Patents

Literature

147results about How to "Sound insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

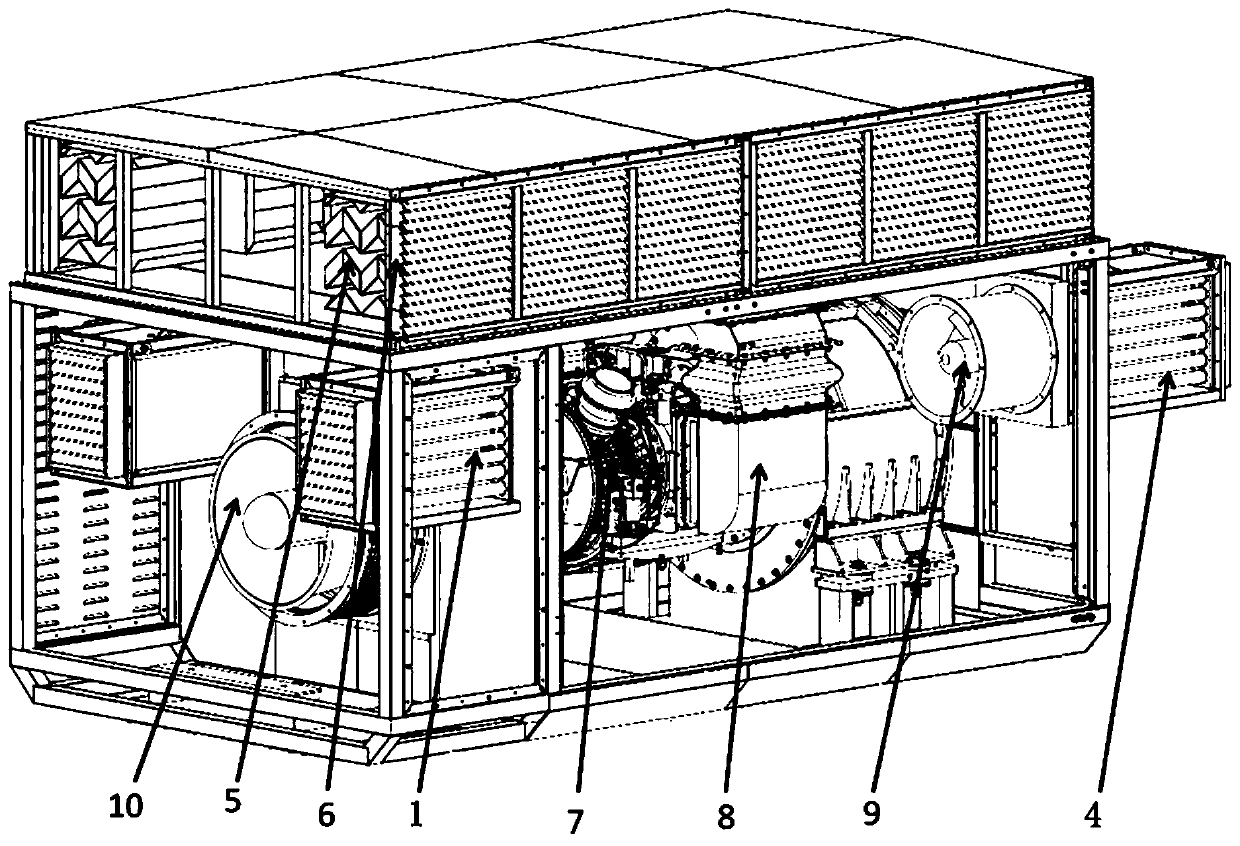

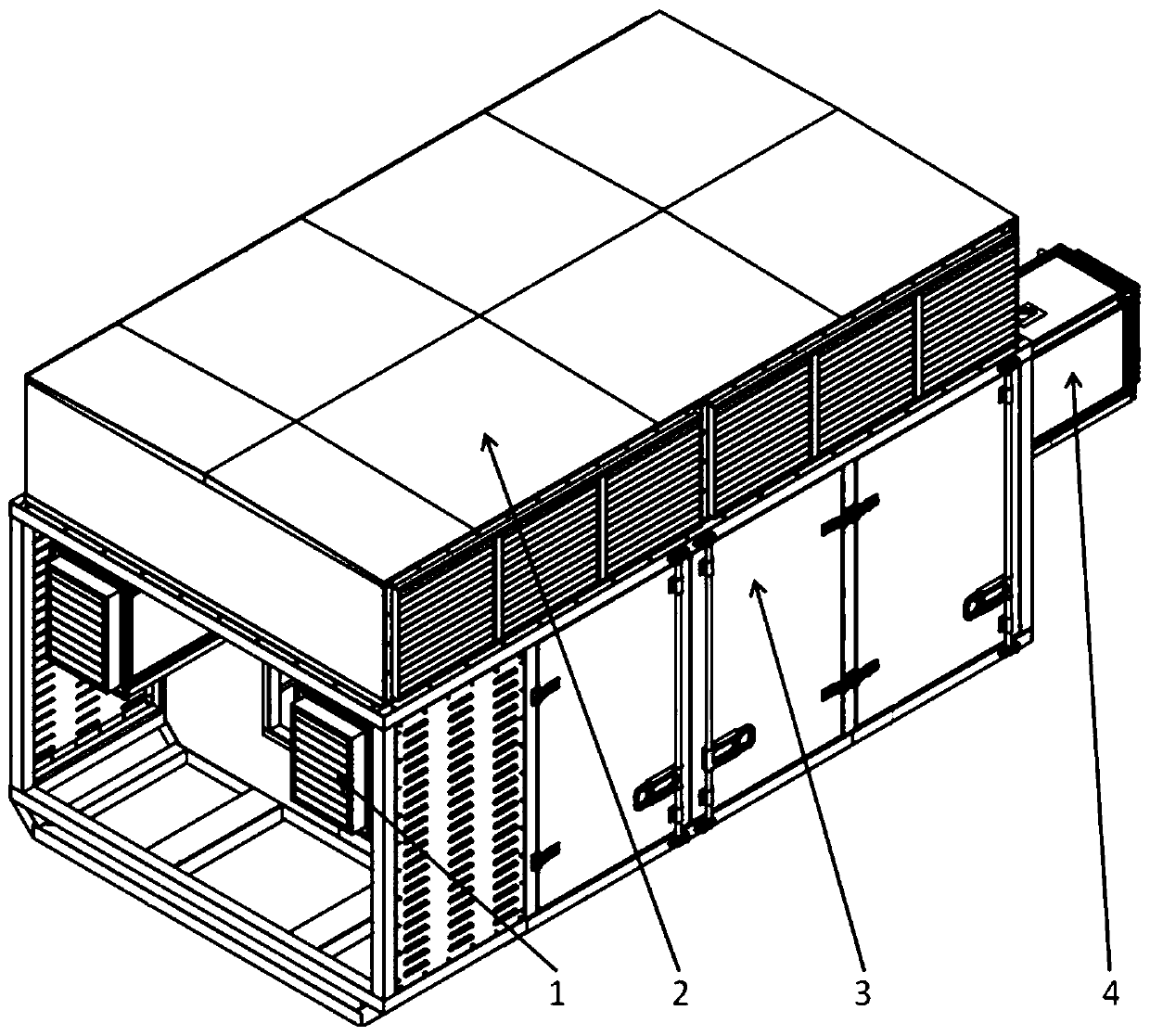

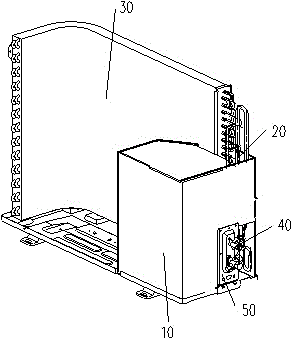

Sound insulation cabin of turbine engine

PendingCN110454285AAchieve noise reductionAchieve ventilationTurbine/propulsion engine coolingEngine fuctionsEngineeringNoise reduction

The invention discloses a sound insulation cabin of a turbine engine. The sound insulation cabin is arranged on the turbine engine in a sleeving mode, and comprises a cabin body, an intake noise reduction unit and a ventilation noise reduction unit; the intake noise reduction unit and the ventilation noise reduction unit are arranged on the cabin body, and the periphery of the cabin body is filledwith sound insulation materials; and the intake noise reduction unit is used for intake noise reduction of the turbine engine, and the ventilation noise reduction unit is used for noise reduction ofa ventilation system of the turbine engine. The sound insulation cabin has the beneficial effects that the intake noise reduction unit is additionally arranged at an air inlet of the turbine engine, and intake noise reduction of the turbine engine is achieved; the ventilation noise reduction unit is additionally arranged in the transmission direction of the turbine engine, and the ventilation andcooling noise reduction for the turbine engine is achieved; the periphery of the cabin body is filled with the sound insulation materials, and the overall noise reduction for the periphery of the turbine engine is achieved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

