Patents

Literature

181results about How to "Support stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

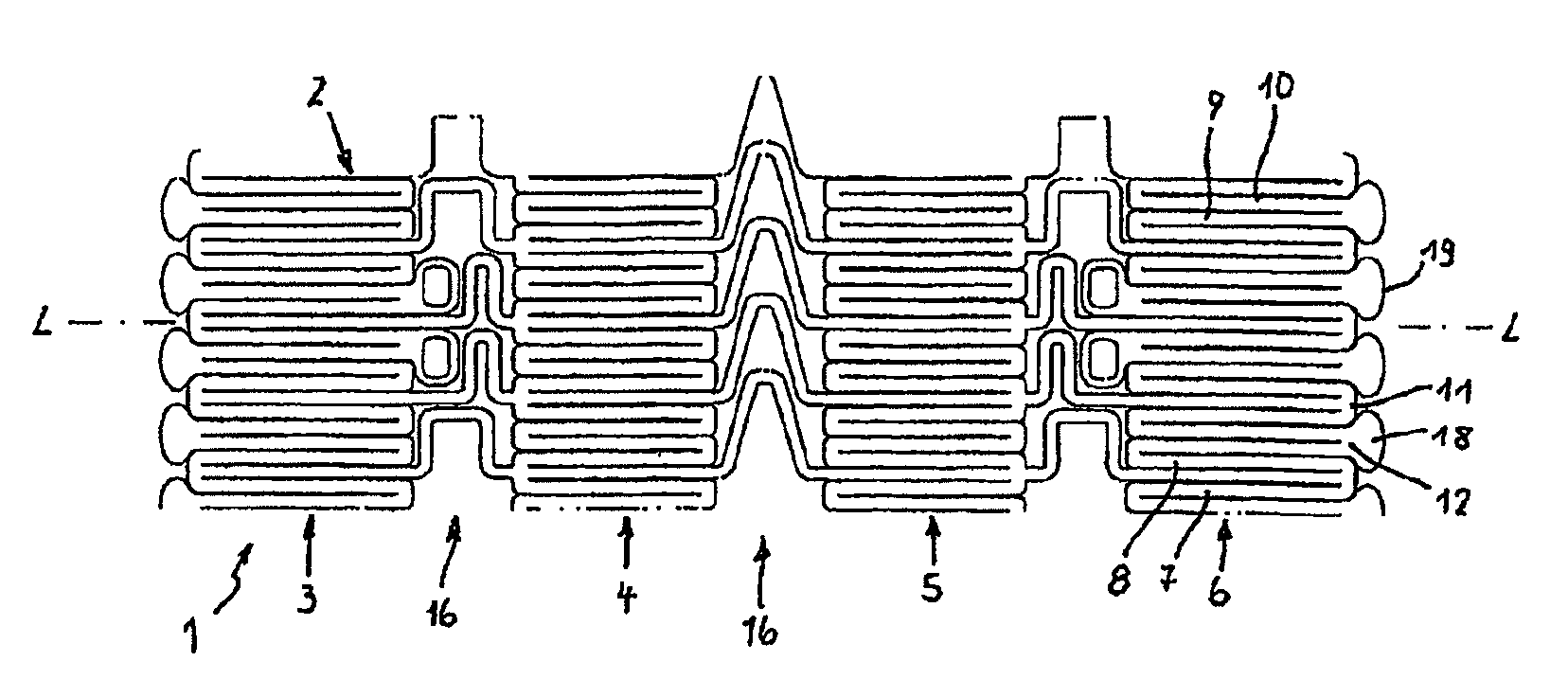

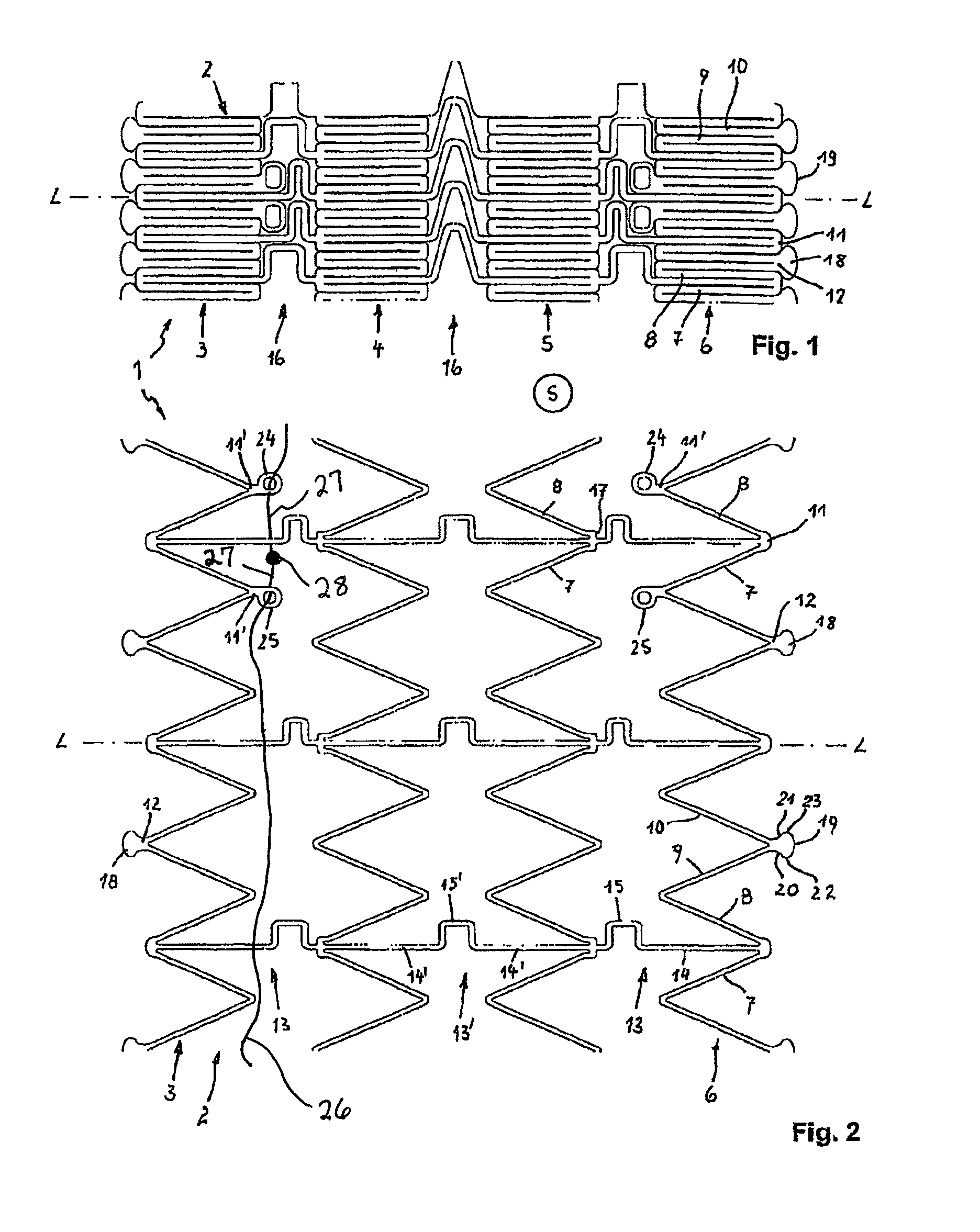

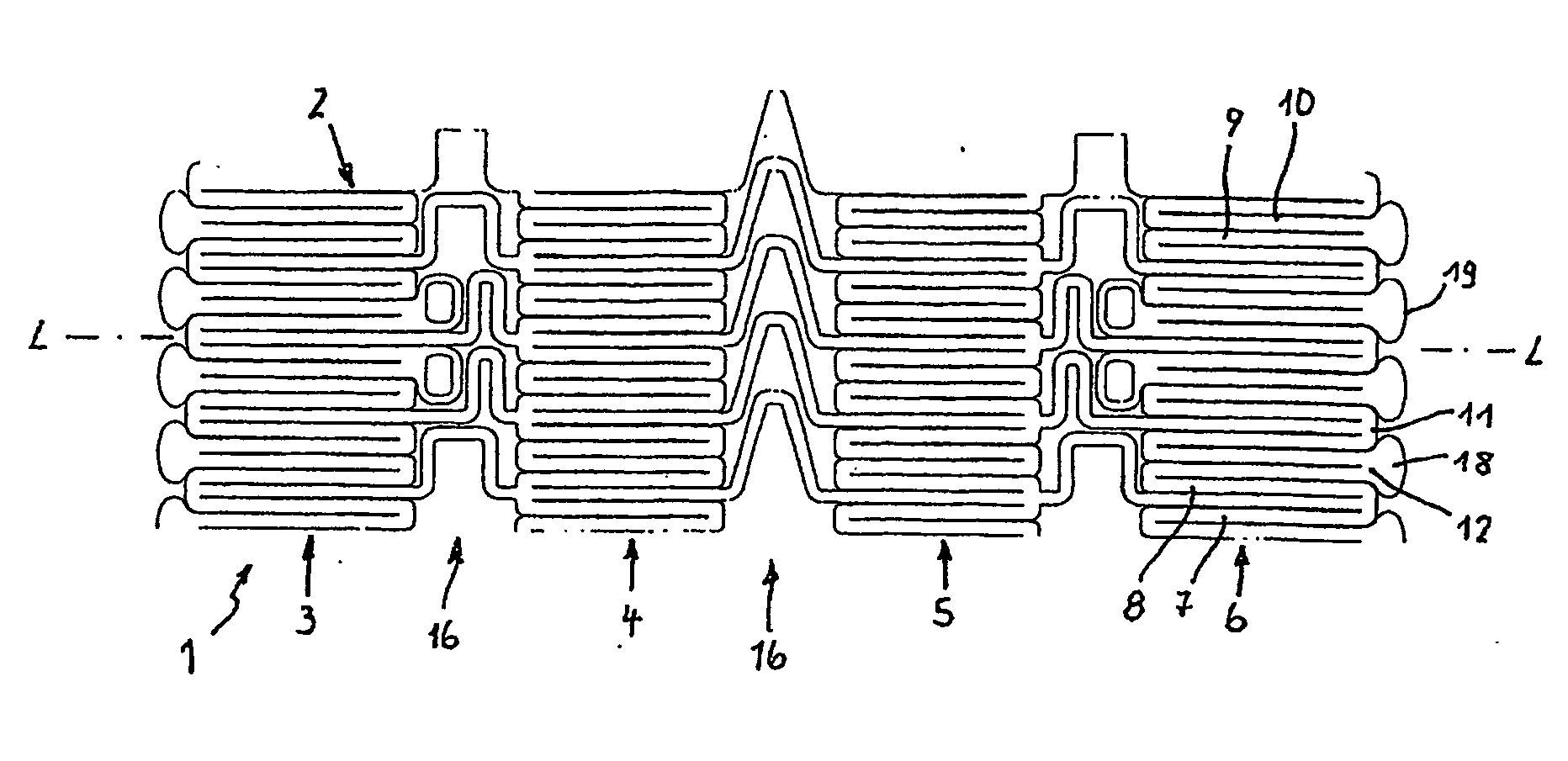

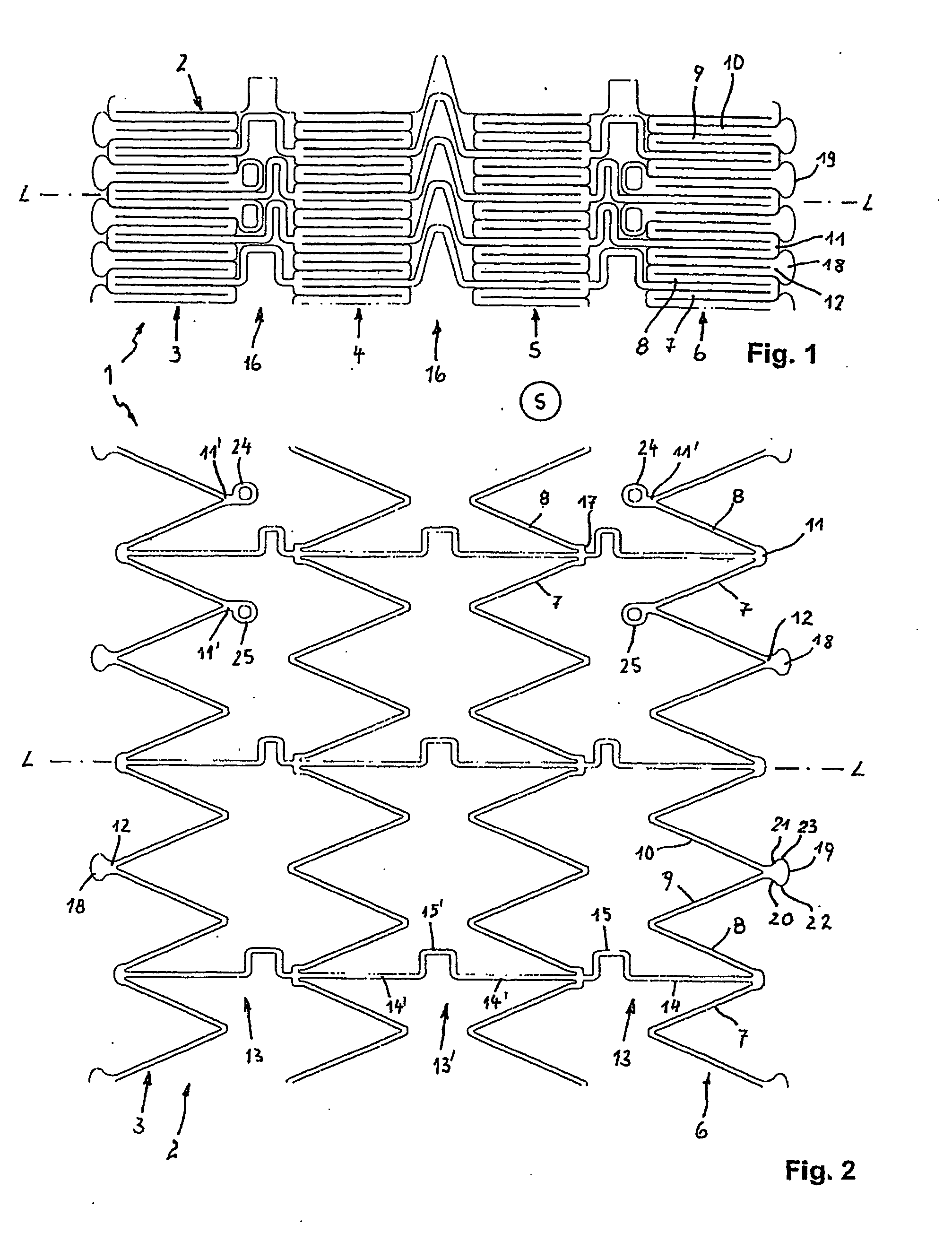

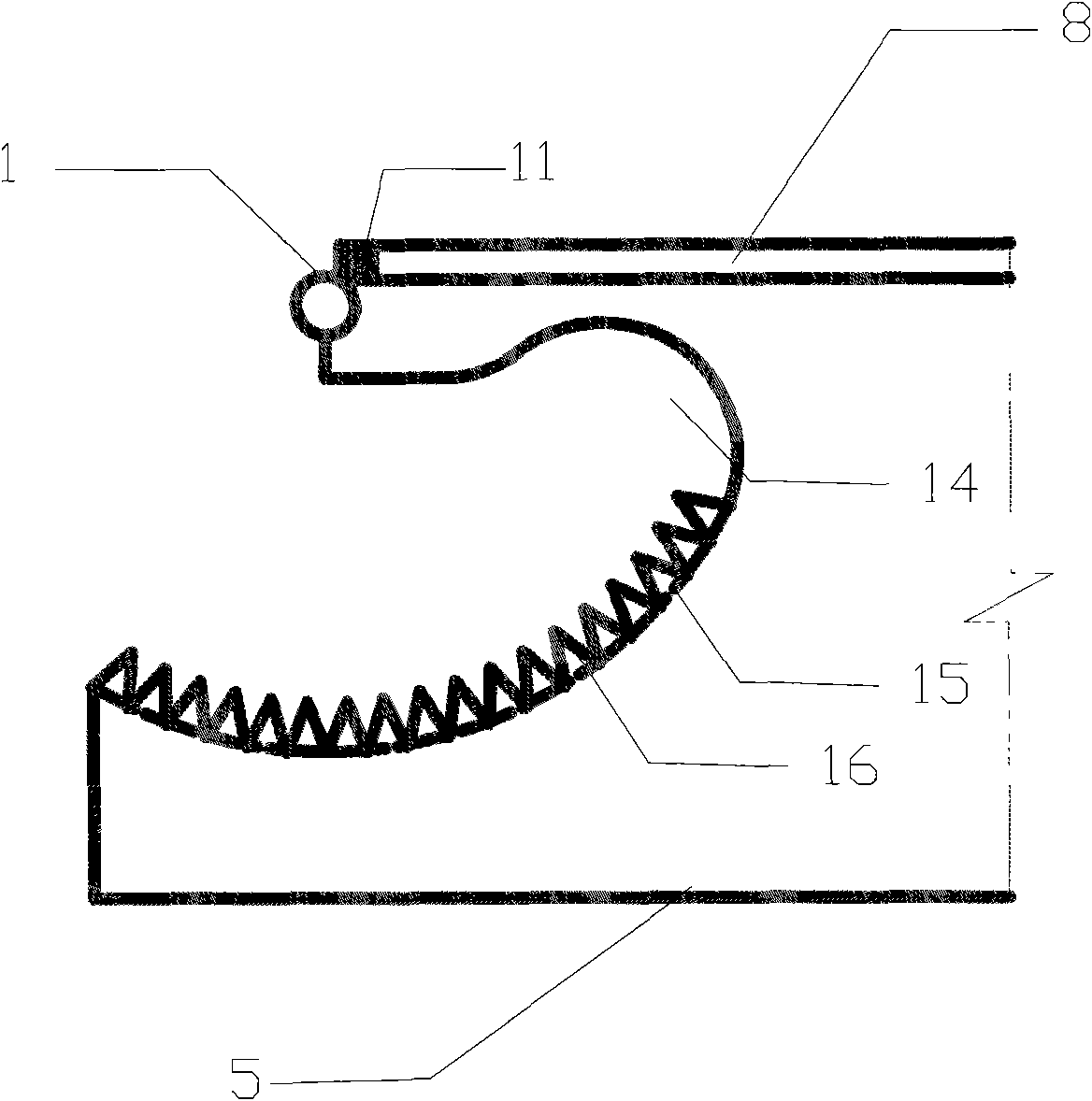

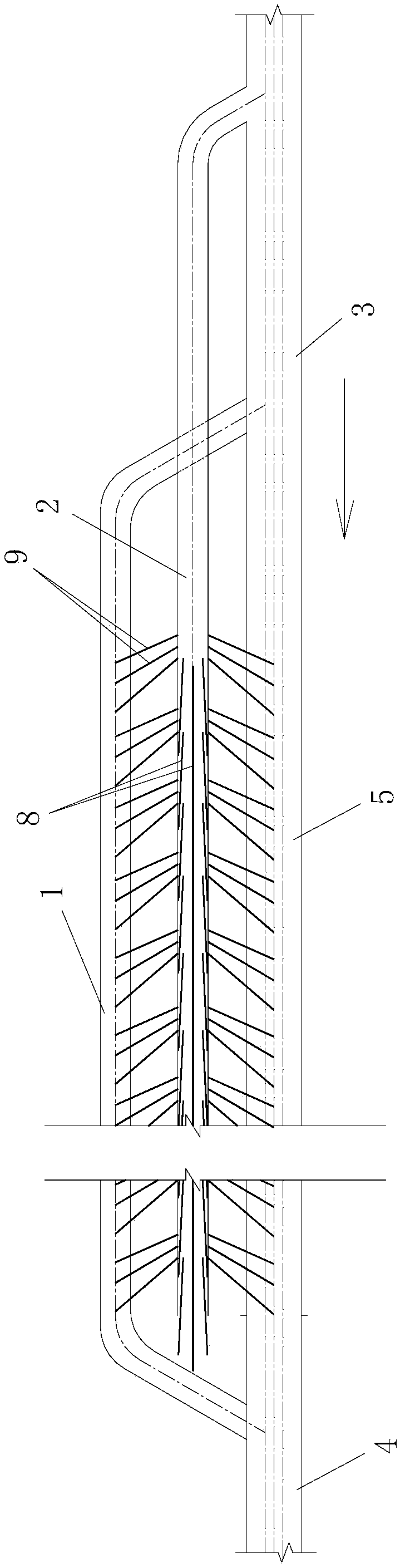

Removable stent

The invention is relative to a stent with a tubular support frame consisting of axially successively following, interconnected annular segments which support frame is surrounded on its outside by a thread. The thread ends are guided via a deflection from the outside into support frame, where they are coupled by a connector consisting of a material visible in x-rays. Deflection is realized by two deflection elements in the form of eyelets provided on annular segments. Deflection elements are arranged on the circumference of support frame at an interval from one another and are provided on end-side annular segments, viewed in longitudinal direction of the stent.

Owner:MERIT MEDICAL SYST INC

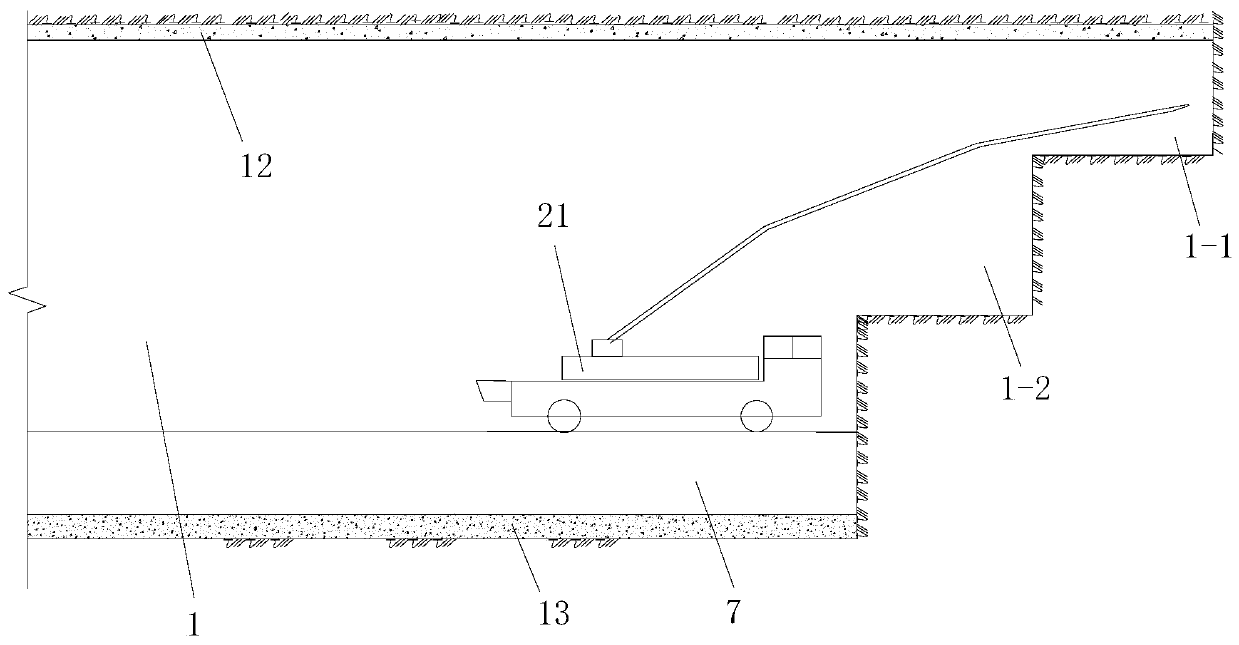

Large-section loess tunnel construction method

The invention discloses a large-section loess tunnel construction method, which comprises the following steps that: the whole section is divided into an upper part, a middle part, a lower part and a bottom part, wherein the middle part is divided into a middle left area, a middle right area and a middle intermediate area, the lower part is divided into a lower left area, a lower right area and a lower intermediate area, the four parts are excavated in a benching tunneling method with altitude differences, the upper part is 3-5m in front of the front middle part, the middle part is 3-5m in front of the front lower part, the lower part is 10m in front of the front bottom part, and the step-by-step tunneling excavation is carried out. The invention is suitable for collapsed loess areas, realizes the safe and reliable construction and saves a large number of temporary supporting steel frames. Due to the arc-shaped pilot tunnel method, the loop can be formed rapidly during excavation, the disturbance to the surrounding rock is low, the primary support is stable, the traditional construction method is further improved to be the 'two-step and four-part excavation method', and the construction cycle period is short. Moreover, the invention can speed up the progress of the project, shorten the construction period, and reduce the cost of the project.

