Timbering device for hydraulic support withdrawing and fully-mechanized mining timbering equipment

A technology of hydraulic supports and support devices, which is applied to mining equipment, mine roof supports, earthwork drilling and mining, etc., which can solve the problems of low production efficiency, high labor intensity, and low support strength, so as to improve production efficiency and save manpower Cost, Effects of Improved Security and Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

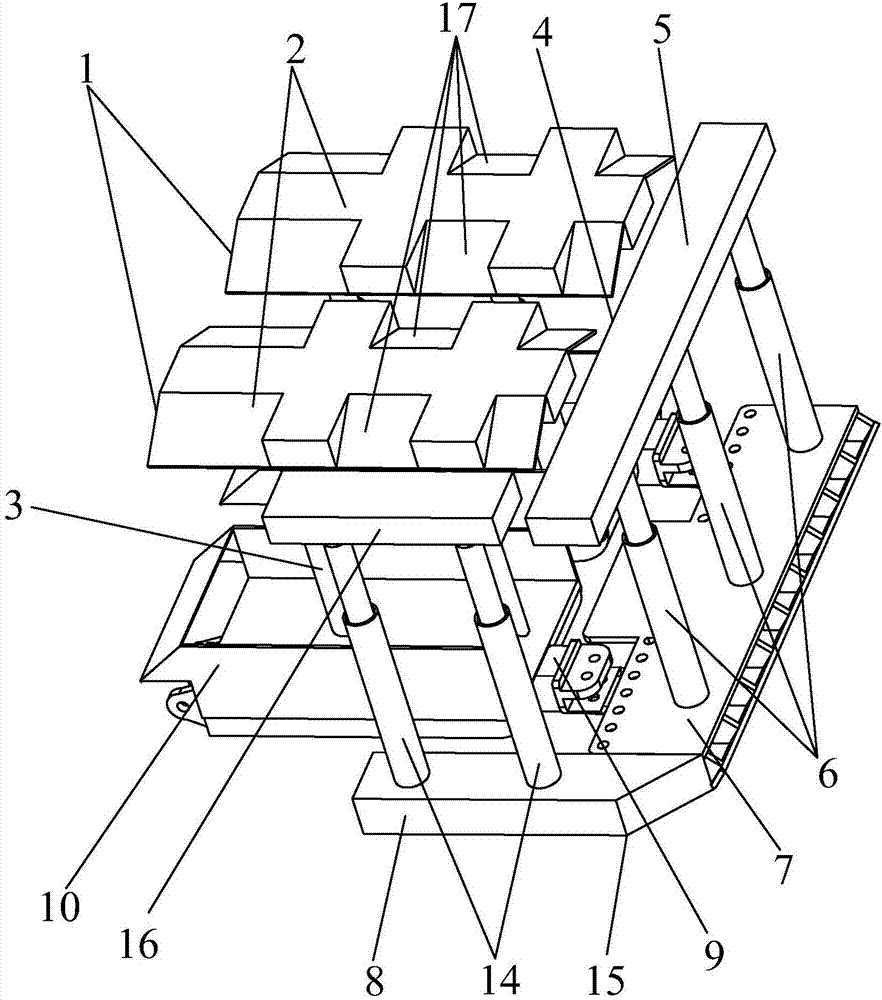

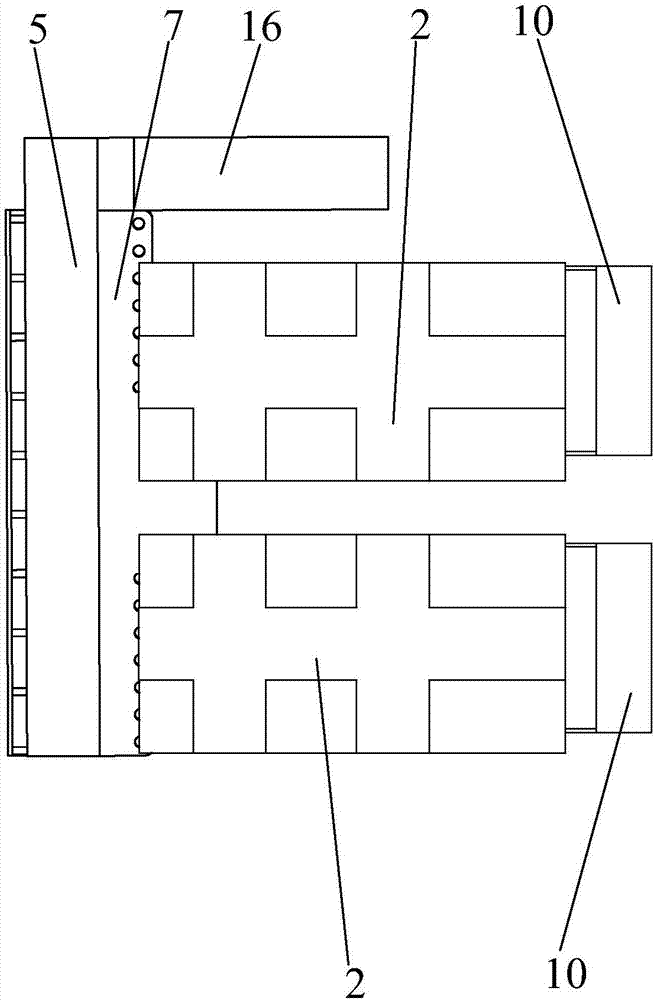

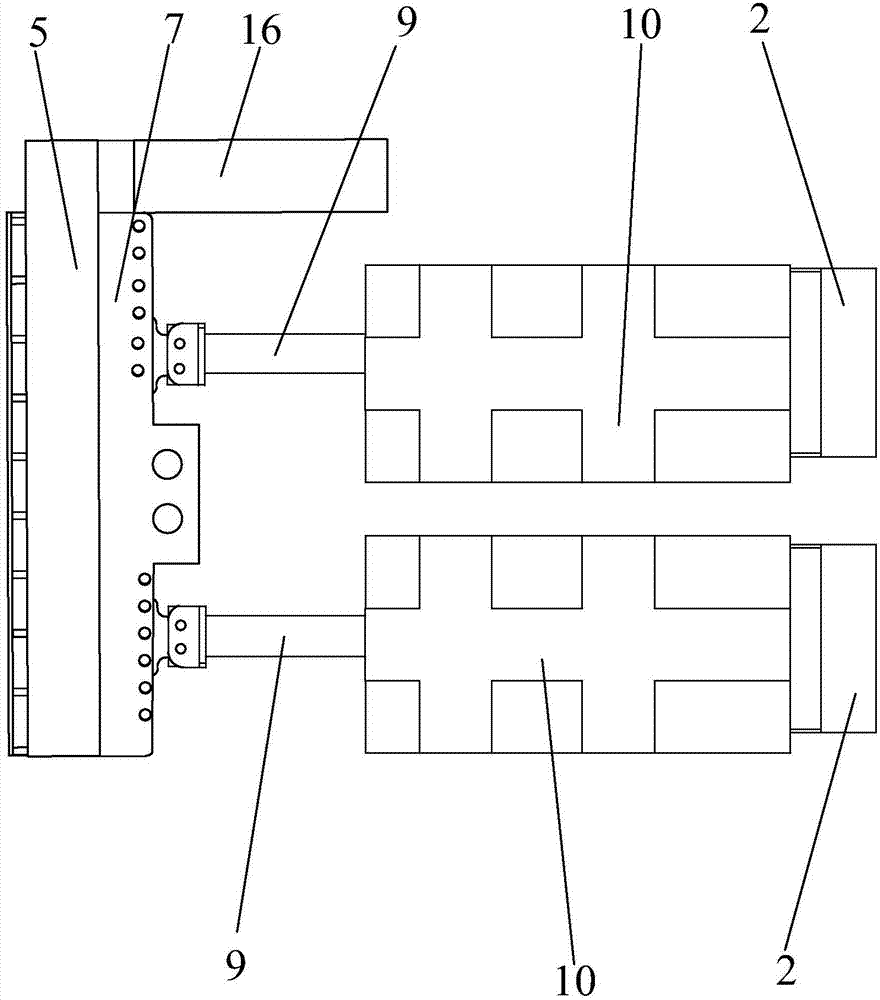

[0028] combine Figure 1-Figure 6 As shown, the support device for the retraction of the hydraulic support of the present invention includes a first support assembly 4, a second support assembly 1, and a pusher 9, and one end of the pusher 9 is connected to the second support assembly 1, and the other end is connected to On the first support assembly 4; the pushing device 9 can realize the state adjustment of shrinkage and stretching. During the action of the pushing device 9, the distance between the first support assembly 4 and the second support assembly 1 is adjusted, For the adjustment of the device 9 , the first support assembly 4 and the second support assembly 1 advance alternately to realize the movement and position adjustment of the first support assembly 4 and the second support assembly 1 . The stretching and shrinking of the pushing device 9, the lifting of the first support assembly 4 and the second support assembly 1 have all realized mechanized control, withou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com