Excavation method for tunnel passing through high-angle thrust water-rich and sand-rich fault

A tunnel excavation, high-angle technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as sudden water gushing, sand gushing, slow construction progress, and affecting construction safety and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

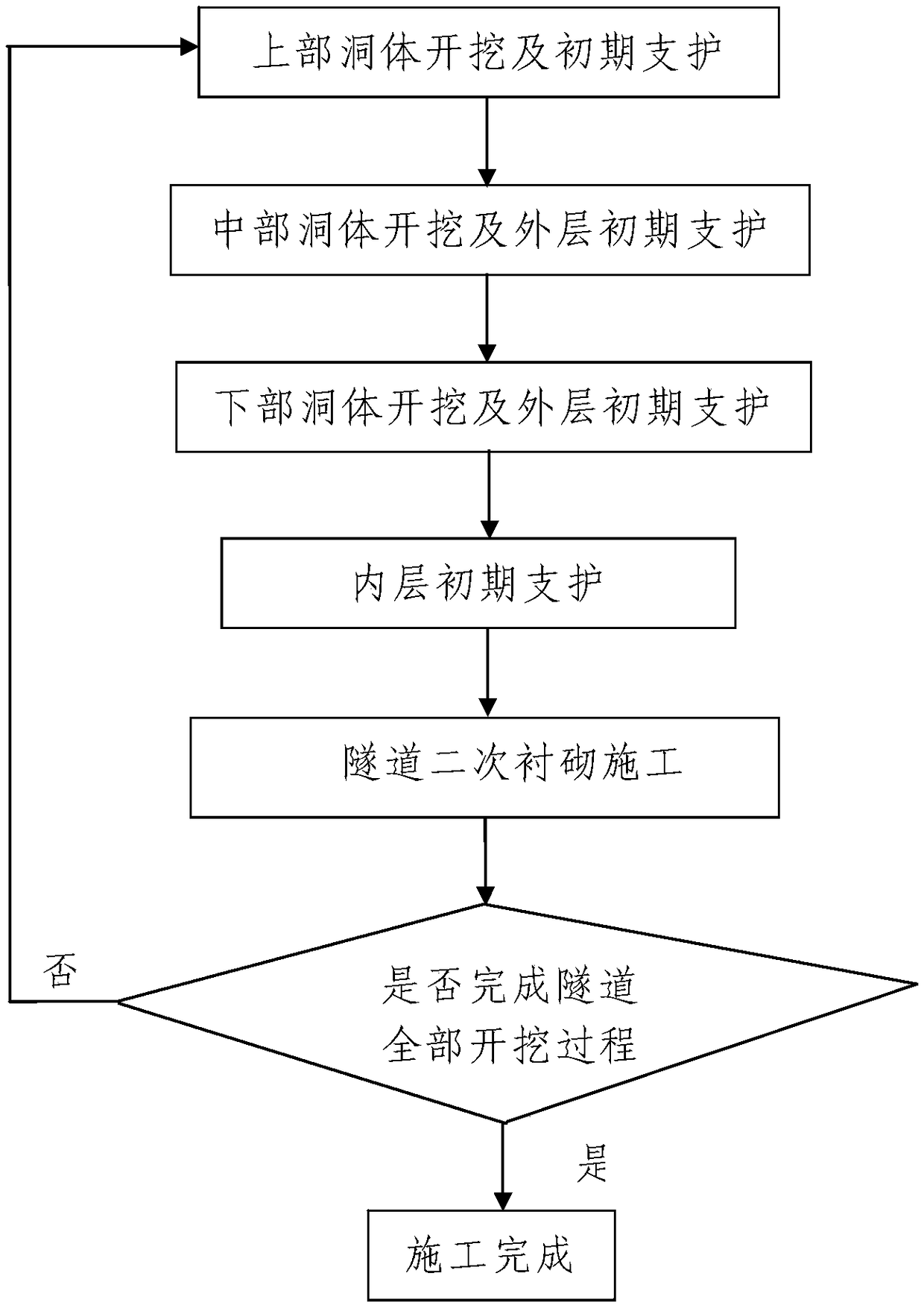

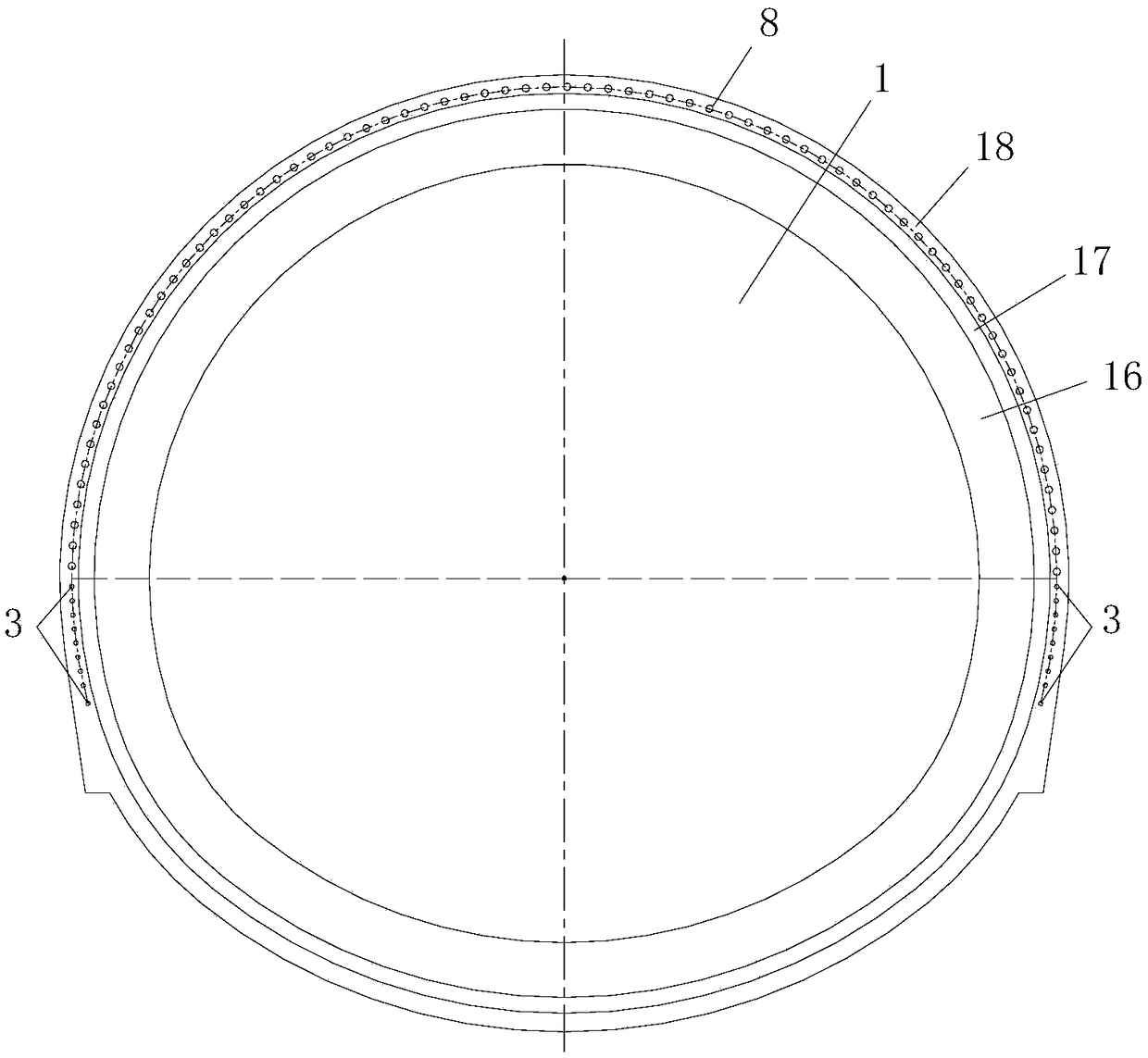

[0093] like figure 1 A method for excavating a tunnel crossing a high-angle thrusting water-rich sand-rich fault is shown. The tunnel hole 1 of the constructed tunnel is divided into an upper hole body, a middle hole body 1-2, and a lower hole body 1-3 from top to bottom. , the upper hole is divided into a left pilot hole 1-11 and a right pilot hole 1-12 on the right side of the left pilot hole 1-11, see figure 2 and Figure 8 ;

