Lactobacillus plantarum producing exopolysaccharides

A technology of Lactobacillus plantarum and whey, applied in the field of microorganisms, can solve the problems of high cost, no treatment system, pollution, etc., and achieve the effect of improving flavor substances and good product properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

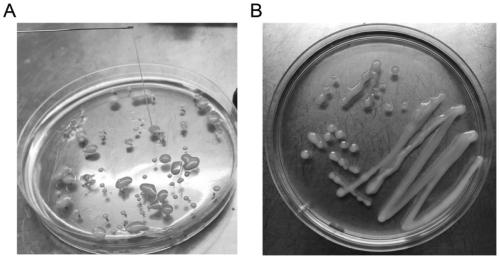

[0045] Example 1 Isolation and screening of exopolysaccharide-producing lactobacillus

[0046] (1) Dilution of sample solution: Use a sterile 1mL pipette to draw 1mL sample solution into a sterile small test tube and dilute it with sterile physiological saline to a dilution of 10 -1 , 10 -2 , 10 -3 , 10 -4 , 10 -5 , 10 -6 , 10 -7 , 10 -8 , 10 -9 , 10 -10 , 10 -11 , 10 -12 . Choose a dilution of 10 -4 to 10 -12 The diluent is ready for use.

[0047] (2) Separation of plates: first, under the condition of aseptic operation on the ultra-clean bench, the sterilized MRS solid medium containing calcium carbonate is poured onto the plate, and after the temperature is room temperature, the above dilution is drawn with a pipette gun. 10 -4 to 10 -12 0.1mL of fermentation broth. Pouring and coating onto the culture dish of the MRS solid medium containing calcium carbonate by pouring method and coating method respectively, each dilution was repeated twice, and packed wit...

Embodiment 2

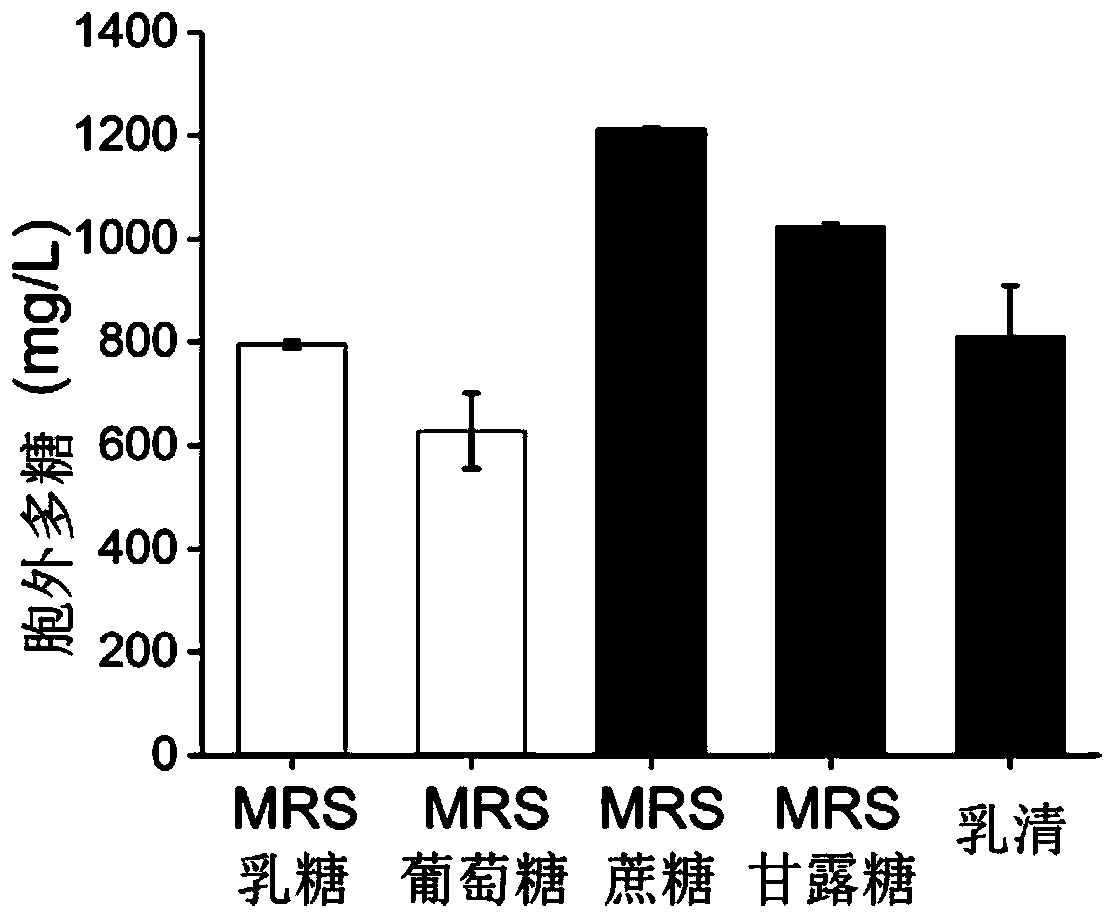

[0050] Embodiment 2 monosaccharide composition analysis

[0051] According to the "monosaccharide composition analysis method" in the specific embodiment, the monosaccharide composition is analyzed, and the results are as follows Figure 4 As shown, the extracted polysaccharides are mainly composed of glucose, mannose, galactose and galacturonic acid, with contents of 260, 27, 82 and 20 μmol / g, respectively.

Embodiment 3

[0052] The identification of embodiment 3 bacterial strains

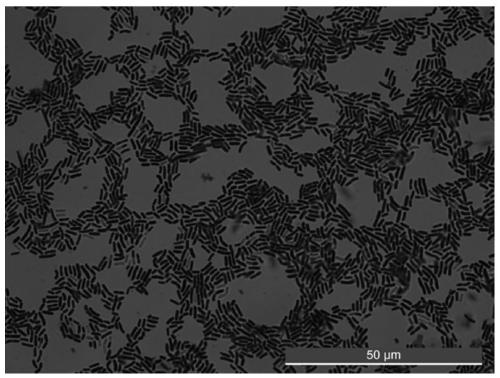

[0053] (1) Bacterial morphology observation and Gram staining

[0054] Use an inoculation loop to pick up a small amount of bacterial samples in the ultra-clean bench and spread them evenly on the glass slide, then heat to kill the bacteria with an alcohol lamp, add ammonium oxalate crystal violet dropwise, and stain for 1 min. Rinse off excess staining solution on the washed slides with water, and blot dry with absorbent paper. Add a small amount of iodine-potassium iodide solution dropwise, let stand for 1min, then wash with water, blot dry with absorbent paper, add ethanol continuously dropwise for decolorization, until the outflowing liquid is colorless, then wash with water. Finally, counterstain with saffron stain for 30 s. After staining, observe with a microscope, Gram-positive bacteria are purple, and Gram-negative bacteria are red. As a result of the identification, the isolated lactic acid bacteria are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com