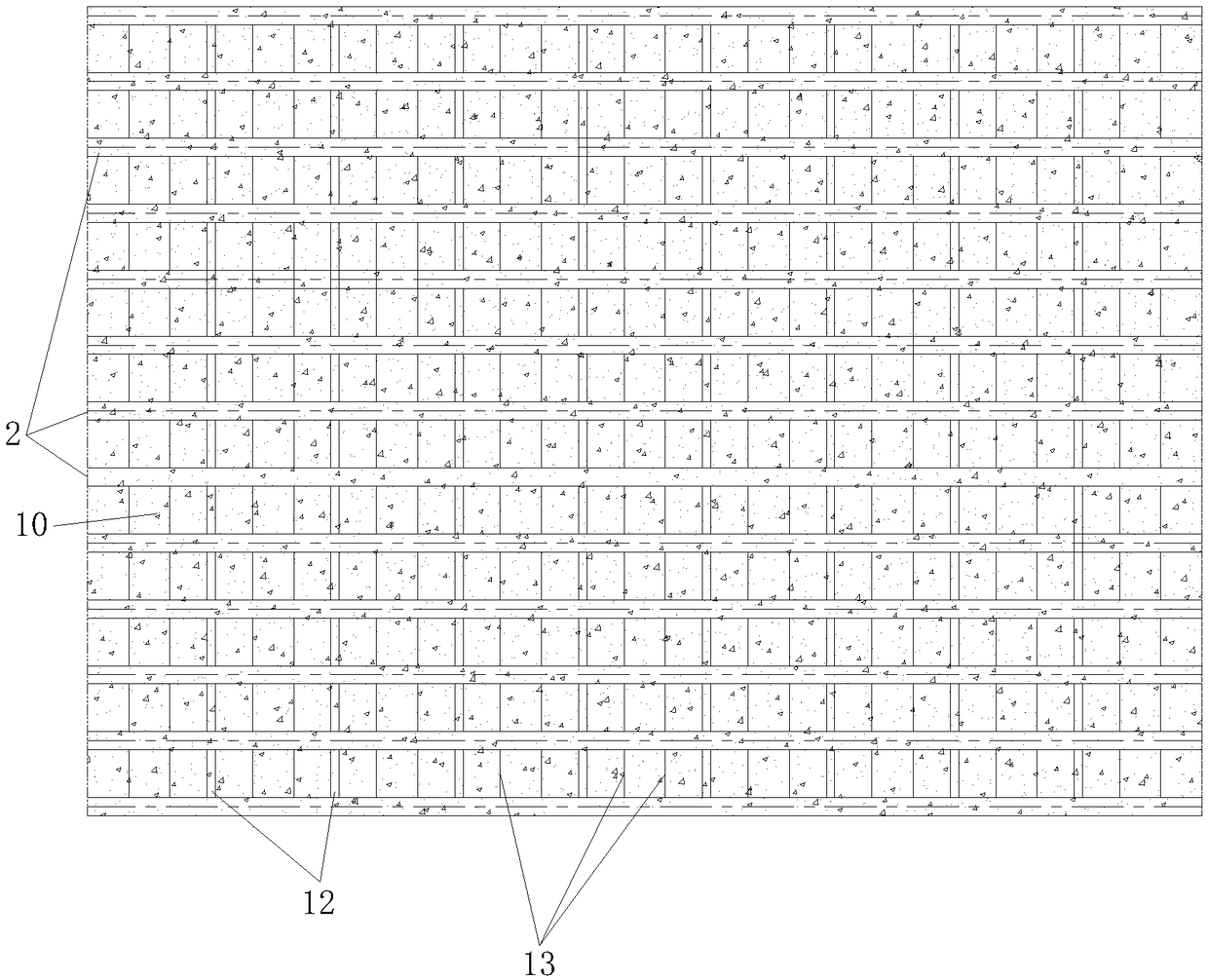

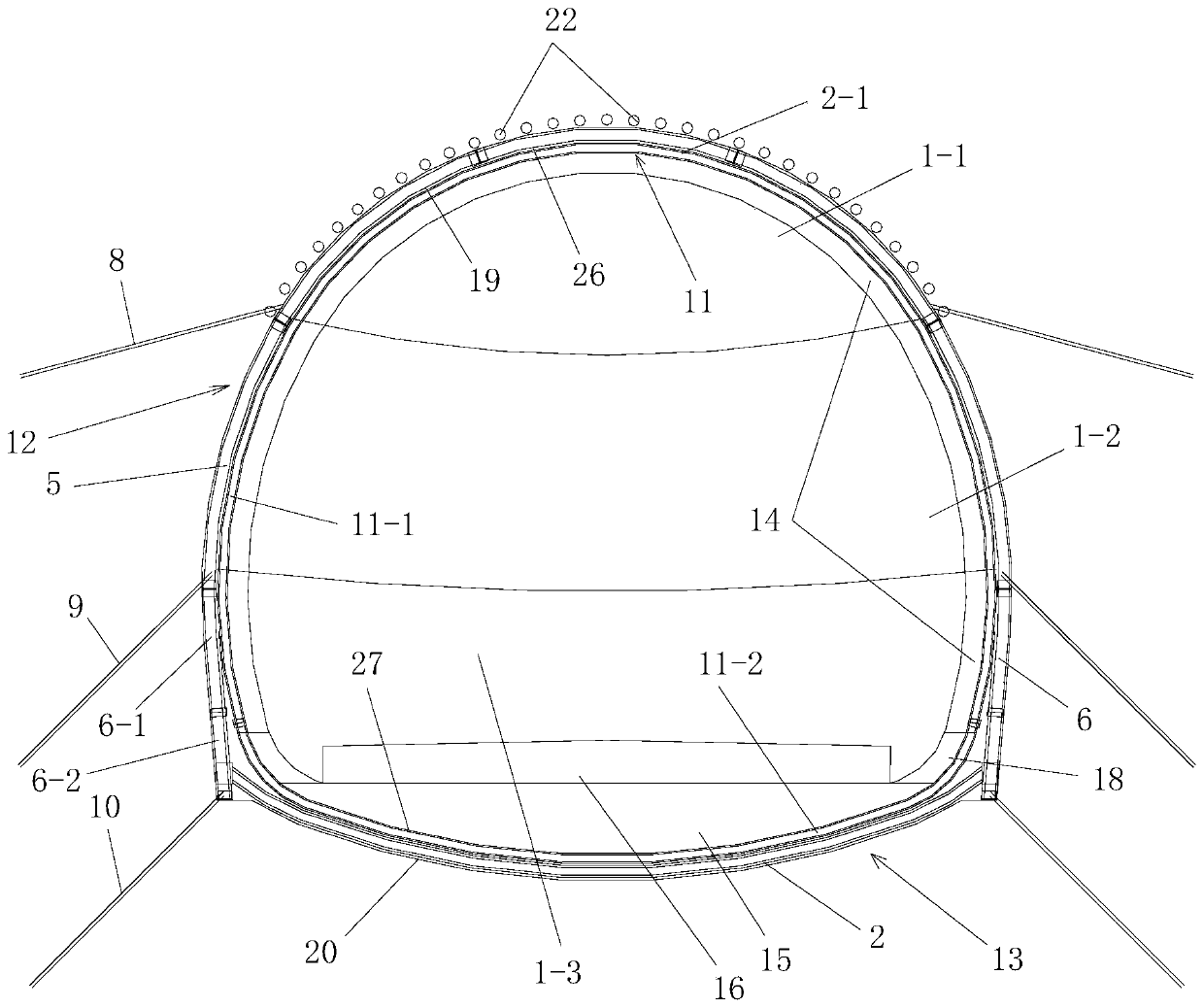

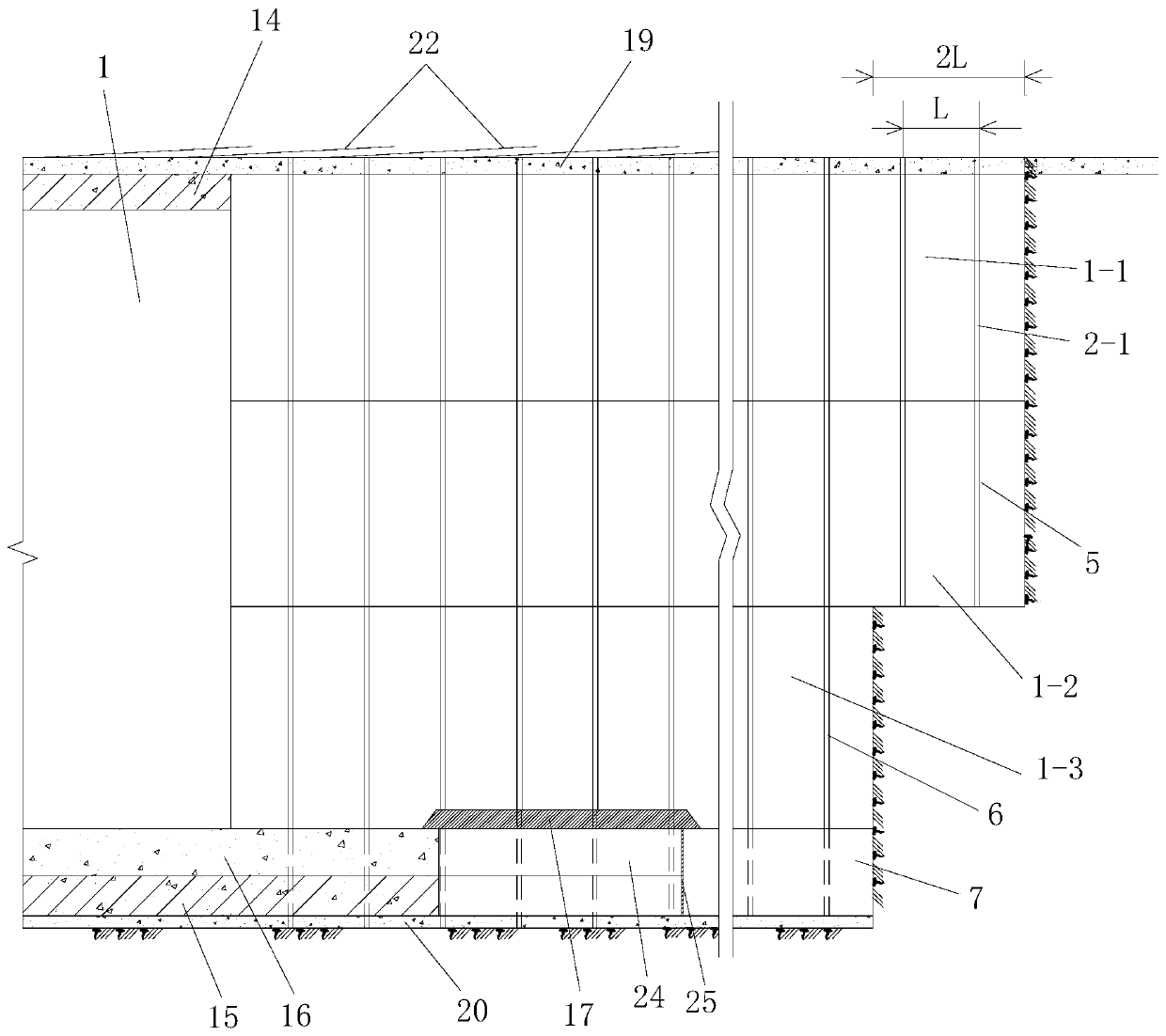

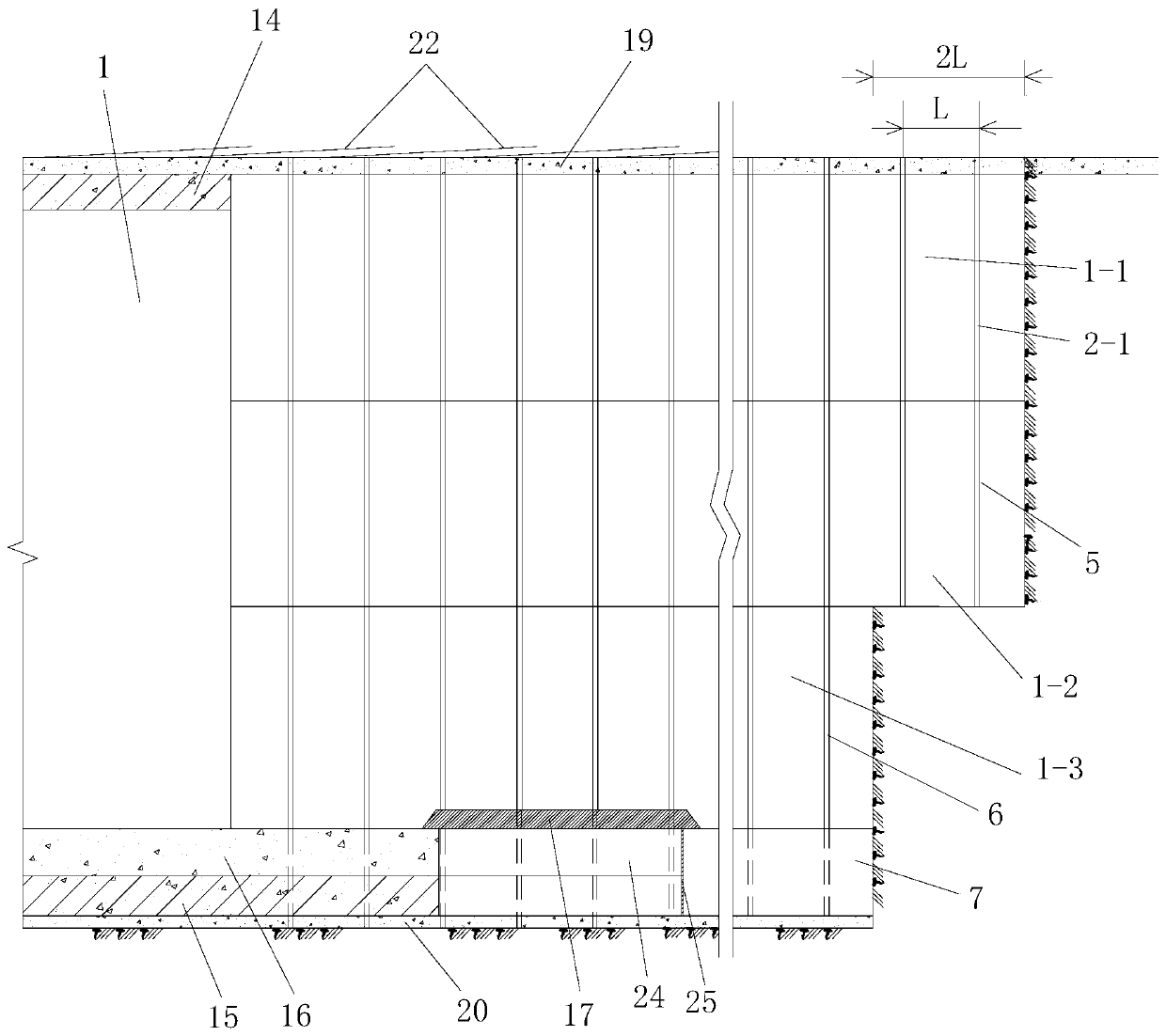

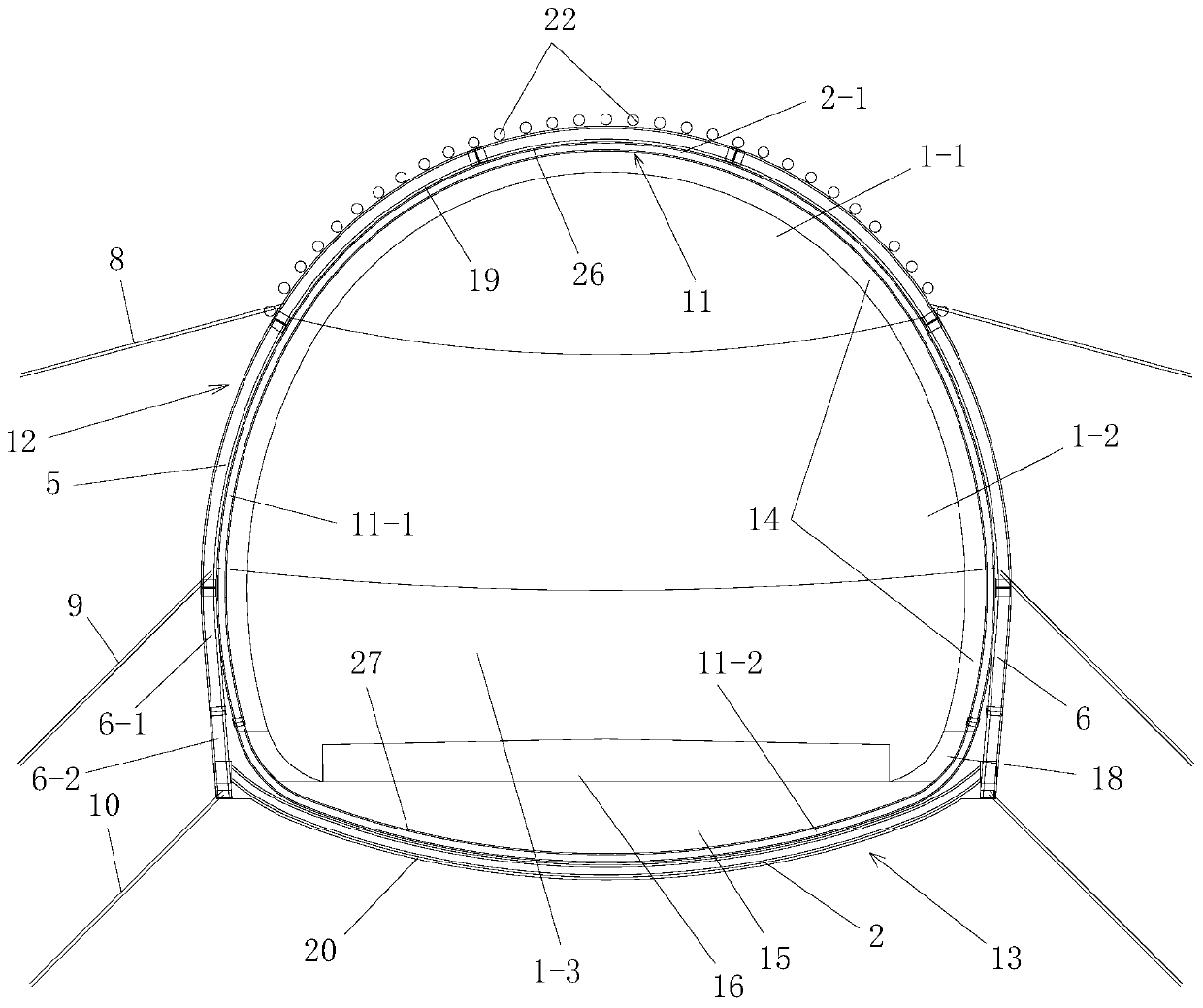

The invention discloses a construction method of a large-section tunnel crossing fault fracture zone. The construction tunnel cavern is divided into a tunnel upper cavern body, a tunnel lower cavern body and a tunnel bottom cavern body from top to bottom; the tunnel upper cavern body comprises a left pilot tunnel and a right pilot tunnel; the tunnel lower cavern body is divided into a left cavernbody, a left-middle cavern body, a right-middle cavern body and a right cavern body from left to right; practical construction comprises the following steps: (I) excavating the tunnel upper cavern body; (II) excavating the tunnel lower cavern body; (III) excavating the tunnel bottom. The method disclosed by the invention has the advantages of simple steps, reasonable design, convenience in construction and good using effect; only the upper half section of the tunnel is excavated by median septum excavation, thus the excavation section is reduced, and the vault stability is guaranteed; moreover, the left and right pilot tunnels have enough space and thus the construction is facilitated; meanwhile, a full-section support system and a mid-partition temporary support structure are both supported through lower bearing beams and are connected to form an overall support system with a stable structure, thus sinking of the primary support arching can be avoided while the stability of primary support is effectively guaranteed.