Owner:CHINA RAILWAY 23RD BUREAU GRP THIRD ENG CO LTD

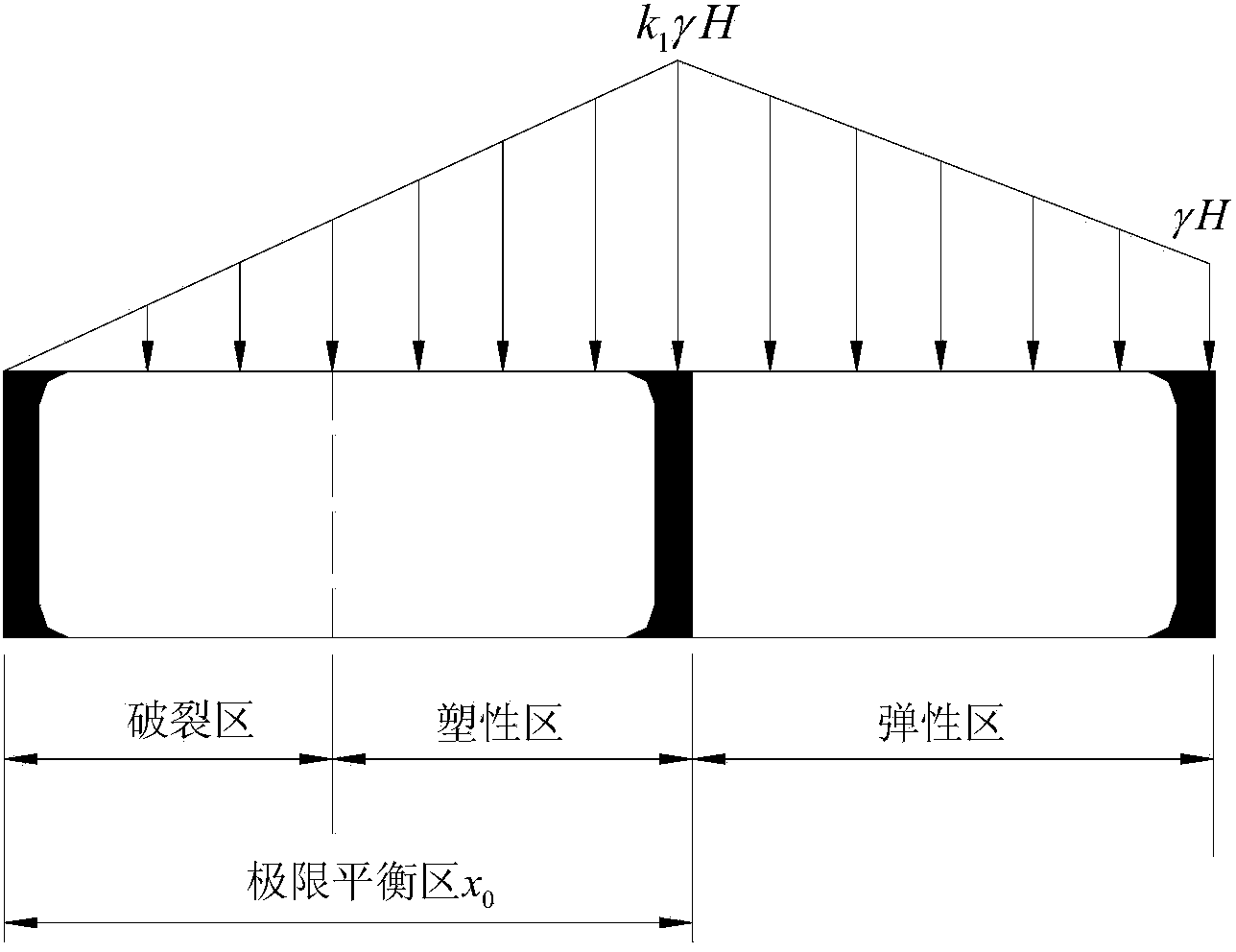

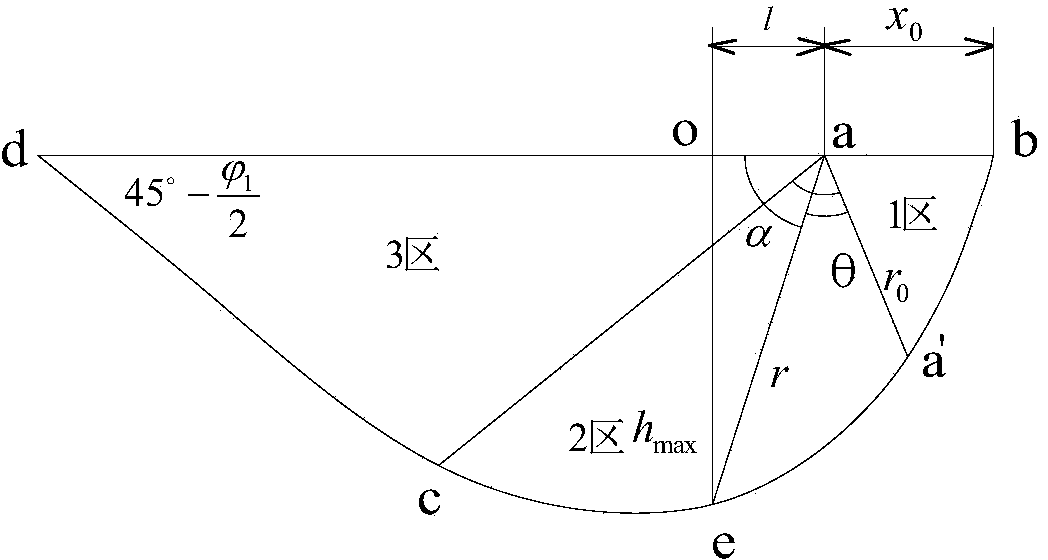

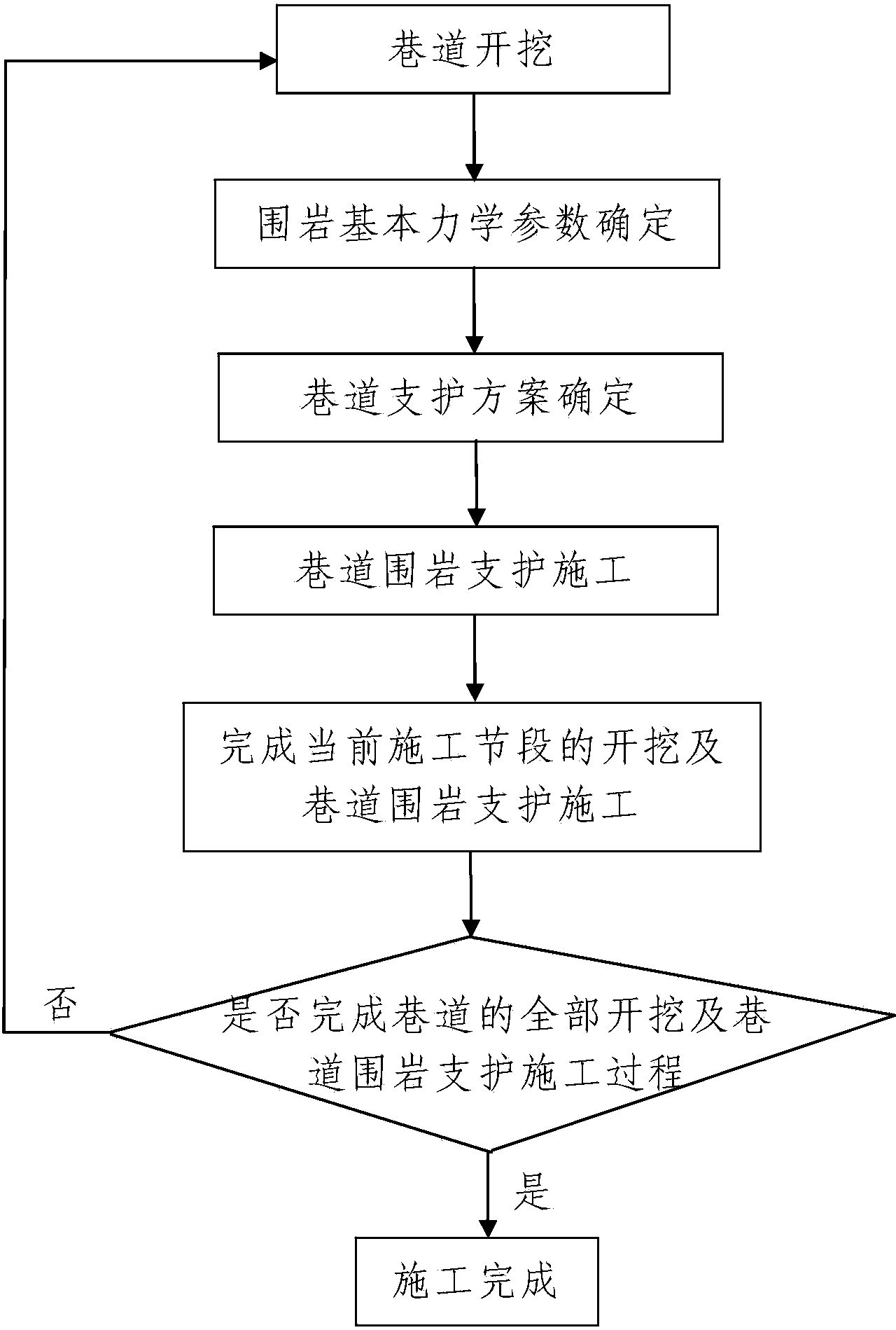

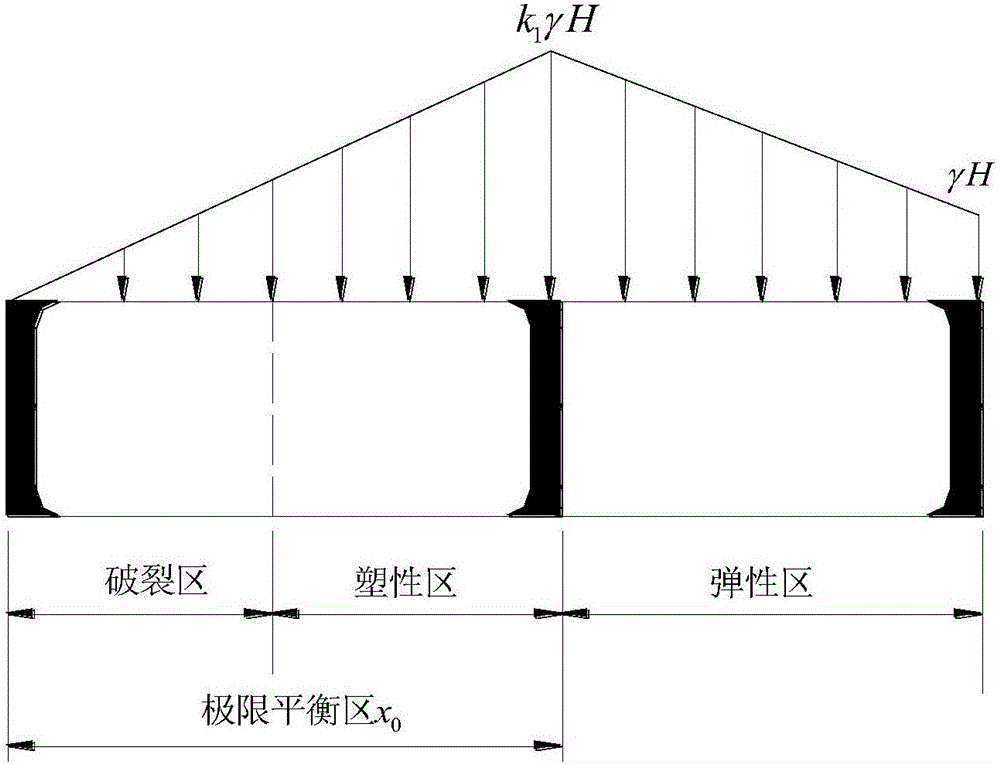

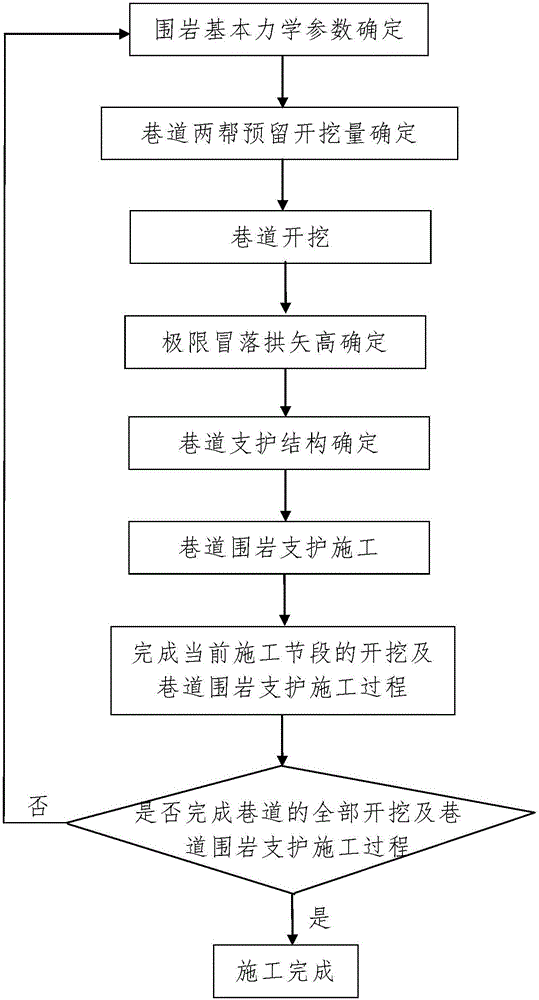

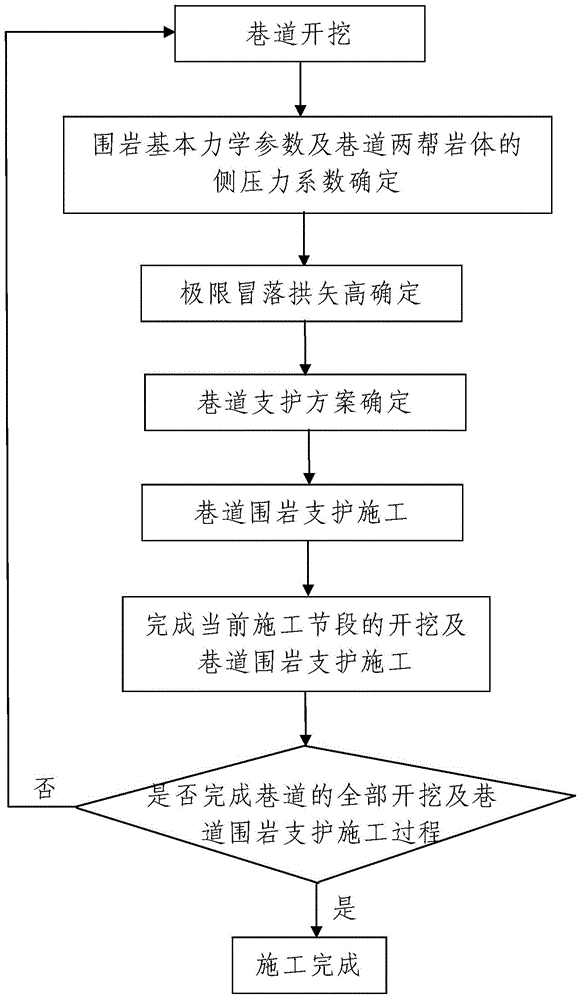

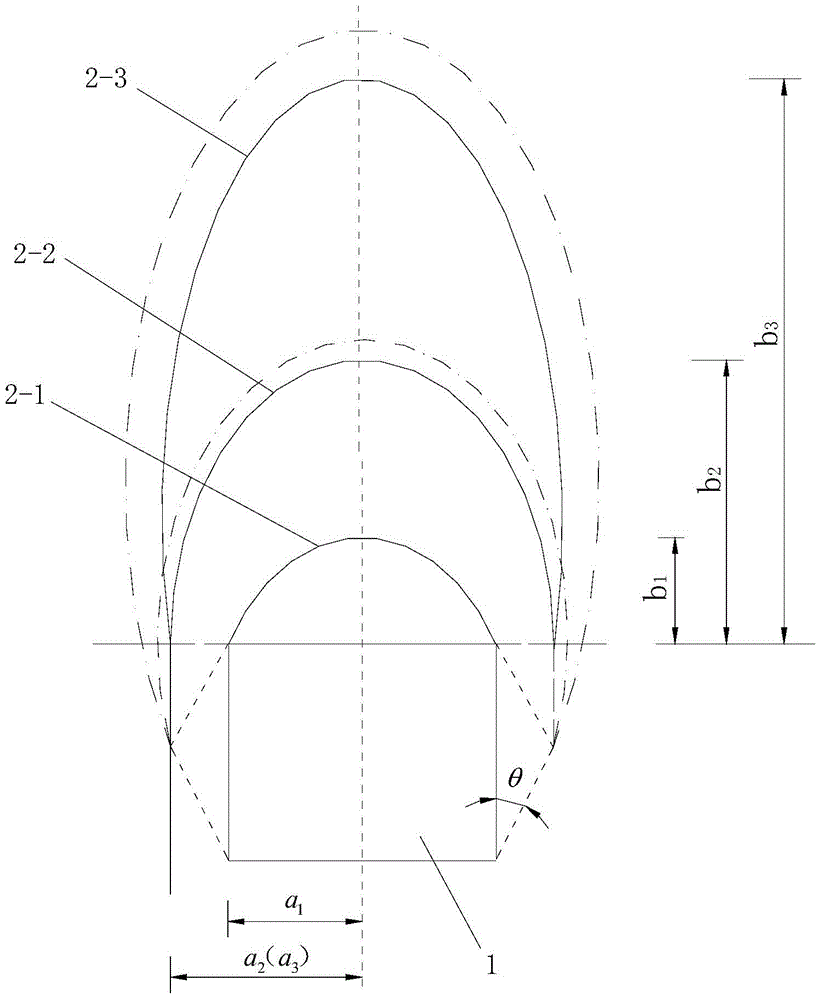

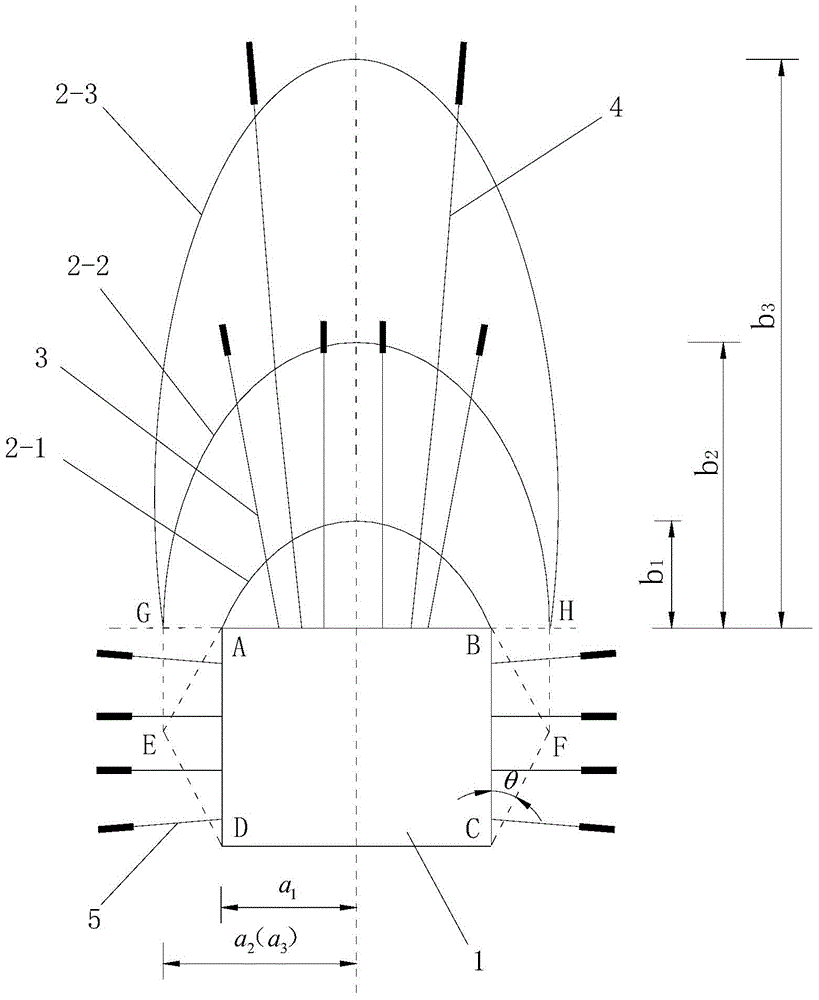

Rectangular roadway surrounding rock deformation and failure control method

The invention discloses a rectangular roadway surrounding rock deformation and failure control method which comprises steps as follows: 1), a roadway is excavated; 2), basic mechanical parameters of a surrounding rock are determined; 3), a roadway support scheme is determined as follows: roadway side unstability is judged, the caving arch rise is determined when the roadway side is in a stable state, the width of roadway side olistolith, the caving arch rise, the roadway side limit equilibrium area width, the maximum failure depth of a roadway bottom board and a horizontal distance between the maximum failure depth position and an adjacent roadway side wall are determined when the roadway side is in an unstable state, and a roadway support unit structure is determined; 4), a roadway surrounding rock support is constructed; 5), the next section is excavated, and the roadway surrounding rock support is constructed; and 6), the step 5) is repeated until all excavation and roadway surrounding rock support construction processes of the rectangular roadway are completed. The method is simple in step, convenient to implement and good in use effect, the roof caving and bottom swelling problems of the rectangular roadway can be effectively solved, and deformation and failure of the roadway surrounding rock can be effectively controlled.

Owner:XIAN UNIV OF SCI & TECH

Removable Stent

ActiveUS20070276463A1Supports longitudinal stabilityEasy to processStentsBlood vesselsBraced frameEngineering

The invention is relative to a stent with a tubular support frame consisting of axially successively following, interconnected annular segments which support frame is surrounded on its outside by a thread. The thread ends are guided via a deflection from the outside into support frame, where they are coupled by a connector consisting of a material visible in x-rays. Deflection is realized by two deflection elements in the form of eyelets provided on annular segments. Deflection elements are arranged on the circumference of support frame at an interval from one another and are provided on end-side annular segments, viewed in longitudinal direction of the stent.

Owner:MERIT MEDICAL SYST INC

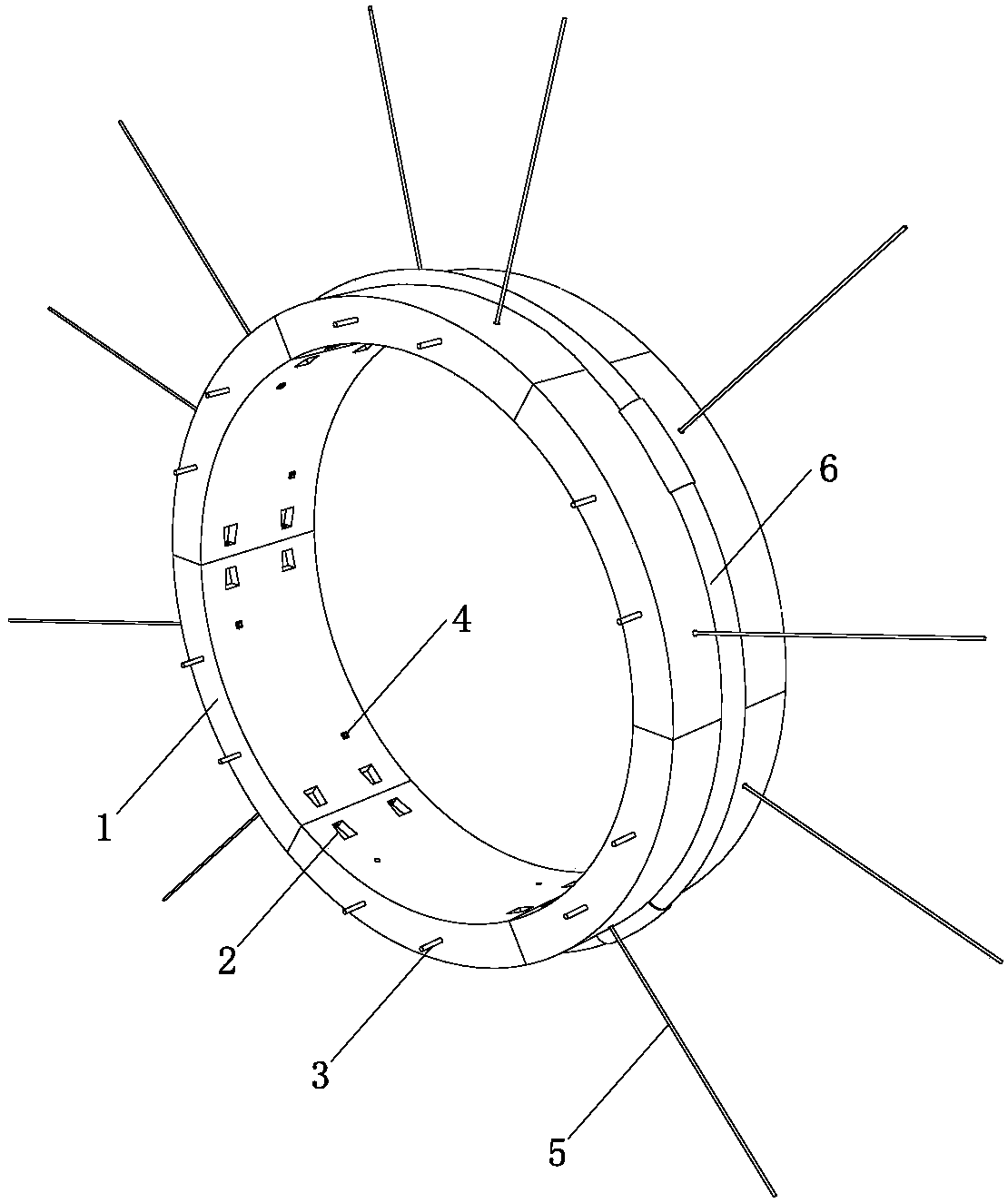

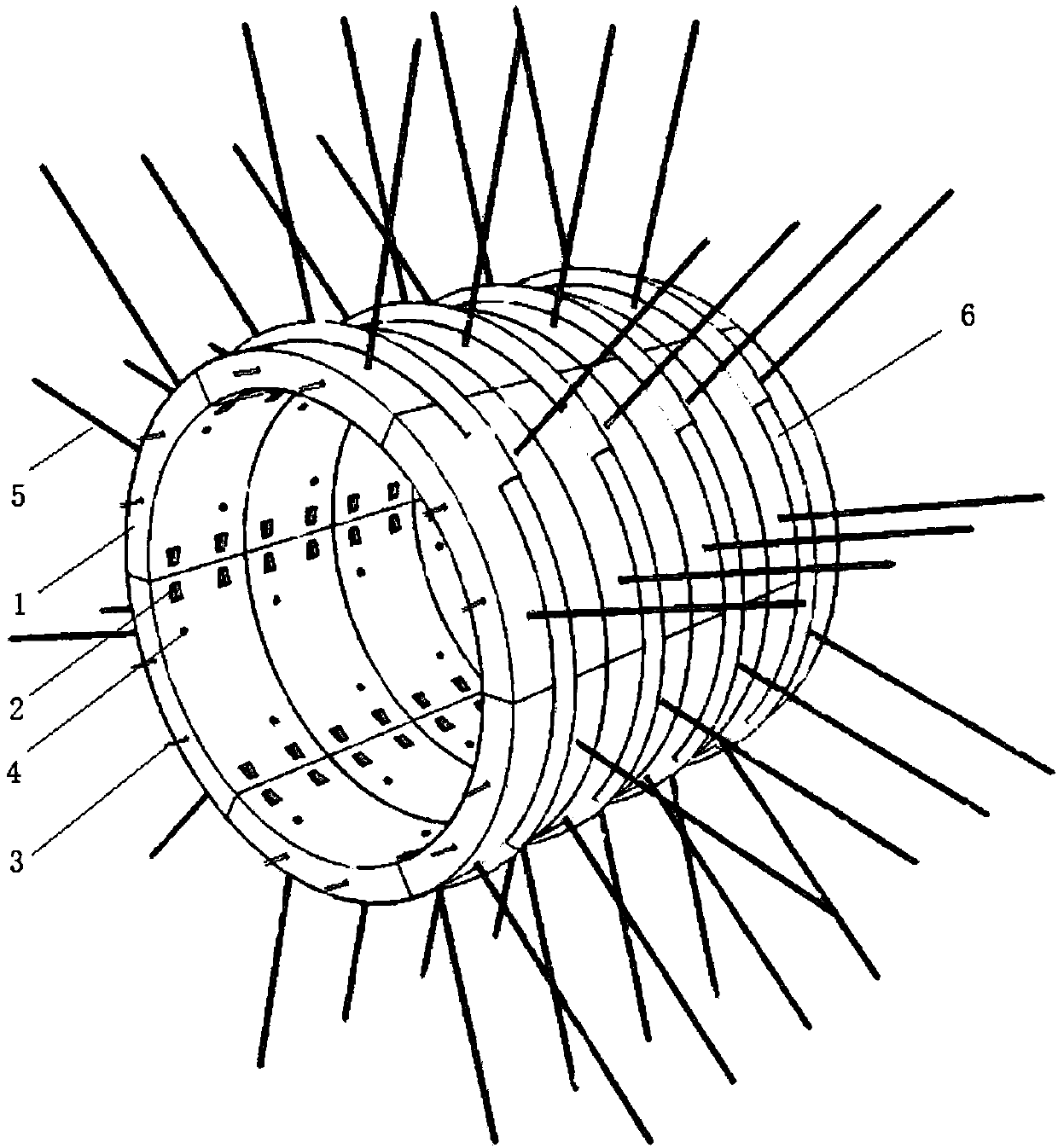

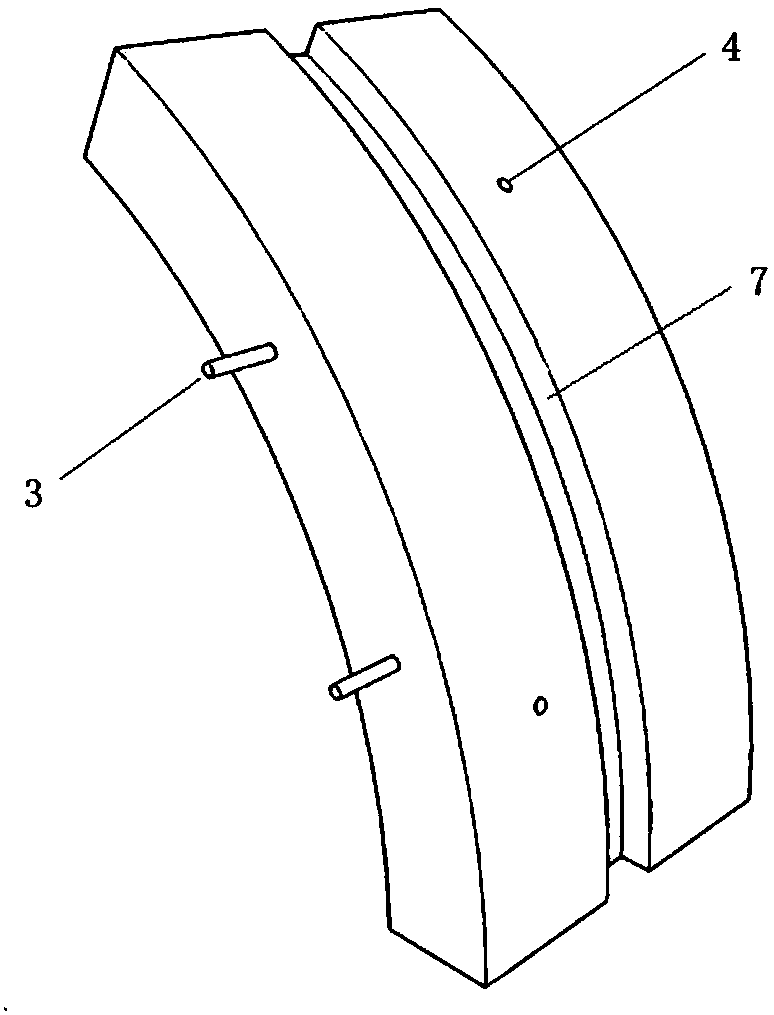

Assembled type support and protection structure based on outer steel arch and inner concrete plate and construction method of assembled type support and protection structure

The invention relates to an assembled type support and protection structure based on an outer steel arch and an inner concrete plate. The assembled type support and protection structure comprises a steel arch and a concrete support, wherein the concrete support is of a multi-piece arced plate assembling structure; the steel arch is arranged on the outer side of the concrete support; the concrete support and the steel arch are fixed on surrounding rock of a roadway / tunnel through anchor rods. By adopting the composite support and protection structure provided by the invention, the reinforced steel concrete casting and maintenance time is saved on the basis that a relatively large bearing force is ensured, and the support and protection construction speed is greatly increased. By adopting the assembled type support and protection structure, a novel technical way is provided for support and protection of deep well roadways and soft rock roadways, and a novel support and protection methodis provided for the field of roadway / tunnel support and protection.

Owner:SHANDONG JIANZHU UNIV

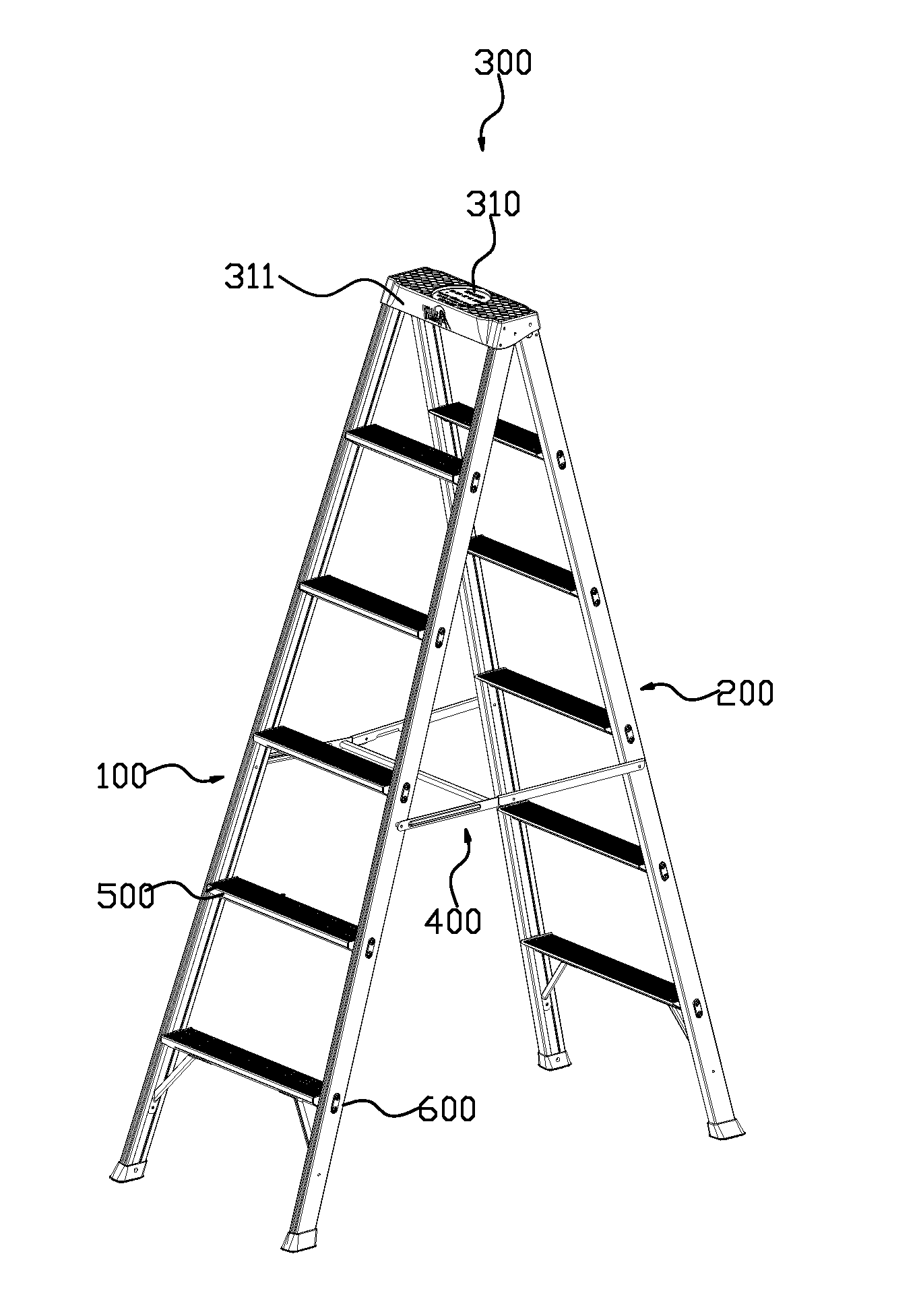

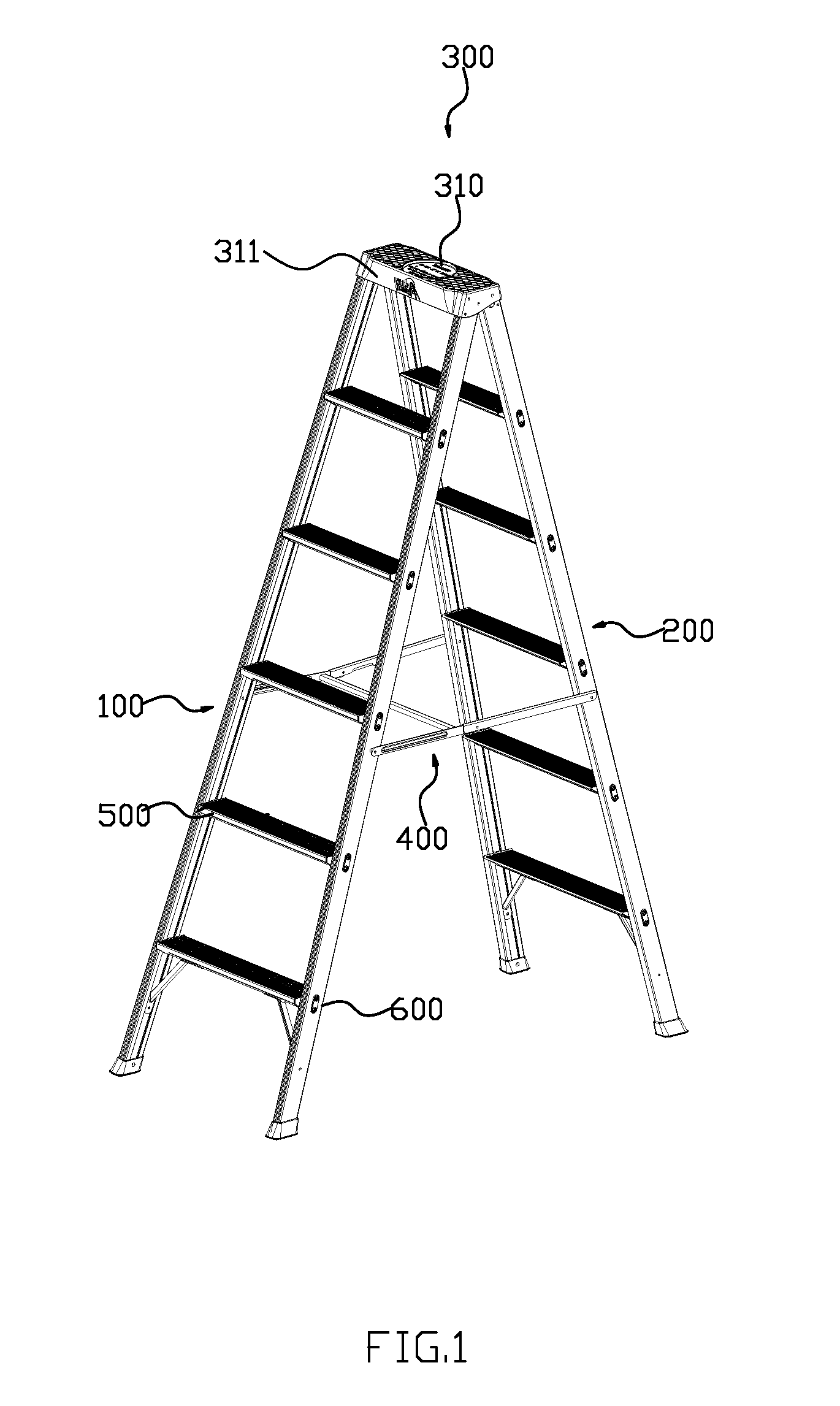

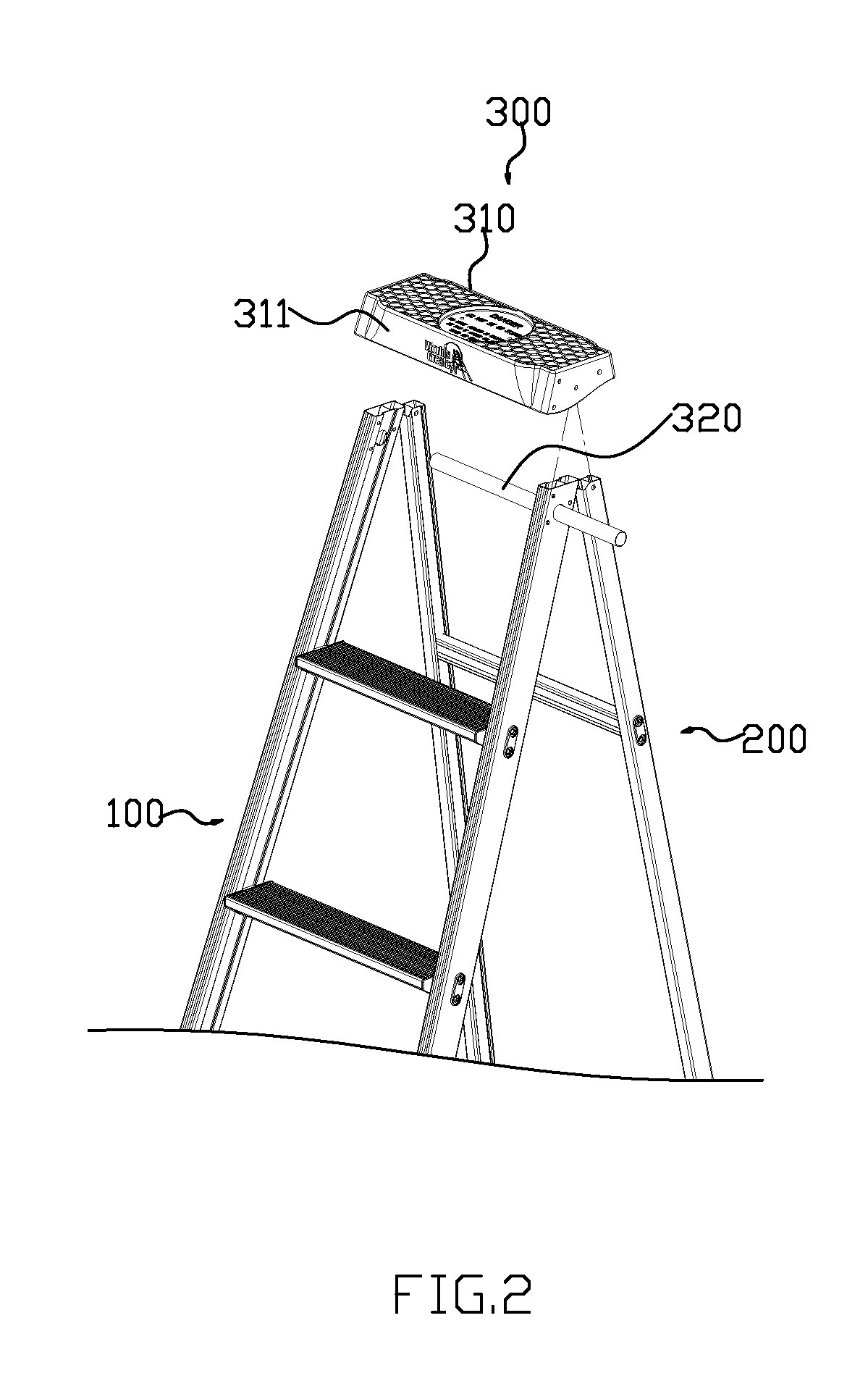

Lambdoidal ladder

A lambdoidal ladder comprises front struts (100), back struts (200), treads (500), a folding device) 400, a connection device (600) and a platform (300). Wherein the platform (300) is connected to the front strut (100) and the back strut (200), and the structure between the front strut and the back strut is a rotatable connection; the platform (300) comprises a body (310) and a transverse rod (320) which goes through the front strut (100), an orientation slot (314) matching to the transverse rod (320) is set under the body (310); the folding device (400) fixed to the middle part of the front strut and the back strut is constructed a hinge with a H figuration; the tread (500) is fixed to the front and back struts by the connection device (600).

Owner:NEW TEC INTEGRATION (XIAMEN) CO LTD

Hydraulic support withdrawing system and method

The invention discloses a hydraulic support withdrawing system and method and belongs to the technical field of hydraulic supports. The hydraulic support withdrawing system comprises at least two shield supports and a withdrawing platform. A moving beam is arranged between the shield supports and the withdrawing platform. The two sides of the moving beam are fixedly connected with a moving jack at the bottoms of the shield supports and one end of the withdrawing platform respectively. The shield supports are arranged on one side of the moving beam in parallel, and one shield support is located on the side of a hydraulic support to be withdrawn. Each shield support comprises a base and a net pushing device. The withdrawing system is high in safety coefficient, and labor is saved.