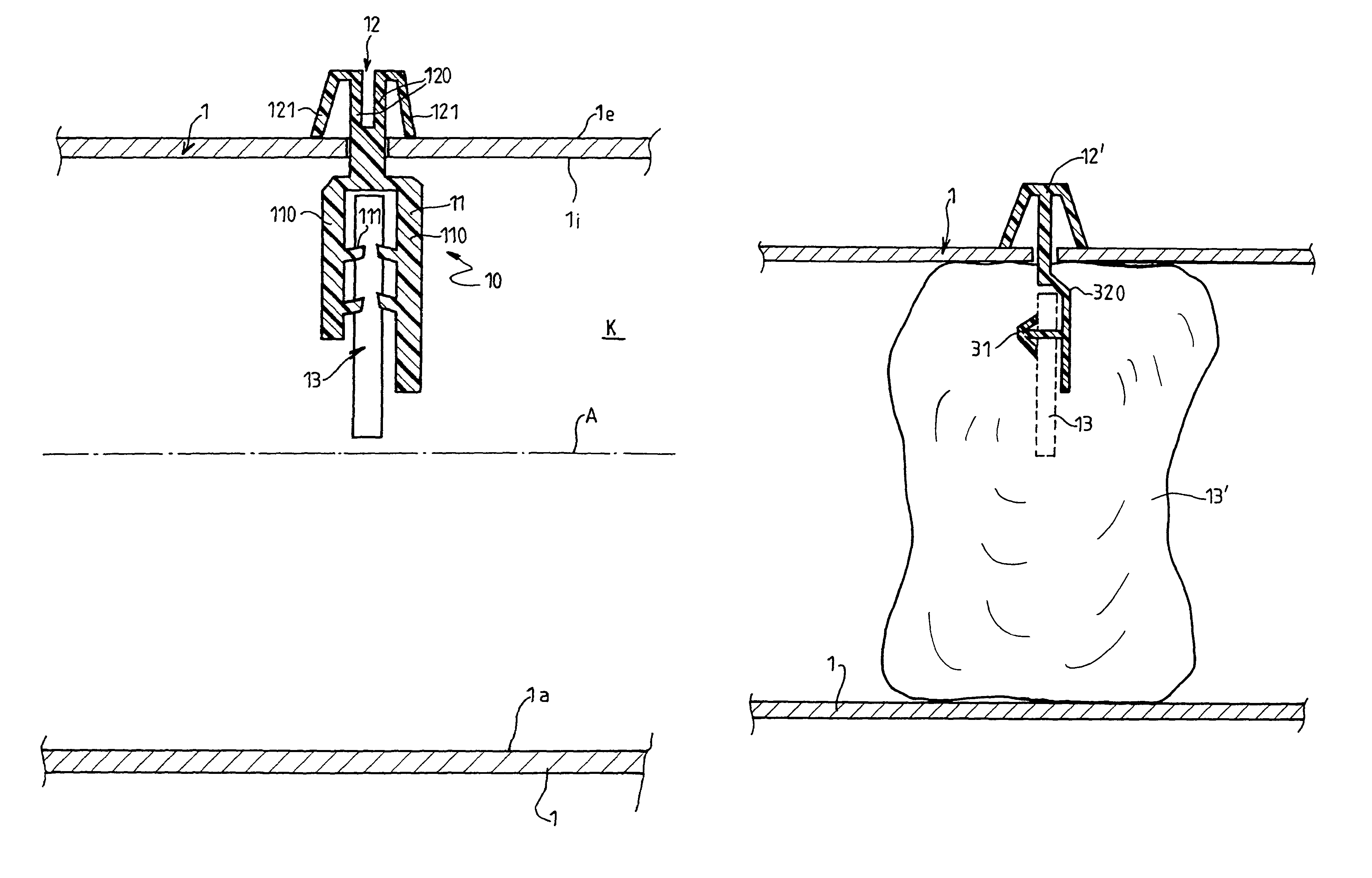

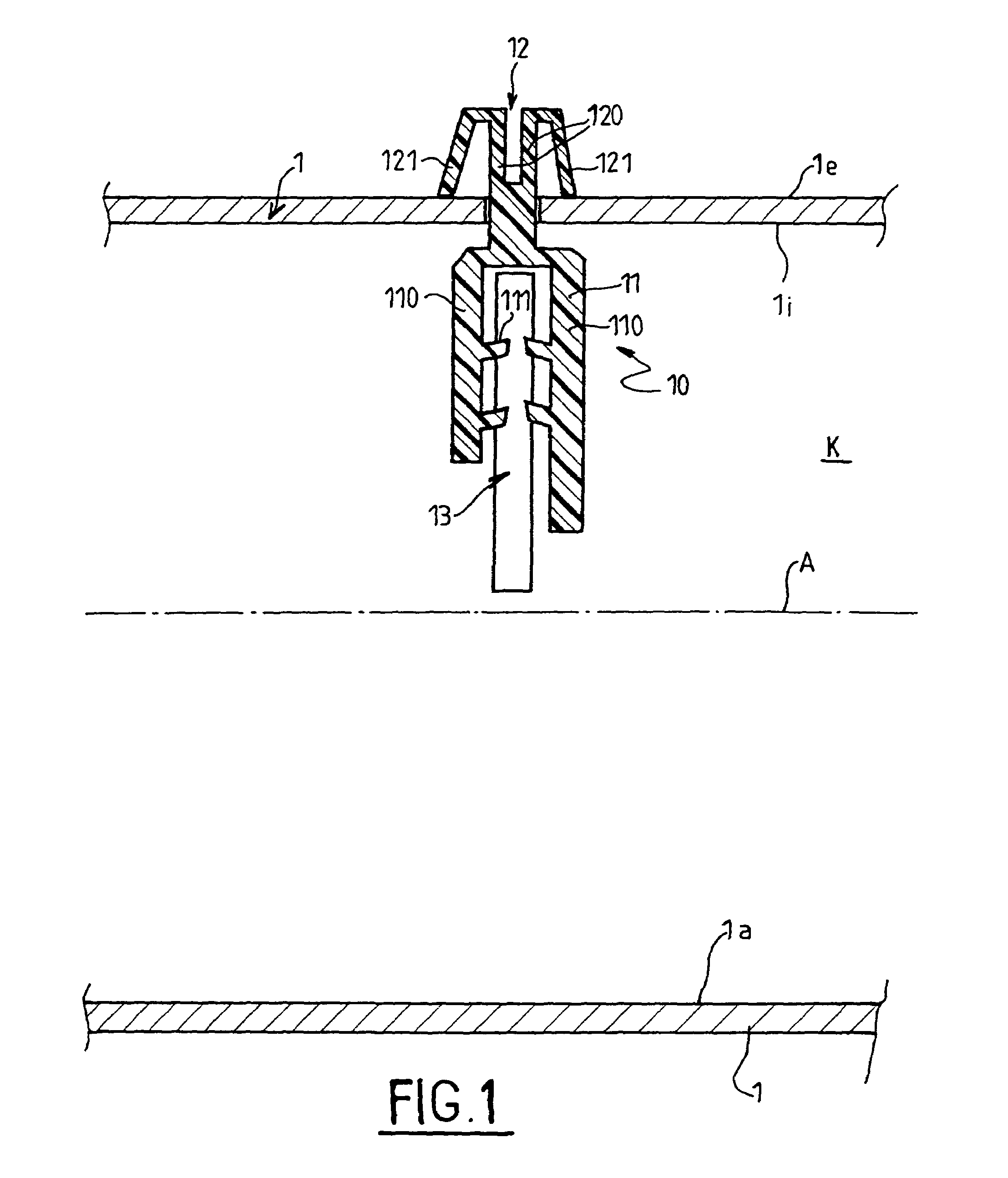

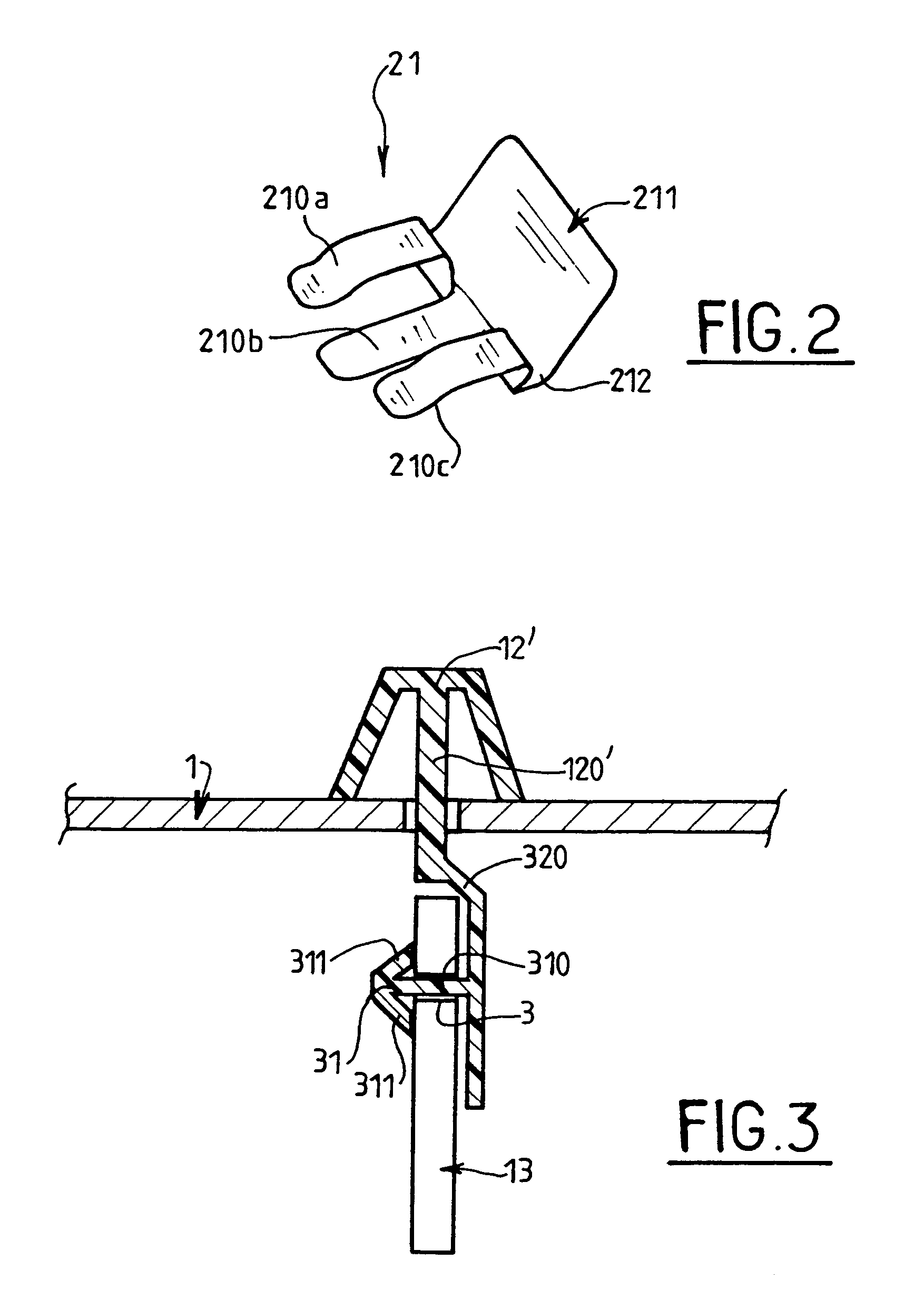

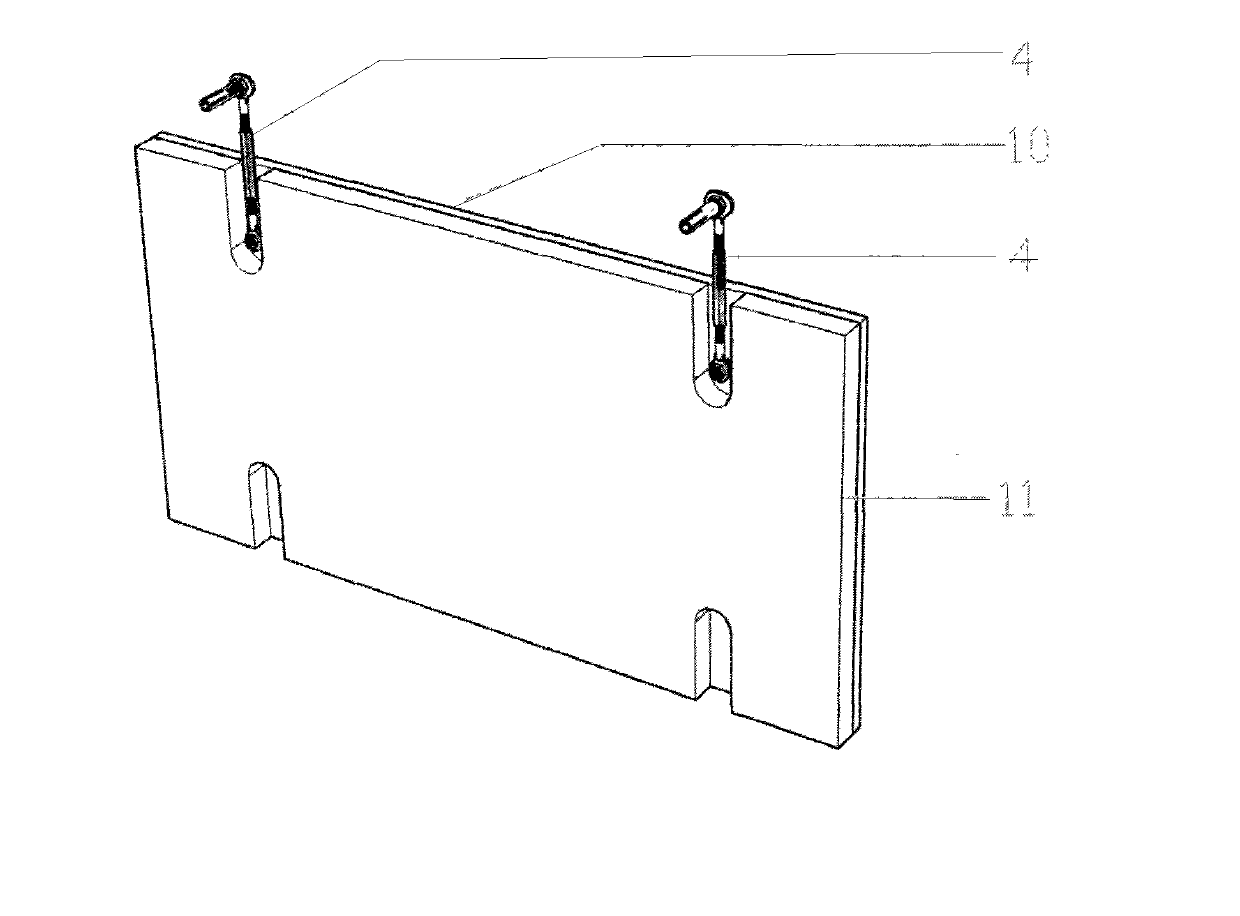

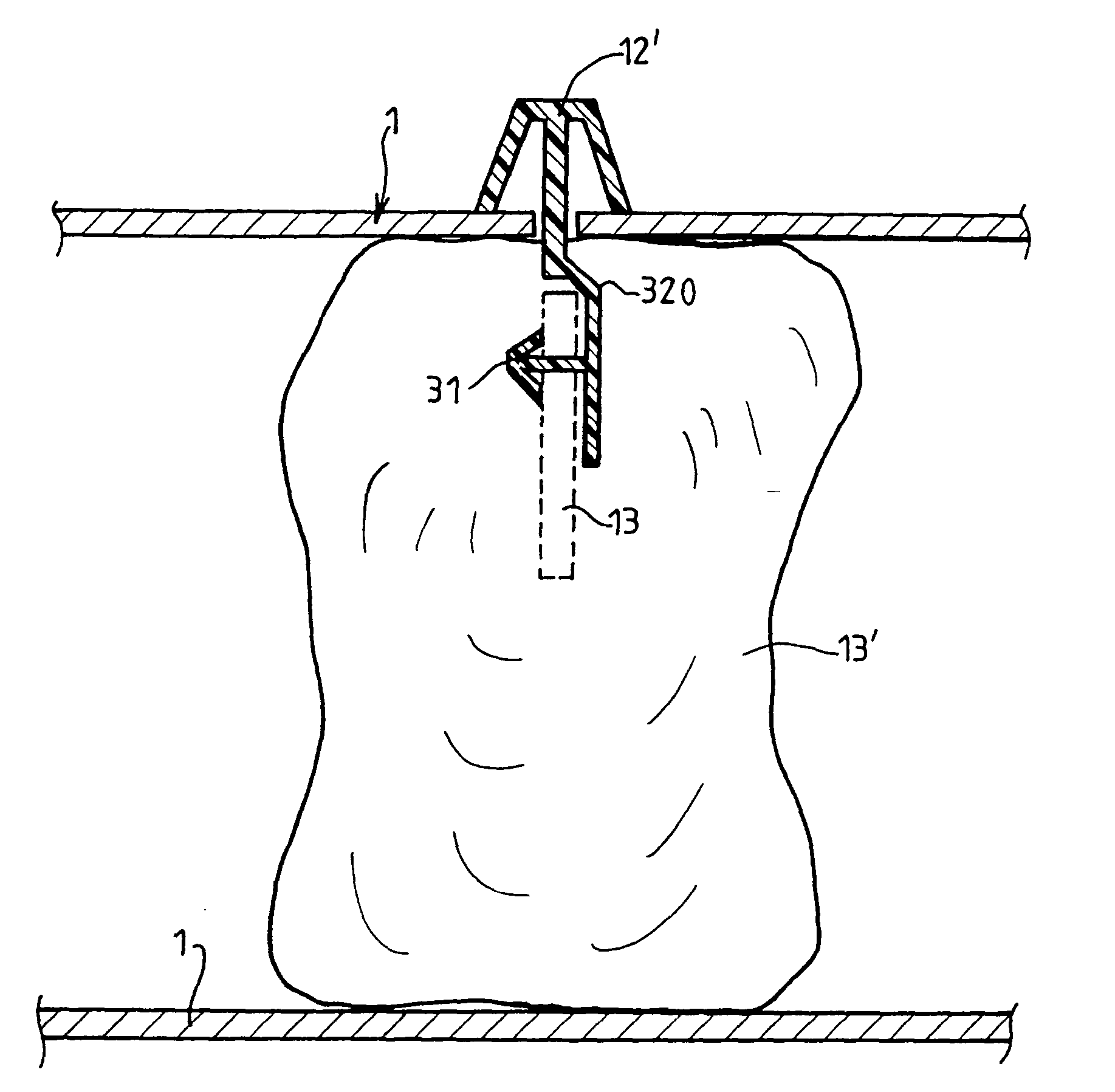

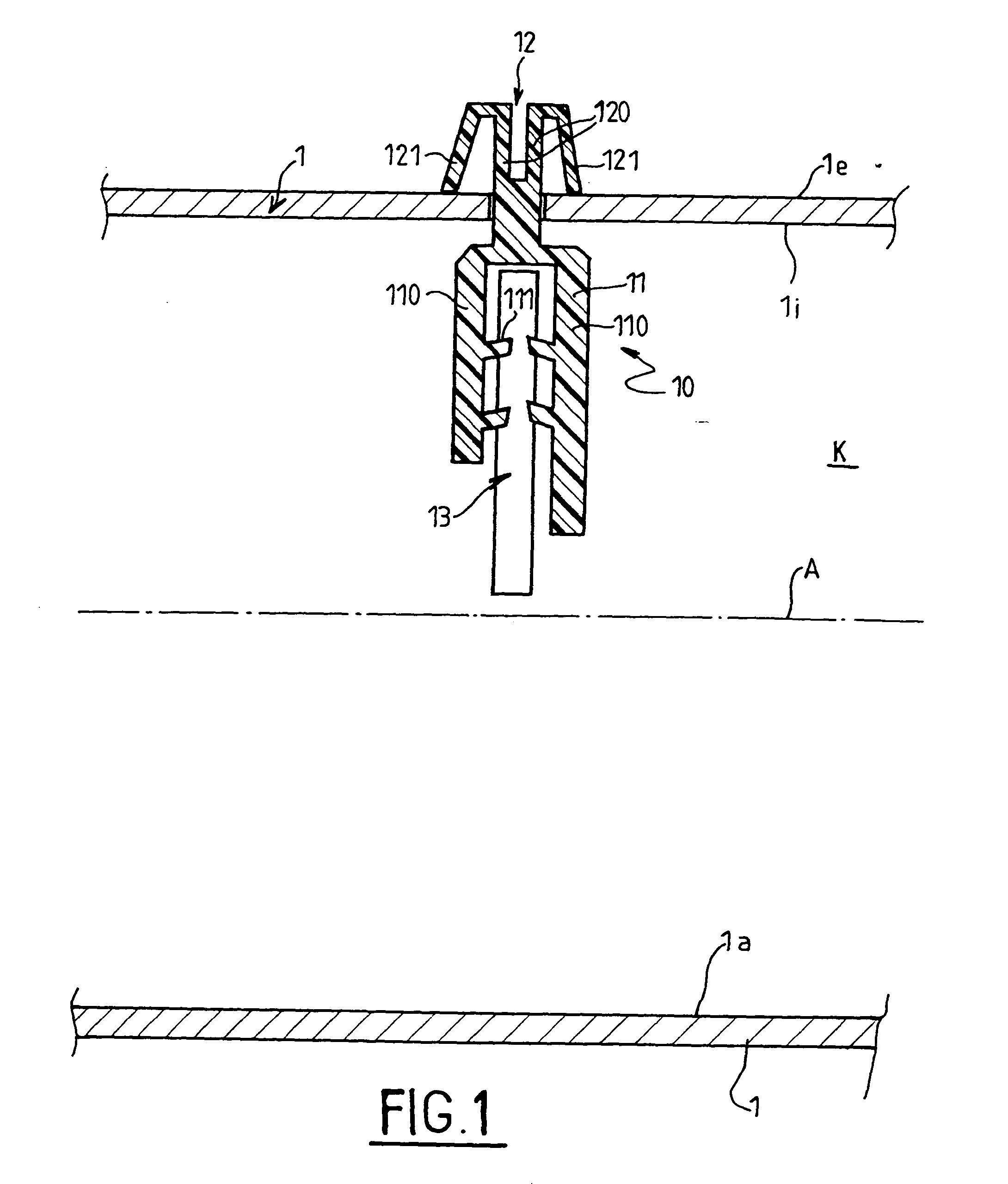

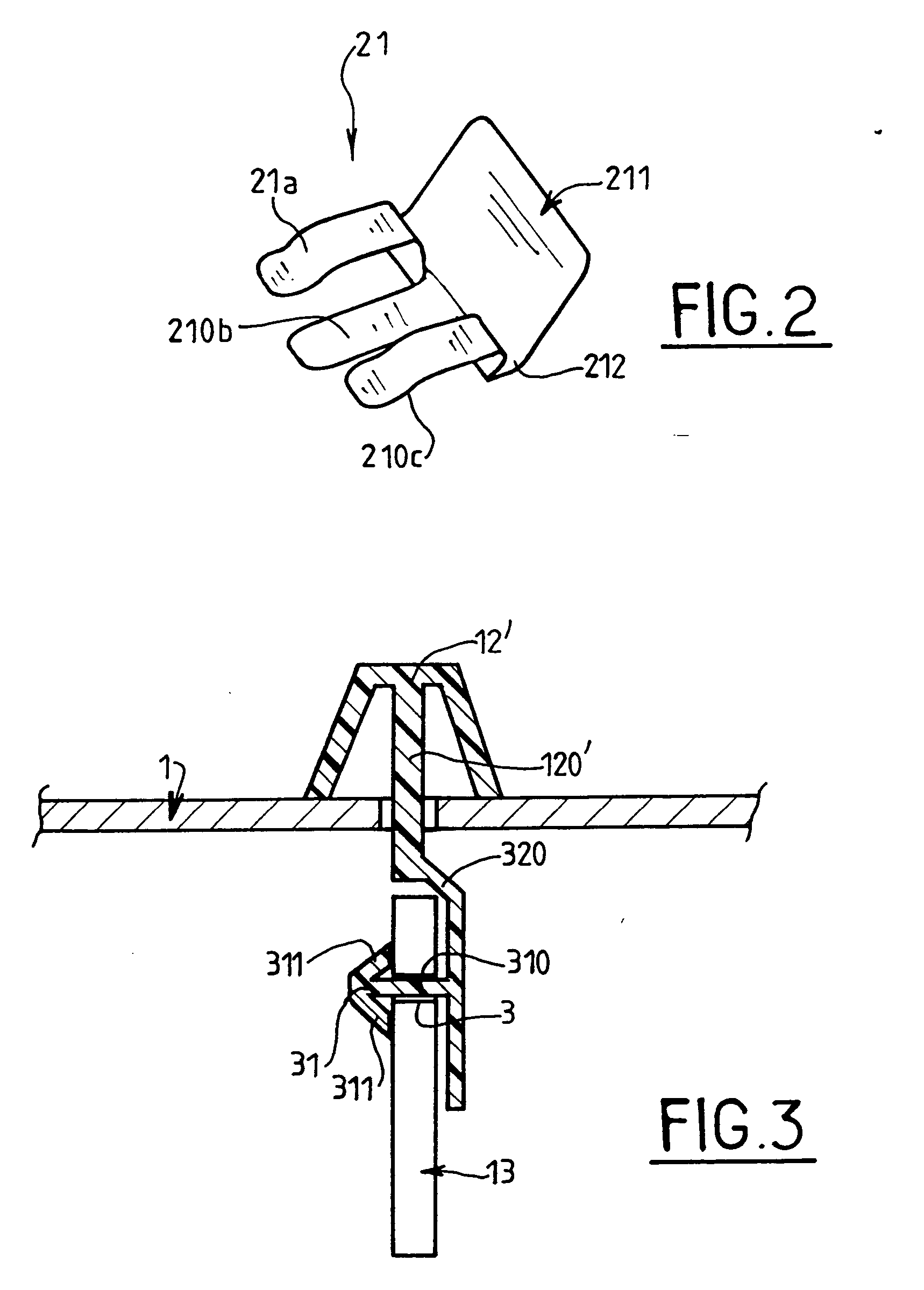

Sound insulation assembly for mounting in a tubular part, and a tubular part fitted with such assemblies, in particular a motor vehicle part

A sound insulation in tubular parts regardless of the section shape of the part, uses a piece of material that is suitable for expanding over the entire section of the section, which piece is mounted using a support suitable for fixing to the wall of the tube that is to be insulated. In a particular embodiment, a sound insulation assembly mounted in a part presenting a longitudinal direction and a tubular wall comprises a wafer that is thermally expandable to form a foam, said wafer having two parallel main faces and extending essentially along a main plane from a first wall portion towards the diametrically opposite wall portion, together with a wafer support comprising a clamp for retaining the wafer prior to expansion and coupled to fixing means in the form of a clip for fixing to the first wall portion of the part.

Owner:SEALANTS EURO SAS

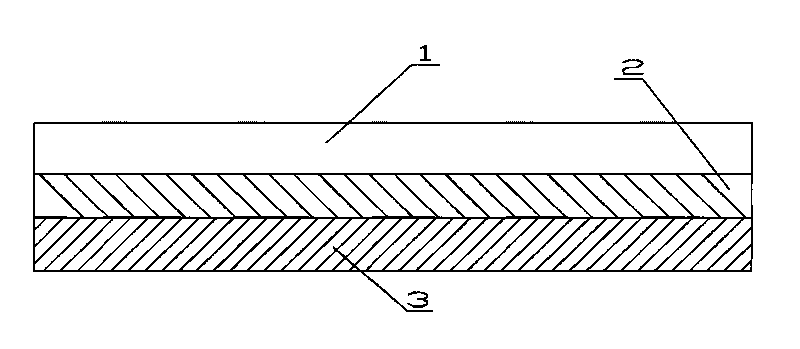

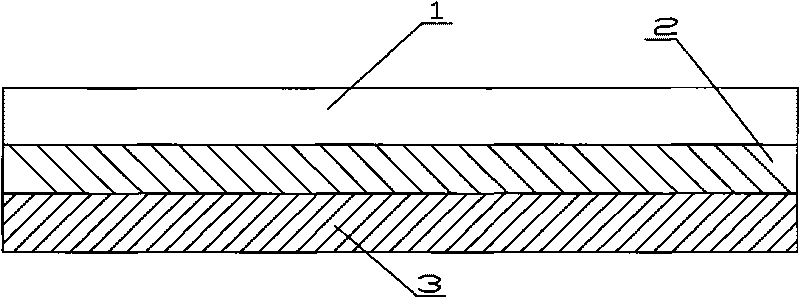

Universal health-care board and preparation method thereof

ActiveCN102514254AGood elastic recoveryGood strength and elasticityStuffed mattressesLamination ancillary operationsFiberSurface layer

Owner:JIANGSU REDBUD DYEING TECH CO LTD

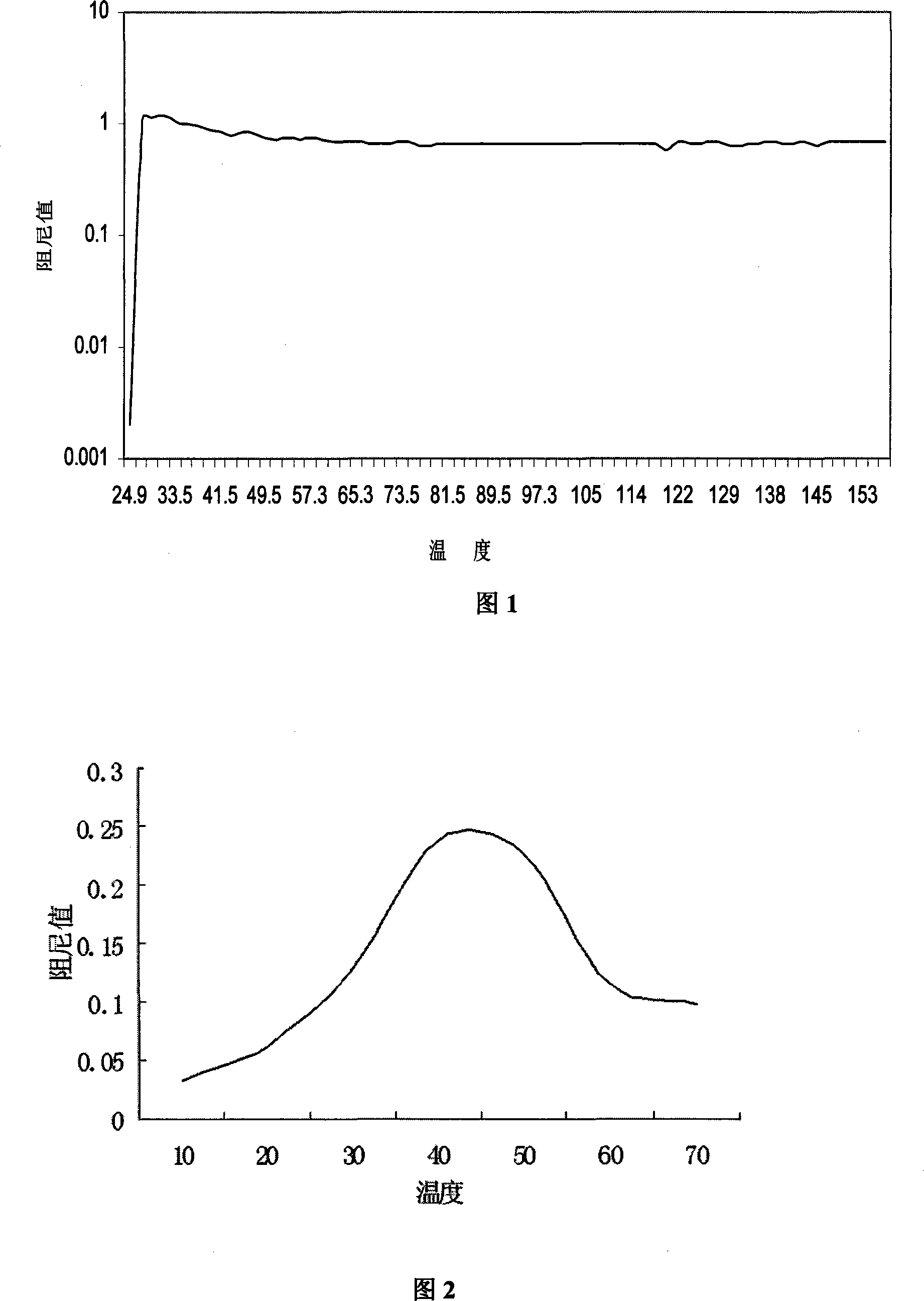

Polyacrylates interpenetrating network polymer emulsion and high damping material thereof

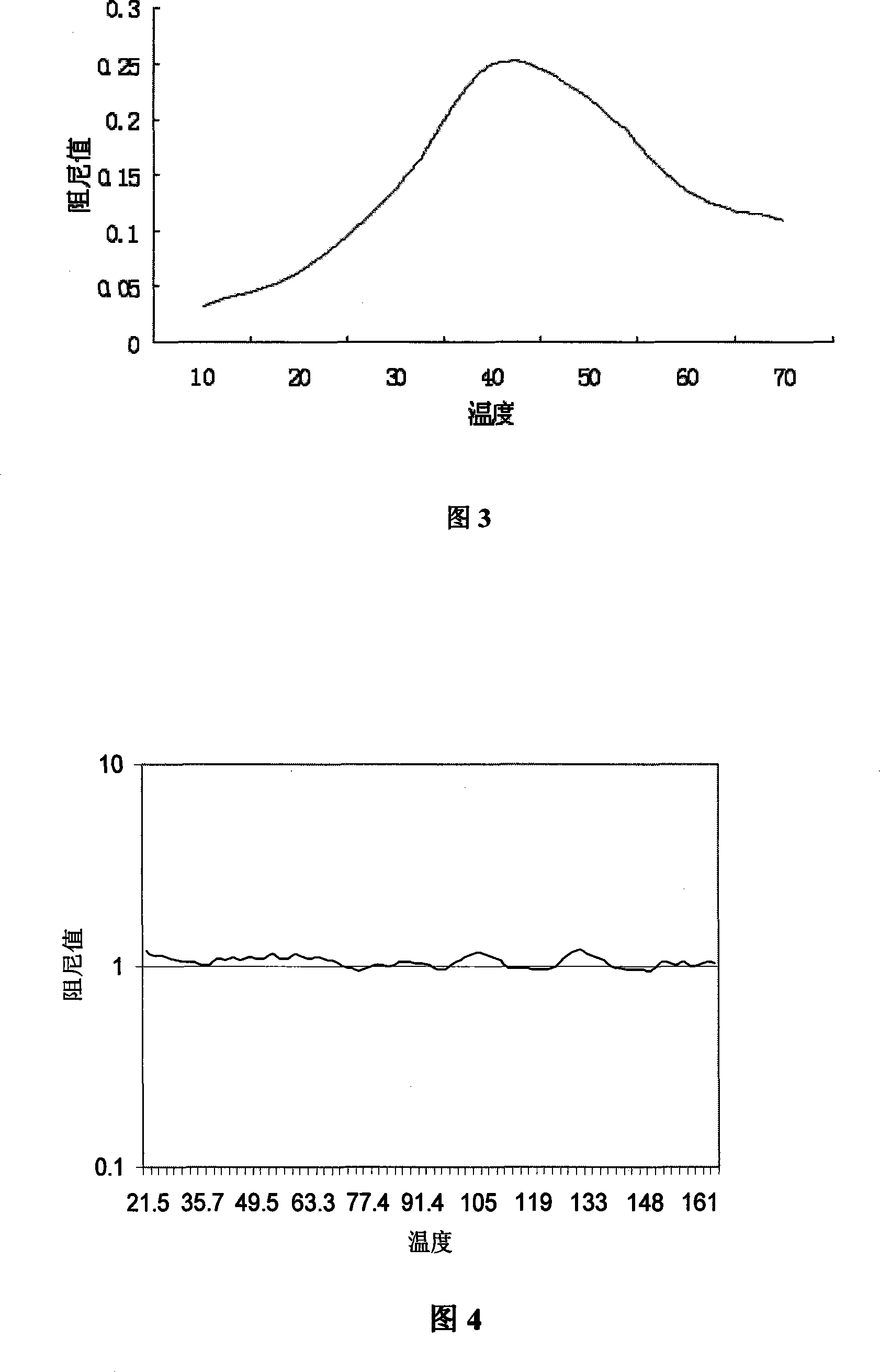

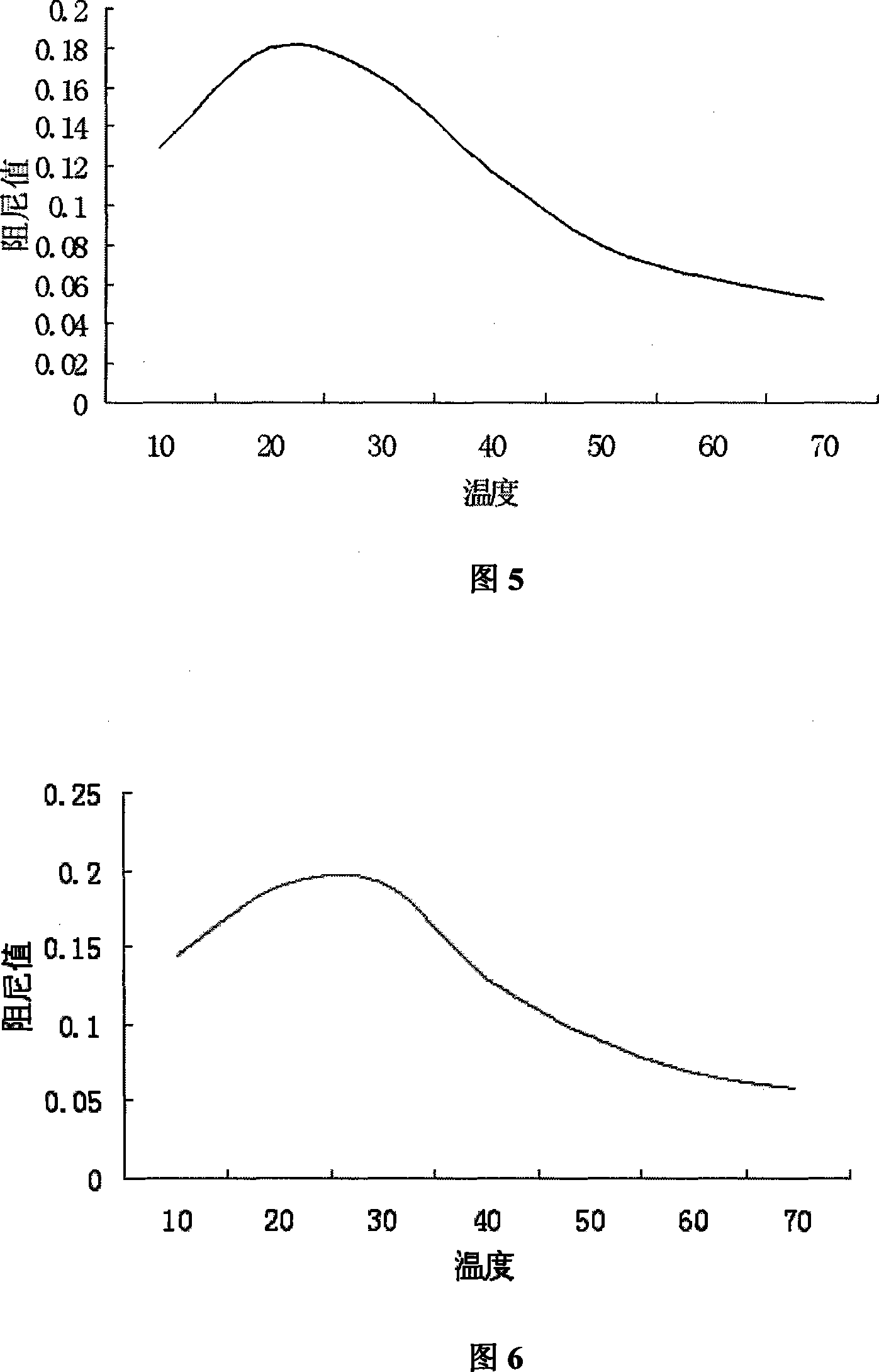

The invention provides polyacrylic ester interpenetrating network polymer emulsion and highly damped materials, pertaining to the high molecular polymer technological field. The polymer emulsion group consists of protecting adhesive, emulsifier, activator, buffering agent, cross-linking agent, water and monomers, wherein, the monomers comprises butyl acrylate, methacrylic acid, acrylic acid epoxy propyl ester, cinnamene, etc., and polymerize in an interpenetrating network shape. The highly damped materials used for decreasing vibration of vehicles are prepared by the emulsion after addition agent, filing materials and water are added. Since the emulsion of the invention, hollow glass microbeads and talc are used as the important components of the filling materials, the high molecular adhesive and elastic material of the invention has better damped performance, the tenacity and elasticity of the material are enhanced, the intensity of tension, and flexural rigidity resistance and wearing resistance of the material are improved, therefore, the effects of vibration decreasing, noise decreasing, sound and heat insulation can be achieved under various complicated conditions.

Owner:JILIN UNIV

Method for paving and sticking stone materials or ceramic tiles

The invention provides a construction method for paving and sticking stone materials or ceramic tiles on a wall or floor. The construction method comprises the following steps: sticking an extruded sheet on the back of a plate to be paved and stuck in advance and mounting stainless steel back bolts; sticking and hanging materials to be paved and stuck on the wall by using adhesive and hanging pieces so as to achieve a firm paving and sticking effect.

Owner:陈晓通

Sound insulation assembly for mounting in a tubular part, and a tubular part fitted with such assemblies, in particular a motor vehicle part

ActiveUS20040070232A1Low costSound insulationVehicle seatsPipe elementsMobile vehicleMotor vehicle part

The invention seeks to solve the problem of providing sound insulation in tubular parts regardless of the section shape of the part that is to be insulated, and without using an insert that is of high cost. To this end, the invention proposes using a piece of material that is suitable for expanding over the entire section of the section, which piece is mounted using a support suitable for fixing to the wall of the tube that is to be insulated. In a particular embodiment, a sound insulation assembly mounted in a part presenting a longitudinal direction and a tubular wall comprises a wafer that is thermally expandable to form a foam, said wafer having two parallel main faces and extending essentially along a main plane from a first wall portion towards the diametrically opposite wall portion, together with a wafer support comprising a clamp for retaining the wafer prior to expansion and coupled to fixing means in the form of a clip for fixing to the first wall portion of the part.

Owner:SEALANTS EURO SAS

Waste-cotton composite automotive carpet

ActiveCN101716902AWith shockproof effectLow costVehicle arrangementsNon-woven fabricsResistPolyester

The invention relates to a waste-cotton composite automotive carpet comprising a fabric layer, a backing layer and an adhesive layer of the fabric layer and the backing layer. The waste-cotton composite automotive carpet is characterized in that the fabric layer is made of polyester; the adhesive layer is formed by melting polyethylene at a high temperature; the backing layer is formed by mixing mekralon, polyester and waste cotton. The invention adopts a three-layer structure so that the surface style of the product can be kept, and the carpet has shockproof action due to the relatively loose backing layer which forms a porous structure by combing and prickling polypropylene, waste cotton and mixed polyester fiber to take the soundproofing and thermal-insulating effects; polypropylene added to the backing layer is melted at a high temperature to satisfy the molding requirement of the carpet and replace a traditional adhesive (such as acrylic acid); the polyethylene between the fabric layer and the backing layer is melted at a high temperature to take the adhesive, waterproof and crease-resist effects; the backing layer adopts recycled leftovers so as to recycle the original leftovers, lessen the environmental pollution and decrease the cost.

