Tunnel excavation staggered type supporting device

A support device and staggered technology, applied in the installation of bolts, mine roof supports, mining equipment, etc., can solve the problems of needing to stop operation, backward support means, and difficulty in moving the frame, etc., so as to improve the time and step distance. The effect of improving support quality and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

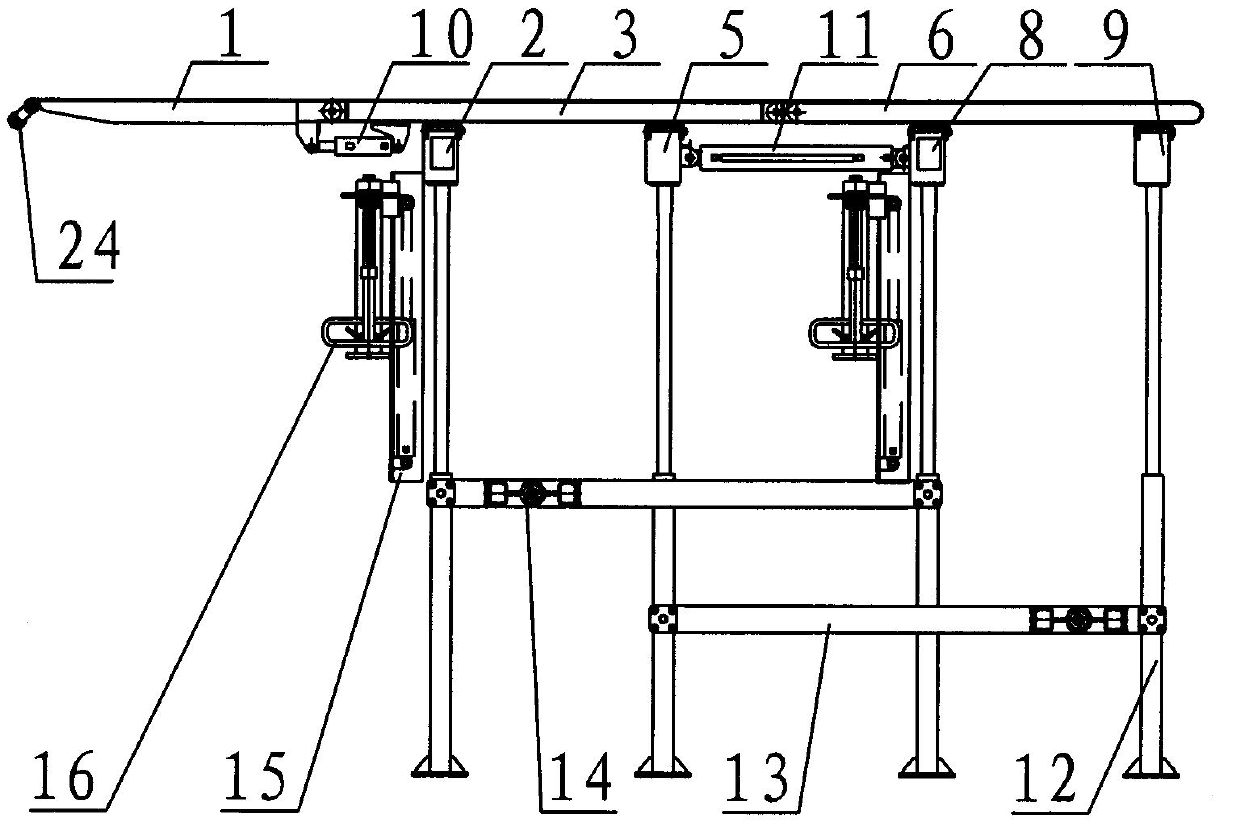

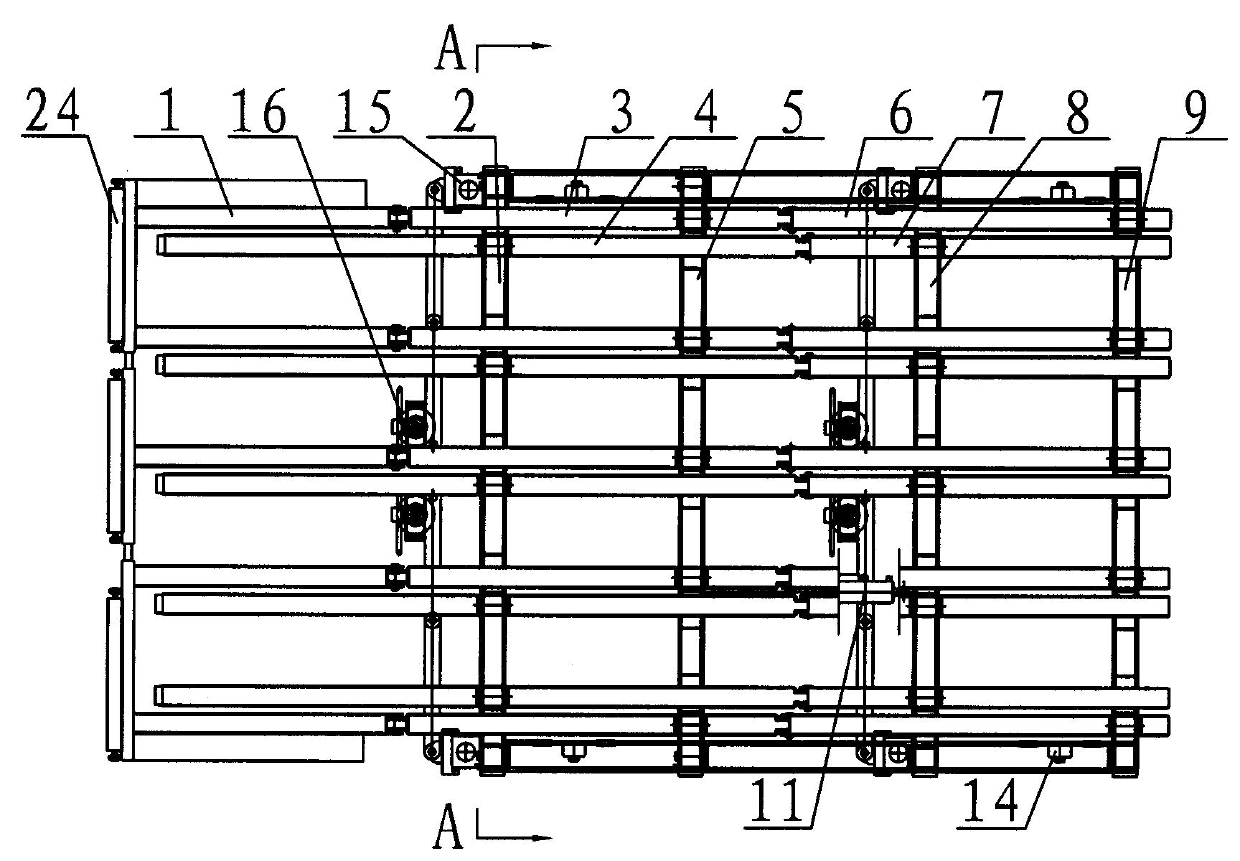