Owner:SHANDONG LUNAN GRP ENERGY EQUIP MFG

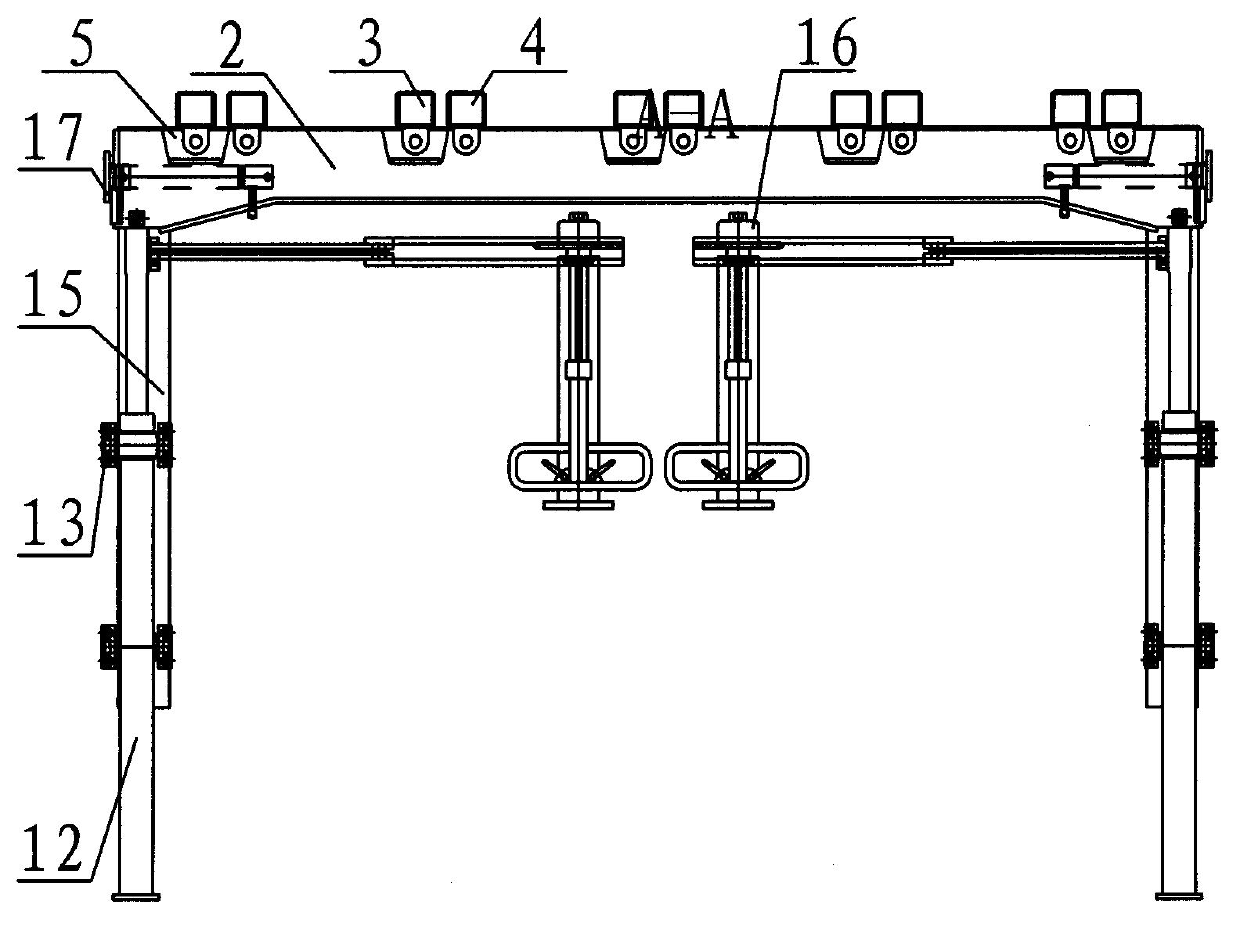

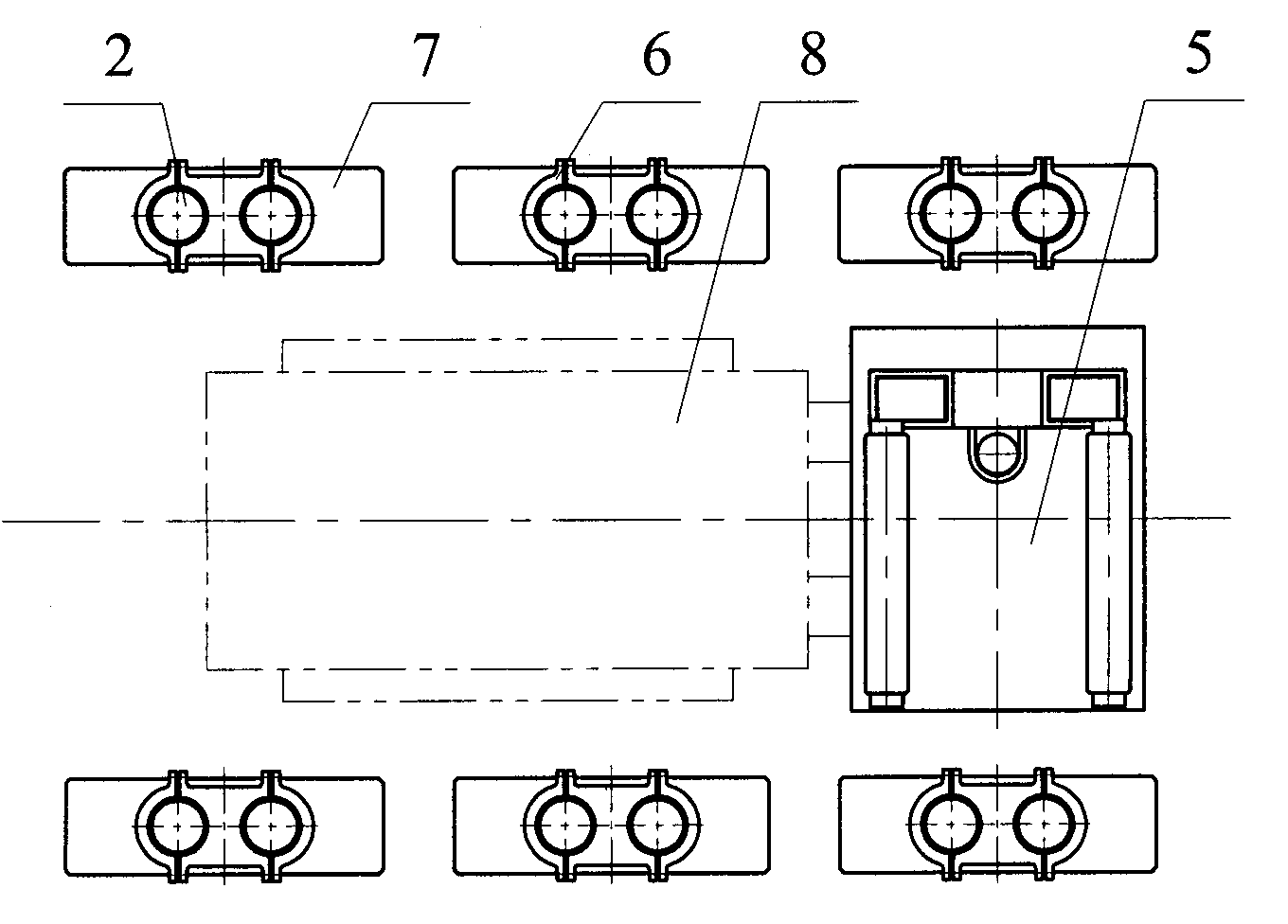

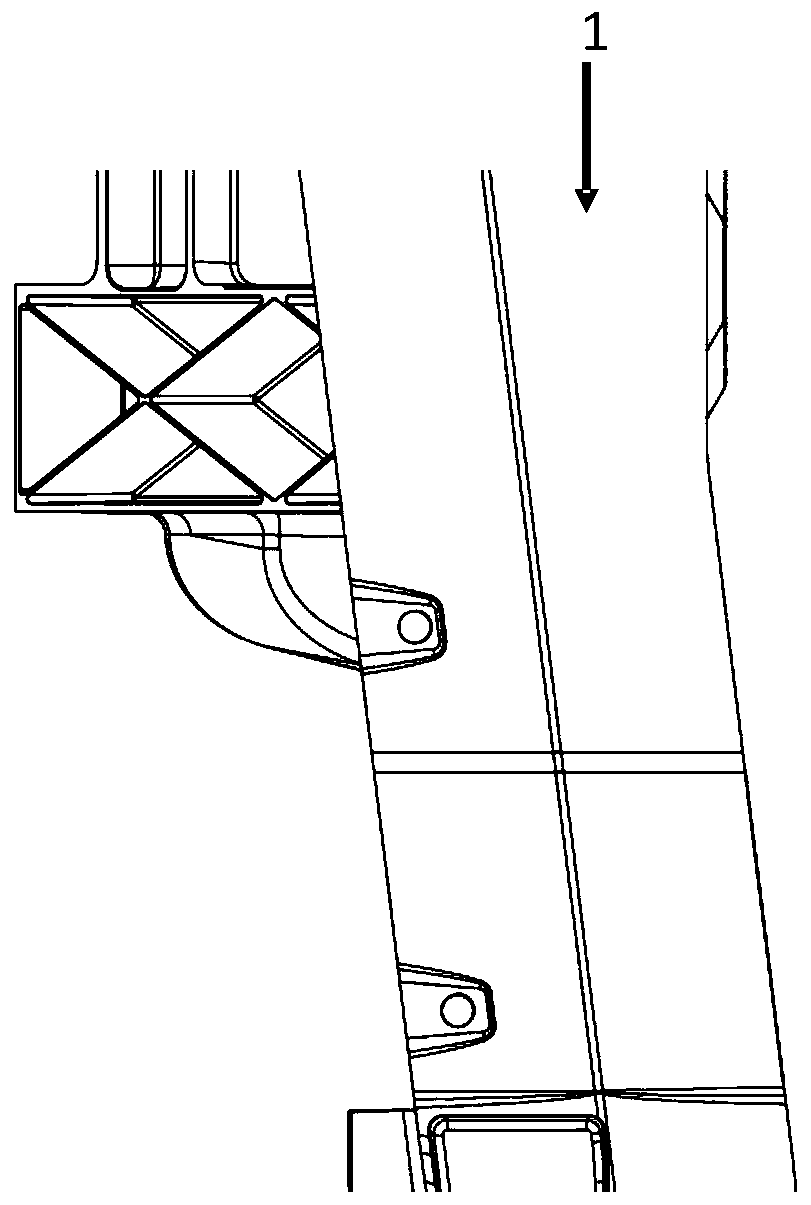

Tunnel excavation staggered type supporting device

ActiveCN102654060AImprove support qualityEliminate risk from high-hazard operationsMine roof supportsAnchoring boltsHydraulic cylinderRock bolt

The invention provides a tunnel excavation staggered type supporting device, which solves the problems in prior art of lagging supporting means, difficulty in moving, operation at a halt state, low efficiency and the like. The tunnel excavation staggered type supporting device comprises a hydraulic stand column as a support and a beam frame consisting of transverse beams and vertical beams. According to the technical main points, the beam frame comprises a girder frame and a secondary beam frame; auxiliary anchoring rod devices are arranged at the side parts of an auxiliary front beam and an auxiliary back beam; the front end of a main front vertical beam is hinged with a front beam assembly; a moving hydraulic cylinder is hinged between the main front beam and the auxiliary back beam; and the hydraulic stand column moves synchronously by means of assembling with a connecting rod together. The tunnel excavation staggered type supporting device provided by the invention has the advantages of reasonable structural design, stable supporting and moving, convenience in dismounting and maintenance, and high security and reliability. The tunnel excavation staggered type supporting device is entirely suitable for field and in-time support using conditions, can mechanically support an ejector plate which is just exposed to a tunnel excavation working face in time, can assist tunnel permanent supporting operations, such as an auxiliary screen, an anchoring rod and the like, and cover the continuous operation through a comprehensive mechanical excavator, so that the supporting quality and the excavation operation efficiency of the ejector plate of a tunnel can be obviously improved.

Owner:沈阳天安特种机器人有限公司

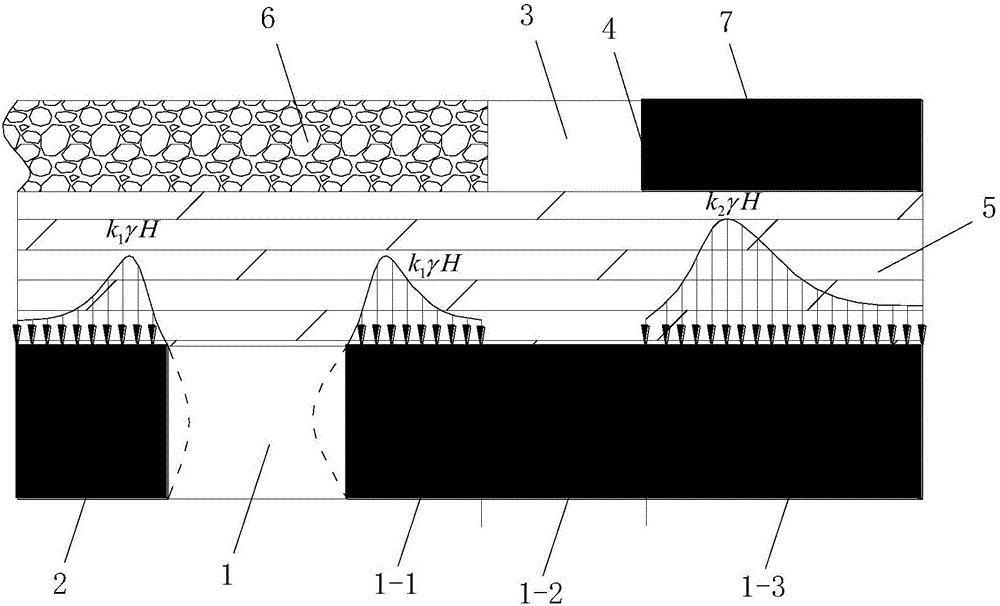

Short-distance coal seam roadway excavating and supporting method

ActiveCN106014423AThe method steps are simpleEasy to implementUnderground chambersTunnel liningSupporting systemShortest distance

The invention discloses a short-distance coal seam roadway excavating and supporting method. The method comprises steps as follows: 1, basic mechanical parameters of surrounding rock are determined; 2, reserved excavated volumes of two sides of a roadway are determined; 3, the roadway is excavated; 4, a roadway side supporting structure is determined and comprises roadway supporting units and grouted rock bolts which are arranged in a staggered manner, and the roadway supporting units comprise top plate supporting systems, bottom plate supporting systems and roadway side supporting systems; and the limit caving arch rise is determined; 5, the roadway supporting structure is determined; 6, roadway surrounding rock supporting construction is performed; 7, excavation of the next section and roadway surrounding rock supporting construction are performed; 8, the step 7 is repeated multiple times, and the short-distance coal seam roadway construction process is completed. The method is simple, reasonable in design, convenient to realize and good in use effect, the reserved excavated volumes of the two sides of the roadway are determined respectively according to surrounding rock deformation conditions of the short-distance lower coal seam roadway, and whole section supporting is performed on the roadway through combination of the grouted rock bolts with the roadway supporting units.

Owner:鄂尔多斯市国源矿业开发有限责任公司

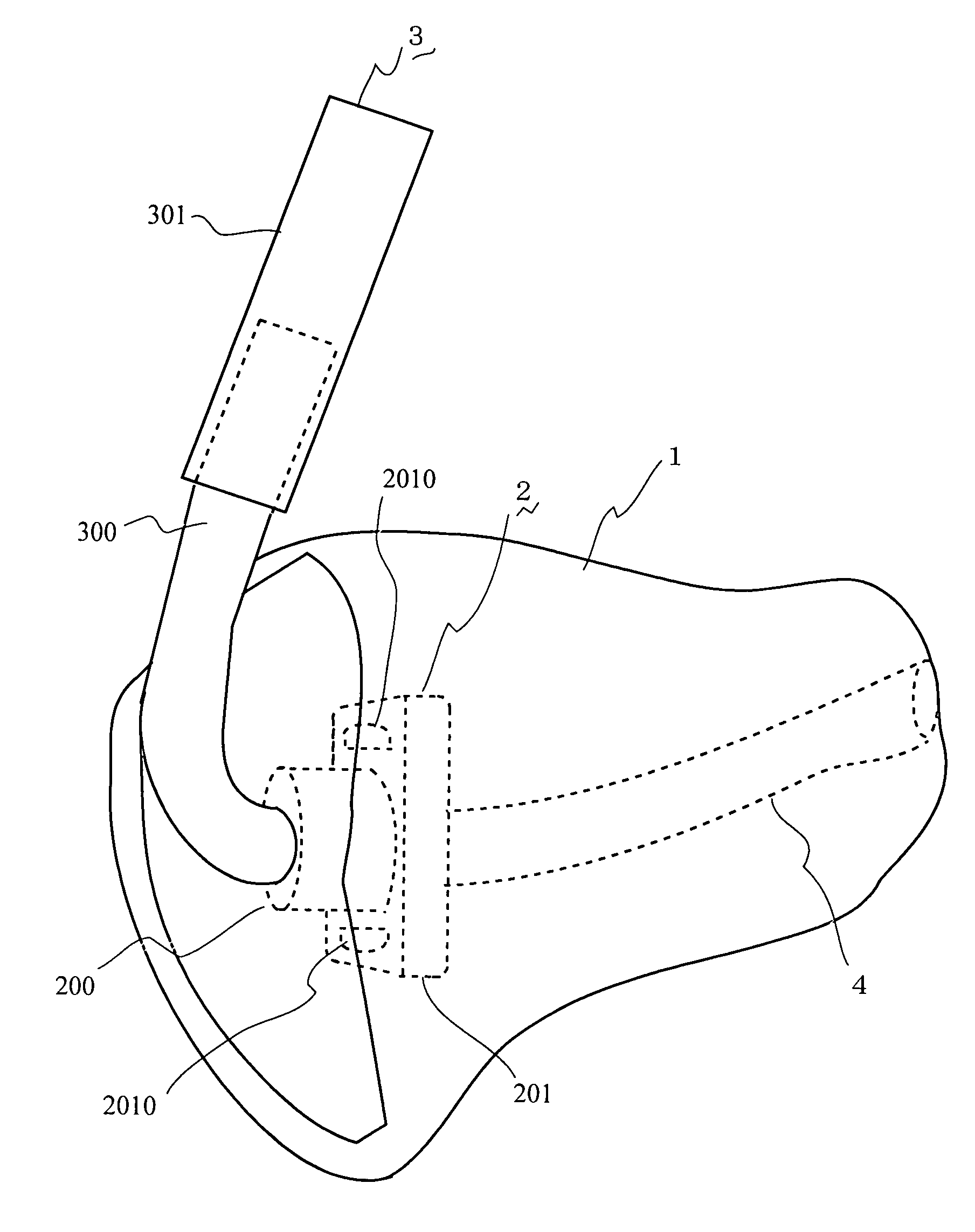

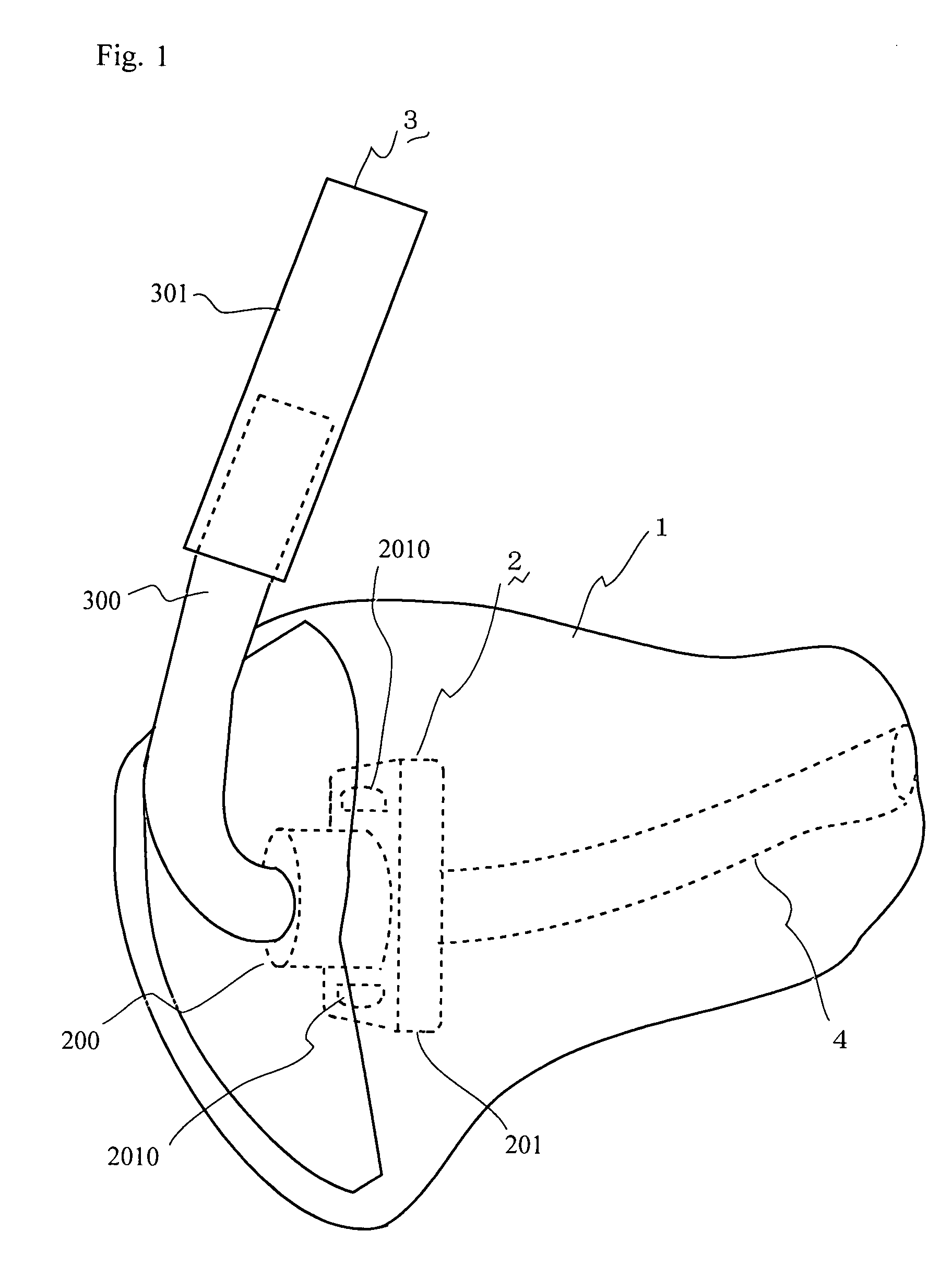

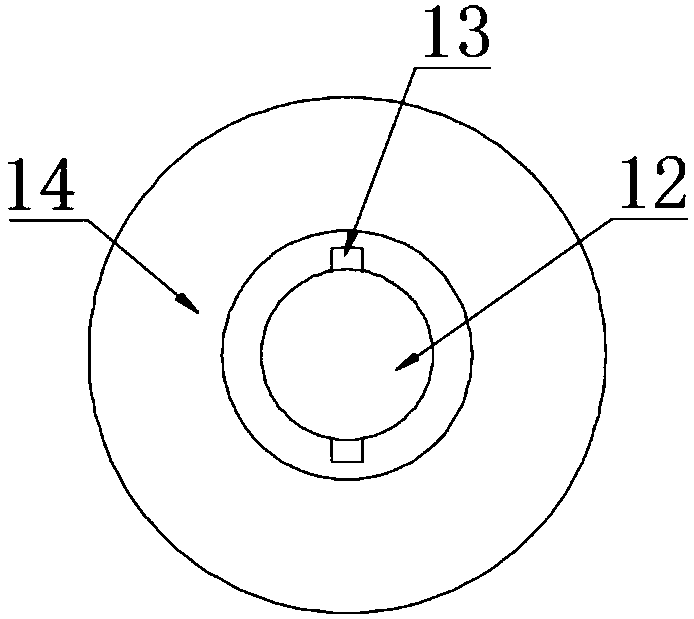

Ear Mold

InactiveUS20090141920A1Easy to useImprove stabilityBehind the ear hearing aidsHearing aids mounting/interconnectionInstabilityEarmold

[Technical Problem] In regard to an ear mold for a hearing aid, there are provided the ear mold which a metal bush is settled in a tube for joint of the hearing aid, said metal bush has been used on account of settlement of said tube for joint of the hearing aid, and which a tube is adhered by an adhesive, the adhesive has been used on account of settlement of said tube. However, said ear mold has disadvantages that said tube is easily moved for the reason of instability, said tube drops out from the ear mold, and the ear mold occurred the problem of a phenomenon of a howling by sound leak-out.[Technical Solution] The ear mold which is configured by embedding a connection and fixation member (A hub) 2 having a hole for connection to a hearing aid body and an introductory-hole of a forming material of said ear mold 2010 into the ear mold 1 on the basis of an ear impression. The connection and fixation member (the hub) 2 is embedded into the ear mold 1 when molding of the ear mold.

Owner:SUYAMA DENTAL LAB

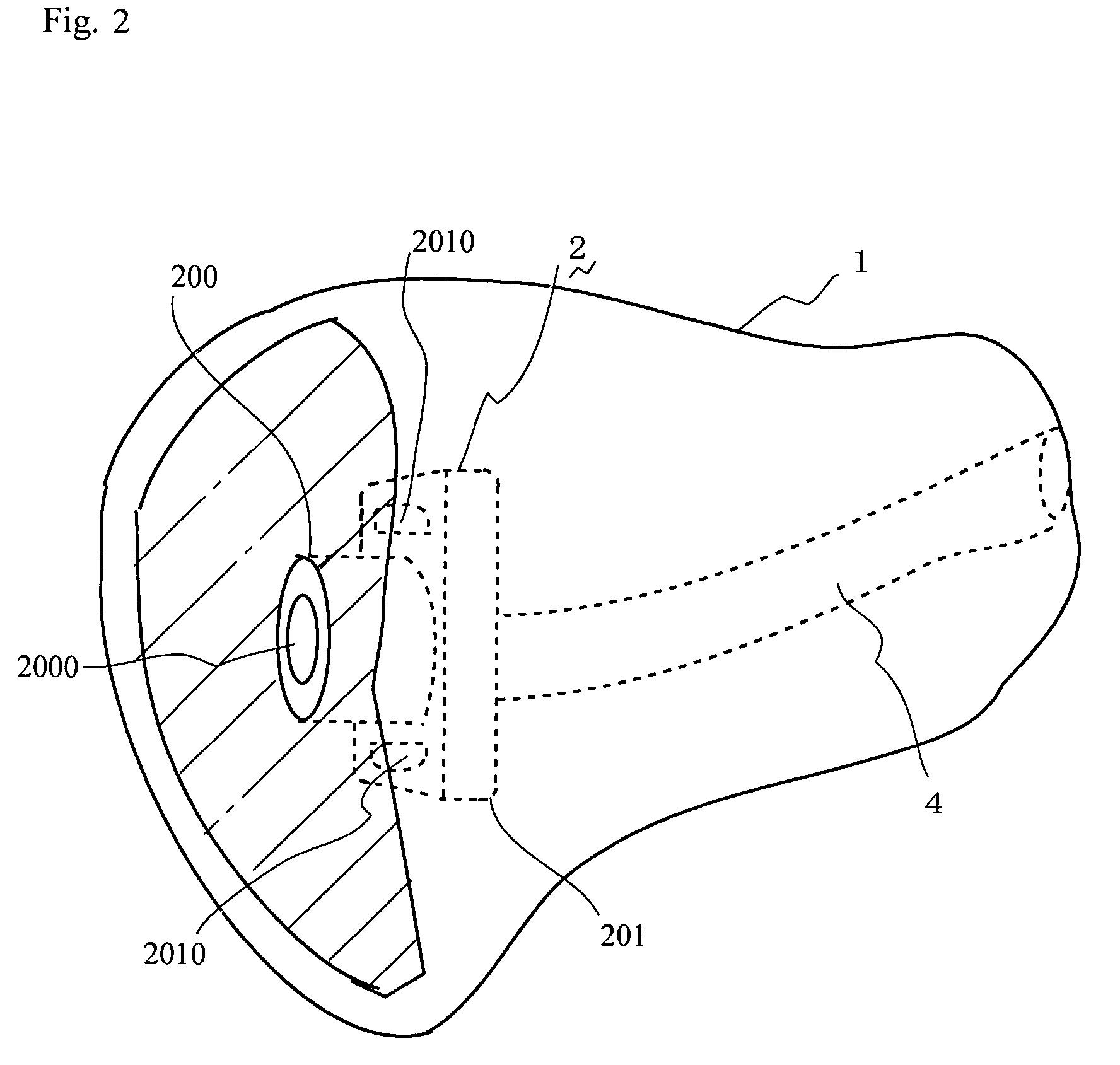

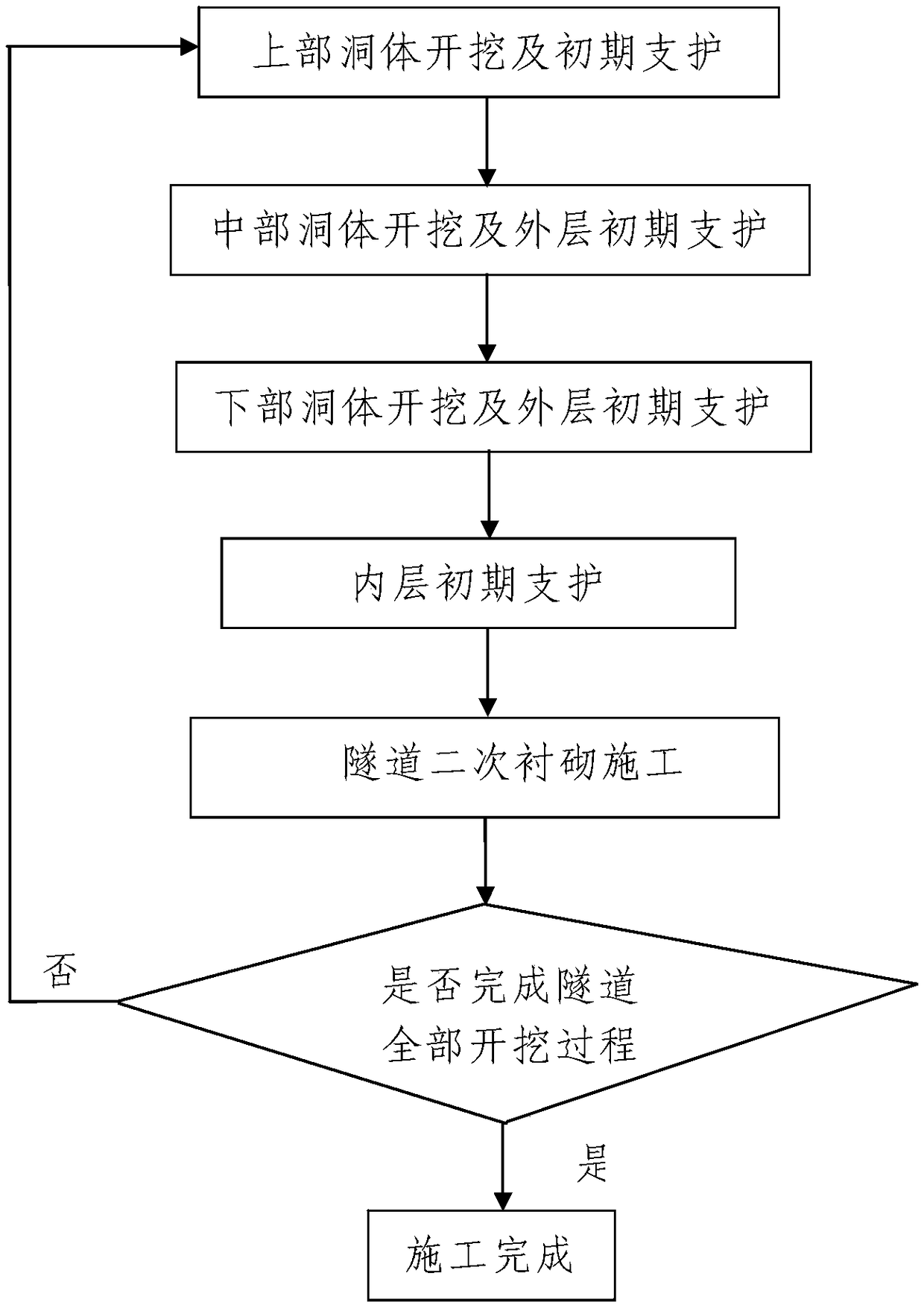

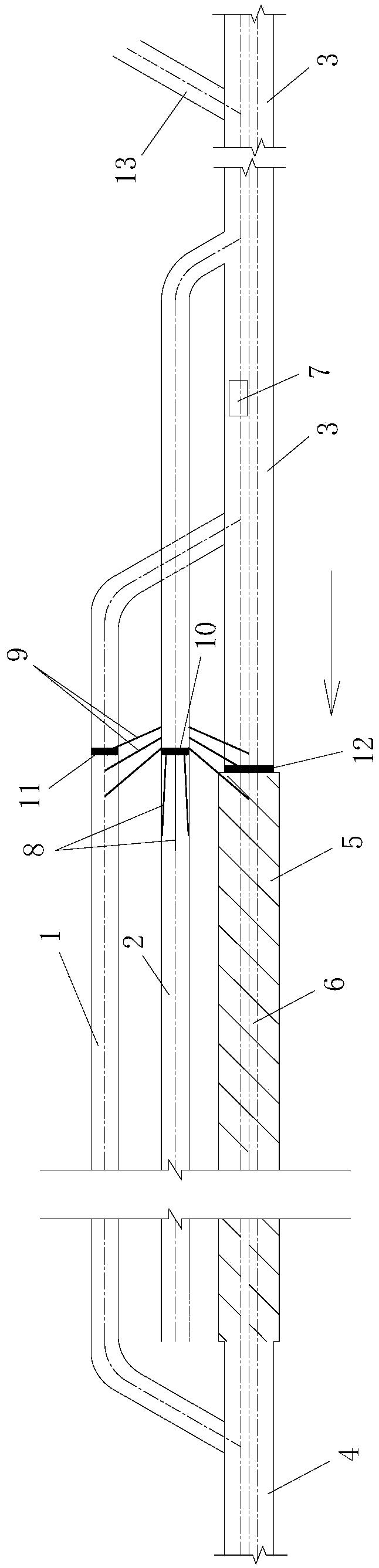

Excavation method for tunnel passing through high-angle thrust water-rich and sand-rich fault

ActiveCN109209398ASimple structureReasonable designUnderground chambersTunnel liningHigh angleStep method

The invention discloses an excavation method for a tunnel passing through a high-angle thrust water-rich and sand-rich fault. A construction tunnel hole is divided from the top to the bottom into an upper hole body, a central hole body, and a lower hole body, wherein the upper hole body is divided into a left guide hole and a right guide hole. A primary support structure of the tunnel hole is a double-layer primary support structure. During the excavation of the construction tunnel, the construction tunnel is divided into a plurality of tunnel segments from the back to the front for excavation. During the excavation of any one tunnel segment, the method comprises the steps: 1, performing the excavation of the upper hole body and the primary supporting; 2, performing the excavation of the central hole body and the primary supporting of an outer layer; 3, performing the excavation of the lower hole body and the primary supporting of the outer layer; 4, performing the primary supporting of an inner layer; 5, repeatedly performing the steps 1-4 for many times, and completing the excavation of the tunnel. The method is simple in step, is reasonable in design, is convenient for construction, is good in use effect, employs a three-step method for the excavation of the tunnel hole, employs double primary support structure for the full-section support of the tunnel hole after excavation, and can guarantee the safety of the tunnel structure later.

