Roadway advanced supporting supports capable of assisting machinery to move

A technology of advanced support and auxiliary machinery, which is applied to mine roof supports, mining equipment, earthwork drilling, etc., can solve the problems of low operation efficiency, slow frame moving speed, and complicated operation, so as to achieve safe and reliable use and avoid repeated support. , the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

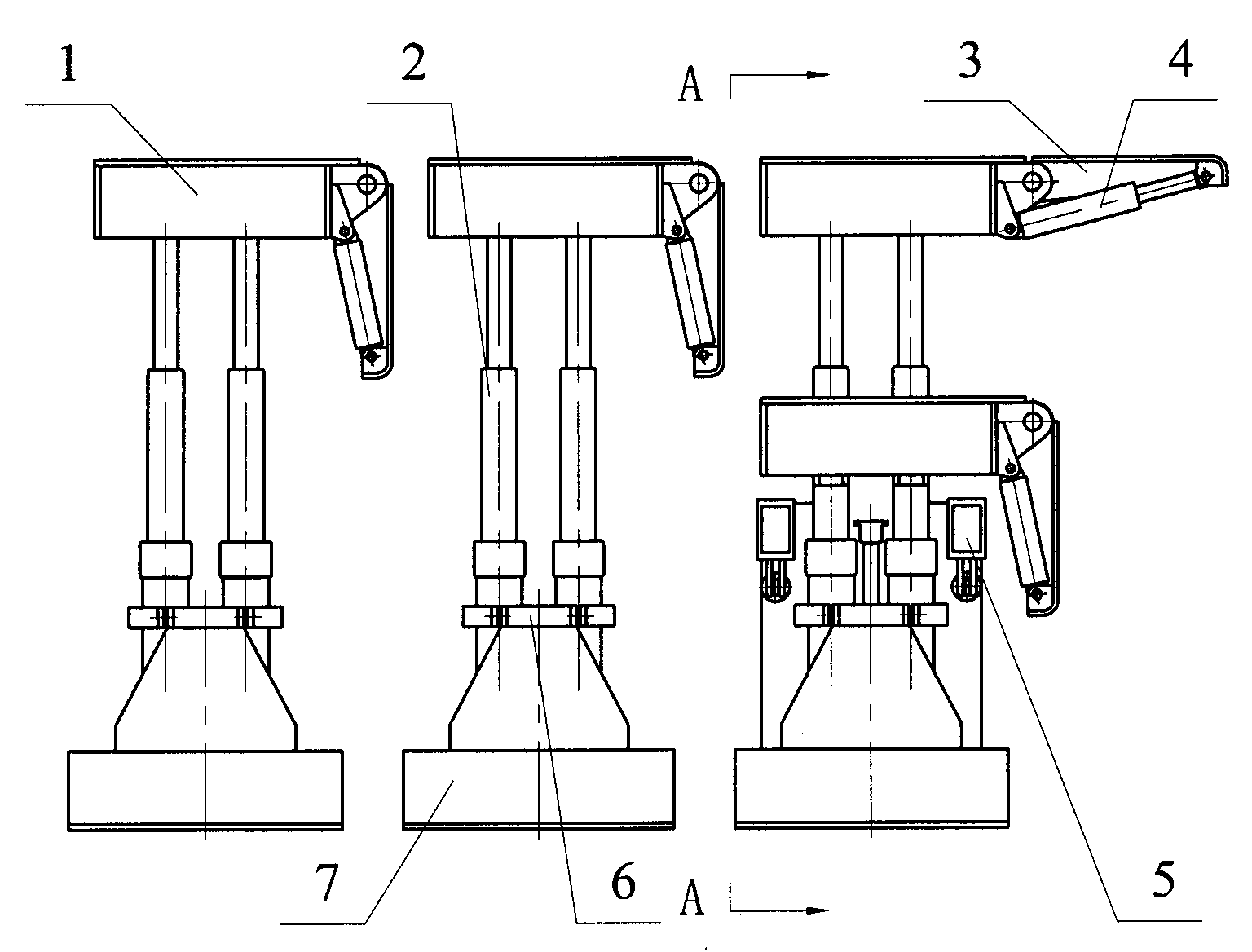

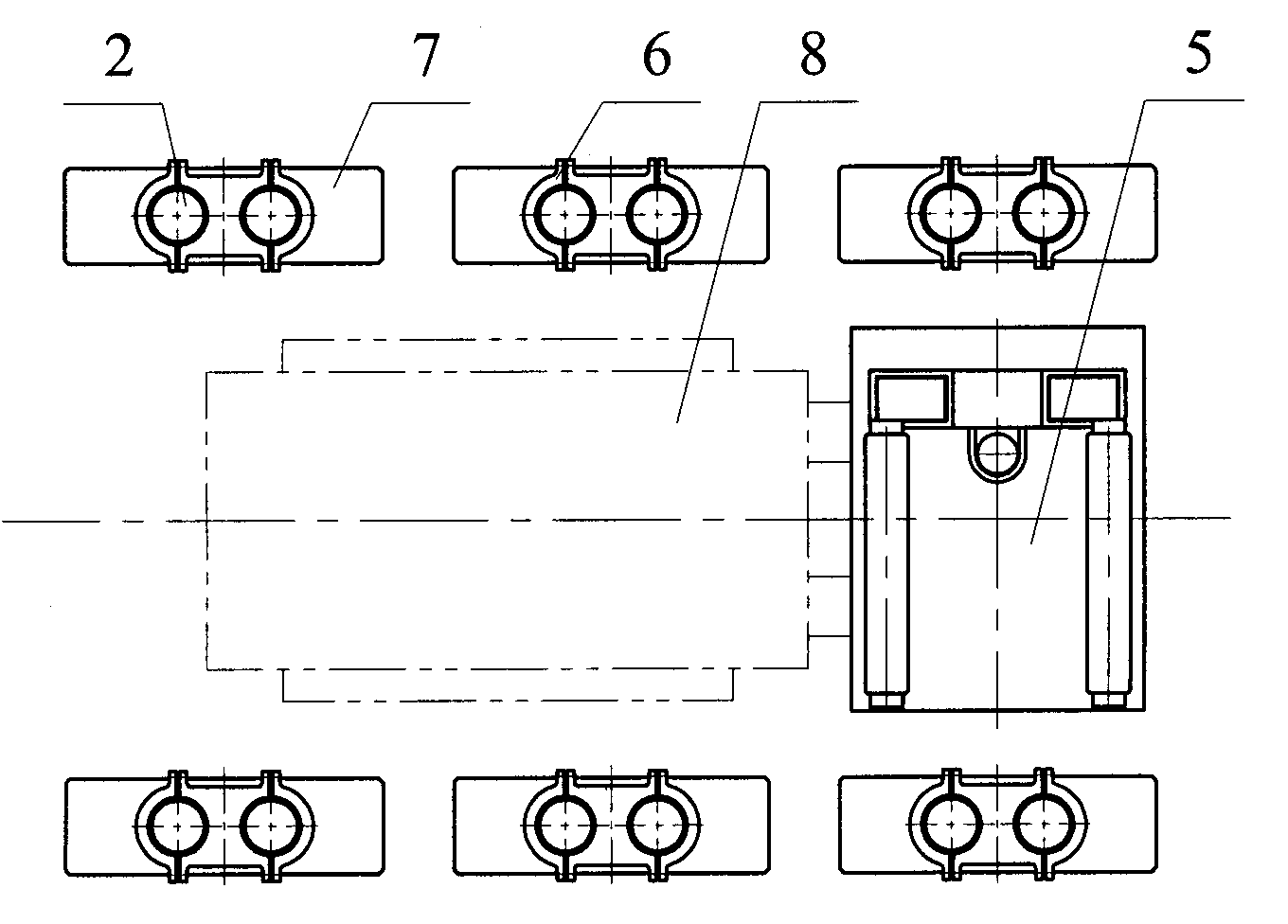

