Construction method of large-section tunnel crossing fault fracture zone

A construction method and technology of crushing zone, applied in tunnels, tunnel linings, earthwork drilling and other directions, can solve the problems of arch frame distortion, unguaranteed safety and quality, and increased collapse risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

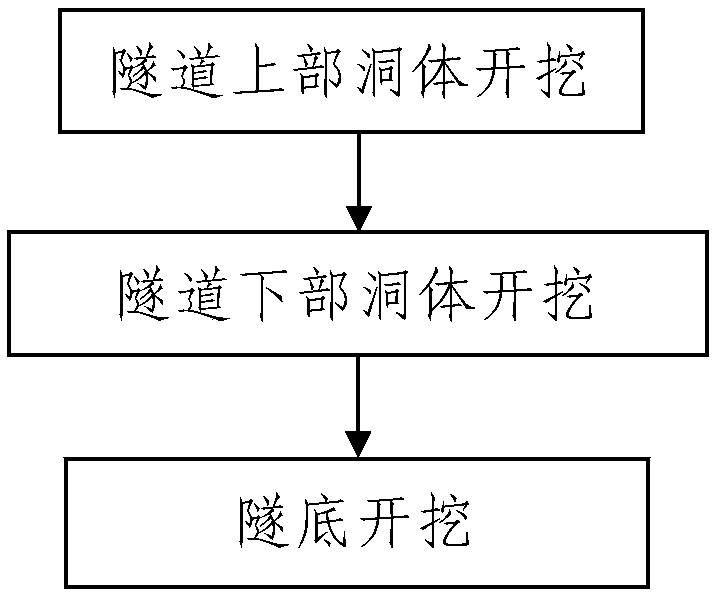

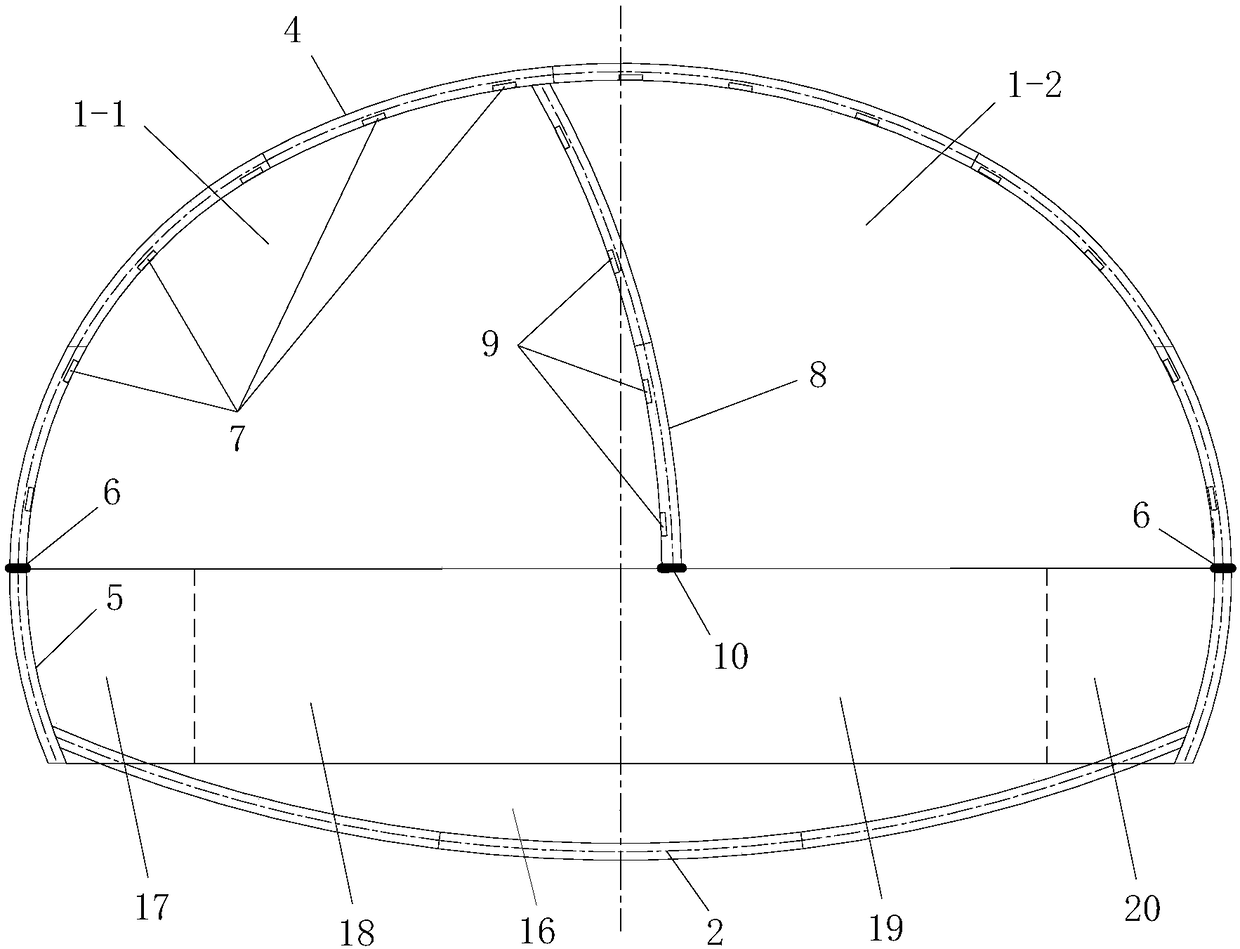

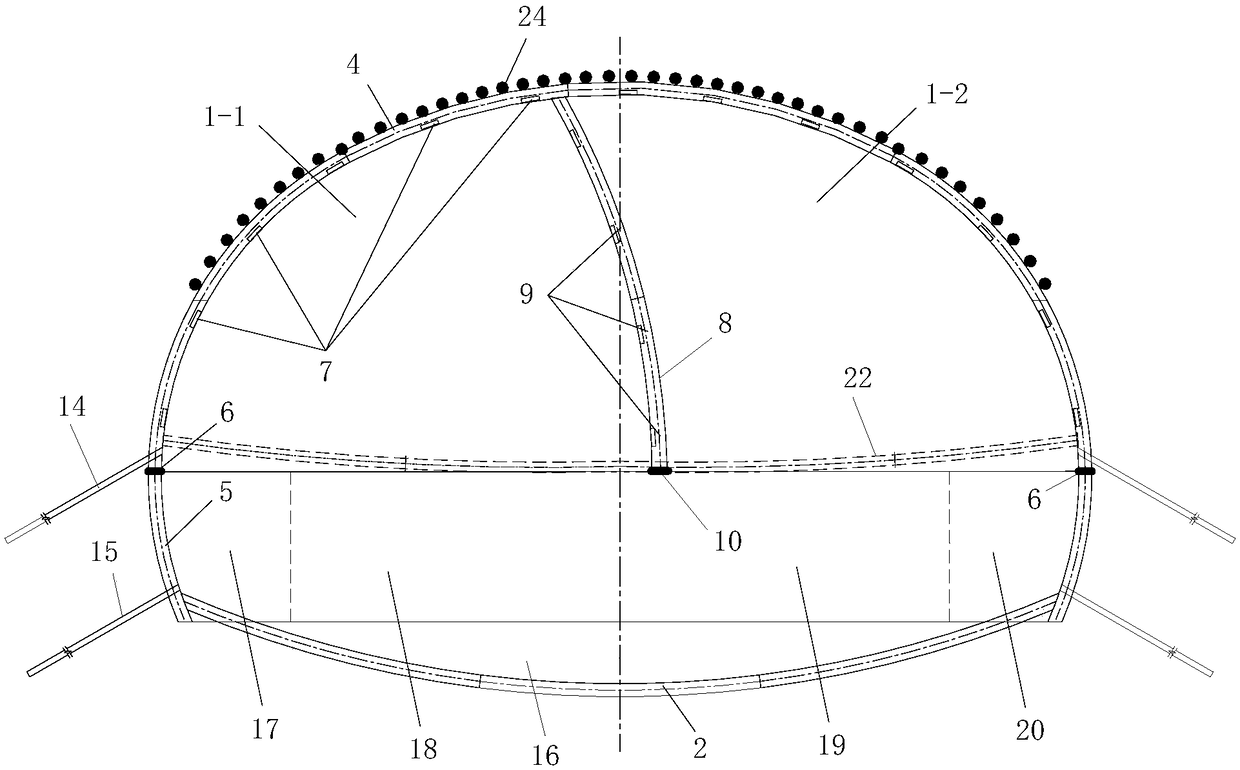

[0086] Such as figure 1 Shown is a construction method for a large-section tunnel crossing a fault fracture zone. The tunnel hole of the constructed large-section tunnel is divided into a tunnel upper hole body 1, a tunnel lower hole body, and a tunnel bottom hole body 16 from top to bottom. The excavation width of the tunnel body 16 gradually decreases from top to bottom and its upper excavation width is smaller than the distance between the bottom of the left and right side walls of the tunnel hole; the tunnel upper tunnel body 1 includes a left pilot hole 1-1 and a The right pilot tunnel 1-2 on the right side of the left pilot tunnel 1-1; the lower tunnel body of the tunnel is divided into a left tunnel body 17, a left middle tunnel body 18, a right middle tunnel body 19 and a right side tunnel body from left to right. Hole body 20, described left side hole body 17 and right side hole body 20 are left and right symmetrically arranged, and the cross-section of described left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com