Owner:CHINA RAILWAY 20 BUREAU GRP

Stability control construction method of water-enriched soft rock tunnel passing through fault crushed zone

ActiveCN110905530AThe method steps are simpleReasonable designUnderground chambersDrainageSupporting systemArchitectural engineering

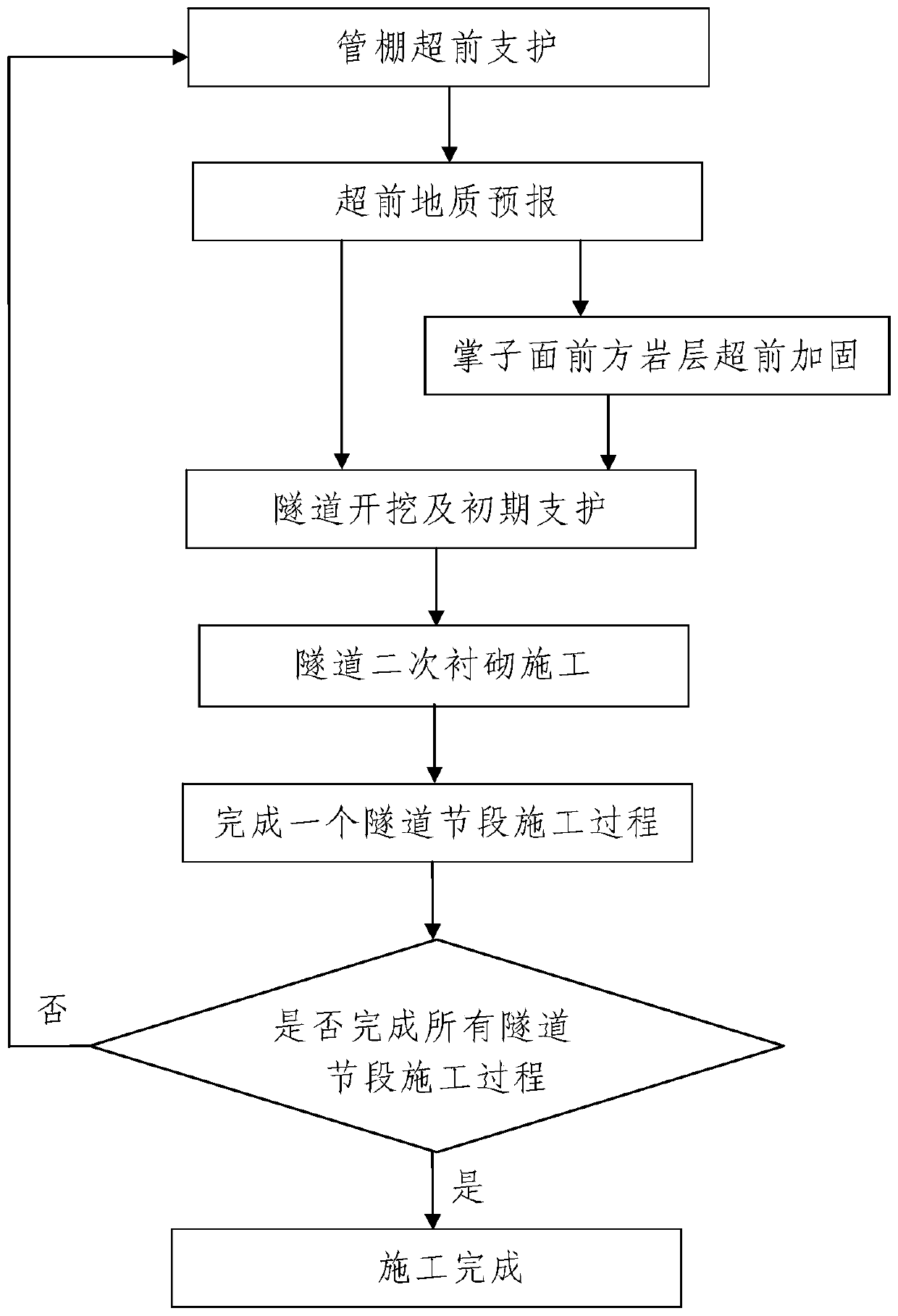

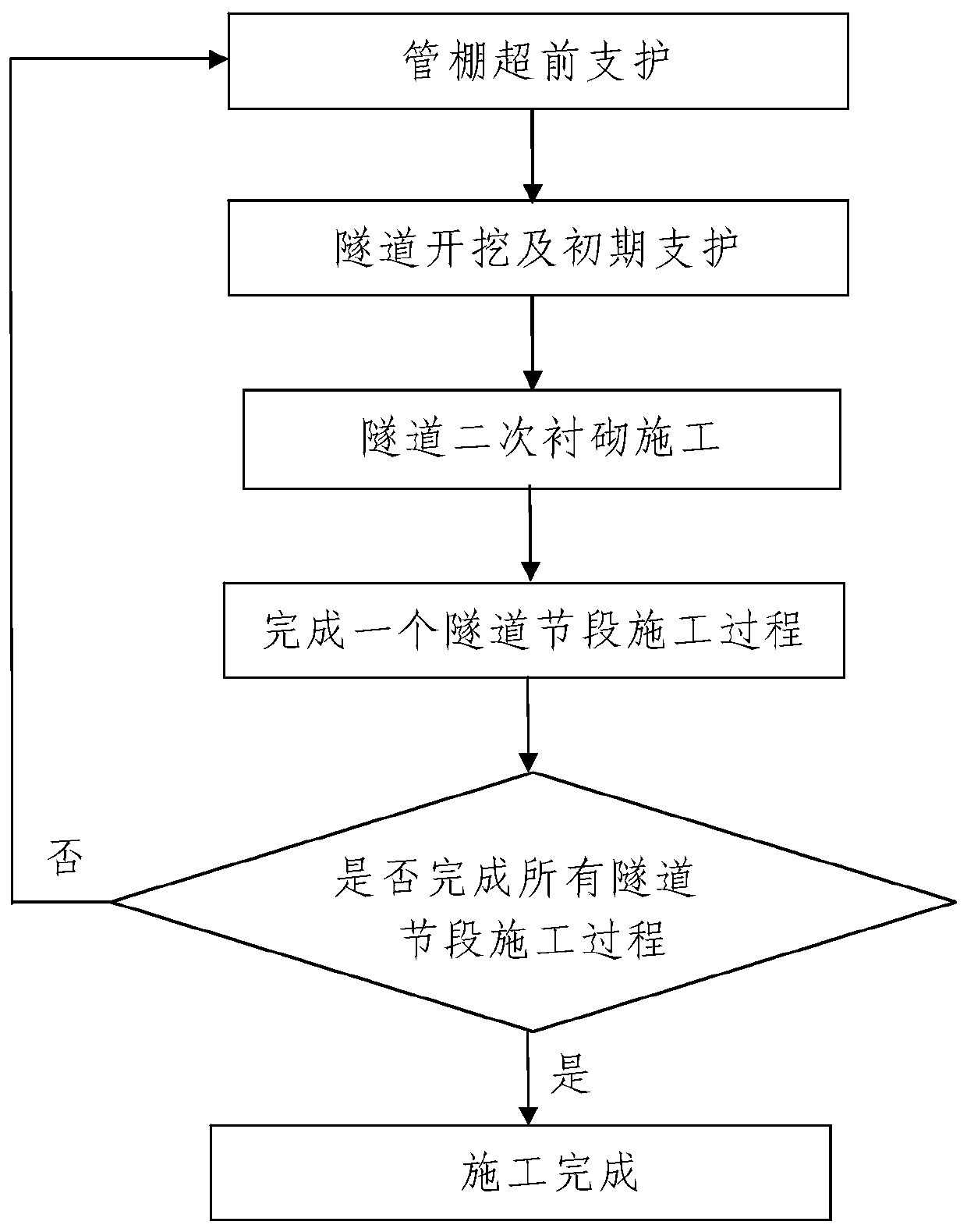

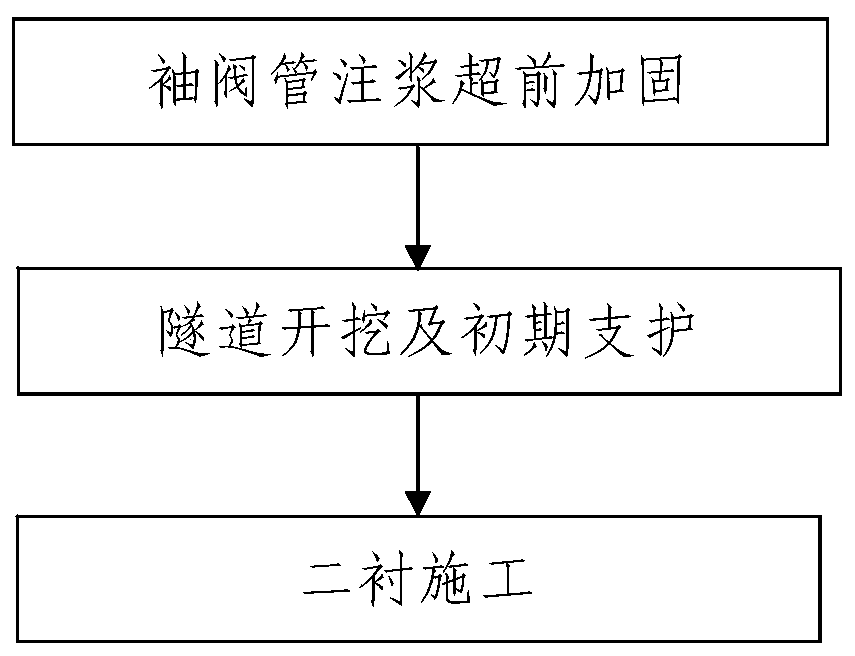

The invention discloses a stability control construction method of a water-enriched soft rock tunnel passing through a fault crushed zone. A plurality of tunnel segments in a construction tunnel are constructed respectively from back to front. During construction of any one of the tunnel segments, the method comprises the following steps: 1, performing pipe shed forepoling; 2, performing tunnel excavation and preliminary bracing: performing upper peripheral side cavity excavation and preliminary bracing, performing a reserved core soil area cavity excavation and preliminary bracing, excavatingthe cavity which is excavated firstly and performing preliminary bracing as well as excavating the cavity which is excavated secondly and performing preliminary bracing; and 3, performing tunnel secondary lining construction. The method is reasonable in design, simple and convenient in construction and good in use effect; before excavation, the upper cavity is subjected to forepoling by a self-drilling pipe shed and is excavated by a two-step method, so that the excavation efficiency is effectively improved; and meanwhile, an integral supporting system with a stable structure, which is formedby connecting a surrounding rock integral reinforced structure outside the cavity and a tunnel preliminary bracing structure and tunnel secondary lining, can effectively improve the stability of thetunnel structure and guarantee the later safety of the tunnel structure.

Owner:中铁二十局集团第二工程有限公司

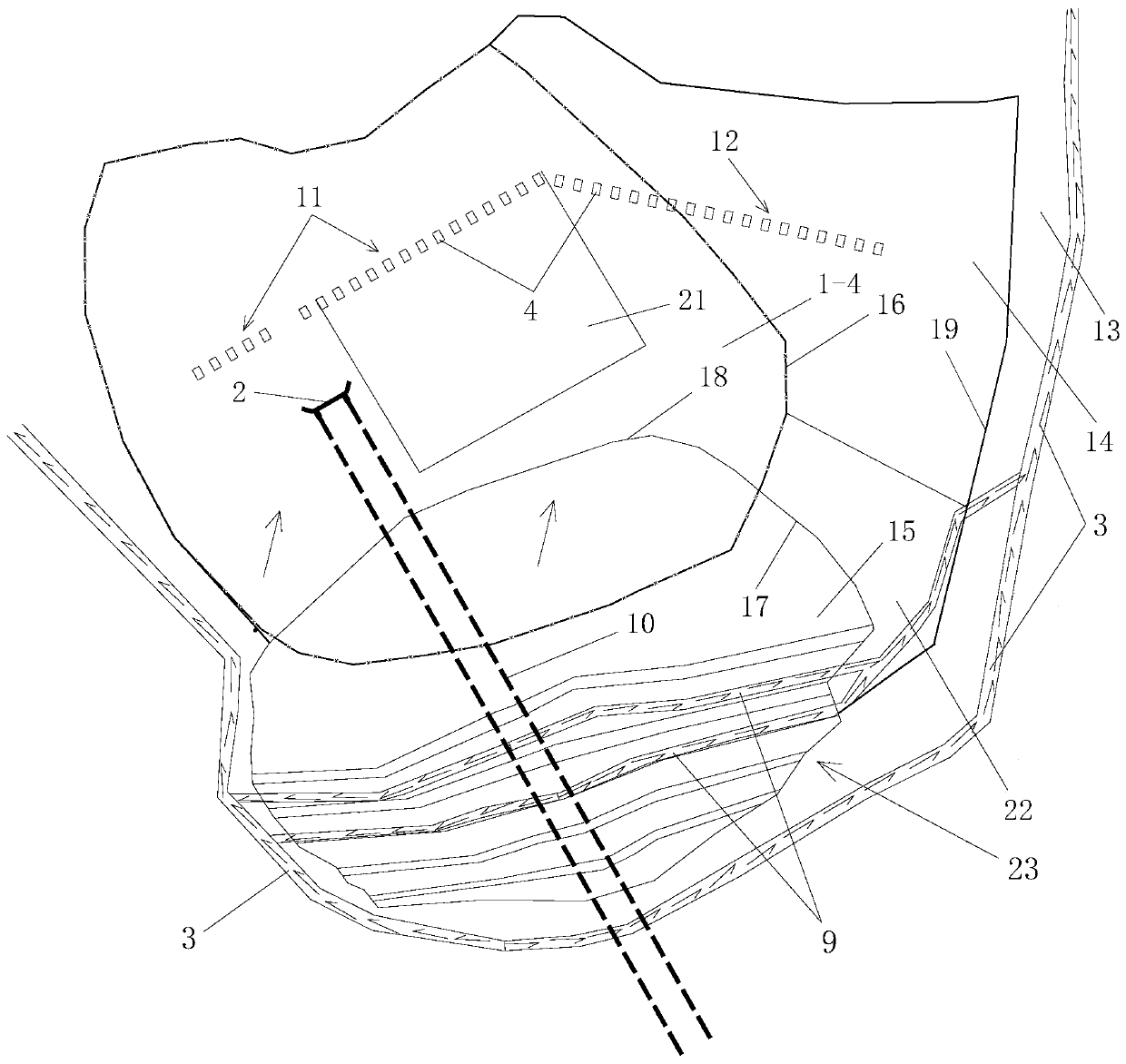

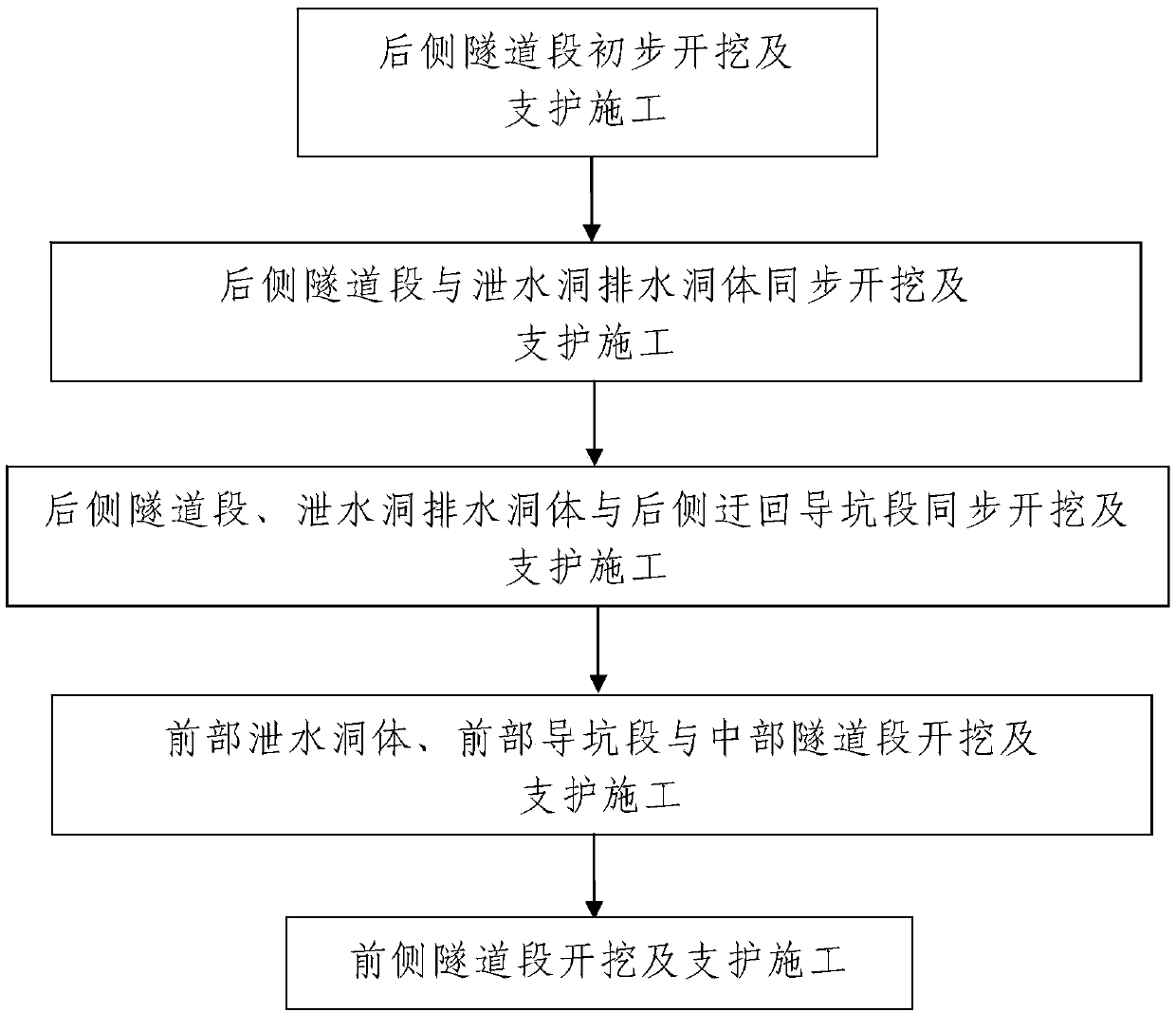

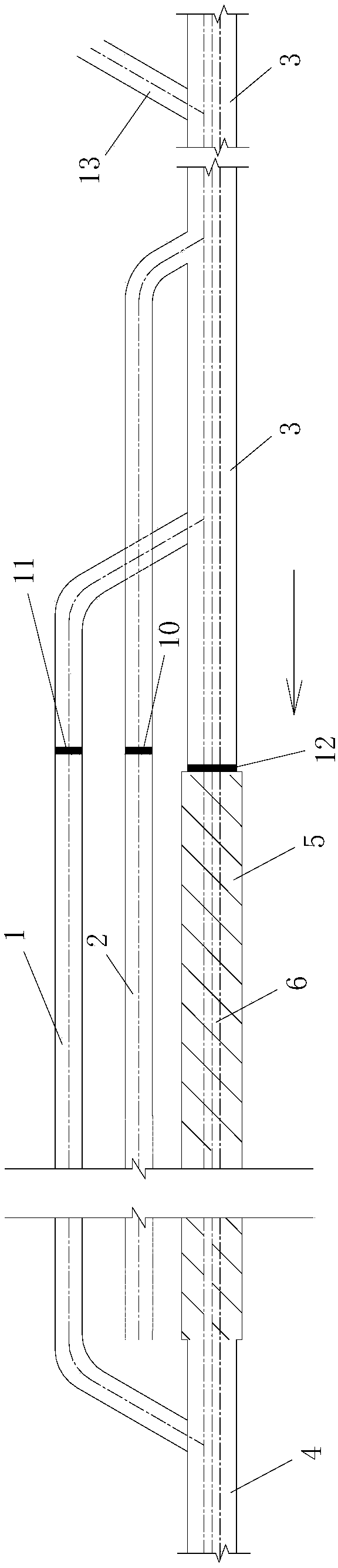

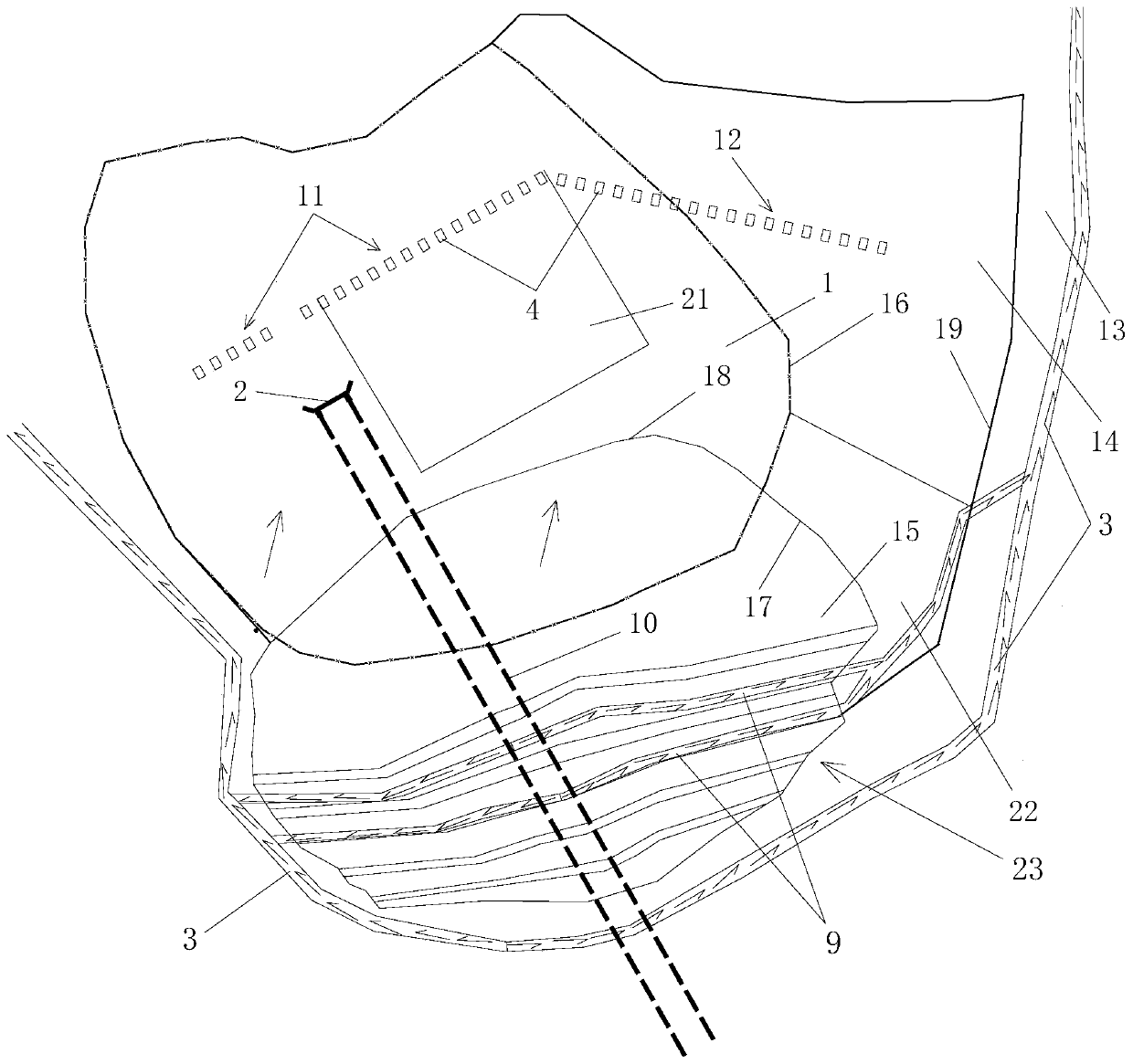

Construction method for tunnel passing through high-angle thrust water-rich and sand-rich fault

ActiveCN109209397AThe method steps are simpleReasonable designUnderground chambersDrainageStructural safetyHigh angle

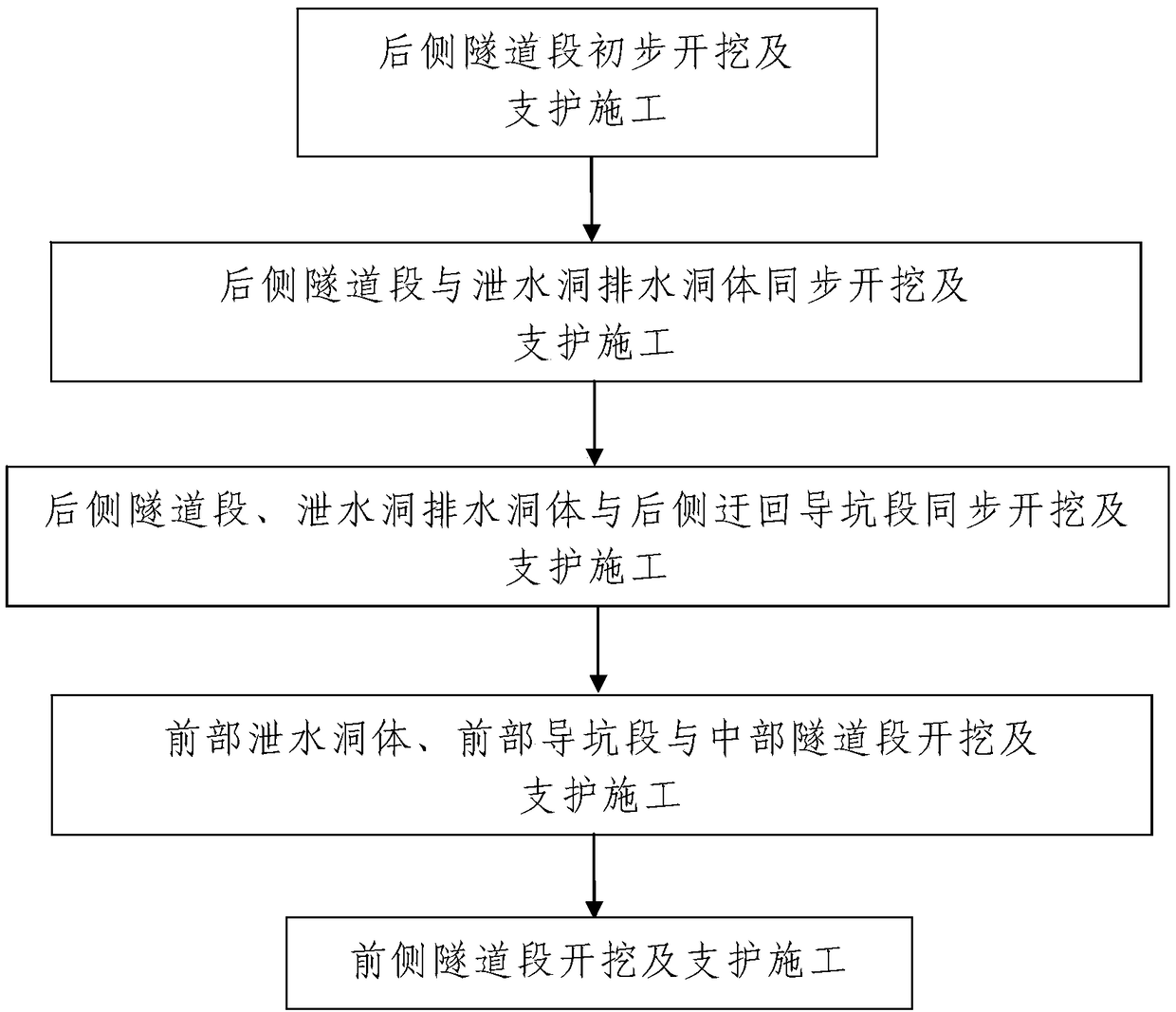

The invention discloses a construction method for a tunnel passing through a high-angle thrust water-rich and sand-rich fault. The method comprises the steps: 1, performing the preliminary excavationand the supporting construction of a rear tunnel segment; 2, performing the synchronous excavation and the supporting construction of the rear tunnel segment and a water drainage hole body of a waterdrainage hole; 3, performing the synchronous excavation and the supporting construction of the rear tunnel segment, the water drainage hole body of the water drainage hole and a rear detouring headingsegment; 4, performing the excavation and the supporting construction of a front water drainage hole body, a front heating segment and a central tunnel segment; 5, performing the excavation and the supporting construction of a front tunnel segment. According to the invention, the water on the upper wall of the fault is drained through a high-level water drainage hole between a tunnel front hole and a detouring heading pit, and the auxiliary water drainage is performed through the detouring heading pit, and the fault condition in front of the tunnel face of the front hole can be explored in advance, thereby guaranteeing the construction safety of each tunnel face. The method employs the three-step method for the excavation of the tunnel front hole, employs double preliminary supporting structures for the full-section supporting after excavation, can guarantee the safety of the tunnel structure later, and shortens the construction cycle.