Owner:CHINA RAILWAY 20 BUREAU GRP

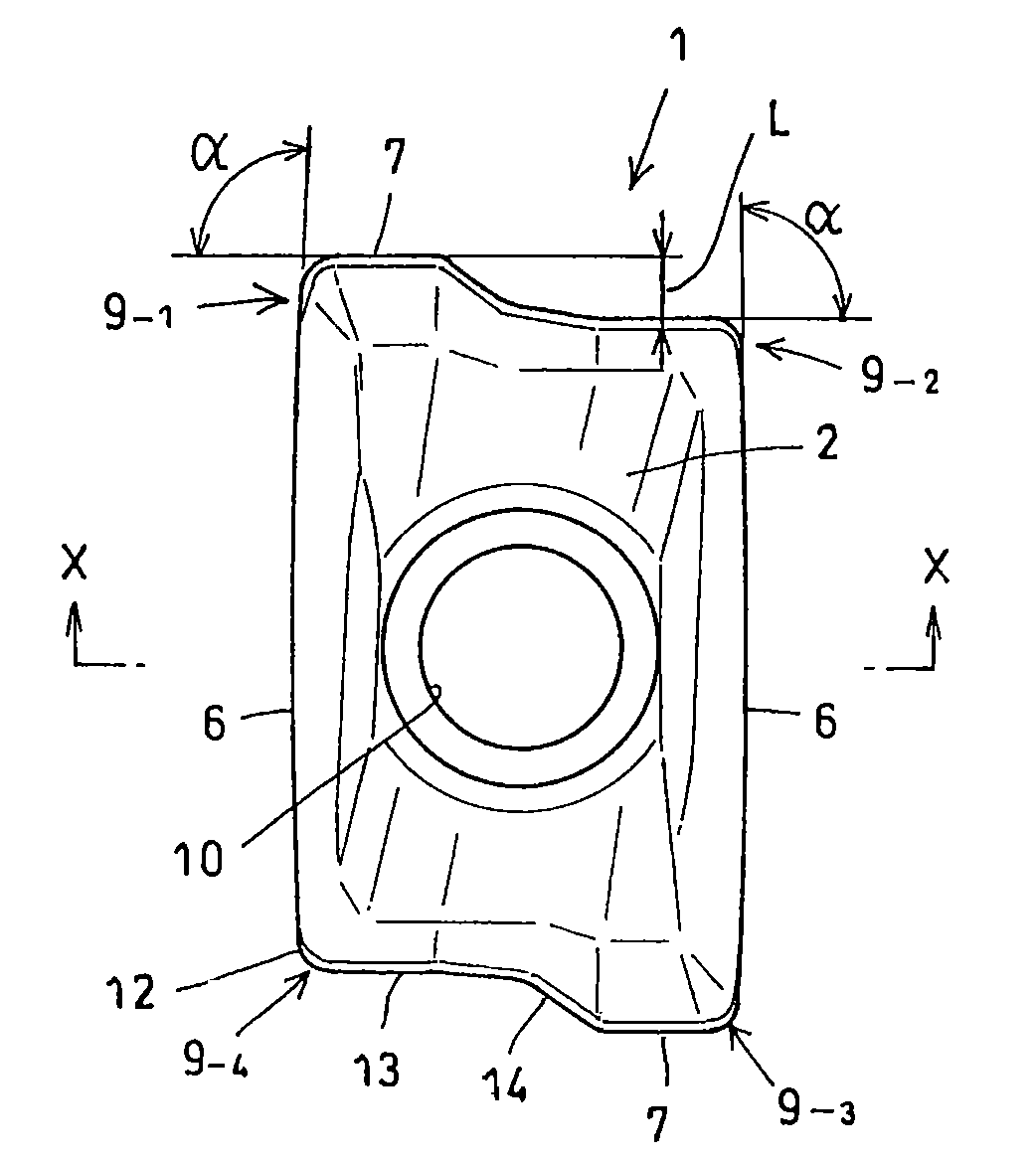

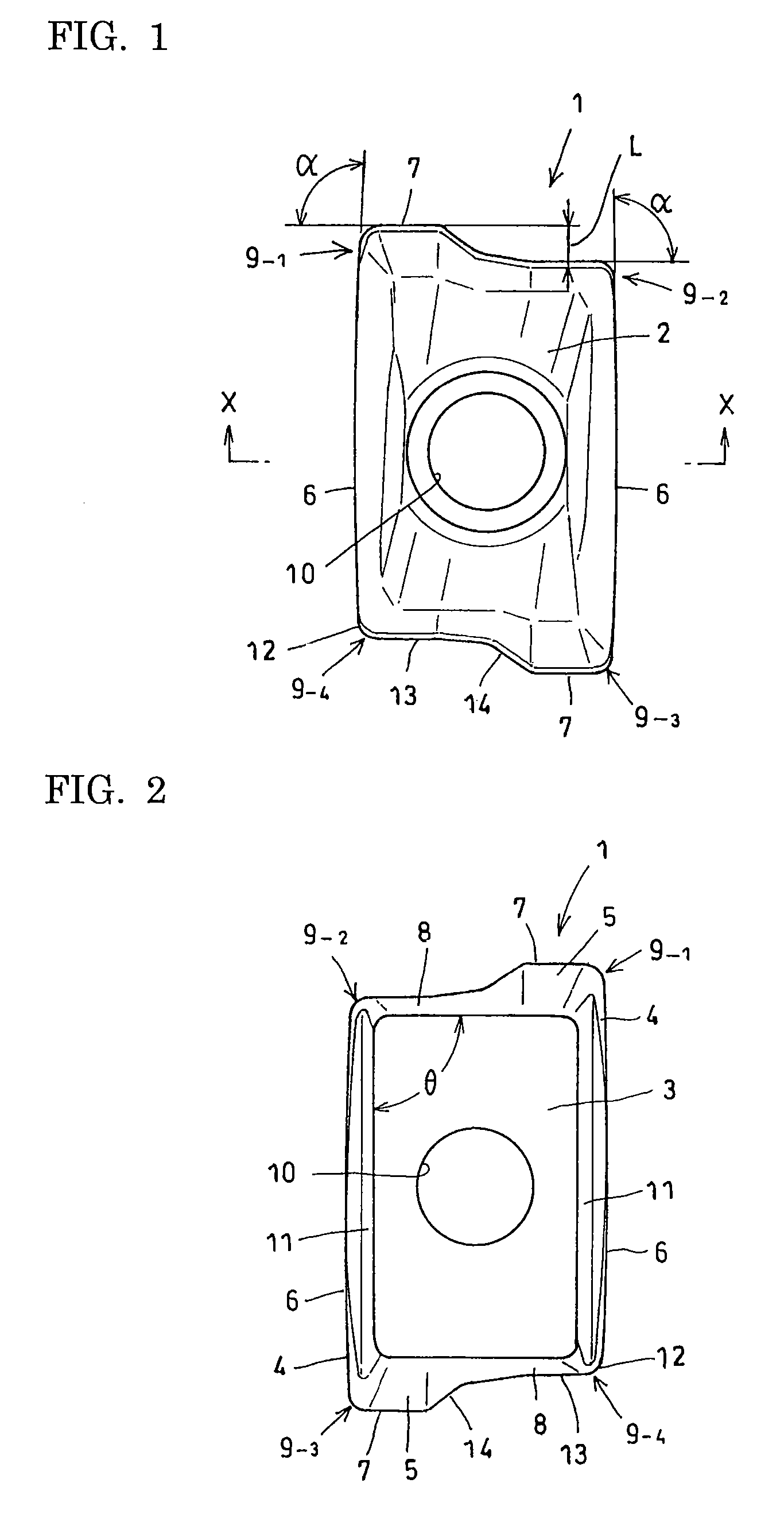

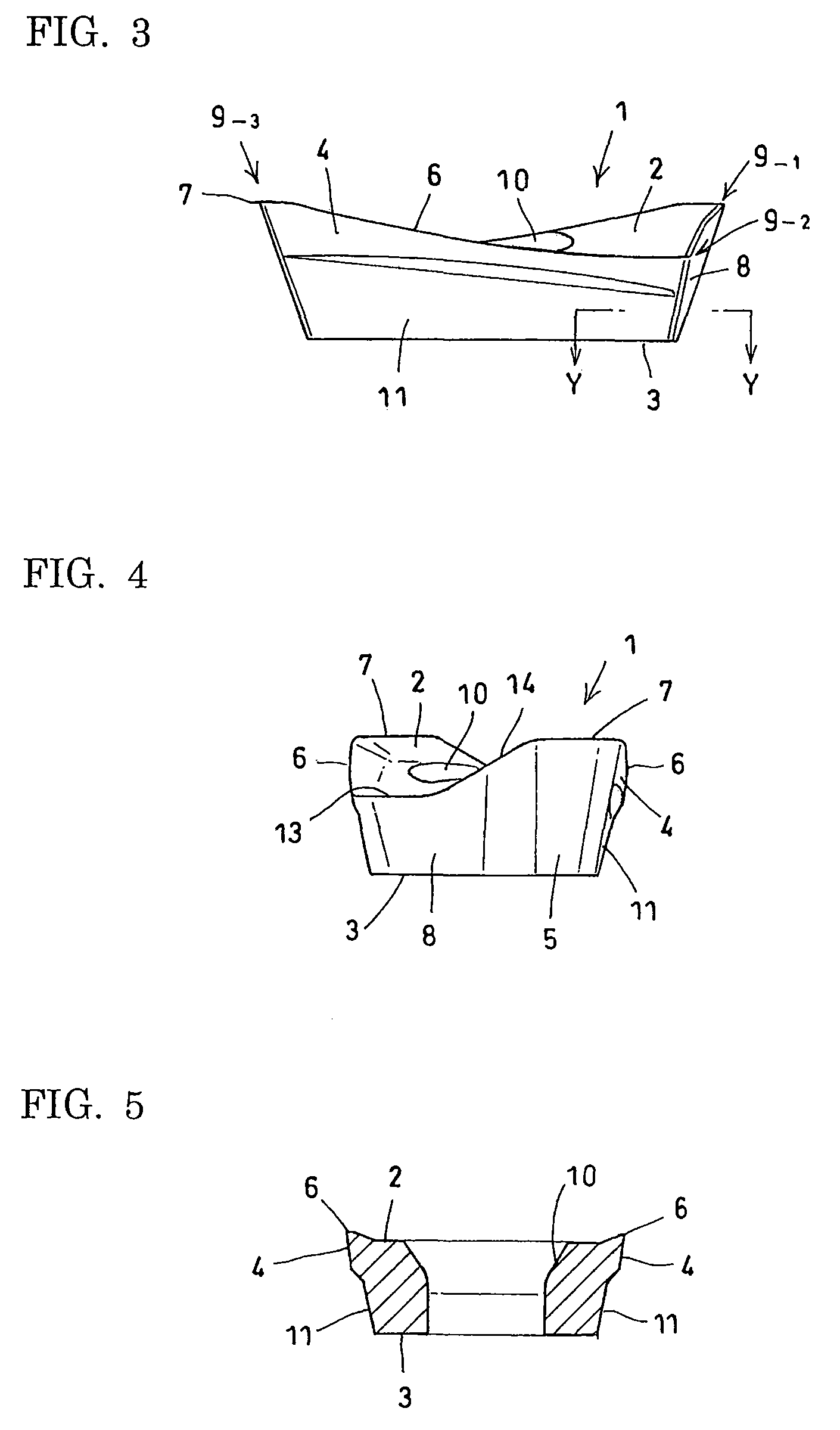

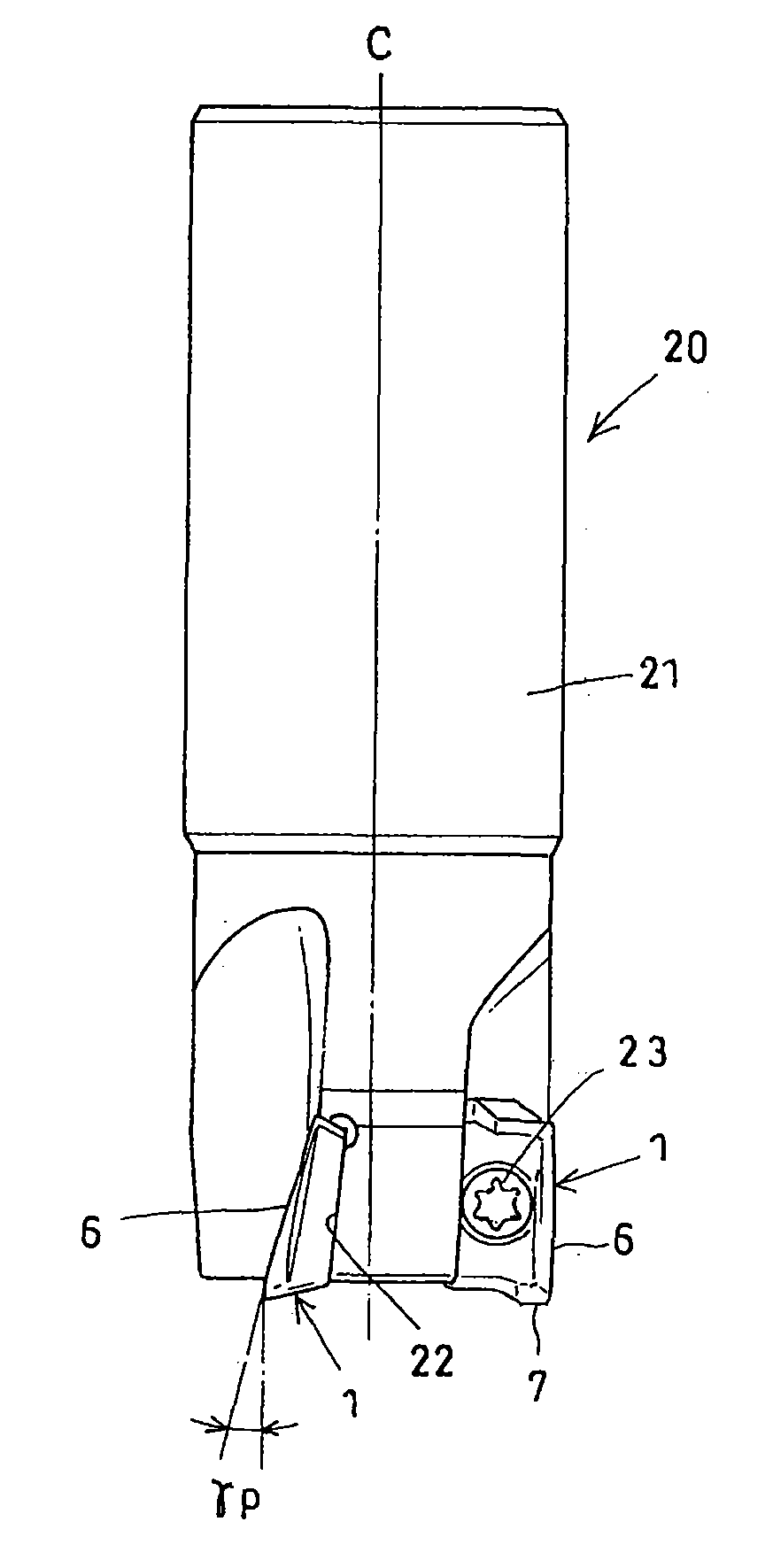

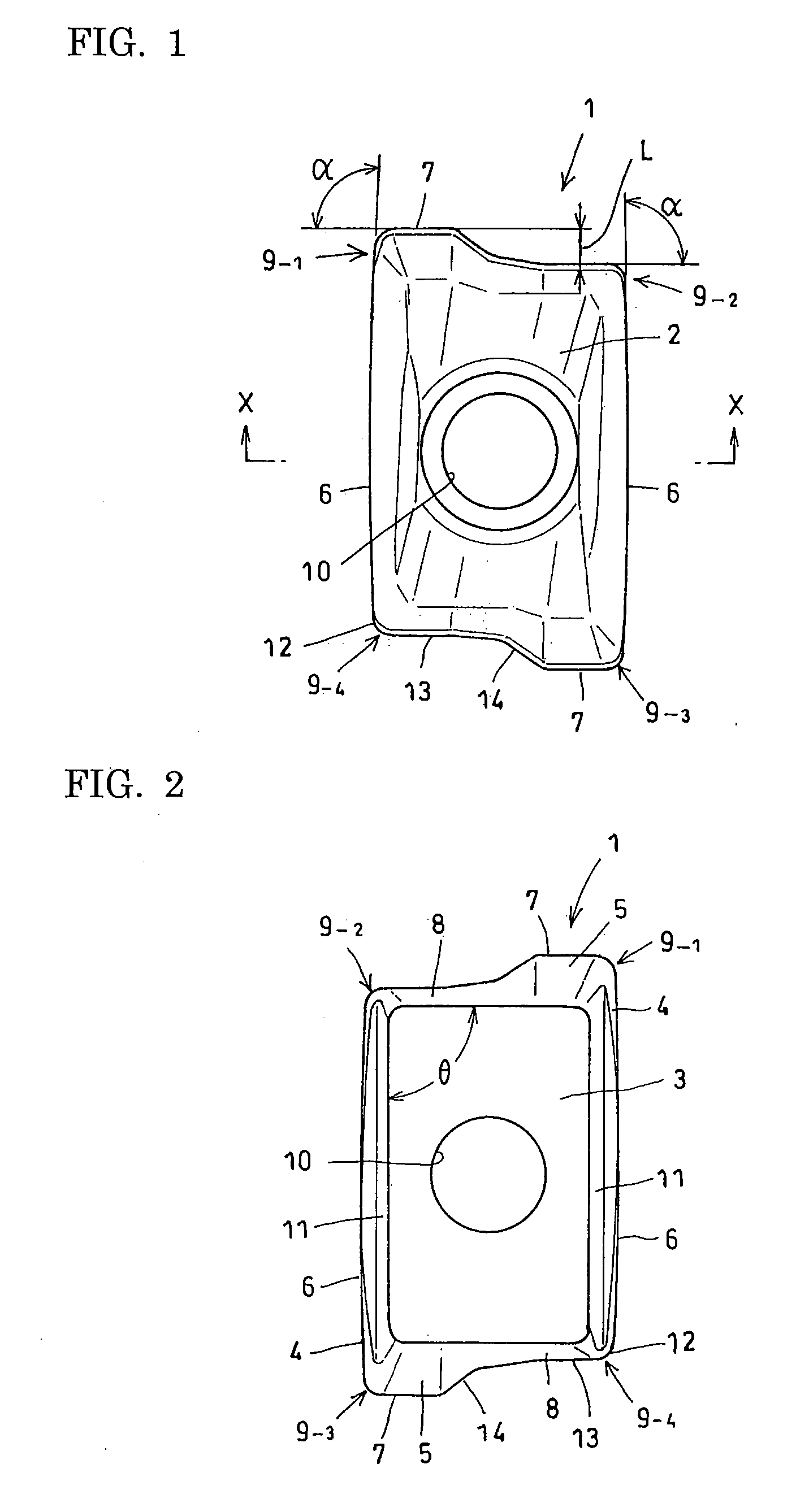

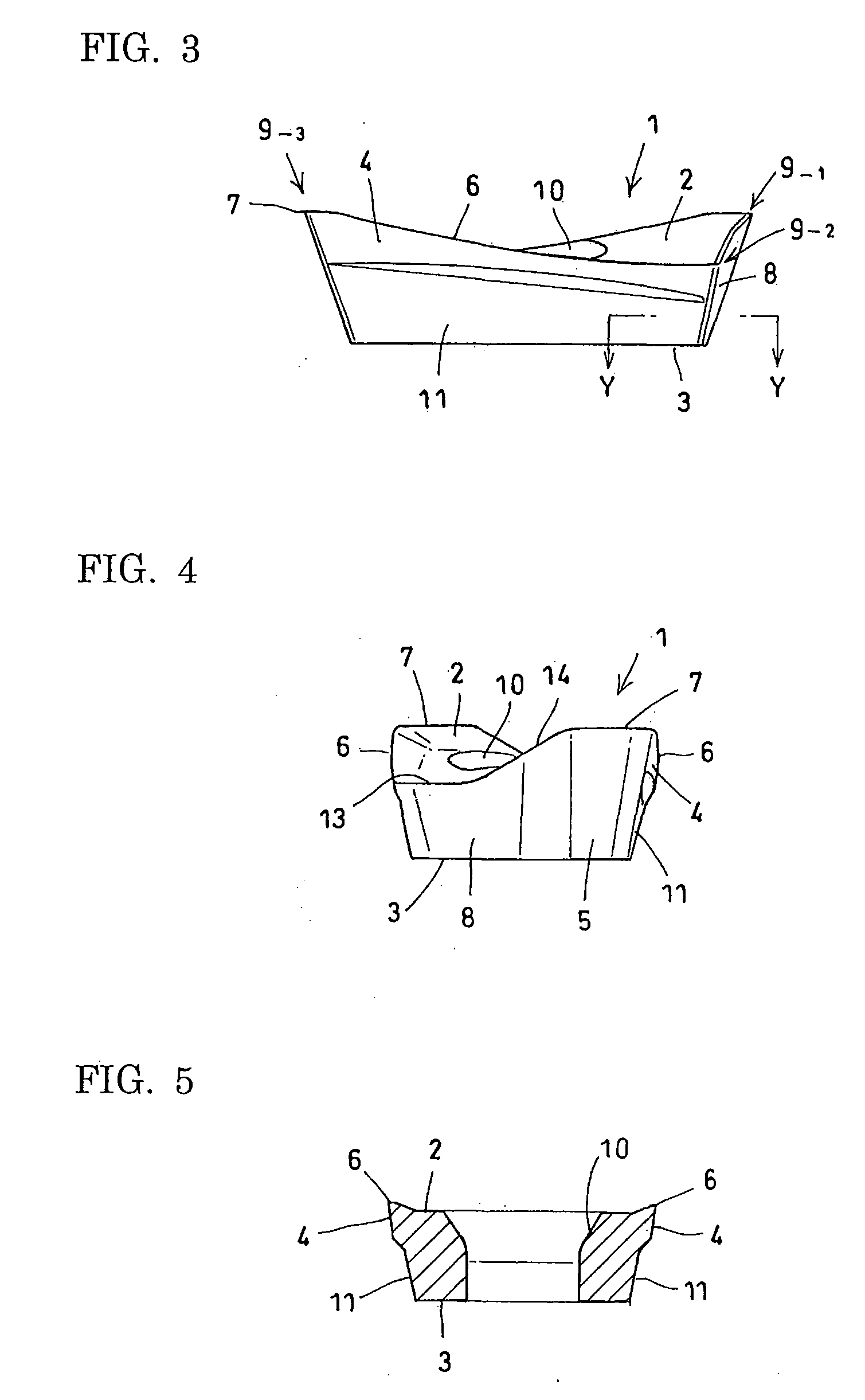

Throw-away insert and milling cutter using throw-away insert

A throw-away insert includes: an upper and bottom surface; two side surfaces; two end surfaces; a main cutting section formed from a ridge line positioned at the intersection between the side surfaces and the upper surface; a secondary cutting section formed from a ridge line positioned at the intersection between the end surfaces and the upper surface; an axial support surface supported by an insert pocket of a cutter body; and noses formed at the corners of the upper surface. The corner angles of the noses when seen from above are essentially right angles. The axial support surface is formed as a section of the end surface. The secondary cutting section is parallel to the ridge line at the upper end of the axial support surface and the bottom surface. The upper end of the axial support surface is positioned so that it is projected more in the direction of the longitudinal axis of the main cutting section than the ridge line of the upper end.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

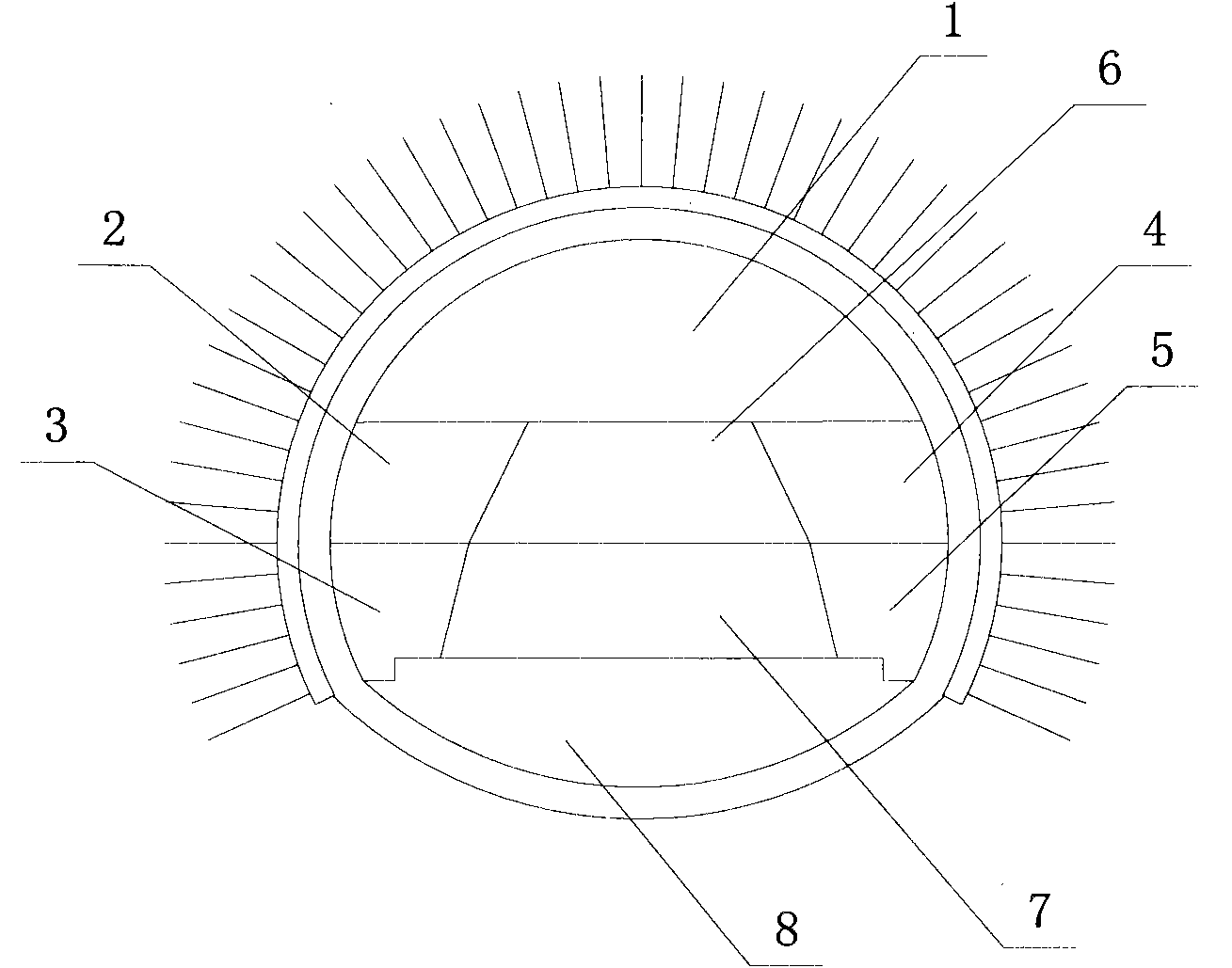

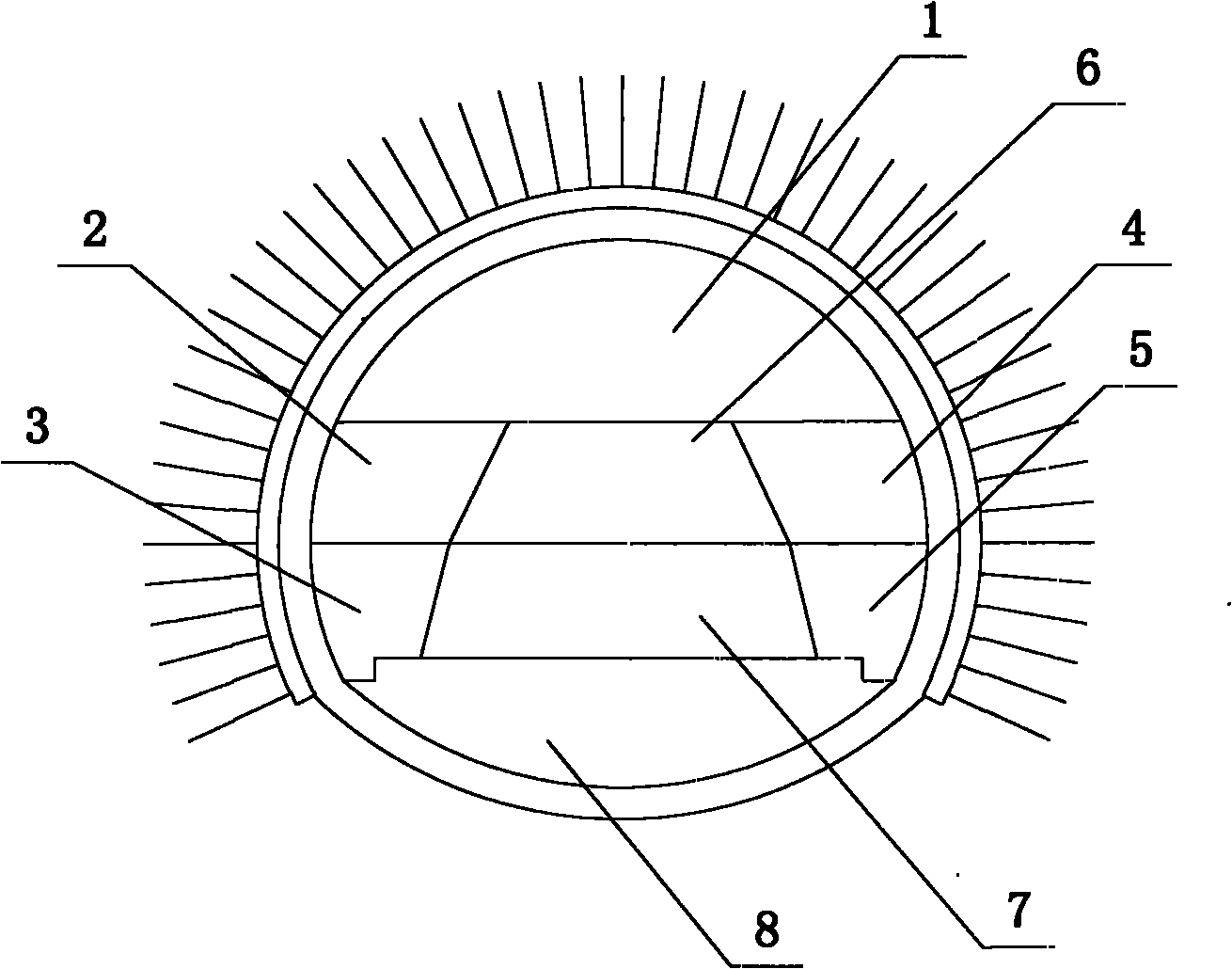

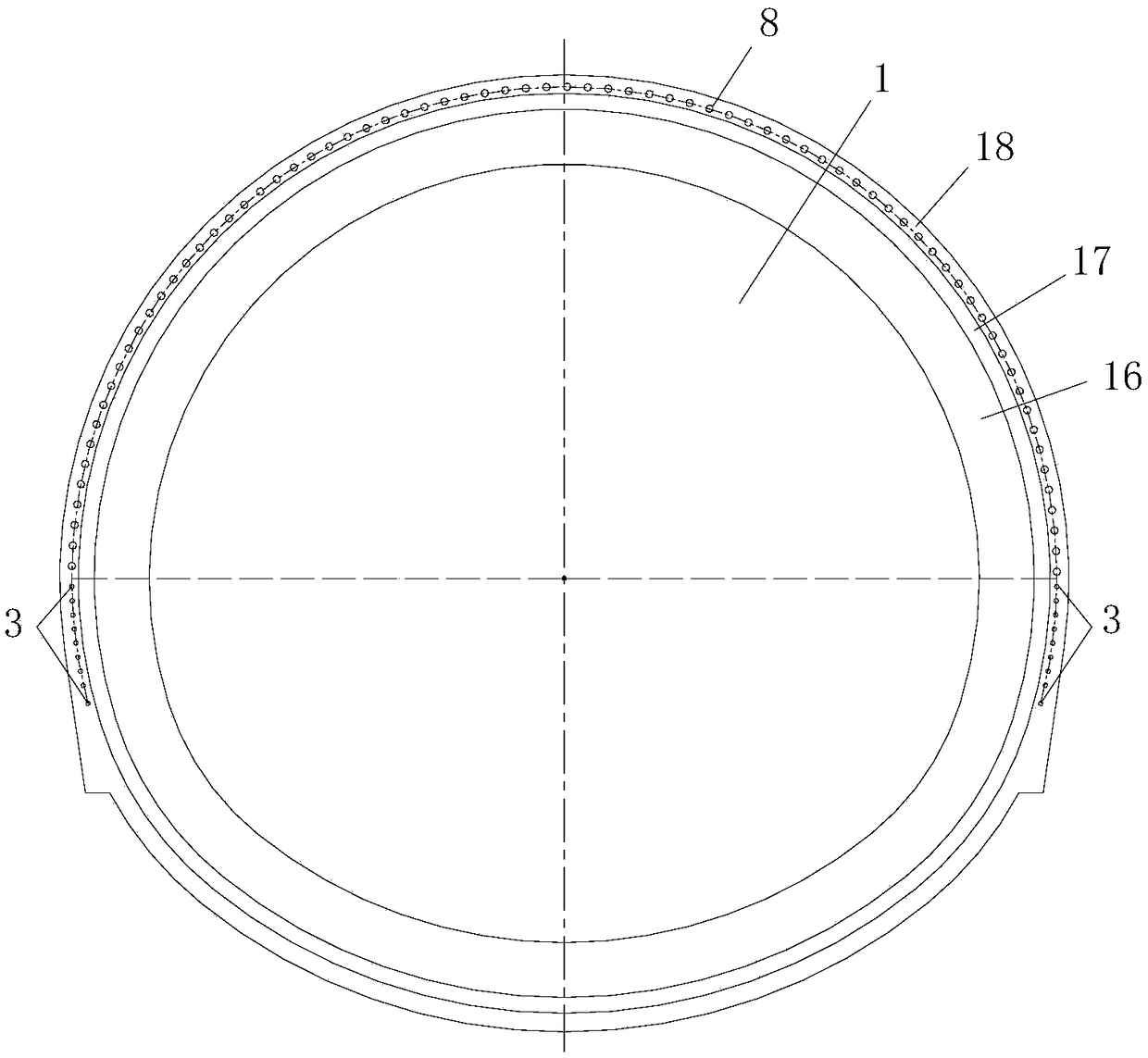

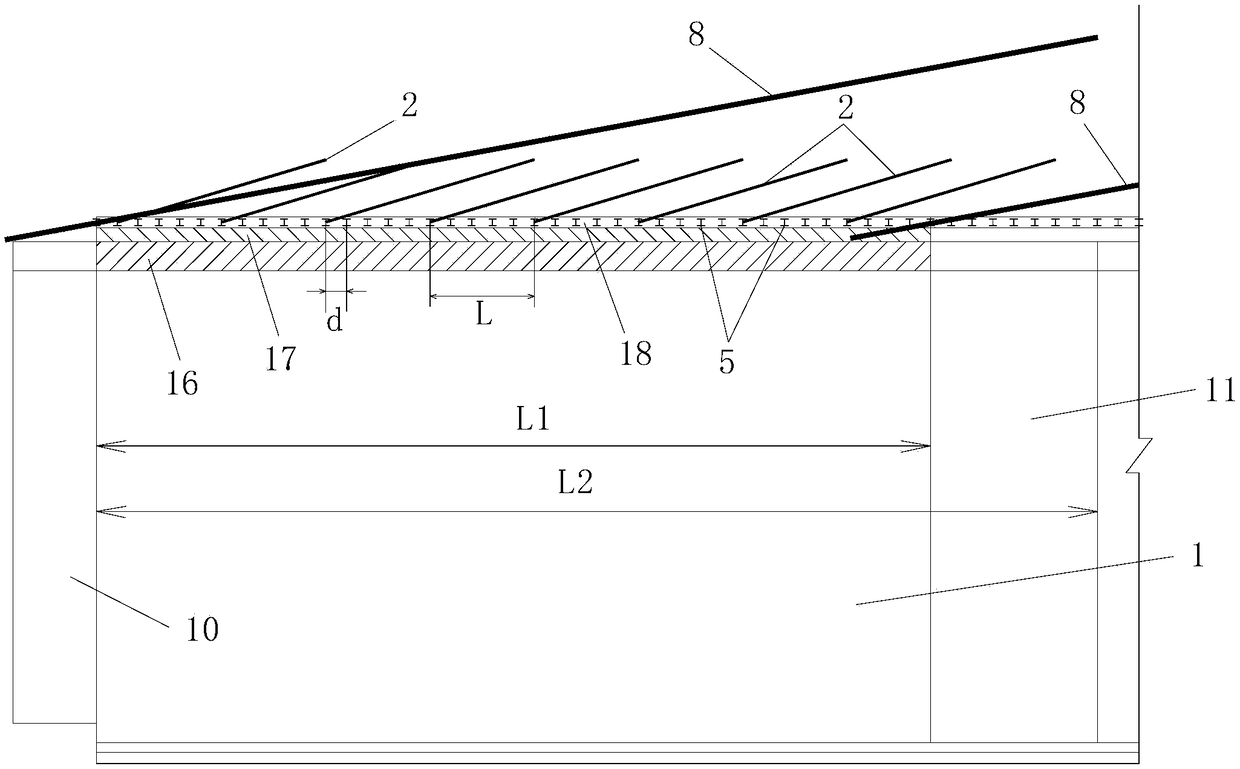

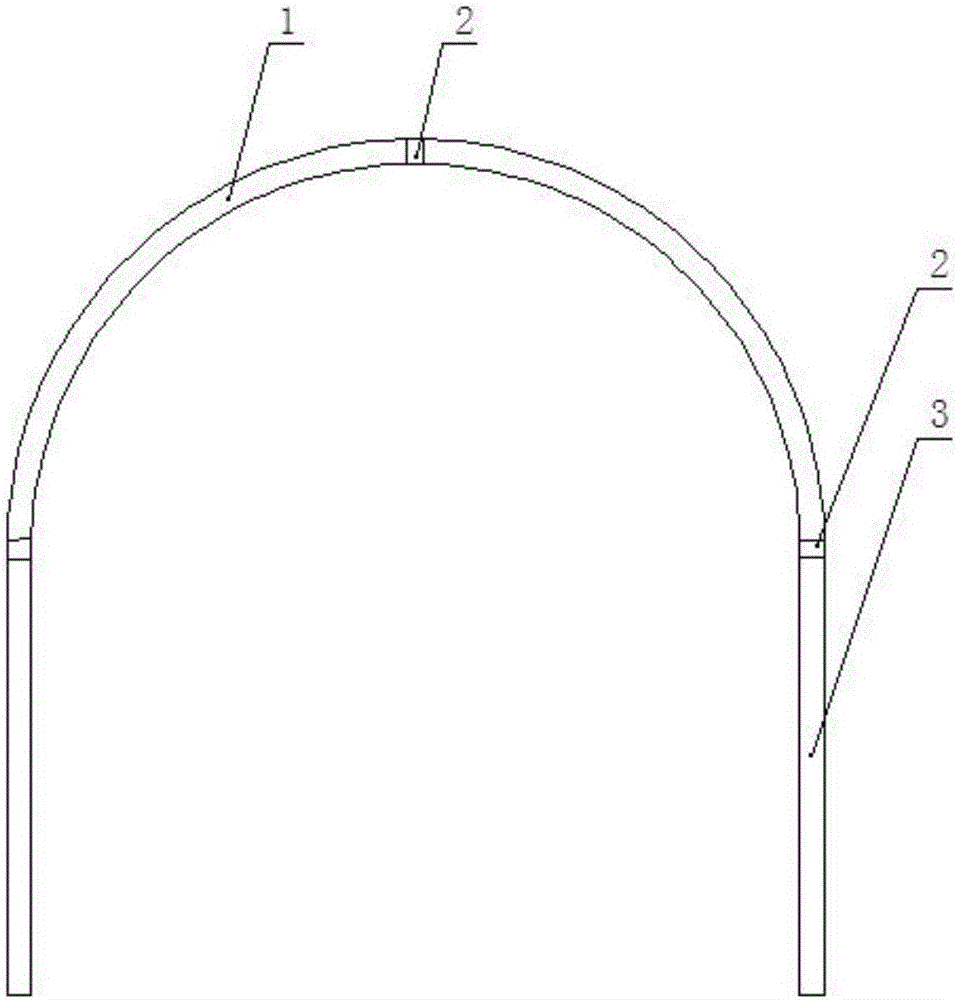

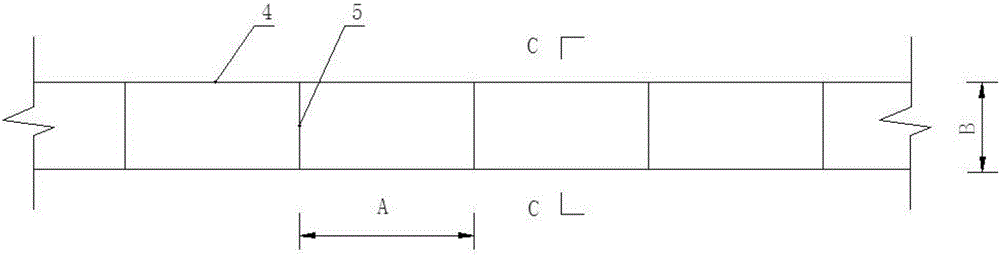

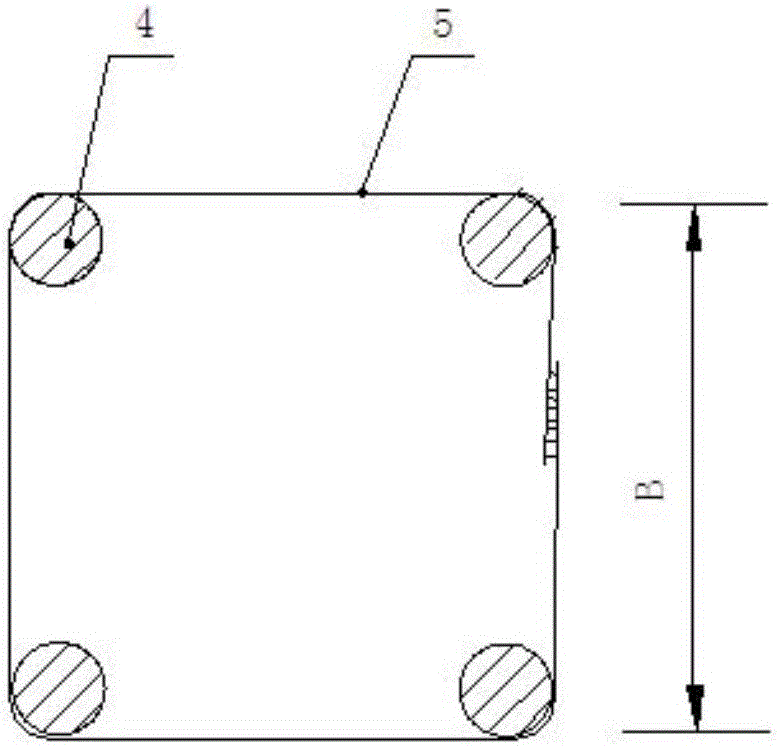

Steel grating assisted diversion tunnel preliminary bracing structure and method

InactiveCN105781593ASolve the problem of temporary supportReduce construction costsUnderground chambersTunnel liningGratingMaterials science