Owner:怡星(无锡)汽车内饰件有限公司

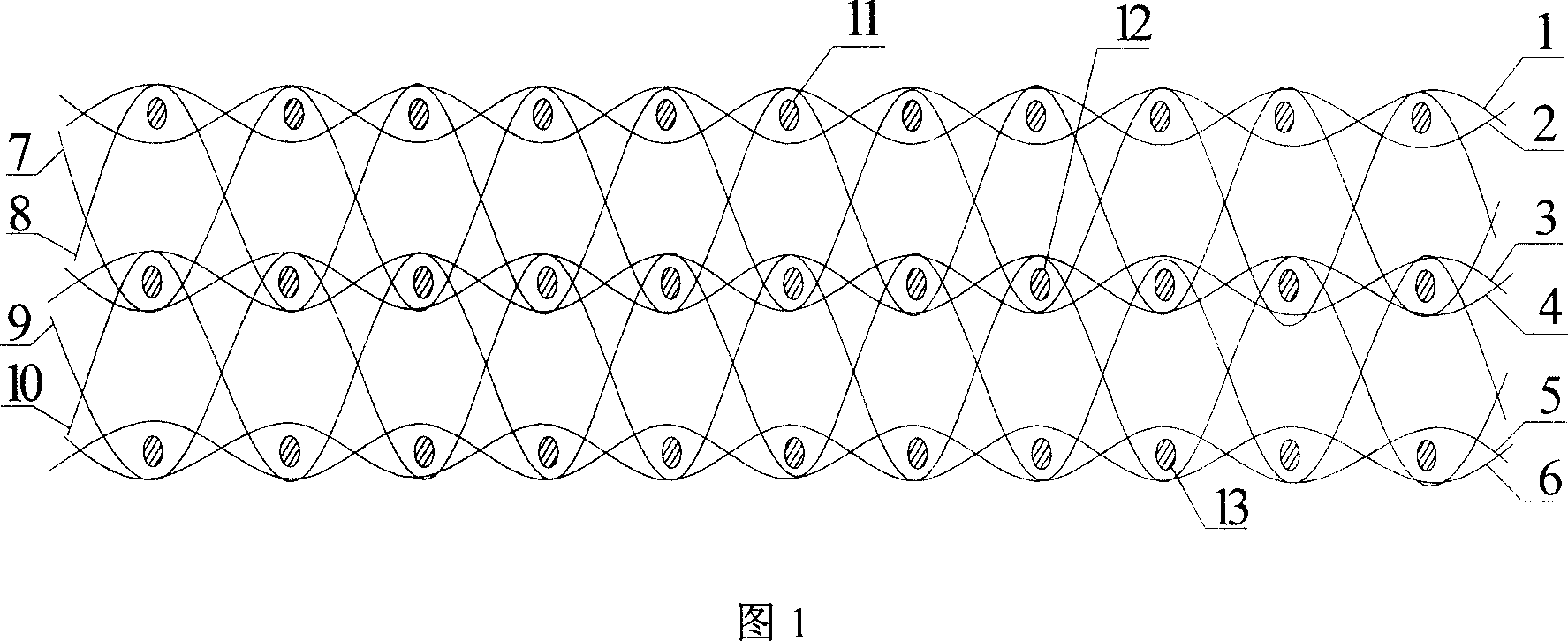

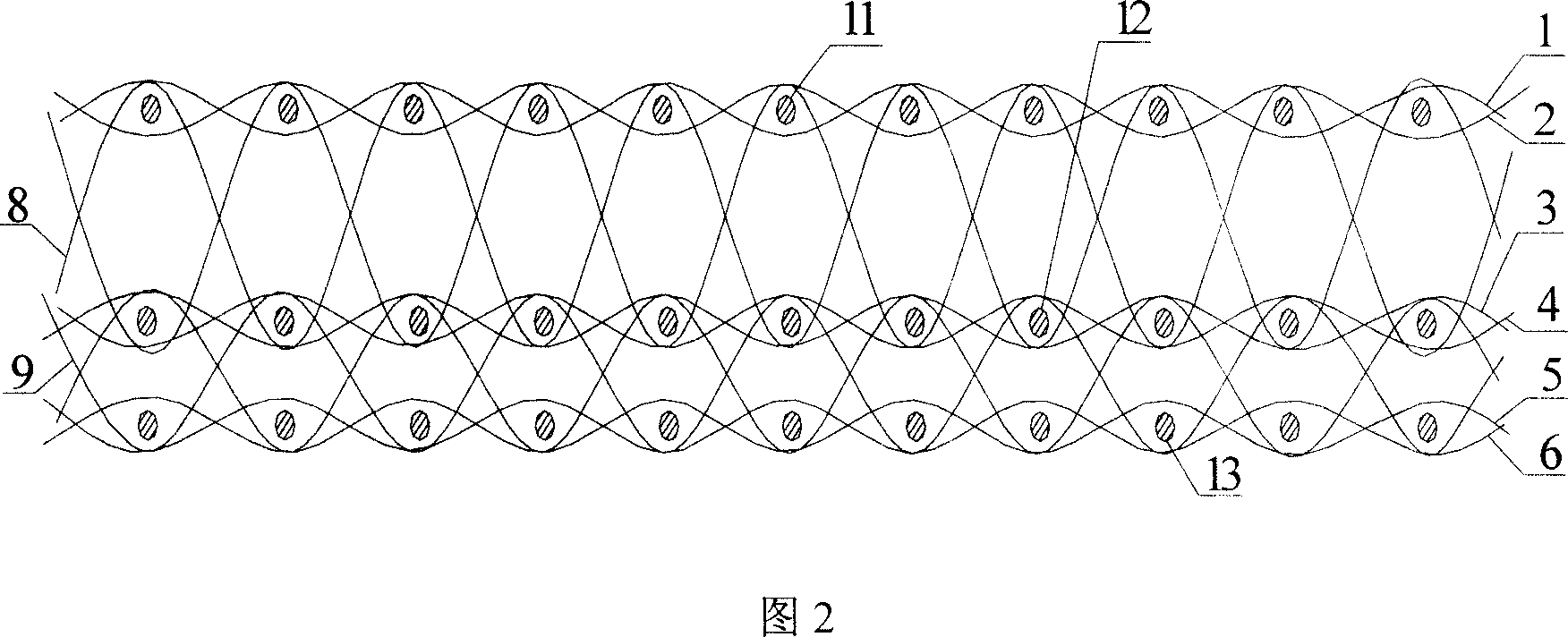

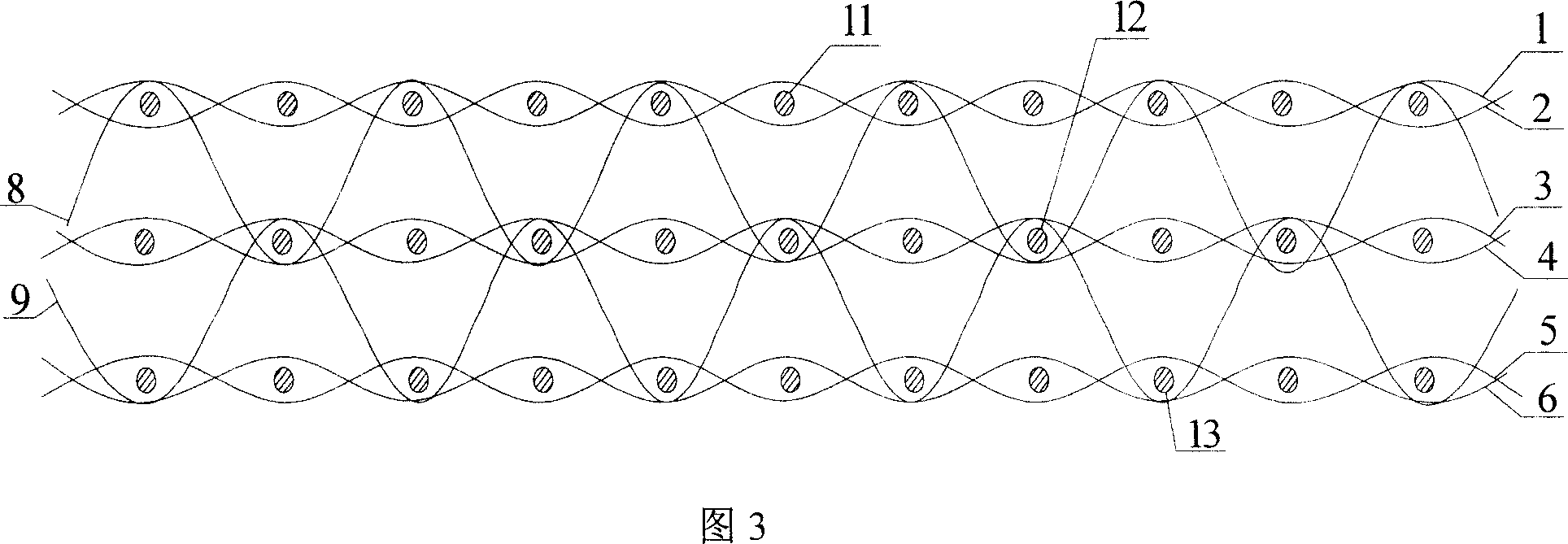

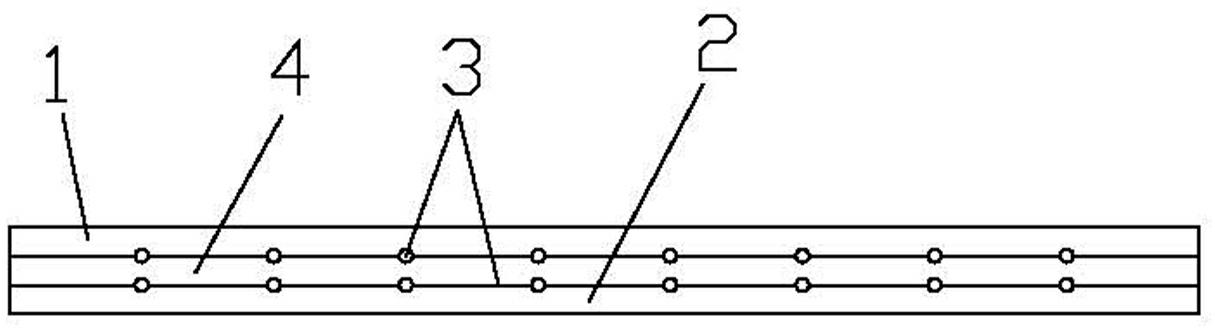

Three-dimensional hollow double sandwiched fabric

InactiveCN1974899ANot too high problem solvingImprove impact resistanceWoven fabricsEngineeringWeft yarn

The three-dimensional hollow double sandwiched fabric consists of one upper layer interwoven with two upper ground warp layers and one upper weft yarn layer, and one lower layer interwoven with two lower ground warp layers and one lower weft yarn layer, as well as one middle layer interwoven with two middle ground warp layers and one middle weft yarn layer. The weft yarn layers in the upper layer, the middle layer and the lower layer are also interwoven with the poil warps, so that the upper layer, the middle layer and the lower layer are connected integrally to form one hollow double sandwiched structure. The fabric of the present invention is uses as reinforcing body of composite material, and the composite material with the fabric is light, high in impact strength, high in antiwear performance, high in bending performance and high in rigidity. The double sandwiched structure may be also used in heat insulation, anticorrosion, real-time monitoring, etc.

Owner:SINOMA SCI & TECH

Composite health care pad and manufacture method thereof

InactiveCN102514257AGuaranteed performanceGuaranteed breathabilityStuffed mattressesLamination ancillary operationsFiberSurface layer

The invention discloses a composite health care pad, which comprises a middle layer, wherein an upper surface layer and a lower surface layer are respectively arranged on the upper surface and the lower surface of the middle layer, a layer of blocking layer is respectively arranged between the middle layer and the upper surface layer and / or between the middle layer and the lower surface layer. The upper surface layer and the lower surface layer are non-woven layers containing 5%-50% low-melting-point fibers, and the middle layer is a non-woven layer containing the following components: fibrilia and 5%-50% of low-melting-point fibers. The blocking layers are non-woven layers containing 5%-100% of fibrilia, and the content of fibrilia in the composite health care pad ranges from 5% to 65%. The invention further discloses a manufacture method of the composite health care pad, which includes the following steps: respectively manufacturing the middle layer, the upper surface layer, the lower surface layer and the blocking layers, sequentially overlaying all the layers, and carrying out procedures including drying in a drying oven, cold rolling, cooling, cutting, inspection and packing. The composite health care pad and the manufacture method thereof solve the problems that the existing mattress can become damp and mildewed easily, can be damaged by worms, is apt to be layered, and is poor in ventilation and inconvenient to use caused by the fact that hard fibers in the middle of the mattress prick out.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

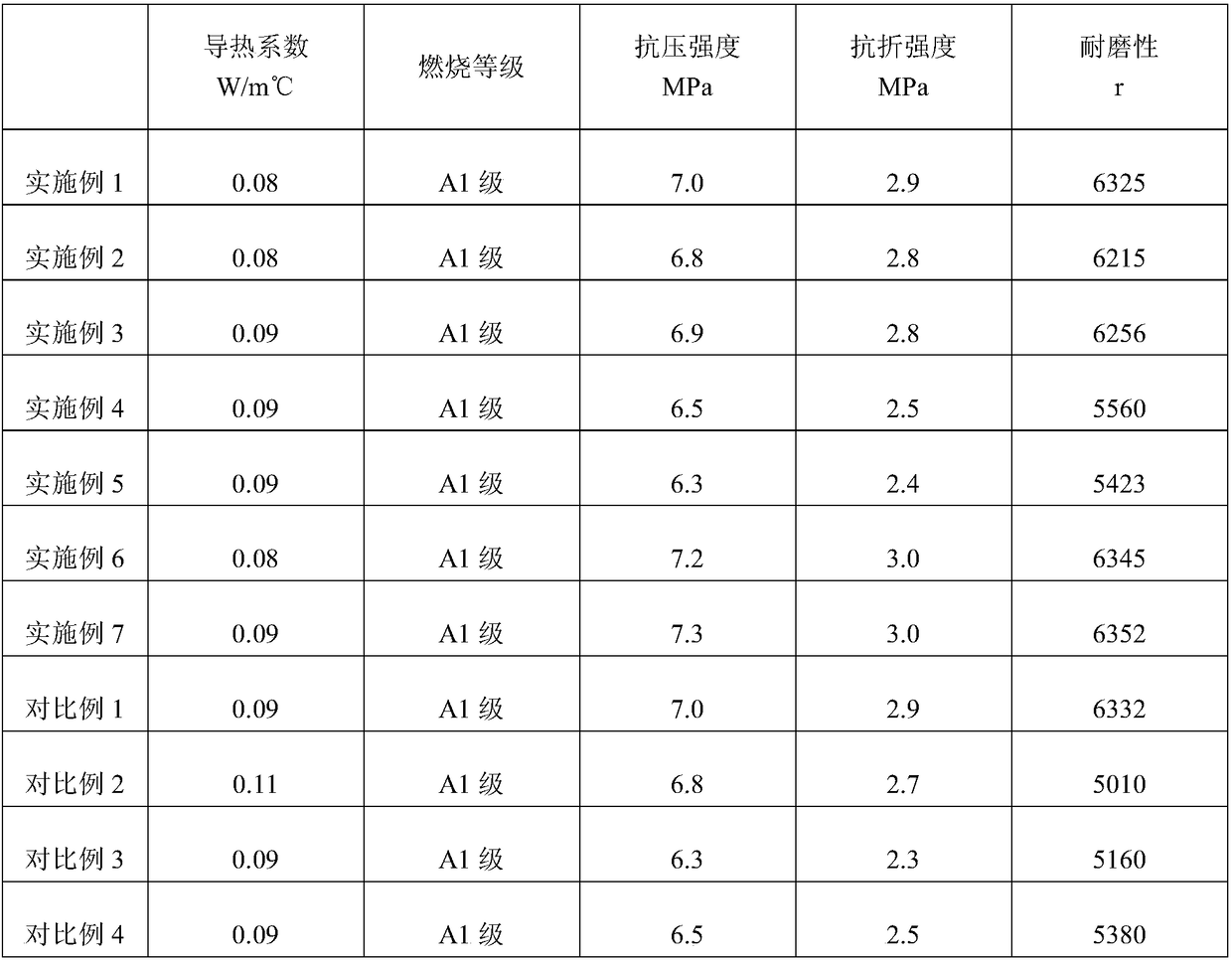

Lightweight, high-strength and high-toughness foamed ceramic decorative integrated board and production method thereof

ActiveCN109291549AFlame retardantWith insulationLaminationLamination apparatusSodium phosphatesWear resistant

The invention discloses a lightweight, high-strength and high-toughness foamed ceramic decorative integrated board. The board comprises a foamed lightweight material layer, a high-toughness decorativesurface layer and a wear-resistant coating layer; the foamed lightweight material layer comprises stone tailings, graphene, zirconia, a high-temperature flux, clay, a stabilizer and a dispergator; and the high-toughness decorative surface layer includes an AC foaming agent, the stabilizer, calcium carbonate, high-strength resin, a processing aid and a lubricant. The wear-resistant coating layer comprises graphene, silicon carbide whiskers, corundum powder, vermiculite, kaolin, a flame retardant, nanometer titanium dioxide, sodium phosphate, sodium silicate, hydroxyethyl cellulose, a silicone-acrylic emulsion and silica sol. The high-toughness decorative surface layer made from soft porcelain and the foamed lightweight material layer are bonded by compression molding, and the surface of the high-toughness decorative surface layer is coated with the wear-resistant coating layer, so the board has the advantages of good toughness, light weight, high strength, flame retardation, thermal insulation, good waterproof and impermeable effects and good anti-aging effect.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

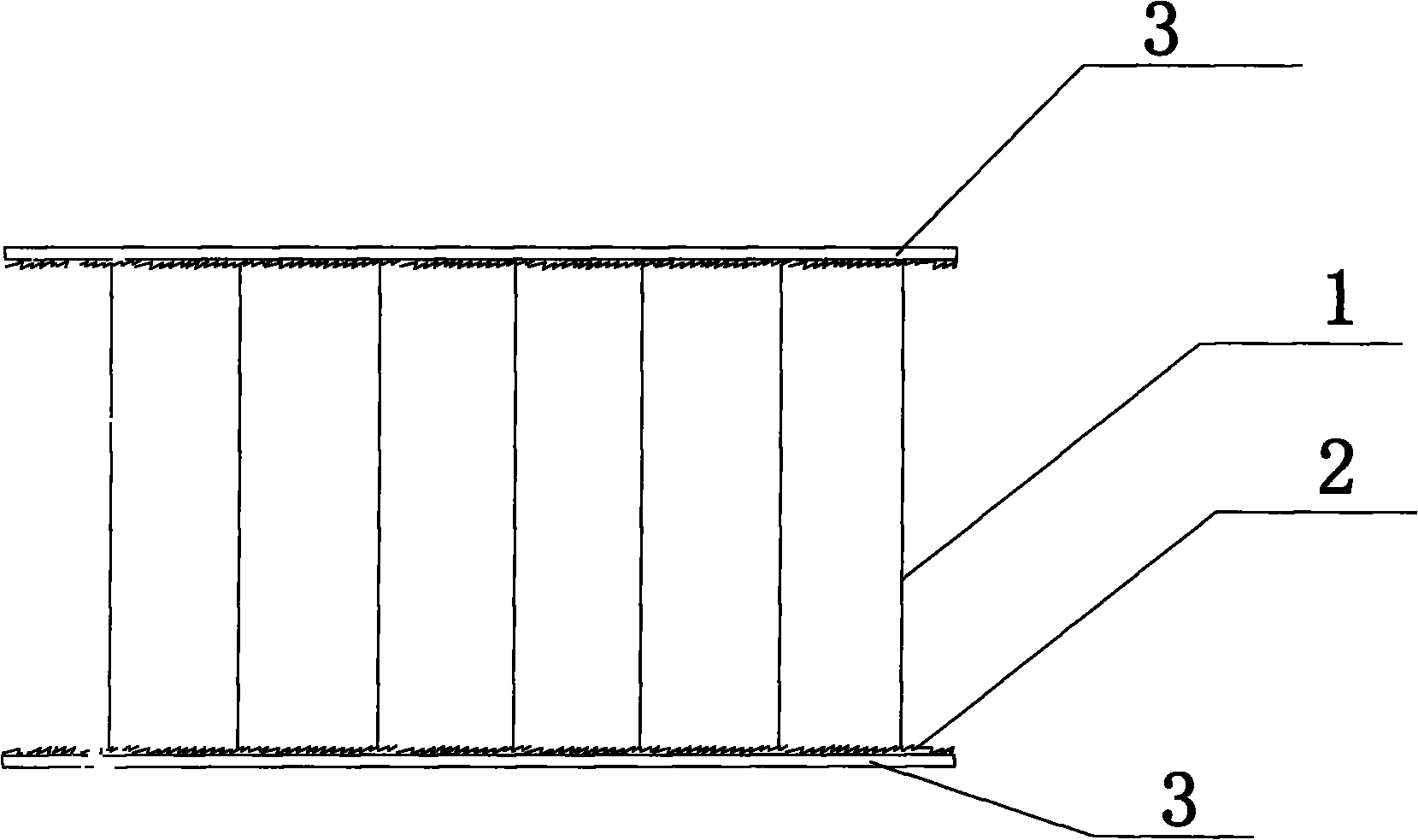

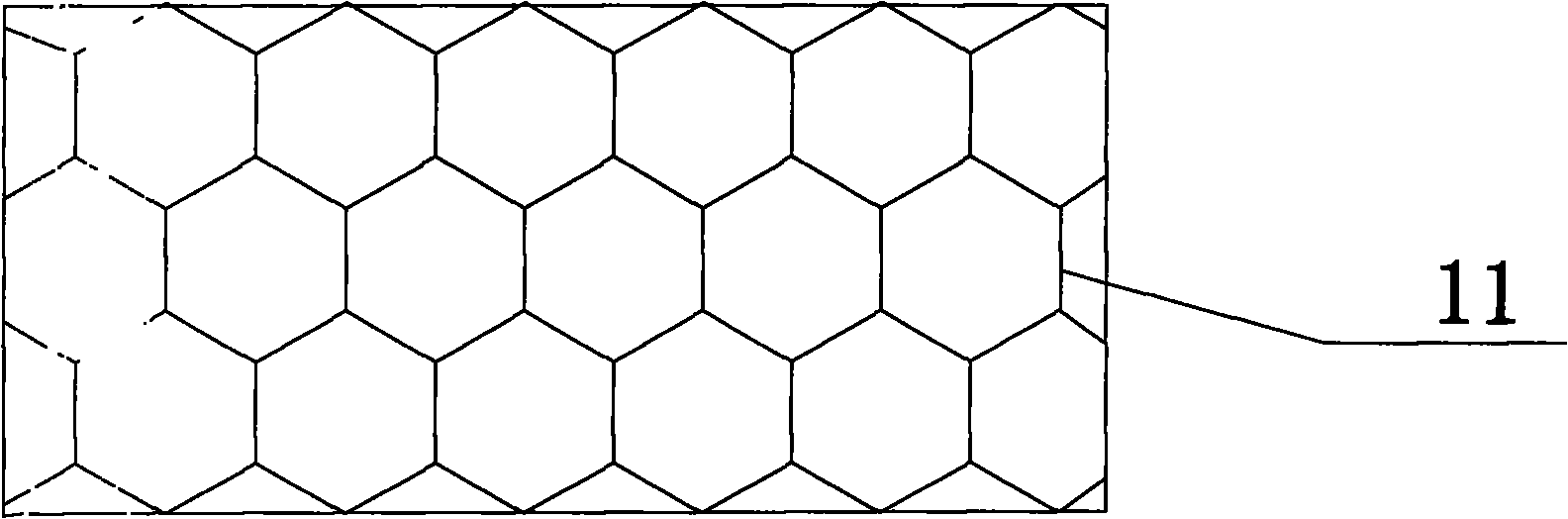

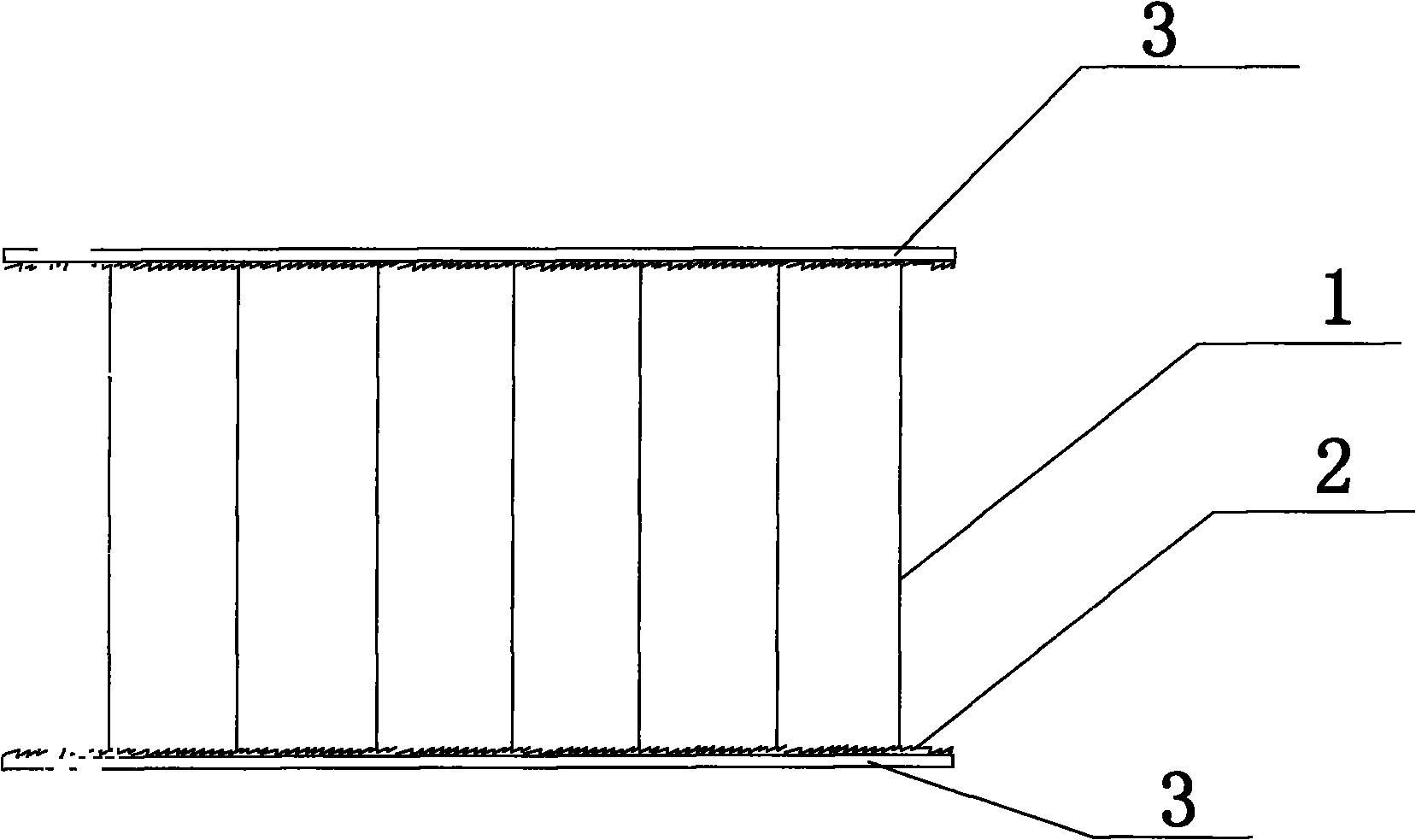

A kind of high-strength polyester fiberglass honeycomb composite board and its production process

InactiveCN102261162AHigh tensile strengthStop the flowConstruction materialCovering/liningsPolyesterThermal insulation

The invention discloses a high-strength polyester glass fiber honeycomb composite board and its production process, which comprises a three-layer structure, the middle layer is a hexagonal honeycomb core; the upper and lower sides of the hexagonal honeycomb core are provided with thin steel wire mesh; The upper and lower sides of the wire mesh are provided with polyester fiberglass boards. The invention adopts the anti-bending principle of the reinforced concrete slab, that is, on the basis of the polyester fiberglass honeycomb composite slab, a thin steel wire mesh with tensile effect is added on both sides, similar to the steel bars in the reinforced concrete slab, so that the polyester fiberglass honeycomb The tensile strength of the composite board has been doubled, and it is used for marine floors, building scaffolding, formwork, etc. Its tensile, bending and impact resistance properties are superior to ordinary boards, and it is light in weight and has a long service life. Obtaining the maximum force with the smallest material is an incomparable feature of other materials, and it is the preferred lightweight material in the construction industry at present. Because the honeycomb core in the honeycomb composite panel is divided into many closed cells, the air flow is prevented, and the heat and sound waves are greatly hindered. Therefore, it has the effect of heat insulation, heat preservation and sound insulation, and the installation is convenient and fast.

Owner:青岛同力得塑料蜂巢有限公司

Composite environmental-friendly cushion and preparation method thereof

InactiveCN102514258AGuaranteed performanceGuaranteed breathabilityStuffed mattressesLamination ancillary operationsFiberSurface layer

The invention discloses a composite environmental-friendly cushion which comprises a middle layer and upper and lower surface layers. The middle layer comprises a first middle layer, a second middle layer and a bonding layer. The upper and lower surface layers are non-woven layers comprising 5 percent to 50 percent of low melting point fibers. The first and second middle layers are non-woven layers which respectively comprise the following components: bastose and 5 percent to 50 percent of low melting point fibers. The bonding layer mainly consists of the low melting point fibers. In the whole composite environmental-friendly cushion, the content of the bastose is within the range of 5 percent to 65 percent. The invention also discloses a preparation method of the composite environmental-friendly cushion, which comprises the following steps of: respectively preparing the middle layer, the upper and lower surface layer and the bonding layer; then sequentially paving the layers; and preparing the composite environmental-friendly cushion by processes of processing by an oven, cold milling, cooling, cutting, inspecting and packaging. Due to the adoption of the composite environmental-friendly cushion and the preparation method thereof, which are disclosed by the invention, the problem that the existing mattress is easy to affect with damp, mildew, breed worms and deteriorate, is easy to layer and has poor air permeability is solved.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Shock-resistance light-weight fireproof plate

The invention discloses a light-weight fireproof plate, which is simple in structure, convenient to manufacture and high in shock resistance. One or more layers of flexible net layers are arranged between an upper base material and a lower base material which are made of fireproof materials; and the upper base material, the lower base material and the flexible net layers are integrated together. The light-weight fireproof plate is fireproof, dampproof, soundproof, waterproof and deformation-proof, has light weight, high shock resistance, and can be widely applied in building fields, such as partition walls, floors, floor splints and the like.

