Template connecting piece capable of regulating and controlling angle

A technology for connectors and templates, which is applied to the connectors of formwork/formwork/work frame, the preparation of building components on site, construction, etc., which can solve the problems of affecting the appearance quality of concrete, inaccurate angle setting, and leakage of concrete grout, etc. problems, achieve rapid installation and disassembly, simple structure, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

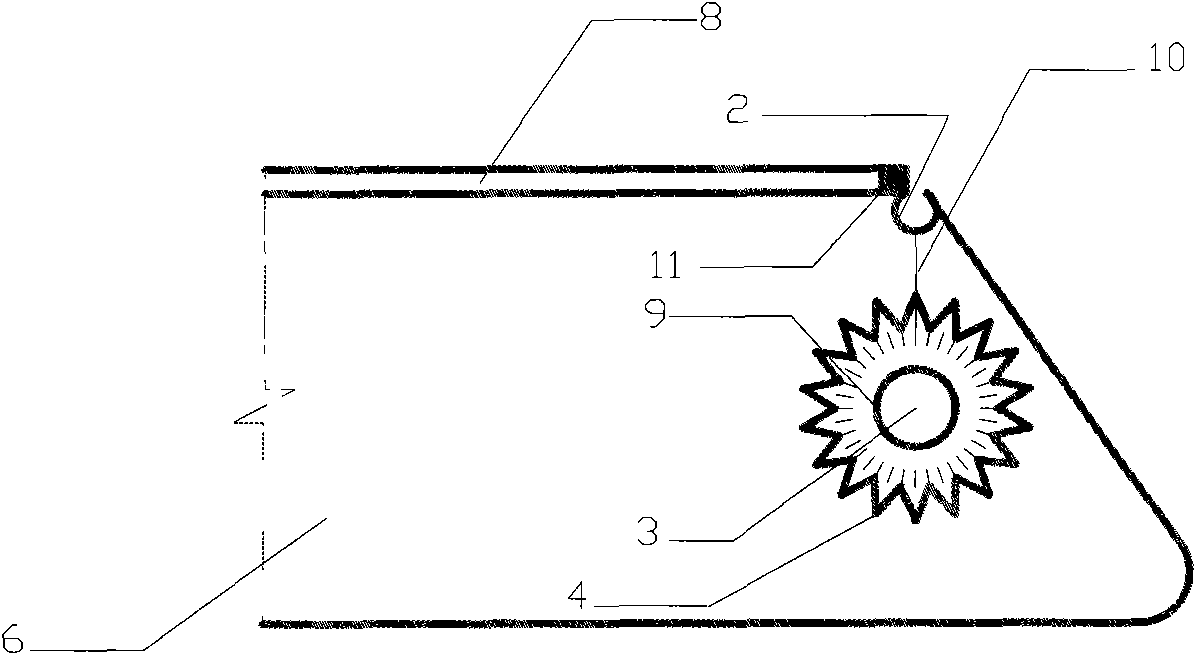

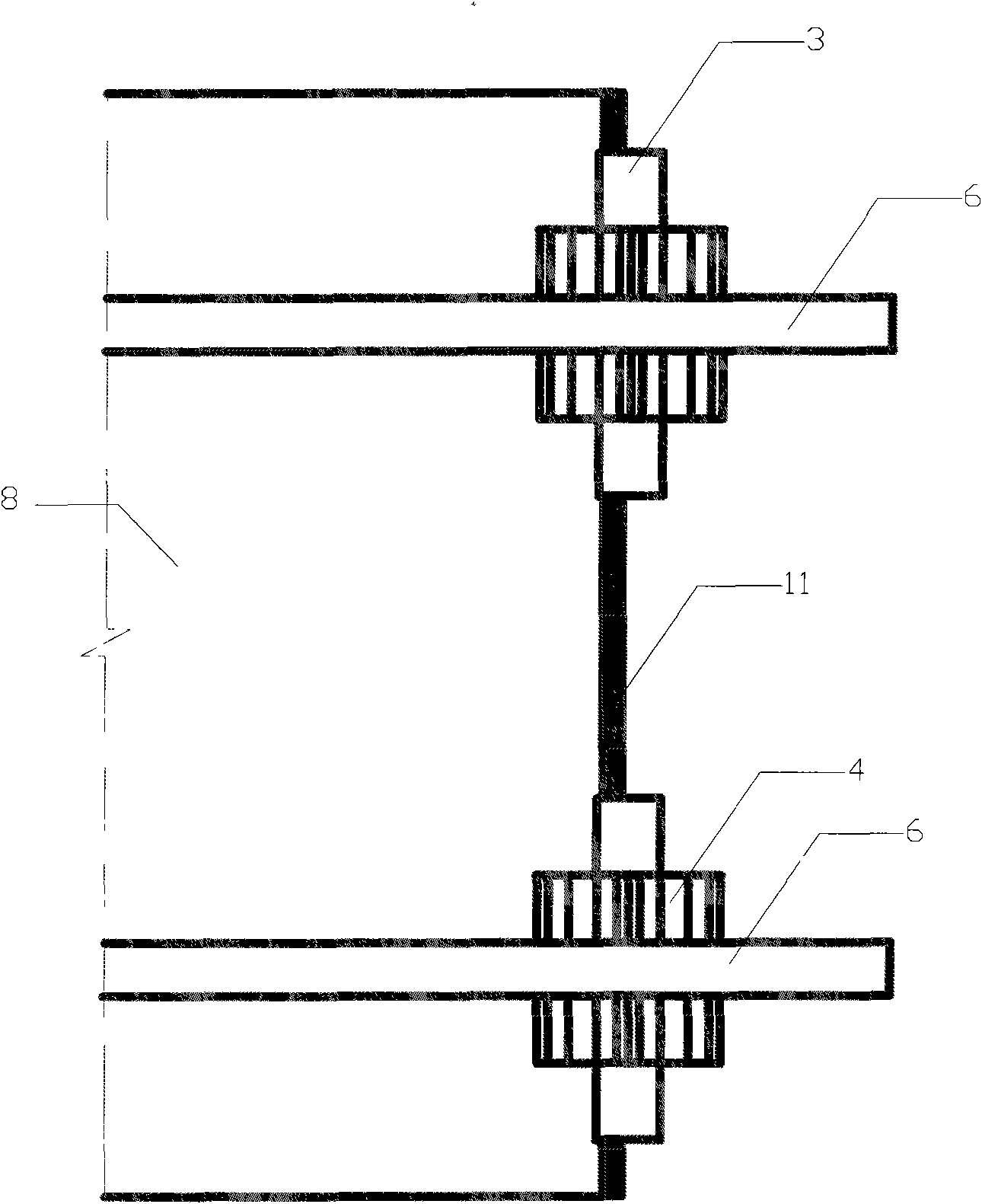

[0022] Such as figure 1 , 2 , 3, 4 and 7 can be used for the chamfering construction of formwork with chamfers in the range of 150° to 240°.

[0023] The first sub-component 5 is connected with the connection rotation shaft penetration hole 2 on the second sub-component 6 by means of the connection rotation shaft 1, which can be connected temporarily or permanently, depending on the needs of the work. The template 8 is provided with a rubber bead 11 on the chamfered contact edge, and the first and second sub-components 5 and 6 are arranged on the template 8 along the chamfered boundary; the angle adjustment gear 4 is set on the gear rotating shaft 3 . Butt the second sub-member 6 with the first sub-member 5, when the saw teeth on the gear just mesh, read the reading of the relative scale gauge 9 relative to the standard scale line 10, and calculate the scale corresponding to the angle adjustment gear when the angle to be flipped is reached , rotate the second sub-component 6...