The invention relates to a steel grating assisted diversion tunnel preliminary bracing structure. The steel grating assisted diversion tunnel preliminary bracing structure comprises vertical sections and an arch-shaped section, wherein the arch-shaped section is of a circular arc structure, the vertical sections are symmetrically connected to two end parts of the arch-shaped section, the vertical sections and the arch-shaped section are all of structures of steel grating units, each steel grating unit comprises four main reinforcements and a plurality of hoopings, the hoopings are horizontally and evenly arranged at intervals, and the main reinforcements are welded at four corners in each hooping. According to the steel grating assisted diversion tunnel preliminary bracing structure, four main reinforcements and a plurality of hoopings form an integral steel grating unit to form an arching frame. The steel grating assisted diversion tunnel preliminary bracing structure effectively solves the difficult problem of temporary supporting of a local crushing part of surrounding rock, the construction cost is reduced, and a series of potential safety hazards caused by crushing of the surrounding rock is eliminated. The steel grating assisted diversion tunnel preliminary bracing structure is simple and has scientific and reasonable design and simple manufacture process, the construction efficiency is effectively improved, the construction cost is reduced and thus the steel grating assisted diversion tunnel preliminary bracing structure has wide promotion and application value.

Owner:THE THIRD CONSTR CO LTD OF CTCE GRP

Recovery roadway supporting method based on determination of rise of caving arch

The invention discloses a recovery roadway supporting method based on determination of the rise of a caving arch. The method comprises the following steps: (1), excavating a roadway; (2), determining the basic mechanical parameters of surrounding rock and side pressure coefficient of rock masses at two sides of the roadway; (3), determining the rise of limit caving arches, namely determining the rise b2 of the first limit caving arch and the rise b3 of the second limit caving arch according to the determined side pressure coefficient lambda in combination with the basic mechanical parameters of surrounding rock; (4), determining a roadway supporting scheme, namely respectively determining a roadway top plate shallow supporting structure and a roadway top plate deep supporting structure according to b2 and b3; (5), supporting the surrounding rock of the roadway; (6), excavating the next section of roadway, and supporting the surrounding rock of the roadway; and (7), repeating the step (6) for many times till the rectangular roadway is completely excavated and the surrounding rock of the roadway is supported. The recovery roadway supporting method based on determination of the rise of the caving arch, which is disclosed by the invention, is simple in step, convenient to realize, good in use effect and low in construction cost; the top plate of the rectangular roadway can be effectively reinforced; repairing operation of the rectangular roadway is avoided.

Owner:XIAN UNIV OF SCI & TECH

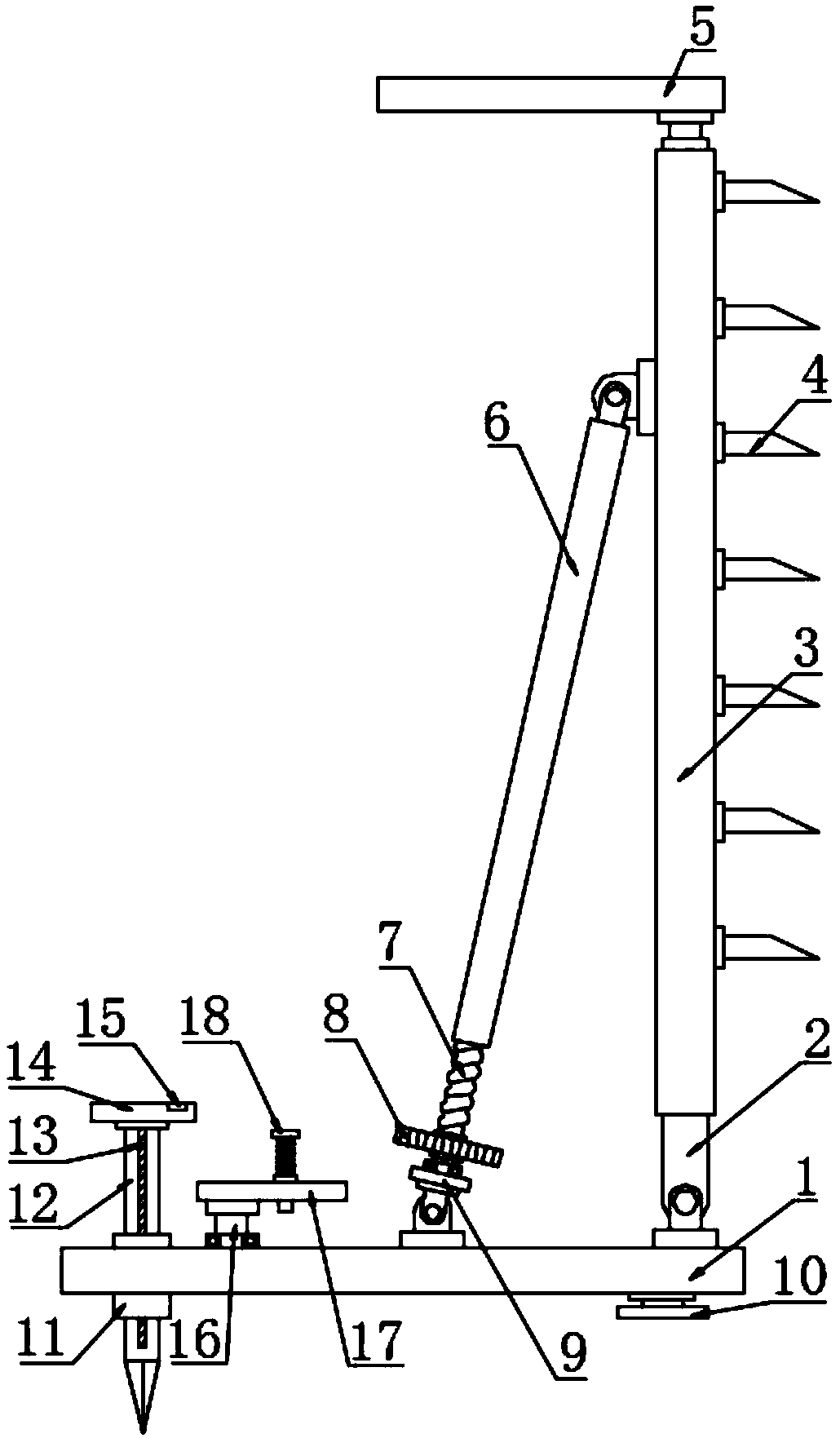

Slope support structure and support method

The invention discloses a slope support structure and a support method. The left side of a bottom plate is fixedly connected with a sleeve. The sleeve penetrates through the bottom plate. A drill rodis sleeved in the sleeve. Limiting convex strips are symmetrically arranged on the two sides of the drill rod. Grooves are symmetrically arranged on the two sides of the inner ring of the sleeve. Thelimiting convex strips are embedded in the grooves of the inner ring of the sleeve. The lower portion of the drill rod is pointed. The upper end of the drill rod is fixedly connected with a top disc.A limiting hole is formed in the upper surface of the right side of the top disc. A rotating shaft is arranged on the right side of the sleeve. The lower end of the rotating shaft is in bearing rotaryconnection with the upper surface of the bottom plate, and the upper end of the rotary shaft is fixedly connected with a press plate. The press plate is eccentrically arranged at the upper end of therotating shaft. A through hole is formed in the middle of the press plate, and a pin shaft is connected in the through hole in an inserted manner. By means of the support structure, a triangle has stability, a lead screw is driven to rotate by rotating an adjusting wheel, the lead screw drives a threaded barrel to move, then a telescopic plate is driven to stretch out and draw back along a fixedplate to adjust the inclination angle while moving, and slopes of different angles can be supported.

Owner:EAST CHINA UNIV OF TECH

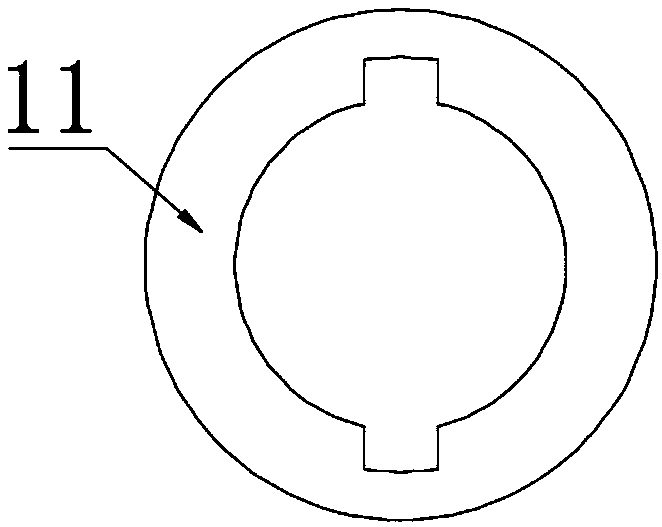

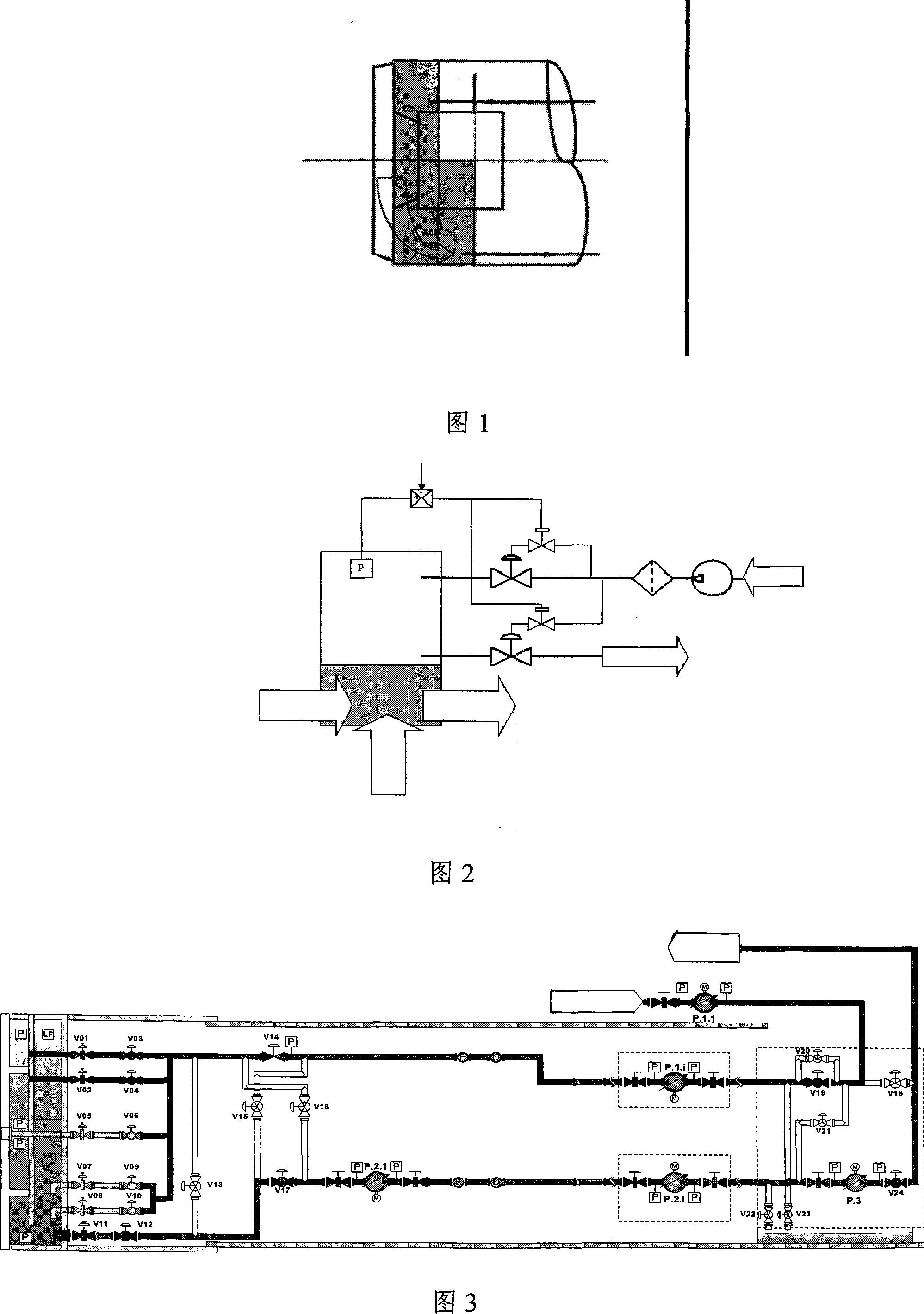

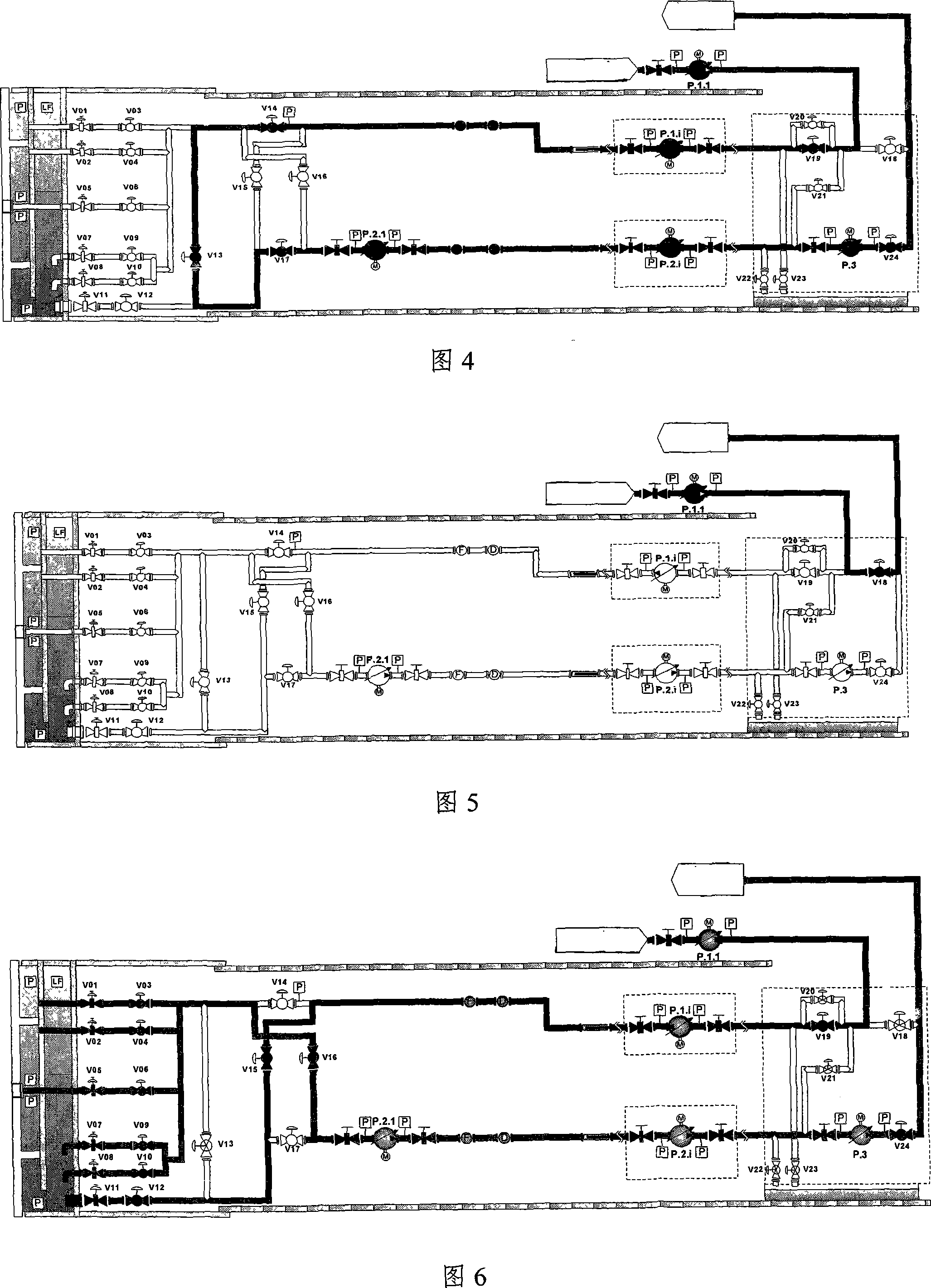

Gas cushion type mud water pressurization equilibration shield machine

Disclosed is a cushion-type slurry-pressured balance shield machine applied in the tunnel project construction machinery industry, which consists of four operation modes such as excavation mode, bypass mode, isolation mode and reverse mode. Working principles of the machine are as follows: the cushion-type slurry-pressured balance shield machine is a slurry shield which adjusts the confining pressure in an excavation chamber in virtue of a cushion, and bentonite slurry which is a liquid medium with certain pressure is used to support and stabilize tunnel face in the process of excavating unstable strata; control of the pressure on the tunnel face is realized through controlling the pressure of the cushion and the elevation of the interface between the slurry and the cushion, so as to achieve the purpose of reducing disturbance to the strata; and a clapboard is arranged in a shield slurry chamber to divide the slurry chamber into two parts, the frontal surface of the clapboard is filled with pressured slurry and the part above a shield axis on the rear surface of the clapboard is filled with compressed air, thereby forming a cushion. With light disturbance to the strata and little sedimentation, the device is suitable for constructions in high underground water pressure, river bottom and submarine tunnel, and has a wide application scope of soil, an easy control system, a stable shoring of the strata of the excavation ground and a convenient control of surface subsidence.

Owner:SHENYANG HEAVY MACHINERY GROUP

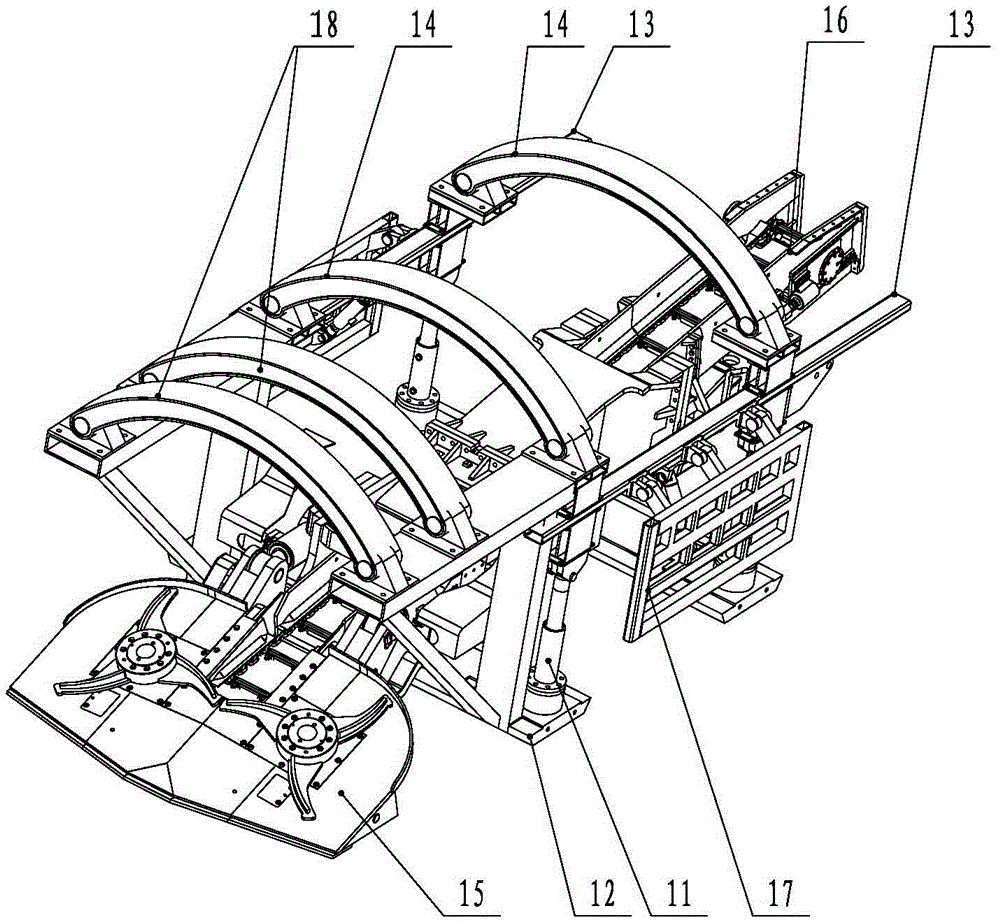

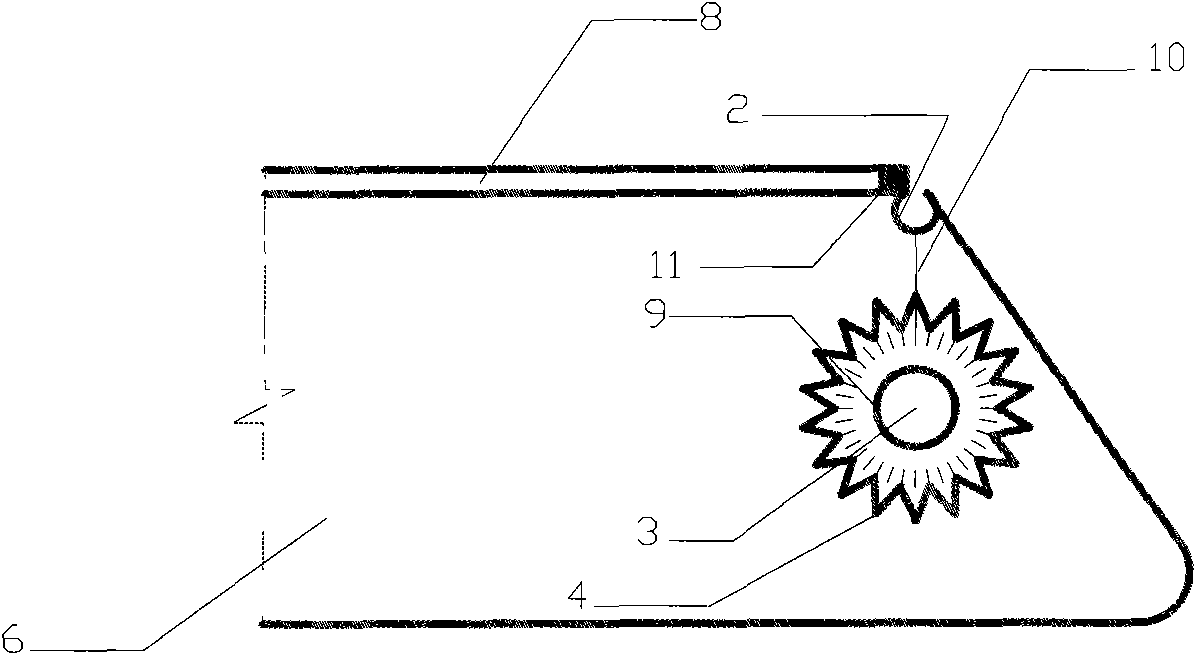

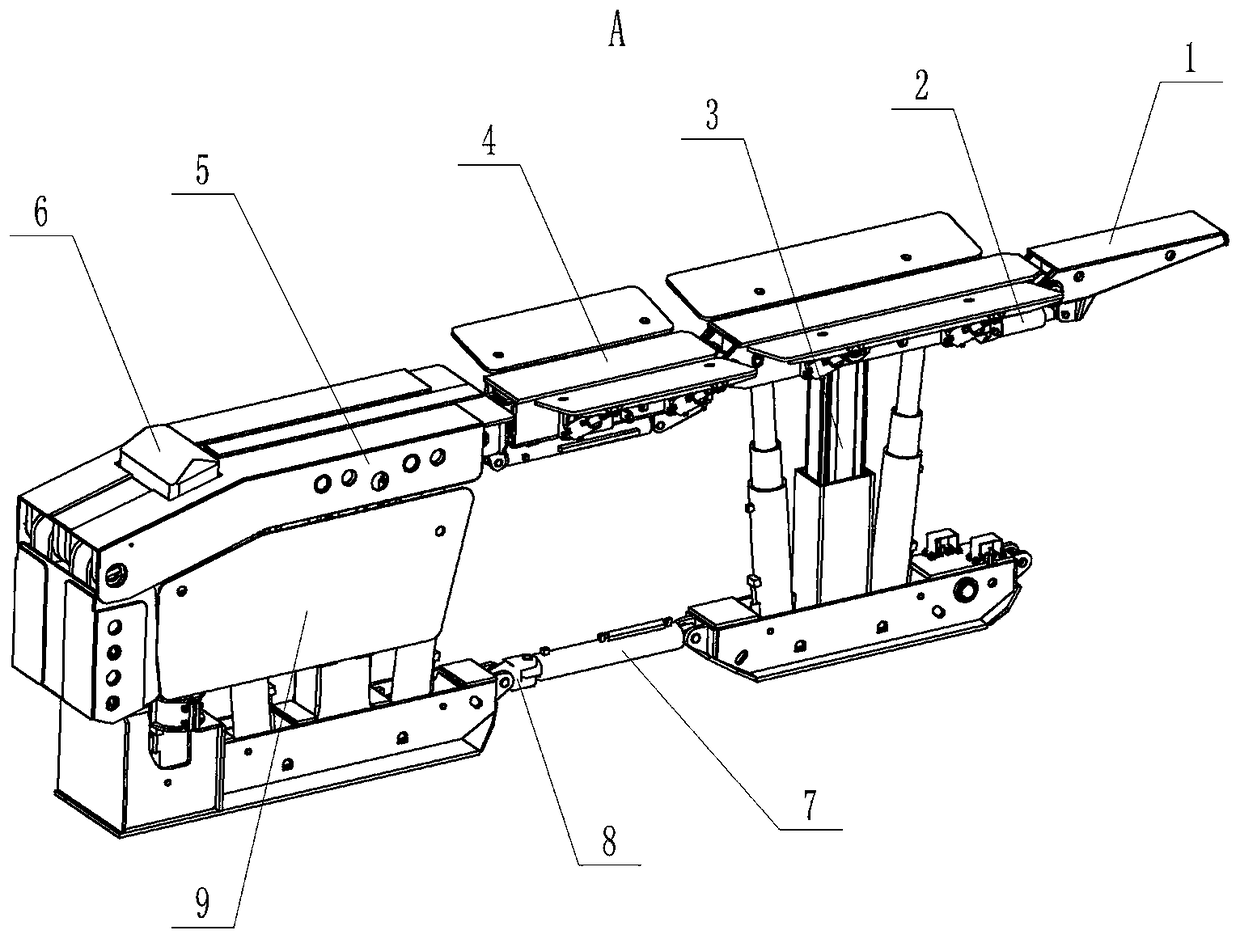

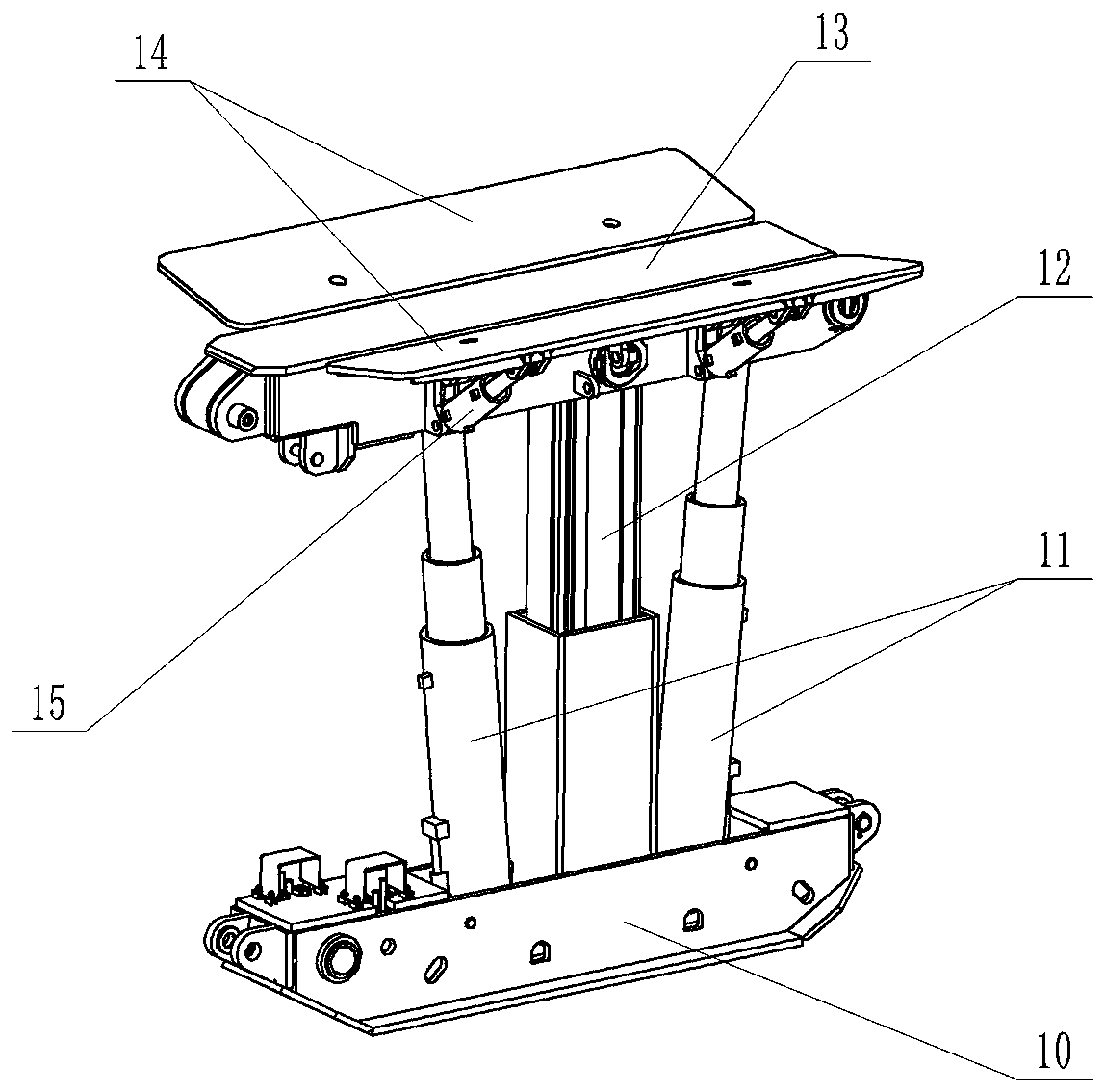

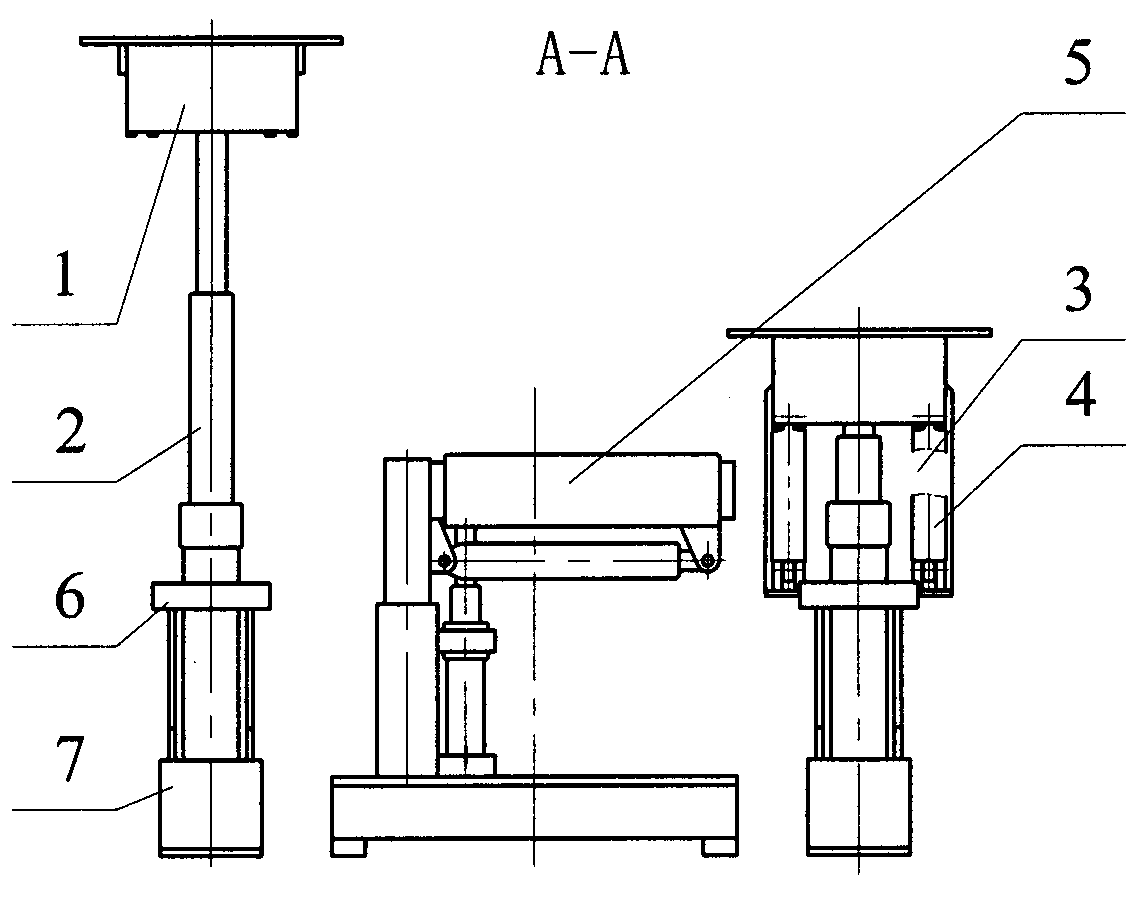

Pre-supporting combined unit suitable for soft rock tunneling

ActiveCN105604558AAvoid lack of forward forceSmooth progressMine roof supportsTunnelsEngineeringMechanical engineering

A pre-supporting combined unit suitable for soft rock tunneling comprises a tail unit, a main unit, a cutting portion and a conveying device. A forepoling bar is arranged at the front end of the main unit. The pre-supporting combined unit is technically characterized in that the main unit comprises a main-unit main supporting set and a main-unit auxiliary supporting set which are staggered from rear to front, the main-unit main supporting set comprises a connecting plate I, a supporting oil cylinder I, a longitudinal beam I, a top beam I and a lateral supporting plate I, and the main-unit auxiliary supporting set comprises a connecting plate II, a supporting oil cylinder II, a longitudinal beam II and a top beam II; the tail unit comprises a tail-unit main supporting set and a tail-unit auxiliary supporting set which are staggered from rear to front, the tail-unit main supporting set comprises a connecting plate III, a supporting oil cylinder III, a longitudinal beam III, a top beam III and a lateral supporting plate II, and the tail-unit auxiliary supporting set comprises a connecting plate IV, a supporting oil cylinder IV, a longitudinal beam IV and a top beam IV. The problem that existing tunneling machines are poor in safety and difficult in back operation is solved fundamentally, and the pre-supporting combined unit has the advantages of low equipment wear and stability in moving.

