Excavation and supporting method for tunnel crossing high-angle thrust water-rich and sand-rich fault

A tunnel excavation, high-angle technology, applied in tunnels, tunnel linings, drainage, etc., can solve problems that affect construction safety and efficiency, and are prone to sudden water gushing, sand gushing, water gushing and sand gushing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

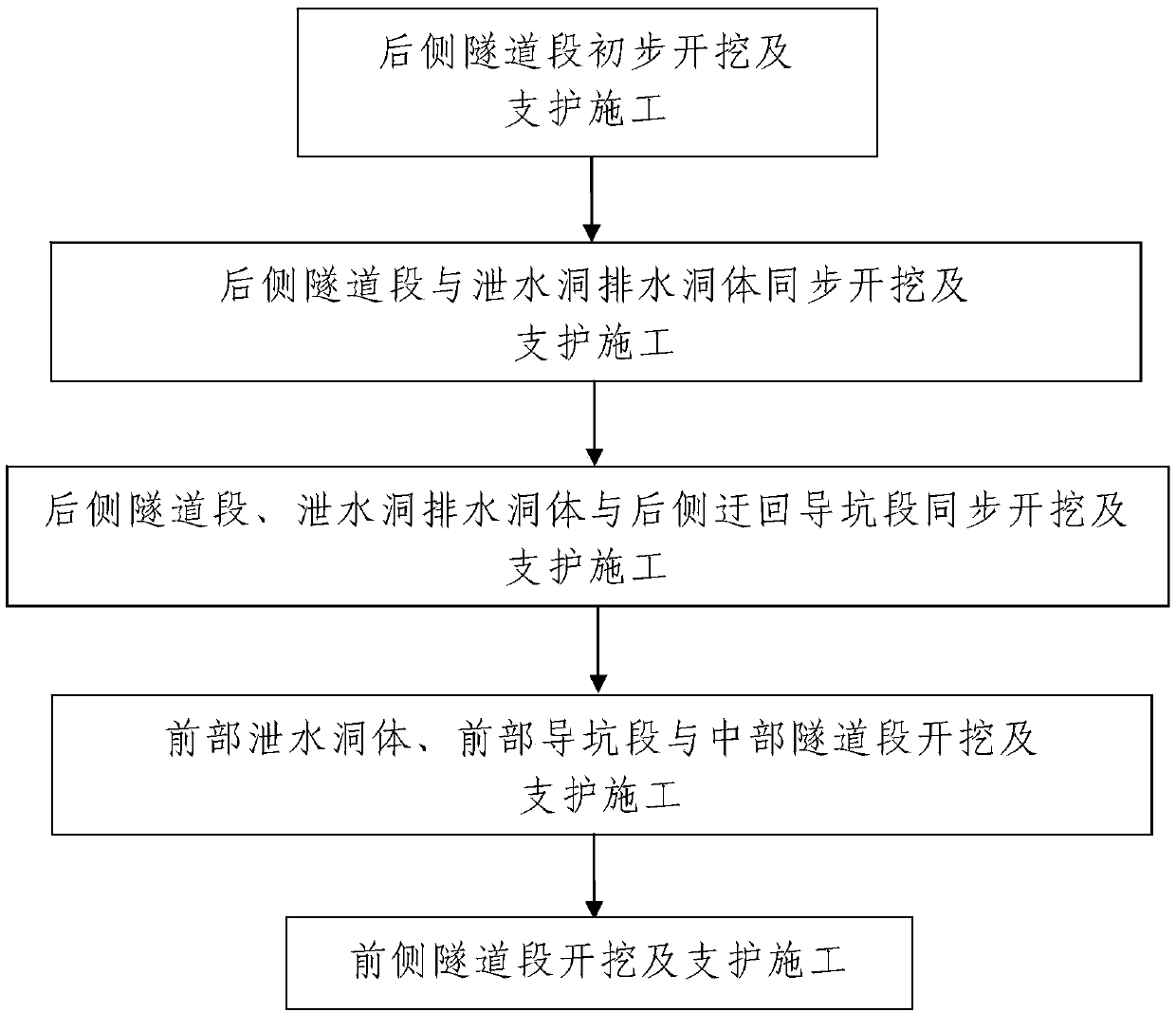

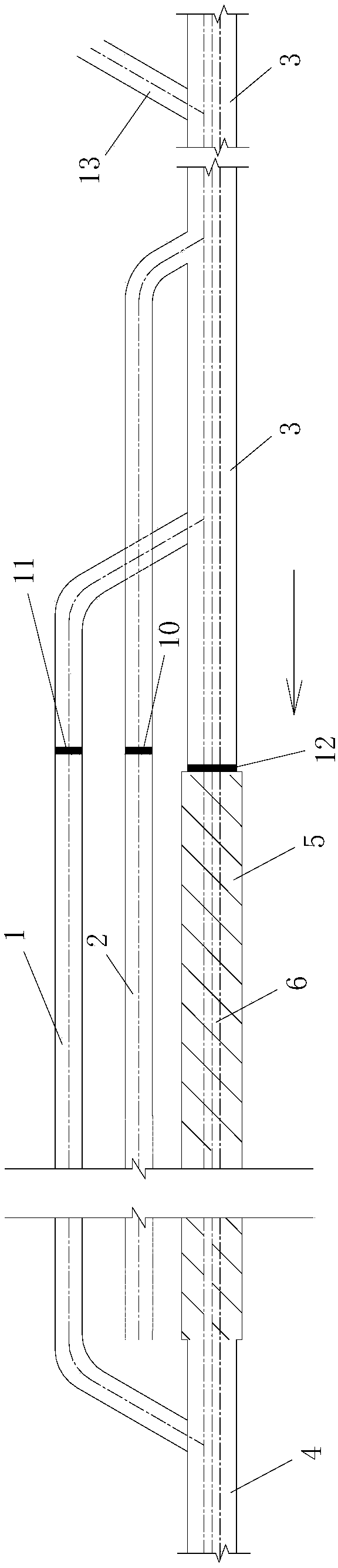

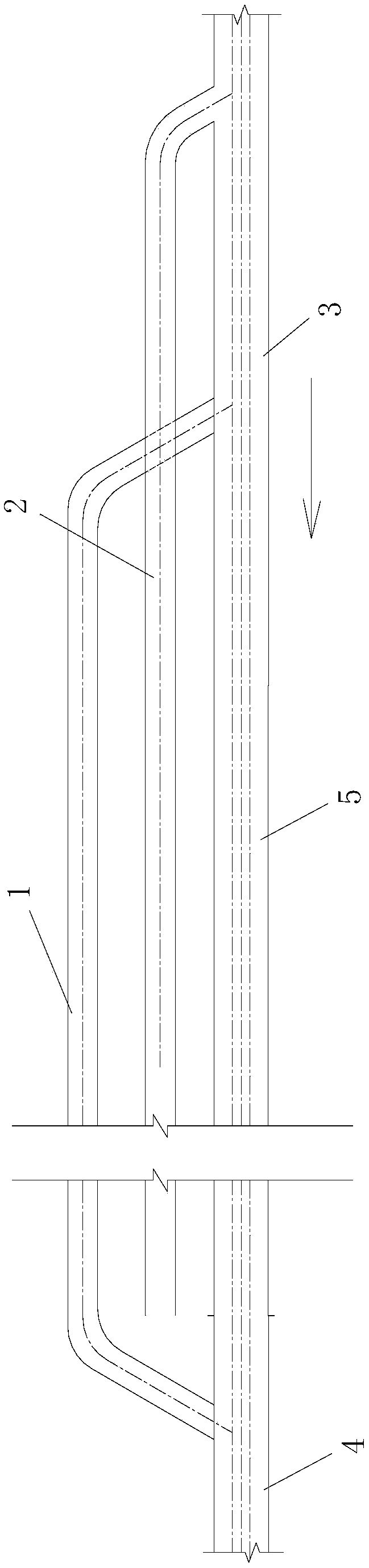

[0136] Such as figure 1 Shown is a tunnel excavation and support method that crosses a high-angle thrusting water-rich and sand-rich fault. The tunnel 21 of the constructed tunnel is divided into the rear tunnel section 3 and the front side of the rear tunnel section 3 Tunnel section 4 and the middle tunnel section 5 which is connected between the rear tunnel section 3 and the front tunnel section 4 and passes through the high-angle thrust water-rich and sand-rich fault 6, see details figure 2 , image 3 with Figure 4 On the same side of the main tunnel 21 of the tunnel under construction, there are a roundabout pilot pit 1 and a discharge tunnel 2. The roundabout pilot pit 1 and the discharge tunnel 2 are all passing through the high-angle thrusting water-rich and sand-rich fault 6 from back to front The detour pilot pit 1 is a detour pilot pit excavated between the rear tunnel section 3 and the front tunnel section 4, the detour pilot pit 1 and the construction tunnel 21 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lap length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com