Owner:CHINA RAILWAY 20 BUREAU GRP

Tunnel arch wall primary support limit-intruding arch-replacing construction method based on gantry-type supporting

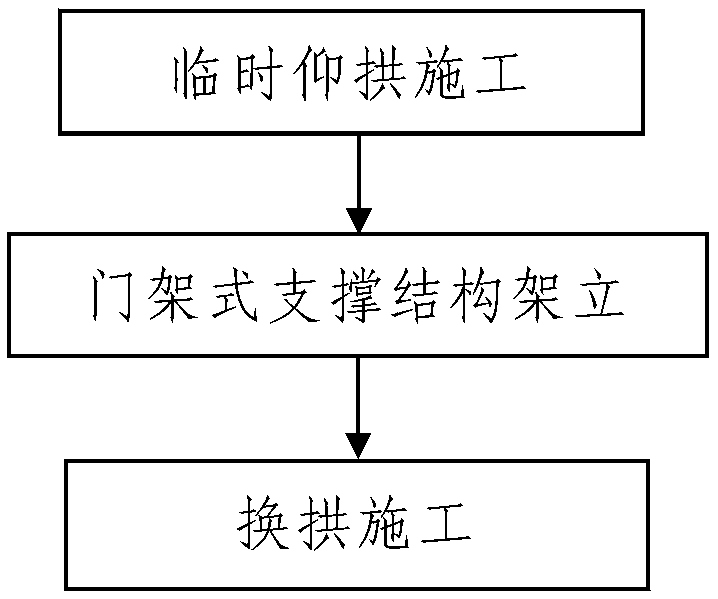

ActiveCN108915728AThe method steps are simpleReasonable designUnderground chambersTunnel liningSteel frameStructural integrity

Owner:CHINA RAILWAY 20 BUREAU GRP +1

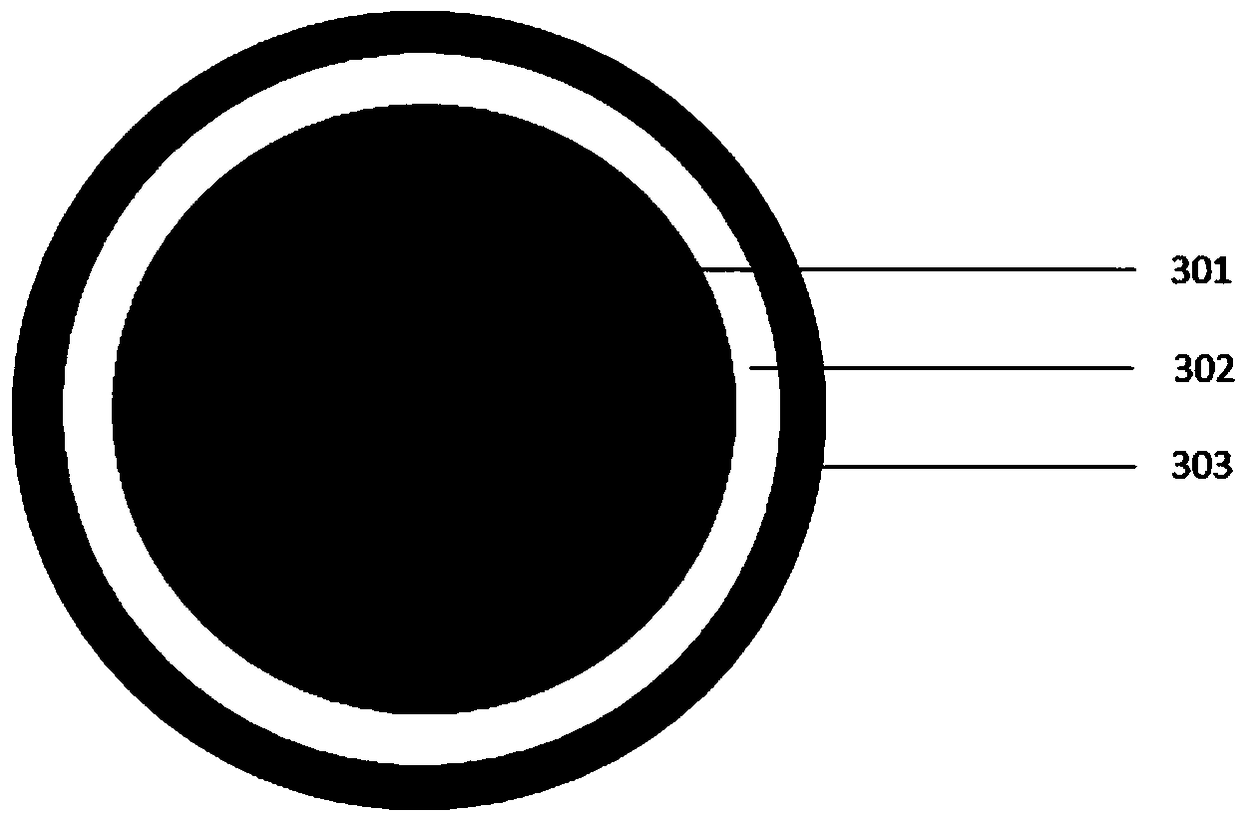

Medical degradable zinc-based alloy intravascular stent product

The invention relates to the fields of a medical material and an apparatus thereof, and provides an in-vivo degradable implantable intravascular stent product. The product comprises 1) an in-vivo degradable implantable zinc-based metal material; 2) the intravascular stent product produced by the zinc-based alloy material in the step 1) is in a pipenet structure; 3) a magnesium metal film coating is uniformly distributed and deposed at the surface of the pipenet stent product; and 4) the magnesium film coating is coated with a degradable polymer coating, and the polymer coating can contains therapeutic drugs. The zinc based alloy has the advantages of excellent mechanical properties, strong corrosion controllability, and excellent compatibility. According to the intravascular stent product,surface special arrangement is benefit for keeping a complete initial structure, is benefit for stent endothelialization, reduces an inflammatory reaction, and reduces local inflammation, restenosisand thrombus risk in the stent after stent implantation.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

Method for constructing water-rich weak surrounding rock tunnel crossing fault broken belt

ActiveCN110924959AThe method steps are simpleReasonable designUnderground chambersTunnel liningArchitectural engineeringRock tunnel

The invention discloses a method for constructing a water-rich weak surrounding rock tunnel crossing a fault broken belt. The method comprises the following steps that firstly, construction is carriedout on a plurality of tunnel sections in a construction tunnel from front to rear, and when any tunnel section is constructed, the construction method comprises the following steps that 1, advanced support is carried out on a pipe shed; 2, tunnel excavation and initial support are carried out, wherein upper peripheral side hole excavation and initial support are carried out, reserved core soil area hole excavation and initial support are carried out, first hole excavation and initial support are carried out firstly and thereafter second hole excavation and initial support is carried out; and3, tunnel secondary lining construction is carried out. The method has the beneficial effects that the design is reasonable, construction is easy and convenient, and the use effect is good; the self-drilling pipe shed is adopted to carry out advanced support on the upper hole body before excavation, and two-step method excavation is adopted, so that the construction efficiency can be effectively improved; meanwhile, the whole reinforcing structure of the hole peripheral rock, the tunnel primary support structure in holes and the tunnel secondary lining are connected to form an integral supportsystem with a stable structure, the stability of the tunnel structure can be effectively improved, and the safety of the later tunnel structure is ensured.

Owner:中铁二十局集团第二工程有限公司

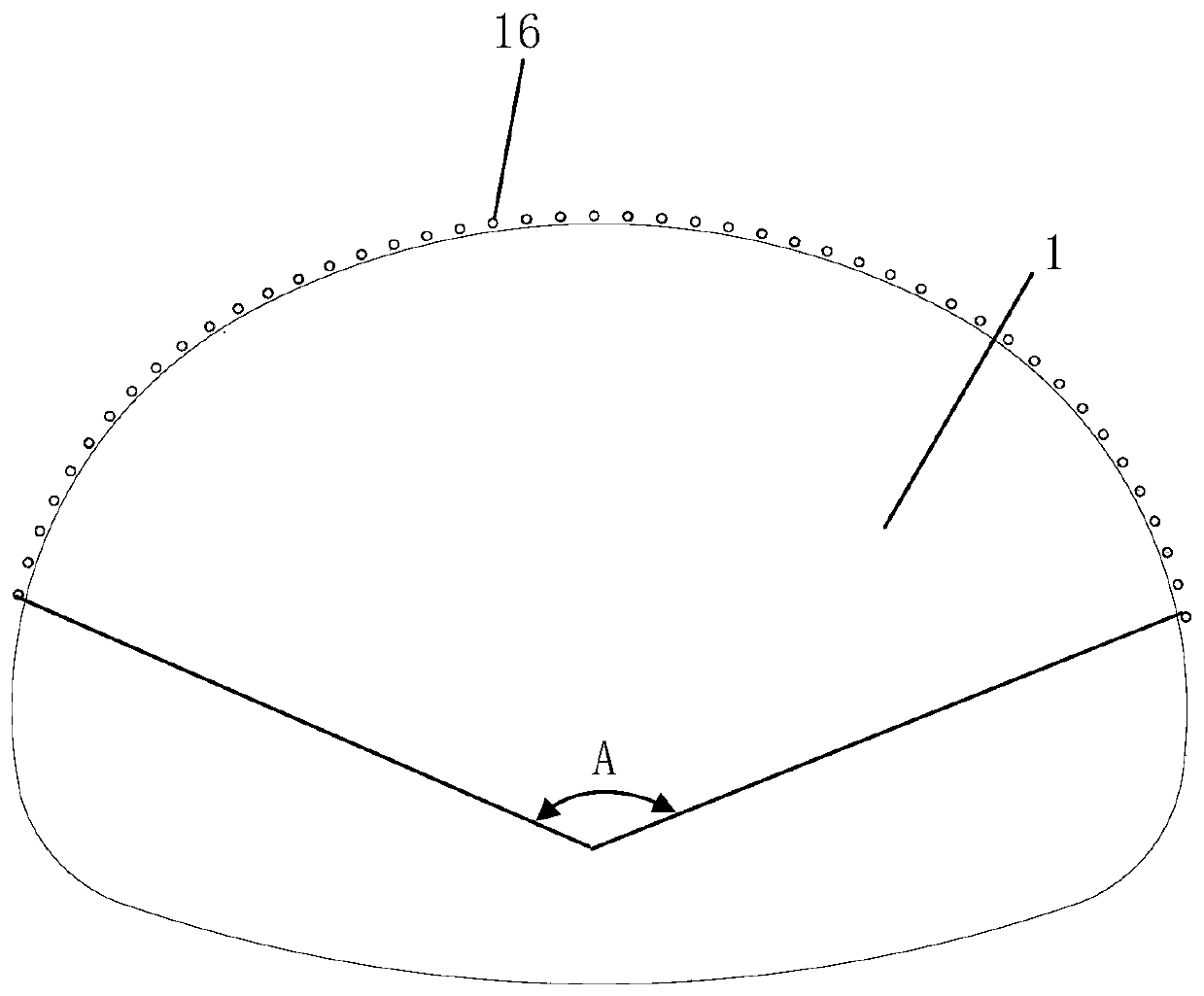

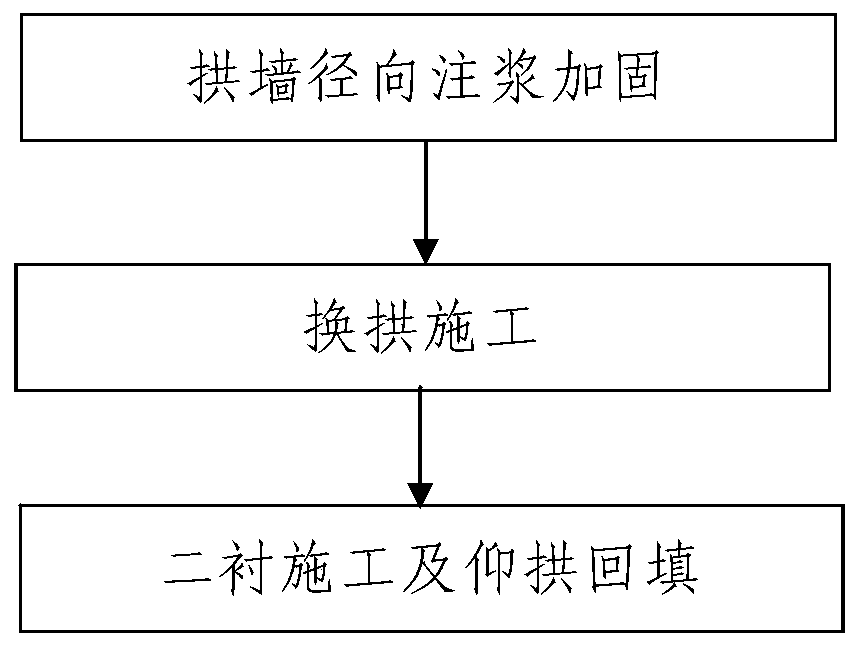

Method for beyond-limit arch replacing construction during preliminary bracing of large-section loess tunnel

ActiveCN110656959AThe method steps are simpleReasonable designUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a method for beyond-limit arch replacing construction during preliminary bracing of a large-section loess tunnel. The method includes the steps of firstly, conducting radial grouting reinforcement on an arch wall, wherein radial grouting reinforcement is conducted on an arch replacing required section where arch replacing is required in the constructed loess tunnel from back to front; and secondly, conducting arch replacing construction, wherein a reinforced preliminary bracing structure in the arch replacing required section is detached, and preliminary bracing construction is conducted on the arch replacing required section synchronously in the detaching process. The method is simple in step, reasonable in design, simple in construction and good in use effect; theradial grouting reinforcement is conducted on the arch wall to reinforce the arch wall of a tunnel hole first, so the structural stability of the tunnel in the arch replacing process is ensured; segmented reinforcing is conducted on the preliminary bracing structure of the tunnel through a plurality of sleeve arch units for a reinforced sleeve arch in the arch replacing required section, so detaching is convenient; and moreover, the sleeve arch units are complementary and together improve the supporting force, so the adverse effects on the structural stability of the tunnel in the detaching process of each sleeve arch unit can be effectively reduced, and the safety and reliability of the arch replacing construction process are ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

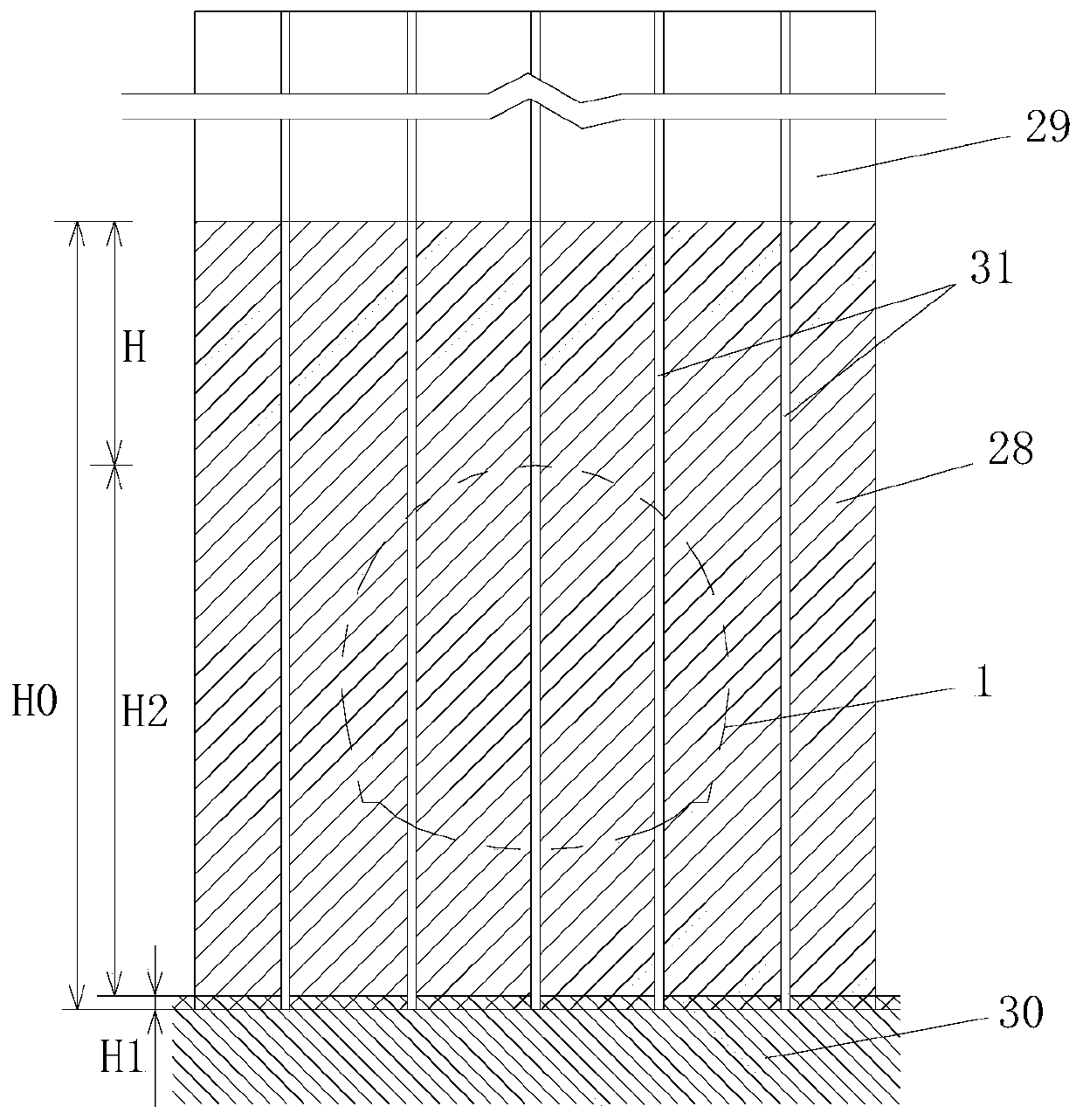

Loess tunnel foundation base reinforcing structure and method based on high pressure jet grouting piles

PendingCN110671131AReasonable designReduce construction costsUnderground chambersTunnel liningStructural engineeringGeotechnical engineering

The invention discloses a loess tunnel foundation base reinforcing structure and method based on high pressure jet grouting piles. The structure comprises the multiple rows of high pressure jet grouting piles for reinforcing soil on the lower portion of a tunnel, and each high pressure jet grouting pile passes through a tunnel invert structure and a collapsible loess stratum from top to bottom andthen extends into a non collapsible loess stratum. The method comprises the following steps of firstly, tunnel excavating and preliminary bracing; secondly, second lining construction; and thirdly, foundation base reinforcing. The structure is reasonable in design, easy and convenient to construct and good in use effect. The multiple rows of high pressure jet grouting piles are adopted for carrying out foundation base reinforcing on a loess tunnel, a loess tunnel foundation base can be simply and rapidly effectively reinforced, the tunnel foundation base settling volume can be effectively controlled, meanwhile, the upper surface of a secondary lining inverted arch is adjusted to the horizontal plane, a construction platform is provided for the high pressure jet grouting piles, the loess tunnel foundation base reinforcing process can be further quickened, the high pressure jet grouting piles and the tunnel invert structure are fastened and connected into a whole, and the loess tunnel foundation base reinforcing effect can be further improved.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