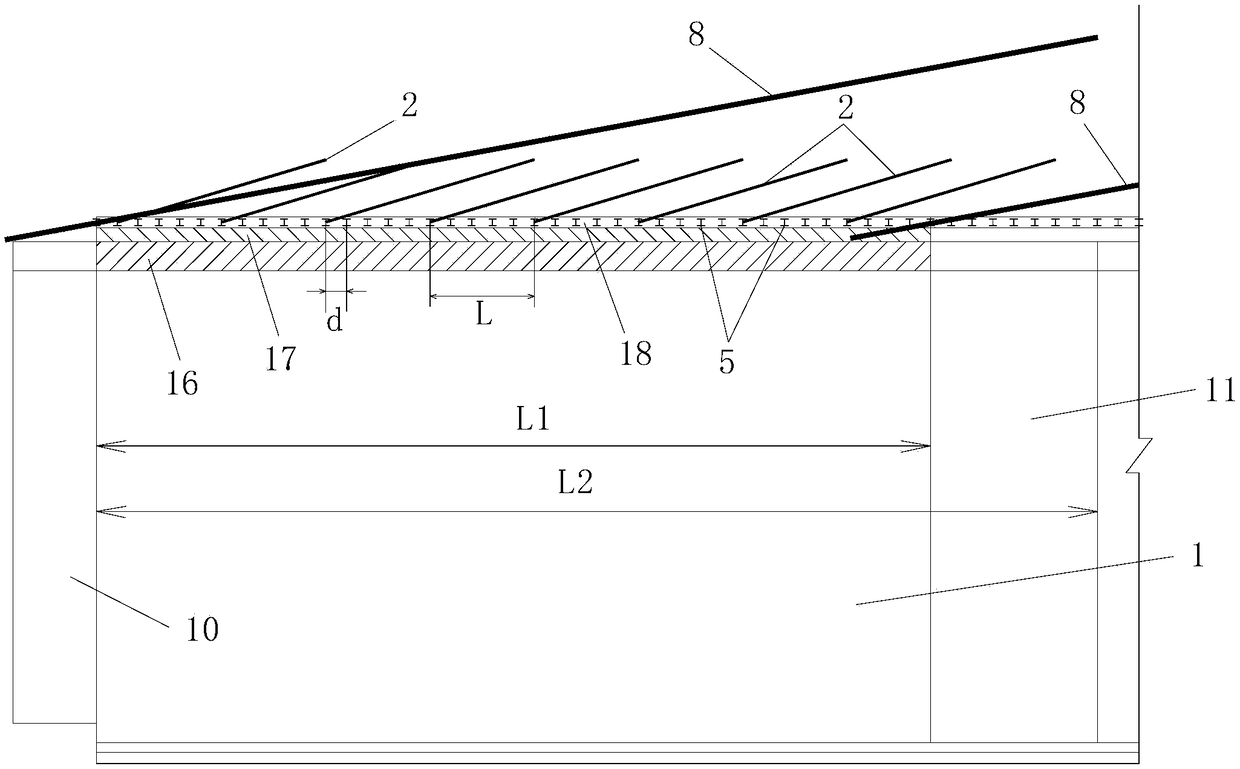

[0094] like Figure 9 , Figure 10 and Figure 11 As shown, the primary support structure of the tunnel hole 1 is a double-layer primary support structure, and the double-layer primary support structure includes a concrete primary spraying layer 5- 2. Multi-pronged steel arch 5 supporting the tunnel hole 1 and standing on the inner side of the concrete primary spraying layer 5-2, and a concrete respraying layer formed by a layer of concrete sprayed on the concrete primary spraying layer 5-2 5-1. The tunnel hole 1 is supported by multiple struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com