Owner:佛山市欧朗板业有限公司

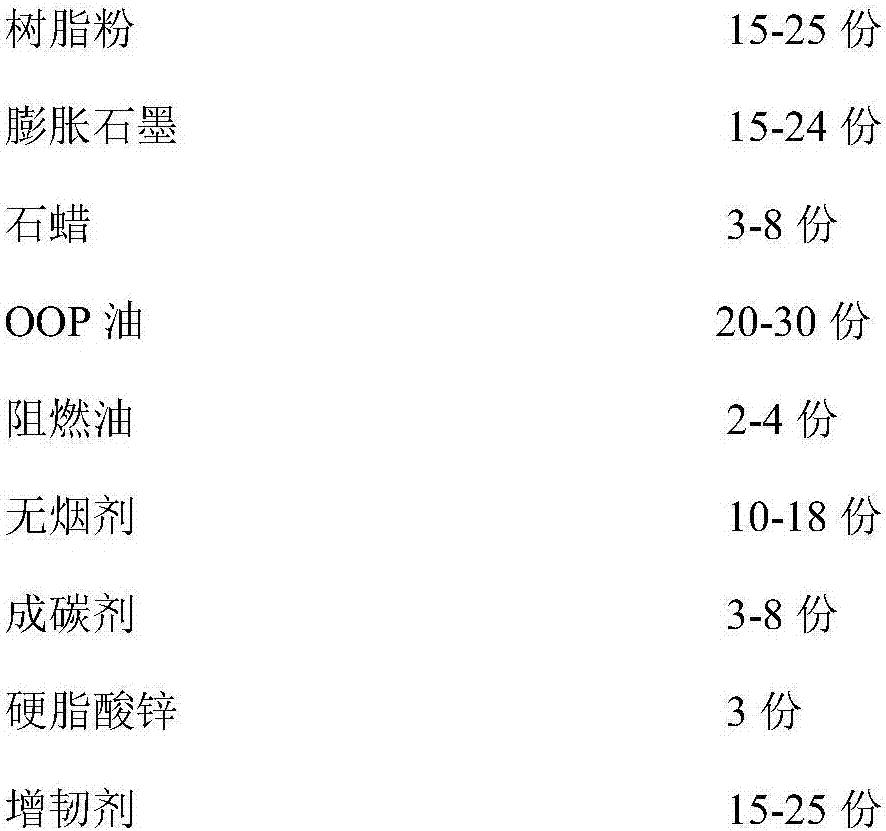

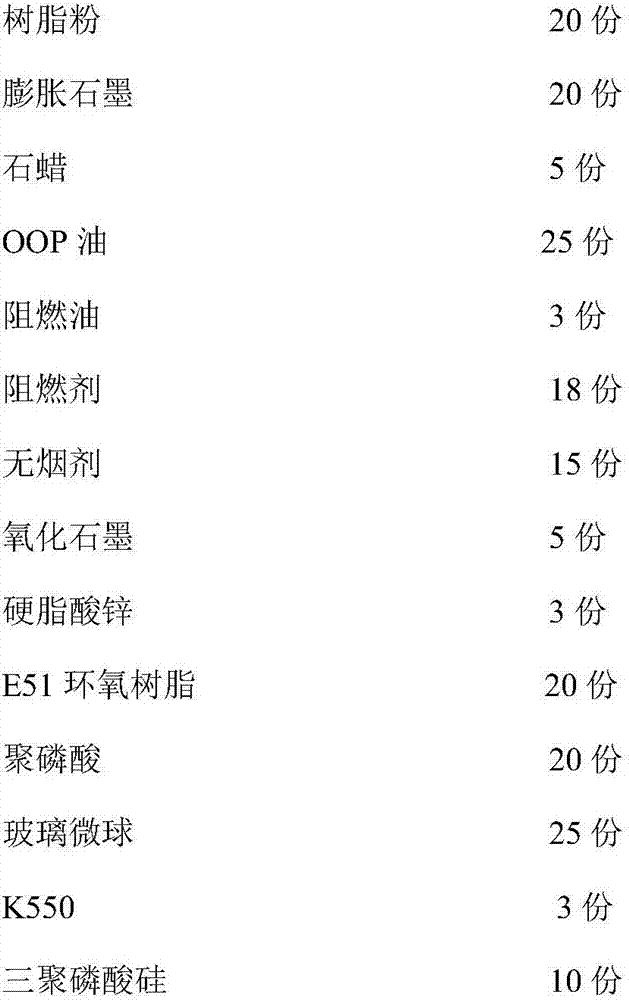

Fireproof expansion sealing strip and preparation method thereof

The invention discloses a fireproof expansion sealing strip which has the effects of shock absorption, fire protection, water resistance, sound insulation, thermal insulation, dust prevention and fixing. A sheath of the sealing strip adopts modified PVC; modified expanded graphite is formed inside the sealing strip; expanded graphite inside the fireproof sealing strip on the market can become loose and drop off after being burnt in a big fire, sealing effect is easy to lose, and black toxic smoke can be produced, so that the harm to human body in a fire scene can be improved. The fireproof sealing strip can be expanded but not become loose and drop off after being burnt in a big fire, can maintain integrity, reduce the extension of the fire, cannot generate black smoke, is good in expansibility, completeness and sealing property in case of a fire, and is good in ageing resistance at ordinary times.

Owner:尹书祥

Natural fiber health-care board and preparation method thereof

ActiveCN102514256AGuaranteed performanceGuaranteed breathabilityLaminationLamination apparatusPolymer scienceSurface layer

The invention discloses a natural fiber health-care board which consists of a middle layer and a surface layer arranged on the upper surface or the lower surface of the middle layer. The surface layer is a non-woven layer comprising 5 percent to 50 percent of low melting point fibers. The middle layer is a non-woven layer which comprises the following components: bastose and 5 percent to 50 percent of low melting point fibers. In the natural fiber health-care board, the content of the bastose is within the range of 5 percent to 65 percent. The invention also discloses a preparation method of the natural fiber health-care board, which comprises the following steps of: respectively preparing the middle layer and the upper or lower surface layer; then sequentially paving the layers; and preparing the natural fiber health-care board by processes of processing by an oven, cold milling, cooling, cutting, inspecting and packaging. Due to the adoption of the natural fiber health-care board and the preparation method thereof, which are disclosed by the invention, the problem that the existing mattress is easy to affect with damp, mildew, breed worms and deteriorate, is easy to layer and has poor air permeability is solved.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Ultra-bright negative ion glazed brick and production process thereof

ActiveCN108331281AEvenly distributedSufficient and balanced bonding areaCovering/liningsBrickUltra fine

The invention discloses an ultra-bright negative ion glazed brick. The negative ion concentration of the ultra-bright negative ion glazed brick is 5-10 times higher than that of a common glazed brick,and at the same time, a crystal structure reflects light to enable the glazed brick more bright. The glazed brick comprises a bottom layer green body, a sound-insulation insulating layer, a top layergreen body, a base glaze layer, a functional layer and an overglaze layer; the bottom green body and the top green body comprise stone powders, sand, ultra-fine negative ion powders, diatom mud, mud,waste residues and broken mud of ceramic and water; the sound-insulation insulating layer includes a polyamide mesh, asbestos fibers and gypsum powders; the base glaze layer includes potassium sodiumfeldspar, quartz, alumina, washed soil, burnt talc, zirconium silicate and ultra-fine negative ion crystals; the functional layer includes ultra-fine negative ion crystals, activated carbon, diatom mud and glass beads; and the overglaze layer includes potassium sodium feldspar, barium carbonate, dolomite, zinc oxide, burnt talc, burnt soil, washed soil, corundum, nanometer titanium dioxide, and ultra-fine negative ion crystals.

Owner:GUANGDONG BAIQIANG CERAMICS CO LTD

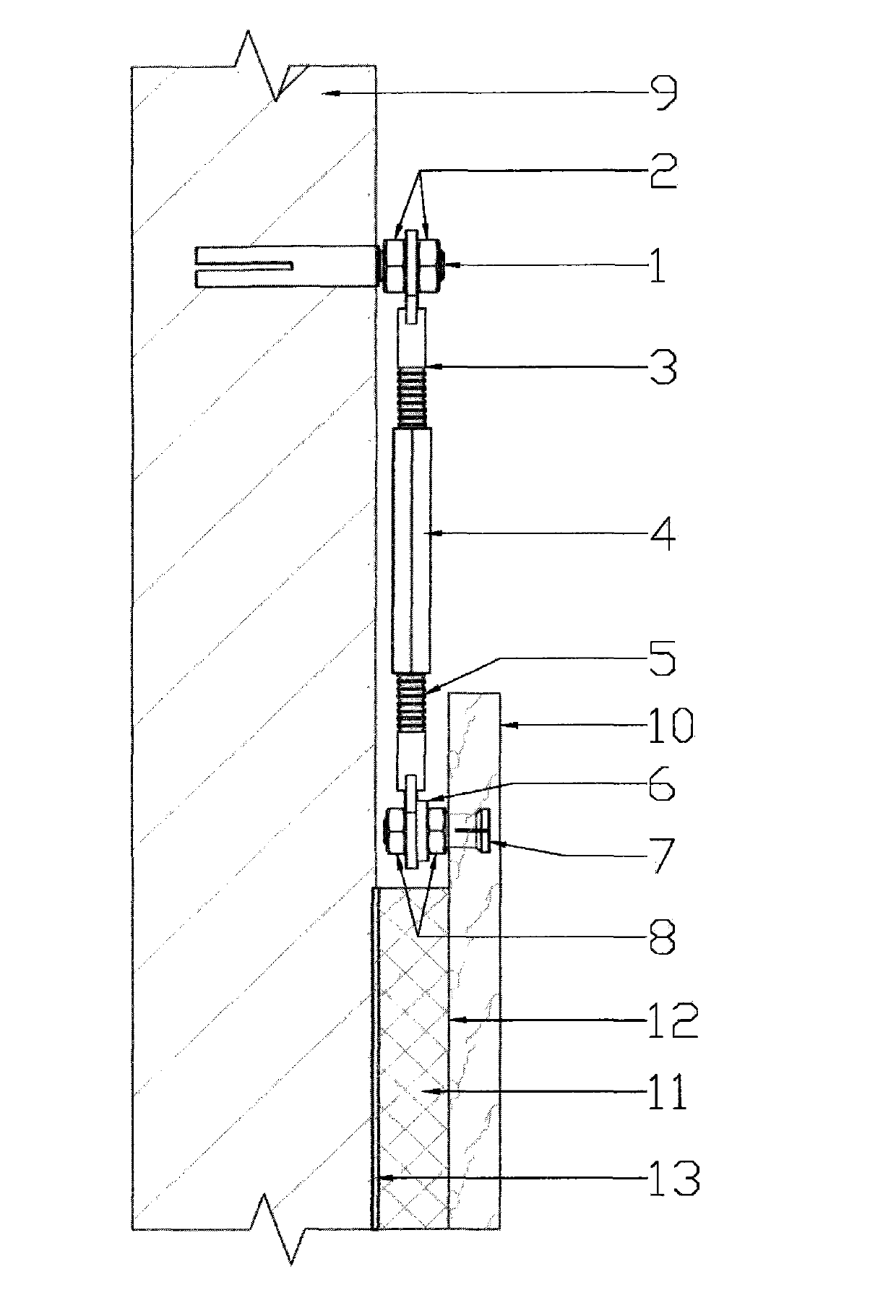

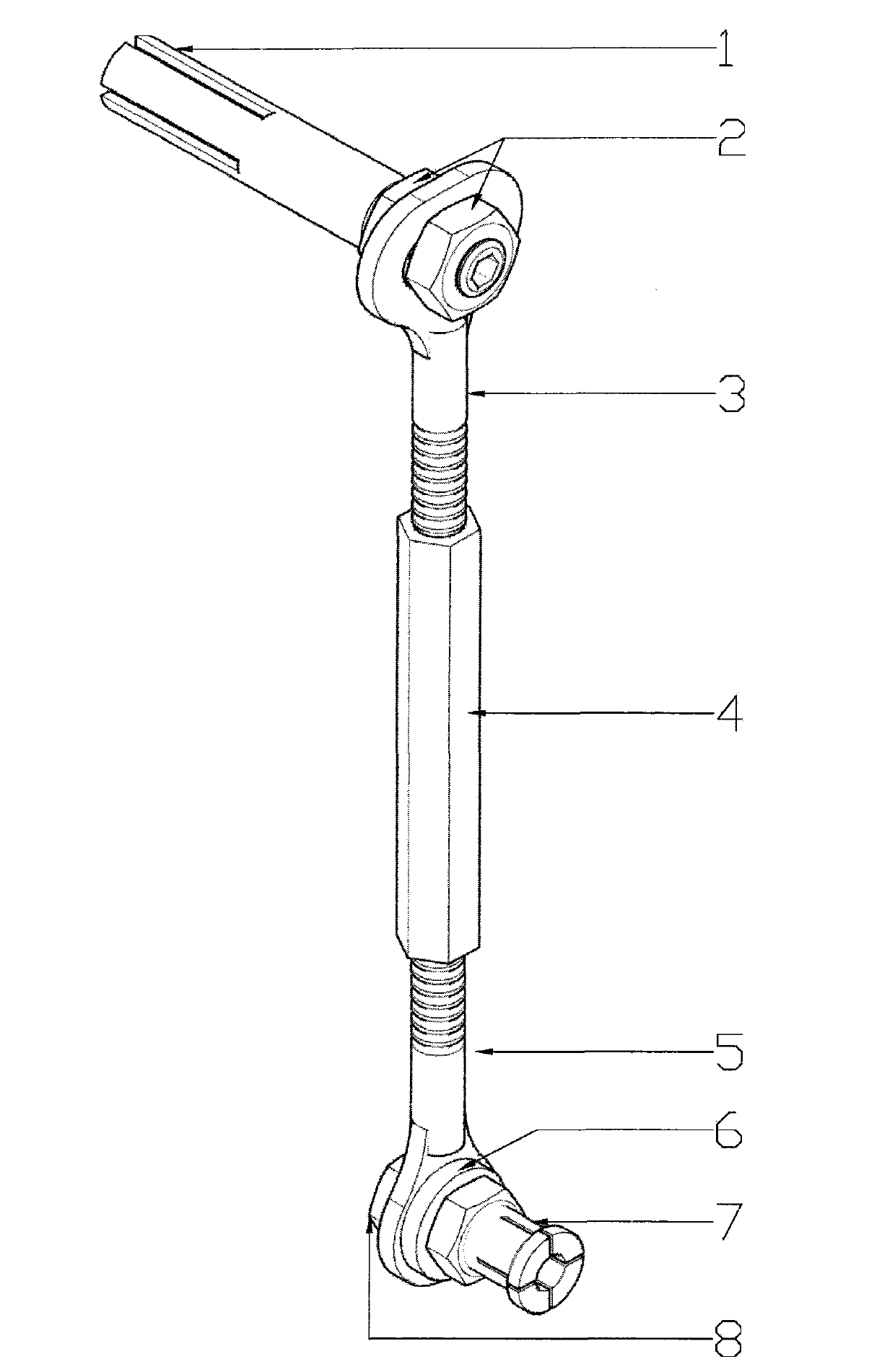

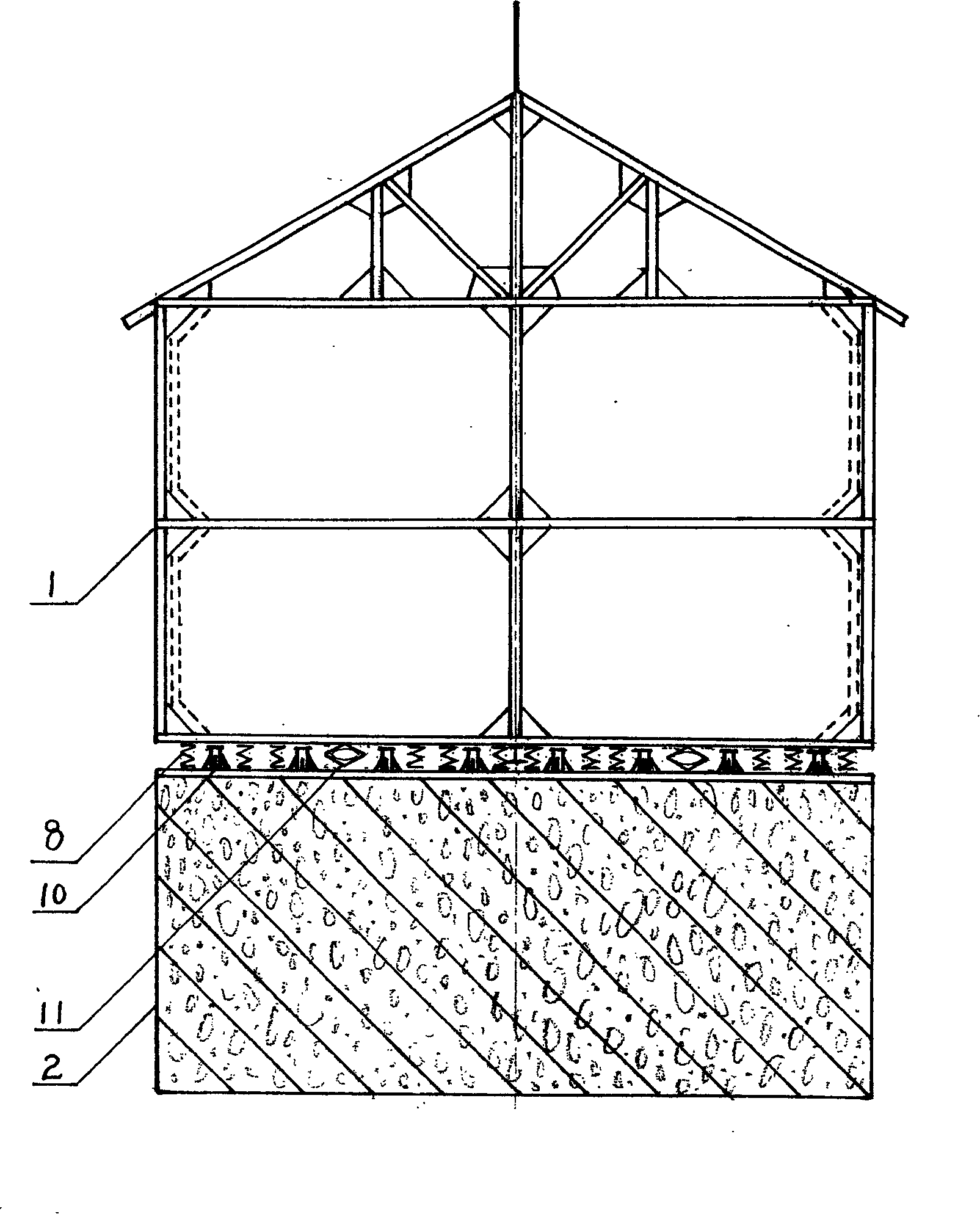

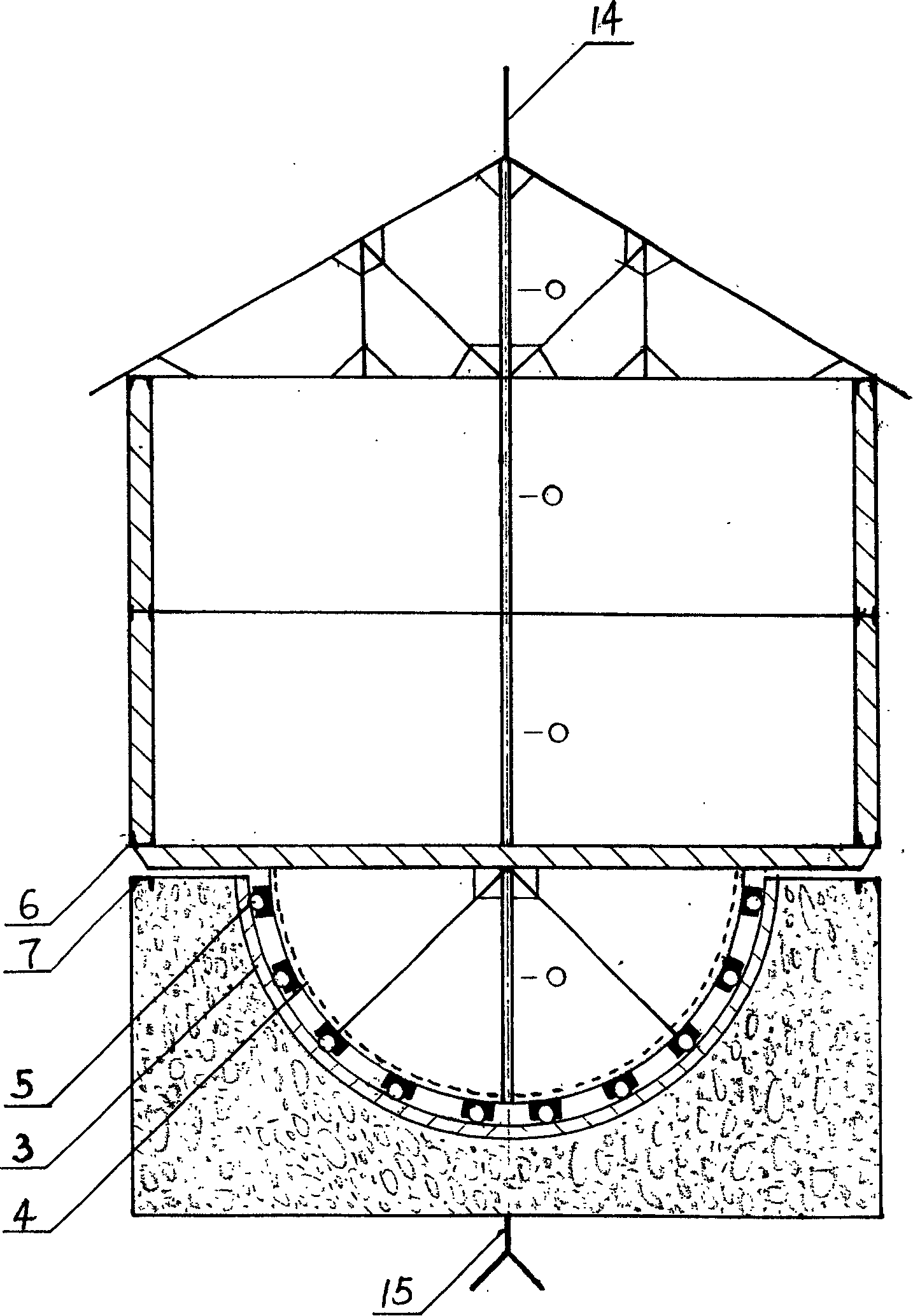

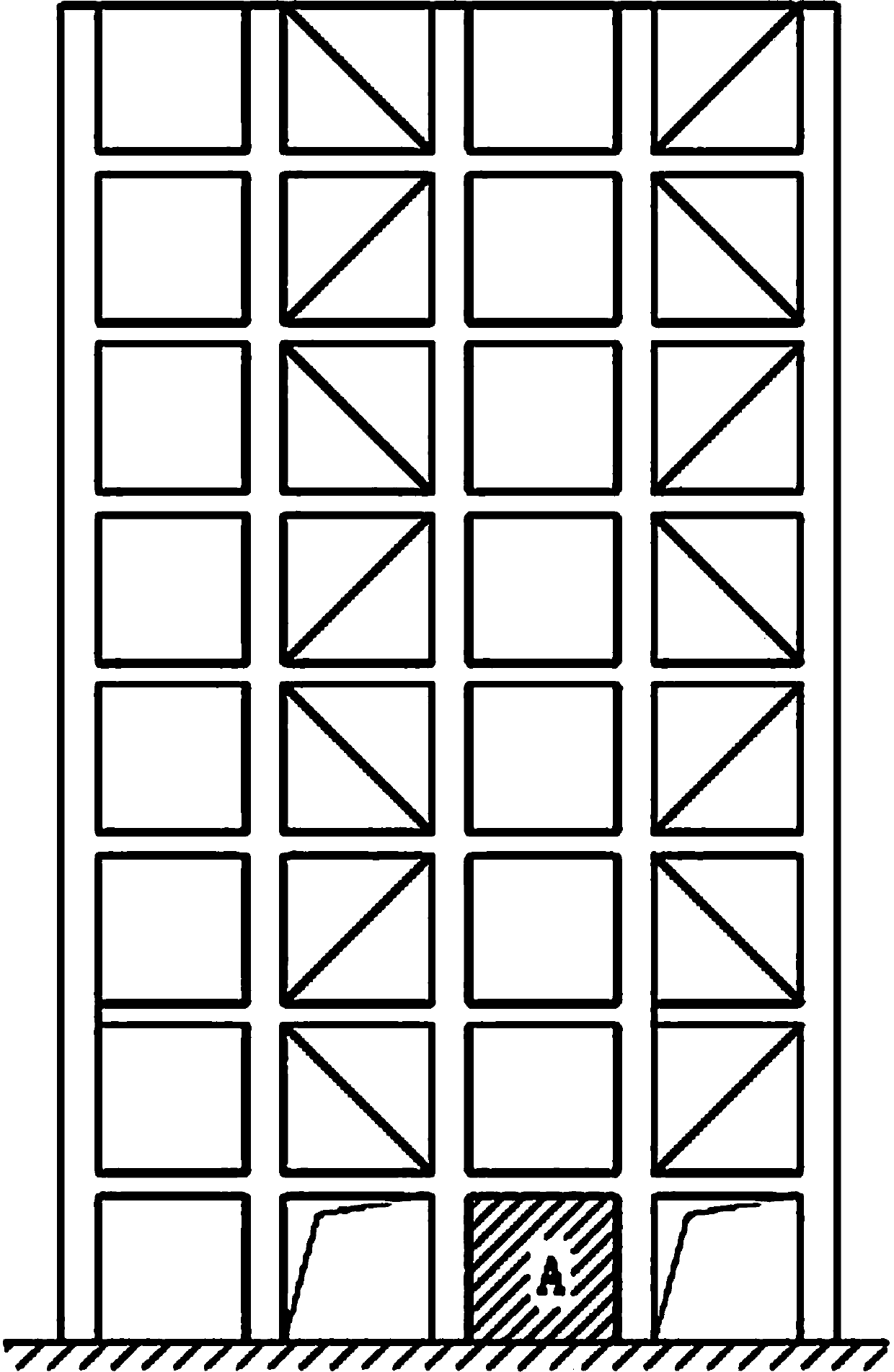

Monolithic-construction automatic damping storied building

"Integral structure, automatic shock-absorbing building" consists of the overall steel structure frame, interior and exterior decoration of the building, automatic shock-absorbing system, horizontal and vertical linkage levers and structural parts outside the building; it can automatically absorb shocks in a major earthquake, but cannot The destruction and collapse of the overall structure cannot cause casualties and deaths. In the design of the main building, bricks and cement in the current construction industry are not used, and all new building materials in the building materials market are used for decoration. This can solve the problem of construction problems. The heavy manual labor problem that the industry has not solved for thousands of years can be factory-produced and installed at the construction site when the number of buildings is large.