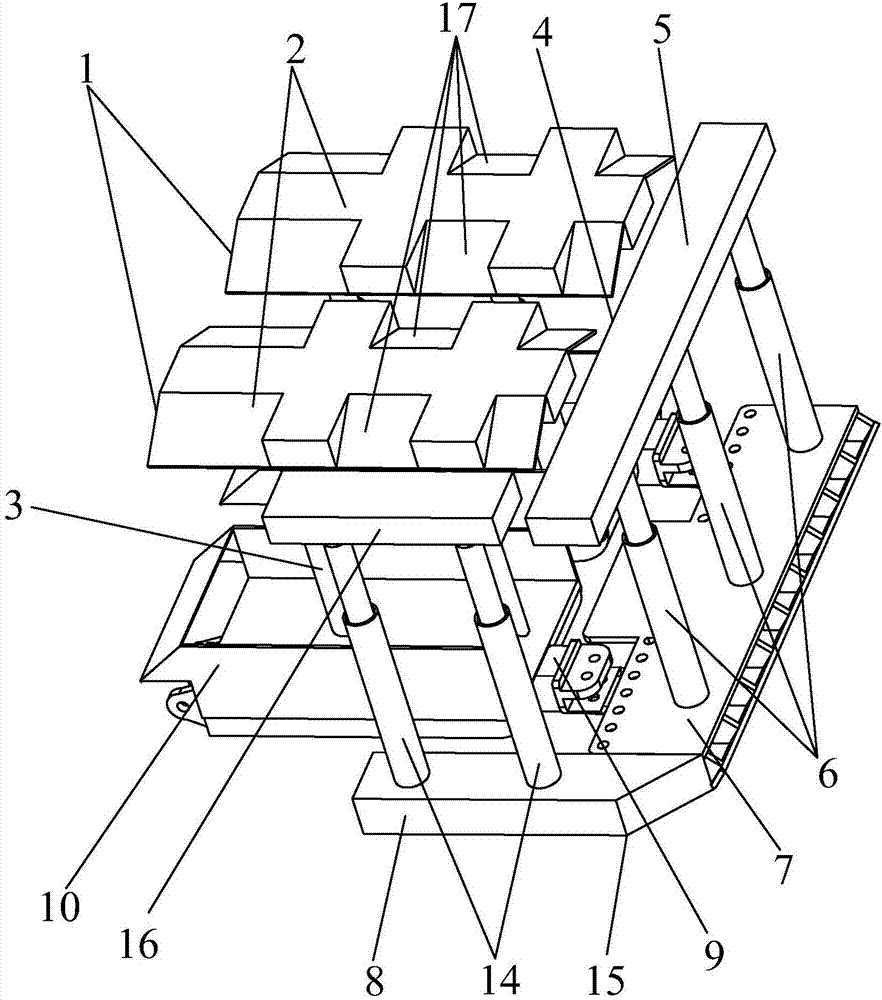

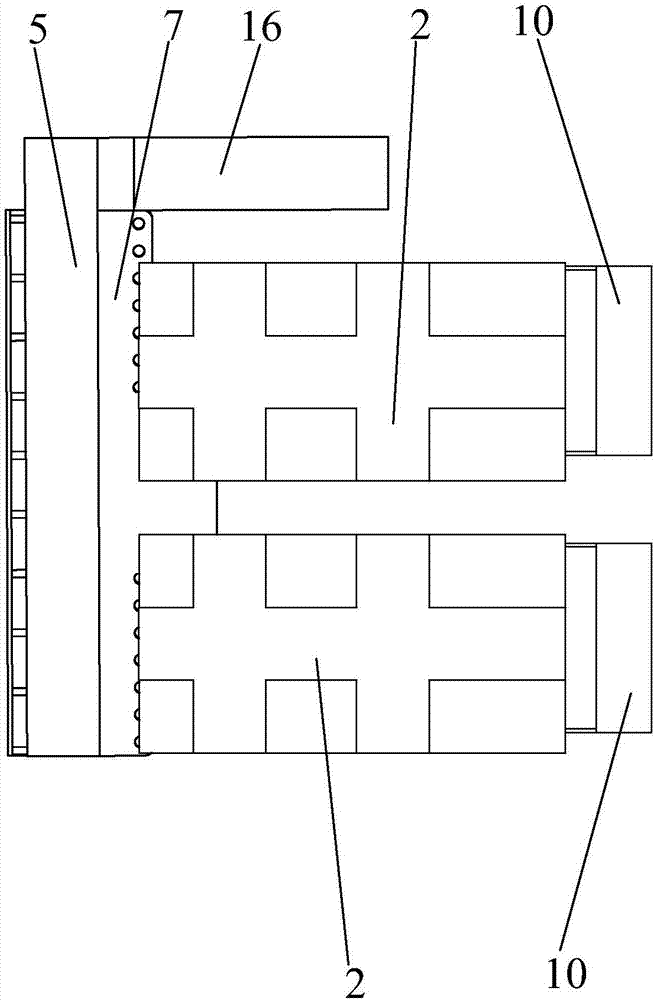

Temporary shoring system of tunnel arch wall initial shoring intruding limiting arch replacing construction

PendingCN108868834ASimple structureReasonable designUnderground chambersTunnel liningTunnel constructionSteel frame

The invention discloses a temporary shoring system of tunnel arch wall initial shoring intruding limiting arch replacing construction. The system comprises a temporary inverted arch arranged in a to-be-changed arch section and multiple portal type supporting structures which are arranged from front to back, and the temporary inverted arch is located at the inner side bottom of a tunnel upper portion hole; in the to-be-changed arch section, to-be-changed arch frames are to-be-supported arch frames except an initial replacing arch frame, each to-be-supported arch frame is supported through one portal type supporting structure, the temporary inverted arch comprises multiple temporary inverted arch supporting frames and longitudinal connecting structures, and each portal type supporting structure comprises a portal type supporting frame and a supporting assembly which is arranged on the same tunnel cross section with the portal type supporting frame. The system has the advantages of reasonable design, convenient construction and good using effect, the temporary inverted arch is taken as the basis and the portal type supporting structures are adopted, the structural comprehensiveness ishigh, the foundation is firm, the problems of tilting and collapsing of tunnel arch replacing steel frames can be effectively solved, the arch replacing construction process is safe and reliable, andthe tunnel construction process is not influenced.

Owner:CHINA RAILWAY 20 BUREAU GRP

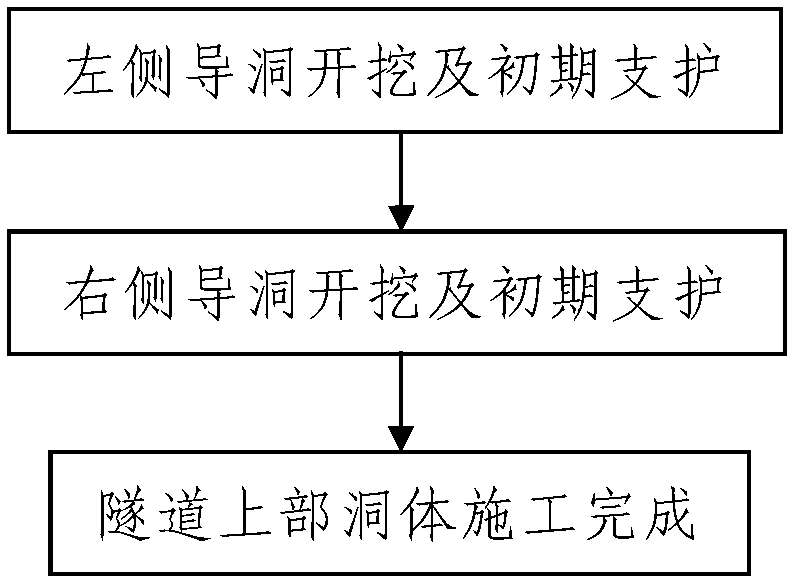

Method of constructing center division of upper bench of tunnel crossing stratum fracture zone

ActiveCN108979667AThe method steps are simpleReasonable designUnderground chambersTunnel liningSupporting systemFracture zone

The invention discloses a method of constructing a center division of an upper bench of a tunnel crossing a stratum fracture zone. Upper bench excavation is performed on a construction tunnel from rear to front so as to obtain an excavated tunnel upper hole; a center division temporary support structure is arranged in the tunnel upper hole; a tunnel primary support structure of the tunnel upper hole includes an arch wall anchor net spray support structure and an arch wall rigid support system. The upper bench excavation includes I, excavating a left guide hole, and carrying out primary supporting; II, excavating a right guide hole and carrying out primary supporting. The method has simple steps, reasonable design, good construction simplicity and good service effect; a tunnel upper half section is excavated by means of a center division method, excavation section is narrowed, and stability of an arch top is guaranteed; both the arch wall rigid support system and the center division temporary support structure are supported via a lower bearing beam and are connected into an integrated stable-structure support system; settling of a primary support arch frame in the upper hole can beavoided, and stability of primary supporting can be effectively guaranteed.

Owner:CHINA RAILWAY 20 BUREAU GRP

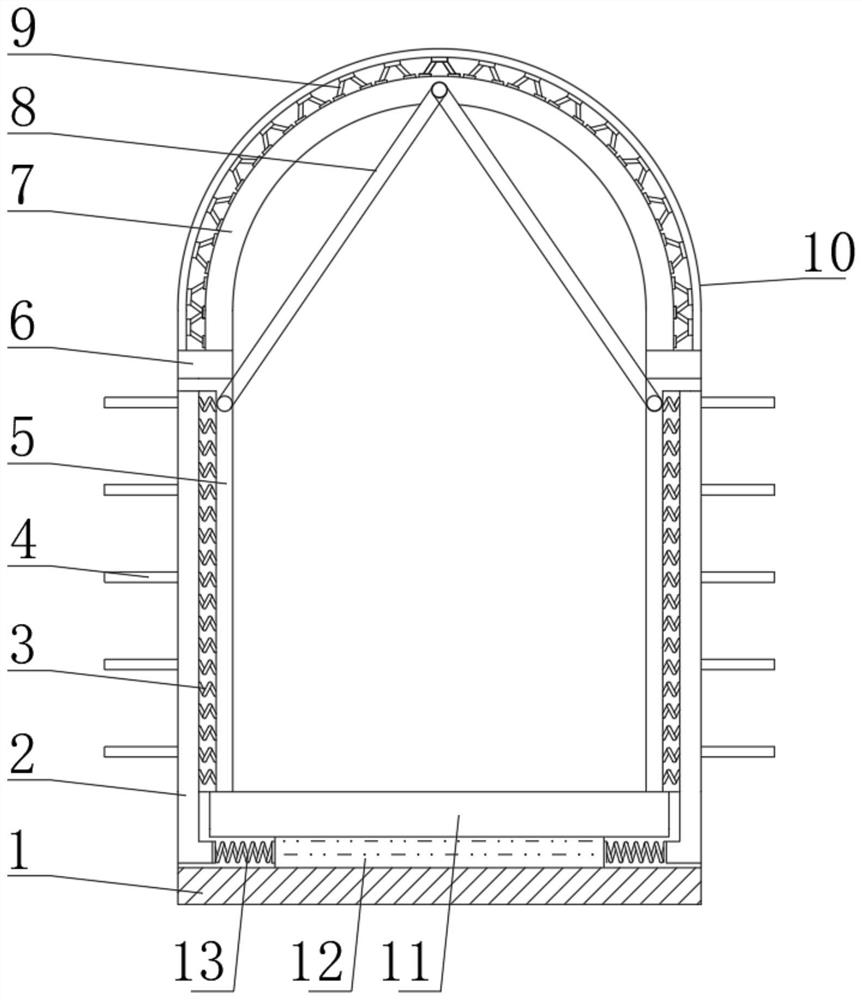

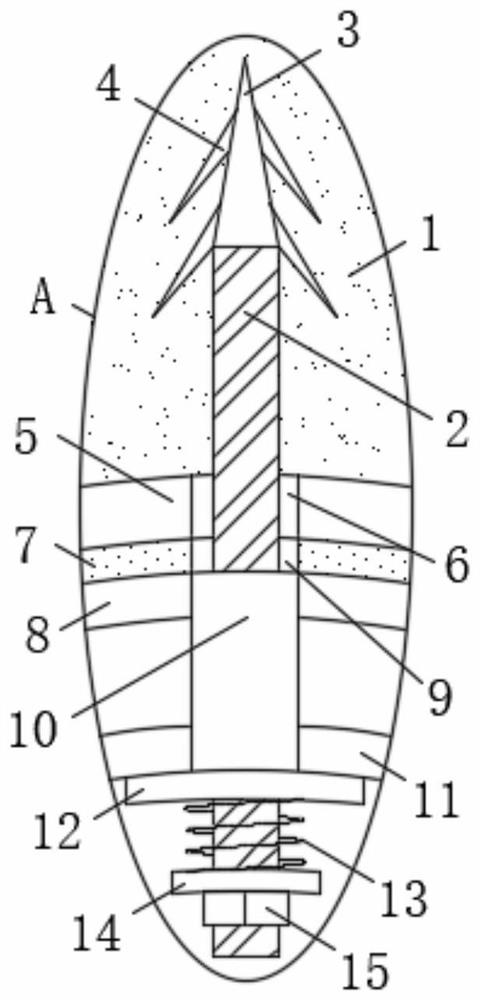

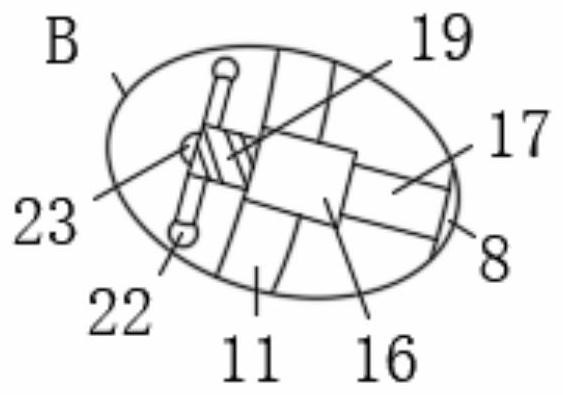

Anti-rock-burst supporting frame for mining

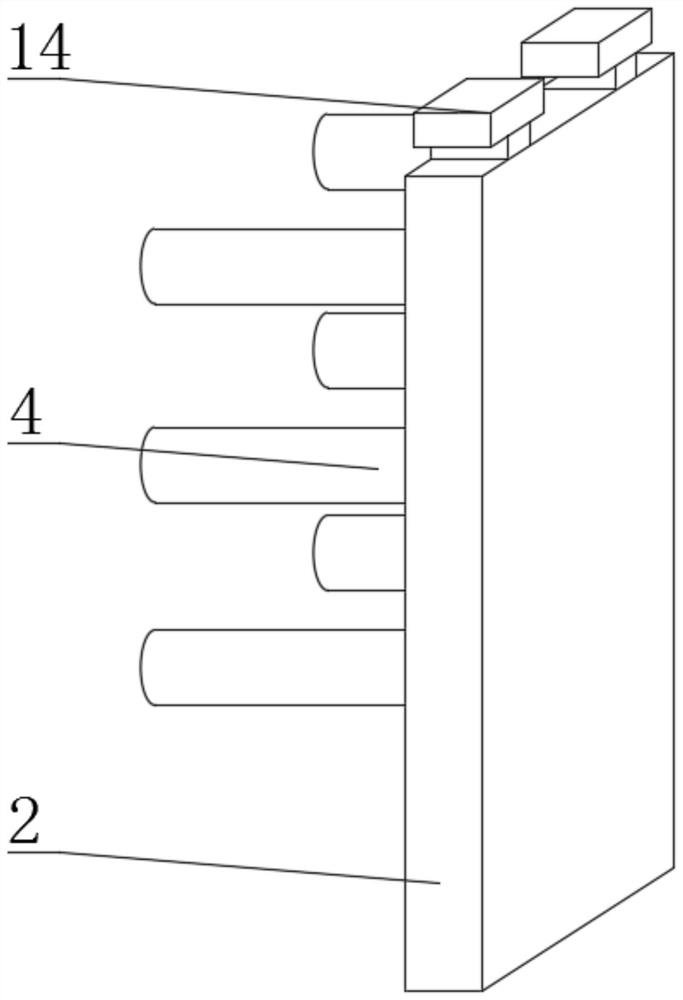

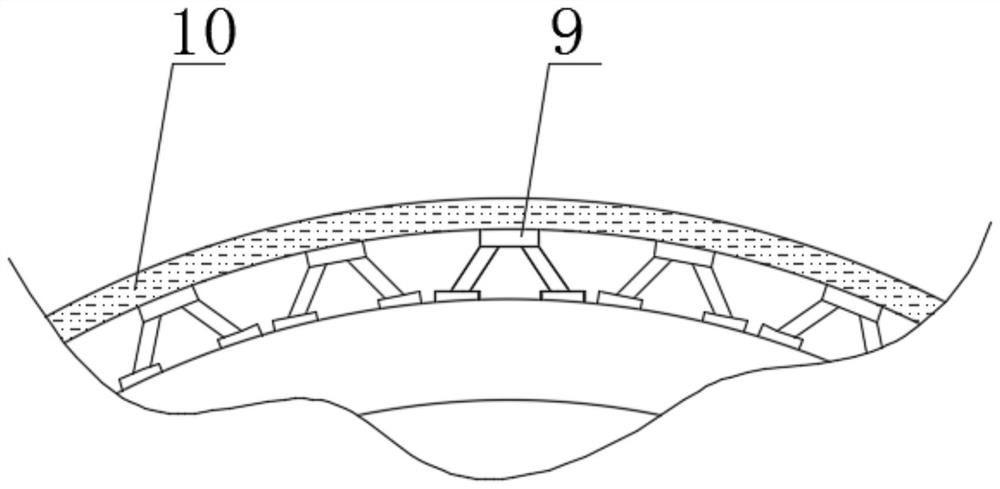

InactiveCN111779515AEnsure support stabilityImprove support stabilityUnderground chambersNon-rotating vibration suppressionRubber sheetRock bolt

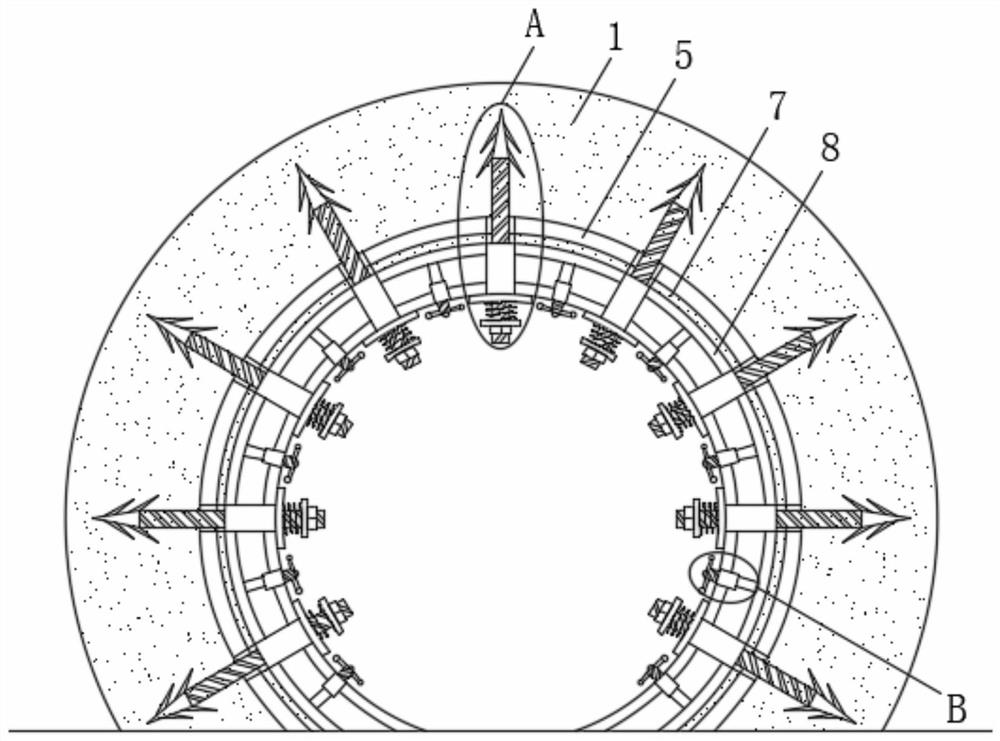

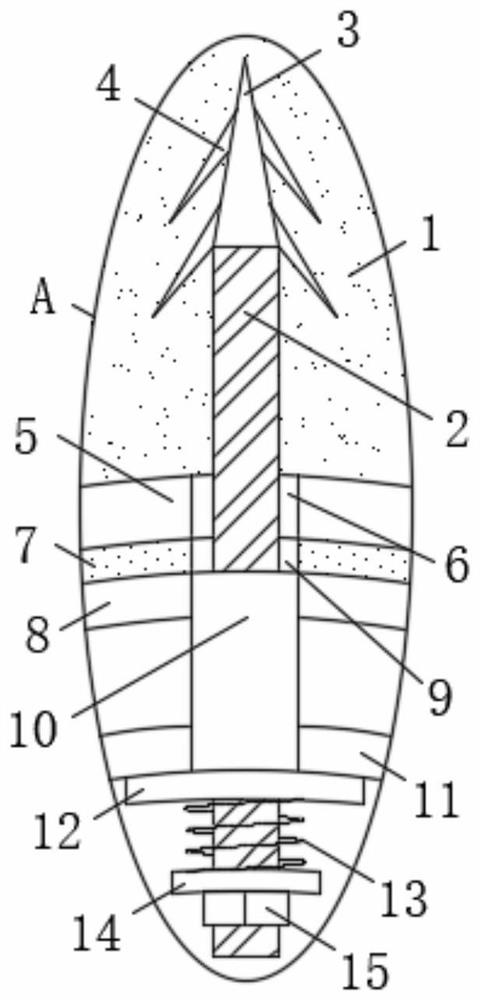

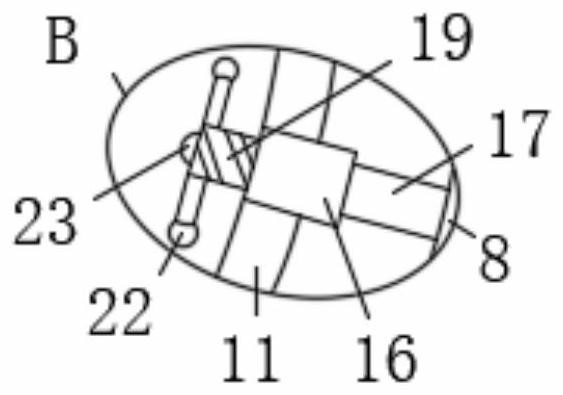

The invention discloses an anti-rock-burst supporting frame for mining. The anti-rock-burst supporting frame includes a fixed bottom plate, a load-bearing block, a pressure plate, a supporting plate,a buffer plate, rubber plates, an arc-shaped supporting plate and an arc-shaped compression-resistant plate; if impact force generated due to rock burst born by a top plate of a tunnel is born by thearc-shaped supporting plate, the arc-shaped compression-resistant plate and a triangular supporting frame, the pressure is transmitted to the two rubber plates, the rubber plates are deformed to buffer the impact force, and after buffering is performed, the rubber plates are reset; and if compact force generated due to the rock burst born by a side wall of the tunnel is applied to the buffer platethrough anchor rods, the buffer plate moves toward a weighing block after stressed, a first spring and a second spring are stressed and deformed to buffer the impact force, and the first spring and the second spring are reset after the buffering is completed to ensure the stability of the supporting on the tunnel. A better supporting effect can be played on the tunnel, and the impact force can bebuffered when the rock burst occurs, so that the impact on the supporting frame is reduced, and the service life is prolonged.

