Waste-cotton composite automotive carpet

A technology for car carpets and fabric layers, applied to vehicle parts, special positions of vehicles, non-woven fabrics, etc., can solve the problems of high cost and unfavorable automobile development, and achieve the effect of cost reduction and environmental pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

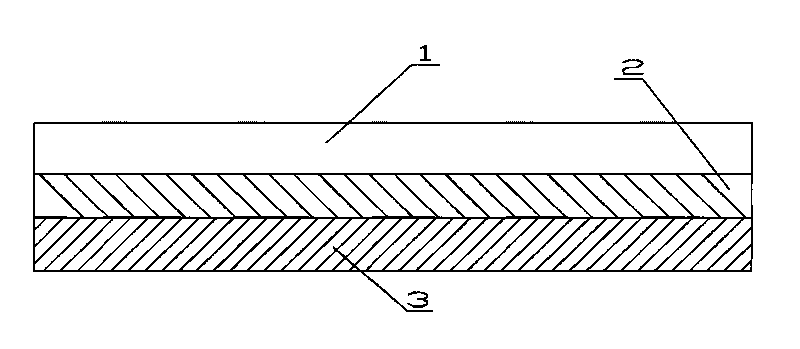

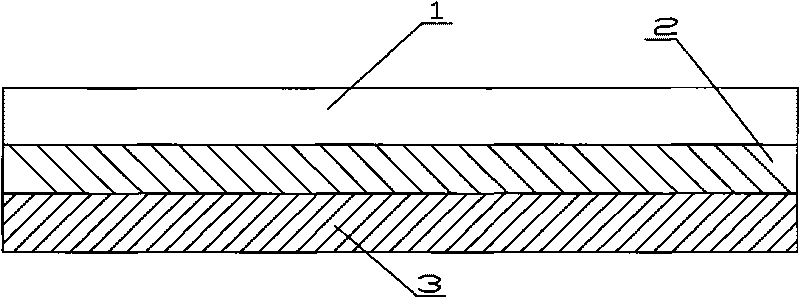

[0015] Example 1: A kind of waste cotton composite car carpet

[0016] Fabric layer preparation: take polyester fiber to open and mix uniformly; then transfer the polyester fiber to the carding machine through the cotton storage box to form a fiber web; send the fiber web to the netting machine and lay it into multiple layers The multi-layer fiber web is transported to the needle punching machine for needle punching to form a fabric layer with a needle punch density of 35 needles / cm²; the needle punch depth of the needle punch is 3mm and the speed 3m / min; then the fabric layer is transported to the raising machine for raising, the raised pile height is 5.6mm, and the raised pile density is 450 needles / square centimeter;

[0017] The preparation of the bottom material layer: take the polypropylene fiber, polyester fiber and waste cotton with a weight percentage of 10:35:55 to open and mix them uniformly; send them to the carding machine through the cotton storage box to form a fib...

Embodiment 2

[0019] Example 2: A waste cotton composite car carpet

[0020] Fabric layer preparation: take polyester fiber to open and mix uniformly; then transfer the polyester fiber to the carding machine through the cotton storage box to form a fiber web; send the fiber web to the netting machine and lay it into multiple layers The multi-layer fiber web is transported to the needle punching machine for needling to form a fabric layer with a needle punch density of 105 needles / cm²; the needle punch depth of the needle punch is 9mm and the speed It is 9m / min; then the fabric layer is transported to the raising machine for raising, the pile height of the raised pile is 7.6mm, and the pile density of the raised pile is 750 stitches / square centimeter;

[0021] The preparation of the bottom material layer: take the polypropylene fiber, polyester fiber and waste cotton with a weight percentage of 40:20:40 to open and mix them uniformly; transport them to the carding machine through the cotton stora...

Embodiment 3

[0023] Embodiment three: a kind of waste cotton composite car carpet

[0024] Fabric layer preparation: take polyester fiber to open and mix uniformly; then transfer the polyester fiber to the carding machine through the cotton storage box to form a fiber web; send the fiber web to the netting machine and lay it into multiple layers The fiber web; then the multi-layer fiber web is transported to the needle punching machine for needle punching to form a fabric layer with a needle punch density of 75 needles / cm²; the needle punch depth of the needle punch is 6mm, and the speed 6m / min; then the fabric layer is transported to the raising machine for raising, the pile height of the raised pile is 6.6mm, and the pile density of the raised pile is 600 stitches / square centimeter;

[0025] The preparation of the bottom material layer: take the polypropylene fiber, polyester fiber and waste cotton with a weight percentage of 25:50:25 to open and mix them uniformly; send them to the carding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com