Owner:籍跃中

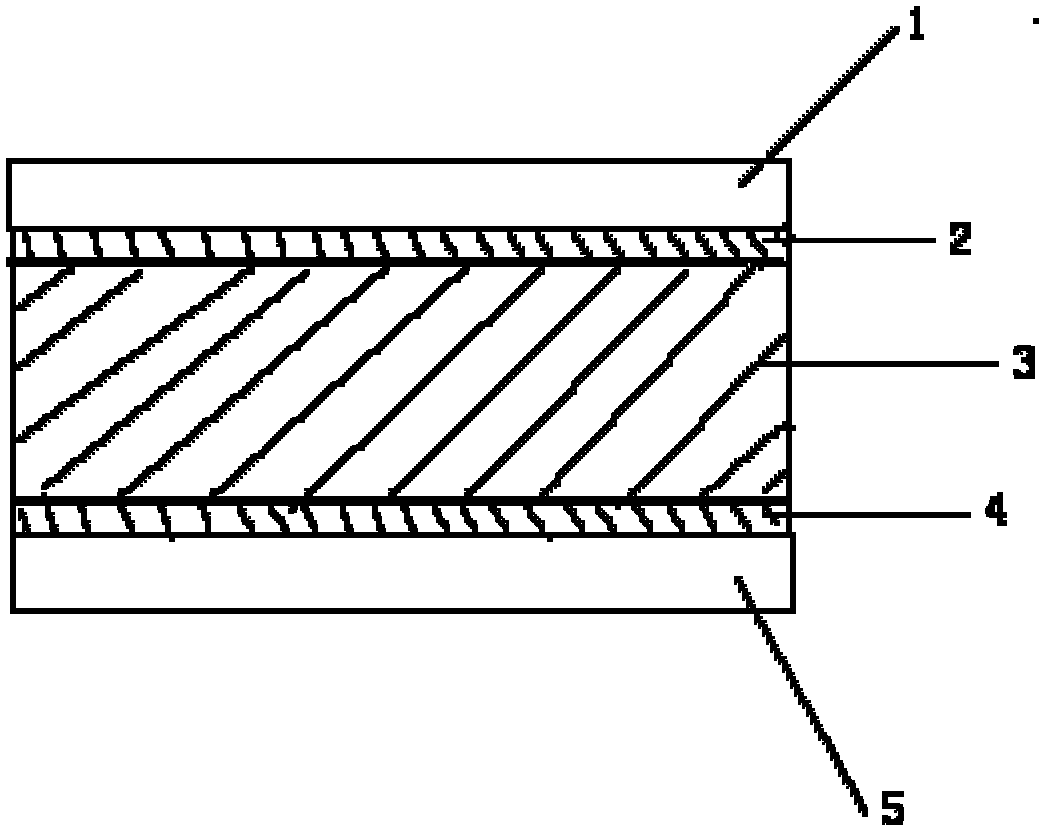

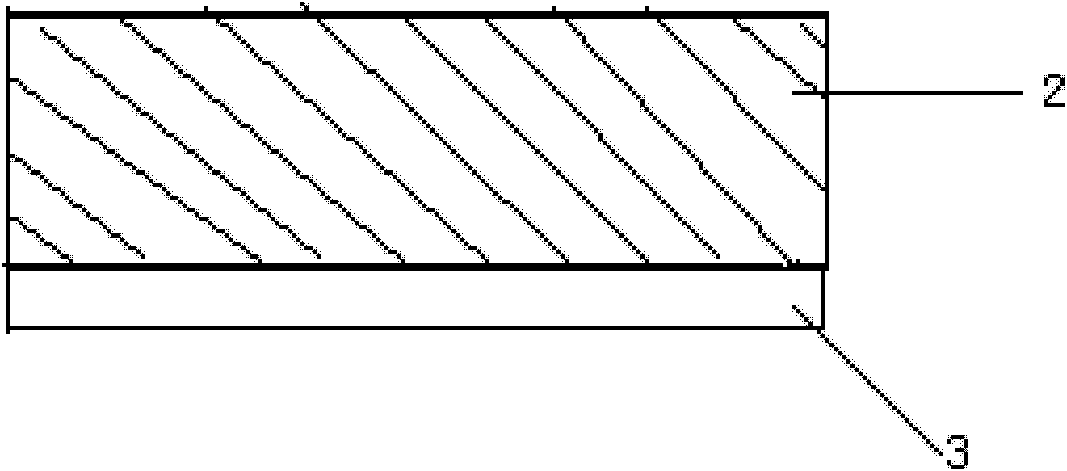

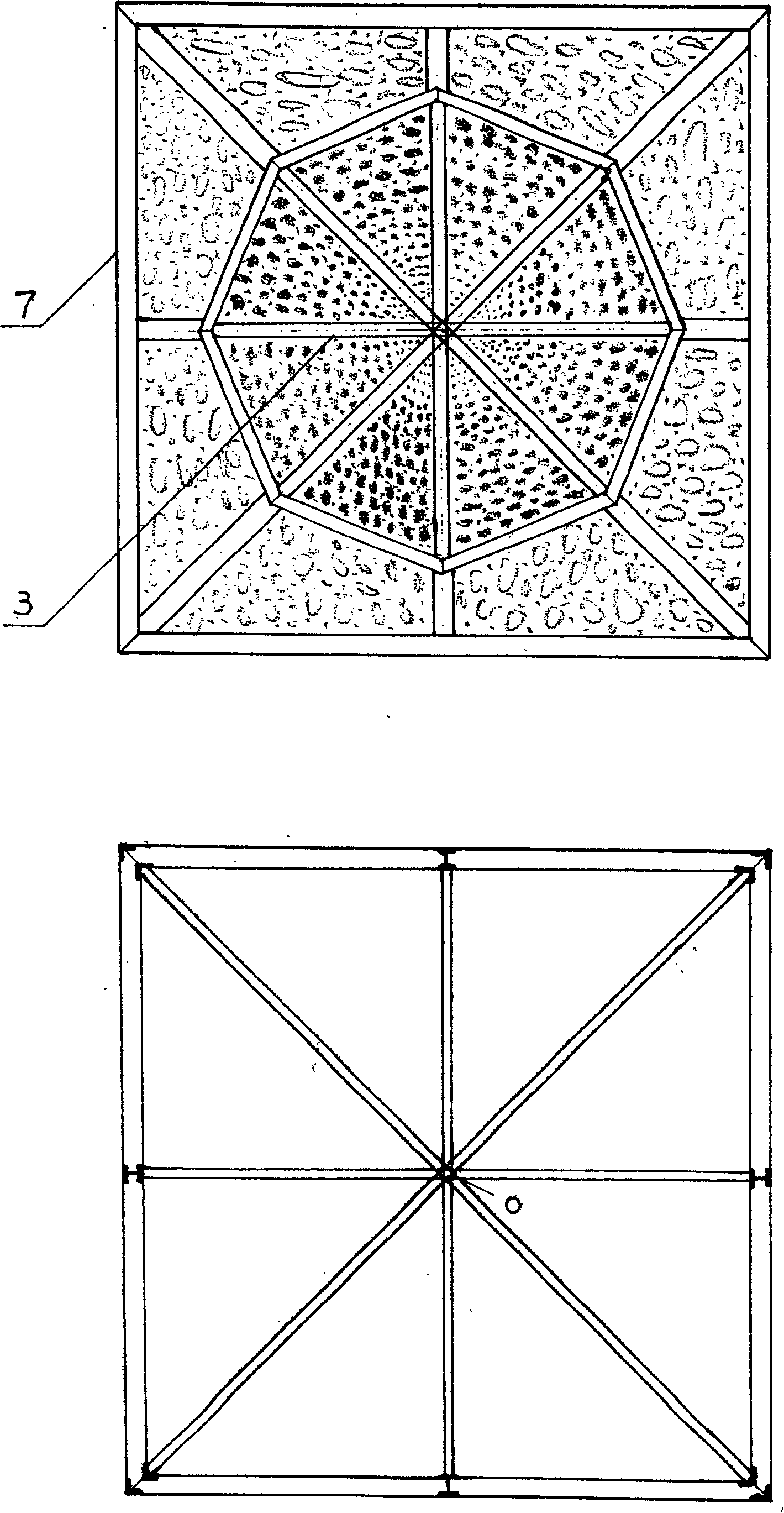

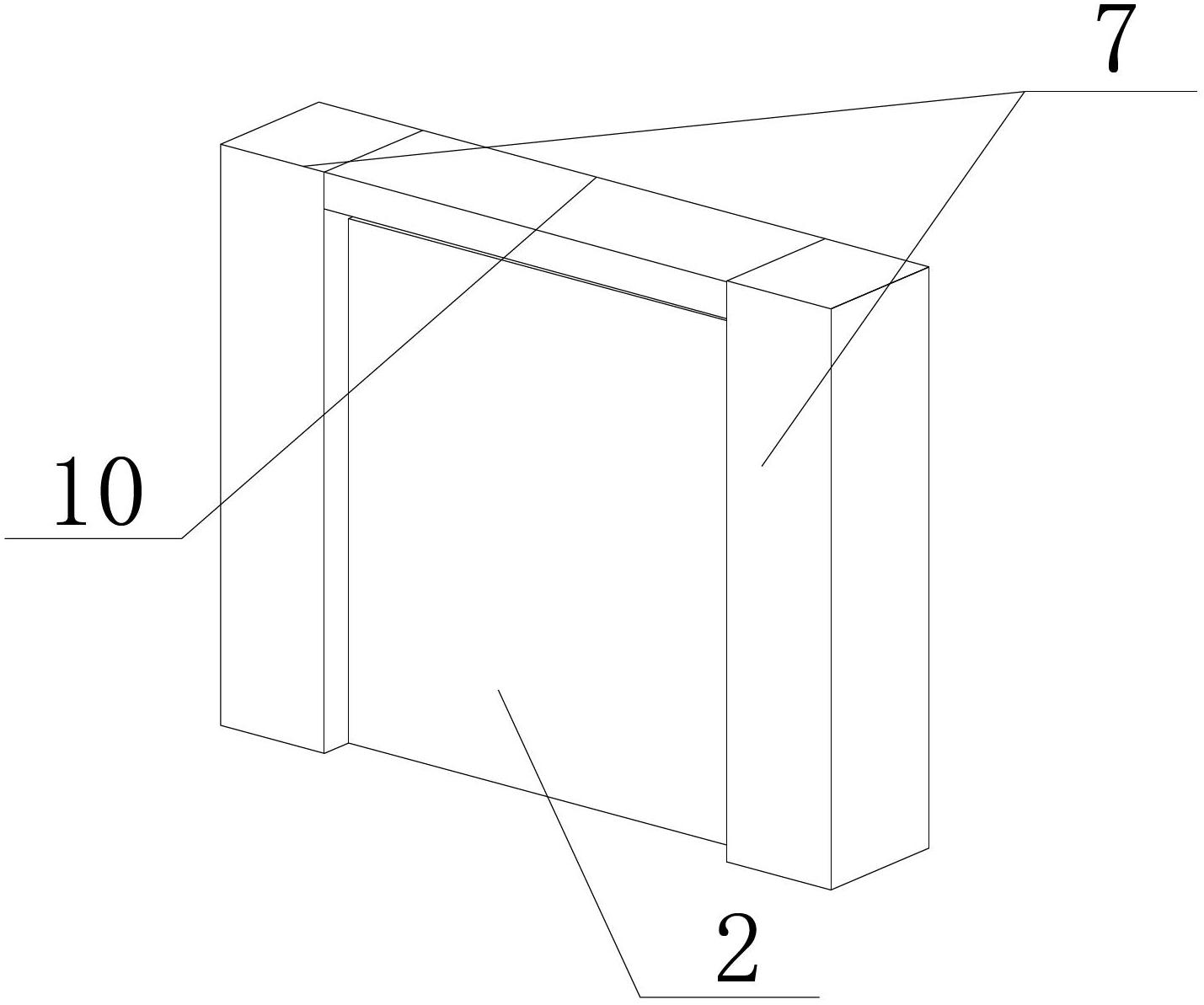

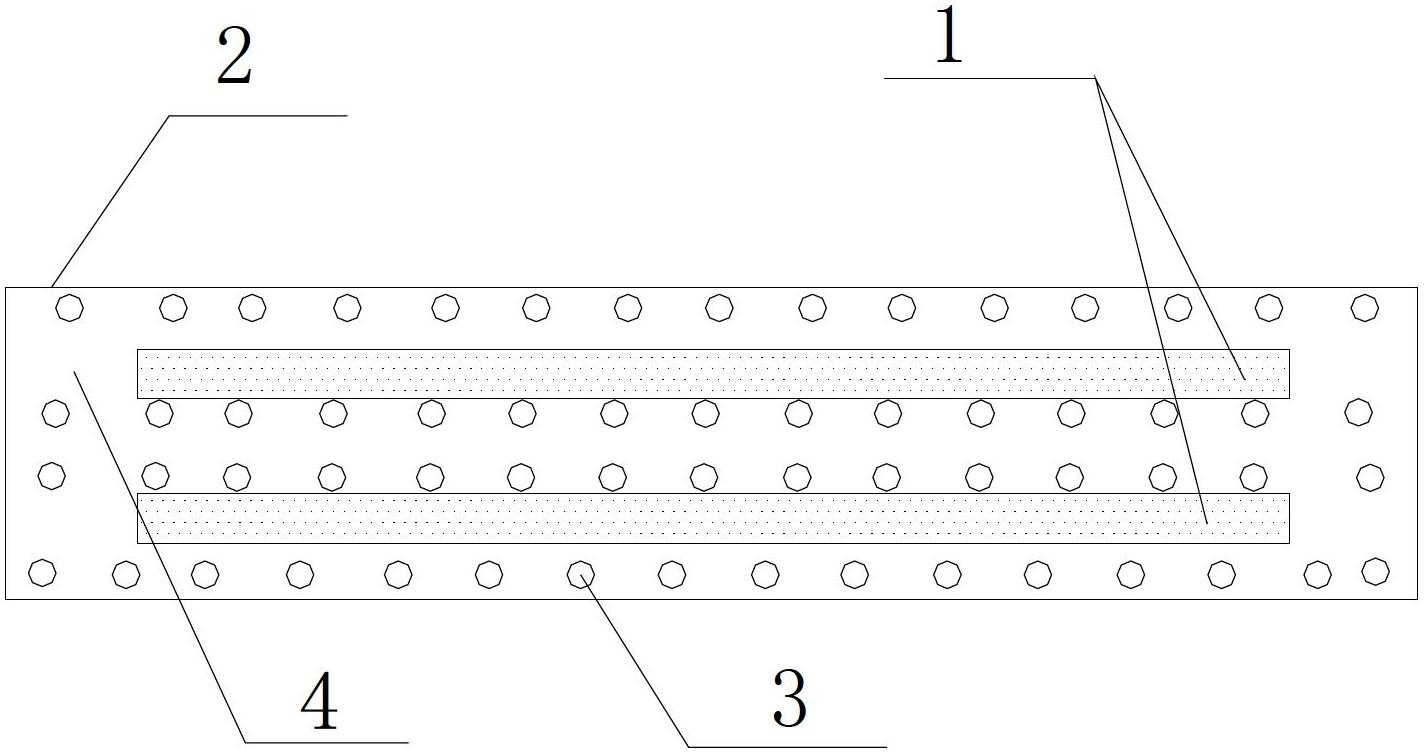

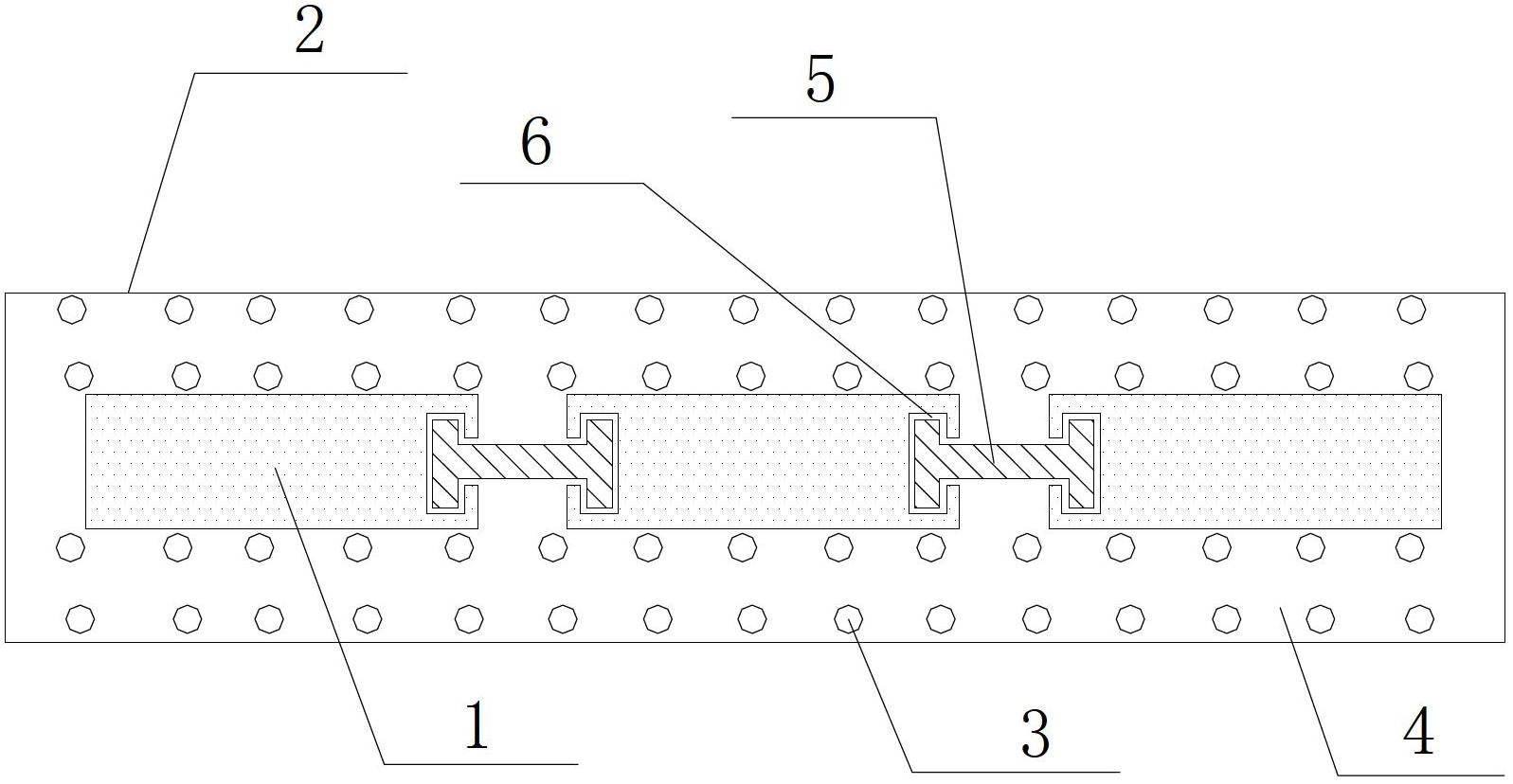

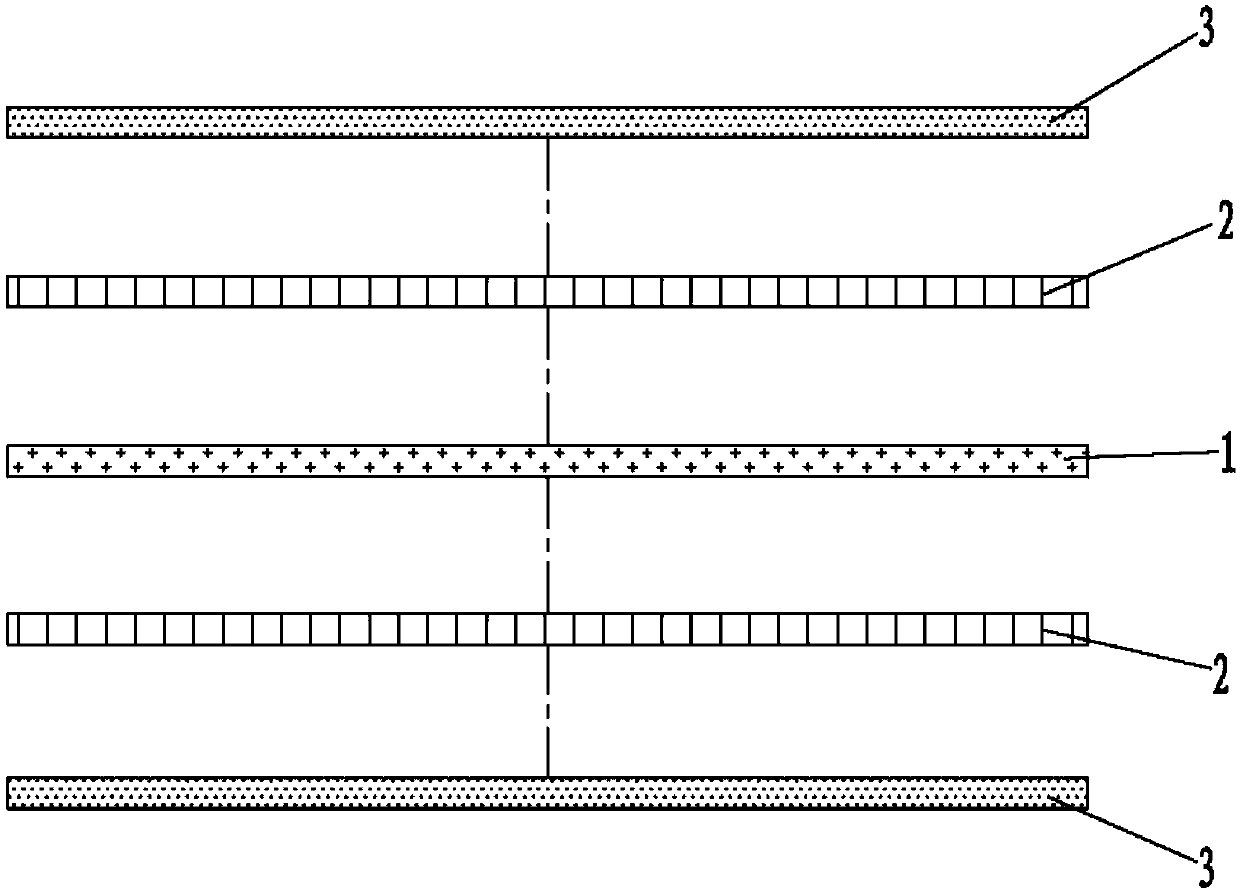

Sound insulation cotton, air-conditioning outdoor unit and sound insulation structure mounting method

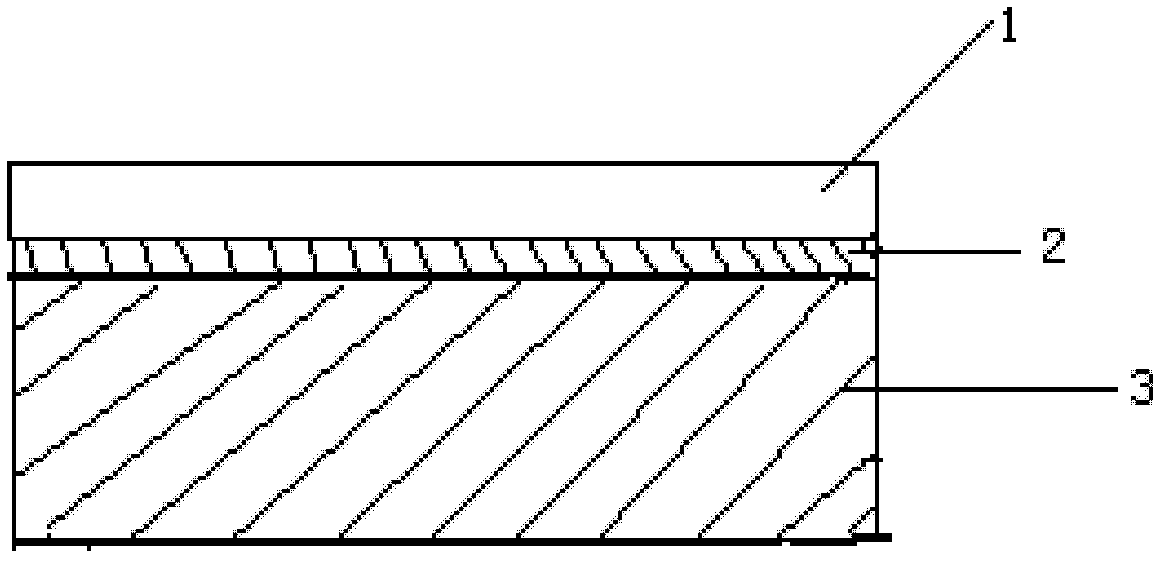

ActiveCN106142768ASound insulationPlay a role in damping vibrationLighting and heating apparatusElectrical equipmentFiberSound wave

The invention discloses sound insulation cotton, an air-conditioning outdoor unit and a sound insulation structure mounting method. The sound insulation cotton sequentially comprises a porous sound absorbing layer, a sound insulation shock absorption layer and a resonant sound absorbing layer from inside to outside, wherein the porous sound absorbing layer is used for absorbing high-frequency noise and made of open-celled fiber materials, and the resonant sound absorbing layer is used for absorbing middle and low frequency noise and made of closed cell foam materials. By the aid of the porous sound absorbing layer, the sound insulation shock absorption layer and the resonant sound absorbing layer from inside to outside, sound wave energy of various frequency bands emitted by a compressor is absorbed and weakened, noise is effectively reduced, and customer satisfaction is improved.

Owner:广东科龙嘉科电子有限公司

Environment-friendly outer wall and construction method thereof

InactiveCN102691361AReduce stacking laborEfficient use ofWallsBuilding material handlingDie castingRebar

The invention discloses an environment-friendly outer wall which comprises an inner module, a outer module disposed outside the inner module, fixing columns located at two ends of the outer module, and a cross beam covered on the top of the outer module. By the aid of the inner module, the outer wall is anti-seismic, warm-preserving, heat-insulating, and sound-insulating. The outer module comprises a concrete layer and fixing reinforcing steel bars penetrating the interior of the concrete layer. The fixing reinforcing steel bars increase stability of the outer wall. The outer module is formed by pouring of concrete so that labor amount of wall building is reduced, work efficiency is enhanced, and production cost is lowered. In addition, the inner module is formed by straws through die-casting, so that amount of raw materials is reduced, effective utilization of waste is achieved, and energy conservation and environmental protection are achieved.

Owner:苏州金楠新能源墙体工程有限公司

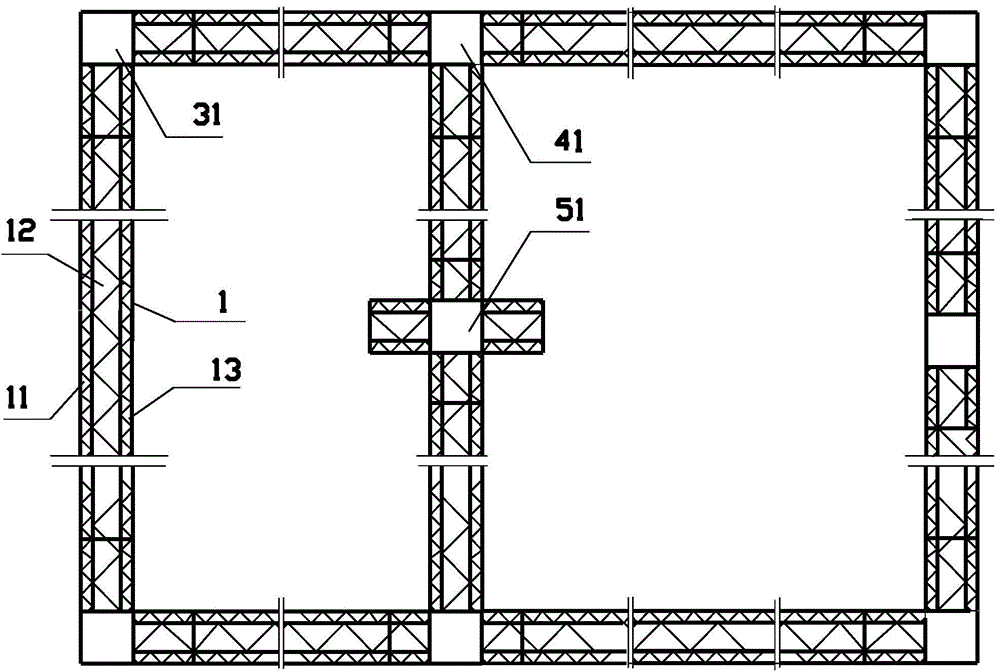

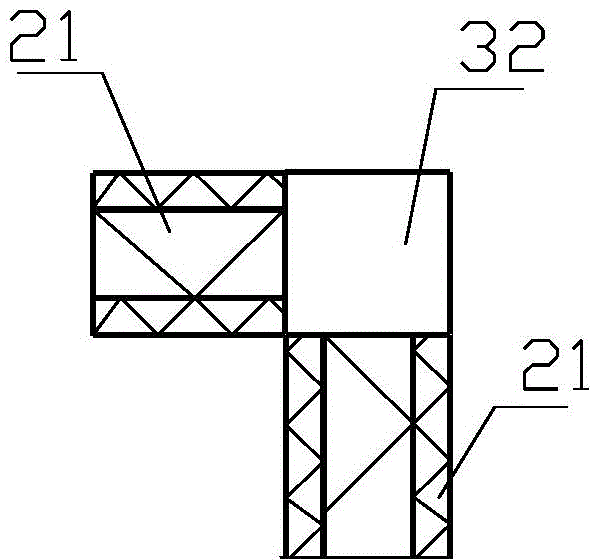

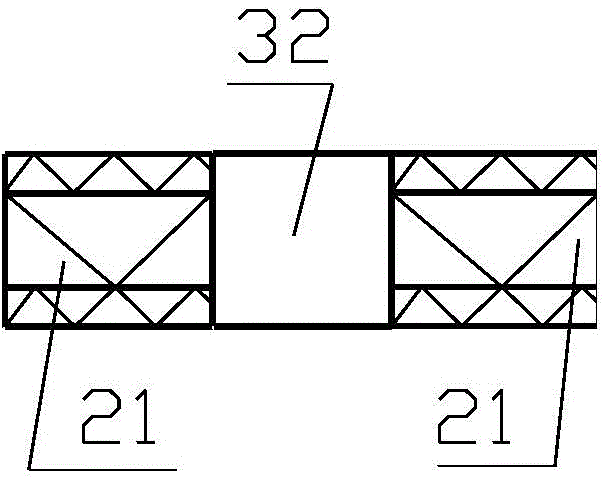

A combined house plate wall structure and a digital printing production method thereof

InactiveCN104895215AAvoid damageGuaranteed StrengthWallsCeramic shaping apparatusThermal insulationEconomic benefits

The invention provides a combined house plate wall structure comprising long and short flat and straight members and connecting joints. The long and short flat and straight members include external thermal insulation layers and wall body layers. The connecting joints include corner members, T-shaped members and T-shaped members. The long flat and straight members and the short flat and straight members of the connecting joints are combined and connected to form a combined house plate wall. The invention also provides a digital printing production method and installation method of the combined house plate wall structure. For digital printing of building houses, the house plate wall structure is decomposed according to standards and industrial standard production is performed separately, and the damage caused to environments by site construction is reduced to the greatest extent; columnar drum bodies and internally concave spaces reserved in the building components serve as pouring and tamping formworks of columns and beams of building structures, so that the overall strength and rigidity of buildings are guaranteed and the time and expenses for formwork erecting are saved; the installing cost is greatly reduced and the installing time is reduced; the structure and the method represent remarkable technical progress and can bring great economic benefits.