Owner:HUATING COAL GRP +2

Large-section loess tunnel supporting system and supporting construction method

PendingCN110761808AReasonable structural designEasy constructionUnderground chambersTunnel liningGeotechnical engineeringStructure support

The invention discloses a large-section loess tunnel supporting system and a supporting construction method. The large-section loess tunnel supporting system comprises a tunnel forepoling structure, atunnel initial supporting structure and a tunnel secondary lining. The upper surface of an inverted arch secondary lining in the tunnel secondary lining is a horizontal plane, and an inverted arch backfill layer is arranged on the horizontal plane. The supporting construction method comprises the following steps of firstly digging a tunnel and conducting initial supporting; and secondly constructing the secondary lining and backfilling the inverted arch. The large-section loess tunnel supporting system is reasonable in design, easy and convenient to construct, high in construction efficiencyand good in use effect, the tunnel forepoling structure, the tunnel initial supporting structure and the tunnel secondary lining constitute a combined supporting system to stably and reliably supportthe large-section loess tunnel, the upper surface of the inverted arch of the secondary lining is adjusted to be a horizontal plane, the construction process of the inverted arch of the tunnel can beeffectively simplified, and the rigidity of the inverted arch of the tunnel is greatly improved; in this way, the construction efficiency of the tunnel secondary lining is improved, the ring sealingtime of the tunnel secondary lining is shortened, the integrity of the tunnel secondary lining is higher, and the overall force bearing effect is better.

Owner:CHINA RAILWAY 20 BUREAU GRP

High-ground-stress weak surrounding rock tunnel supporting structure and construction method thereof

ActiveCN111764931APrevent seepageEnsure support stabilityMining devicesUnderground chambersRock tunnelTorsion spring

The invention discloses a high-ground-stress soft surrounding rock tunnel supporting structure and a construction method thereof, and belongs to the technical field of traffic engineering facilities.The high-ground-stress soft surrounding rock tunnel supporting structure includes weak surrounding rock and an intelligent control circuit arranged on one side of the weak surrounding rock. A threadedanchor rod is connected inside the weak surrounding rock in an embedded mode, a surrounding rock sealing layer is poured at the position, corresponding to the threaded anchor rod, of the inner arc surface of the weak surrounding rock, and the threaded anchor rod is located in a sealing layer buffer opening formed in the surface of the surrounding rock sealing layer. Through the mutual cooperationof the designed surrounding rock sealing layer, a water-resisting layer, a cushion plate, an inner supporting body, a torsion spring, the threaded anchor rod, a first nut and a second nut, the abnormality change and rapidly expansion of the weak surrounding rock are avoided, with the cooperation of the surrounding rock sealing layer and the water-resisting layer, the surrounding rock sealing layer has the windproof, sealing and stable abilities, and the water-resisting layer can prevent water in the weak surrounding rock from seeping out and eroding a tunnel.

Owner:浙江省衢州市交通建设集团有限公司

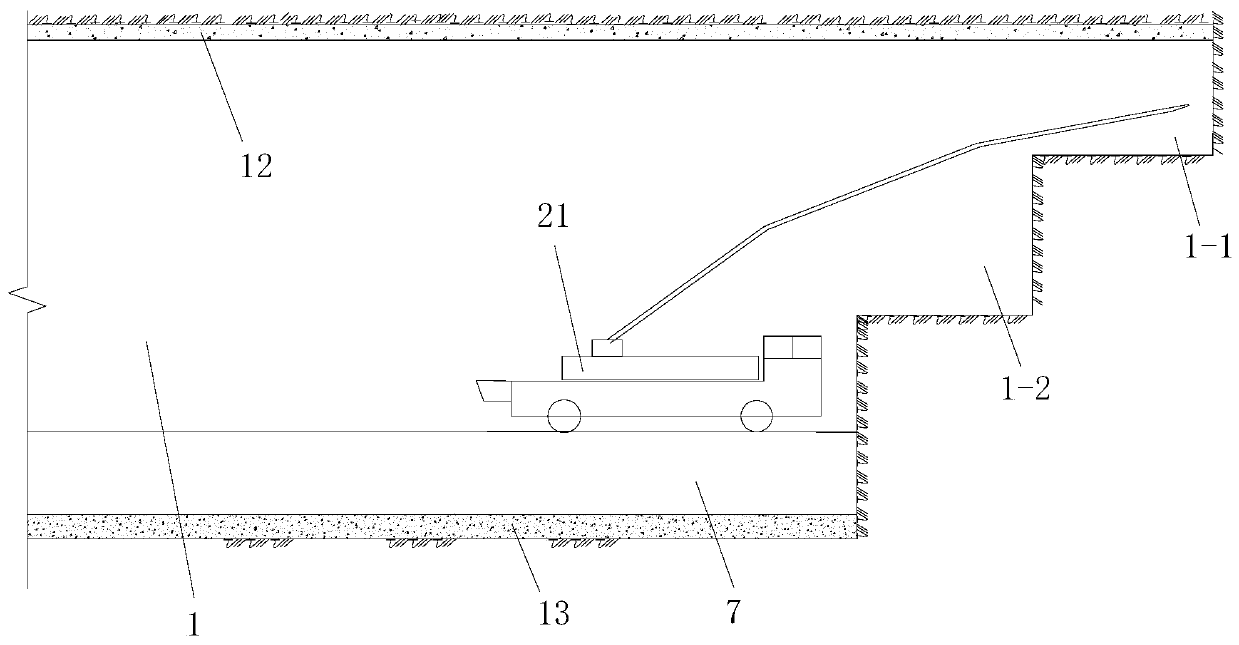

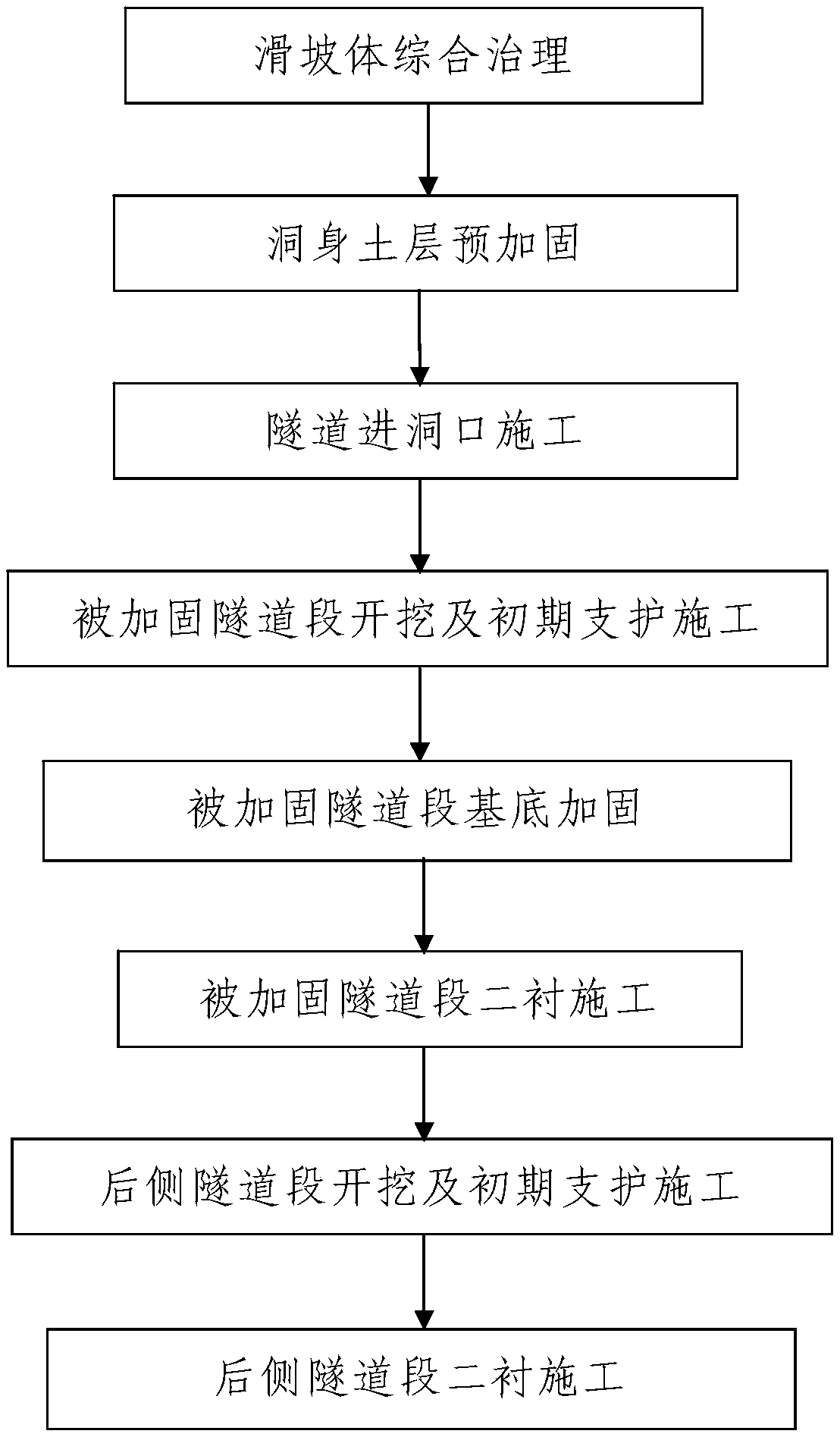

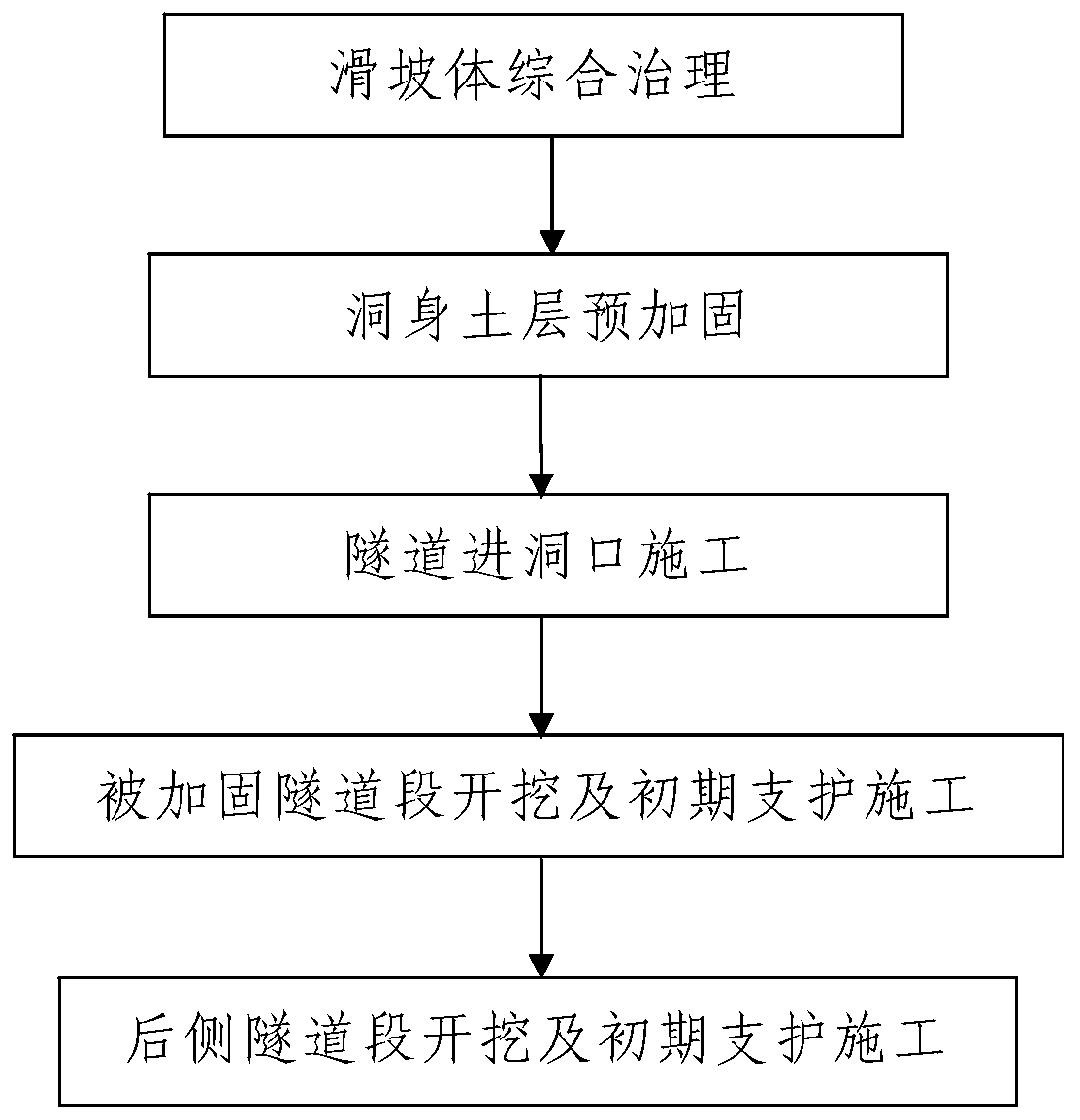

Construction method of loess tunnel entrance section through landslide mass

ActiveCN110778328AThe method steps are simpleReasonable designUnderground chambersExcavationsLandslideStructural engineering

The invention discloses a construction method of a loess tunnel entrance section through a landslide mass. The method comprises the following steps that 1, an entrance soil layer is pre-reinforced; 2,a tunnel entrance is constructed; 3, excavation and initial support construction is conducted on the reinforced tunnel section; 4, a reinforced tunnel section base is reinforced; 5, the reinforced tunnel section is subjected to secondary lining construction; 6, excavation and initial support construction is conducted on a rear side tunnel section; and 7, the rear side tunnel section is subjectedto secondary lining construction. The method is reasonable in design, simple and convenient to construct and good in use effect, cement-soil mixed piles are adopted for pre-reinforcement before excavation, a construction process of the tunnel entrance section through the landslide mass is guaranteed to be safe and reliable, meanwhile, the tunnel entrance section is excavated by adopting a three-step excavation method, the reinforced tunnel section base is reinforced, an excavation process of the tunnel entrance section through the landslide mass can be guaranteed to be safe and reliable, in addition, the influence on the stability of a soil layer on the circumferential side of the tunnel entrance is small, and the stability of the excavated and formed tunnel entrance can be effectively improved.

Owner:CHINA RAILWAY 20 BUREAU GRP

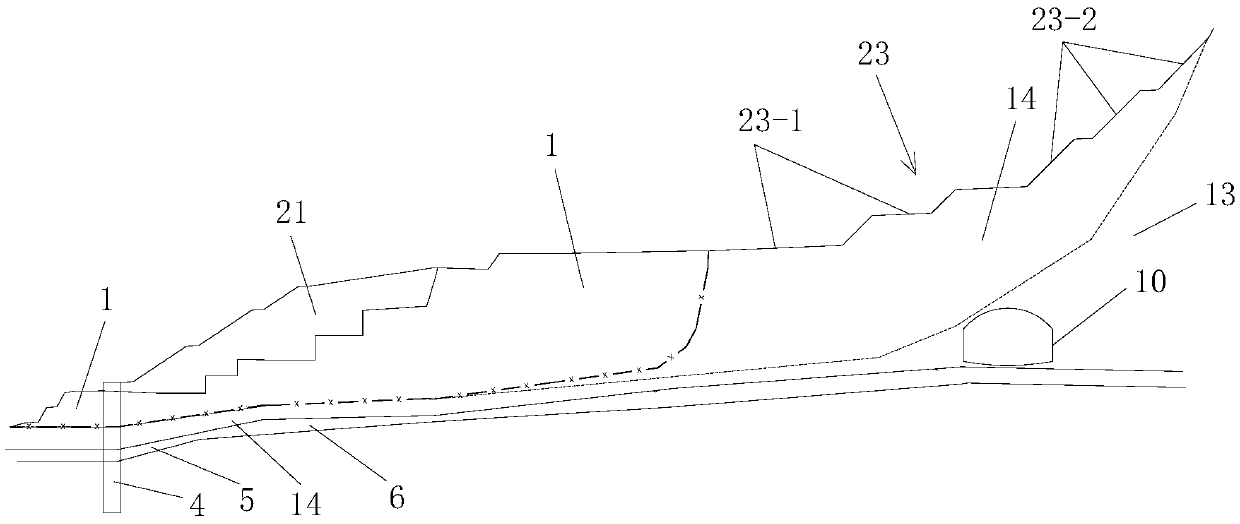

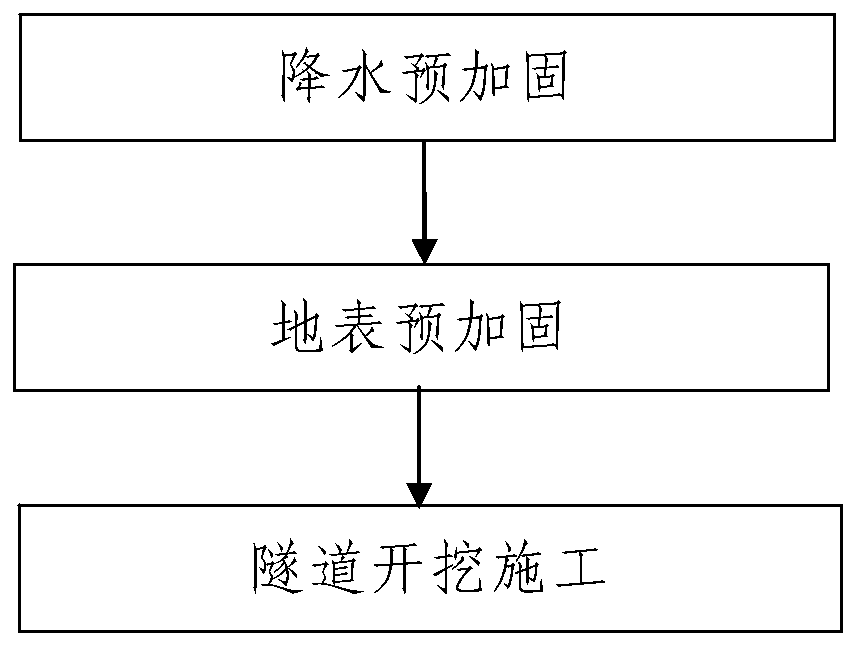

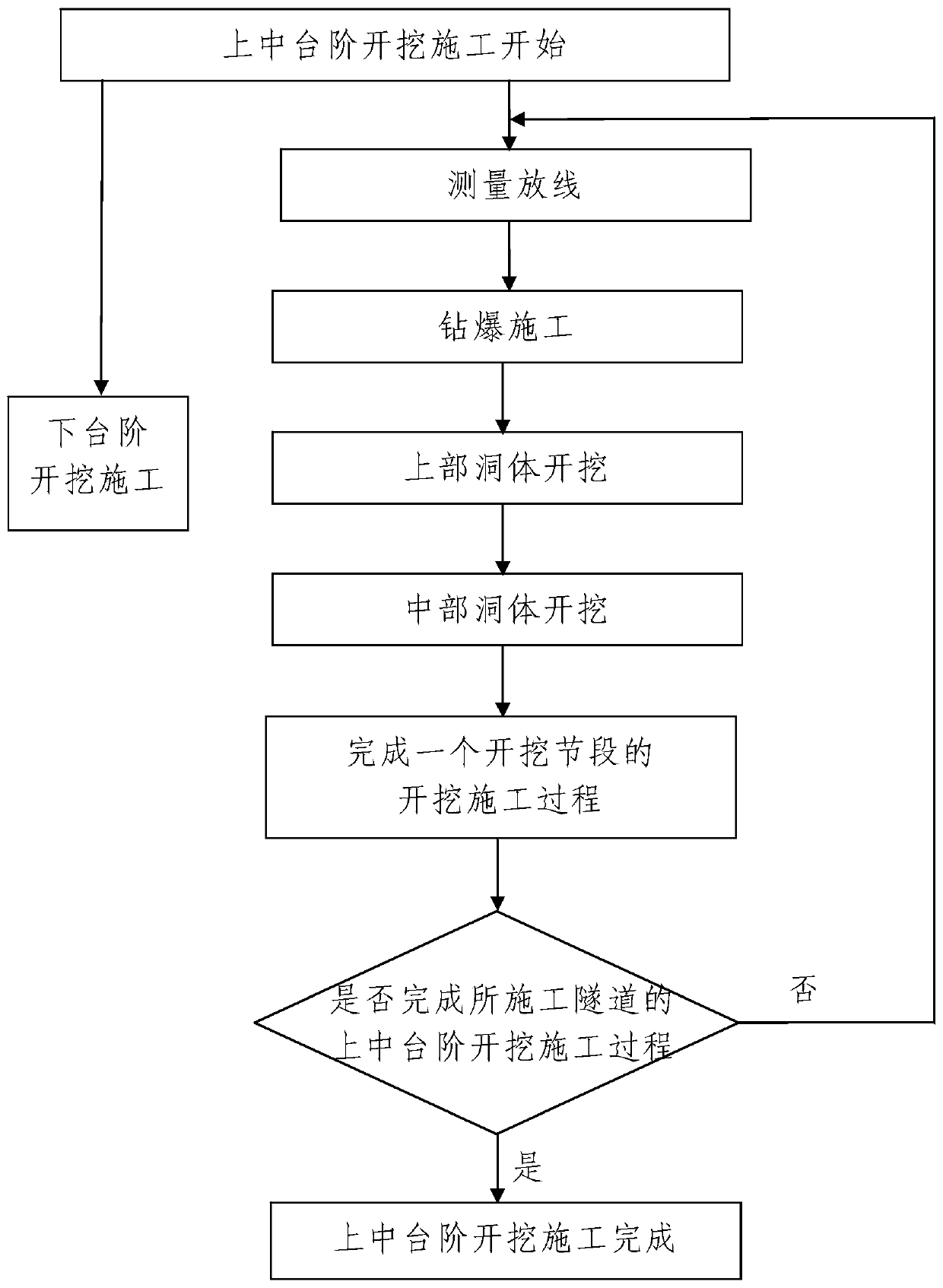

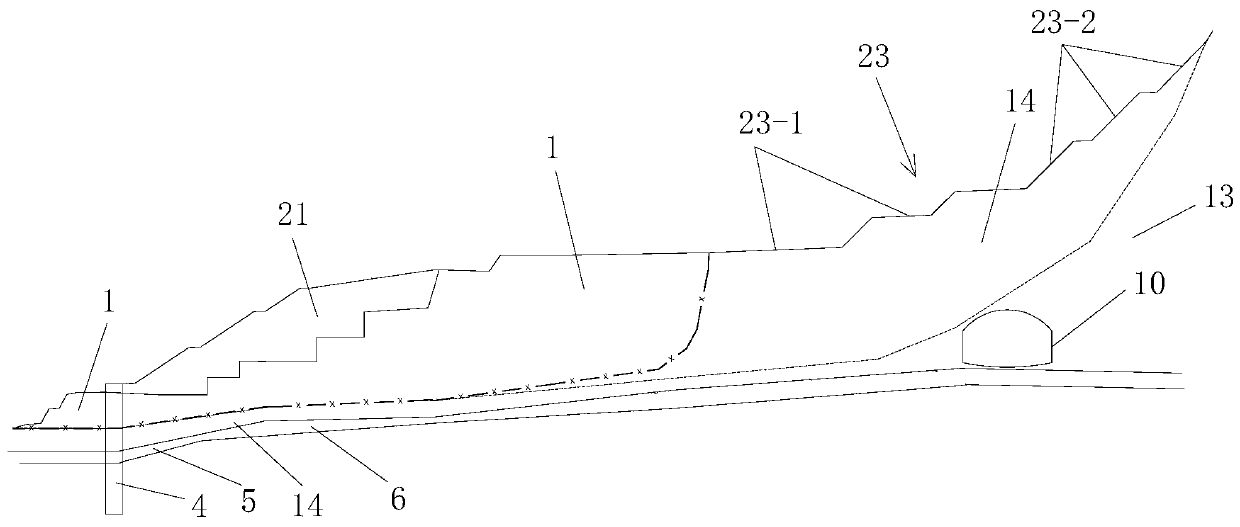

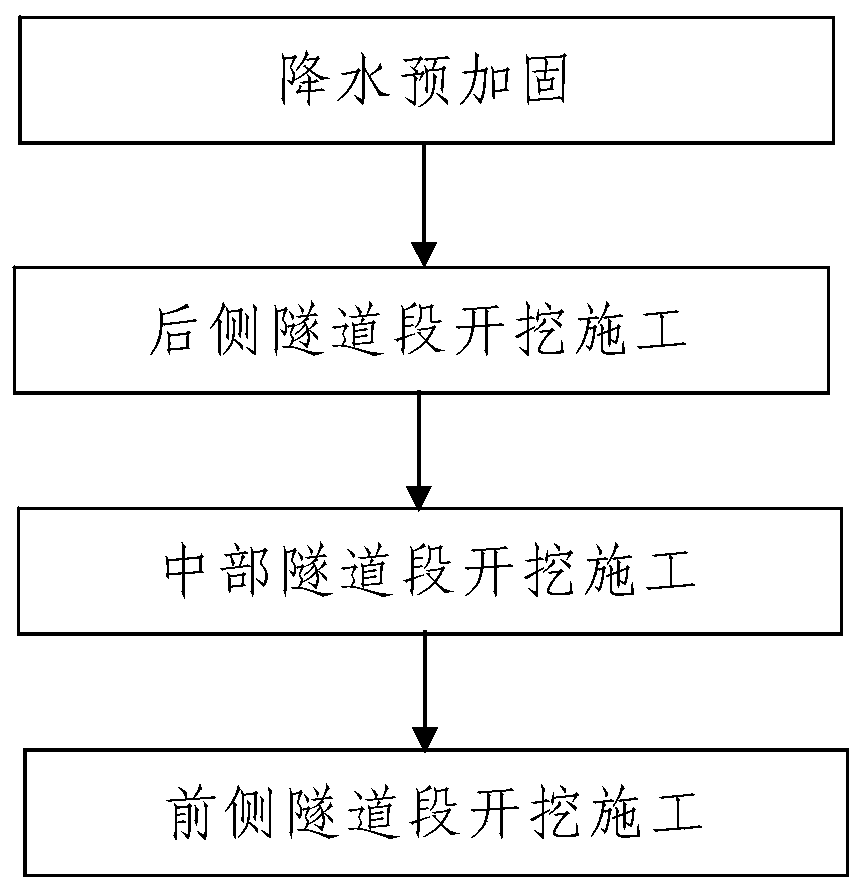

Tunnel portal section pre-reinforcement and excavation construction method based on partition blasting

