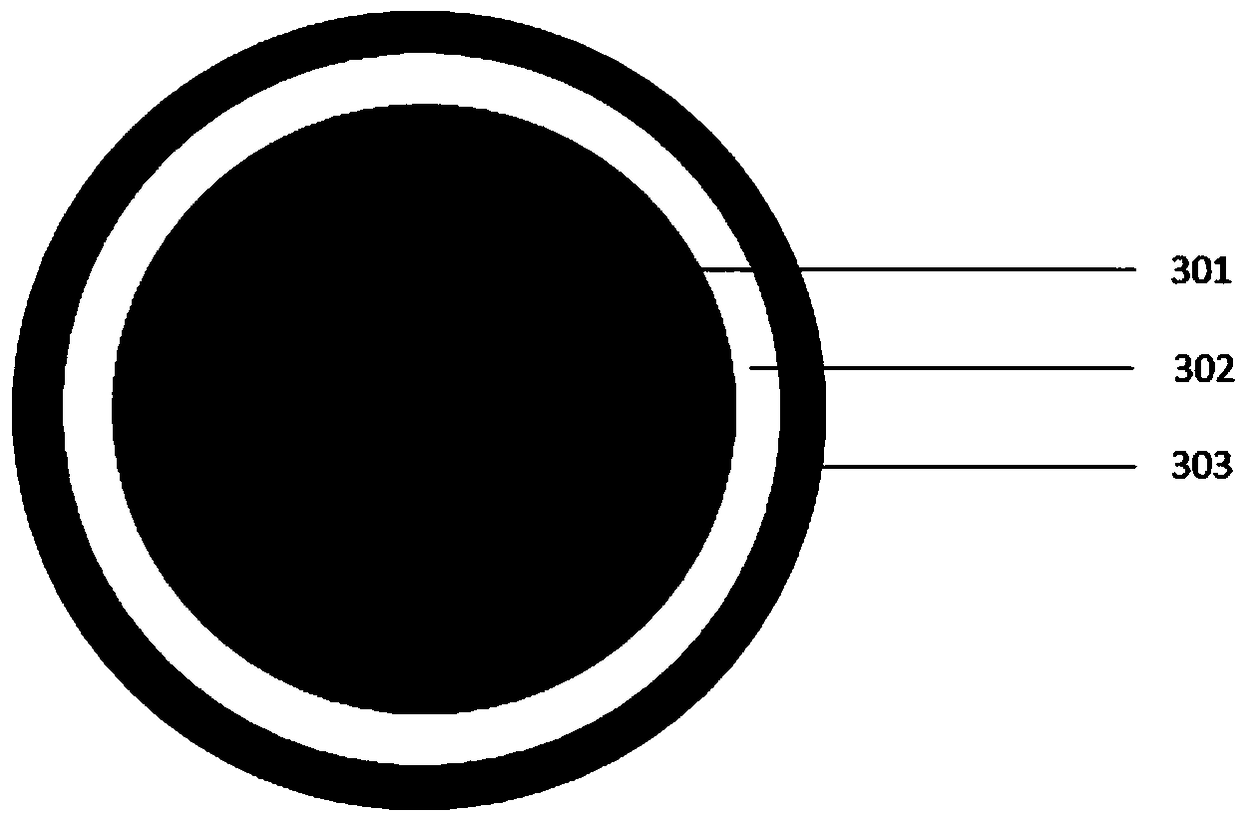

Medical degradable zinc-based alloy intravascular stent product

A vascular stent and a technology for degrading polymers, applied in the field of implantable vascular stent products, can solve the problems of poor controllability of corrosion rate, insufficient strength and toughness, slow corrosion rate, etc., and achieve excellent corrosion resistance, uniform corrosion, and good comprehensive performance. The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples of the present invention are given to further illustrate the present invention, but not to limit the scope of the present invention.

[0029] The specific implementation is as follows:

[0030] During the implementation of the present invention, pure zinc (purity is 99.99%), pure lithium (purity is 99.9%), pure magnesium (purity is 99.99%), Zn-Cu and Zn-Ti master alloy are used as raw materials to prepare, and then use vacuum induction The melting furnace was melted and cast in a 6 kg high-purity graphite crucible to obtain 12 kinds of alloy ingots, and their specific chemical compositions were shown in Table 1 after being detected by ICP-AES.

[0031] The chemical composition of the medical degradable zinc-based alloy material that table 1 present invention implements

[0032]

[0033] After smelting, the zinc-based alloy materials smelted in 12 different examples were turned to remove scale and necking, fully preheated at 210°C for 3 hours, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com