Hydraulic support withdrawing system and method

A technology of hydraulic support and cover support, which is applied in the direction of pillars/supports, earth drilling, mining equipment, etc., which can solve the problems of labor-consuming, time-consuming safety factor, easy injury to operators, and high risk of dismantling, so as to save costs , The steering method is simple and fast, and the effect of saving underground space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

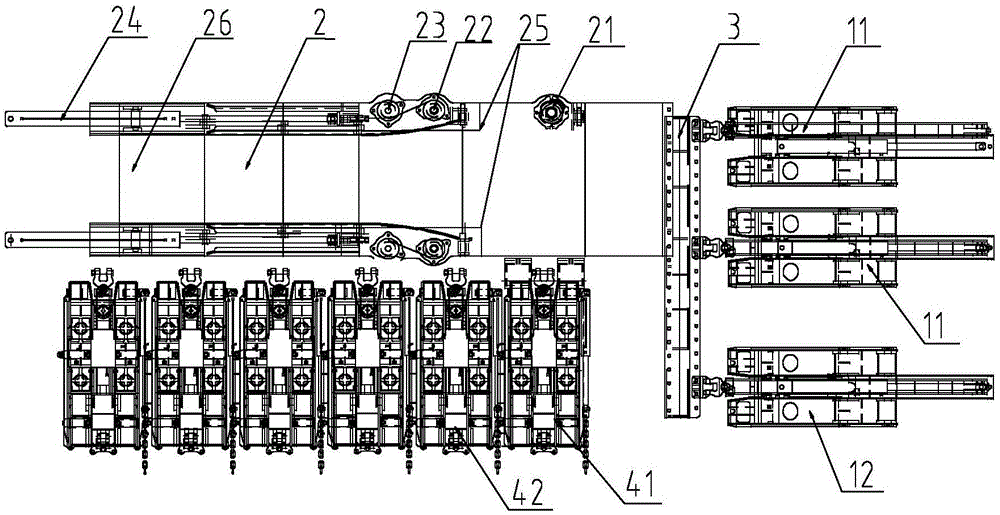

[0039] Such as figure 1 As shown, a hydraulic support retraction system includes a shield support 11, a shield support 12 and a retraction platform 2, and a push beam 3 is arranged between the shield support 11, the shield support 12 and the retreat platform 2, and the push The two sides of the beam 3 are fixedly connected with the push jack at the bottom of the shield support 11 and one end of the retraction platform 2 by bolts, and the cross-sectional shape of the push beam 3 is "H" type; there are three shield supports, and the shield support 11 and the cover support 12 are arranged in parallel on one side of the push beam 3, and the cover support 12 is located on one side of the hydraulic support 41 to be withdrawn, that is, the position of the hydraulic support just withdrawn; the withdrawal platform 2 is provided with a second One slope, the first slope is opposite to the hydraulic support 41 to be withdrawn, so that the hydraulic support 41 can be pulled and moved to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com