ActiveCN110847929AConstruction safetyStable structureUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a tunnel portal section pre-reinforcement and excavation construction method based on partition blasting. The construction method comprises the following steps of 1, precipitation pre-reinforcement; 2, earth surface pre-reinforcement, and specifically, reinforcing the surface of a backfill section in a construction tunnel portal section through adopting a cement soil stirring pile; and 3, tunnel excavation construction, and specifically, carrying out excavation construction from rear to front in a plurality of excavation sections, wherein the process comprises the following steps of surveying and setting out, performing drilling and blasting construction, excavating an upper portal body, excavating a middle portal body and excavating a lower portal body. The construction method is reasonable in design, simple and convenient in construction and good in use effect; the underground water level is reduced through precipitation pre-reinforcement, and then surroundingrock is effectively reinforced; after the backfill section is subjected to surface pre-reinforcement through using the cement soil stirring pile, a three-step synchronous excavation mode is used forcarrying out partition blasting excavation, so that it is ensured that the tunnel excavation process is safe and reliable and a tunnel structure is stable.

Owner:CHINA RAILWAY 20 BUREAU GRP

Timbering device for hydraulic support withdrawing and fully-mechanized mining timbering equipment

ActiveCN107152298ARealize mechanized controlNo manual operationMine roof supportsStructural engineeringMechanical engineering

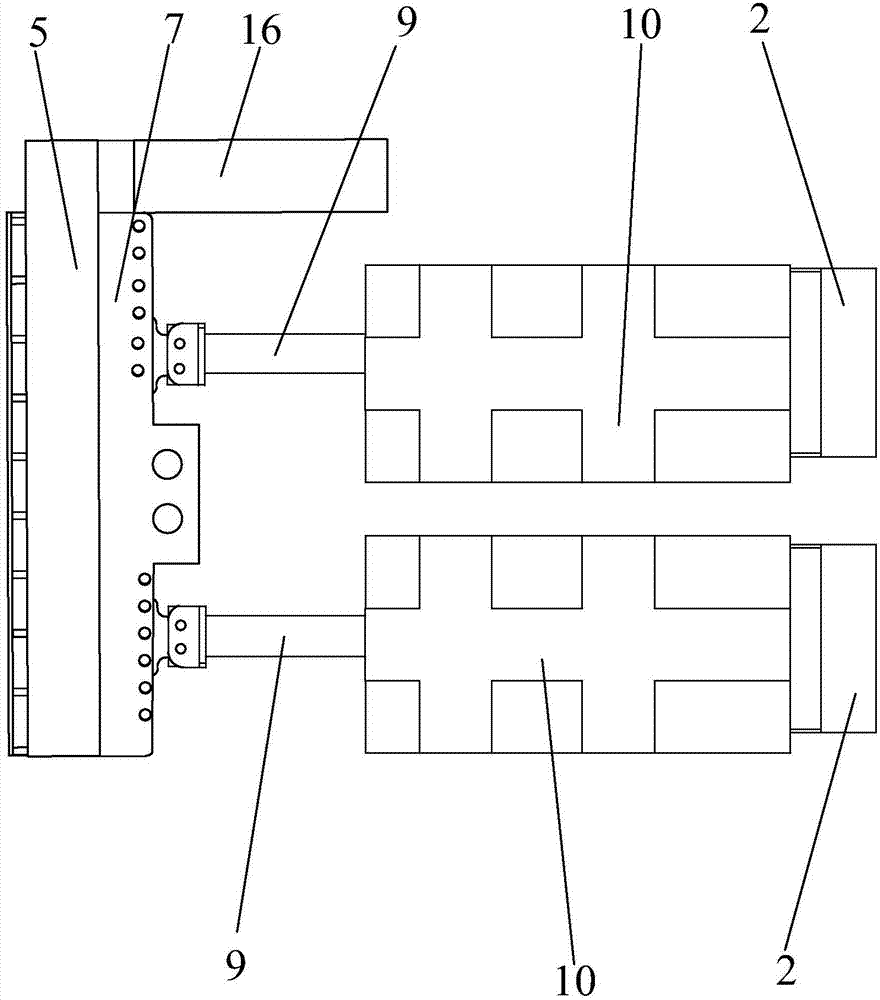

The invention discloses a timbering device for hydraulic support withdrawing and fully-mechanized mining timbering equipment and relates to the field of coal mine fully-mechanized mining equipment. The invention aims to provide a timbering device for hydraulic support withdrawing and fully-mechanized mining timbering equipment which have the advantages of high mechanization degree, safety and stability, high production efficiency, simple structure, low cost and easy operation. The timbering device for hydraulic support withdrawing comprises a first timbering component, a second timbering component and a push device, wherein one end of the push device is connected with the second timbering component, and the other end of the push device is connected with the first timbering component; the first timbering component comprises a first timbering beam, a first lifting driver and a supporting cross beam; the second timbering component comprises a second timbering beam, a second lifting driver and a base. The fully-mechanized mining timbering equipment disclosed by the invention comprises the timbering device for hydraulic support withdrawing, a shield support and a timbering support, wherein a to-be-withdrawn support and the shield support form a fully-mechanized mining face triangular area; the timbering device for hydraulic support withdrawing is arranged in the fully-mechanized mining face triangular area and on the gob side of the shield support.

Owner:南京石诚井巷装备有限责任公司

Tunnel construction method for passing through boundary strata of earth and stone

ActiveCN110985003AEffective reinforcementThe method steps are simpleUnderground chambersDrainageArchitectural engineeringDrilling and blasting

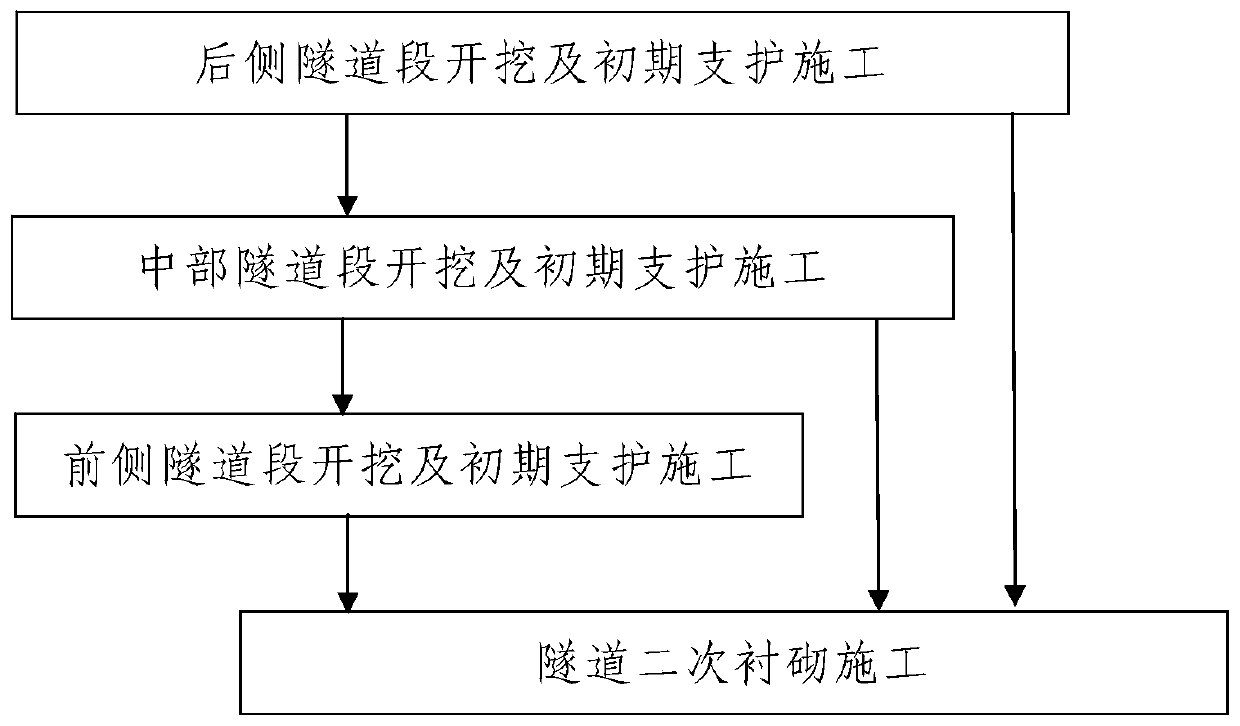

The invention discloses a tunnel construction method for passing through the boundary stratum of earth and stone. The tunnel construction method comprises the following steps: I, excavation of a reartunnel segment and initial supporting construction; II, excavation of a middle tunnel segment and initial supporting construction; III, excavation of a front tunnel segment and initial supporting construction, wherein the rear tunnel segment, the middle tunnel segment and the front tunnel segment are all three-step synchronous excavated tunnel segments; and in the process of excavation from rear to front, constructing the secondary lining of the tunnel on the inner side of the initial supporting structure of the constructed tunnel from rear to front. The tunnel construction method has the advantages of reasonable design, simple construction and good use effect. The tunnel construction method selects an appropriate drilling and blasting method according to the position relationship betweenthe earth and stone interface and a tunnel hole, adopts a three-step synchronous excavation way to carry out blasting excavation, can ensure the safe and reliable excavation process of the tunnel passing through the boundary stratum of earth and stone, and can ensure the stable structure of the tunnel. Moreover, in the excavation process, the initial supporting structure and the secondary lining of the tunnel are adopted to provide stable and reliable supporting for the large-section tunnel.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

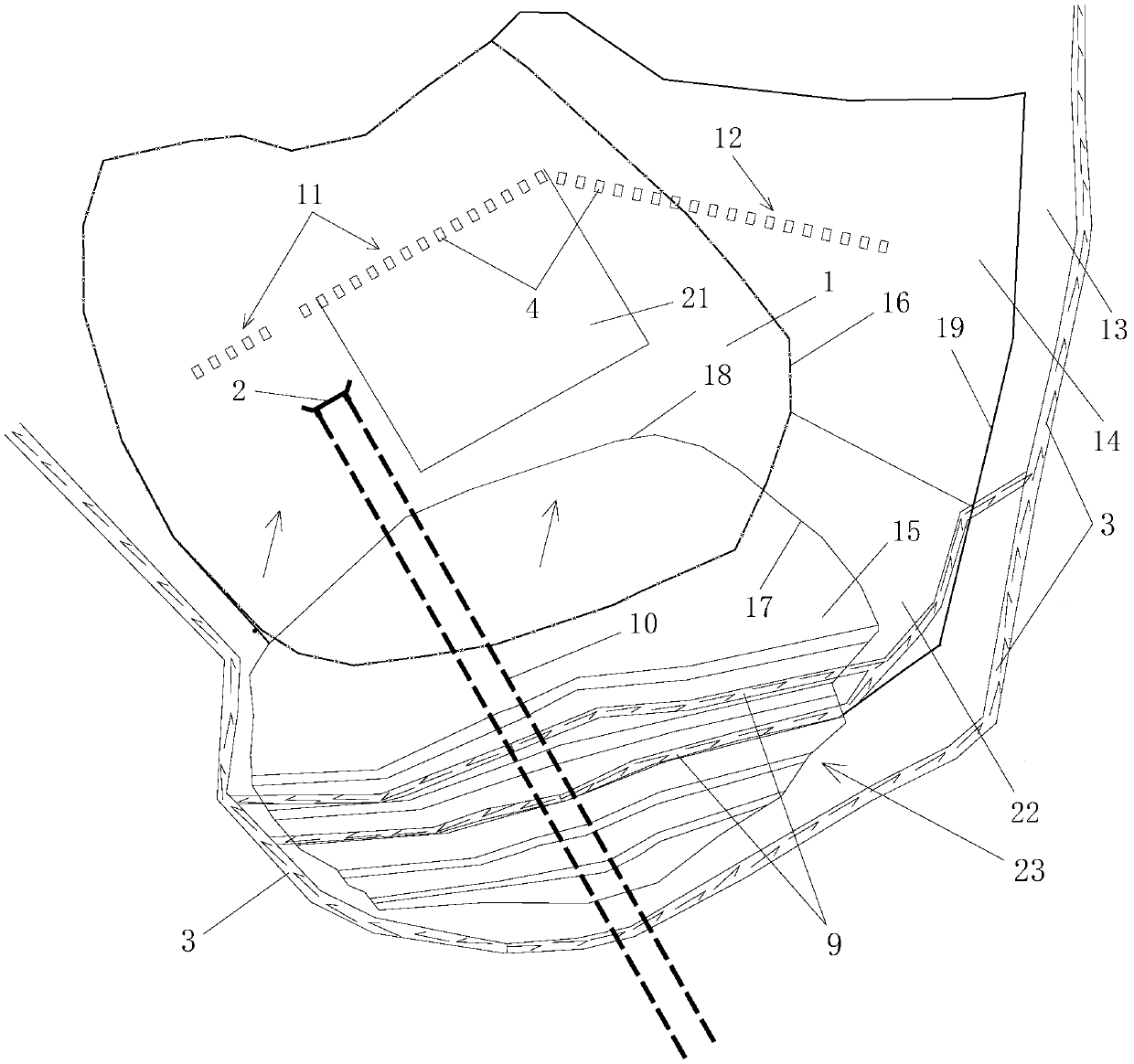

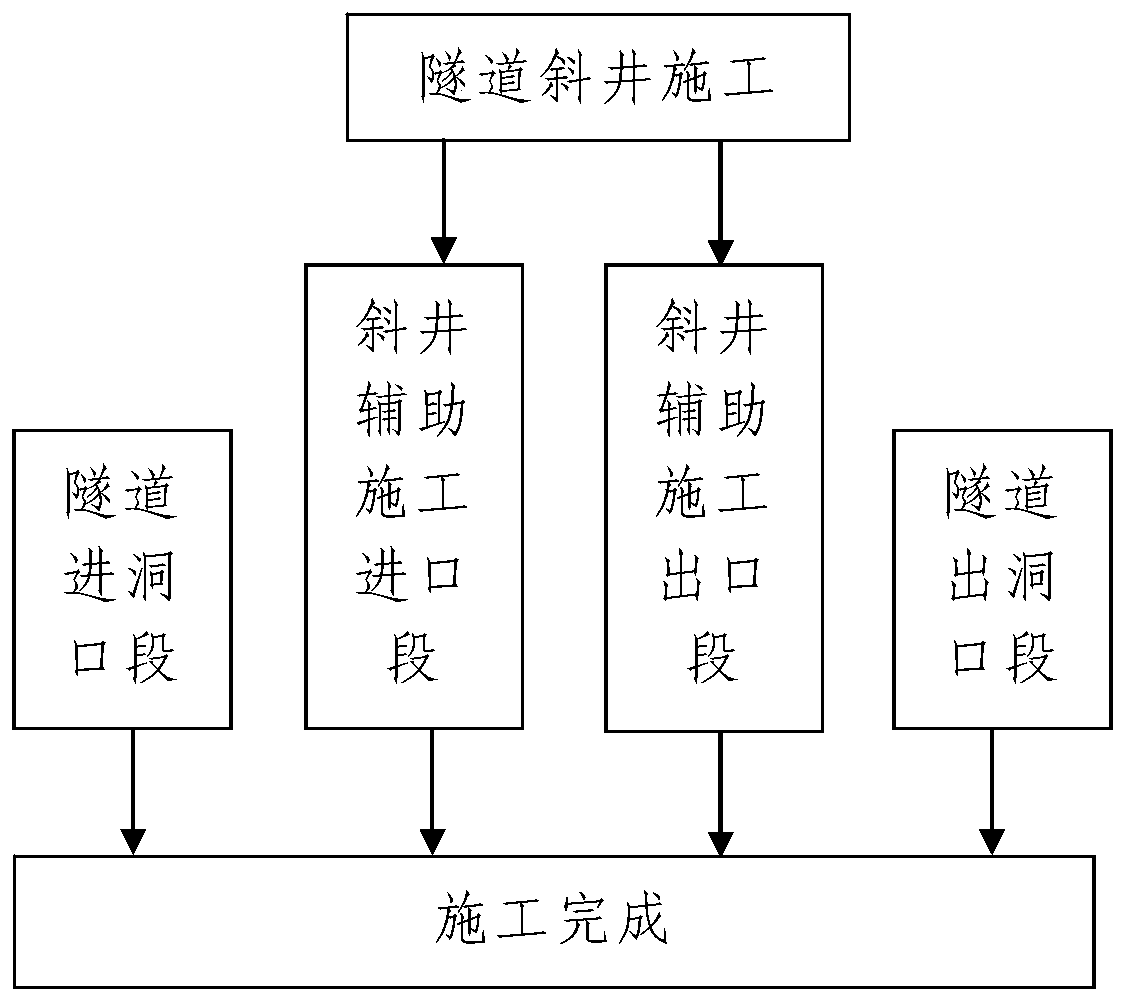

Through landslide body loess tunnel construction method

ActiveCN110905529AThe method steps are simpleReasonable designUnderground chambersTunnel liningTrackwayLandslide

The invention discloses a through landslide body loess tunnel construction method. The through landslide body loess tunnel construction method comprises the following steps of constructing a tunnel entrance section and a tunnel exit section simultaneously; and respectively constructing an inclined shaft auxiliary construction inlet section and an inclined shaft auxiliary construction outlet section through a tunnel inclined shaft when the tunnel entrance section and the tunnel exit section are constructed. The through landslide body loess tunnel construction method is reasonable in design, convenient to construct and good in using effect; the loess strata in the construction area where the tunnel entrance section is positioned is subjected to reinforcement treatment by using a cement soilmixing pile in advance before excavation, and the reinforcement length and the reinforcement depth are effectively limited; a loose soil body on a hole body of a tunnel hole is solidified in advance so as to ensure the safety and reliability of the construction process of a hole inlet section of the through landslide body loess tunnel; meanwhile, in the construction process of the tunnel by adopting a three-step excavation method, the construction process of track plates is completed synchronously, so that the construction process of the loess tunnel can be completed easily, conveniently and quickly; and the stability of an excavated and formed tunnel hole can be effectively improved.

