Stainless steel whitening solution and whitening technique thereof

A stainless steel and whitening technology, applied in the field of whitening solution and its whitening process, can solve the problems of high risk factor, great environmental harm, no metallic luster, etc., and achieve the effect of small risk factor and low environmental harm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Stainless steel whitening solution provided by the present invention, with water as solvent, contains in every liter of this solution:

[0018] Nitric acid 4%-10%;

[0019] Phosphoric acid 10-40g;

[0020] Boric acid 2-5g;

[0021] Acetic acid 5-30g;

[0022] Ammonium sulfate 10-30g;

[0023] Trisodium phosphate 10-30g;

[0024] Ammonium bifluoride 15-35g.

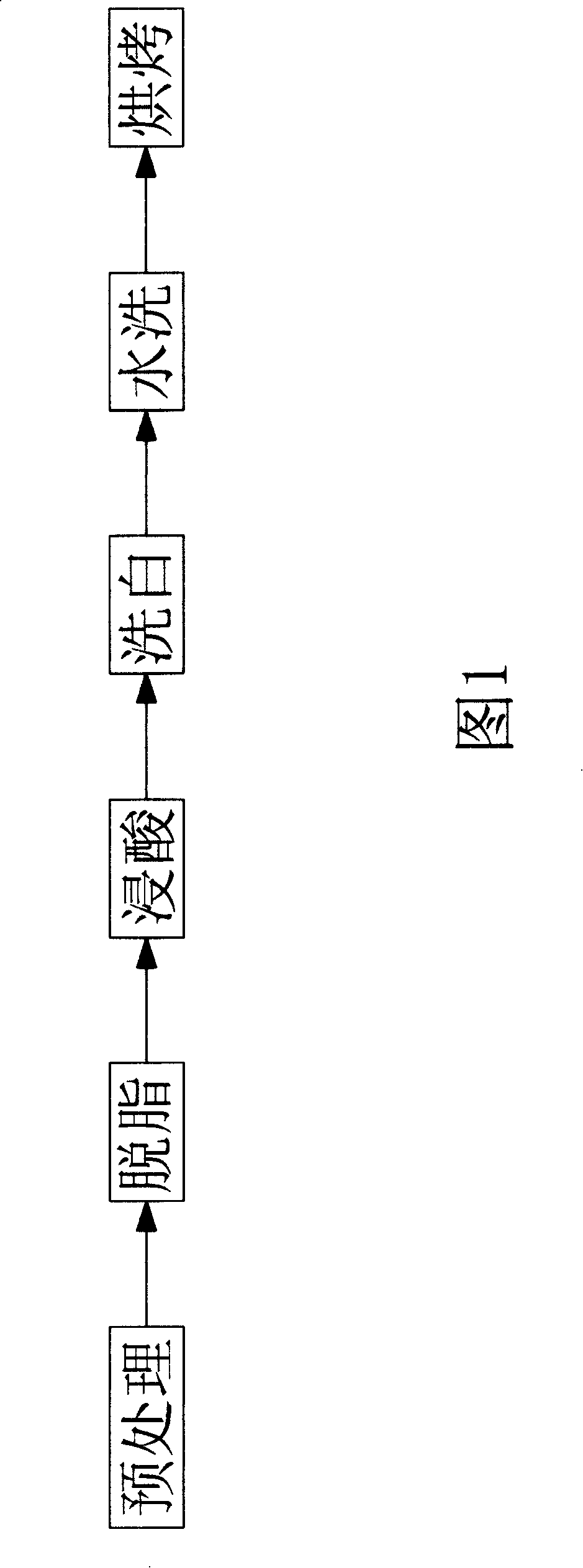

[0025] Please refer to FIG. 1 , which is a process flow diagram of using the stainless steel whitening solution of the present invention to wash the surface of stainless steel.

[0026] As shown in Figure 1, the technological process is:

[0027] Pretreatment is mainly to remove impurities and dirt on the surface of stainless steel;

[0028] Degrease, put the pretreated stainless steel into a solution containing sodium hydroxide 5g / L and sodium dodecylbenzenesulfonate 3g / L at a temperature of 40°C for 5 minutes;

[0029] Pickling, put the degreased stainless steel into a solution containing 5% sulfuric acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com