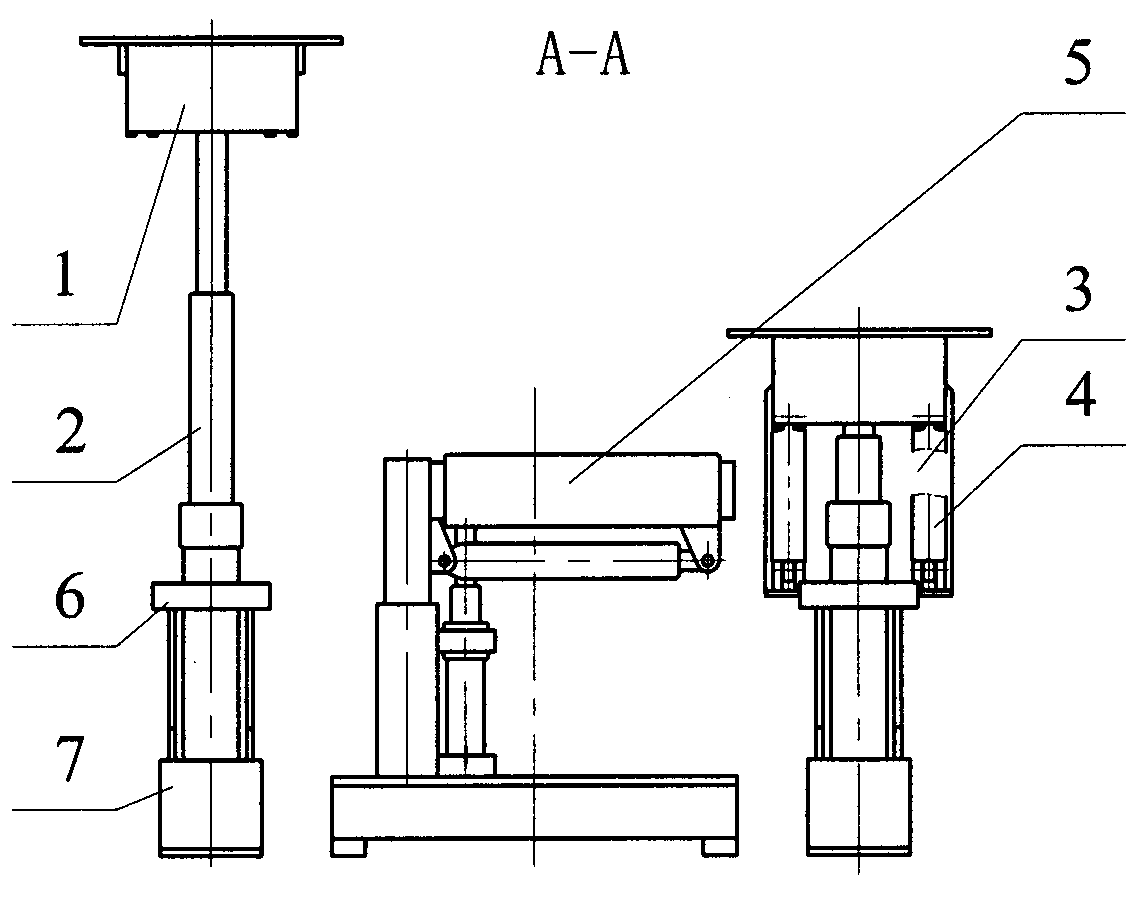

[0021] according to Figure 1~5 The specific structure of the present invention will be described in detail. The roadway advance support bracket for auxiliary mechanical movement includes an advance support bracket composed of a top beam 1, a base 7, and a hydraulic column 2, and an auxiliary moving mechanism and the like. The lower parts of the two hydraulic columns 2 hinged on the base 7 are fixed together by the fastening frame 6; Support bracket. The two advanced support supports are horizontally arranged as a group, and multiple sets of advanced support supports are respectively arranged longitudinally and continuously along the roadway to form support for the roof.

[0022]Auxiliary moving mechanism is made up of moving mechanical arm 5 and transport cart 8. The moving mechanical arm 5 is horizontally arranged between the two advanced support brackets to be moved. Driven by the transport vehicle 8 matched with the moving mechanical arm 5, each advanced support is move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com