Owner:CHINA RAILWAY 20 BUREAU GRP

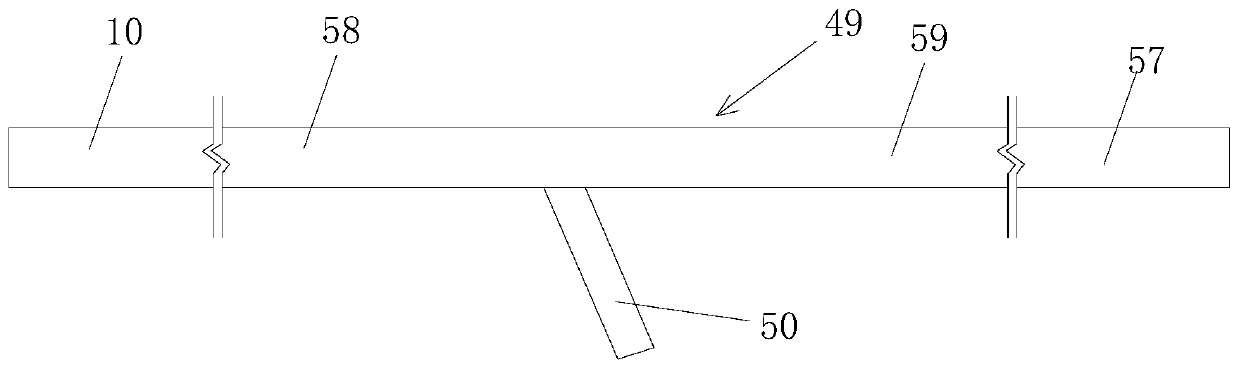

Excavation and supporting method for tunnel crossing high-angle thrust water-rich and sand-rich fault

ActiveCN109555528AThe method steps are simpleReasonable designUnderground chambersDrainageHigh angleStep method

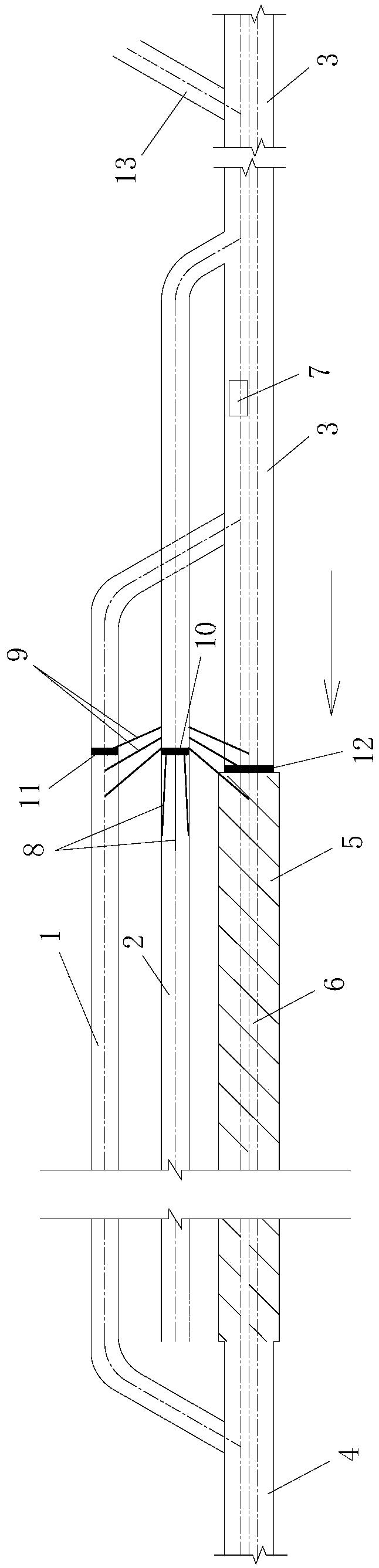

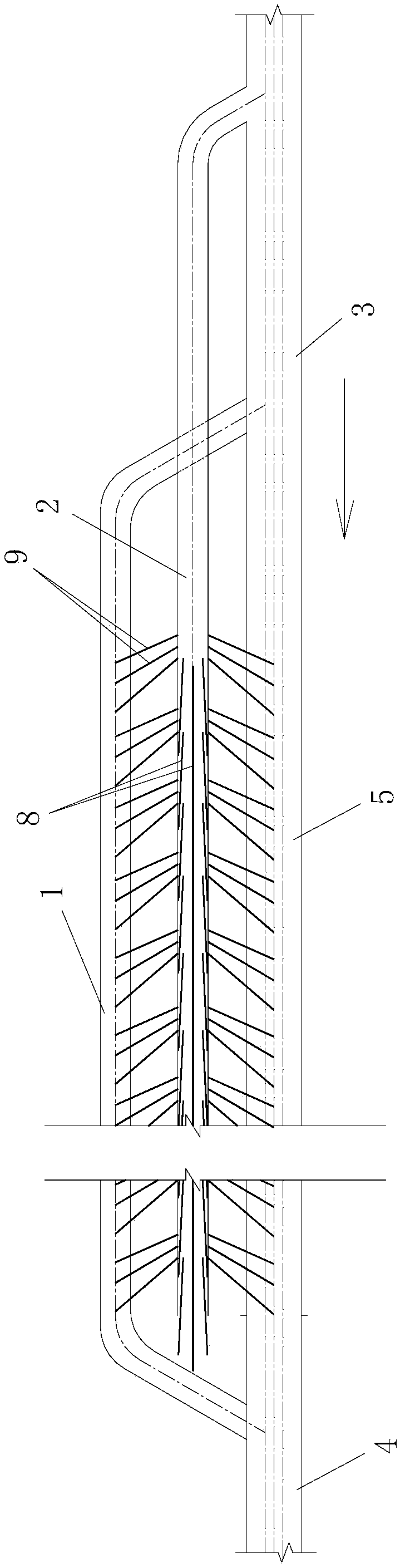

The invention discloses an excavation and supporting method for a tunnel crossing a high-angle thrust water-rich and sand-rich fault. A circuitous pilot tunnel and a drainage tunnel are arranged on asame side of a tunnel main hole. When excavation and supporting construction is carried out on a construction tunnel, the excavation and supporting method for the tunnel crossing the high-angle thrustwater-rich and sand-rich fault comprises the steps that 1, preliminary excavation and supporting construction is carried out on a rear side tunnel segment; 2, synchronous excavation and supporting construction is carried out on a rear side tunnel segment and a drainage tunnel body of the drainage tunnel; 3, the synchronous excavation and supporting construction is carried out on the rear side tunnel segment, the drainage hole body of the drainage tunnel and a rear side circuitous pilot tunnel segment; 4, the excavation and supporting construction is carried out on a front drainage tunnel body, a front pilot tunnel segment and a middle tunnel segment; and 5, the excavation and supporting construction is carried out on a front side tunnel segment. According to the excavation and supportingmethod for the tunnel crossing the high-angle thrust water-rich and sand-rich fault, the steps are simple, design is reasonable, construction is simple and convenient, the using effect is good, the tunnel hole is excavated by adopting a three-step method, full fracture surface supporting is carried out on the tunnel hole by adopting a double-layer preliminary supporting structure after excavation,and the safety of a later tunnel structure can be ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

Large-section tunnel stability control construction method capable of passing through earth and stone boundary stratum

ActiveCN110863832AThe method steps are simpleReasonable designUnderground chambersBlastingArchitectural engineeringStructural engineering

The invention discloses a large-section tunnel stability control construction method capable of passing through an earth and stone boundary stratum, and an earth and stone interface is positioned in an upper hole of a constructed tunnel. During excavation construction on the constructed channel, the large-section tunnel stability control construction method comprises the following steps: I, upperand middle step excavation step: performing upper and middle step excavation construction on the constructed tunnel in multiple excavation sections from rear to front, wherein the process of performing upper and middle step excavation construction on any excavation section comprises surveying and setting out, drilling and blasting construction, upper hole excavation and middle hole excavation; andII, lower step excavation construction. The large-section tunnel stability control construction method is reasonable in design, is simple and convenient in construction, is good in use effect, separately performs blasting region division on an upper blasting region in an upper step and a middle blasting region on a middle step, defines layout position of each blast hole in each blasting region, can effectively prevents tunnel face collapse or arch crown collapse caused by relatively great vibrations generated by blasting while large-section once explosive load is too great, ensures a safe andreliable tunnel excavation process, and can ensure a stable tunnel structure.

Owner:CHINA RAILWAY 20 BUREAU GRP

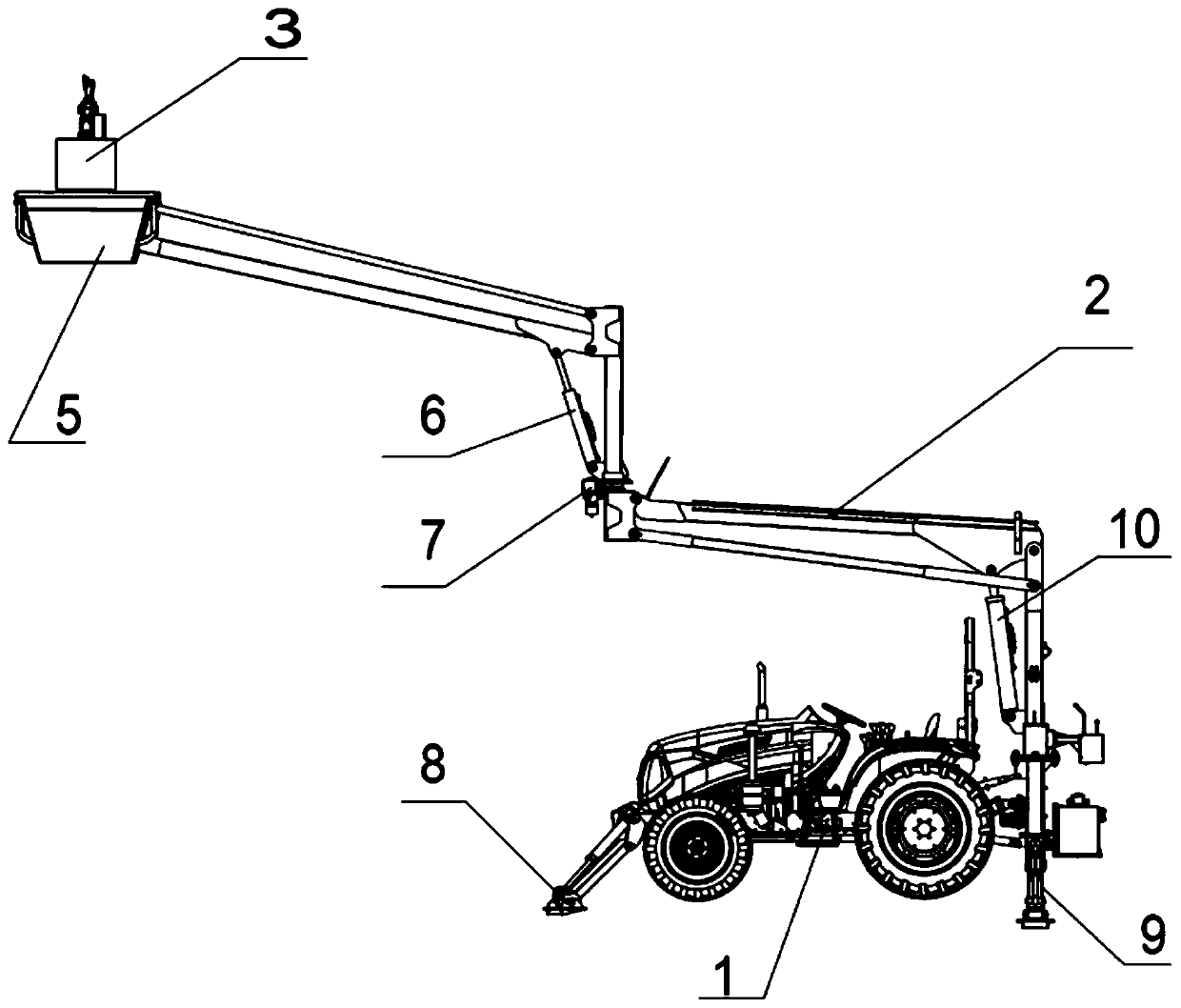

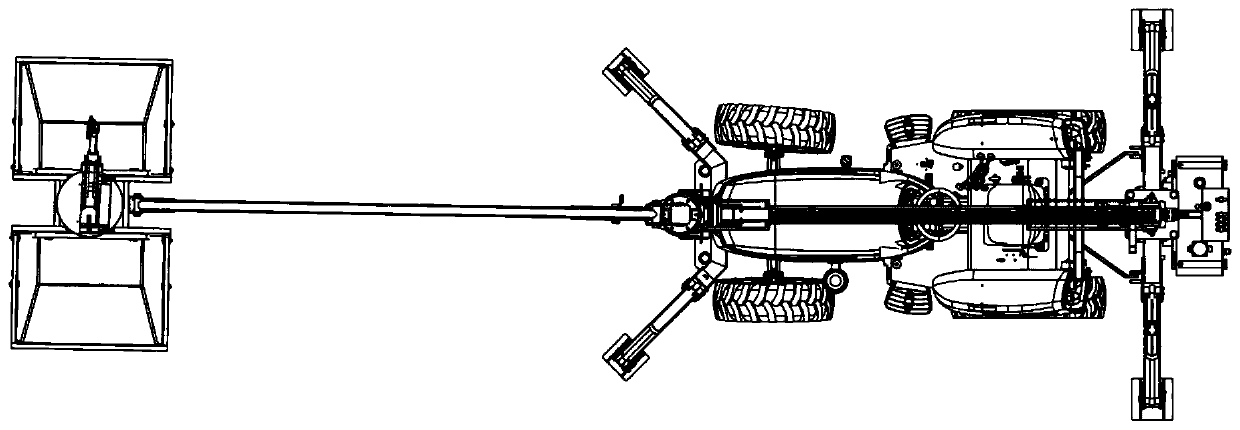

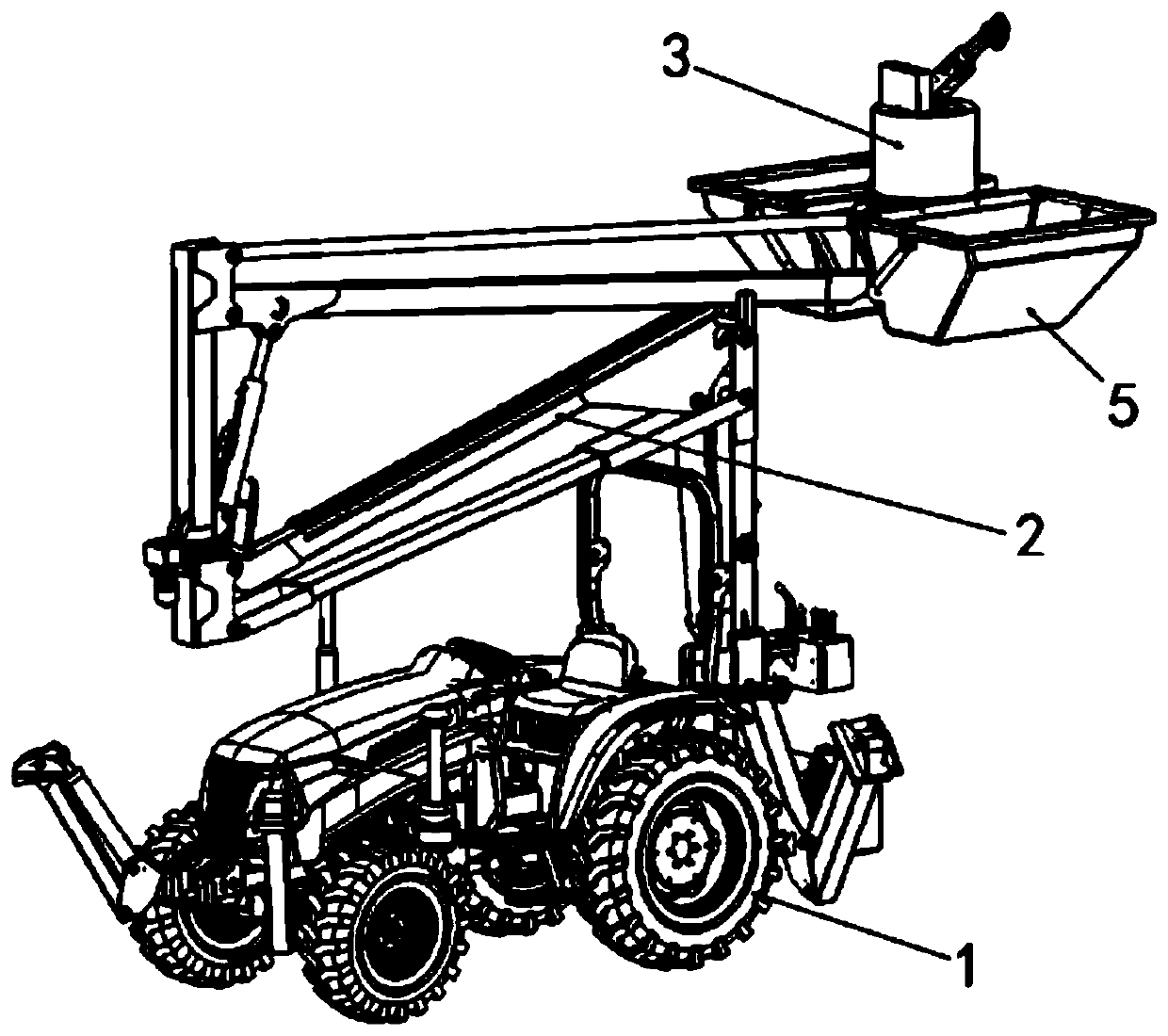

Date palm garden multifunctional management device

ActiveCN111165338AImprove labor productivityHomework easyCuttersLifting devicesAgricultural scienceAgricultural engineering

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

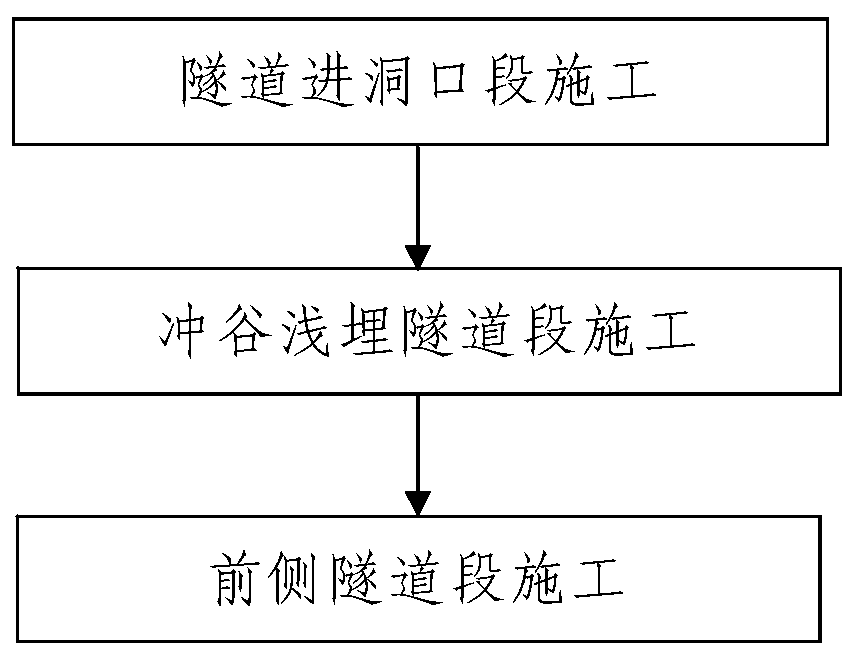

Construction method of water-rich loess tunnel capable of passing through loess gulley

ActiveCN110792440AThe method steps are simpleReasonable designUnderground chambersTunnel liningTunnel constructionLoess

The invention discloses a construction method of a water-rich loess tunnel capable of passing through a loess gulley. The water-rich loess tunnel comprises a tunnel entrance entering section, a gulleyshallow-buried tunnel section and a front side tunnel section, wherein the gulley shallow-buried tunnel section is connected between the tunnel entrance entering section and the front side tunnel section; the construction method comprises the following steps: 1, constructing the tunnel entrance entering section; 2, constructing the gulley shallow-buried tunnel section; and 3, constructing the front side tunnel section. The construction method is simple in step, reasonable in design, simple and convenient in construction and excellent in using effect; the reasonable look-ahead reinforcing method and the tunnel base reinforcing method are selected to reinforce the tunnel soil mass according to different stratums of the tunnel entrance entering section, the gulley shallow-buried tunnel section and the front side tunnel section, the excavation process of the water-rich large-cross-section loess tunnel can be effectively ensured to be safe and reliable, and the stability of the dug formedtunnel can be effectively improved.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

Pre-reinforcement and excavation construction method for tunnel entrance segment of loess tunnel passing through slip mass

ActiveCN110821512AThe method steps are simpleReasonable designTunnelsBulkheads/pilesStructural engineeringLoess

The invention discloses a pre-reinforcement and excavation construction method for a tunnel entrance segment of a loess tunnel passing through a slip mass. The method comprises the following steps offirstly, tunnel body soil layer pre-reinforcement, secondly, tunnel entrance construction of the tunnel, thirdly, excavation and preliminary bracing construction of the reinforced tunnel segment, andfourthly, excavation and preliminary bracing construction of the rear tunnel segment. By means of the method, design is reasonable, construction is simple and convenient, and the use effect is good; before excavation, cemented soil stirring piles are adopted for carrying out reinforcement treatment on the loess stratum of the construction area where the tunnel entrance segment of the tunnel is located in advance, the reinforcement length and reinforcement depth are effectively limited, loose soil of the tunnel body of the tunnel is solidified in advance, it is ensured that the construction process of the tunnel entrance segment of the tunnel passing through the slip mass is safe and reliable, and the structure of the tunnel entrance segment, formed through construction, of the tunnel is stable; and meanwhile, a three-step excavation method is adopted for excavating the tunnel entrance segment of the tunnel, it can be ensured that the excavation process of the tunnel entrance segment ofthe tunnel passing through the slip mass is safe and reliable, and the influence on stability of soil layers around the tunnel is small.