Embodiment 2

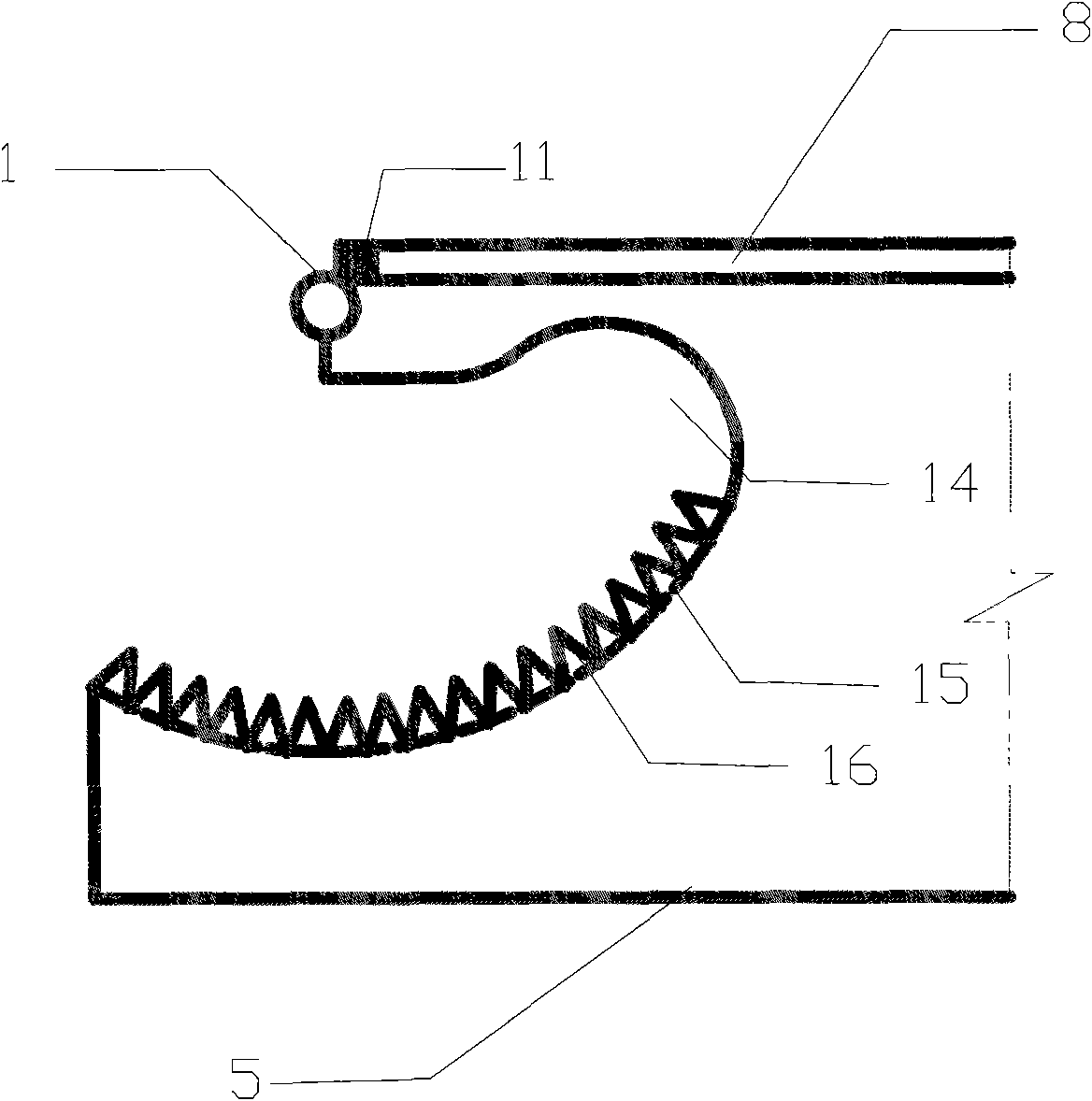

[0030] Such as Figure 5 , 6 As shown in and 7, it can be used for chamfering construction of formwork with chamfers in the range of 0°~150°.

[0031] The first sub-component 5 is connected with the connection rotation shaft penetration hole 2 on the second sub-component 6 by means of the connection rotation shaft 1, which can be connected temporarily or permanently, depending on the needs of the work. The template 8 is provided with a rubber bead 11 on the chamfered contact edge, and the first and second sub-components 5 and 6 are arranged on the template 8 along the chamfered boundary; the angle adjustment gear 4 is set on the gear rotating shaft 3 . Butt the second sub-member 6 with the first sub-member 5, when the saw teeth on the gear just mesh, read the reading of the relative scale gauge 9 relative to the standard scale line 10, and calculate the scale corresponding to the angle adjustment gear when the angle to be flipped is reached , rotate the second sub-component ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com