Owner:马义和

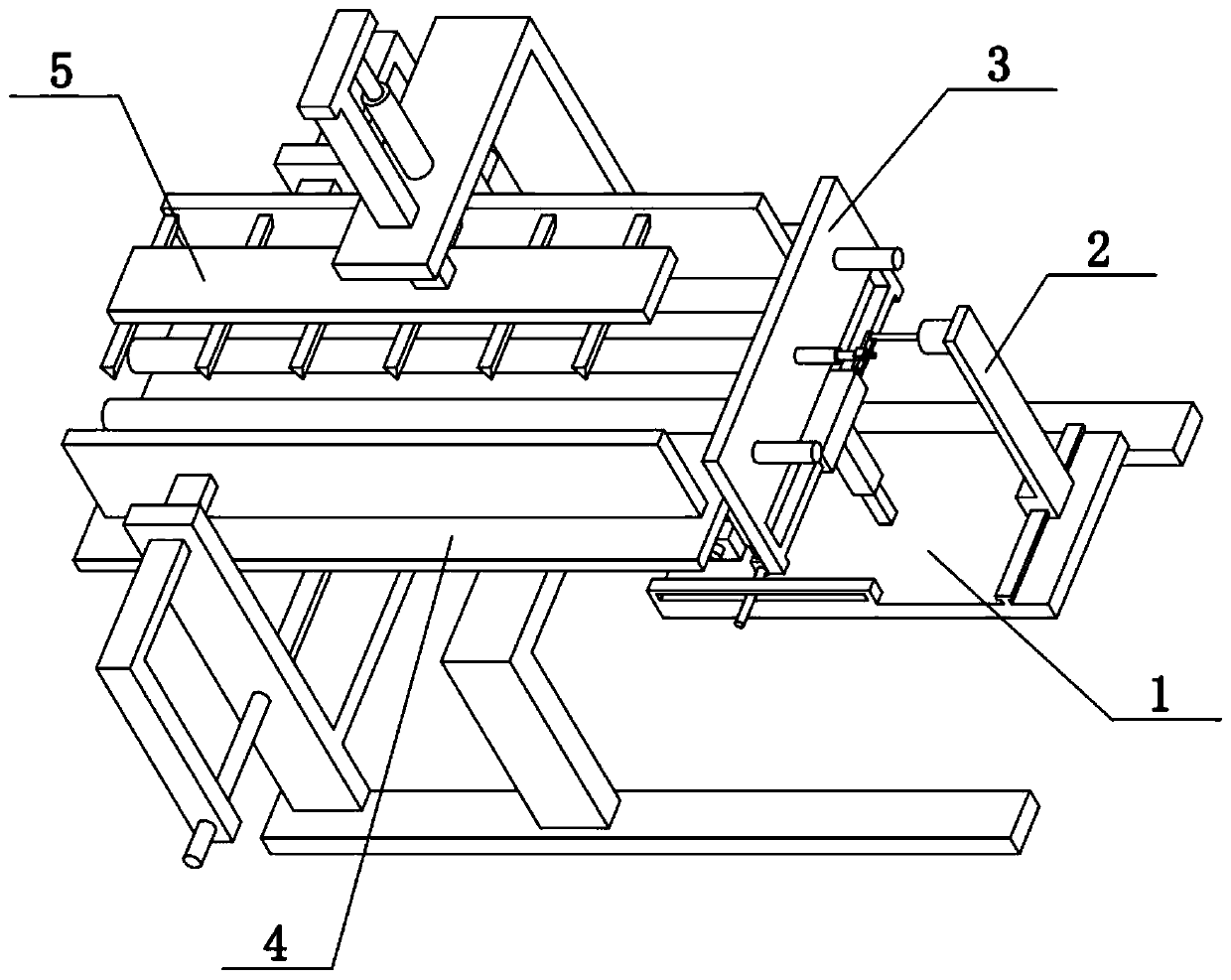

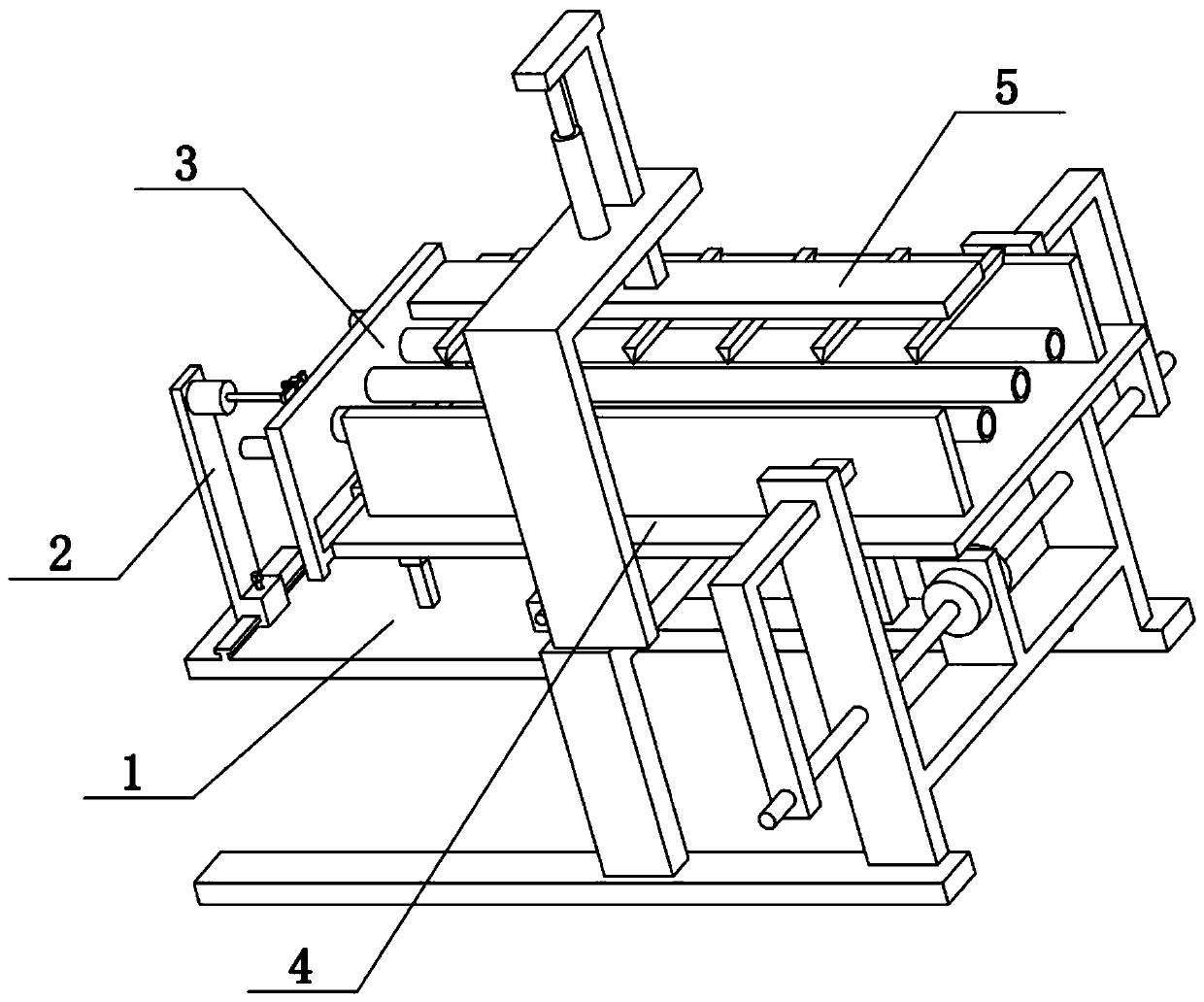

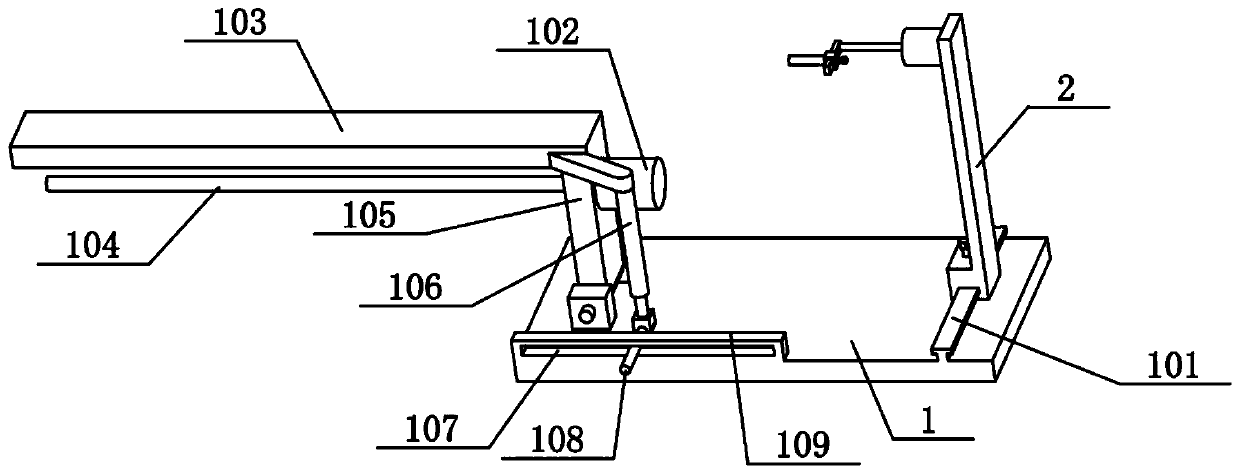

Concrete prefabricated part machining device and machining method

ActiveCN111231063ASave materialSound insulationMouldsMould auxillary partsElectric machineryStructural engineering

The invention relates to the field of concrete prefabricated part machining, in particular to a concrete prefabricated part machining device and a machining method. The method comprises the followingsteps that 1, concrete is placed on the upper side of a supporting plate, the front and rear sides of the concrete are blocked by two clamping plates, and the concrete is laid at a certain thickness to form a concrete prefabricated part; 2, a plurality of hollow round rods are inserted into the plate-shaped concrete, and the hollow round rods form a plurality of hollow holes in the concrete in anexpanding mode; 3, the plurality of hollow round rods are driven to move along a circular track in the concrete through a motor II, and then the hollow holes in the concrete are expanded; and 4, the plurality of hollow round rods are extracted from the concrete after the plurality of hollow round rods expand the holes, and then the concrete prefabricated part is waited to solidify. The concrete prefabricated part machining device comprises the motor II, a rotating shaft, an inserting shaft, a circumferential rotating rod, a side plate, a cylinder, the hollow round rods, a vertical column, a vertical sleeve, a fixing sleeve and a sliding rail rod.