Owner:CHINA RAILWAY 20 BUREAU GRP

Construction method of soil-stone boundary tunnel passing through loess valleys

ActiveCN110700860AEffective reinforcementThe method steps are simpleUnderground chambersTunnel liningGround water levelStructure support

The invention discloses a construction method of a soil-stone boundary tunnel passing through loess valleys. The construction method comprises the following steps of 1, precipitation pre-reinforcement; 2, excavation construction of a rear side tunnel section; 3, excavation construction of a middle tunnel section; and 4, excavation construction of a front side tunnel section, wherein the middle tunnel section and the front side tunnel section are three-step synchronous excavation tunnel sections; and in the excavation process from back to front in the step 2, the step 3 and the step 4, primarysupport is synchronously carried out on the excavated tunnel from back to front, and secondary lining of the tunnel is constructed on the inner side of the constructed and formed tunnel primary support structure from back to front. The construction method is reasonable in design, simple and convenient to construct and good in use effect, the underground water level is reduced through precipitationpre-reinforcement, surrounding rock is effectively reinforced, then blasting excavation is carried out in a three-step excavation mode, so that the excavation process of the soil-stone boundary tunnel passing through the loess valleys can be ensured to be safe and reliable, and the stability of the tunnel structure can be ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

A kind of high ground stress weak surrounding rock tunnel support structure and construction method thereof

ActiveCN111764931BPrevent seepageEnsure support stabilityMining devicesUnderground chambersRock tunnelRock bolt

Owner:浙江省衢州市交通建设集团有限公司

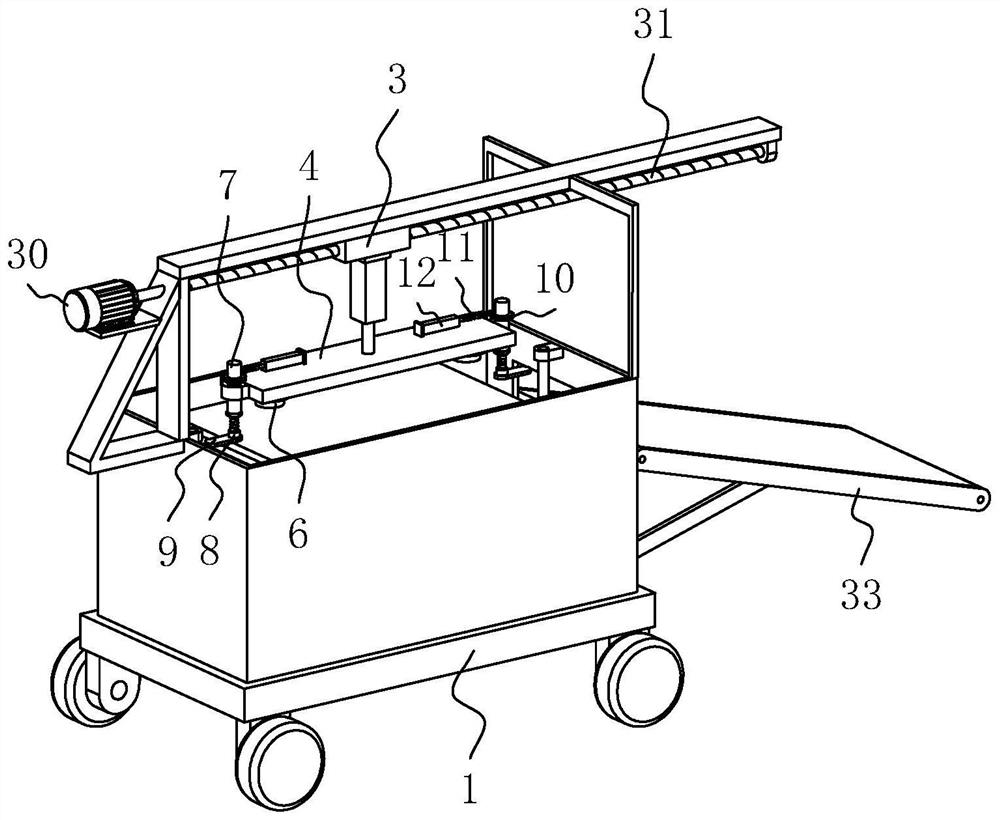

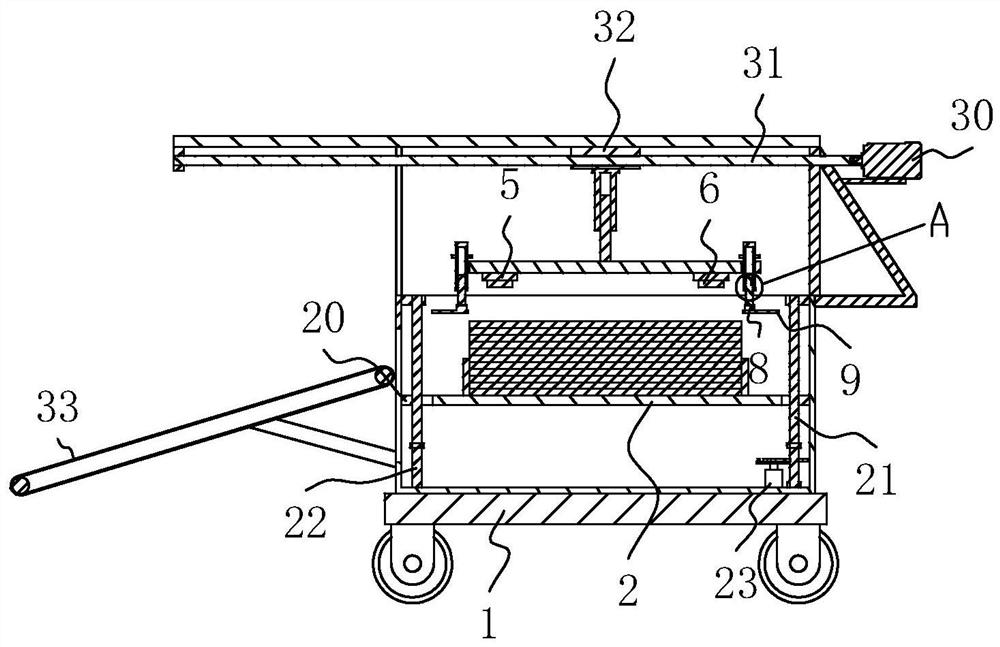

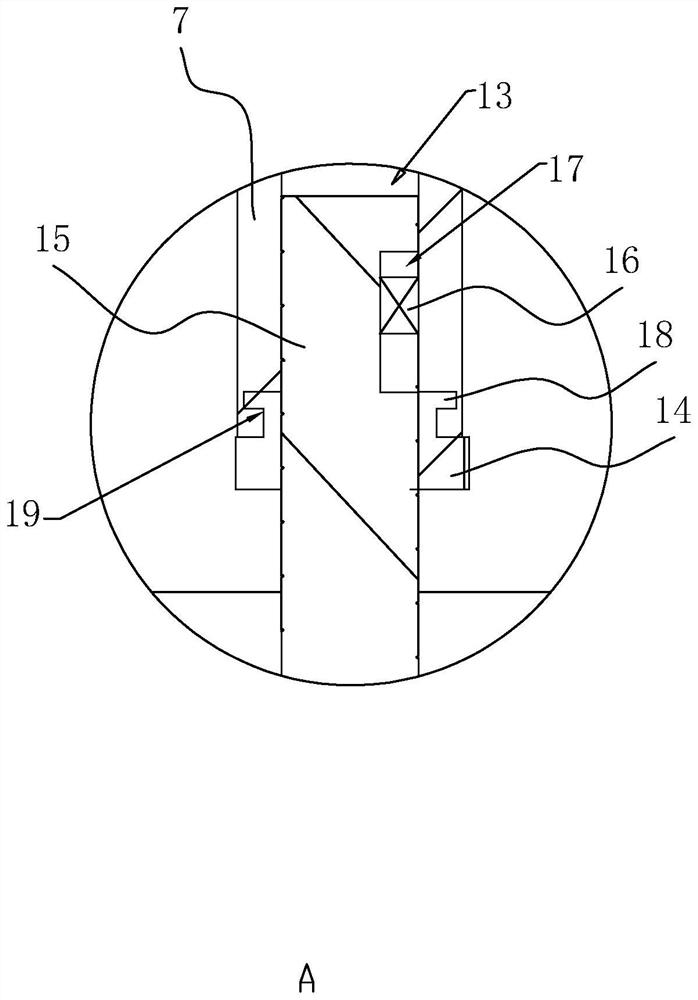

Semi-automatic corrugated beam guardrail plate mounting machine and working method thereof

PendingCN113931105AEnsure support stabilityEasy to transportRoadway safety arrangementsSemi automaticStructural engineering

The invention relates to a semi-automatic corrugated beam guardrail plate mounting machine and a working method thereof and relates to the field of guardrail equipment mounting. The semi-automatic corrugated beam guardrail plate mounting machine comprises a putting vehicle, and a storage mechanism and a conveying mechanism which are arranged in the putting vehicle; the storage mechanism comprises a storage plate arranged in the putting vehicle in a lifting mode, a support connected to the interior of the putting vehicle in a sliding mode and a lifting plate arranged on the support in a lifting mode, the putting vehicle is provided with a power assembly, the lifting plate is provided with a plurality of lifting blocks, and the lifting blocks are provided with electromagnets used for adsorbing guardrail plates; the lifting plate is rotationally connected with a rotating rod, the rotating rod is provided with a lifting rod in a lifting mode, an end, away from the rotating rod, of the lifting rod is fixedly connected with a supporting block, and the lifting plate is provided with a driving assembly. The machine is advantaged in that the guardrail plate is convenient to take and place, the whole process is high in active degree, and labor intensity of workers is greatly reduced.

Owner:聊城市交通发展有限公司

Deep-buried loess tunnel deformation control construction structure based on cover arch and method

PendingCN110671132AReasonable designEasy constructionUnderground chambersTunnel liningArchitectural engineeringDeformation control

The invention discloses a deep-buried loess tunnel deformation control construction structure based on a cover arch and a method. The structure comprises a tunnel primary support structure body for primary support of a tunnel and the reinforcement cover arch arranged on the inner side of the tunnel primary support structure body, wherein the tunnel primary support structure body and the reinforcement cover arch form a reinforced primary support structure body. The method comprises the following steps of 1, carrying out tunnel excavation and primary support; and 2, carrying out reinforcement arc arch construction. The structure and the method have the advantages of being reasonable in design, simple and convenient in construction and good in use effect, the reinforcement cover arch is adopted to reinforce the tunnel primary support structure body and form the reinforced primary support structure body, an isolation layer is arranged between the reinforcement arc arch and the tunnel primary support structure body, in addition, the reinforcement cover arch adopts a plurality of cover arch units to reinforce the tunnel primary support structure body in a segmented mode, so that the construction is simple and convenient, moreover, the reinforced primary support structure body formed by construction has certain self-adaptive capacity and can effectively adapt to the deformation condition of soil mass on the peripheral side of the tunnel, and therefore the deformation resistance of the reinforced primary support structure body can be effectively enhanced.

Owner:CHINA RAILWAY 20 BUREAU GRP

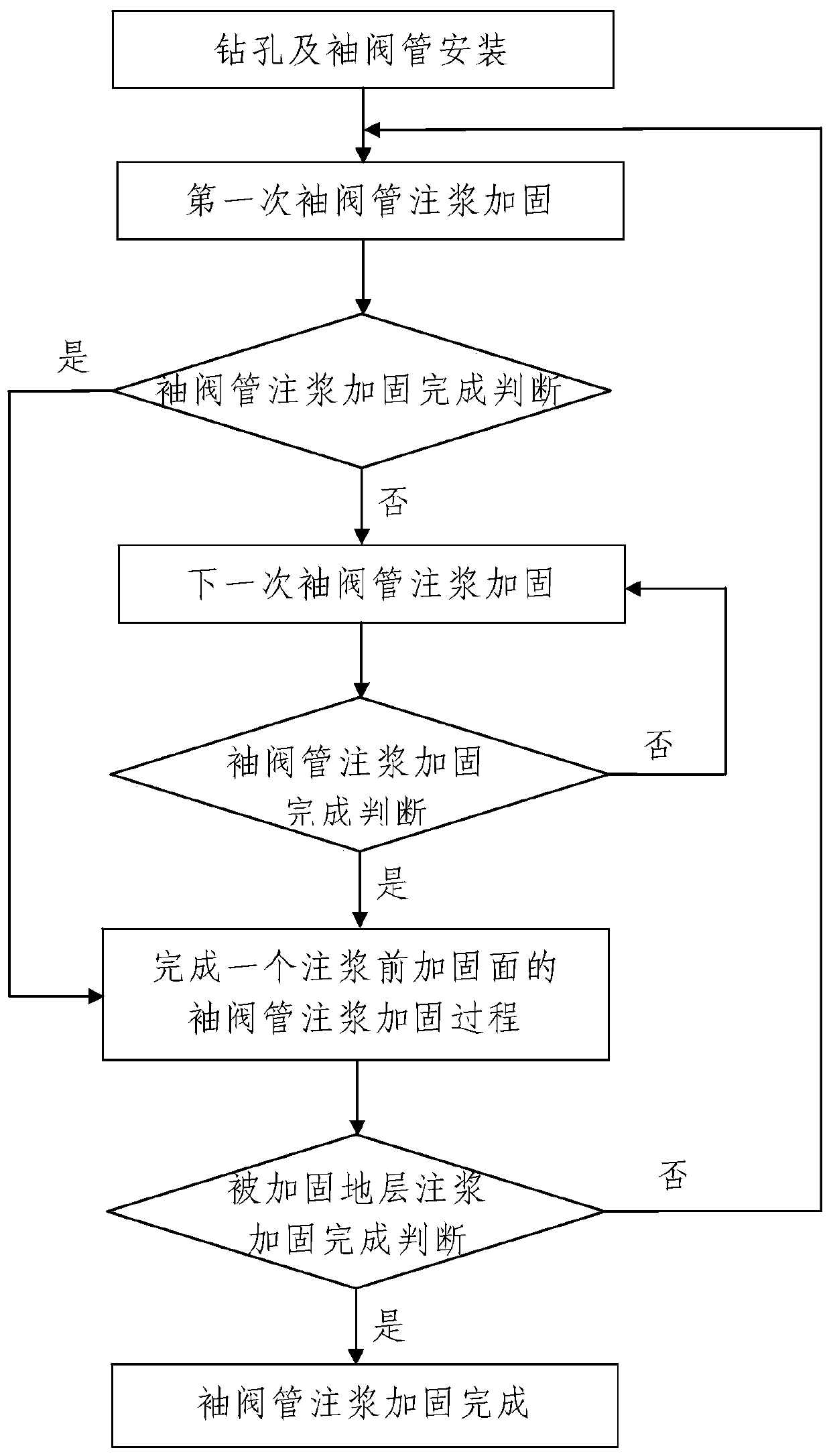

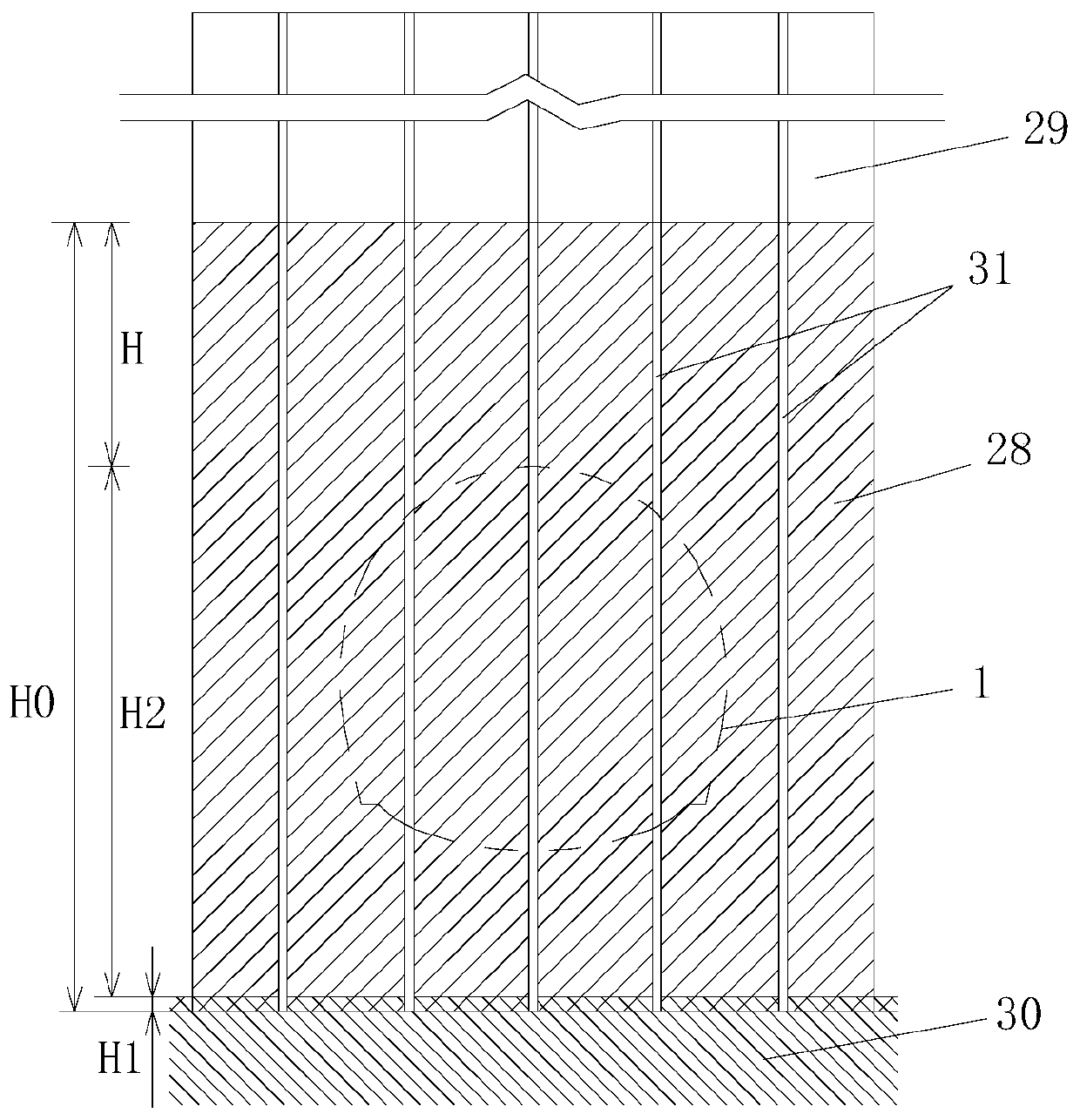

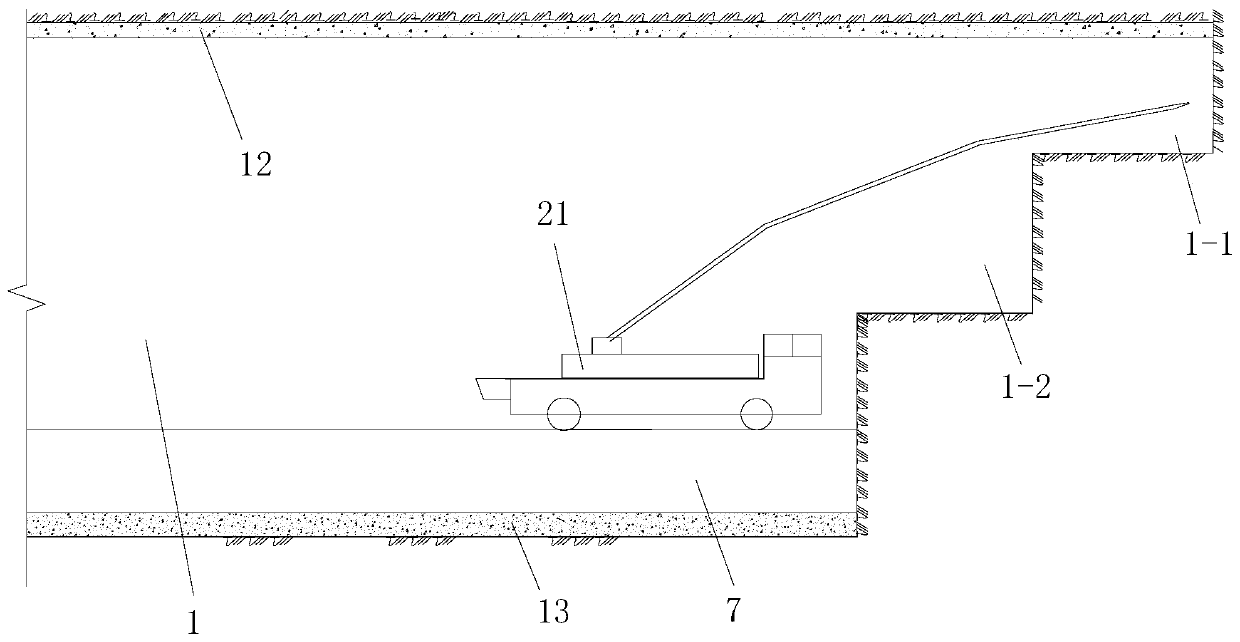

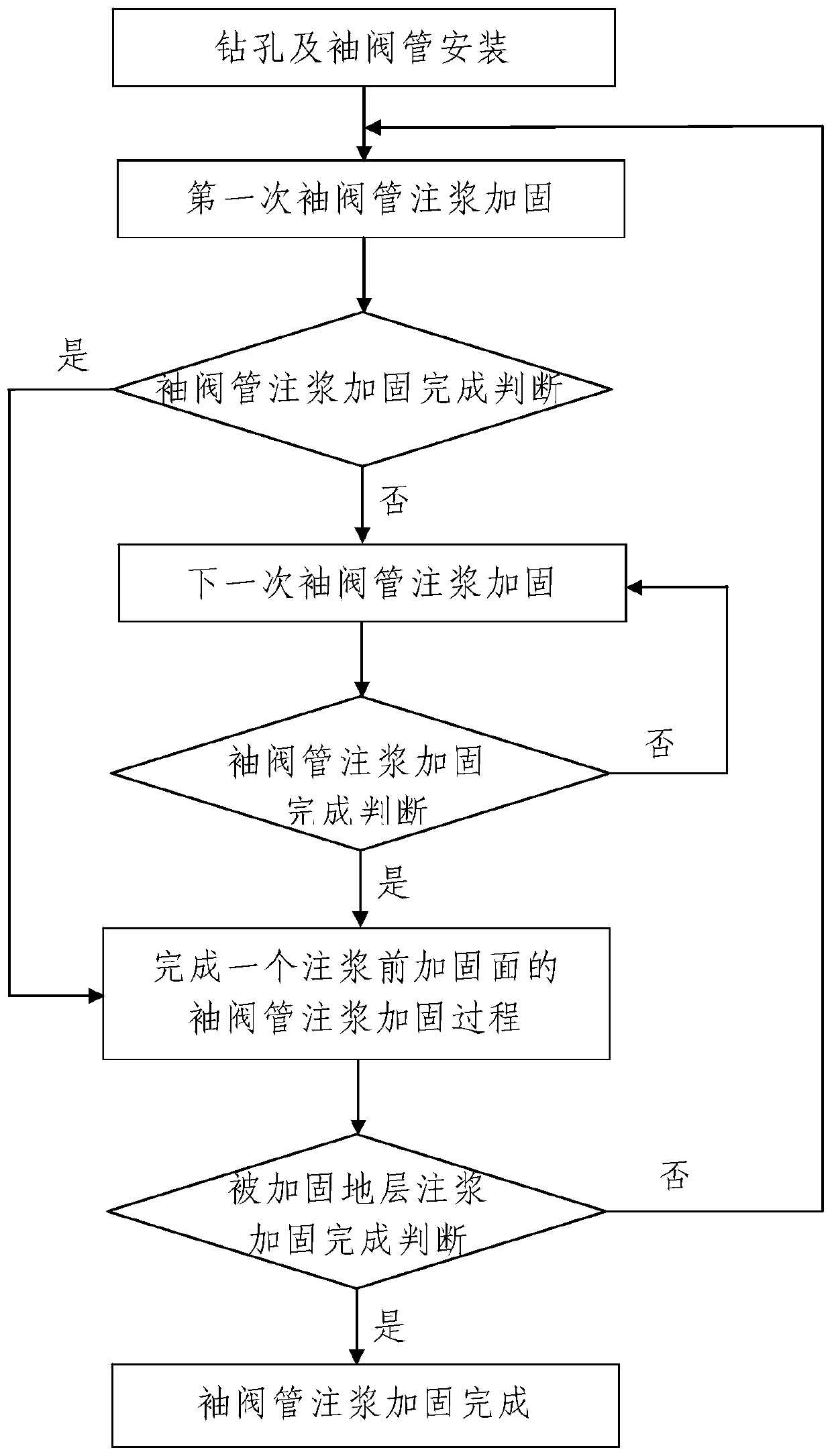

Construction method of shallow-buried tunnel in loess gully

ActiveCN110761795AThe method steps are simpleReasonable designUnderground chambersTunnel liningEarth surfacePipe

The invention discloses a construction method of a shallow-buried tunnel in a loess gully. The construction method comprises the following steps: 1, grouting a sleeve valve pipe for advancing reinforcement: carrying out sleeve valve pipe grouting for reinforcement on a stratum in the construction area of the constructed shallow-buried tunnel; 2, carrying out tunnel excavation and preliminary bracing; and 3, constructing a second lining. The construction method is simple in step, reasonable in design, simple and convenient in construction and excellent in using effect; the sleeve valve pipe isadopted and a plurality of rows of grouting holes are adopted to grout the reinforced stratum for reinforcement; the range of the reinforced stratum is specifically limited; both the tunnel hole bodyand the tunnel base can be reinforced, and the reinforcement effect is reliable; the shallow-buried tunnel construction method is particularly suitable for advancing reinforcement and excavation construction of the shallow-buried tunnel section which is positioned in a loess gully and is adjacent to an earth and stone interface, and the earth's surface of the shallow-buried tunnel is a silting-upland layer. The construction method can effectively ensure safety and reliability of the excavation process of the shallow-buried tunnel in the loess gully, can effectively improve the stability of the excavated tunnel hole and can effectively improve the bearing force of the tunnel base.

Owner:CHINA RAILWAY 20 BUREAU GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com