Owner:LIAONING TECHNICAL UNIVERSITY

Template connecting piece capable of regulating and controlling angle

InactiveCN101818568APouring appearance is of good qualityQuality improvementAuxillary members of forms/shuttering/falseworksSlurryEngineering

The invention relates to a template connecting piece capable of regulating and controlling an angle. The template connecting piece can measure and regulate the angle in a range of 0 to 240 degrees in template construction rapidly and lock immediately, and can be used for quickly setting the included angle of a bracket bridging. The template connecting piece consists of two sub-components and a locking device. A using method comprises the following steps of: assembling the sub-components to form a rotating system; fixing the sub-components on a template; calculating a corner and rotating the subcomponents; and locking the sub-components after reaching a required angle so as to fulfill the aim of setting a chamfer angle. The template connecting piece has the advantages of wide application, simple connecting piece mode, simple and intuitive method for reading corner reading, confirm support without adverse phenomena of template distortion, concrete slurry outleakage or the like, good concrete cast appearance quality, repeated use, fast assembly and disassembly, quickness and convenience,, simple operation procedure, and great improvement on construction speed.

Owner:HOHAI UNIV

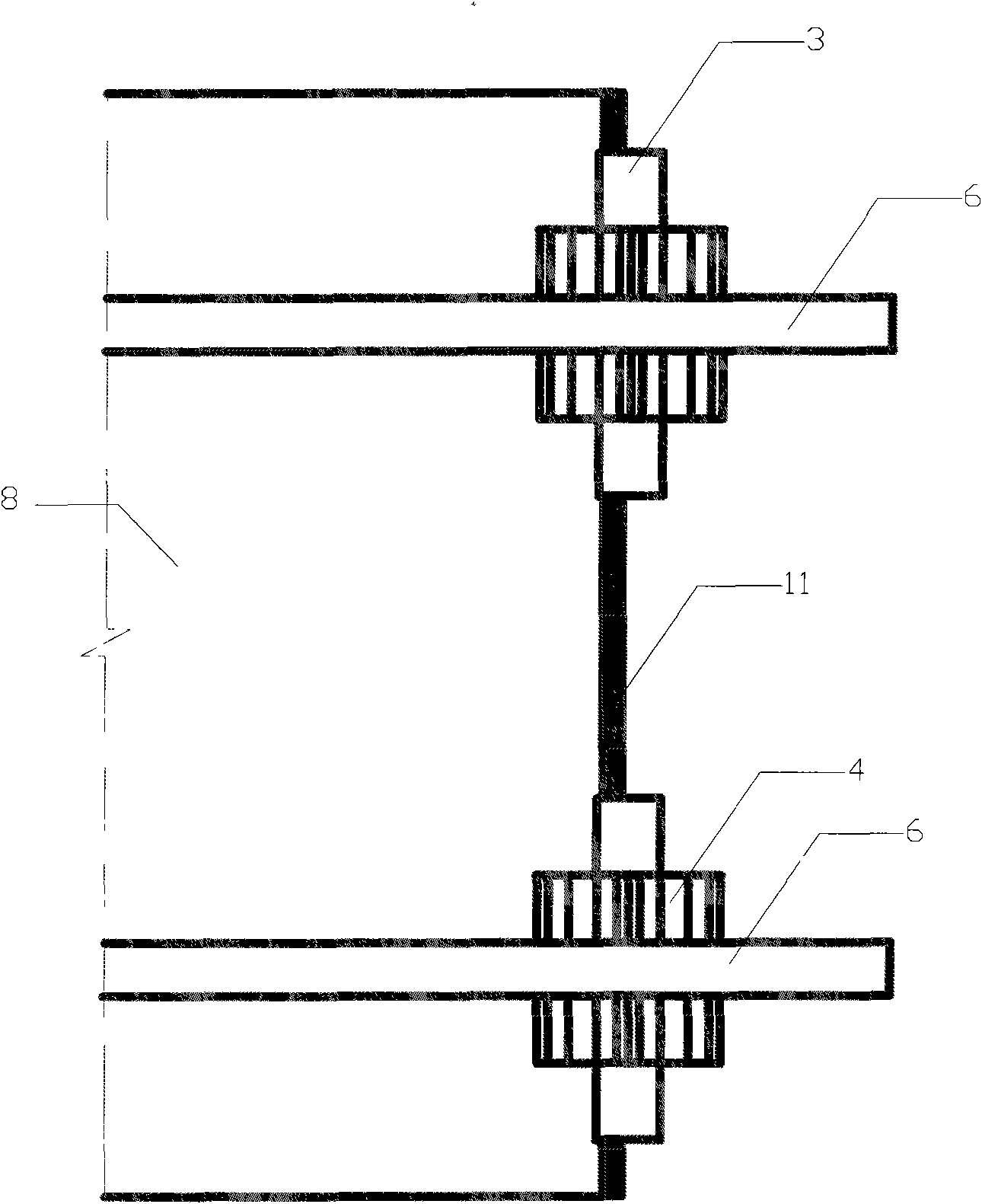

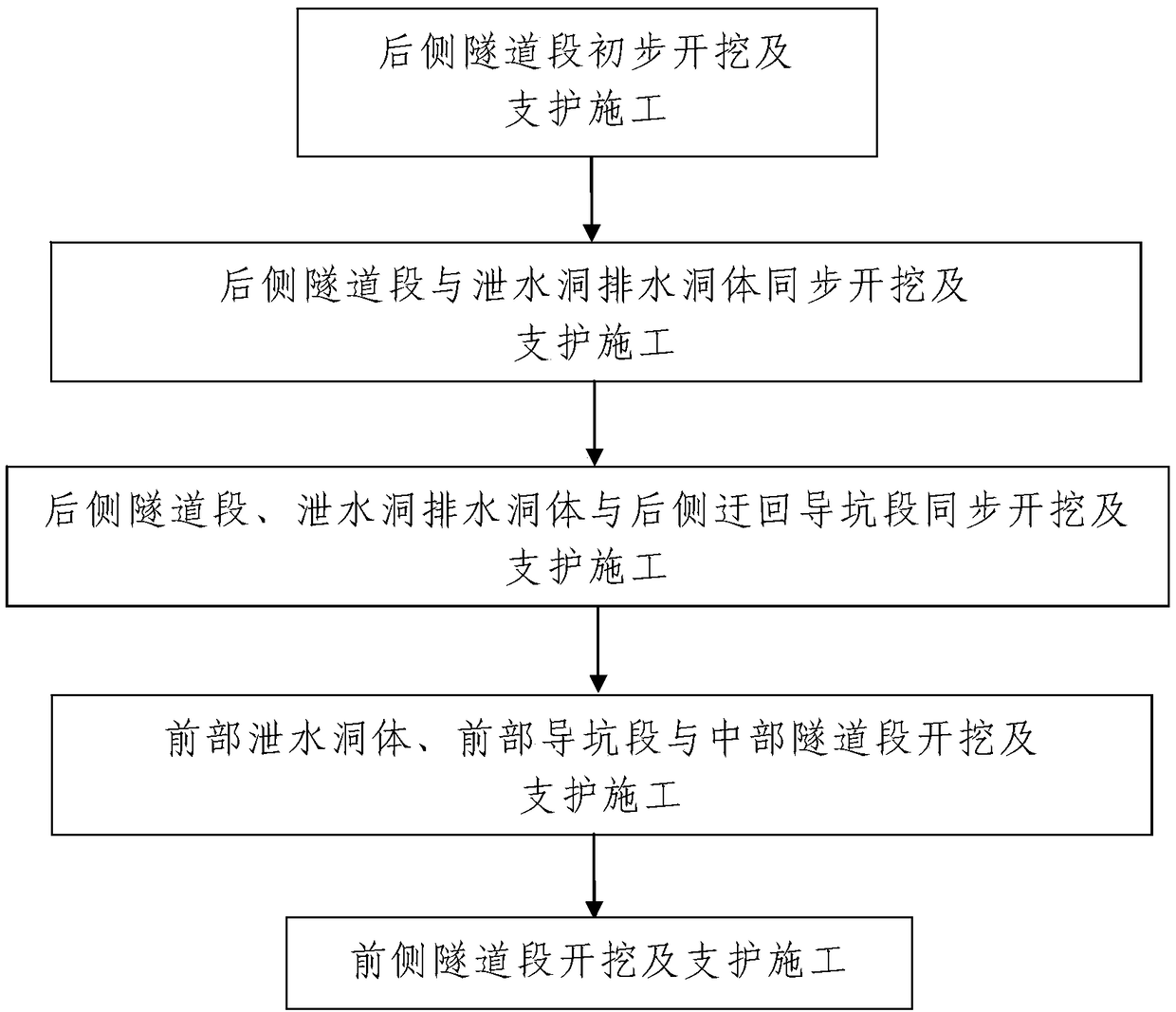

Construction method for tunnel passing through high-angle thrust water-rich and sand-rich fault

ActiveCN109209397AThe method steps are simpleReasonable designUnderground chambersDrainageStructural safetyHigh angle

The invention discloses a construction method for a tunnel passing through a high-angle thrust water-rich and sand-rich fault. The method comprises the steps: 1, performing the preliminary excavationand the supporting construction of a rear tunnel segment; 2, performing the synchronous excavation and the supporting construction of the rear tunnel segment and a water drainage hole body of a waterdrainage hole; 3, performing the synchronous excavation and the supporting construction of the rear tunnel segment, the water drainage hole body of the water drainage hole and a rear detouring headingsegment; 4, performing the excavation and the supporting construction of a front water drainage hole body, a front heating segment and a central tunnel segment; 5, performing the excavation and the supporting construction of a front tunnel segment. According to the invention, the water on the upper wall of the fault is drained through a high-level water drainage hole between a tunnel front hole and a detouring heading pit, and the auxiliary water drainage is performed through the detouring heading pit, and the fault condition in front of the tunnel face of the front hole can be explored in advance, thereby guaranteeing the construction safety of each tunnel face. The method employs the three-step method for the excavation of the tunnel front hole, employs double preliminary supporting structures for the full-section supporting after excavation, can guarantee the safety of the tunnel structure later, and shortens the construction cycle.

Owner:CHINA RAILWAY 20 BUREAU GRP

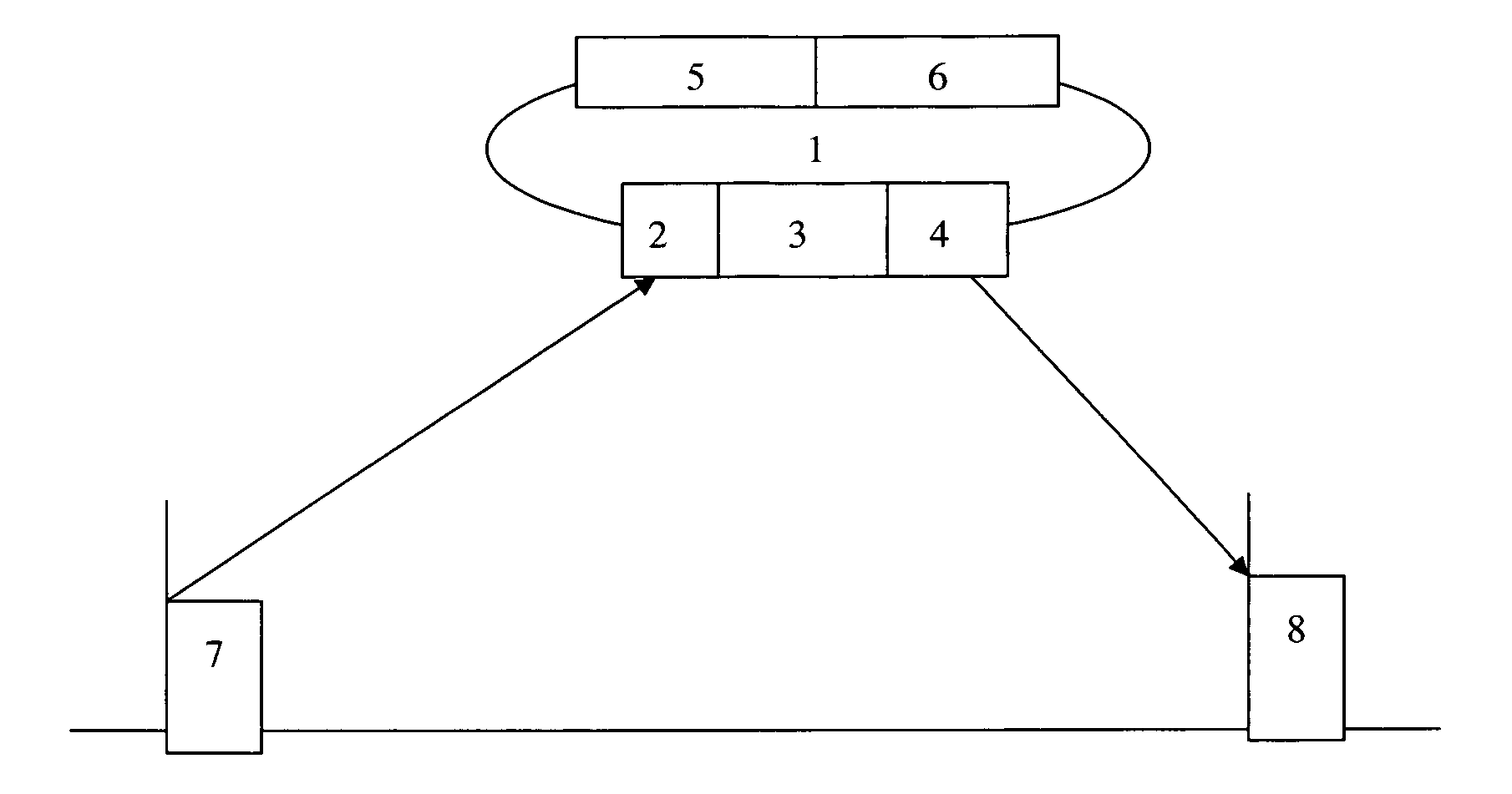

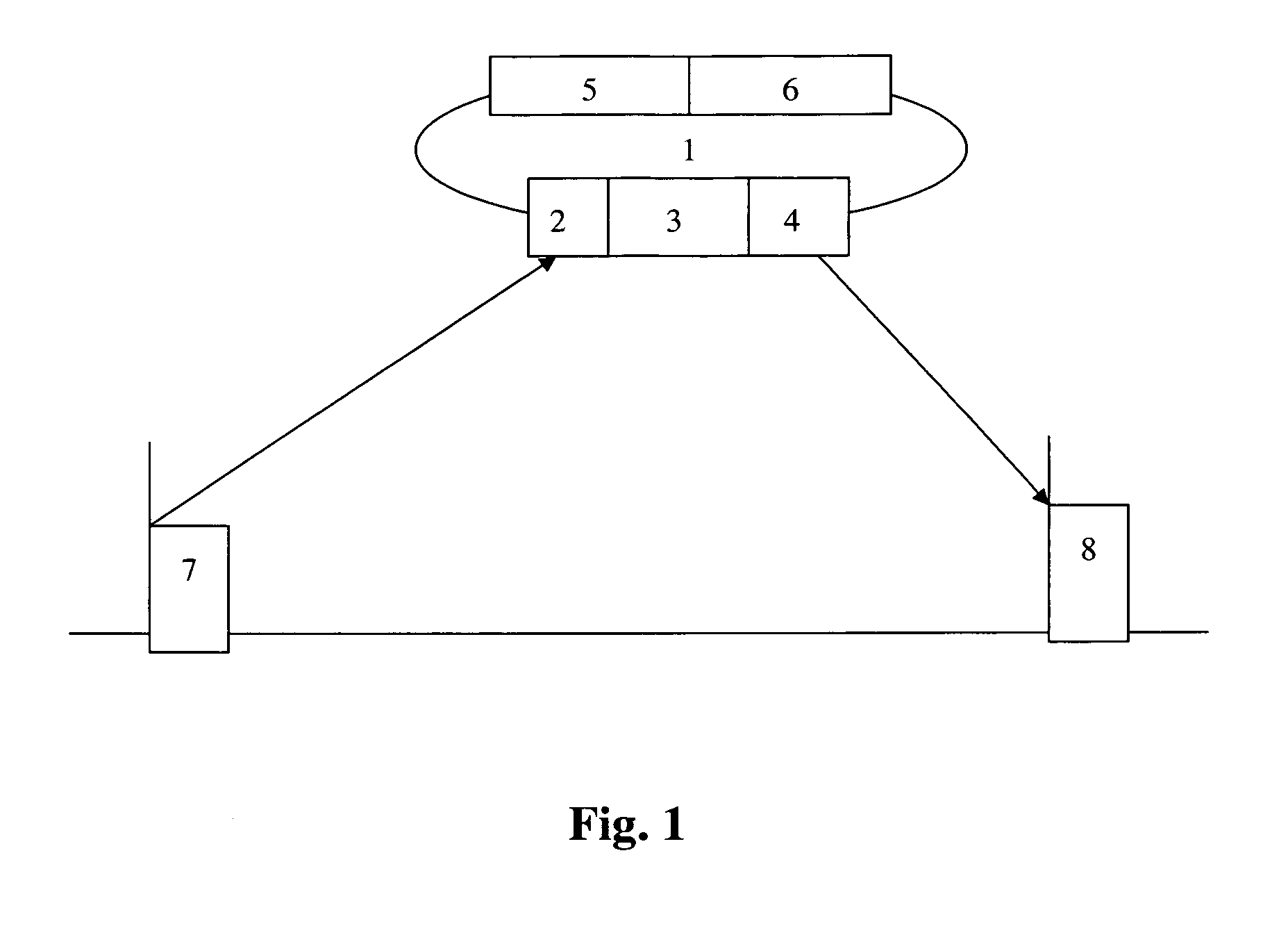

Autonomous stratospheric lighter-than-air aircraft and method for providing radio and optical communication, television broadcasting and monitoring

InactiveUS20120168555A1Support stabilityImprove accuracyConvertible aircraftsUnmanned aerial vehiclesMonitoring systemMulti aspect

The invention relates to an autonomous stratospheric aircraft which is lighter than air, and to a method for providing radio and optical communication, television broadcasting and monitoring with the aid of communication equipment arranged on the aircraft. The present invention can be used for producing lighter-than-air aircraft as well as global and regional communication and television broadcasting and multi-aspect monitoring systems and networks.