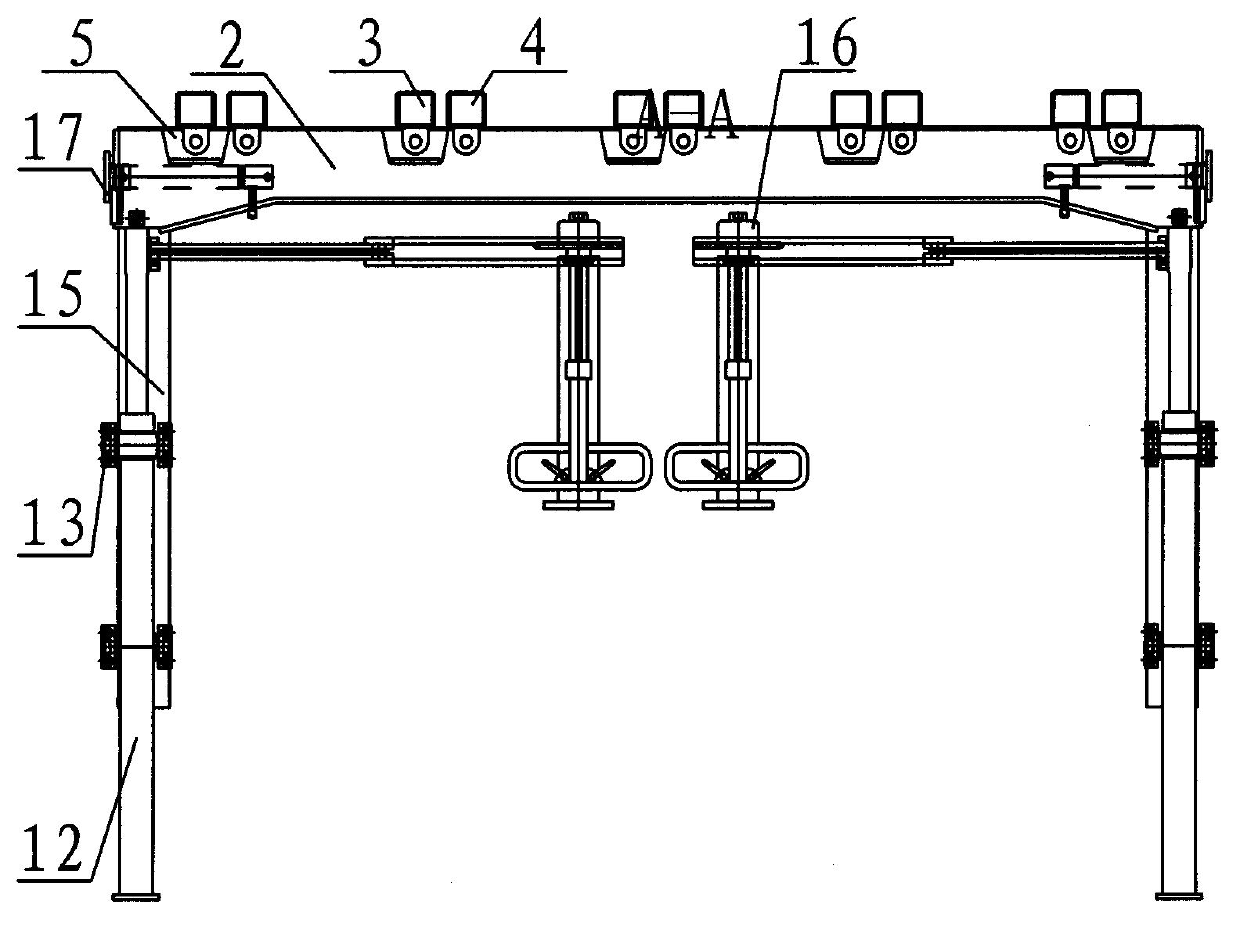

[0020] according to Figure 1~6The specific structure of the present invention will be described in detail. The staggered support device for roadway excavation includes a hydraulic column 12 as a support hinged at the bottom of the beam through a pin shaft, and a beam frame composed of a plurality of beams and parallel beams. The beam frame includes a main beam frame and an auxiliary beam frame. The main beam frame is a frame formed by connecting the main front beam 5, the main rear beam 9 and the mutually hinged main front beam 3 and the main rear beam 6. The auxiliary beam frame is a frame formed by connecting the auxiliary front beam 2, the auxiliary rear beam 8, and the auxiliary front beam 4 and the auxiliary rear beam 7 hinged to each other. Auxiliary bolting devices 15 are set at the side of the auxiliary front beam 2 and the auxiliary rear beam 8. The front end of the main front beam 3 of the main beam frame is hinged with the front beam assembly 1 for laying the net...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com