Owner:广东永基电力器材厂有限公司

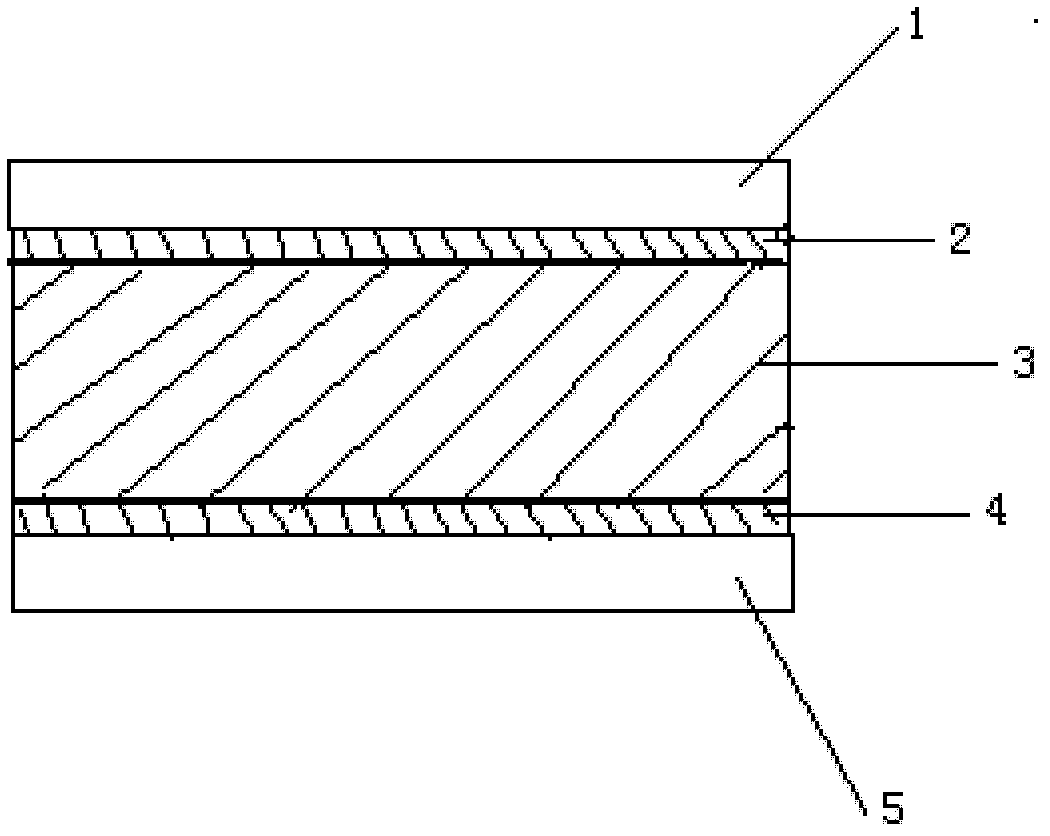

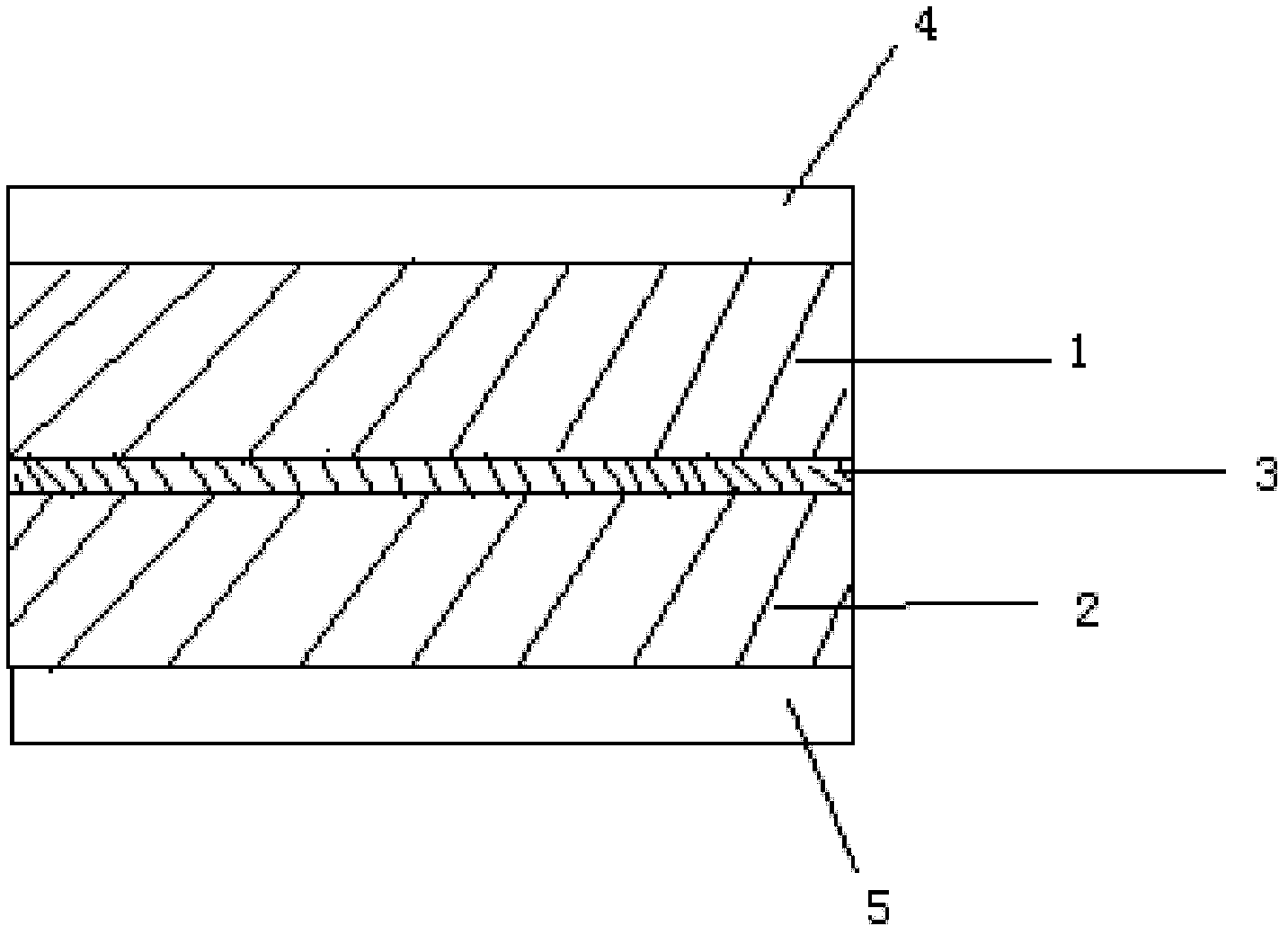

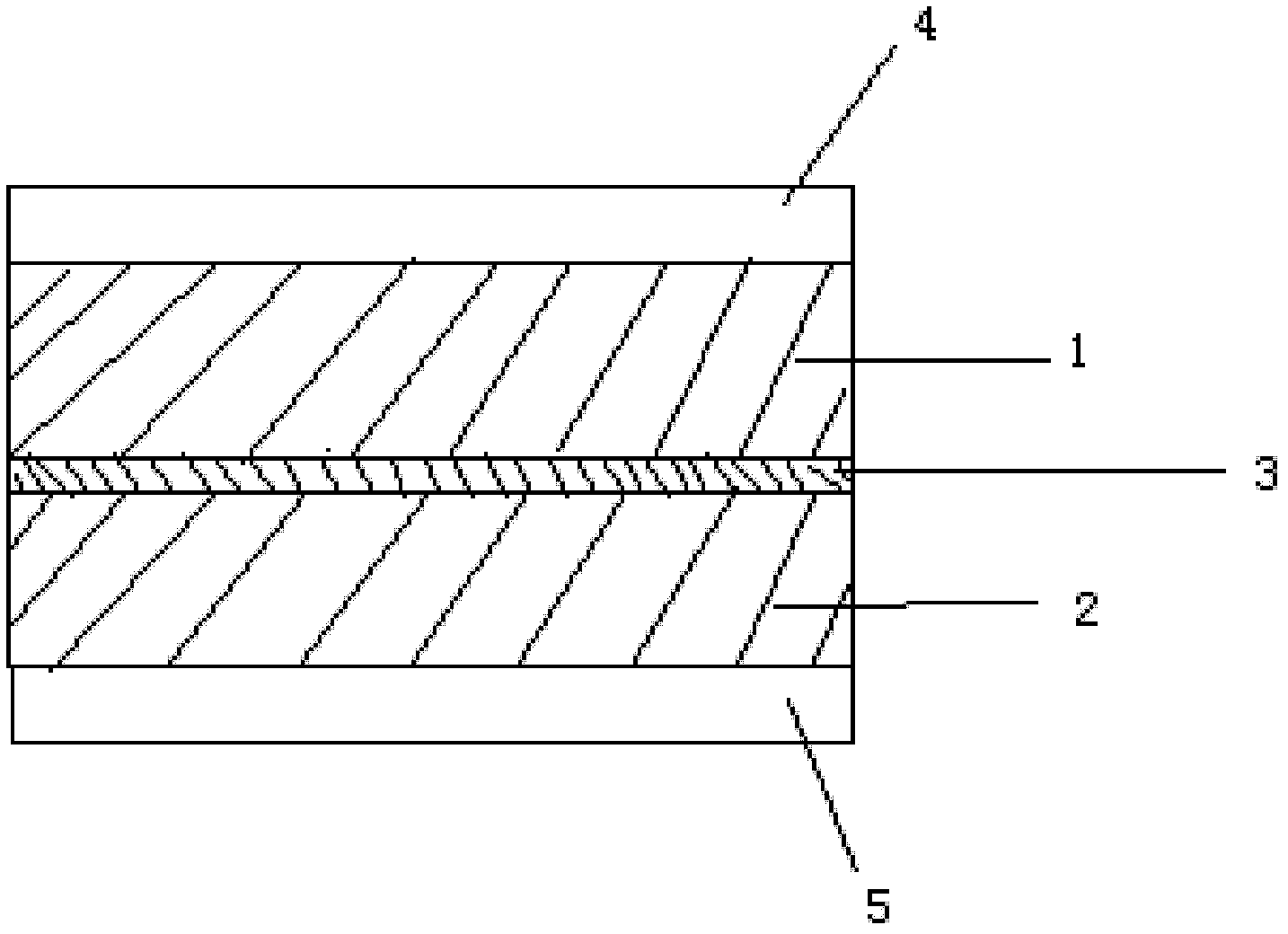

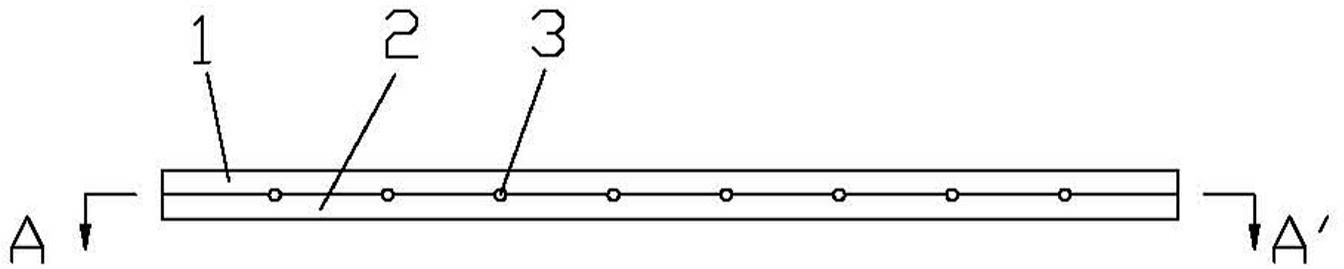

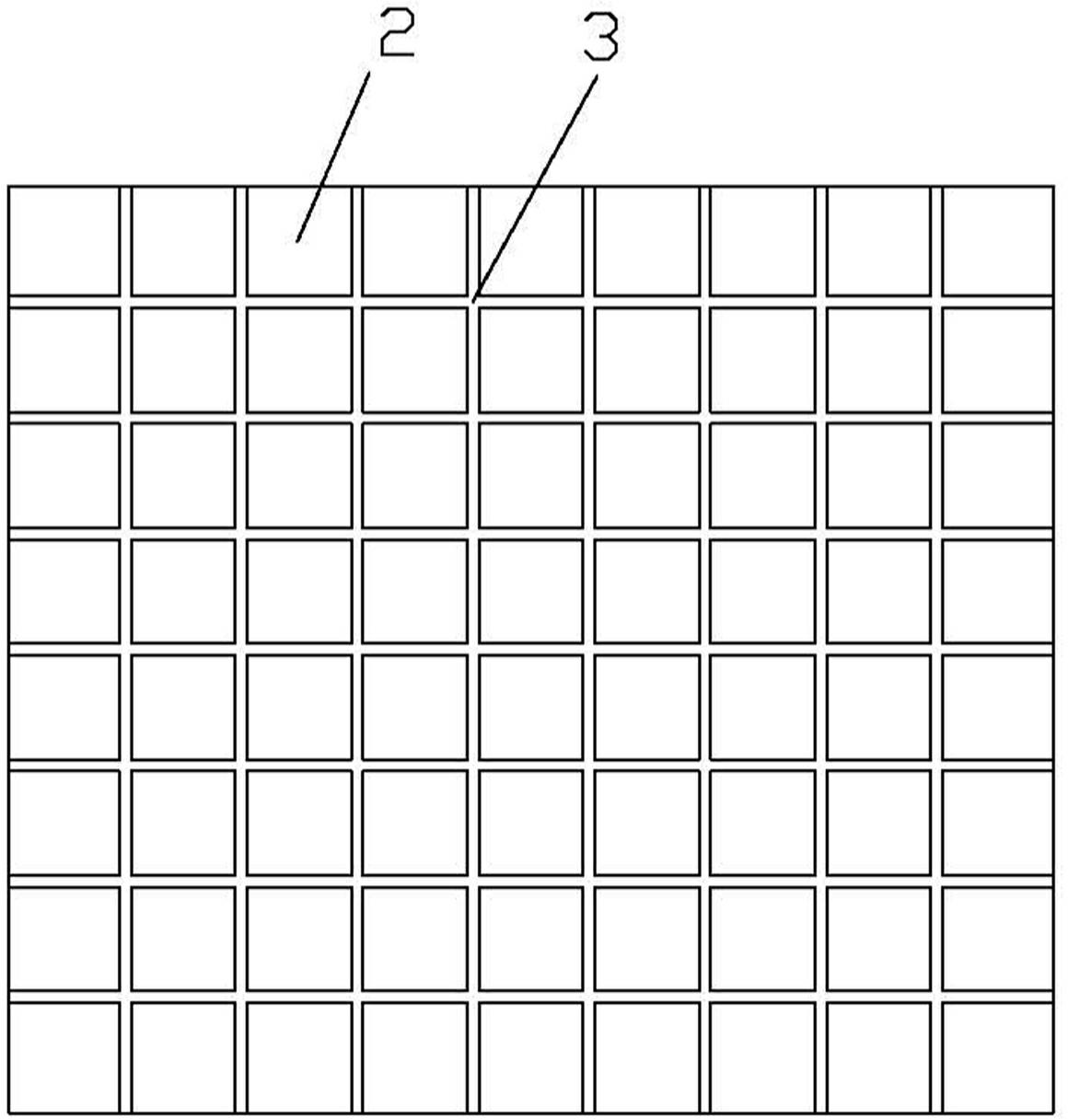

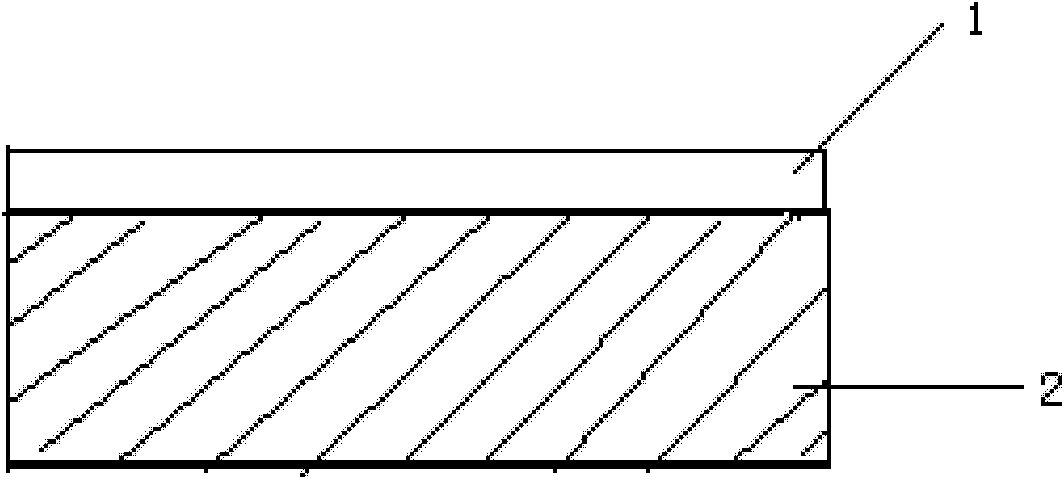

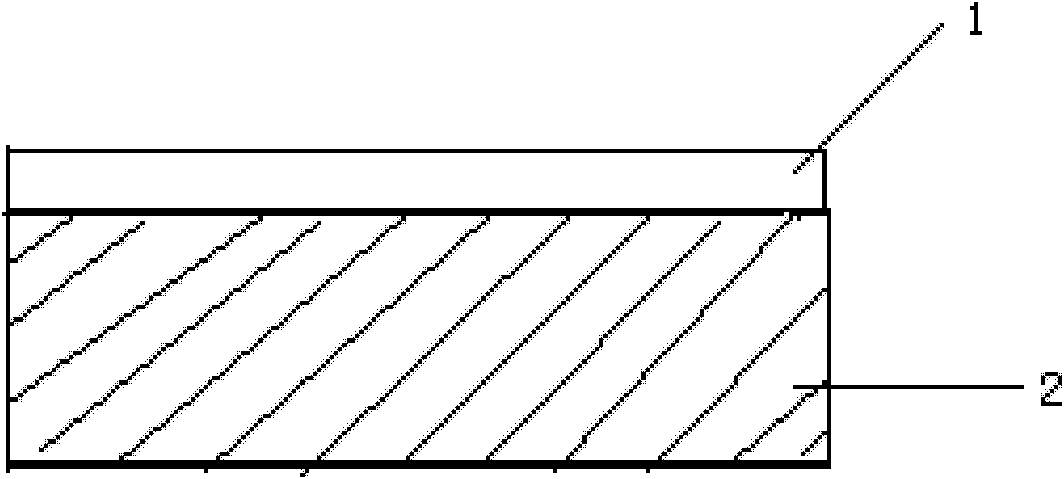

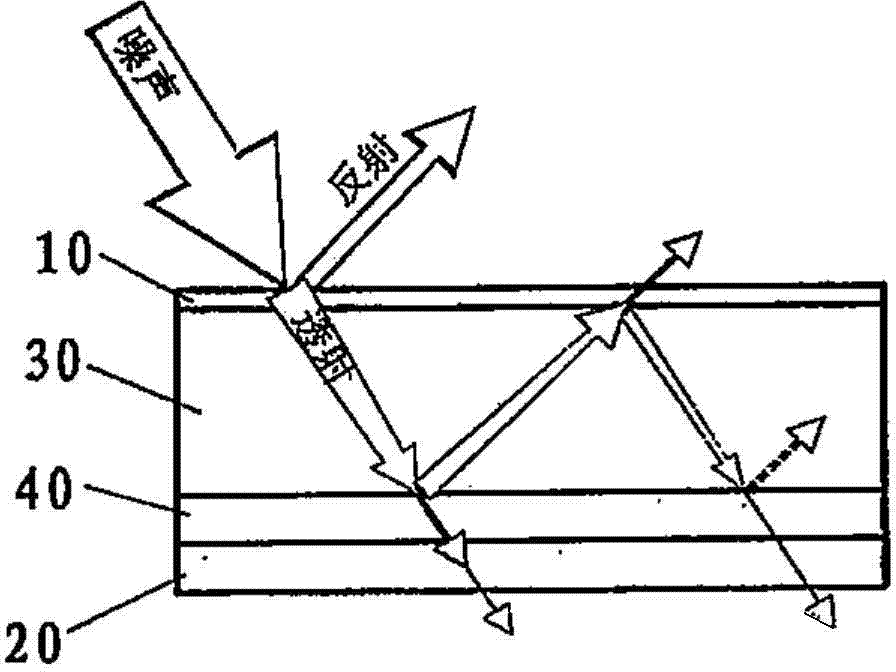

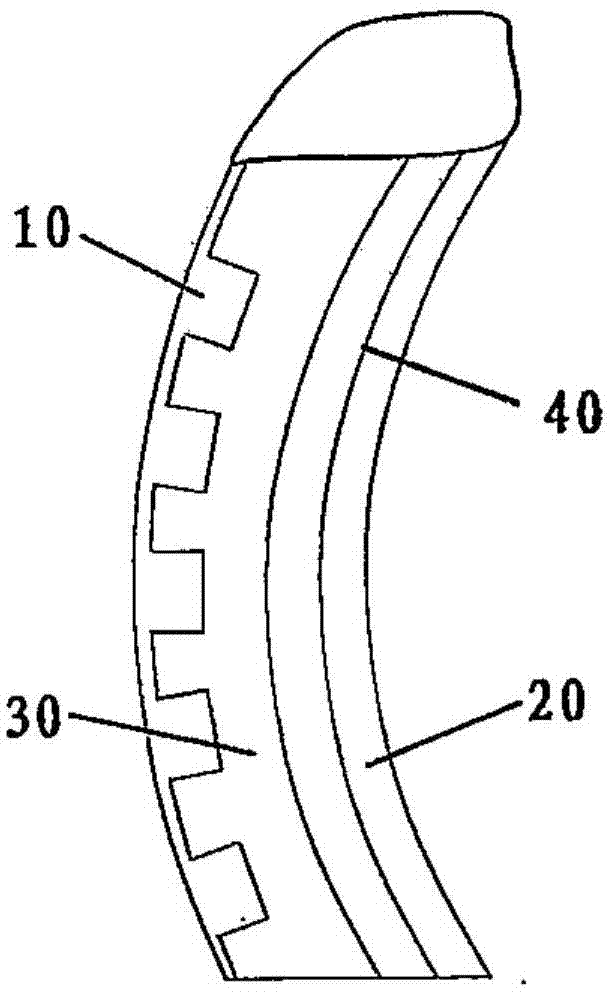

Sound insulation airplane wallboard

ActiveCN104210645AImprove sound insulation performanceOvercome Confining Space WeightFuselage insulationEngineeringAbsorption effect

The invention provides a sound insulation airplane wallboard. The sound insulation airplane wallboard comprises a skin positioned at an outer side, an internal decoration board positioned at an inner side and sound insulation and heat insulation cotton positioned between the skin and the internal decoration board, wherein the sound insulation airplane wallboard also comprises a phonon crystal material layer positioned between the sound insulation and heat insulation cotton and the internal decoration plate. The sound insulation airplane wallboard increases the effective sound absorption thickness of the sound insulation and heat insulation cotton without increasing the weight and space basically in order to improve the integral sound absorption effect of the sound insulation and heat insulation cotton.

Owner:COMAC +1

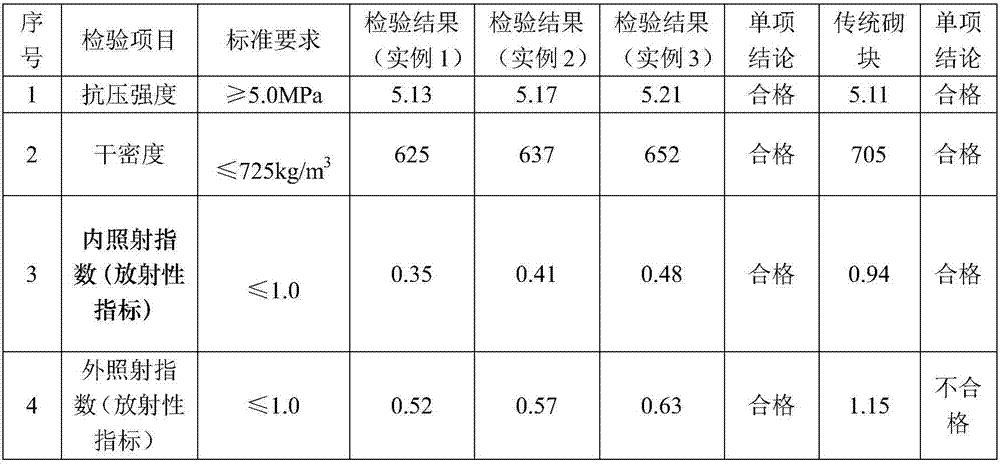

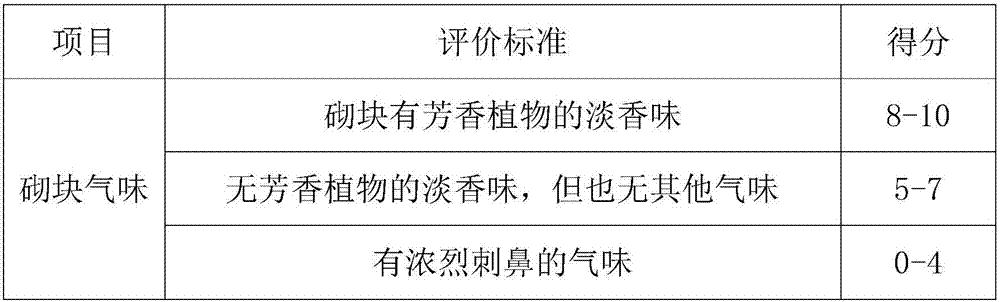

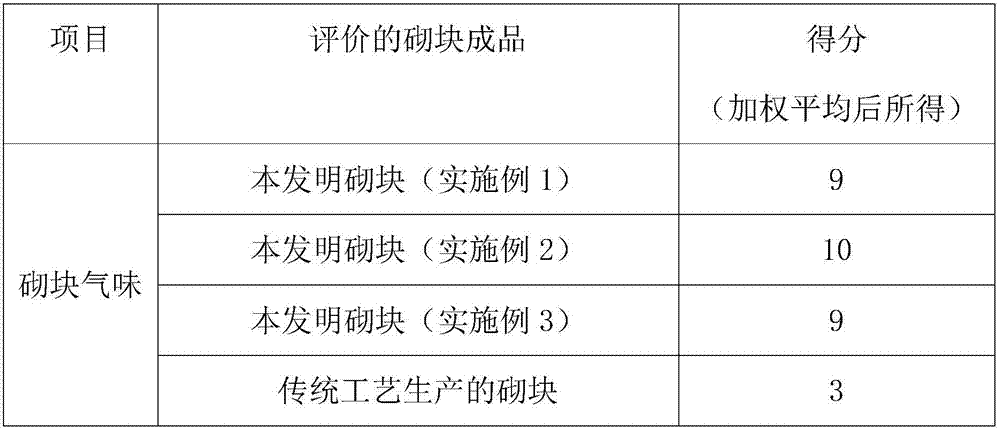

Environment-friendly autoclaved aerated concrete block

InactiveCN107344836AProtect your healthImprove working environmentBuilding componentsCeramicwareBrickAdditive ingredient

The invention discloses an environment-friendly autoclaved aerated concrete block which consists of the following raw materials in parts by weight: 5-10 parts of fresh aloes, 5-10 parts of fresh thyme, 20-30 parts of oil shale ashes, 15-25 parts of cement, 10-20 parts of kieselguhr, 0.04-0.12 part of a foaming agent and 32-40 parts of water. The environment-friendly autoclaved aerated concrete block is prepared through the procedures of crushing, stirring, casting molding, delaying curing and pre-curing, turnover cutting and autoclaved curing; the aloe and the thyme are added to the ingredients, so that the concrete block has aromatic odors of plants, also has relatively good antibacterial and bactericidal effects, the radioactivity of the block is reduced and the bodies of a block production worker and an installation worker are protected; and through the addition of the kieselguhr, the produced brick is capable of adsorbing indoor toxic and harmful substances such as formaldehyde, benzene and ammonia, decomposing the peculiar smell in air and effectively protecting good health of indoor residents, is an environment-friendly building material, and has relatively good ecological and economical benefits.

Owner:GUIZHOU UNIV

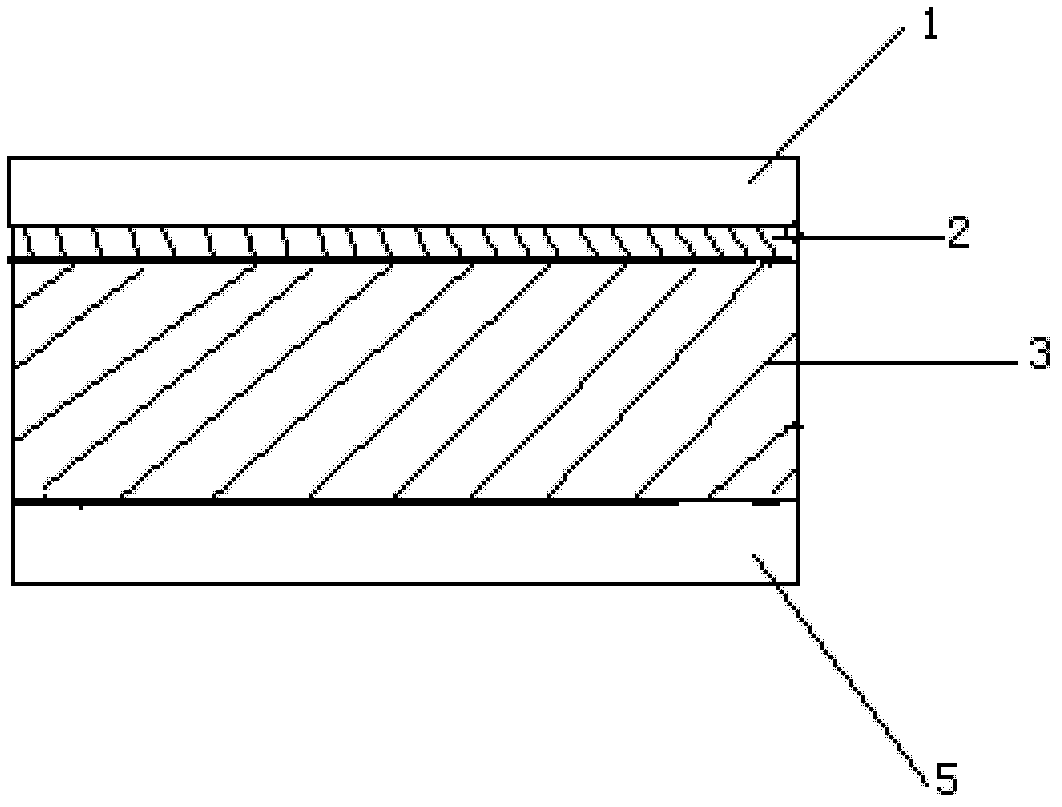

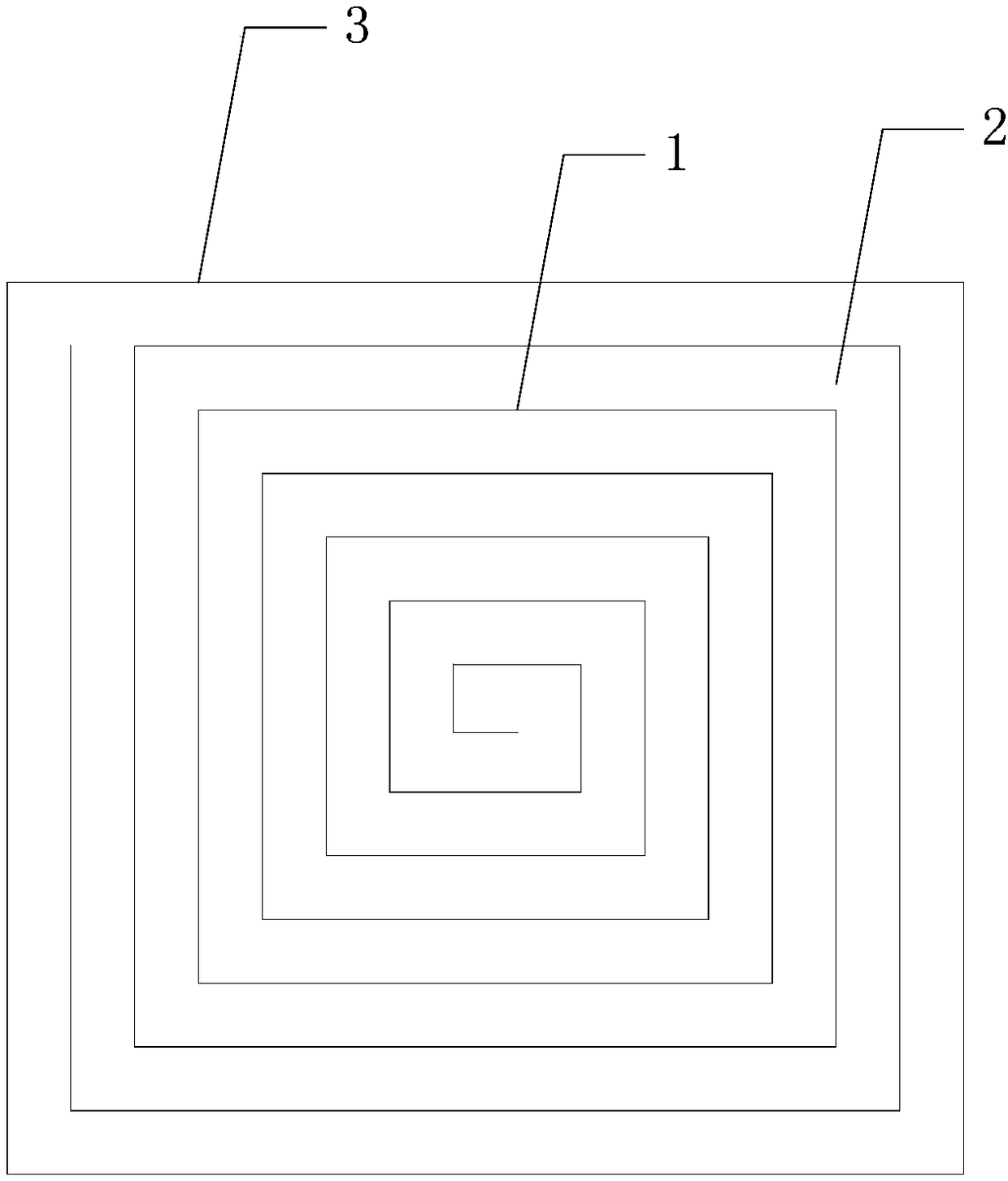

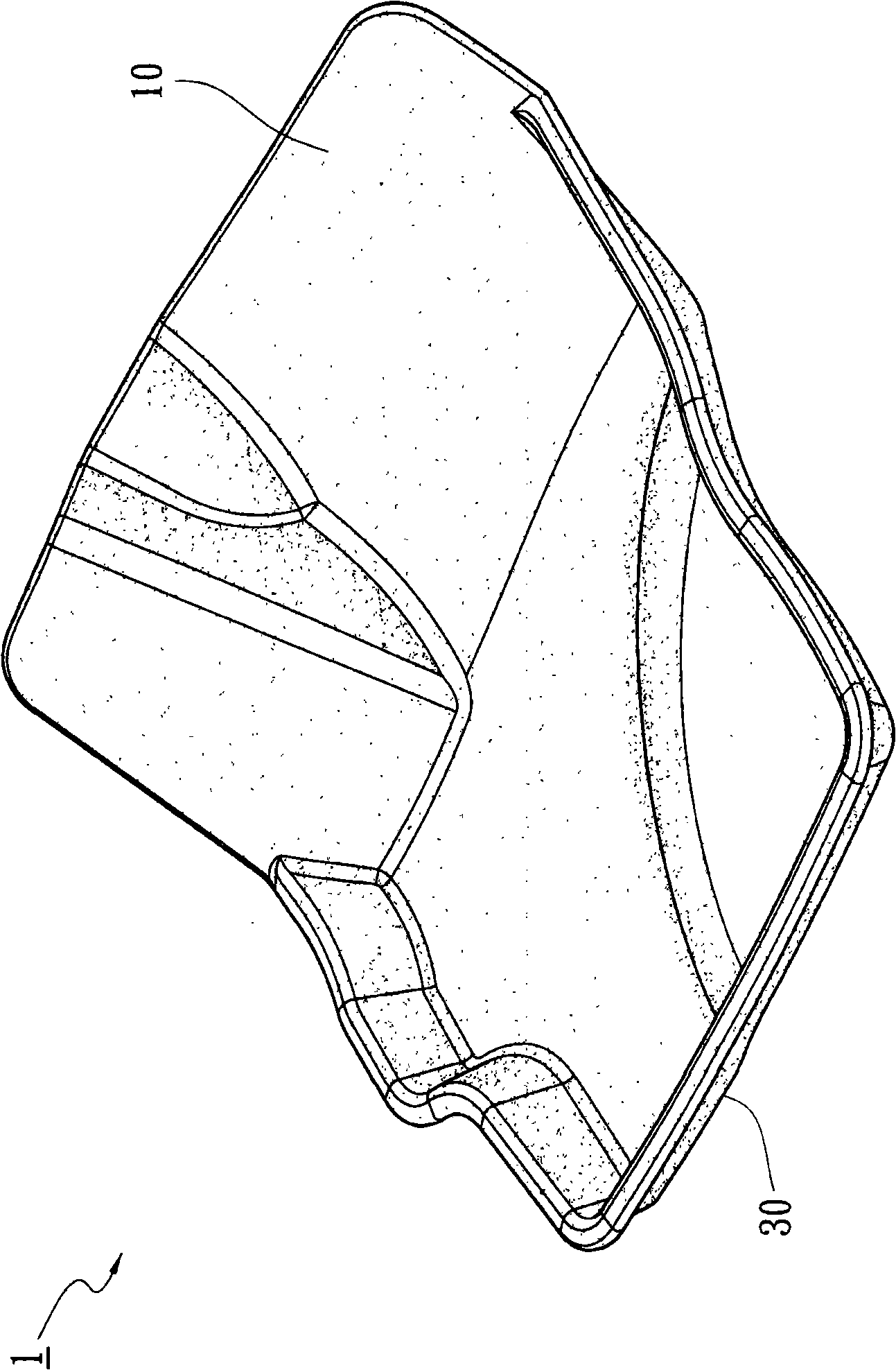

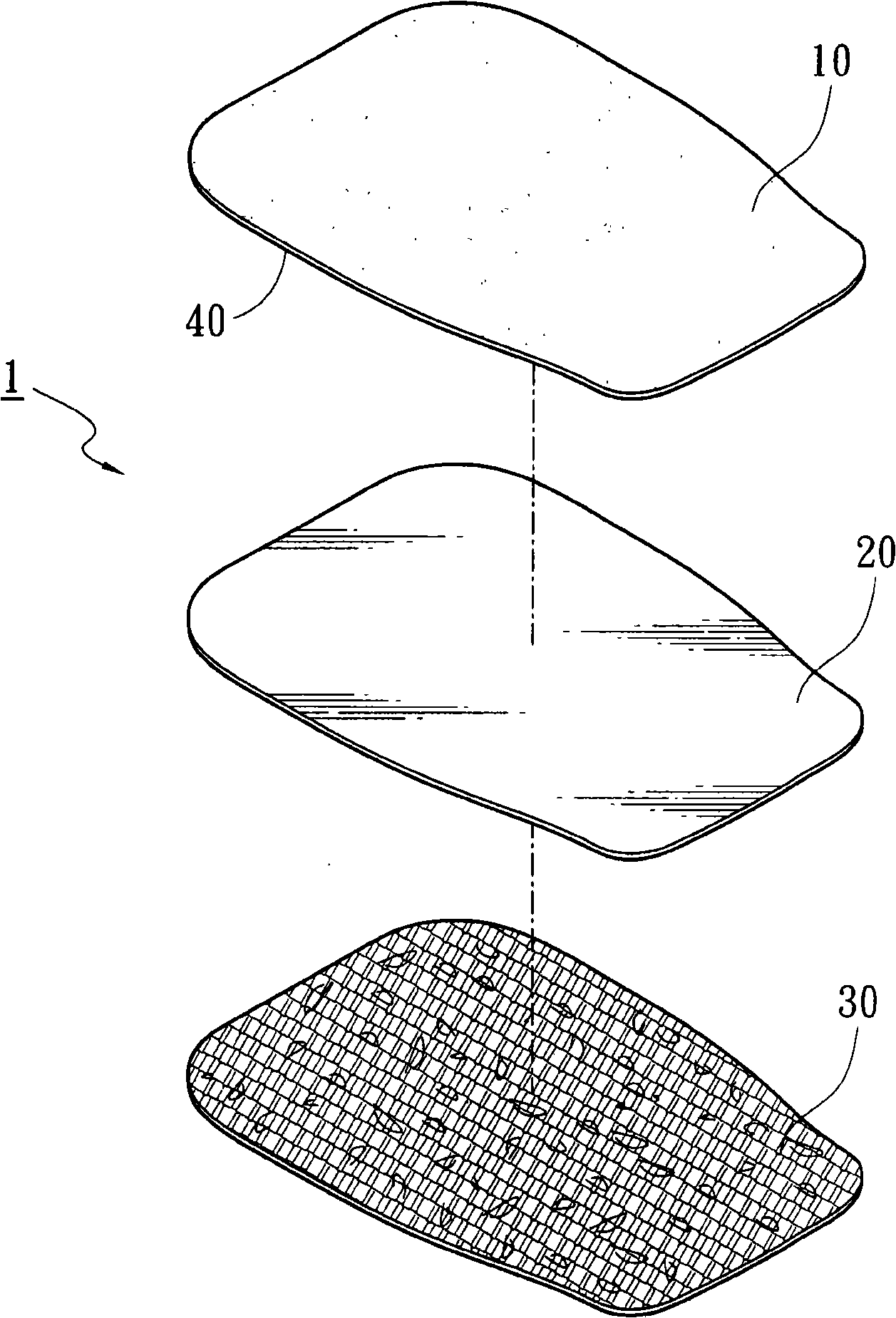

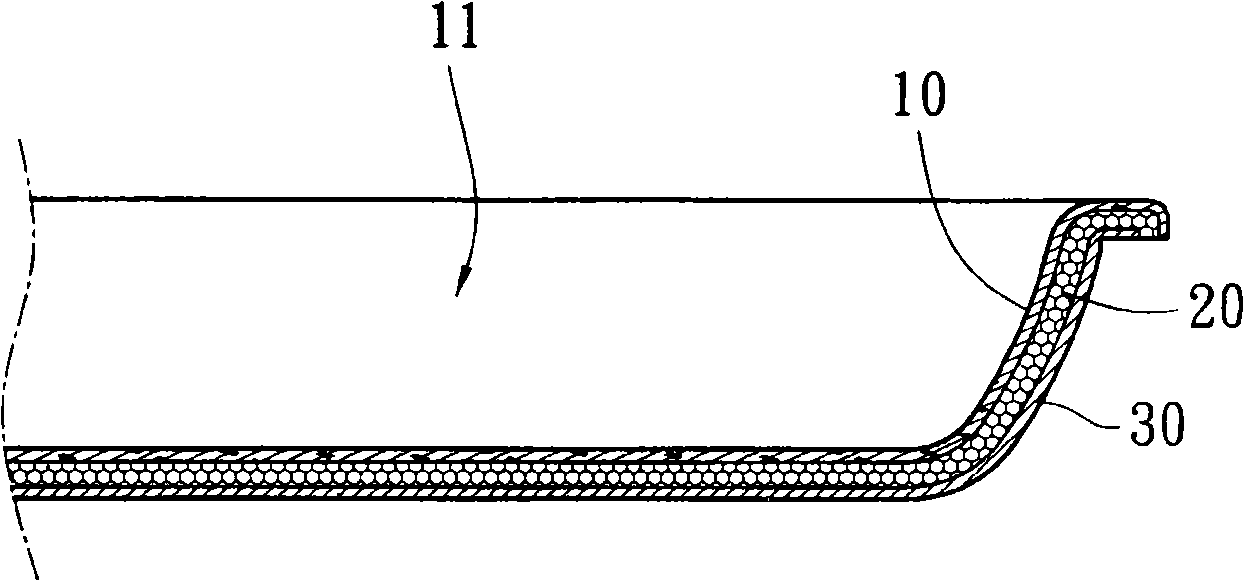

Sound insulating and absorbing mat structure of automobile

InactiveCN101570151AEasy to produceSound insulationVehicle arrangementsPunchingThermoplastic elastomer

The invention relates to a sound insulating and absorbing mat structure of an automobile, at least comprising a waterproof layer positioned at the upper layer and a sound-absorbing layer positioned at the lower layer. The waterproof layer at the upper layer is made of foam materials, and the sound-absorbing layer at the lower layer is made of needle punching cotton with sound-absorbing effect; the waterproof layer can be even additionally provided with materials of blankets and thermoplastic elastomers (TPE); and components of each layer are jointed and formed together by a mould pressing technology. The mat has a plurality of effects of sound insulation, cushion, shock absorption, sound absorption, water resistance, light weight and low manufacture cost.