Owner:SHCHERBAKOV ANDREI YURIEVICH +1

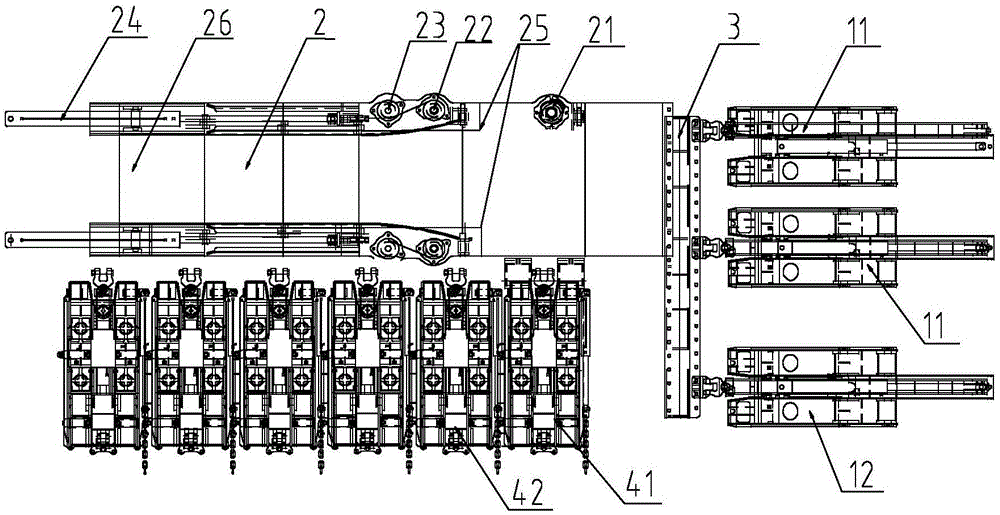

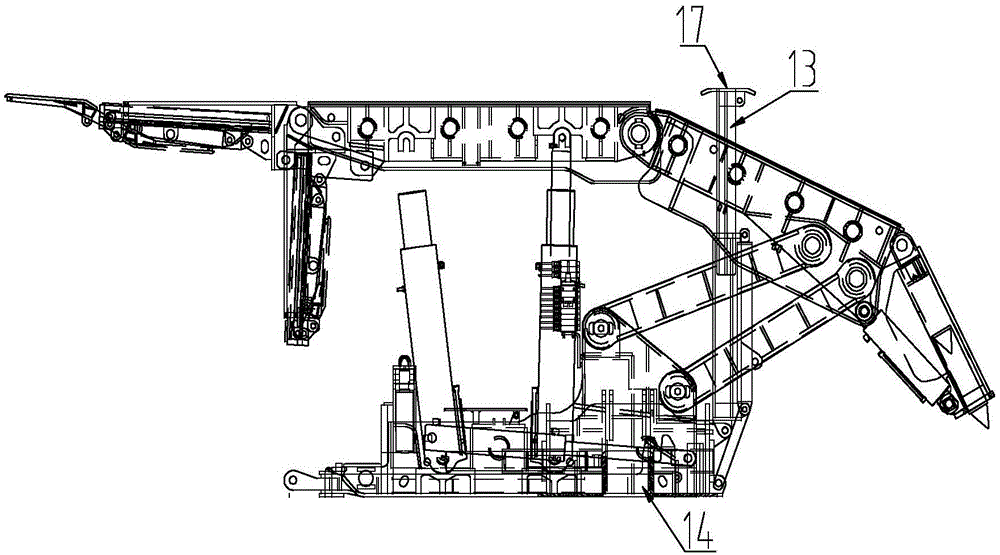

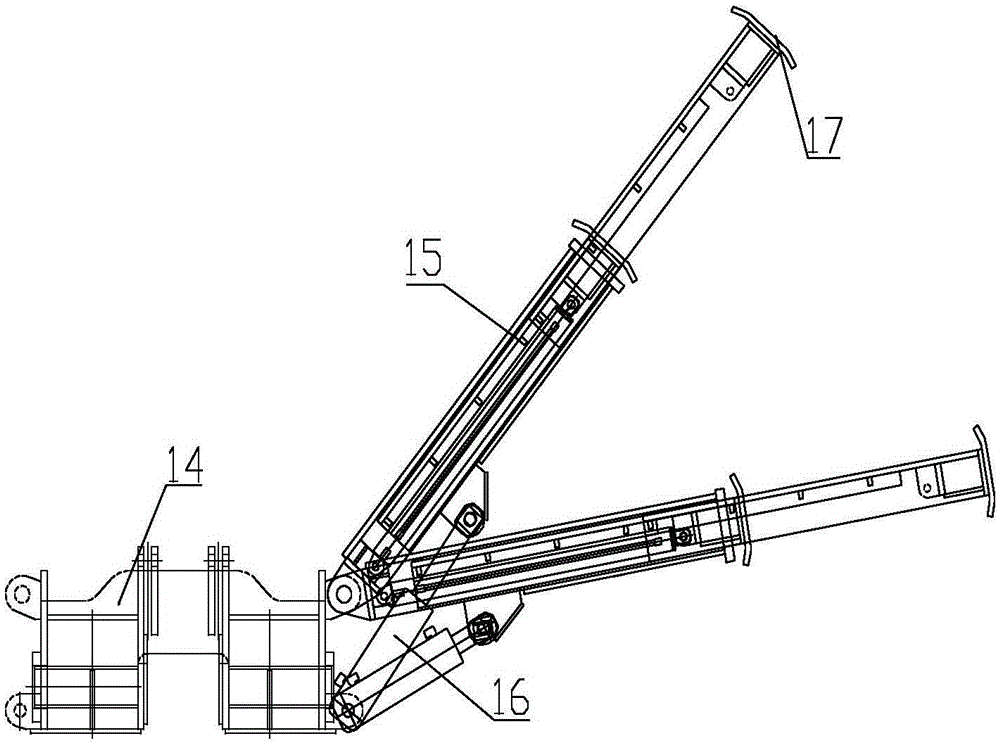

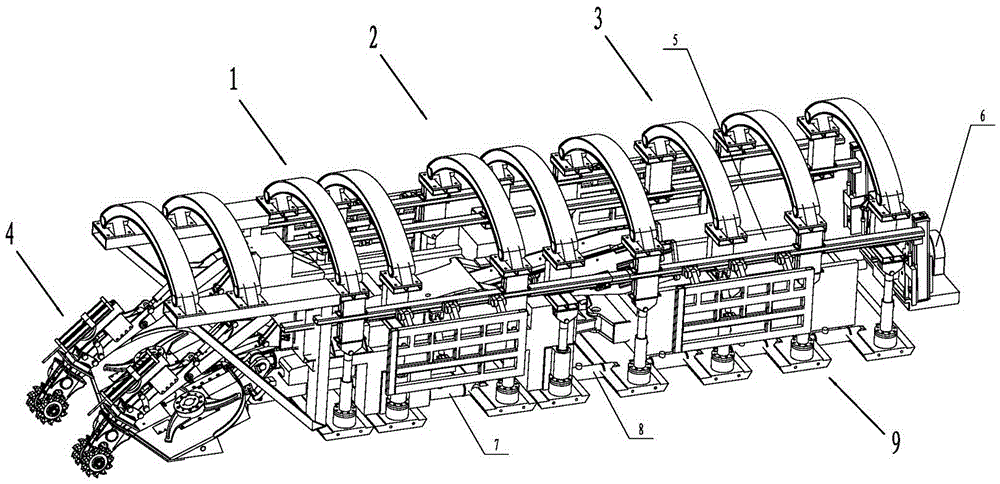

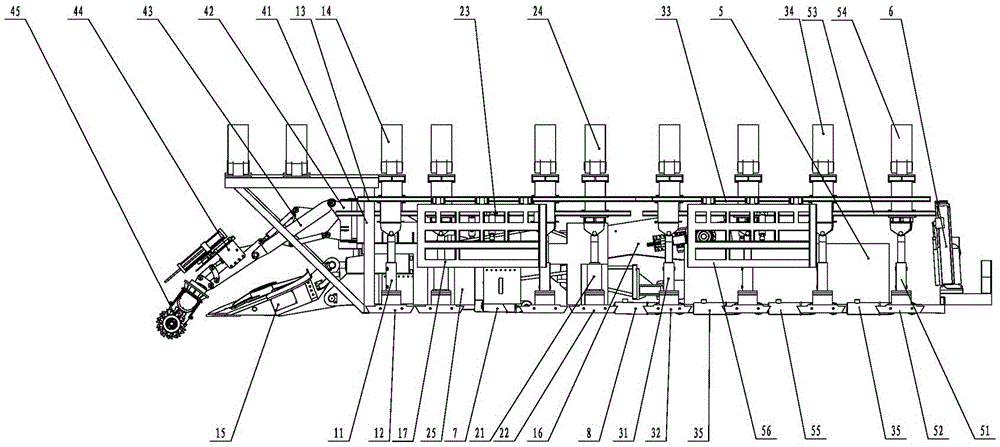

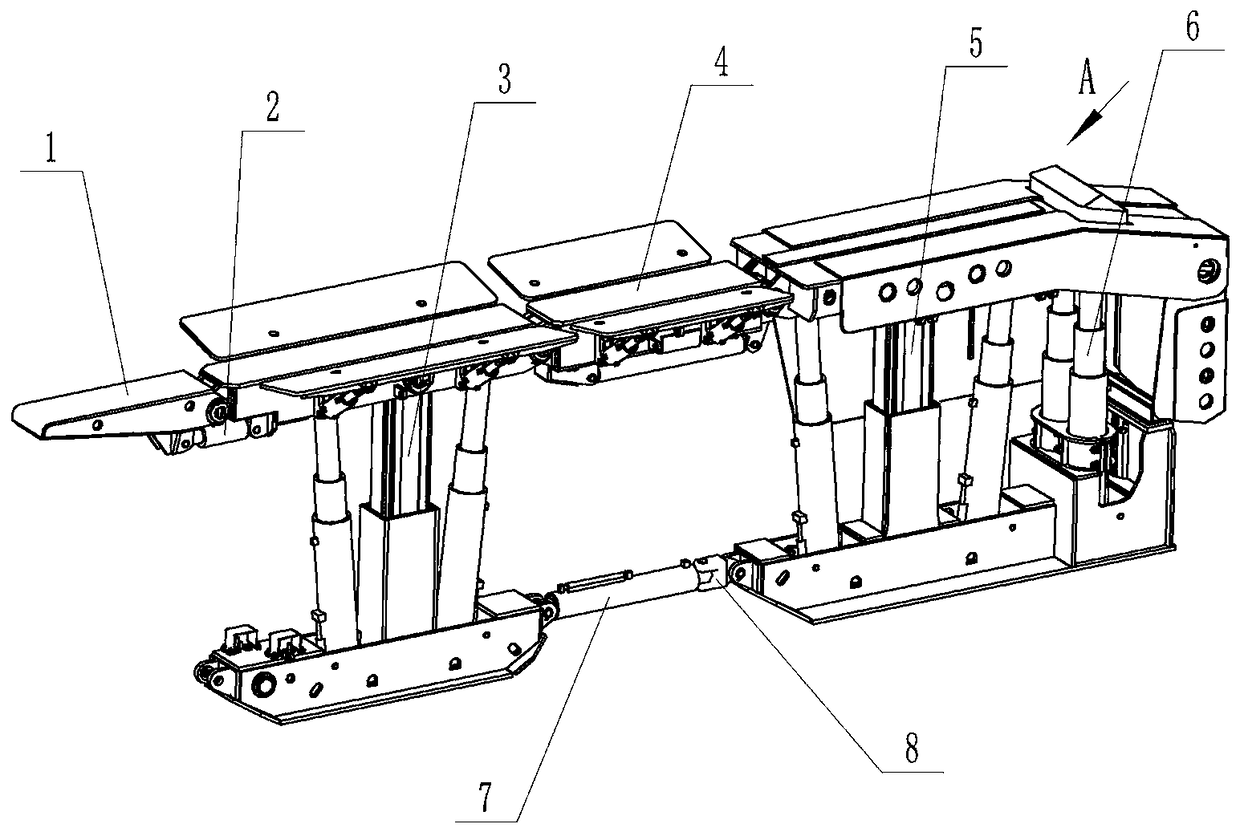

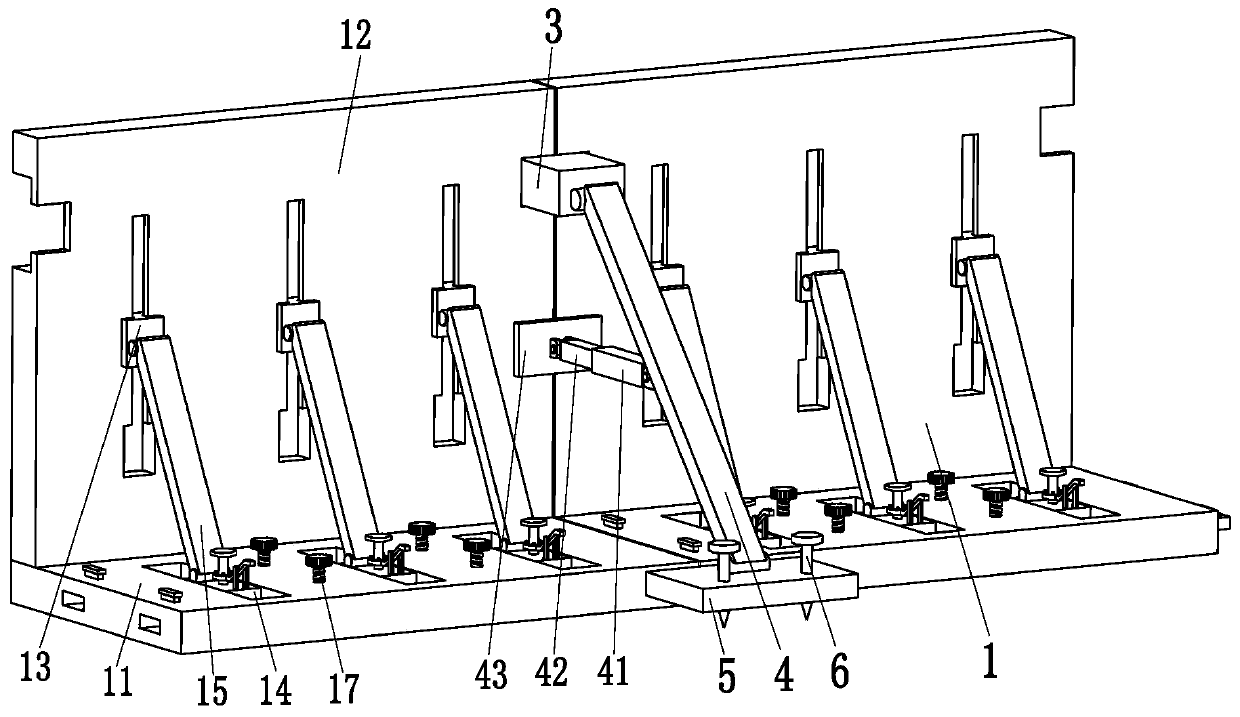

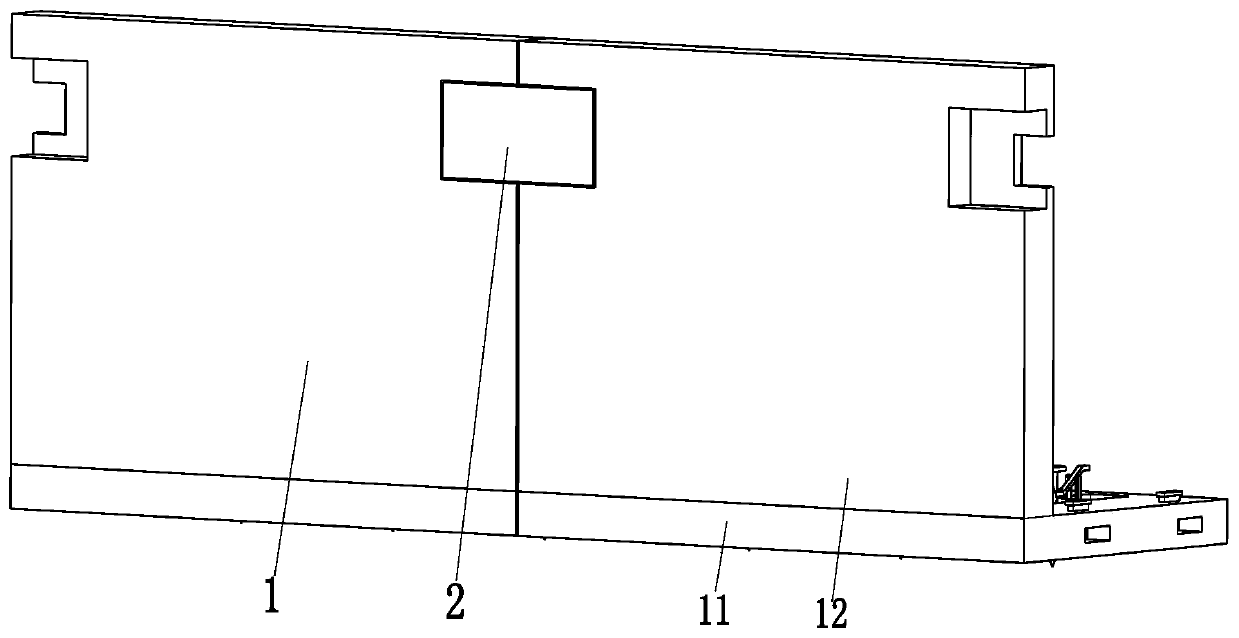

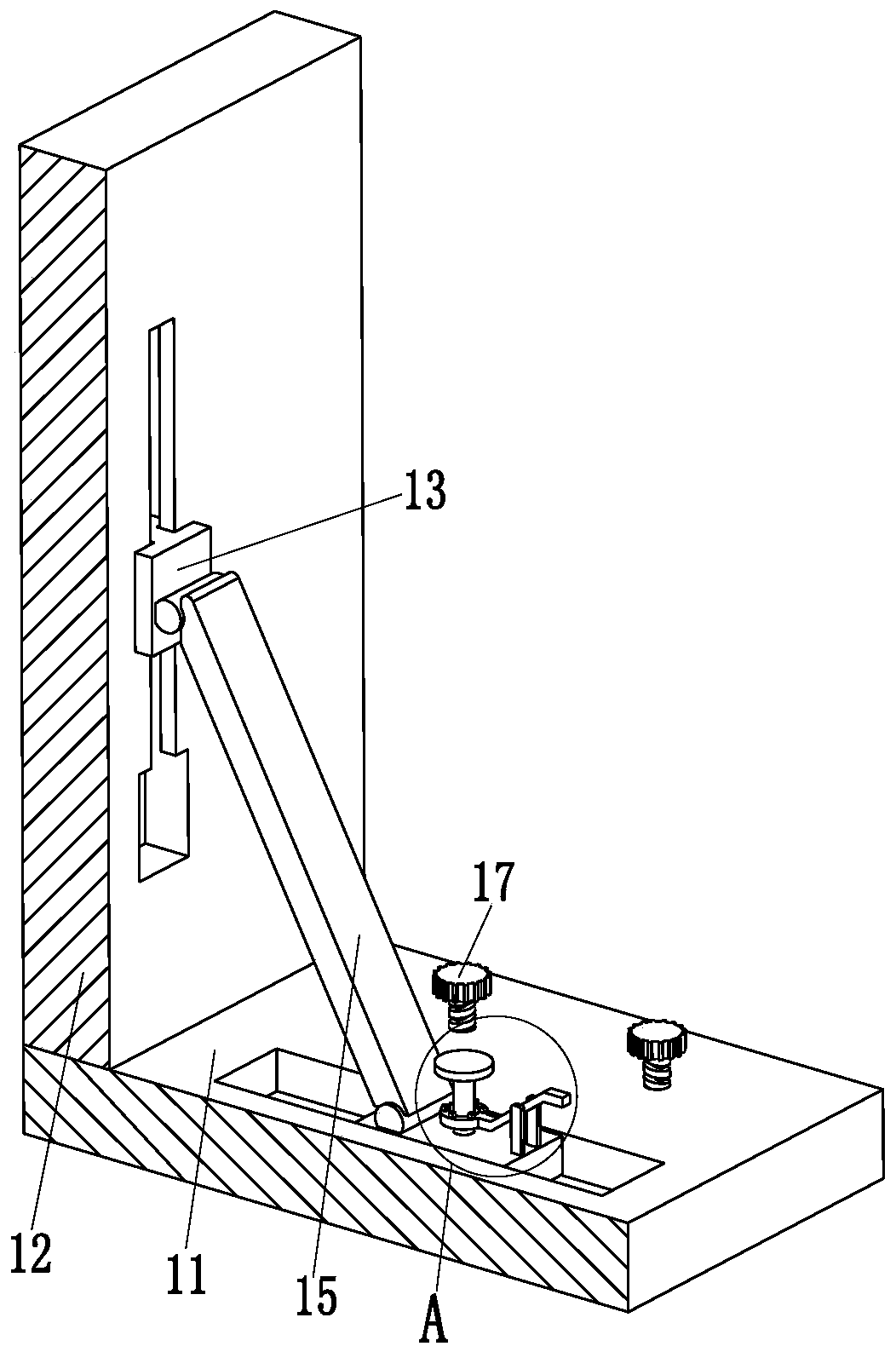

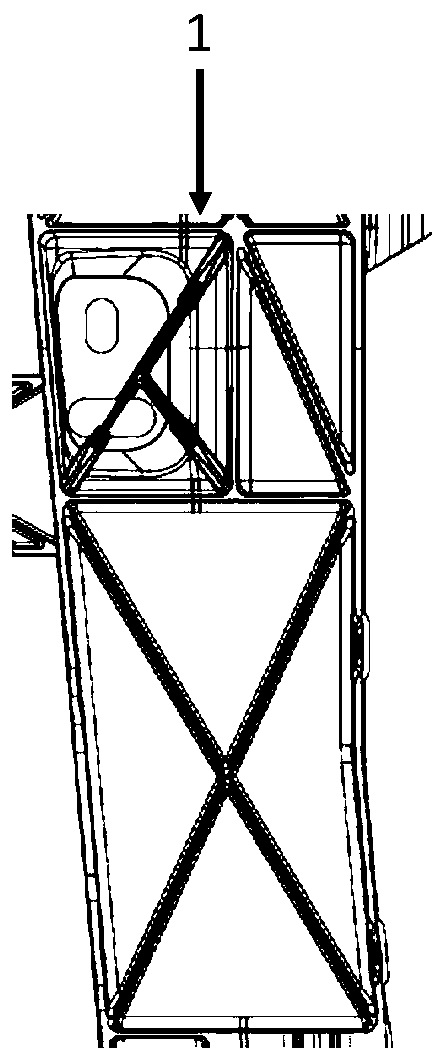

Special-shaped support equipment for ends of fully mechanized coal face

PendingCN108374684AReduce Convergence DeformationImprove support qualityMine roof supportsSpelunkingHydraulic cylinder

The invention provides special-shaped support equipment for ends of a fully mechanized coal face, and solves the problems of complicated support processes, great operation labor intensity, low supportstrength, poor safety and influence on the advance speed of the fully mechanized coal face in the prior art. The special-shaped support equipment comprises a front support bracket composed of a top beam and a base, and is characterized in that a swing front beam is arranged at the front end of the top beam of the front support bracket, and a front beam hydraulic cylinder is arranged between the swing front beam and the top beam of the front support bracket; a bracket moving hydraulic cylinder is arranged between a base of a rear top cutting bracket arranged behind the front support bracket and a base of the front support bracket; a top beam of the rear top cutting bracket is connected with the top beam of the front support bracket through a middle telescopic beam; and a top cutting deviceis arranged at the rear part of the rear top cutting bracket. The special-shaped support equipment is reasonably designed, is compact in structure, can perform full-section support and blockage on asuspending roof area of the tail of a transport machine, so as to reduce convergence and deformation of a laneway, can perform forced caving on a roof, and achieves low labor intensity, high support efficiency and safety and reliability in use.

Owner:陕西陕煤黄陵矿业有限公司

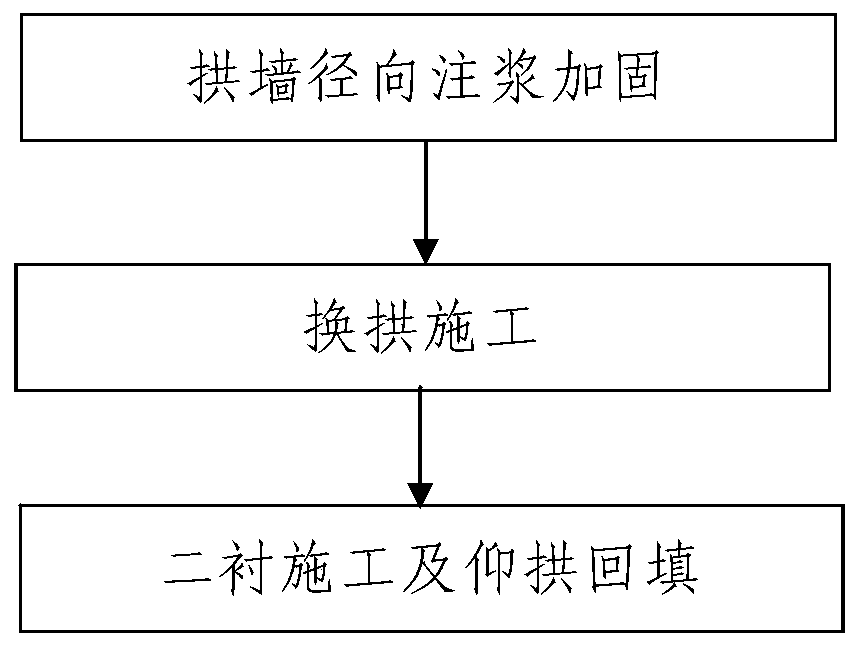

Method for beyond-limit arch replacing construction during preliminary bracing of large-section loess tunnel

ActiveCN110656959AThe method steps are simpleReasonable designUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a method for beyond-limit arch replacing construction during preliminary bracing of a large-section loess tunnel. The method includes the steps of firstly, conducting radial grouting reinforcement on an arch wall, wherein radial grouting reinforcement is conducted on an arch replacing required section where arch replacing is required in the constructed loess tunnel from back to front; and secondly, conducting arch replacing construction, wherein a reinforced preliminary bracing structure in the arch replacing required section is detached, and preliminary bracing construction is conducted on the arch replacing required section synchronously in the detaching process. The method is simple in step, reasonable in design, simple in construction and good in use effect; theradial grouting reinforcement is conducted on the arch wall to reinforce the arch wall of a tunnel hole first, so the structural stability of the tunnel in the arch replacing process is ensured; segmented reinforcing is conducted on the preliminary bracing structure of the tunnel through a plurality of sleeve arch units for a reinforced sleeve arch in the arch replacing required section, so detaching is convenient; and moreover, the sleeve arch units are complementary and together improve the supporting force, so the adverse effects on the structural stability of the tunnel in the detaching process of each sleeve arch unit can be effectively reduced, and the safety and reliability of the arch replacing construction process are ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

Loess tunnel foundation base reinforcing structure and method based on high pressure jet grouting piles

PendingCN110671131AReasonable designReduce construction costsUnderground chambersTunnel liningStructural engineeringGeotechnical engineering

The invention discloses a loess tunnel foundation base reinforcing structure and method based on high pressure jet grouting piles. The structure comprises the multiple rows of high pressure jet grouting piles for reinforcing soil on the lower portion of a tunnel, and each high pressure jet grouting pile passes through a tunnel invert structure and a collapsible loess stratum from top to bottom andthen extends into a non collapsible loess stratum. The method comprises the following steps of firstly, tunnel excavating and preliminary bracing; secondly, second lining construction; and thirdly, foundation base reinforcing. The structure is reasonable in design, easy and convenient to construct and good in use effect. The multiple rows of high pressure jet grouting piles are adopted for carrying out foundation base reinforcing on a loess tunnel, a loess tunnel foundation base can be simply and rapidly effectively reinforced, the tunnel foundation base settling volume can be effectively controlled, meanwhile, the upper surface of a secondary lining inverted arch is adjusted to the horizontal plane, a construction platform is provided for the high pressure jet grouting piles, the loess tunnel foundation base reinforcing process can be further quickened, the high pressure jet grouting piles and the tunnel invert structure are fastened and connected into a whole, and the loess tunnel foundation base reinforcing effect can be further improved.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

Frame structure for asphalt road construction

ActiveCN110512497AImprove paving effectSupport stabilityRoads maintainenceEngineeringUltimate tensile strength

The invention relates to a frame structure for asphalt road construction. The frame structure for asphalt road construction comprises supporting units, positioning plates, connecting blocks, rotatingrods, locking supporting plates and locking clamping pins. The supporting units are evenly distributed in the transverse direction, and the positioning plates are connected between the every two adjacent supporting units. The connecting blocks are installed on the front side surfaces of the positioning plates. The connecting blocks penetrate through the supporting units. The locking supporting plates are located at the lower ends of the front sides of the supporting units. The rotating rods are connected between the connecting blocks and the locking supporting plates through pin shafts, and the locking clamping pins are connected to the locking supporting plates in a sliding fit mode. According to the frame structure for asphalt road construction, the problems that when a wooden frame of an existing asphalt road blocks the outer end of the road, the side, attached to the road, of the wooden frame is prone to skewing due to the fact that the support strength of the wooden frame to the road is low, and the wooden frame is not stable, installation and removal steps of the wooden frame are complicated and hand labor is increased due to the fact that the wooden frame is not firmly locked on the ground of the outside of the road are solved.

Owner:HUBEI IND CONSTR GRP

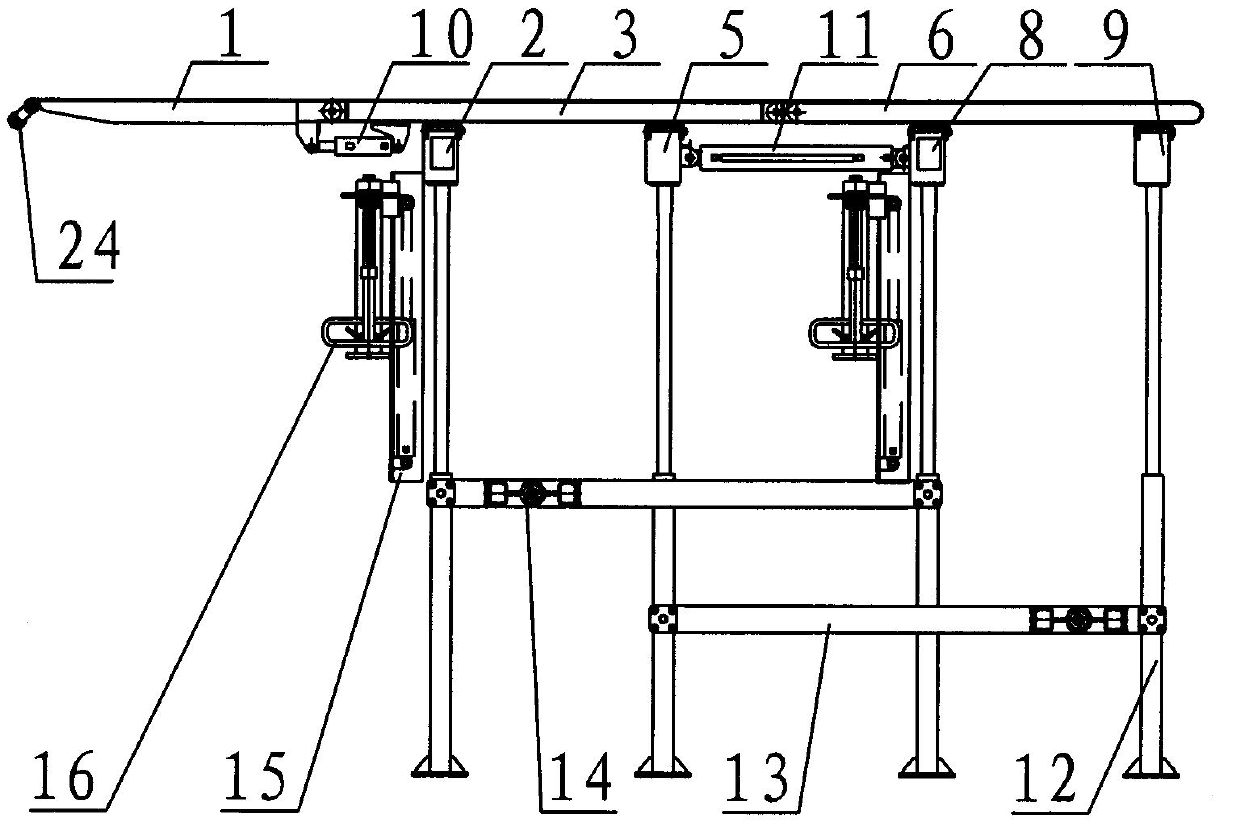

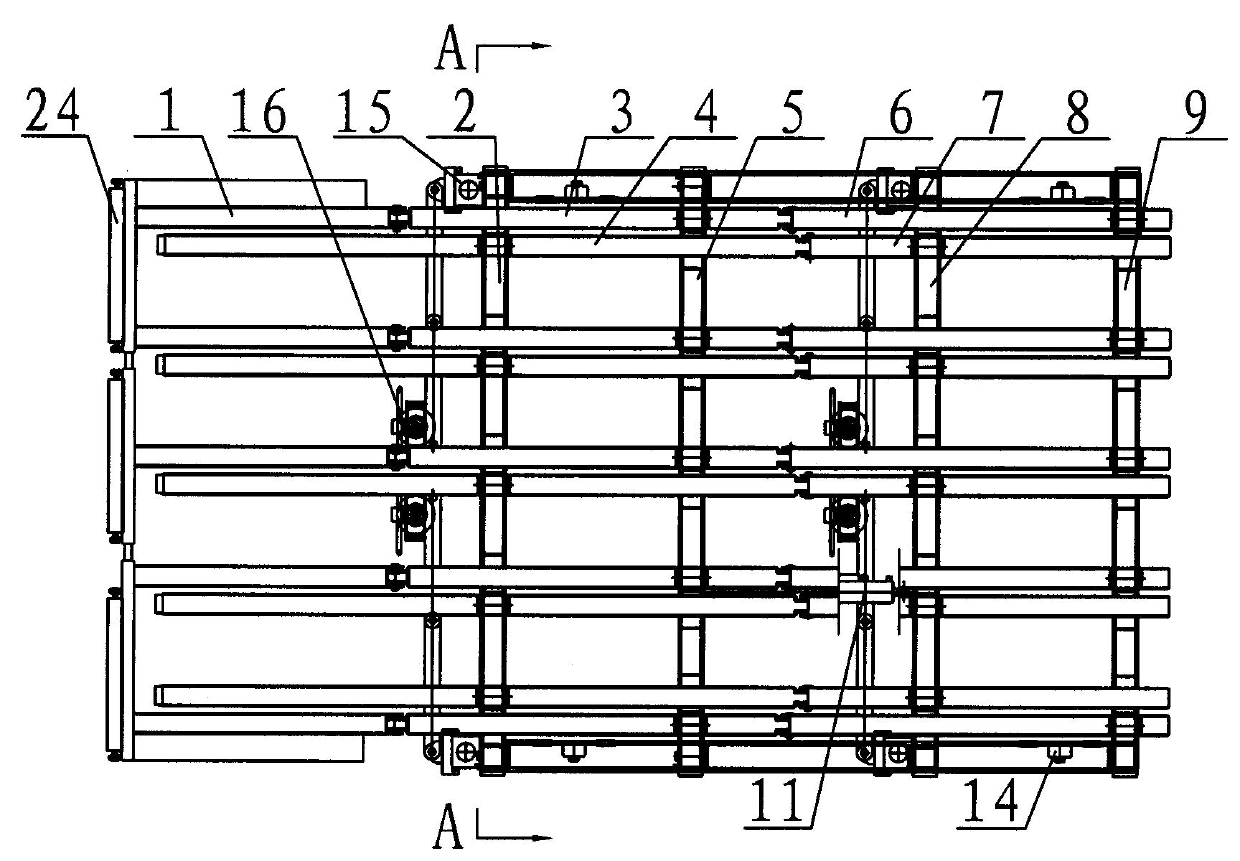

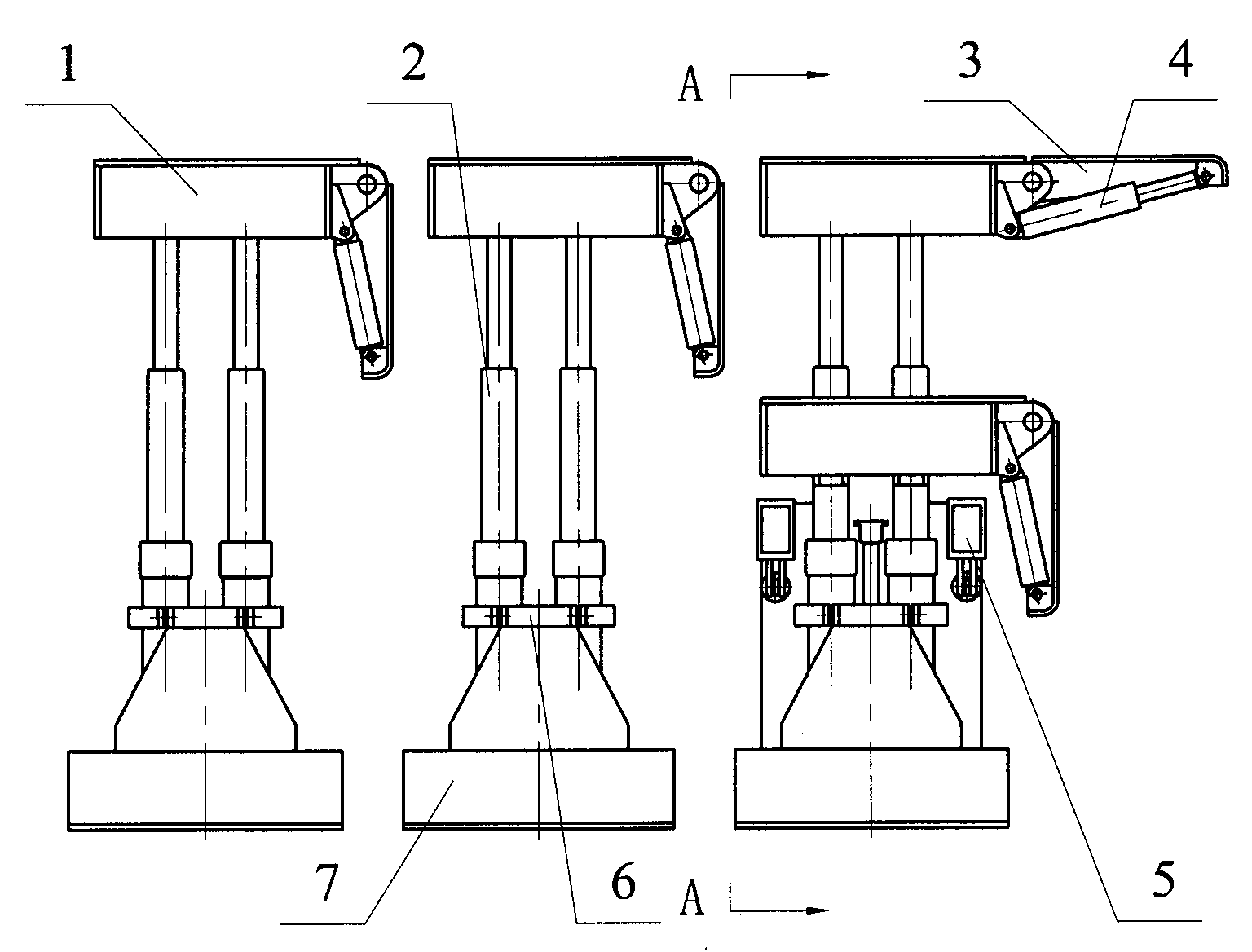

Roadway advanced supporting supports capable of assisting machinery to move

The invention provides roadway advanced supporting supports capable of assisting machinery to move. The roadway advanced supporting supports capable of assisting the machinery to move solve the problems that repeated supporting, complex operation and low working efficiency in the prior art for a floppy coal top roadway and a long-distance advanced supporting roadway. The roadway advanced supporting supports capable of assisting the machinery to move comprise advanced supporting supports which are composed of top beams, bases, and hydraulic upright columns which are connected between the top beams and the bases in a hinge joint mode and an auxiliary moving mechanism. The roadway advanced supporting supports capable of assisting the machinery to move are characterized in that the lower portions of the two hydraulic upright columns which are connected on one base in a hinge joint mode are fixed together through a fastening support, the lateral end of each top beam is connected with a top protective plate in a hinge joint mode through a telescope hydraulic cylinder, the two advanced supporting supports are a set in parallel in a transverse mode, a plurality of sets of advanced supporting supports are longitudinally continuously arranged along a roadway, and therefore supporting to a top plate is formed; and moving support mechanical arms are arranged between a set of two advanced supporting supports to be moved, are matched with a transport cart, and move each advanced supporting support along the roadway in a longitudinal sequence. The roadway advanced supporting supports capable of assisting the machinery to move are reasonable in structure and design, stable in supporting, convenient to operate, safe to use, and capable of reducing the effect of advanced supporting operation to working face coal mining production.

Owner:SHENYANG TIAN AN TECH CO LTD

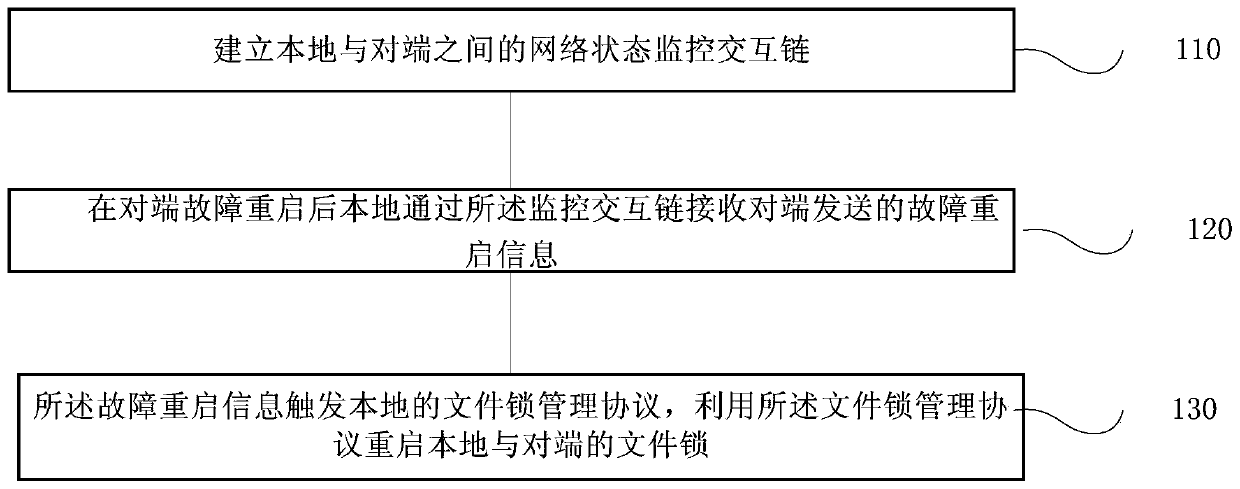

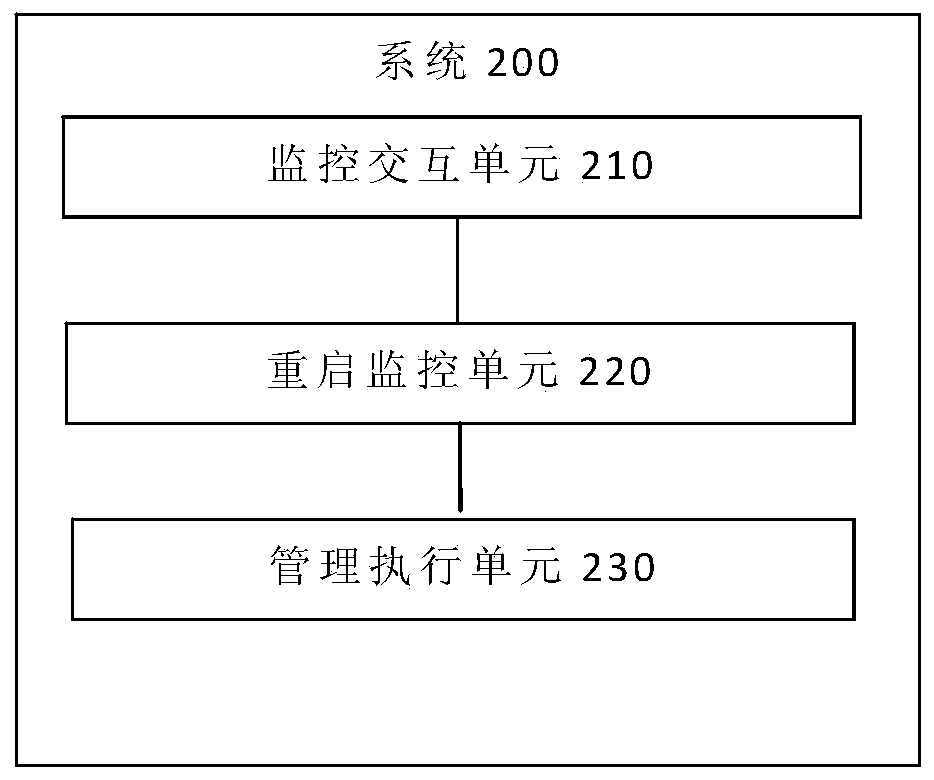

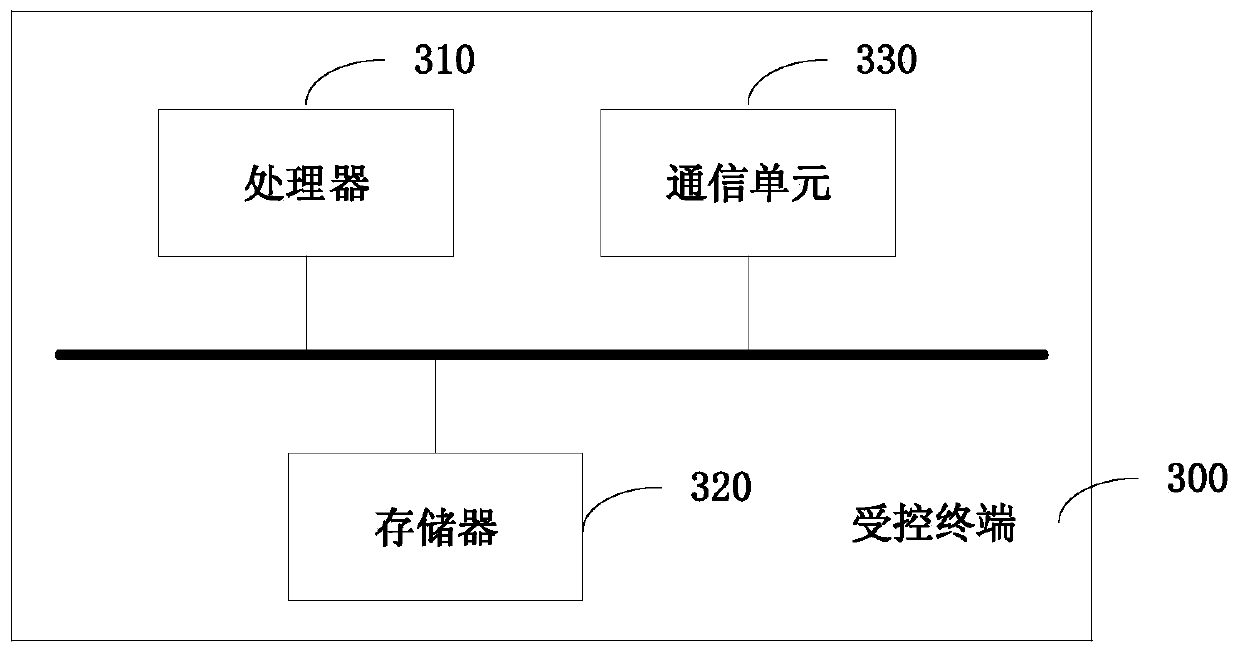

Distributed file lock fault processing method and system, terminal and storage medium

PendingCN110990190AAvoid missingEnsure consistencyDigital data information retrievalDigital data protectionFile lockingComputer engineering

The invention provides a distributed file lock fault processing method and a system, a terminal and a storage medium. The method comprises the following steps: establishing a network state monitoringinteraction chain between a local end and an opposite end; receiving fault restart information sent by the opposite terminal locally through the monitoring interaction link after fault restart of theopposite terminal; and triggering a local file lock management protocol by the fault restart information, and restarting local and opposite file locks by utilizing the file lock management protocol. According to the method, data consistency is guaranteed, concurrent access of multiple clients and stability of the system are supported, after one party is restarted due to a fault, the authorized file lock is immediately recovered, and the situation that the file is lost due to the fact that operation is interrupted is avoided.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

