Through landslide body loess tunnel construction method

A technology of loess tunnel and construction method, which is applied in the direction of tunnel, tunnel lining, earthwork drilling and mining, etc., can solve the problems of difficult construction, easy occurrence of landslide, hidden danger of tunnel construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

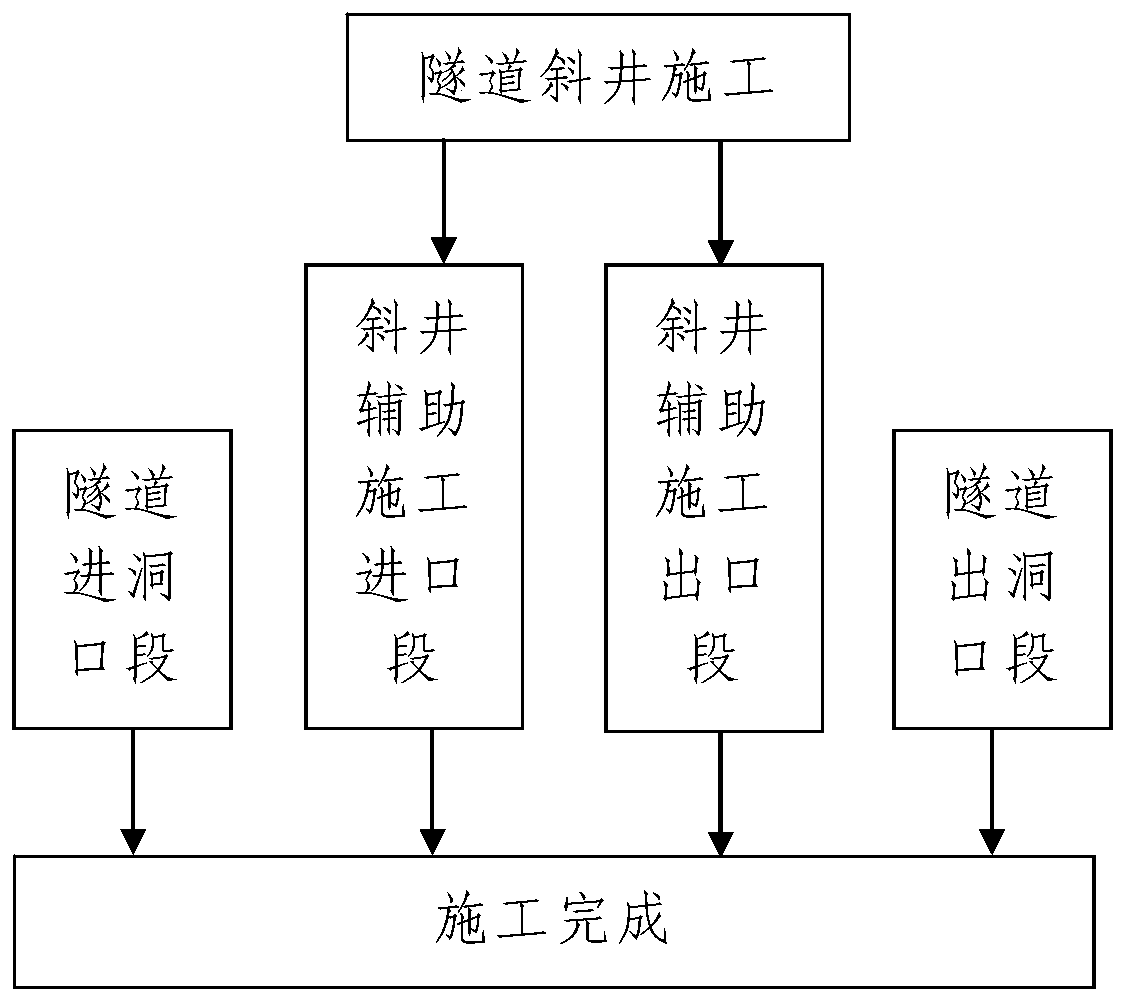

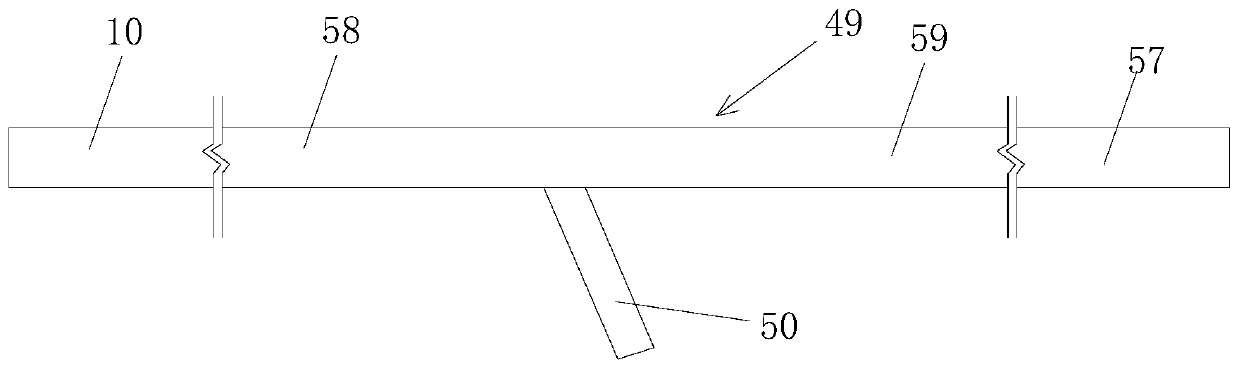

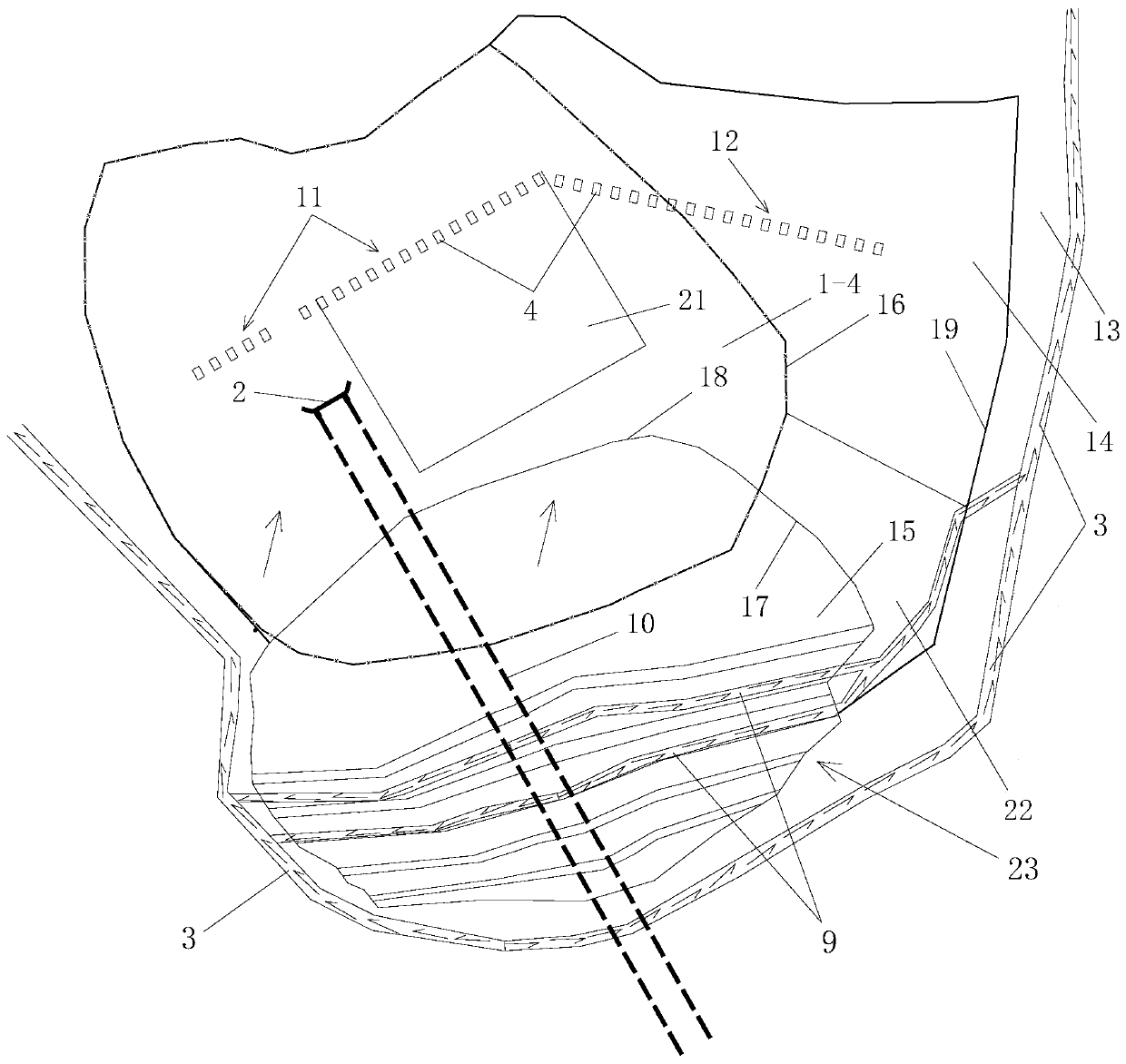

[0135] Such as figure 1 A kind of construction method of the loess tunnel passing through the landslide is shown, the tunnel 49 side of the loess tunnel constructed is provided with a tunnel inclined shaft 50, the length of the tunnel 49 is greater than 1500m and its excavation section is greater than 100m 2 , see figure 2 The main hole 49 of the tunnel is a straight tunnel, and the main hole 49 of the tunnel is divided into the tunnel entrance section 10, the tunnel exit section 57 and the middle connection between the tunnel entrance section 10 and the tunnel exit section 57 Section, the inclined shaft 50 of the tunnel intersects with the middle connecting section and the intersection between them is the inclined shaft intersection, the middle connecting section is the auxiliary construction section of the inclined shaft and it takes the inclined shaft intersection as the The boundary is divided into an inclined shaft auxiliary construction entrance section 58 and an incli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com