Owner:FORMOSA SAINT JOSE

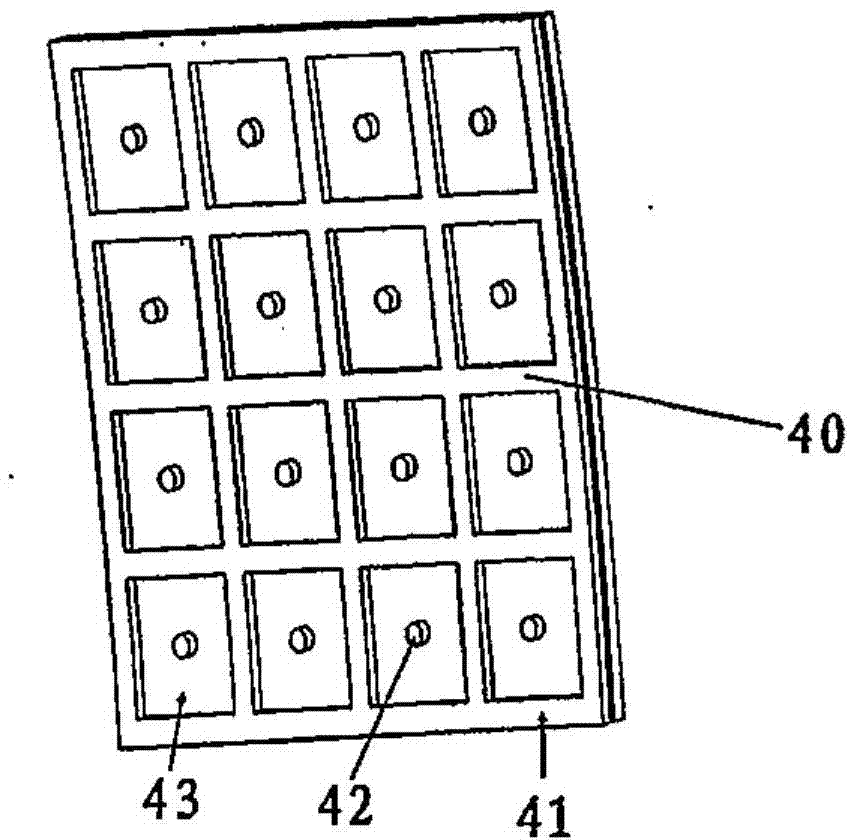

Processing technology of air-permeable glass material structure and air-permeable glass material structure

PendingCN107630653ASimple structureImprove lighting effectsLamination ancillary operationsInsect protectionPathogenic microorganismPunching

The invention discloses a processing technology of an air-permeable glass material structure. According to the technology, firstly, the front and back surfaces of the substrate are coated with a graphene coating or an anti-static scratch-resisting functional coating to form function layers on the front and back surfaces of the substrate, wherein the graphene coating is prepared from 20-50 parts oftackifier, 2-15 parts of graphene dispersion solution, 0.01-0.5 part of surfactant and 5-20 parts of deionized water; the function layer is coated with a protective membrane or covered with a protective membrane in a heated mode; punching is conducted on the material surface through adoption of a laser mode or a plasma mode or a needle roller mode or a chemical corrosion mode or a mechanical continuous working mode; slitting, rolling and packaging are conducted, and then the air-permeable glass material structure is prepared by the technology. The processing technology is simple and low in cost, the prepared air-permeable glass material structure is simple, and the problems that due to draught-free indoor air, pathogenic microorganisms are generated and the concentration of harmful gas including formaldehyde, carbon dioxide and the like is high can be solved; ventilation of a sealed space is achieved by opening a window, and meanwhile, the indoor temperature loss can remain at the lowest amount; the air-permeable glass material structure has the good functions of sound insulation, dust prevention, wind prevention, rain prevention, mosquito and pest prevention and collision and falling prevention and can meet the demand for light collection performance.

Owner:上海谷奇核孔膜科技股份有限公司

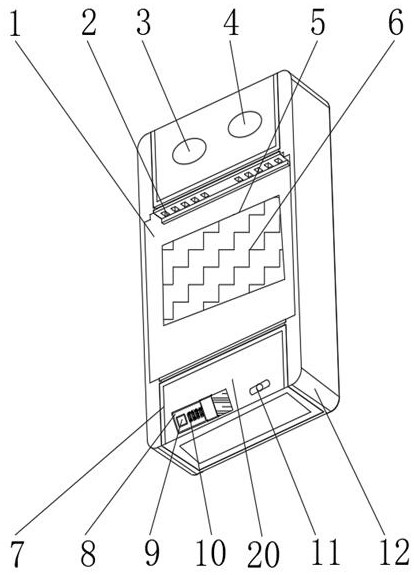

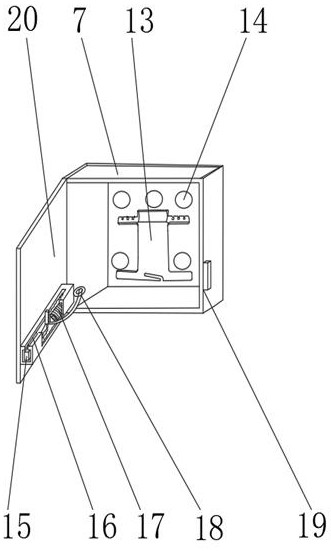

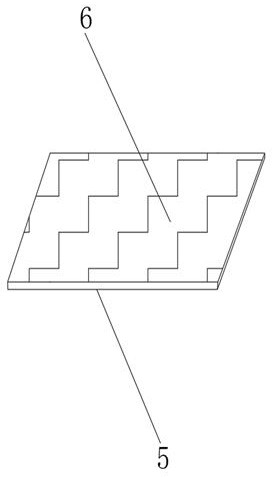

Electric energy meter capable of preventing electricity larceny

PendingCN111638395APrevent electricity theftEasy to operateTime integral measurementElectric energyEngineering

The invention discloses an electric energy meter capable of preventing electricity larceny. An outer surface of a front end of an electric energy meter main body panel is fixedly connected with an observation window, an outer surface of a front end of the observation window is fixedly connected with a self-cleaning coating, a first fixing piece and a second fixing piece are arranged on the outer surface of the upper end of the electric energy meter main body panel. The interior of the electric energy meter main body panel is fixedly connected with a heat dissipation port, the outer surface ofthe lower end of the electric energy meter main body panel is fixedly connected with a connecting wire protection box with a coded lock, and an outer surface of a front end of the connecting wire protection box with the coded lock is fixedly connected with a box door. The electric energy meter capable of preventing electricity larceny is provided with the connecting wire protection box with the coded lock, the self-cleaning coating and the anti-collision corner protectors, electricity larceny caused by private line refitting of people can be prevented, self-cleaning can be conducted, observation is convenient, the electric energy meter can be better protected, damage caused by collision is prevented, and better use prospects are brought.

Owner:宁波泰丰源电气有限公司

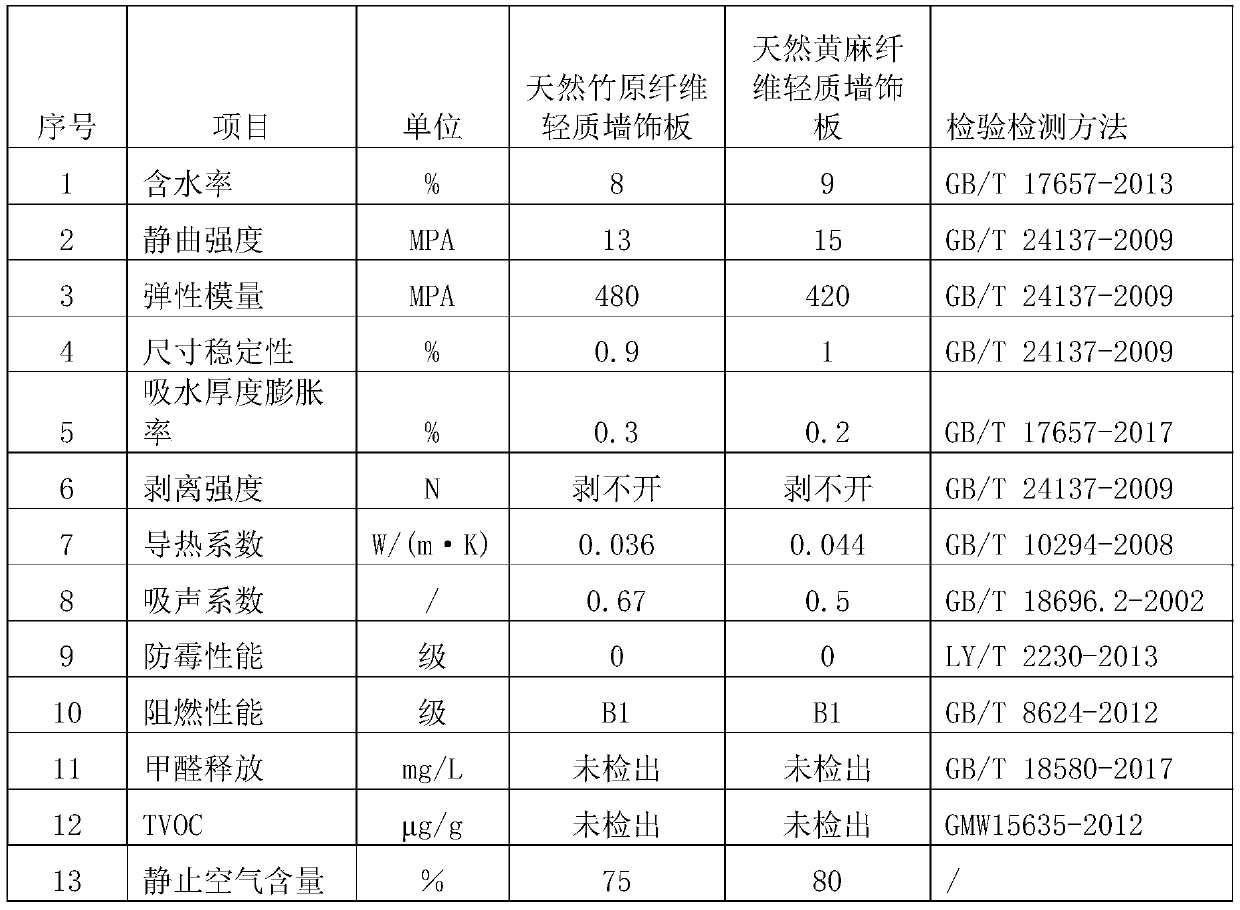

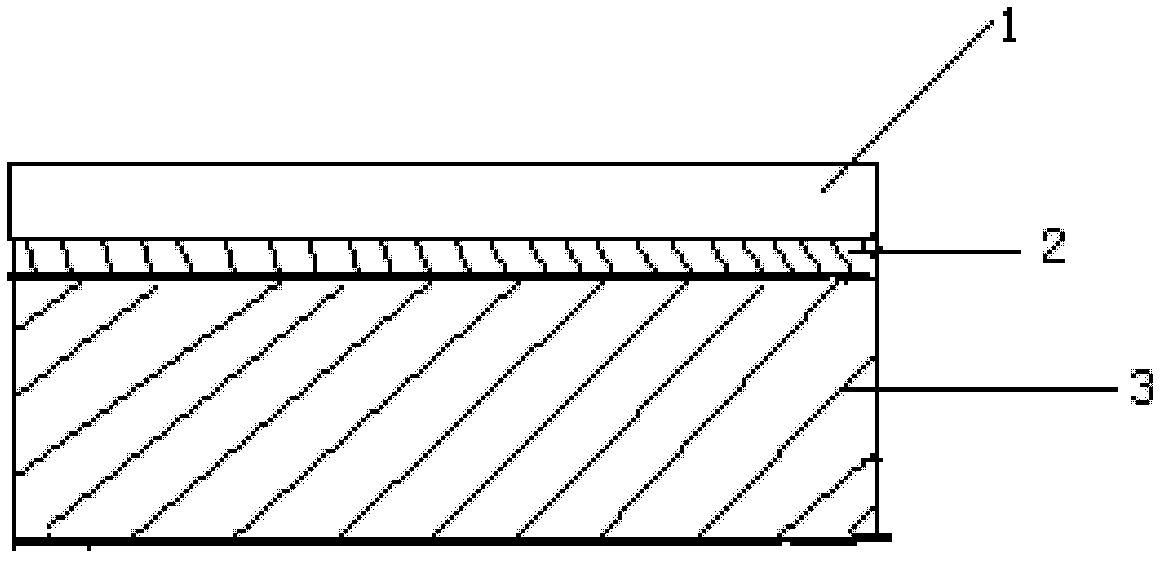

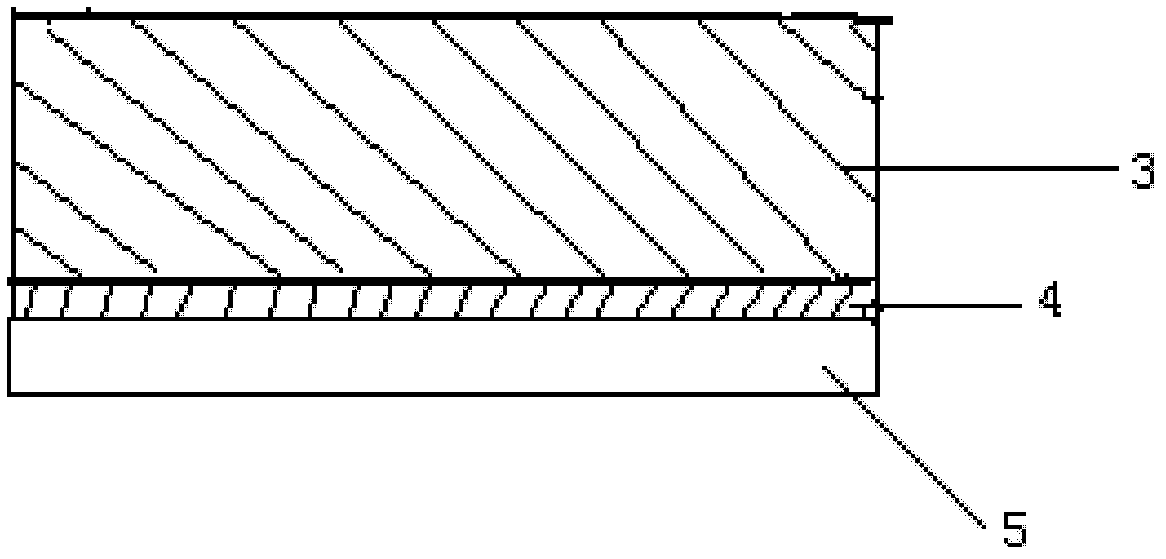

Light wall veneer and preparation method thereof

PendingCN111331990AMeet different aesthetic needsDemand constraintsCovering/liningsLamination ancillary operationsPolyesterPolymer science

The invention discloses a light wall veneer. The light wall veneer comprises a decorative surface layer and a natural fiber reinforced polypropylene plate layer; the decorative surface layer and the natural fiber reinforced polypropylene plate layer are bonded through a moisture curing reaction type polyurethane hot melt adhesive; the natural fiber reinforced polypropylene plate layer is composedof a transition layer, a middle layer and a balance layer, the natural fiber reinforced polypropylene plate layer is formed by: three-dimensionally interweaving 40-60% of natural fiber and 60-40% of polypropylene staple fiber to form a fiber felt, adhering the transition layer and the balance layer to two sides of the fiber felt respectively, and then conducting hot-pressing bonding; wherein the transition layer and the balance layer are polyester non-woven fabrics made of the same material, and the natural fiber reinforced polypropylene plate layer is bonded with the decorative surface layerthrough the transition layer. The natural fiber offcut used in the light wall veneer can be recycled by 100% after being opened, volatile pollutants cannot be generated in the production process, thelight wall veneer is environmentally friendly, and can meet different aesthetic requirements.

Owner:SHANGHAI SHENGFENG BUILDING MATERIAL TECH

Natural fiber composite health-care cushion and preparation method thereof

ActiveCN102514274AGuaranteed performanceGuaranteed breathabilityStuffed mattressesLayered productsSurface layerNatural fiber

The invention discloses a natural fiber composite health-care cushion which comprises a middle layer. A surface layer is arranged on the upper surface or the lower surface of the middle layer. A block layer is arranged between the middle layer and the surface layer. The surface layer is a non-woven layer comprising 5 percent to 50 percent of low melting point fibers. The middle layer is a non-woven layer which comprises the following components: bastose and 5 percent to 50 percent of low melting point fibers. The block layer is a non-woven layer comprising 5 percent to 100 percent of low melting point fibers. In the natural fiber composite health-care cushion, the content of the bastose is within the range of 5 percent to 65 percent. The invention also discloses a preparation method of the natural fiber composite health-care cushion, which comprises the following steps of: respectively preparing the middle layer, the upper or lower surface layer and the block layer; then sequentially paving the layers; and preparing the natural fiber composite health-care cushion by processes of processing by an oven, cold milling, cooling, cutting, inspecting and packaging. Due to the adoption ofthe natural fiber composite health-care cushion and the preparation method thereof, which are disclosed by the invention, the problem that the existing mattress is easy to affect with damp, mildew, breed worms and deteriorate, is easy to layer, has poor air permeability and is discomfortable to use due to protruded hard fibers in the middle of the mattress is solved.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

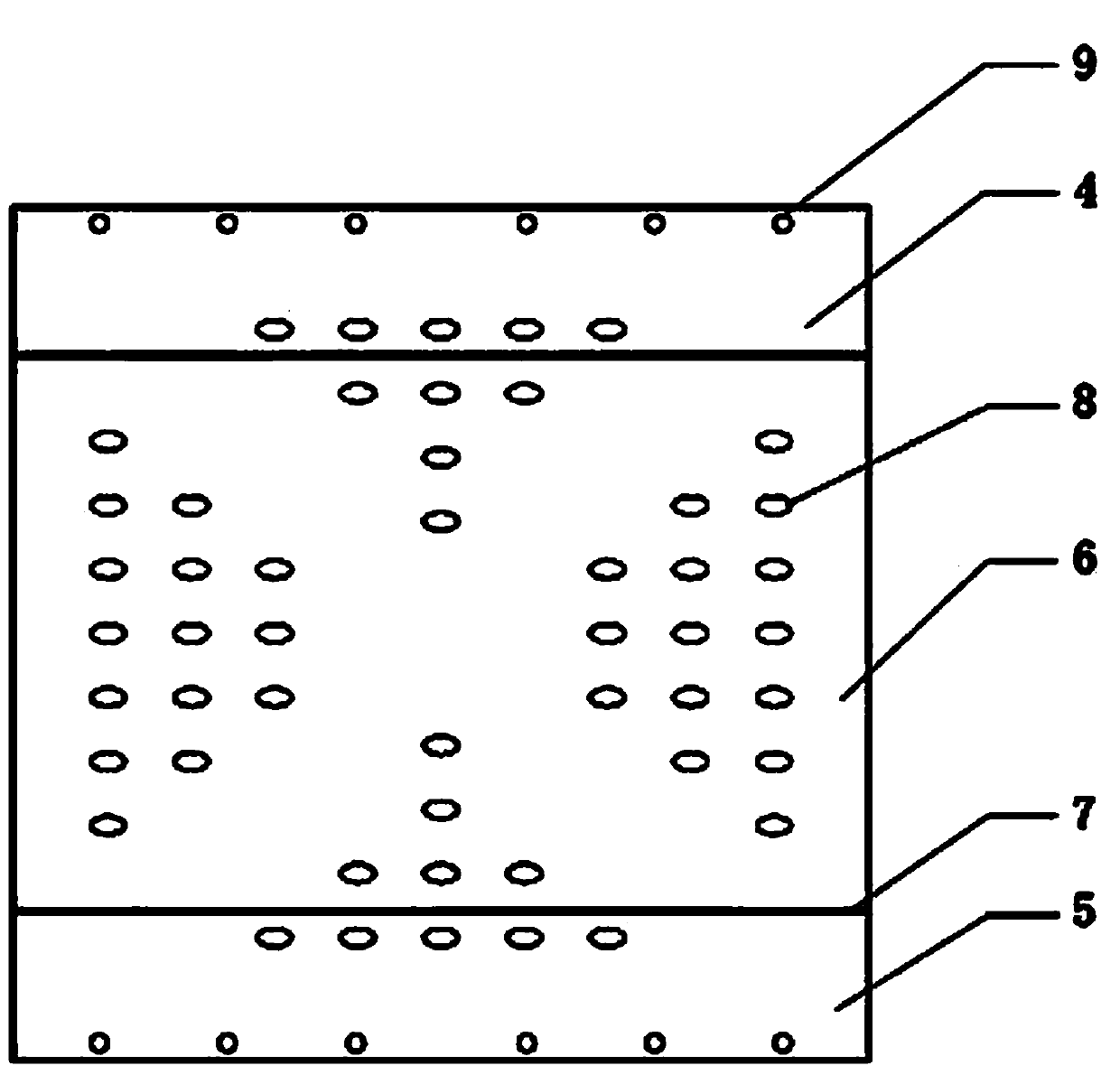

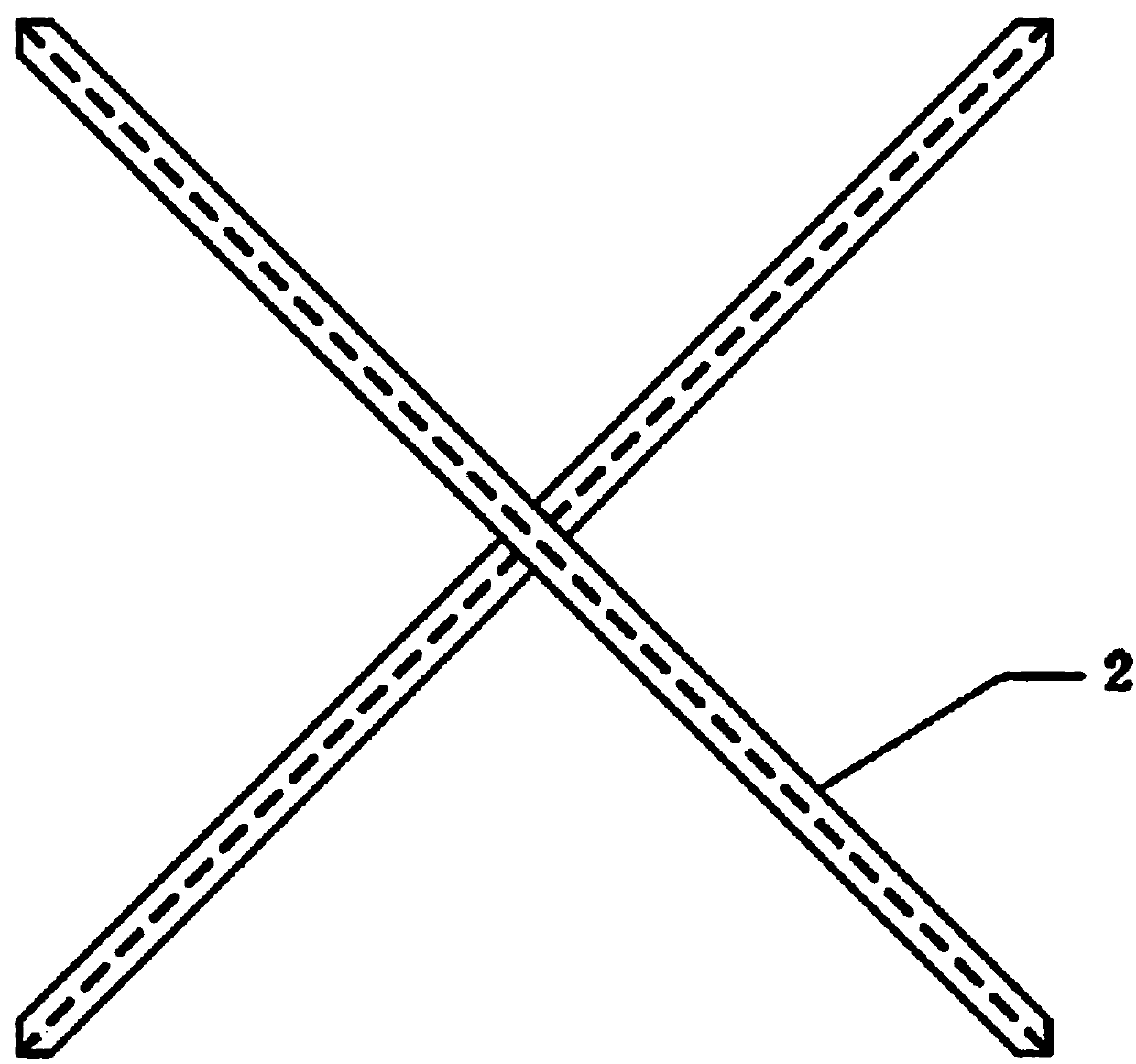

Anti-buckling energy consumption steel plate shear wall with concealed brace

InactiveCN103726585APrevent bucklingPrevent out-of-plane bucklingWallsShock proofingSteel platesBuckling-restrained brace

The invention relates to an anti-buckling energy consumption steel plate shear wall with a concealed brace. The shear wall comprises an infilled energy consumption steel plate, the concealed brace and a concrete plate. The infilled energy consumption steel plate and the concealed brace are connected into a whole and jointly work, wherein the concealed brace is welded into the position, being applied with large centralized force, of the infilled energy consumption steel plate, and therefore the infilled energy consumption steel plate and the concealed brace jointly resist the large centralized force; an isolating layer is arranged between the infilled energy consumption steel plate and the concrete plate, and therefore the infilled energy consumption steel plate and the concrete plate can relatively move; an isolating layer is arranged at the contact position of the outer surface of the concealed brace and the concrete plate, and therefore the concealed brace and the concrete plate can relatively move; a proper amount of plastic foam is filled into the contact position of the inner surface of the concealed brace and the concrete plate, and therefore the concrete plate can be prevented from being squeezed and damaged in the deformation process. The shear wall has the advantages of high side lurch resistance, good ductility and outstanding energy consumption capacity of an anti-buckling restrained brace and an anti-buckling steel plate wall, and can solve the problem of performance degeneration caused by buckling of edges of a steel plate wall.

Owner:TONGJI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com