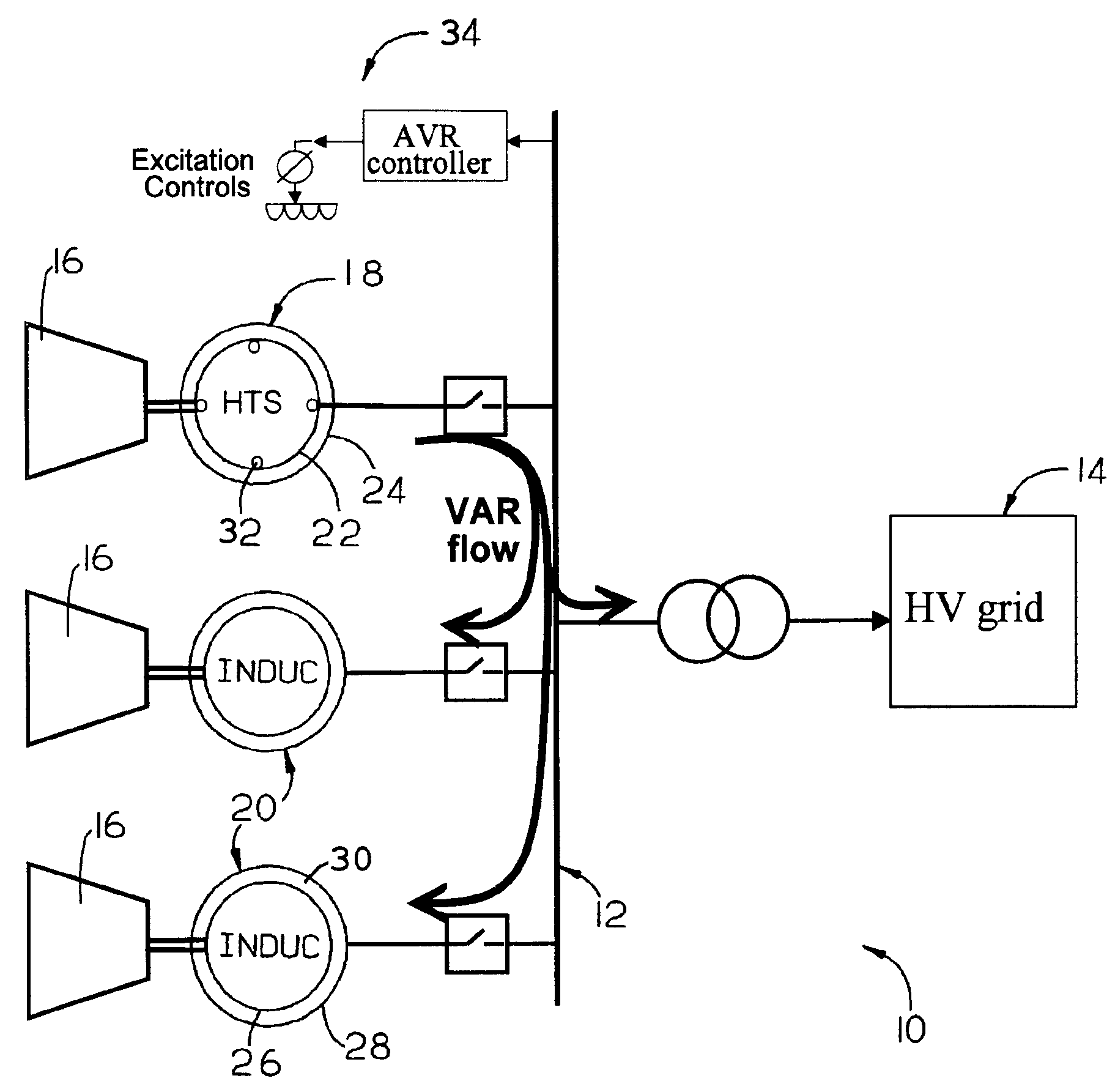

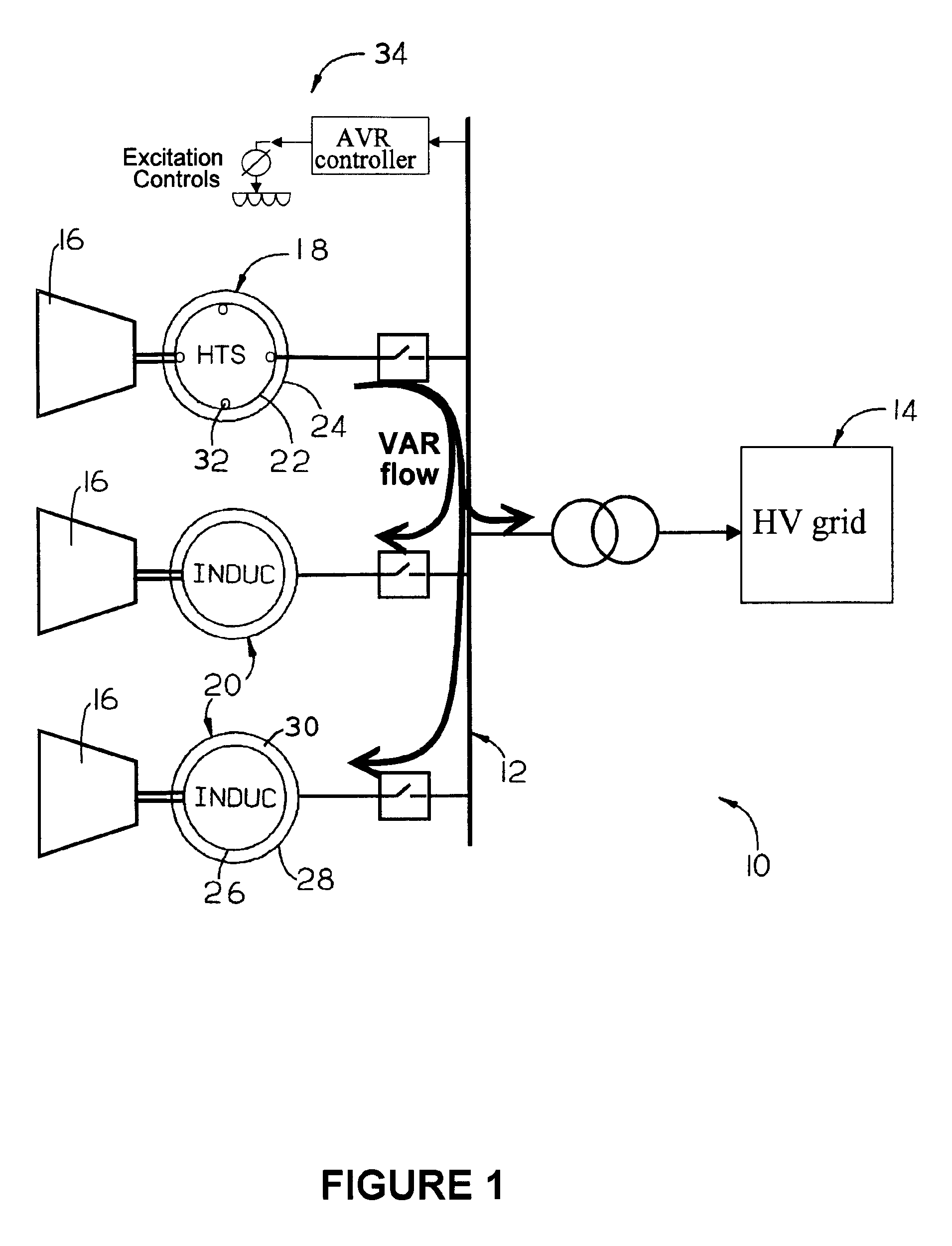

Hybrid synchronous/induction generator power plant

InactiveUS6930471B2Low efficiencyAcceptable efficiencyWindingsEmergency protective circuit arrangementsPower stationEngineering

A power generation plant comprising a power generating unit that includes at least one first generator, such as an induction generator, coupled to at least one synchronous generator having a rotor with a superconducting (SC) coil. The induction generator and the SC synchronous generator are coupled so that the SC synchronous generator supplies the induction generator with reactive power. Sufficient reactive power is preferably generated by the SC synchronous generator to meet the demand of the induction generator for VARs, as well as permit the induction generator to have a relatively large airgap.

Owner:GENERAL ELECTRIC CO

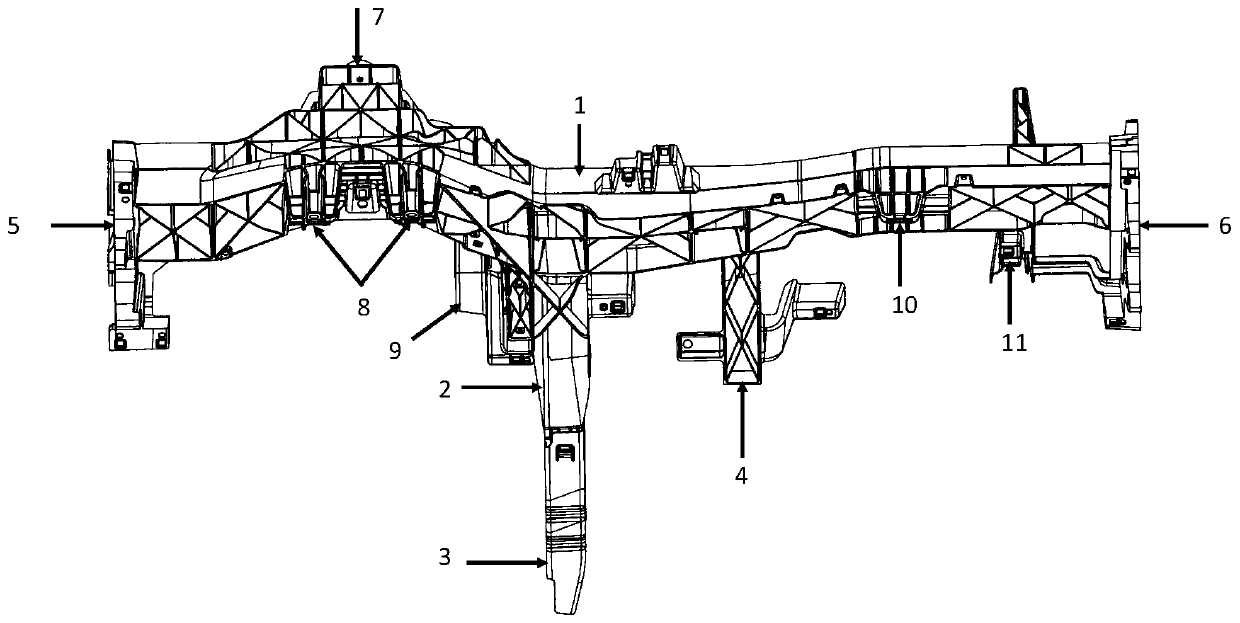

Crossbeam assembly used for automobile instrument board

ActiveCN110116759ASupport stabilityImprove mechanical propertiesSuperstructure subunitsEngineeringInjection moulding

The invention discloses a crossbeam assembly used for an automobile instrument board. The crossbeam assembly comprises a crossbeam assembly body. The crossbeam assembly body comprises a main tubular beam, a first end support, a first longitudinal support, a second longitudinal support and a second end support, wherein the first end support, the first longitudinal support, the second longitudinal support and the second end support are sequentially arranged on the main tubular beam at intervals; a third end support is arranged between the first end support and the first longitudinal support; thefirst longitudinal support and the second longitudinal support are oppositely arranged, extend to the same side and are opposite to the third end support in the extension direction; the side, opposite to the third end support, of the main tubular beam is provided with a steering tubular column connecting support; the connecting position of the main tubular beam and the second longitudinal supportis provided with an electronic module connecting support; the free end of the second longitudinal support is connected with an automobile body floor connecting support; an air bag connecting supportand a glove box connecting support are arranged between the second longitudinal support and the second end support; and the main tubular beam, the first longitudinal support, the second longitudinal support, the first end support, the second end support and the third end support are manufactured through an integrated injection molding process. The provided crossbeam assembly used for the automobile instrument board has sufficient structural strength.

Owner:SAIC GENERAL MOTORS +1

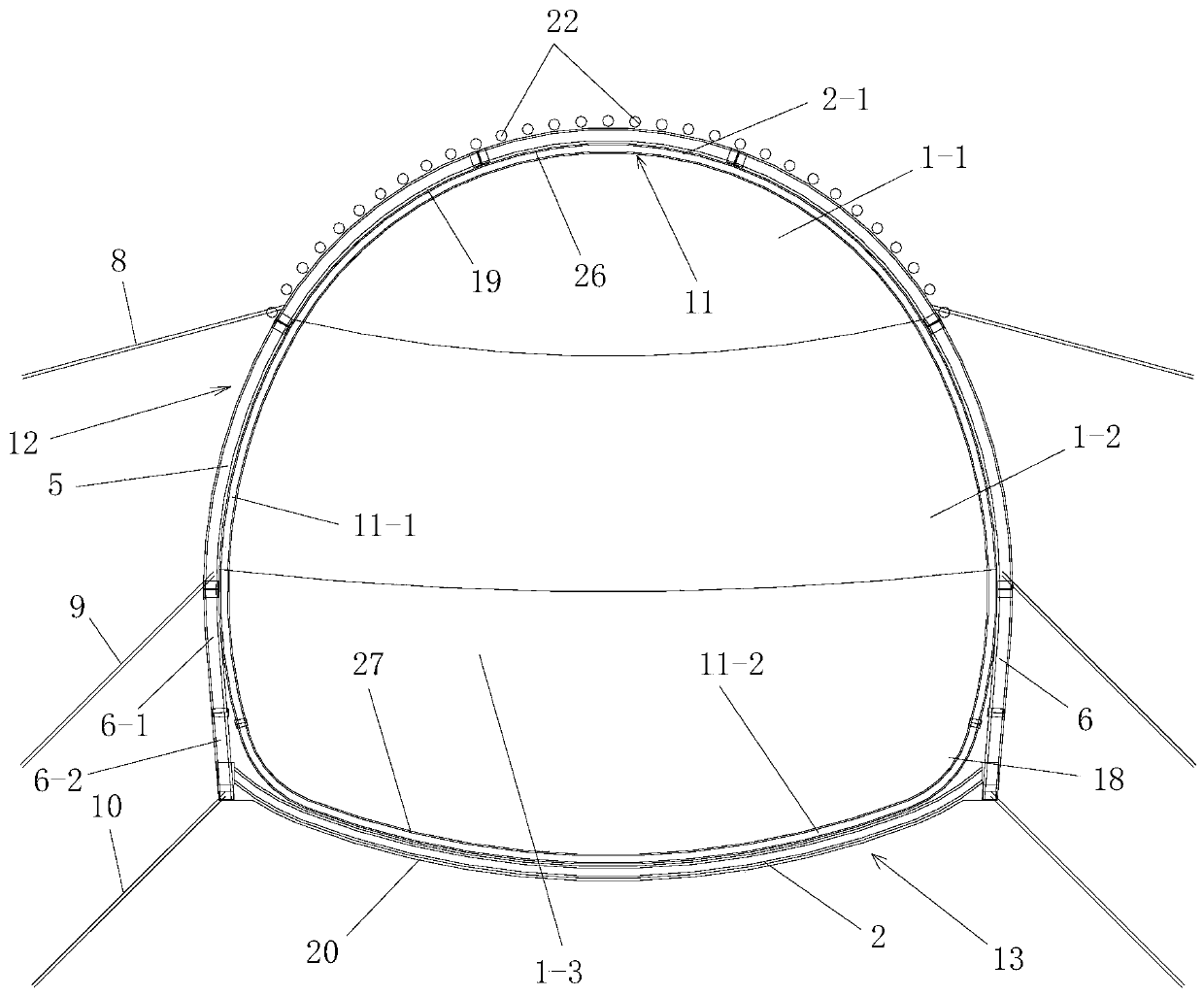

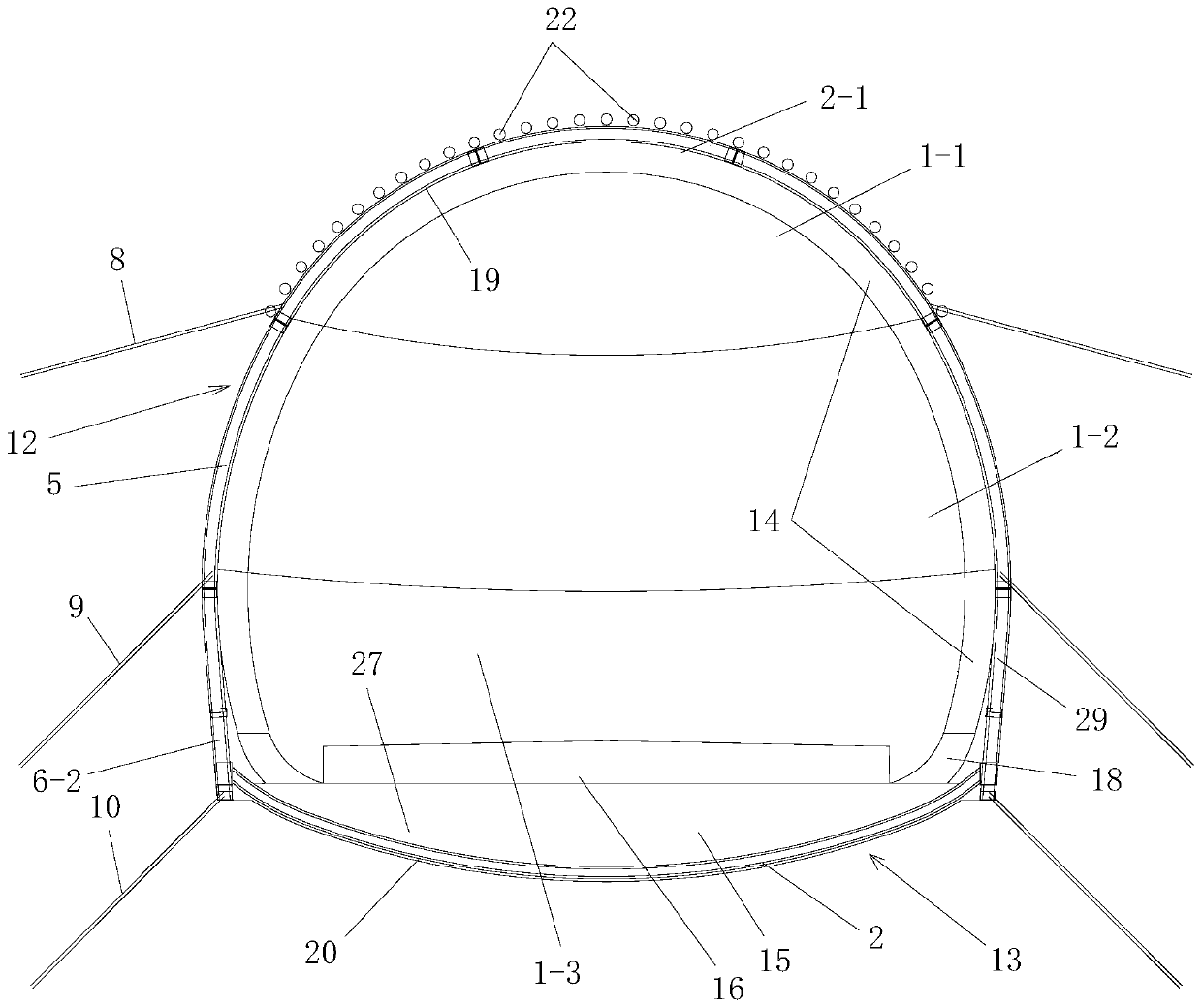

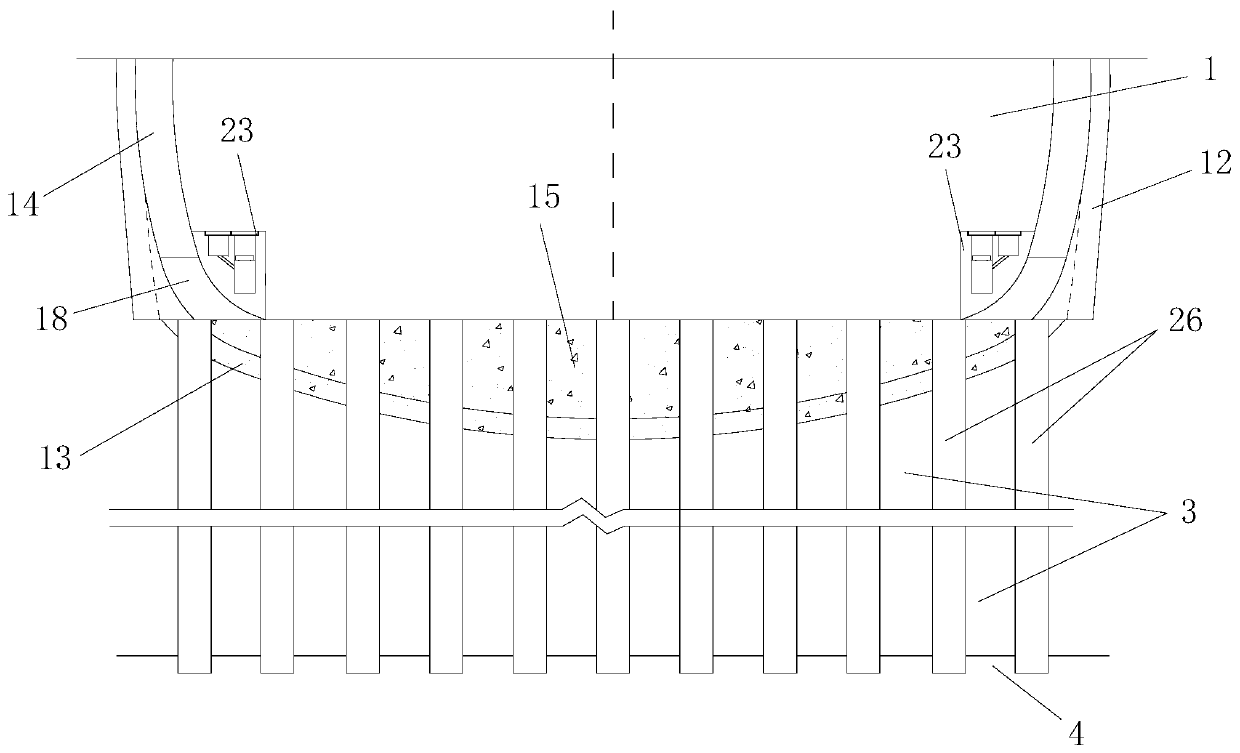

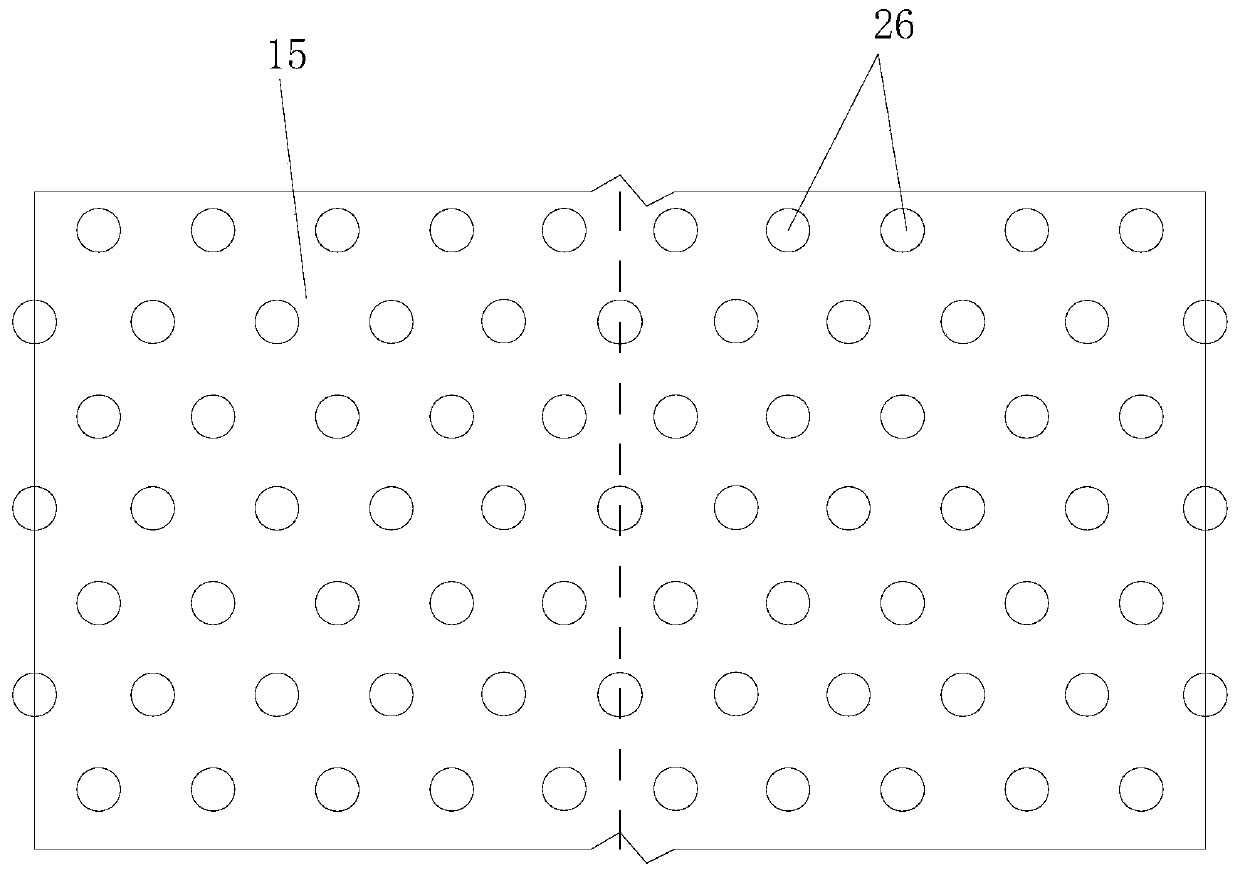

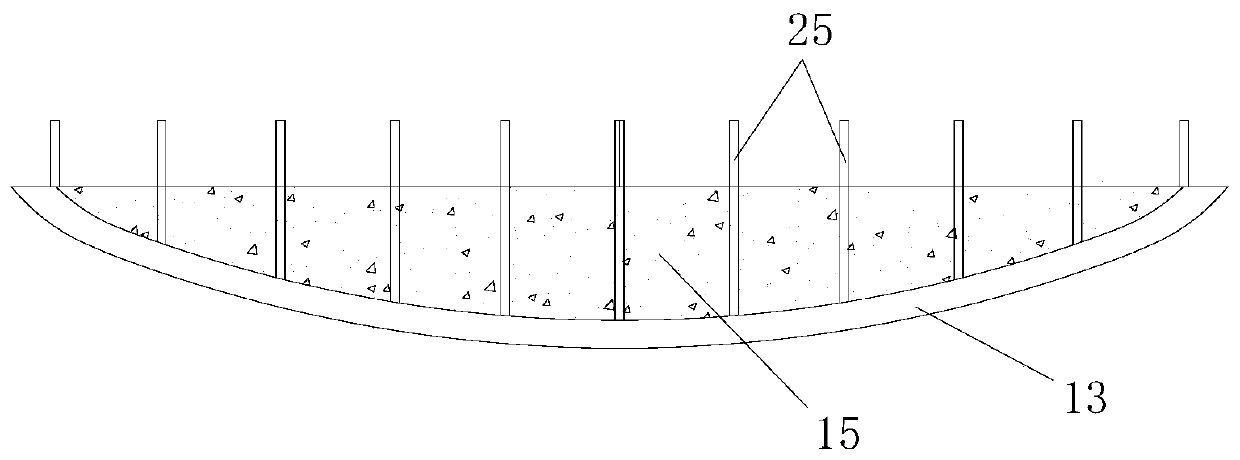

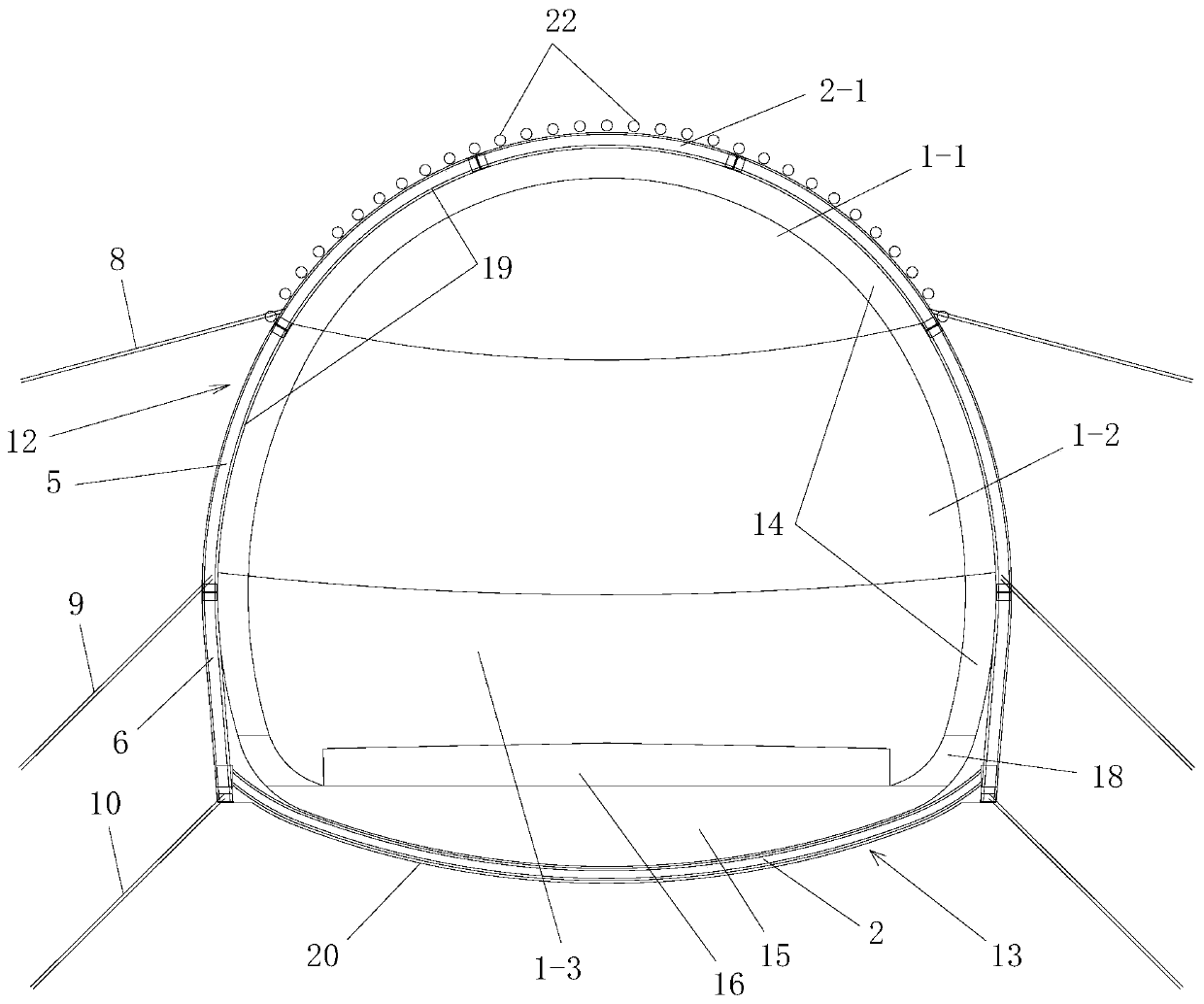

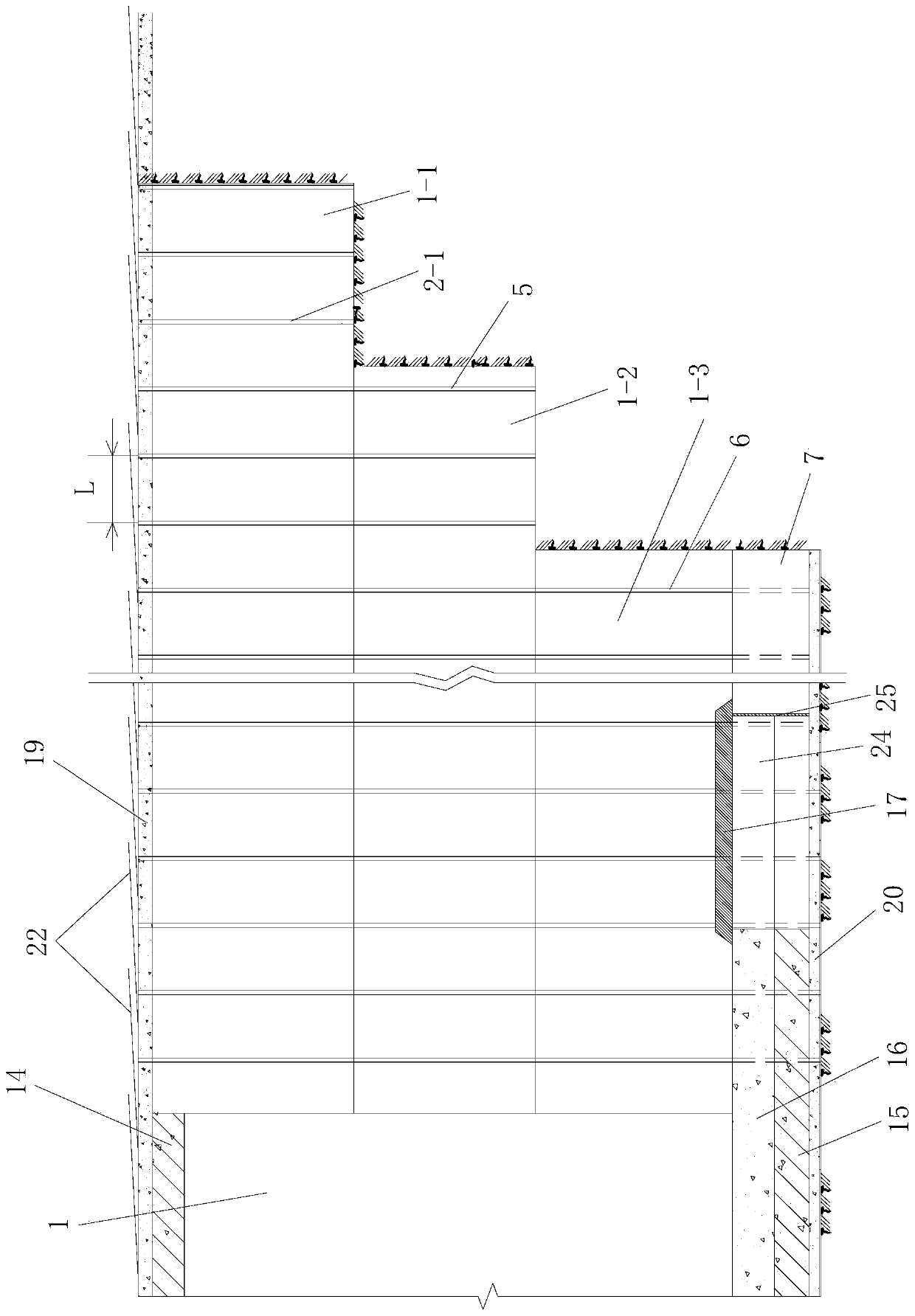

Large-section loess tunnel supporting system and supporting construction method

PendingCN110761808AReasonable structural designEasy constructionUnderground chambersTunnel liningGeotechnical engineeringStructure support

The invention discloses a large-section loess tunnel supporting system and a supporting construction method. The large-section loess tunnel supporting system comprises a tunnel forepoling structure, atunnel initial supporting structure and a tunnel secondary lining. The upper surface of an inverted arch secondary lining in the tunnel secondary lining is a horizontal plane, and an inverted arch backfill layer is arranged on the horizontal plane. The supporting construction method comprises the following steps of firstly digging a tunnel and conducting initial supporting; and secondly constructing the secondary lining and backfilling the inverted arch. The large-section loess tunnel supporting system is reasonable in design, easy and convenient to construct, high in construction efficiencyand good in use effect, the tunnel forepoling structure, the tunnel initial supporting structure and the tunnel secondary lining constitute a combined supporting system to stably and reliably supportthe large-section loess tunnel, the upper surface of the inverted arch of the secondary lining is adjusted to be a horizontal plane, the construction process of the inverted arch of the tunnel can beeffectively simplified, and the rigidity of the inverted arch of the tunnel is greatly improved; in this way, the construction efficiency of the tunnel secondary lining is improved, the ring sealingtime of the tunnel secondary lining is shortened, the integrity of the tunnel secondary lining is higher, and the overall force bearing effect is better.

Owner:CHINA RAILWAY 20 BUREAU GRP

Throw-away insert and milling cutter using throw-away insert

ActiveUS20070031200A1Reducing density variationHigh dimensional accuracyMilling cuttersShaping cuttersMilling cutterNose

A throw-away insert includes: an upper and bottom surface; two side surfaces; two end surfaces; a main cutting section formed from a ridge line positioned at the intersection between the side surfaces and the upper surface; a secondary cutting section formed from a ridge line positioned at the intersection between the end surfaces and the upper surface; an axial support surface supported by an insert pocket of a cutter body; and noses formed at the comers of the upper surface. The corner angles of the noses when seen from above are essentially right angles. The axial support surface is formed as a section of the end surface. The secondary cutting section is parallel to the ridge line at the upper end of the axial support surface and the bottom surface. The upper end of the axial support surface is positioned so that it is projected more in the direction of the longitudinal axis of the main cutting section than the ridge line of the upper end.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com